wheel BUICK ENCLAVE 2010 Workshop Manual

[x] Cancel search | Manufacturer: BUICK, Model Year: 2010, Model line: ENCLAVE, Model: BUICK ENCLAVE 2010Pages: 438, PDF Size: 2.47 MB

Page 300 of 438

10-2 Vehicle Care

Tire Inspection . . . . . . . . . . . . . . 10-50

Tire Rotation . . . . . . . . . . . . . . . 10-50

When It Is Time for NewTires . . . . . . . . . . . . . . . . . . . . . . 10-51

Buying New Tires . . . . . . . . . . . 10-52

Different Size Tires and

Wheels . . . . . . . . . . . . . . . . . . . 10-54

Uniform Tire Quality Grading . . . . . . . . . . . . . . . . . . . 10-54

Wheel Alignment and Tire Balance . . . . . . . . . . . . . . . . . . . 10-56

Wheel Replacement . . . . . . . . 10-56

Tire Chains . . . . . . . . . . . . . . . . . 10-57

If a Tire Goes Flat . . . . . . . . . . 10-58

Tire Sealant and Compressor Kit . . . . . . . . . . . 10-60

Storing the Tire Sealant and Compressor Kit . . . . . . . . . . . 10-68

Tire Changing . . . . . . . . . . . . . . 10-68

Secondary Latch System . . . 10-78

Compact Spare Tire . . . . . . . . 10-80Jump Starting

Jump Starting . . . . . . . . . . . . . . 10-81

Towing

Towing the Vehicle . . . . . . . . . 10-85

Recreational Vehicle Towing . . . . . . . . . . . . . . . . . . . . 10-85

Appearance Care

Exterior Care . . . . . . . . . . . . . . . 10-88

Interior Care . . . . . . . . . . . . . . . . 10-92

Floor Mats . . . . . . . . . . . . . . . . . . 10-95

General Information

For service and parts needs, visit

your dealer/retailer. You will receive

genuine GM parts and GM-trained

and supported service people.

Genuine GM parts have one of

these marks:

Page 321 of 438

Vehicle Care 10-23

Some driving conditions or climates

can cause a brake squeal when the

brakes are first applied or lightly

applied. This does not mean

something is wrong with the brakes.

Properly torqued wheel nuts are

necessary to help prevent brake

pulsation. When tires are rotated,

inspect brake pads for wear and

evenly tighten wheel nuts in the

proper sequence to torque

specifications inCapacities and

Specifications on page 12‑2.

Brake linings should always be

replaced as complete axle sets.

Brake Pedal Travel

See your dealer/retailer if the brake

pedal does not return to normal

height, or if there is a rapid increase

in pedal travel. This could be a sign

that brake service might be

required.

Brake Adjustment

Every time the brakes are applied,

with or without the vehicle moving,

the brakes adjust for wear.

Replacing Brake System Parts

The braking system on a vehicle is

complex. Its many parts have to be

of top quality and work well together

if the vehicle is to have really good

braking. The vehicle was designed

and tested with top-quality brake

parts. When parts of the braking

system are replaced, be sure to get

new, approved replacement parts.

If this is not done, the brakes might

not work properly. For example,

installing disc brake pads that are

wrong for the vehicle, can change

the balance between the front and

rear brakes —for the worse. The

braking performance expected can

change in many other ways if the

wrong replacement brake parts are

installed.

Brake Fluid

The brake master cylinder reservoir

is filled with DOT 3 brake fluid as

indicated on the reservoir cap. See

Engine Compartment Overview

on

page 10‑6for the location of the

reservoir.

There are only two reasons why the

brake fluid level in the reservoir

might go down:

.The brake fluid level goes down

because of normal brake lining

wear. When new linings are

installed, the fluid level goes

back up.

Page 323 of 438

Vehicle Care 10-25

Battery

Refer to the replacement number on

the original battery label when a

new battery is needed.

{DANGER

Battery posts, terminals, and

related accessories contain lead

and lead compounds, chemicals

known to the State of California to

cause cancer and reproductive

harm. Wash hands after handling.

Vehicle Storage

{WARNING

Batteries have acid that can burn

you and gas that can explode.

You can be badly hurt if you are

not careful. SeeJump Starting

on

page 10‑81

for tips on working

around a battery without

getting hurt. Infrequent Usage: Remove the

black, negative (−) cable from the

battery to keep the battery from

running down.

Extended Storage: Remove the

black, negative (−) cable from the

battery or use a battery trickle

charger.

All-Wheel Drive

It is not necessary to check the

all–wheel drive lubricant levels.

A fluid leak is the only reason for

fluid loss. If a leak occurs, take the

vehicle to the dealer/retailer as soon

as possible.

Starter Switch Check

{WARNING

When you are doing this

inspection, the vehicle could

move suddenly. If the vehicle

moves, you or others could be

injured.

1. Before starting this check, be sure there is enough room

around the vehicle.

2. Firmly apply both the parking brake and the regular brake.

See Parking Brake

on

page 9‑27.

Do not use the accelerator

pedal, and be ready to turn off

the engine immediately if it

starts.

3. Try to start the engine in each gear. The vehicle should start

only in P (Park) or N (Neutral).

If the vehicle starts in any other

position, contact your dealer/

retailer for service.

Page 331 of 438

Vehicle Care 10-33

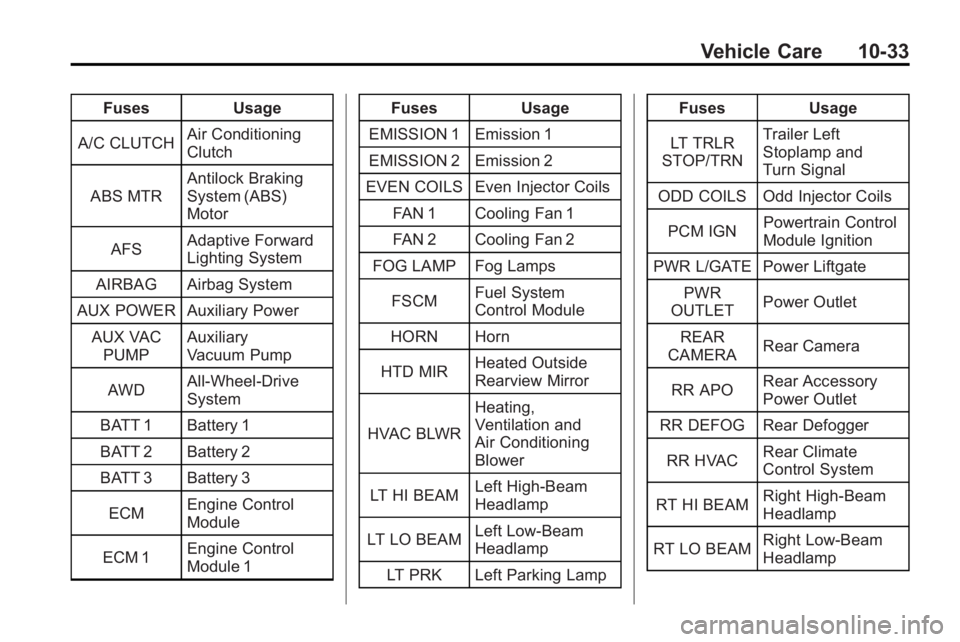

FusesUsage

A/C CLUTCH Air Conditioning

Clutch

ABS MTR Antilock Braking

System (ABS)

Motor

AFS Adaptive Forward

Lighting System

AIRBAG Airbag System

AUX POWER Auxiliary Power

AUX VACPUMP Auxiliary

Vacuum Pump

AWD All-Wheel-Drive

System

BATT 1 Battery 1

BATT 2 Battery 2

BATT 3 Battery 3

ECM Engine Control

Module

ECM 1 Engine Control

Module 1 Fuses

Usage

EMISSION 1 Emission 1

EMISSION 2 Emission 2

EVEN COILS Even Injector Coils FAN 1 Cooling Fan 1

FAN 2 Cooling Fan 2

FOG LAMP Fog Lamps

FSCM Fuel System

Control Module

HORN Horn

HTD MIR Heated Outside

Rearview Mirror

HVAC BLWR Heating,

Ventilation and

Air Conditioning

Blower

LT HI BEAM Left High-Beam

Headlamp

LT LO BEAM Left Low-Beam

Headlamp

LT PRK Left Parking Lamp Fuses

Usage

LT TRLR

STOP/TRN Trailer Left

Stoplamp and

Turn Signal

ODD COILS Odd Injector Coils

PCM IGN Powertrain Control

Module Ignition

PWR L/GATE Power Liftgate PWR

OUTLET Power Outlet

REAR

CAMERA Rear Camera

RR APO Rear Accessory

Power Outlet

RR DEFOG Rear Defogger

RR HVAC Rear Climate

Control System

RT HI BEAM Right High-Beam

Headlamp

RT LO BEAM Right Low-Beam

Headlamp

Page 334 of 438

10-36 Vehicle Care

FusesUsage

HVAC Heating,

Ventilation and

Air Conditioning

INADV/

PWR/LED Inadvertent

Power LED

INFOTMNT Infotainment

LT/TRN/SIG Driver Side Turn

Signal

MSM Memory Seat

Module

PDM Power Mirrors,

Liftgate Release

PWR MODE Power Mode

PWR/MIR Power Mirrors RDO Radio

REAR WPR Rear Wiper

RT/TRN/SIG Passenger Side

Turn Signal

SPARE Spare

STR/WHL/ ILLUM Steering Wheel

Illumination

Relay Side Relays Usage

LT/PWR/ SEAT Driver Side Power

Seat Relay

RT/PWR/ SEAT Passenger Side

Power Seat Relay

PWR/WNDW Power Windows

Relay

PWR/

COLUMN Power Steering

Column Relay

L/GATE Liftgate Relay

LCK Power Lock Relay

REAR/WSW Rear Window

Washer Relay

UNLCK Power Unlock

Relay

Page 335 of 438

Vehicle Care 10-37

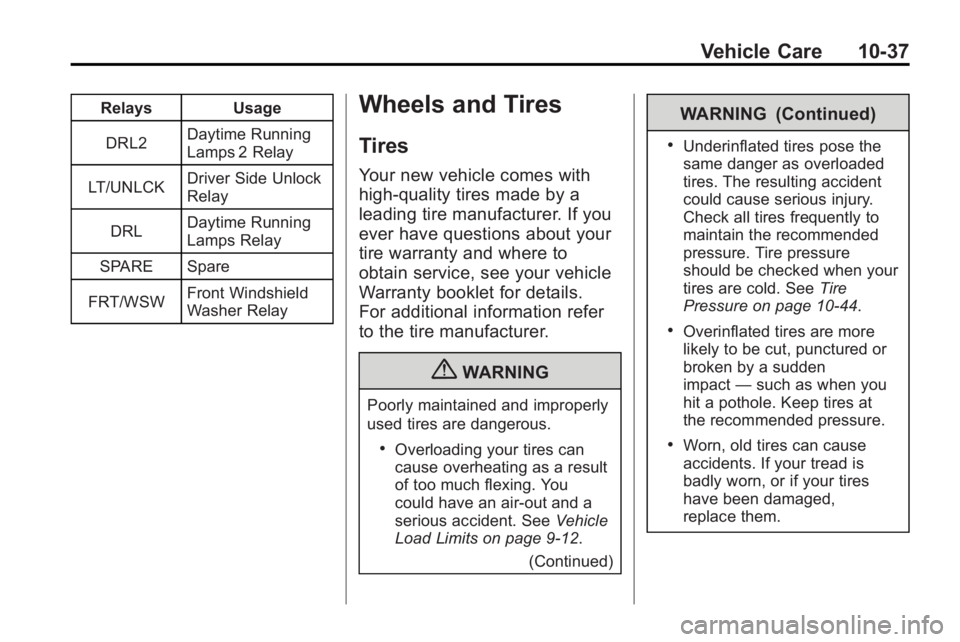

RelaysUsage

DRL2 Daytime Running

Lamps 2 Relay

LT/UNLCK Driver Side Unlock

Relay

DRL Daytime Running

Lamps Relay

SPARE Spare

FRT/WSW Front Windshield

Washer RelayWheels and Tires

Tires

Your new vehicle comes with

high-quality tires made by a

leading tire manufacturer. If you

ever have questions about your

tire warranty and where to

obtain service, see your vehicle

Warranty booklet for details.

For additional information refer

to the tire manufacturer.

{WARNING

Poorly maintained and improperly

used tires are dangerous.

.Overloading your tires can

cause overheating as a result

of too much flexing. You

could have an air-out and a

serious accident. See

Vehicle

Load Limits on page 9‑12.

(Continued)

WARNING (Continued)

.Underinflated tires pose the

same danger as overloaded

tires. The resulting accident

could cause serious injury.

Check all tires frequently to

maintain the recommended

pressure. Tire pressure

should be checked when your

tires are cold. See Tire

Pressure on page 10‑44.

.Overinflated tires are more

likely to be cut, punctured or

broken by a sudden

impact —such as when you

hit a pothole. Keep tires at

the recommended pressure.

.Worn, old tires can cause

accidents. If your tread is

badly worn, or if your tires

have been damaged,

replace them.

Page 339 of 438

Vehicle Care 10-41

(E) Rim Diameter:Diameter of

the wheel in inches.

(F) Service Description

:These

characters represent the load

index and speed rating of the

tire. The load index represents

the load carry capacity a tire is

certified to carry. The speed

rating is the maximum speed a

tire is certified to carry a load.

Tire Terminology and

Definitions

Air Pressure:The amount of

air inside the tire pressing

outward on each square inch of

the tire. Air pressure is

expressed in psi (pounds per

square inch) or kPa (kilopascal). Accessory Weight

:This

means the combined weight

of optional accessories.

Some examples of optional

accessories are, automatic

transmission, power steering,

power brakes, power windows,

power seats, and air

conditioning.

Aspect Ratio

:The relationship

of a tire's height to its width.

Belt

:A rubber coated layer of

cords that is located between

the plies and the tread. Cords

may be made from steel or other

reinforcing materials.

Bead

:The tire bead contains

steel wires wrapped by steel

cords that hold the tire onto

the rim. Bias Ply Tire

:A pneumatic tire

in which the plies are laid at

alternate angles less than

90 degrees to the centerline of

the tread.

Cold Tire Pressure

:The

amount of air pressure in a tire,

measured in psi (pounds per

square inch) or kPa (kilopascal)

before a tire has built up heat

from driving. See Tire Pressure

on page 10‑44.

Curb Weight

:The weight of a

motor vehicle with standard and

optional equipment including the

maximum capacity of fuel, oil,

and coolant, but without

passengers and cargo.

Page 344 of 438

10-46 Vehicle Care

Please note that the TPMS is

not a substitute for proper tire

maintenance, and it is the driver's

responsibility to maintain correct tire

pressure, even if under-inflation has

not reached the level to trigger

illumination of the TPMS low tire

pressure telltale.

Your vehicle has also been

equipped with a TPMS malfunction

indicator to indicate when the

system is not operating properly.

The TPMS malfunction indicator is

combined with the low tire pressure

telltale. When the system detects a

malfunction, the telltale will flash for

approximately one minute and then

remain continuously illuminated.

This sequence will continue upon

subsequent vehicle start-ups as

long as the malfunction exists.

When the malfunction indicator is

illuminated, the system may not

be able to detect or signal low

tire pressure as intended.TPMS malfunctions may occur for a

variety of reasons, including the

installation of replacement or

alternate tires or wheels on the

vehicle that prevent the TPMS from

functioning properly. Always check

the TPMS malfunction telltale after

replacing one or more tires or

wheels on your vehicle to ensure

that the replacement or alternate

tires and wheels allow the TPMS to

continue to function properly.

See

Tire Pressure Monitor

Operation

on page 10‑46for

additional information.

Federal Communications

Commission (FCC) and

Industry and Science Canada

See Radio Frequency Statementon

page 13‑16for information

regarding Part 15 of the Federal

Communications Commission (FCC)

Rules and RSS-210/211 of Industry

and Science Canada.

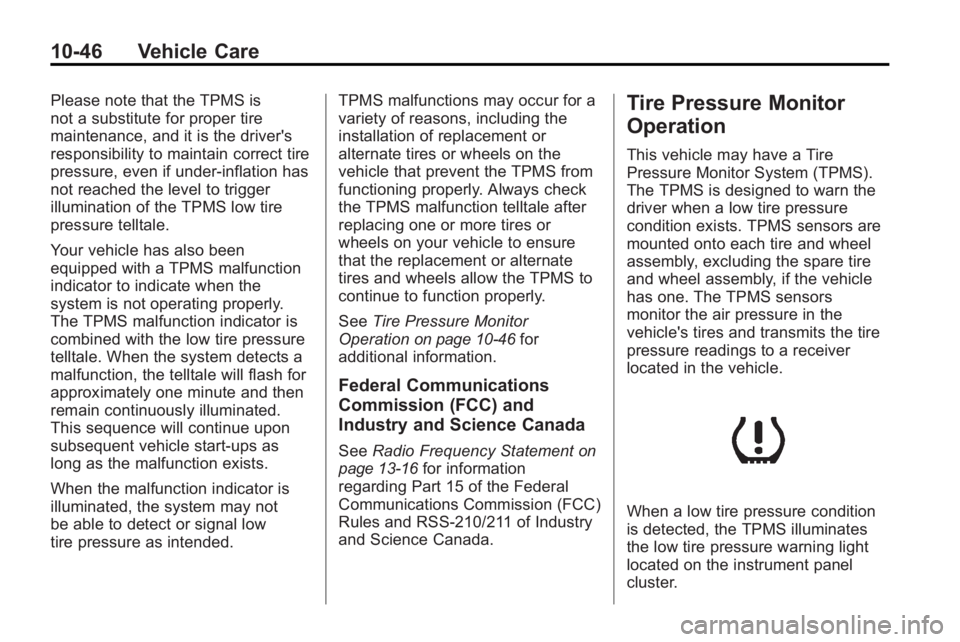

Tire Pressure Monitor

Operation

This vehicle may have a Tire

Pressure Monitor System (TPMS).

The TPMS is designed to warn the

driver when a low tire pressure

condition exists. TPMS sensors are

mounted onto each tire and wheel

assembly, excluding the spare tire

and wheel assembly, if the vehicle

has one. The TPMS sensors

monitor the air pressure in the

vehicle's tires and transmits the tire

pressure readings to a receiver

located in the vehicle.

When a low tire pressure condition

is detected, the TPMS illuminates

the low tire pressure warning light

located on the instrument panel

cluster.

Page 346 of 438

10-48 Vehicle Care

TPMS Malfunction Light and

Message

The TPMS will not function properly

if one or more of the TPMS sensors

are missing or inoperable. When the

system detects a malfunction, the

low tire warning light flashes for

about one minute and then stays on

for the remainder of the ignition

cycle. A DIC warning message is

also displayed. The low tire warning

light and DIC warning message

come on at each ignition cycle until

the problem is corrected. Some of

the conditions that can cause the

malfunction light and DIC message

to come on are:

.One of the road tires has been

replaced with the spare tire,

if your vehicle has one. The

spare tire does not have a

TPMS sensor. The TPMS

malfunction light and DIC

message should go off once you

re-install the road tire containing

the TPMS sensor.

.The TPMS sensor matching

process was started but not

completed or not completed

successfully after rotating the

vehicle's tires. The DIC message

and TPMS malfunction light

should go off once the TPMS

sensor matching process is

performed successfully. See

“TPMS Sensor Matching

Process”later in this section.

.One or more TPMS sensors are

missing or damaged. The DIC

message and the TPMS

malfunction light should go off

when the TPMS sensors are

installed and the sensor

matching process is performed

successfully. See your dealer/

retailer for service.

.Replacement tires or wheels do

not match your vehicle's original

equipment tires or wheels. Tires

and wheels other than those

recommended for your vehicle

could prevent the TPMS from

functioning properly. See Buying

New Tires on page 10‑52.

.Operating electronic devices or

being near facilities using radio

wave frequencies similar to the

TPMS could cause the TPMS

sensors to malfunction.

If the TPMS is not functioning it

cannot detect or signal a low tire

condition. See your dealer/retailer

for service if the TPMS malfunction

light and DIC message comes on

and stays on.

TPMS Sensor Matching

Process

Each TPMS sensor has a unique

identification code. Any time you

rotate your vehicle's tires or replace

one or more of the TPMS sensors,

the identification codes will need to

be matched to the new tire/wheel

position. The sensors are matched

to the tire/wheel positions in the

following order: driver side front tire,

passenger side front tire, passenger

side rear tire, and driver side rear

tire using a TPMS diagnostic tool.

See your dealer/retailer for service.

Page 347 of 438

Vehicle Care 10-49

The TPMS sensors can also be

matched to each tire/wheel position

by increasing or decreasing the

tire's air pressure. If increasing the

tire's air pressure, do not exceed

the maximum inflation pressure

indicated on the tire's sidewall.

To decrease air-pressure out of a

tire you can use the pointed end of

the valve cap, a pencil-style air

pressure gage, or a key.

You have two minutes to match the

first tire/wheel position, and

five minutes overall to match all

four tire/wheel positions. If it takes

longer than two minutes, to match

the first tire and wheel, or more than

five minutes to match all four tire

and wheel positions the matching

process stops and you need to

start over.

The TPMS sensor matching process

is outlined below:

1. Set the parking brake.

2. Turn the ignition switch to ON/RUN with the engine off. 3. Press the Remote Keyless Entry

(RKE) transmitter's LOCK and

UNLOCK buttons at the same

time for approximately

five seconds. The horn sounds

twice to signal the receiver is in

relearn mode and TIRE

LEARNING ACTIVE message

displays on the DIC screen.

4. Start with the driver side front tire.

5. Remove the valve cap from the valve cap stem. Activate the

TPMS sensor by increasing or

decreasing the tire's air pressure

for five seconds, or until a horn

chirp sounds. The horn chirp,

which may take up to

30 seconds to sound, confirms

that the sensor identification

code has been matched to this

tire and wheel position.

6. Proceed to the passenger side front tire, and repeat the

procedure in Step 5. 7. Proceed to the passenger side

rear tire, and repeat the

procedure in Step 5.

8. Proceed to the driver side rear tire, and repeat the procedure in

Step 5. The horn sounds two

times to indicate the sensor

identification code has been

matched to the driver side rear

tire, and the TPMS sensor

matching process is no longer

active. The TIRE LEARNING

ACTIVE message on the DIC

display screen goes off.

9. Turn the ignition switch to LOCK/OFF.

10. Set all four tires to the recommended air pressure

level as indicated on the Tire

and Loading Information label.

11. Put the valve caps back on the valve stems.