tow CADILLAC ESCALADE EXT 2004 2.G Repair Manual

[x] Cancel search | Manufacturer: CADILLAC, Model Year: 2004, Model line: ESCALADE EXT, Model: CADILLAC ESCALADE EXT 2004 2.GPages: 478, PDF Size: 3.43 MB

Page 337 of 478

CAUTION: (Continued)

everyone away from the vehicle until it cools

down. Wait until there is no sign of steam or

coolant before you open the hood.

If you keep driving when your engine is

overheated, the liquids in it can catch ®re. You

or others could be badly burned. Stop your

engine if it overheats, and get out of the

vehicle until the engine is cool.

See ªOverheated Engine Protection Operating

Modeº under

Engine Overheating on page 5-26

for information on driving to a safe place in an

emergency.

Notice:If your engine catches ®re because you

keep driving with no coolant, your vehicle can

be badly damaged. The costly repairs would not be

covered by your warranty. See ªOverheated

Engine Protection Operating Modeº under

Engine

Overheating on page 5-26for information on driving

to a safe place in an emergency.

If No Steam Is Coming From Your

Engine

An overheat warning, along with a low coolant condition,

can indicate a serious problem.

If you get an engine overheat, but see or hear no

steam, the problem may not be too serious. Sometimes

the engine can get a little too hot when you:

·Climb a long hill on a hot day.

·Stop after high-speed driving.

·Idle for long periods in traffic.

·Tow a trailer. See ªDriving on Gradesº under

Towing a Trailer on page 4-55.

If you get the overheat warning with no sign of steam,

try this for a minute or so:

1. Turn on your heater to full hot at the highest fan

speed and open the window as necessary.

2. If you're in a traffic jam, shift to NEUTRAL (N);

otherwise, shift to the highest gear while

driving ± DRIVE (D).

5-27

Page 344 of 478

5. Then replace the pressure cap. Be sure the

pressure cap is hand-tight and fully seated.

Engine Fan Noise

Your vehicle has a clutched engine cooling fan. When

the clutch is engaged, the fan spins faster to provide

more air to cool the engine. In most everyday driving

conditions, the fan is spinning slower and the clutch is

not fully engaged. This improves fuel economy and

reduces fan noise. Under heavy vehicle loading, trailer

towing and/or high outside temperatures, the fan

speed increases as the clutch more fully engages. So

you may hear an increase in fan noise. This is

normal and should not be mistaken as the transmission

slipping or making extra shifts. It is merely the cooling

system functioning properly. The fan will slow down

when additional cooling is not required and the clutch

disengages.

You may also hear this fan noise when you start the

engine. It will go away as the fan clutch partially

disengages.

5-34

Page 347 of 478

Adding Washer Fluid

Your vehicle has a low washer ¯uid message that

comes on when the washer ¯uid is low. The message is

displayed for 15 seconds at the start of each ignition

cycle. When the LOW WASHER FLUID message

is displayed, you will need to add washer ¯uid to the

windshield washer ¯uid reservoir.

The windshield washer

¯uid reservoir is located in

the engine compartment

toward the front of the

vehicle on the driver's side.

Open the cap with the washer symbol on it. Add washer

¯uid until the tank is full.

Notice:

·When using concentrated washer ¯uid, follow

the manufacturer's instructions for adding

water.

·Do not mix water with ready-to-use washer ¯uid.

Water can cause the solution to freeze and

damage your washer ¯uid tank and other parts

of the washer system. Also, water does not

clean as well as washer ¯uid.

·Fill your washer ¯uid tank only three-quarters

full when it is very cold. This allows for

expansion if freezing occurs, which could

damage the tank if it is completely full.

·Do not use engine coolant (antifreeze) in your

windshield washer. It can damage your washer

system and paint.

5-37

Page 367 of 478

4. Pull the top left or right corner of the grill out so the

clips release. This will give you the needed

clearance for removing the headlamp assembly.5. Remove the horizontal pin from the headlamp

assembly by lifting the end of the pin upward

until it unsnaps and then pulling it toward the center

of the vehicle.

5-57

Page 373 of 478

To replace the windshield wiper blade assembly do the

following:

1. Lift the wiper arm and turn the blade until it is

facing away from the windshield.

2. Push the release lever and slide the wiper assembly

toward the driver's side of the vehicle.

3. Install a new blade by reversing Steps 1 and 2.

Tires

Your new vehicle comes with high-quality tires made by

a leading tire manufacturer. If you ever have questions

about your tire warranty and where to obtain service,see your GM Warranty booklet for details. For additional

information refer to the tire manufacturer's booklet

included with your vehicle's Owner's Manual.

{CAUTION:

Poorly maintained and improperly used tires

are dangerous.

·Overloading your tires can cause

overheating as a result of too much

friction. You could have an air-out and a

serious accident. See ªLoading Your

Vehicleº in the Index.

·Underin¯ated tires pose the same danger

as overloaded tires. The resulting accident

could cause serious injury. Check all tires

frequently to maintain the recommended

pressure. Tire pressure should be checked

when your tires are cold.

·Overin¯ated tires are more likely to be

cut, punctured or broken by a sudden

impact Ð such as when you hit a pothole.

Keep tires at the recommended pressure.

·Worn, old tires can cause accidents. If

your tread is badly worn, or if your tires

have been damaged, replace them.

5-63

Page 385 of 478

Make sure the spare tire is stored securely. Push, pull,

and then try to rotate or turn the tire. If it moves,

use the ratchet/wheel wrench to tighten the cable. See

Changing a Flat Tire on page 5-83.

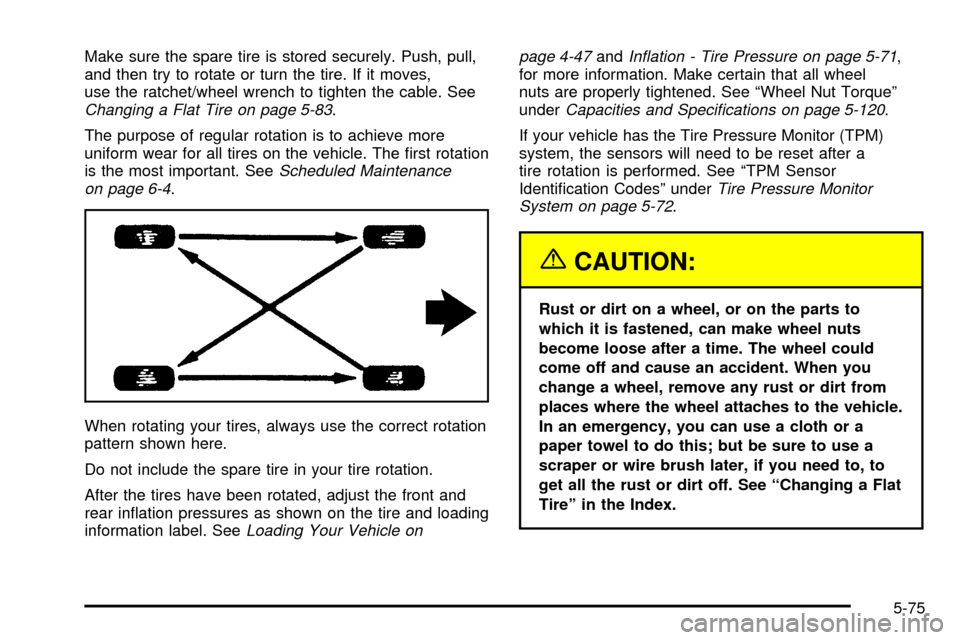

The purpose of regular rotation is to achieve more

uniform wear for all tires on the vehicle. The ®rst rotation

is the most important. See

Scheduled Maintenance

on page 6-4.

When rotating your tires, always use the correct rotation

pattern shown here.

Do not include the spare tire in your tire rotation.

After the tires have been rotated, adjust the front and

rear in¯ation pressures as shown on the tire and loading

information label. See

Loading Your Vehicle onpage 4-47

andIn¯ation - Tire Pressure on page 5-71,

for more information. Make certain that all wheel

nuts are properly tightened. See ªWheel Nut Torqueº

under

Capacities and Speci®cations on page 5-120.

If your vehicle has the Tire Pressure Monitor (TPM)

system, the sensors will need to be reset after a

tire rotation is performed. See ªTPM Sensor

Identi®cation Codesº under

Tire Pressure Monitor

System on page 5-72.

{CAUTION:

Rust or dirt on a wheel, or on the parts to

which it is fastened, can make wheel nuts

become loose after a time. The wheel could

come off and cause an accident. When you

change a wheel, remove any rust or dirt from

places where the wheel attaches to the vehicle.

In an emergency, you can use a cloth or a

paper towel to do this; but be sure to use a

scraper or wire brush later, if you need to, to

get all the rust or dirt off. See ªChanging a Flat

Tireº in the Index.

5-75

Page 392 of 478

If a Tire Goes Flat

It's unusual for a tire to ªblowoutº while you're driving,

especially if you maintain your tires properly. If air goes

out of a tire, it's much more likely to leak out slowly.

But if you should ever have a ªblowout,º here are a few

tips about what to expect and what to do:

If a front tire fails, the ¯at tire will create a drag that

pulls the vehicle toward that side. Take your foot off the

accelerator pedal and grip the steering wheel ®rmly.

Steer to maintain lane position, and then gently brake to

a stop well out of the traffic lane.

A rear blowout, particularly on a curve, acts much like a

skid and may require the same correction you'd use

in a skid. In any rear blowout, remove your foot from the

accelerator pedal. Get the vehicle under control by

steering the way you want the vehicle to go. It may be

very bumpy and noisy, but you can still steer. Gently

brake to a stop, well off the road if possible.{CAUTION:

Lifting a vehicle and getting under it to do

maintenance or repairs is dangerous without

the appropriate safety equipment and training.

The jack provided with your vehicle is

designed only for changing a ¯at tire. If it is

used for anything else, you or others could be

badly injured or killed if the vehicle slips off

the jack. Use the jack provided with your

vehicle only for changing a ¯at tire.

If a tire goes ¯at, the next part shows how to use your

jacking equipment to change a ¯at tire safely.

5-82

Page 397 of 478

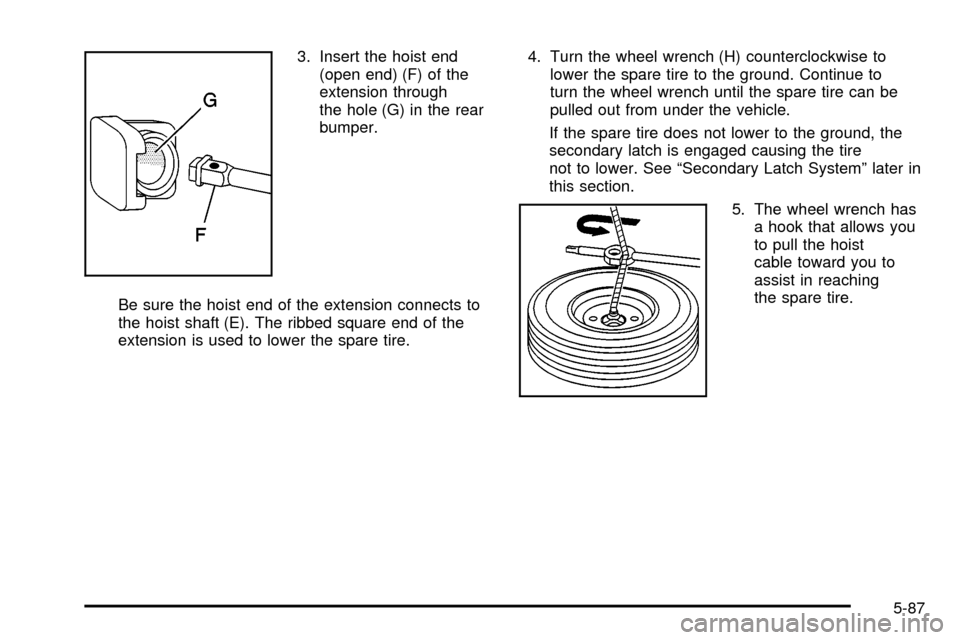

3. Insert the hoist end

(open end) (F) of the

extension through

the hole (G) in the rear

bumper.

Be sure the hoist end of the extension connects to

the hoist shaft (E). The ribbed square end of the

extension is used to lower the spare tire.4. Turn the wheel wrench (H) counterclockwise to

lower the spare tire to the ground. Continue to

turn the wheel wrench until the spare tire can be

pulled out from under the vehicle.

If the spare tire does not lower to the ground, the

secondary latch is engaged causing the tire

not to lower. See ªSecondary Latch Systemº later in

this section.

5. The wheel wrench has

a hook that allows you

to pull the hoist

cable toward you to

assist in reaching

the spare tire.

5-87

Page 402 of 478

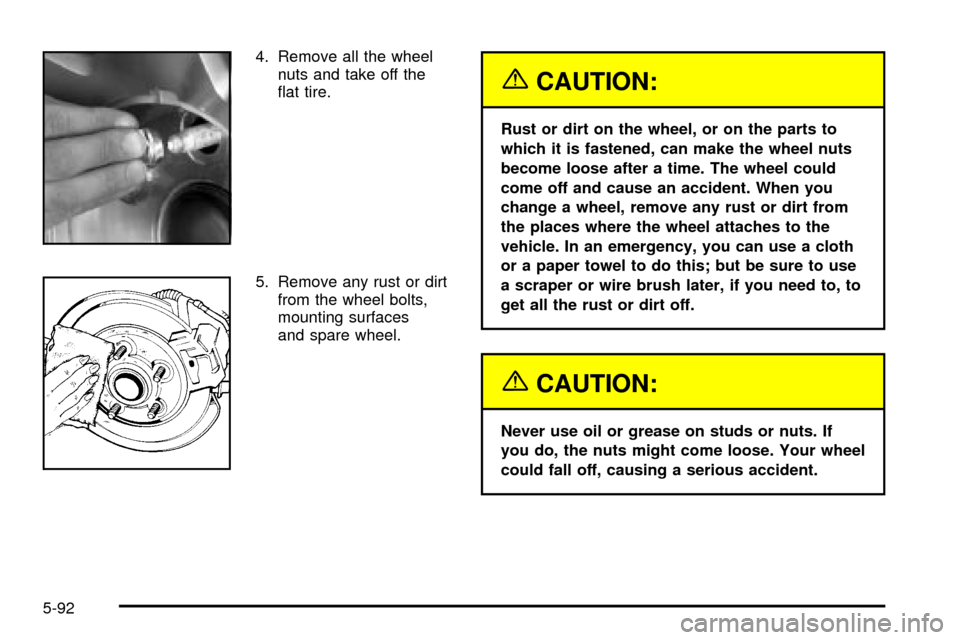

4. Remove all the wheel

nuts and take off the

¯at tire.

5. Remove any rust or dirt

from the wheel bolts,

mounting surfaces

and spare wheel.

{CAUTION:

Rust or dirt on the wheel, or on the parts to

which it is fastened, can make the wheel nuts

become loose after a time. The wheel could

come off and cause an accident. When you

change a wheel, remove any rust or dirt from

the places where the wheel attaches to the

vehicle. In an emergency, you can use a cloth

or a paper towel to do this; but be sure to use

a scraper or wire brush later, if you need to, to

get all the rust or dirt off.

{CAUTION:

Never use oil or grease on studs or nuts. If

you do, the nuts might come loose. Your wheel

could fall off, causing a serious accident.

5-92

Page 403 of 478

6. After mounting the

spare, put the wheel

nuts back on with the

rounded end of the nuts

toward the wheel.

Tighten each wheel nut

by hand. Then use the

wheel wrench to tighten

the wheel nuts until the

wheel is held against

the hub.

7. Turn the wheel wrench counterclockwise to lower

the vehicle. Lower the jack completely.

8. Tighten the nuts ®rmly

in a crisscross

sequence as shown by

turning the wheel

wrench clockwise.

{CAUTION:

Incorrect wheel nuts or improperly tightened

wheel nuts can cause the wheel to come loose

and even come off. This could lead to an

accident. Be sure to use the correct wheel

nuts. If you have to replace them, be sure to

get new GM original equipment wheel nuts.

Stop somewhere as soon as you can and have

the nuts tightened with a torque wrench to the

proper torque speci®cation. See ªCapacities

and Speci®cationsº in the Index for wheel nut

torque speci®cation.

5-93