CADILLAC ESCALADE EXT 2008 3.G Owners Manual

Manufacturer: CADILLAC, Model Year: 2008, Model line: ESCALADE EXT, Model: CADILLAC ESCALADE EXT 2008 3.GPages: 496, PDF Size: 7.02 MB

Page 371 of 496

5. Check that the jumper cables do not have loose

or missing insulation. If they do, you could get a

shock. The vehicles could be damaged too.

Before you connect the cables, here are some

basic things you should know. Positive (+) will go

to positive (+) or to a remote positive (+) terminal

if the vehicle has one. Negative (−) will go to a

heavy, unpainted metal engine part or to a remote

negative (−) terminal if the vehicle has one.

Do not connect positive (+) to negative (−)oryou

will get a short that would damage the battery

and maybe other parts too. And do not connect the

negative (−) cable to the negative (−) terminal on

the dead battery because this can cause sparks.

6. Connect the red

positive (+) cable to

the positive (+) terminal

of the vehicle with

the dead battery. Use

a remote positive (+)

terminal if the

vehicle has one.7. Do not let the other end touch metal. Connect it to

the positive (+) terminal of the good battery. Use a

remote positive (+) terminal if the vehicle has one.

8. Now connect the black negative (−) cable to the

negative (−) terminal of the good battery. Use a

remote negative (−) terminal if the vehicle has one.

Do not let the other end touch anything until the

next step. The other end of the negative (−) cable

does not go to the dead battery. It goes to a

heavy, unpainted metal engine part or to the remote

negative (−) terminal on the vehicle with the dead

battery.

9. Connect the other end of the negative (−) cable to

the remote negative (−) terminal, on the vehicle with

the dead battery.

10. Now start the vehicle with the good battery and run

the engine for a while.

11. Try to start the vehicle that had the dead battery.

If it will not start after a few tries, it probably needs

service.

5-43

Page 372 of 496

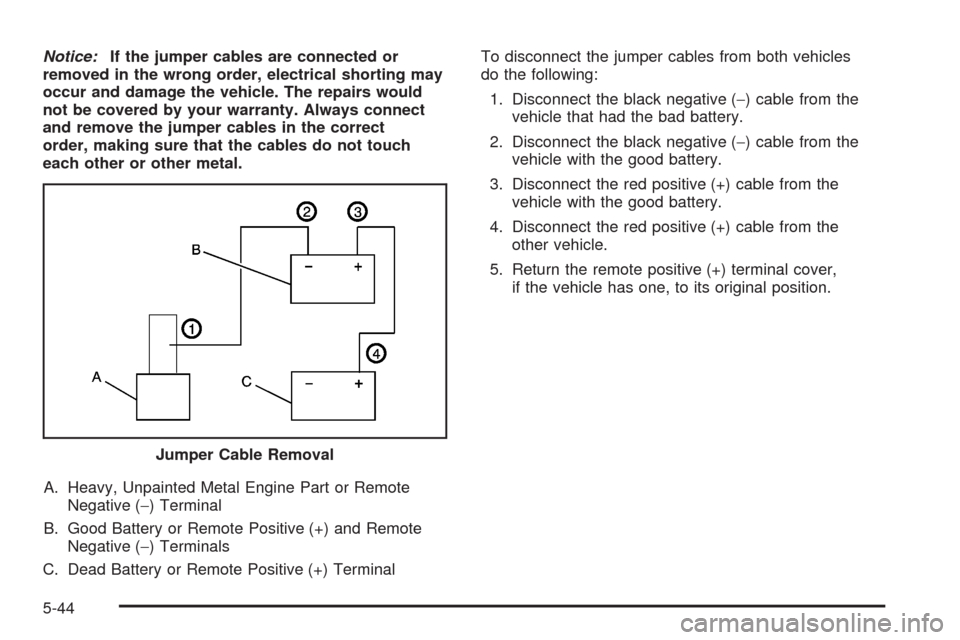

Notice:If the jumper cables are connected or

removed in the wrong order, electrical shorting may

occur and damage the vehicle. The repairs would

not be covered by your warranty. Always connect

and remove the jumper cables in the correct

order, making sure that the cables do not touch

each other or other metal.

A. Heavy, Unpainted Metal Engine Part or Remote

Negative (−) Terminal

B. Good Battery or Remote Positive (+) and Remote

Negative (−) Terminals

C. Dead Battery or Remote Positive (+) TerminalTo disconnect the jumper cables from both vehicles

do the following:

1. Disconnect the black negative (−) cable from the

vehicle that had the bad battery.

2. Disconnect the black negative (−) cable from the

vehicle with the good battery.

3. Disconnect the red positive (+) cable from the

vehicle with the good battery.

4. Disconnect the red positive (+) cable from the

other vehicle.

5. Return the remote positive (+) terminal cover,

if the vehicle has one, to its original position.

Jumper Cable Removal

5-44

Page 373 of 496

All-Wheel Drive

Transfer Case

If your vehicle is equipped with All-Wheel Drive,

be sure to perform the lubricant checks described in

this section. There are two additional systems that need

lubrication.

When to Check Lubricant

Refer to the Maintenance Schedule to determine

how often to check the lubricant. SeeScheduled

Maintenance on page 6-4.

How to Check Lubricant

To get an accurate reading, the vehicle should be

on a level surface.

If the level is below the bottom of the �ller plug hole,

located on the transfer case, you’ll need to add

some lubricant. Add enough lubricant to raise the

level to the bottom of the �ller plug hole. Use care

not to overtighten the plug.(A) Drain Plug (B) Filler Plug

5-45

Page 374 of 496

What to Use

Refer to the Maintenance Schedule to determine what

kind of lubricant to use. SeeRecommended Fluids

and Lubricants on page 6-13.

Rear Axle

When to Check Lubricant

It is not necessary to regularly check rear axle �uid

unless you suspect there is a leak or you hear an

unusual noise. A �uid loss could indicate a problem.

Have it inspected and repaired.

All axle assemblies are �lled by volume of �uid during

production. They are not �lled to reach a certain

level. When checking the �uid level on any axle,

variations in the readings can be caused by factory �ll

differences between the minimum and the maximum

�uid volume. Also, if a vehicle has just been driven

before checking the �uid level, it may appear lower than

normal because �uid has traveled out along the axle

tubes and has not drained back to the sump area.

Therefore, a reading taken �ve minutes after the vehicle

has been driven will appear to have a lower �uid

level than a vehicle that has been stationary for an

hour or two. Remember that the rear axle assembly

must be supported to get a true reading.

How to Check Lubricant

To get an accurate reading, the vehicle should be

on a level surface.

The proper level is from 0.04 inch to 0.75 inch

(1.0 mm to 19.0 mm) below the bottom of the �ller

plug hole, located on the rear axle. Add only enough

�uid to reach the proper level.

5-46

Page 375 of 496

What to Use

Refer to the Maintenance Schedule to determine what

kind of lubricant to use. SeeRecommended Fluids

and Lubricants on page 6-13.

Front Axle

When to Check and Change Lubricant

It is not necessary to regularly check front axle �uid

unless you suspect there is a leak or you hear an

unusual noise. A �uid loss could indicate a problem.

Have it inspected and repaired.

How to Check Lubricant

To get an accurate reading, the vehicle should be on a

level surface.

A:Fill Plug

B:Drain Plug

When the differential is cold, add enough lubricant to

raise the level from 0 (0 mm) to 1/8 inch (3.2 mm)

below the �ller plug hole.

When the differential is at operating temperature

(warm), add enough lubricant to raise the level to the

bottom of the �ller plug hole.1500 Series

5-47

Page 376 of 496

What to Use

Refer to the Maintenance Schedule to determine what

kind of lubricant to use. SeeRecommended Fluids

and Lubricants on page 6-13.

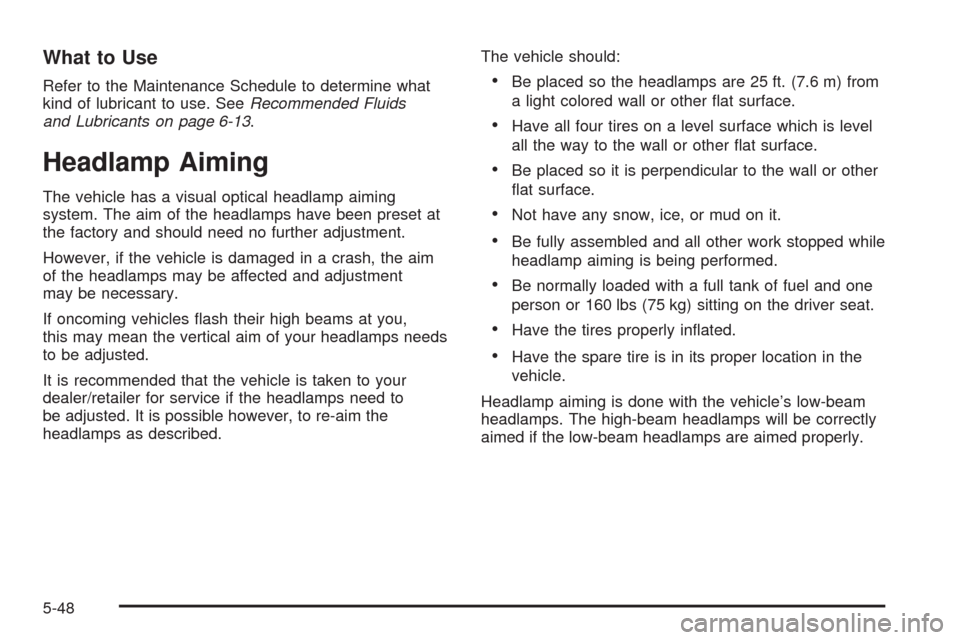

Headlamp Aiming

The vehicle has a visual optical headlamp aiming

system. The aim of the headlamps have been preset at

the factory and should need no further adjustment.

However, if the vehicle is damaged in a crash, the aim

of the headlamps may be affected and adjustment

may be necessary.

If oncoming vehicles �ash their high beams at you,

this may mean the vertical aim of your headlamps needs

to be adjusted.

It is recommended that the vehicle is taken to your

dealer/retailer for service if the headlamps need to

be adjusted. It is possible however, to re-aim the

headlamps as described.The vehicle should:

Be placed so the headlamps are 25 ft. (7.6 m) from

a light colored wall or other �at surface.

Have all four tires on a level surface which is level

all the way to the wall or other �at surface.

Be placed so it is perpendicular to the wall or other

�at surface.

Not have any snow, ice, or mud on it.

Be fully assembled and all other work stopped while

headlamp aiming is being performed.

Be normally loaded with a full tank of fuel and one

person or 160 lbs (75 kg) sitting on the driver seat.

Have the tires properly in�ated.

Have the spare tire is in its proper location in the

vehicle.

Headlamp aiming is done with the vehicle’s low-beam

headlamps. The high-beam headlamps will be correctly

aimed if the low-beam headlamps are aimed properly.

5-48

Page 377 of 496

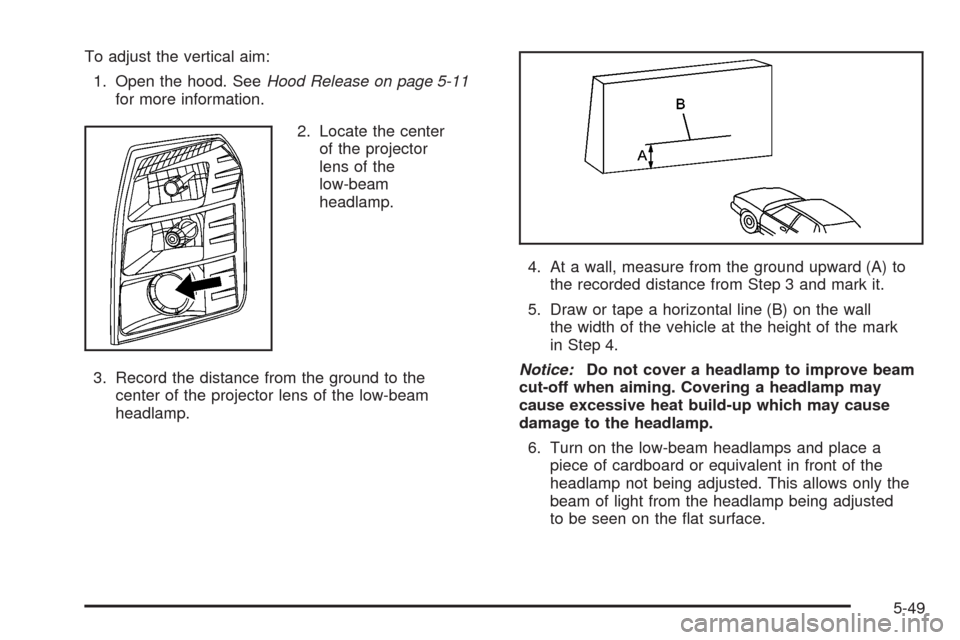

To adjust the vertical aim:

1. Open the hood. SeeHood Release on page 5-11

for more information.

2. Locate the center

of the projector

lens of the

low-beam

headlamp.

3. Record the distance from the ground to the

center of the projector lens of the low-beam

headlamp.4. At a wall, measure from the ground upward (A) to

the recorded distance from Step 3 and mark it.

5. Draw or tape a horizontal line (B) on the wall

the width of the vehicle at the height of the mark

in Step 4.

Notice:Do not cover a headlamp to improve beam

cut-off when aiming. Covering a headlamp may

cause excessive heat build-up which may cause

damage to the headlamp.

6. Turn on the low-beam headlamps and place a

piece of cardboard or equivalent in front of the

headlamp not being adjusted. This allows only the

beam of light from the headlamp being adjusted

to be seen on the �at surface.

5-49

Page 378 of 496

7. Locate the vertical headlamp aiming screws, which

are under the hood near each headlamp assembly.

The adjustment screw can be turned with a

E8 Torx

®socket.

8. Turn the vertical aiming screw until the headlamp

beam is aimed to the horizontal tape line. Turn it

clockwise or counterclockwise to raise or lower the

angle of the beam.9. Make sure that the light from the headlamp is

positioned at the bottom edge of the horizontal tape

line. The lamp on the left (A) shows the correct

headlamp aim. The lamp on the right (B) shows the

incorrect headlamp aim.

10. Repeat Steps 7 through 9 for the opposite

headlamp.

5-50

Page 379 of 496

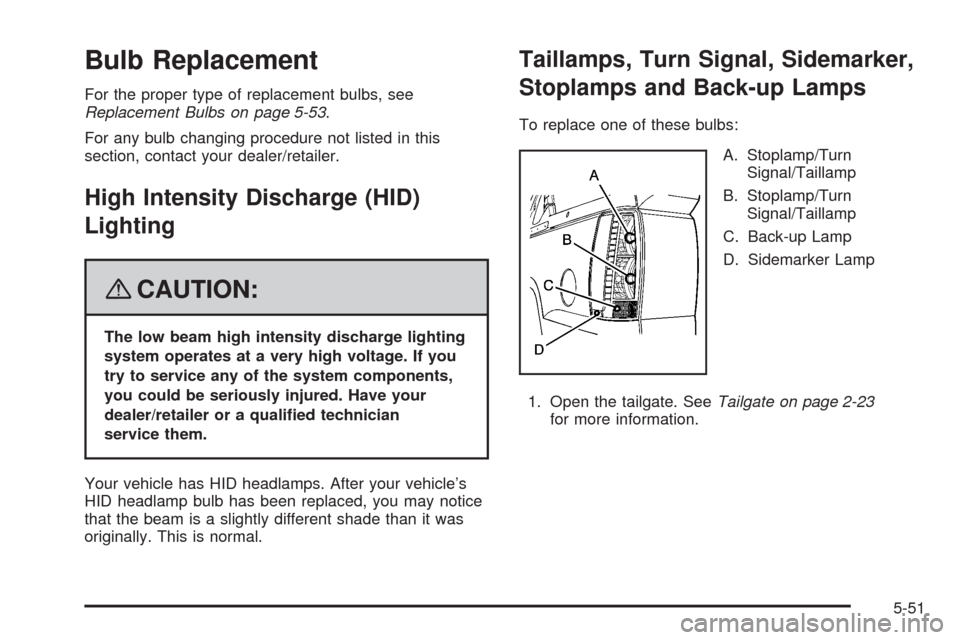

Bulb Replacement

For the proper type of replacement bulbs, see

Replacement Bulbs on page 5-53.

For any bulb changing procedure not listed in this

section, contact your dealer/retailer.

High Intensity Discharge (HID)

Lighting

{CAUTION:

The low beam high intensity discharge lighting

system operates at a very high voltage. If you

try to service any of the system components,

you could be seriously injured. Have your

dealer/retailer or a quali�ed technician

service them.

Your vehicle has HID headlamps. After your vehicle’s

HID headlamp bulb has been replaced, you may notice

that the beam is a slightly different shade than it was

originally. This is normal.

Taillamps, Turn Signal, Sidemarker,

Stoplamps and Back-up Lamps

To replace one of these bulbs:

A. Stoplamp/Turn

Signal/Taillamp

B. Stoplamp/Turn

Signal/Taillamp

C. Back-up Lamp

D. Sidemarker Lamp

1. Open the tailgate. SeeTailgate on page 2-23

for more information.

5-51

Page 380 of 496

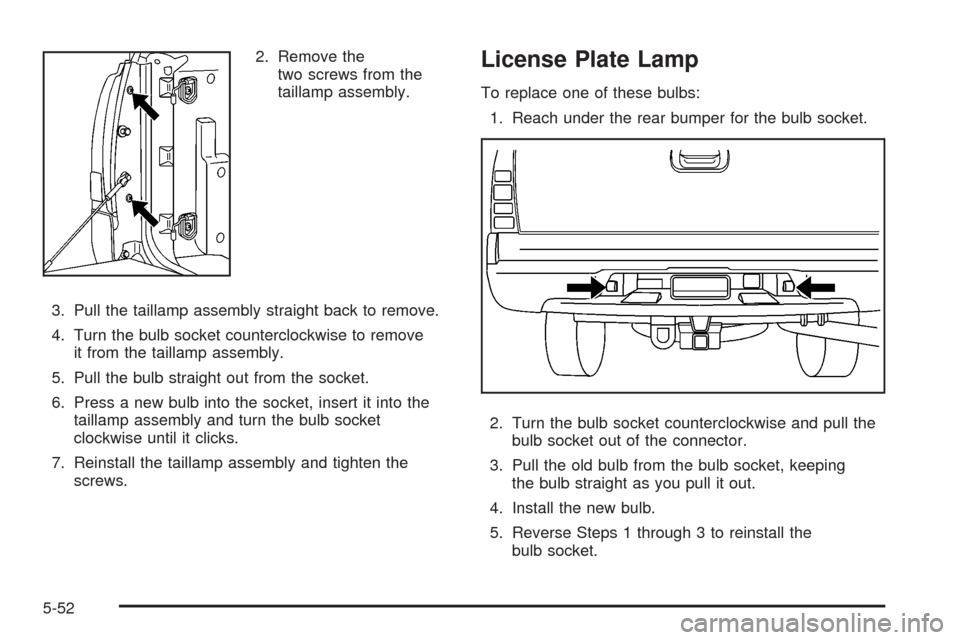

2. Remove the

two screws from the

taillamp assembly.

3. Pull the taillamp assembly straight back to remove.

4. Turn the bulb socket counterclockwise to remove

it from the taillamp assembly.

5. Pull the bulb straight out from the socket.

6. Press a new bulb into the socket, insert it into the

taillamp assembly and turn the bulb socket

clockwise until it clicks.

7. Reinstall the taillamp assembly and tighten the

screws.License Plate Lamp

To replace one of these bulbs:

1. Reach under the rear bumper for the bulb socket.

2. Turn the bulb socket counterclockwise and pull the

bulb socket out of the connector.

3. Pull the old bulb from the bulb socket, keeping

the bulb straight as you pull it out.

4. Install the new bulb.

5. Reverse Steps 1 through 3 to reinstall the

bulb socket.

5-52