clock CADILLAC ESCALADE EXT 2010 3.G Owner's Manual

[x] Cancel search | Manufacturer: CADILLAC, Model Year: 2010, Model line: ESCALADE EXT, Model: CADILLAC ESCALADE EXT 2010 3.GPages: 580, PDF Size: 6.23 MB

Page 466 of 580

7. Locate the vertical headlamp aiming screws, whichare under the hood near each headlamp assembly.

The adjustment screw can be turned with a

E8 Torx

®socket.

8. Turn the vertical aiming screw until the headlamp beam is aimed to the horizontal tape line. Turn it

clockwise or counterclockwise to raise or lower the

angle of the beam.

9. Make sure that the light from the headlamp is

positioned at the bottom edge of the horizontal

tape line. The lamp on the left (A) shows the

correct headlamp aim. The lamp on the right (B)

shows the incorrect headlamp aim.

10. Repeat Steps 7 through 9 for the opposite headlamp.

7-52

Page 468 of 580

2. Remove the twoscrews from the

taillamp assembly. 3. Pull the taillamp assembly straight back to remove.

4. Turn the bulb socket counterclockwise to remove it

from the taillamp assembly.

5. Pull the bulb straight out from the socket.

6. Press a new bulb into the socket, insert it into the taillamp assembly and turn the bulb socket

clockwise until it clicks.

7. Reinstall the taillamp assembly and tighten the screws.

7-54

Page 469 of 580

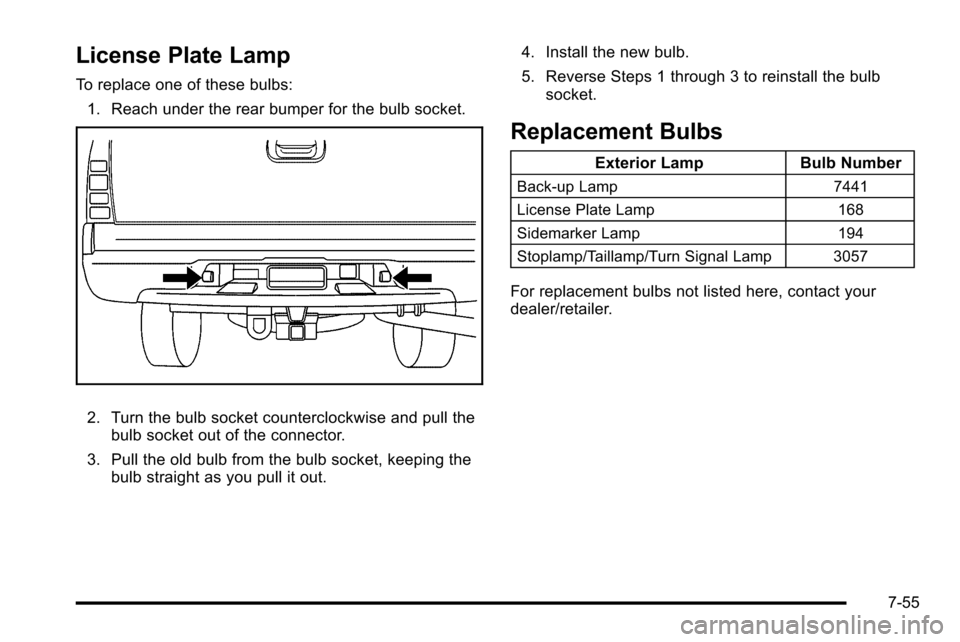

License Plate Lamp

To replace one of these bulbs:1. Reach under the rear bumper for the bulb socket.

2. Turn the bulb socket counterclockwise and pull the bulb socket out of the connector.

3. Pull the old bulb from the bulb socket, keeping the bulb straight as you pull it out. 4. Install the new bulb.

5. Reverse Steps 1 through 3 to reinstall the bulb

socket.

Replacement Bulbs

Exterior Lamp Bulb Number

Back-up Lamp 7441

License Plate Lamp 168

Sidemarker Lamp 194

Stoplamp/Taillamp/Turn Signal Lamp 3057

For replacement bulbs not listed here, contact your

dealer/retailer.

7-55

Page 494 of 580

Removing the Spare Tire and Tools

The jack and the wheel blocks are located under a

cover near the passenger side rear seat.

Rear Seat (Passenger Side) Jack Cover

1. Remove the jack cover by turning the two wing nuts one-quarter turn counterclockwise and pulling

the jack cover off.

A. Wheel Blocks

B. Jack Knob

C. Wing Nut D. Retaining Hook

E. Jack

F. Mounting Bracket

2. Release the jack (E) from the mounting bracket (F) by turning the jack knob (B) on the jack

counterclockwise to release the jack from the

mounting bracket.

7-80

Page 495 of 580

3. Remove the wheel blocks (A) attachedto the jack (E) by turning the wing nut (C)

counterclockwise. Place the wheel blocks where

needed as indicated in previously in this section.

The tools for changing a flat tire are located in the

passenger's side top-box storage unit.

To remove the tools, do the following: 1. Open the top door on the passenger's side top-box storage unit. Use the ignition/door key to unlock it if

it is locked. See Top-Box Storage

on page 3‑76for more information.

2. Remove the black pouch from the storage box. You now have all of the tools you will need to lower

the spare tire and change a flat. To access the spare tire:

A. Spare Tire (Valve

Stem Pointed Down)

B. Hoist Assembly

C. Hoist Cable

D. Tire/Wheel Retainer E. Hoist Shaft

F. Hoist End of Extension Tool G. Hoist Shaft

Access Hole

H. Wheel Wrench I. Jack Handle Extension(s)

J. Spare Tire Lock

7-81

Page 496 of 580

1. Open the hoist shaft access cover on the bumperto access the spare tire lock (J).

2. To remove the spare tire lock, insert the ignition key, turn it clockwise and pull it straight out.

3. Assemble the two jack handle extensions (I) andwheel wrench (H) as shown.

4. Insert the open end ofthe extension (F)

through the hole in the

rear bumper (G) (hoist

shaft access hole).

Be sure the hoist end (F) of the extension connects

to the hoist shaft (E). The ribbed square end of the

extension is used to lower the spare tire.

Do not use the chiseled end of the wheel wrench.

5. Turn the wheel wrench counterclockwise to lower the spare tire to the ground. Continue to turn the

wheel wrench until the spare tire can be pulled out

from under the vehicle.

If the spare tire does not lower to the ground, the

secondary latch is engaged causing the tire not to

lower. See Secondary Latch System

on page 7‑89for more information.

7-82

Page 499 of 580

3. Use the wheelwrench to loosen all

the wheel nuts. Turn

the wheel wrench

counterclockwise to

loosen the wheel nuts.

Do not remove the

wheel nuts yet.

Jacking Locations (Overall View)

A. Front Position

B. Rear Position

{WARNING:

Getting under a vehicle when it is jacked up is

dangerous. If the vehicle slips off the jack, you

could be badly injured or killed. Never get under a

vehicle when it is supported only by a jack.

{WARNING:

Raising your vehicle with the jack improperly

positioned can damage the vehicle and even

make the vehicle fall. To help avoid personal

injury and vehicle damage, be sure to fit the jack

lift head into the proper location before raising the

vehicle.

4. Position the jack under the vehicle as shown.

7-85

Page 500 of 580

Front Position

Front Tire Flat: If the flat tire is on a front tire

of the vehicle, you will need to use the jack

handle (B) and only one jack handle extension (C).

Attach the wheel wrench (D) to the jack handle

extension (C). Attach the jack handle (B) to the

jack (A). Position the jack on the frame behind the

flat tire near the front body mount (E) as shown.

Turn the wheel wrench (D) clockwise to raise the

vehicle. Raise the vehicle far enough off the

ground so there is enough room for the spare tire

to clear the ground.Rear Position

Rear Tire Flat: If the flat tire is on a rear tire of

the vehicle, use the jack handle (B) and both

jack handle extensions (C). Attach the wheel

wrench (D) to the jack handle extensions (C).

Attach the jack handle (B) to the jack (A). Use the

jacking pad (E) provided on the rear axle. Turn the

wheel wrench (D) clockwise to raise the vehicle.

Raise the vehicle far enough off the ground so

there is enough room for the spare tire to clear the

ground.

7-86

Page 502 of 580

{WARNING:

Never use oil or grease on bolts or nuts because

the nuts might come loose. The vehicle's wheel

could fall off, causing a crash.

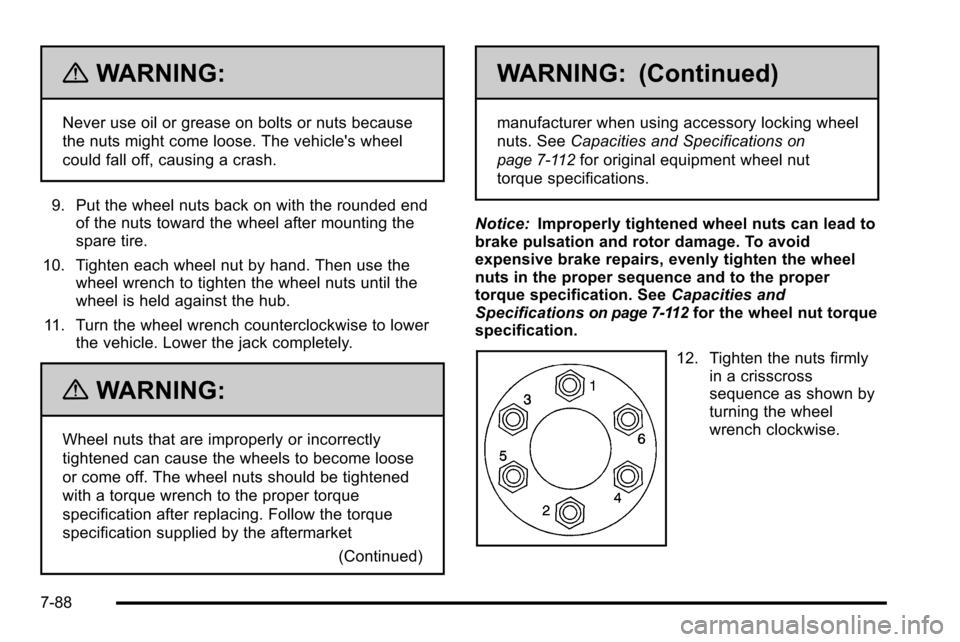

9. Put the wheel nuts back on with the rounded end of the nuts toward the wheel after mounting the

spare tire.

10. Tighten each wheel nut by hand. Then use the wheel wrench to tighten the wheel nuts until the

wheel is held against the hub.

11. Turn the wheel wrench counterclockwise to lower the vehicle. Lower the jack completely.

{WARNING:

Wheel nuts that are improperly or incorrectly

tightened can cause the wheels to become loose

or come off. The wheel nuts should be tightened

with a torque wrench to the proper torque

specification after replacing. Follow the torque

specification supplied by the aftermarket

(Continued)

WARNING: (Continued)

manufacturer when using accessory locking wheel

nuts. SeeCapacities and Specifications

on

page 7‑112

for original equipment wheel nut

torque specifications.

Notice: Improperly tightened wheel nuts can lead to

brake pulsation and rotor damage. To avoid

expensive brake repairs, evenly tighten the wheel

nuts in the proper sequence and to the proper

torque specification. See Capacities and

Specifications

on page 7‑112for the wheel nut torque

specification.

12. Tighten the nuts firmly

in a crisscross

sequence as shown by

turning the wheel

wrench clockwise.

7-88

Page 503 of 580

When you reinstall the regular wheel and tire, you must

also reinstall the center cap. Line the tab on the back of

the tab with the slot in the wheel. Place the cap on the

wheel and press until it snaps into place.

Secondary Latch System

Your vehicle has an underbody-mounted tire hoist

assembly equipped with a secondary latch system. It is

designed to stop the spare tire from suddenly falling off

your vehicle. For the secondary latch to work, the spare

must be installed with the valve stem pointing down.

SeeStoring a Flat or Spare Tire and Tools

on

page 7‑92.

{WARNING:

Before beginning this procedure read all the

instructions. Failure to read and follow the

instructions could damage the hoist assembly and

you and others could get hurt. Read and follow

the instructions listed next. To release the spare tire from the secondary latch:

1. Check under the

vehicle to see if the

cable end is visible.

If the cable is not

visible proceed to

Step 6.

2. If it is visible, first try to tighten the cable by turning the wheel wrench clockwise until you

hear two clicks or feel it skip twice. You cannot

overtighten the cable.

3. Loosen the cable by turning the wrench counterclockwise three or four turns.

4. Repeat this procedure at least two times. If the spare tire lowers to the ground, continue with

Step 5 of Removing the Spare Tire and Tools

on

page 7‑80.

7-89