tow CADILLAC ESCALADE EXT 2010 3.G Repair Manual

[x] Cancel search | Manufacturer: CADILLAC, Model Year: 2010, Model line: ESCALADE EXT, Model: CADILLAC ESCALADE EXT 2010 3.GPages: 580, PDF Size: 6.23 MB

Page 414 of 580

Electric Brake Control Wiring

Provisions

These wiring provisions are included with the vehicle as

part of the trailer wiring package. These provisions are

for an electric brake controller. The instrument panel

contains blunt cut wires near the data link connector for

the trailer brake controller. The harness contains the

following wires:

.Dark Blue: Brake Signal to Trailer Connector

.Red/Black: Battery

.Light Blue/White: Brake Switch

.White: Ground

It should be installed by your dealer/retailer or a

qualified service center.

Trailer Recommendations

Subtract the hitch loads from the Cargo Weight

Rating (CWR). CWR is the maximum weight of the load

the vehicle can carry. It does not include the weight of

the people inside, but you can figure about 150 lbs.

(68 kg) for each passenger. The total cargo load must

not be more than the vehicles CWR.

Weigh the vehicle with the trailer attached, so the

GVWR or GAWR are not exceeded. If using a

weight-distributing hitch, weigh the vehicle without the

spring bars in place.

The best performance is obtained by correctly

spreading out the weight of the load and choosing the

correct hitch and trailer brakes.

For more information see Towing a Trailer

on

page 6‑42.

6-54

Page 429 of 580

A.Engine Air Cleaner/Filter on page 7‑20.

B. Coolant Surge Tank and Pressure Cap. See Cooling System on page 7‑26.

C. Remote Positive (+) Terminal. See Jump Starting

on page 7‑42.

D. Battery on page 7‑41.

E. Engine Oil Fill Cap. See “When to Add Engine Oil”

under Engine Oil on page 7‑15.

F. Automatic Transmission Dipstick (Out of View). See “Checking the Fluid Level” underAutomatic

Transmission Fluid on page 7‑22.

G. Remote Negative (−) Terminal (GND) (Out of View). See Jump Starting on page 7‑42.

H. Engine Oil Dipstick (Out of View). See “Checking

Engine Oil” underEngine Oil on page 7‑15.

I. Engine Cooling Fan (Out of View). See Cooling

System on page 7‑26.

J. Power Steering Fluid Reservoir (Out of View). See Power Steering Fluid on page 7‑36.

K. Brake Master Cylinder Reservoir. See “Brake

Fluid” under Brakes on page 7‑38.

L. Underhood Fuse Block on page 7‑108.

M. Windshield Washer Fluid Reservoir. See “Adding

Washer Fluid” underWindshield Washer Fluid

on

page 7‑37.

Engine Oil

Checking Engine Oil

It is a good idea to check the engine oil level at each

fuel fill. In order to get an accurate reading, the oil must

be warm and the vehicle must be on level ground.

The engine oil dipstick handle is a yellow loop. See

Engine Compartment Overview

on page 7‑14for the

location of the engine oil dipstick.

1. Turn off the engine and give the oil several minutes to drain back into the oil pan. If this is not done, the

oil dipstick might not show the actual level.

2. Pull out the dipstick and clean it with a paper towel or cloth, then push it back in all the way. Remove it

again, keeping the tip down, and check the level.

7-15

Page 436 of 580

Automatic Transmission Fluid

When to Check and Change Automatic

Transmission Fluid

It is usually not necessary to check the transmission

fluid level. The only reason for fluid loss is a

transmission leak or overheating the transmission.

If you suspect a small leak, then use the following

checking procedures to check the fluid level. However,

if there is a large leak, then it may be necessary to have

the vehicle towed to a dealer/retailer service department

and have it repaired before driving the vehicle further.

Notice:Use of the incorrect automatic transmission

fluid may damage the vehicle, and the damages may

not be covered by the vehicle's warranty. Always

use the automatic transmission fluid listed in

Recommended Fluids and Lubricants on page 8‑10.

Change the fluid and filter at the intervals listed in the

Maintenance Schedule. See Scheduled Maintenance

on page 8‑3. Be sure to use the transmission fluid

listed in Recommended Fluids and Lubricantson

page 8‑10.

How to Check Automatic Transmission

Fluid

Notice: Too much or too little fluid can damage your

transmission. Too much can mean that some of the

fluid could come out and fall on hot engine parts or

exhaust system parts, starting a fire. Too little fluid

could cause the transmission to overheat. Be sure

to get an accurate reading if you check your

transmission fluid.

Before checking the fluid level, prepare the vehicle as

follows:

1. Start the engine and park the vehicle on a level surface. Keep the engine running.

2. Apply the parking brake and place the shift lever in P (Park).

3. With your foot on the brake pedal, move the shift lever through each gear range, pausing for about

three seconds in each range. Then, move the shift

lever back to P (Park).

7-22

Page 437 of 580

4. Allow the engine to idle (500–800 rpm) for at least

one minute. Slowly release the brake pedal.

5. Keep the engine running and press the Trip/Fuel button or trip odometer reset stem until TRANS

TEMP (Transmission Temperature) displays on the

Driver Information Center (DIC).

6. Using the TRANS TEMP reading, determine and perform the appropriate check procedure. If the

TRANS TEMP reading is not within the required

temperature ranges, allow the vehicle to cool,

or operate the vehicle until the appropriate

transmission fluid temperature is reached.Cold Check Procedure

Use this procedure only as a reference to determine if

the transmission has enough fluid to be operated safely

until a hot check procedure can be made. The hot

check procedure is the most accurate method to check

the fluid level. Perform the hot check procedure at the

first opportunity. Use this cold check procedure to check

fluid level when the transmission temperature is

between 80°F and 90°F (27°C and 32°C).

1. Locate thetransmission dipstick at

the rear of the engine

compartment, on the

passenger side of the

vehicle.

See Engine Compartment Overview

on page 7‑14for more information.

2. Flip the handle up and then pull out the dipstick and wipe it with a clean rag or paper towel.

3. Install the dipstick by pushing it back in all the way, wait three seconds, and then pull it back out again.

7-23

Page 438 of 580

4. Check both sides of the dipstick and read the lowerlevel. Repeat the check procedure to verify the

reading.

5. If the fluid level is below the COLD check band,add only enough fluid as necessary to bring the

level into the COLD band. It does not take much

fluid, generally less than one pint (0.5L). Do not

overfill.

6. Perform a hot check at the first opportunity after the transmission reaches a normal

operating temperature between 160°F to 200°F

(71°C to 93°C).

7. If the fluid level is in the acceptable range, push the dipstick back in all the way, then flip the handle

down to lock the dipstick in place.

Hot Check Procedure

Use this procedure to check the transmission fluid level

when the transmission fluid temperature is between

160°F and 200°F (71°C and 93°C).

The hot check is the most accurate method to check

the fluid level. The hot check should be performed at

the first opportunity in order to verify the cold check.

The fluid level rises as fluid temperature increases, so it

is important to ensure the transmission temperature is

within range.

1. Locate thetransmission dipstick

at the rear of the

engine compartment,

on the passenger side

of the vehicle.

See Engine Compartment Overview

on page 7‑14for more information.

2. Flip the handle up and then pull out the dipstick and wipe it with a clean rag or paper towel.

3. Install the dipstick by pushing it back in all the way, wait three seconds, and then pull it back out again.

4. Check both sides of the dipstick and read the lower level. Repeat the check procedure to verify the

reading.

7-24

Page 448 of 580

If Steam Is Coming From The Engine

Compartment

{WARNING:

Steam from an overheated engine can burn you

badly, even if you just open the hood. Stay away

from the engine if you see or hear steam coming

from it. Turn it off and get everyone away from the

vehicle until it cools down. Wait until there is no

sign of steam or coolant before you open

the hood.

If you keep driving when the vehicles engine is

overheated, the liquids in it can catch fire. You or

others could be badly burned. Stop the engine if it

overheats, and get out of the vehicle until the

engine is cool.

SeeOverheated Engine Protection Operating

Mode

on page 7‑35for information on driving to

a safe place in an emergency.

If No Steam Is Coming From The

Engine Compartment

The ENGINE OVERHEATED STOP ENGINE or the

ENGINE OVERHEATED IDLE ENGINE message, along

with a low coolant condition, can indicate a serious

problem.

If you get an engine overheat warning, but see or hear

no steam, the problem may not be too serious.

Sometimes the engine can get a little too hot when you:

.Climb a long hill on a hot day.

.Stop after high-speed driving.

.Idle for long periods in traffic.

.Tow a trailer. See Towing a Trailer on page 6‑42.

7-34

Page 449 of 580

If you get the ENGINE OVERHEATED STOP ENGINE

or the ENGINE OVERHEATED IDLE ENGINE message

with no sign of steam, try this for a minute or so:

If the overheat warning is displayed with no sign of

steam:1. Turn the air conditioning off.

2. Turn the heater on to the highest temperature and to the highest fan speed. Open the windows as

necessary.

3. In heavy traffic, let the engine idle in N (Neutral) while stopped. If it is safe to do so, pull off the

road, shift to P (Park) or N (Neutral) and let the

engine idle.

If the temperature overheat gage is no longer in the

overheat zone or an overheat warning no longer

displays, the vehicle can be driven. Continue to drive

the vehicle slow for about 10 minutes. Keep a safe

vehicle distance from the car in front of you. If the

warning does not come back on, continue to drive

normally.

If the warning continues, pull over, stop, and park the

vehicle right away.

If there is no sign of steam, idle the engine for

five minutes while parked. If the warning is still

displayed, turn off the engine until it cools down.

Also, see “Overheated Engine Protection Operating

Mode” later in this section.Overheated Engine Protection

Operating Mode

If an overheated engine condition exists and the

ENGINE POWER IS REDUCED message is displayed,

an overheat protection mode which alternates firing

groups of cylinders helps prevent engine damage.

In this mode, you will notice a loss in power and engine

performance. This operating mode allows the vehicle to

be driven to a safe place in an emergency. Driving

extended miles (km) and/or towing a trailer in the

overheat protection mode should be avoided.

Notice: After driving in the overheated engine

protection operating mode, to avoid engine damage,

allow the engine to cool before attempting any

repair. The engine oil will be severely degraded.

Repair the cause of coolant loss, change the oil

and reset the oil life system. See Engine Oil

on

page 7‑15.

Engine Fan Noise

The vehicle has electric cooling fans. You might hear

the fans spinning at low speed during most everyday

driving. The fans can turn off if no cooling is required.

Under heavy vehicle loading, trailer towing, and/or high

outside temperatures, or if you are operating the air

conditioning system, the fans can change to high

speed and you might hear an increase in fan noise.

7-35

Page 485 of 580

Reset the Tire Pressure Monitor System. SeeTire

Pressure Monitor Operation

on page 7‑67.

Make certain that all wheel nuts are properly

tightened. See “Wheel Nut Torque” under

Capacities and Specifications

on page 7‑112.

{WARNING:

Rust or dirt on a wheel, or on the parts to

which it is fastened, can make wheel nuts

become loose after time. The wheel could

come off and cause an accident. When you

change a wheel, remove any rust or dirt from

places where the wheel attaches to the

vehicle. In an emergency, you can use a

cloth or a paper towel to do this; but be sure

to use a scraper or wire brush later,

if needed, to get all the rust or dirt off.

See Changing a Flat Tire

on page 7‑79.

Make sure the spare tire is stored securely. Push,

pull, and then try to rotate or turn the tire. If it

moves, tighten the cable. See Storing a Flat or

Spare Tire and Tools

on page 7‑92.

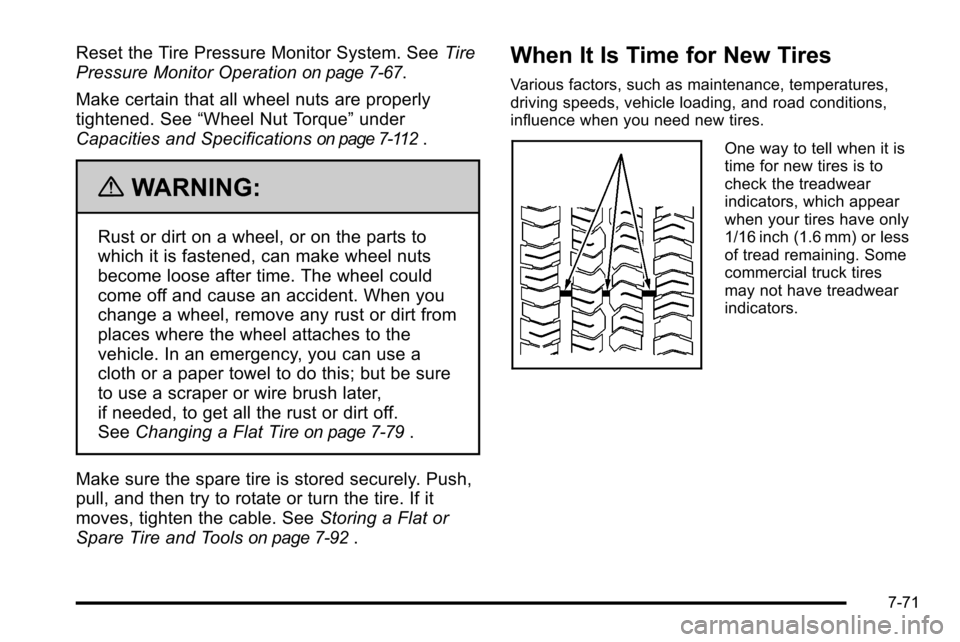

When It Is Time for New Tires

Various factors, such as maintenance, temperatures,

driving speeds, vehicle loading, and road conditions,

influence when you need new tires.

One way to tell when it is

time for new tires is to

check the treadwear

indicators, which appear

when your tires have only

1/16 inch (1.6 mm) or less

of tread remaining. Some

commercial truck tires

may not have treadwear

indicators.

7-71

Page 492 of 580

If a Tire Goes Flat

It is unusual for a tire to blowout while you are driving,

especially if you maintain your vehicle's tires properly.

If air goes out of a tire, it is much more likely to leak out

slowly. But if you should ever have a blowout, here are

a few tips about what to expect and what to do:

If a front tire fails, the flat tire creates a drag that pulls

the vehicle toward that side. Take your foot off the

accelerator pedal and grip the steering wheel firmly.

Steer to maintain lane position, and then gently brake to

a stop well out of the traffic lane.

A rear blowout, particularly on a curve, acts much like a

skid and may require the same correction you would

use in a skid. In any rear blowout remove your foot from

the accelerator pedal. Get the vehicle under control by

steering the way you want the vehicle to go. It may be

very bumpy and noisy, but you can still steer. Gently

brake to a stop, well off the road if possible.{WARNING:

Lifting a vehicle and getting under it to do

maintenance or repairs is dangerous without the

appropriate safety equipment and training. If a

jack is provided with the vehicle, it is designed

only for changing a flat tire. If it is used for

anything else, you or others could be badly

injured or killed if the vehicle slips off the jack. If a

jack is provided with the vehicle, only use it for

changing a flat tire.

If a tire goes flat, the next part shows how to use the

jacking equipment to change a flat tire safely.

7-78

Page 497 of 580

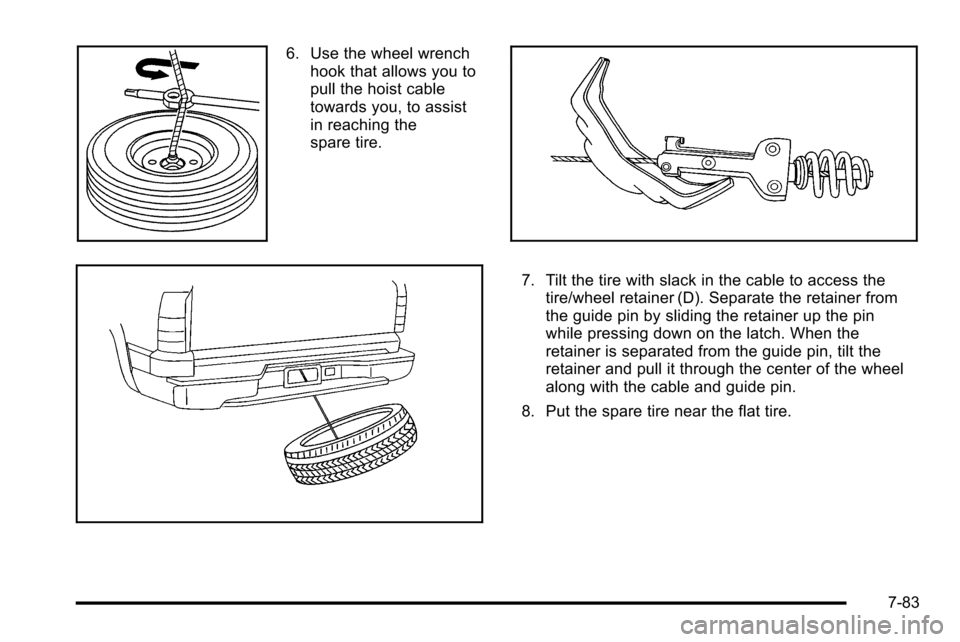

6. Use the wheel wrenchhook that allows you to

pull the hoist cable

towards you, to assist

in reaching the

spare tire.

7. Tilt the tire with slack in the cable to access thetire/wheel retainer (D). Separate the retainer from

the guide pin by sliding the retainer up the pin

while pressing down on the latch. When the

retainer is separated from the guide pin, tilt the

retainer and pull it through the center of the wheel

along with the cable and guide pin.

8. Put the spare tire near the flat tire.

7-83