ECU CHERY TIGGO 2009 Service User Guide

[x] Cancel search | Manufacturer: CHERY, Model Year: 2009, Model line: TIGGO, Model: CHERY TIGGO 2009Pages: 1903, PDF Size: 33.38 MB

Page 133 of 1903

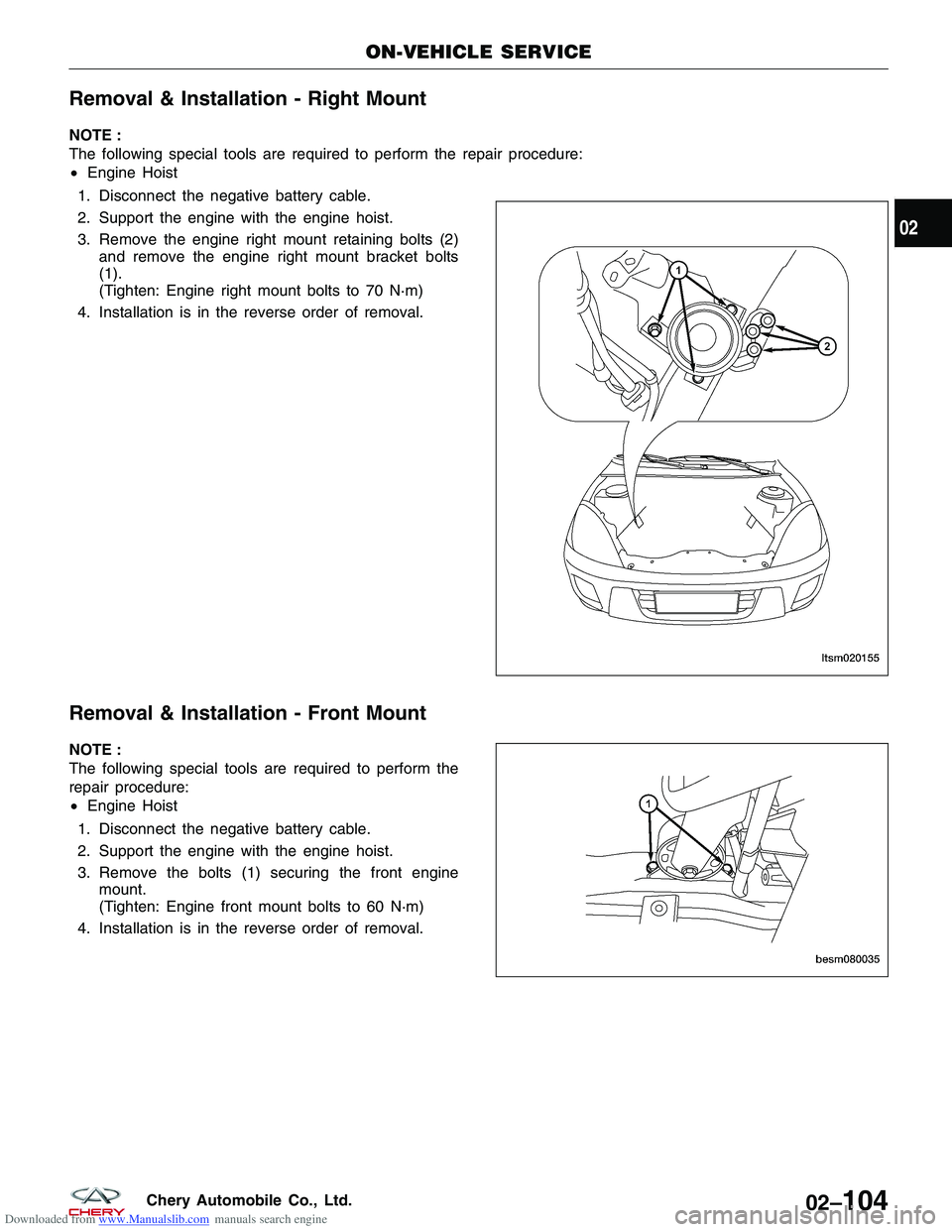

Downloaded from www.Manualslib.com manuals search engine Removal & Installation - Right Mount

NOTE :

The following special tools are required to perform the repair procedure:

•Engine Hoist

1. Disconnect the negative battery cable.

2. Support the engine with the engine hoist.

3. Remove the engine right mount retaining bolts (2) and remove the engine right mount bracket bolts

(1).

(Tighten: Engine right mount bolts to 70 N·m)

4. Installation is in the reverse order of removal.

Removal & Installation - Front Mount

NOTE :

The following special tools are required to perform the

repair procedure:

• Engine Hoist

1. Disconnect the negative battery cable.

2. Support the engine with the engine hoist.

3. Remove the bolts (1) securing the front engine mount.

(Tighten: Engine front mount bolts to 60 N·m)

4. Installation is in the reverse order of removal.

ON-VEHICLE SERVICE

LTSM020155

BESM080035

02

02–104Chery Automobile Co., Ltd.

Page 138 of 1903

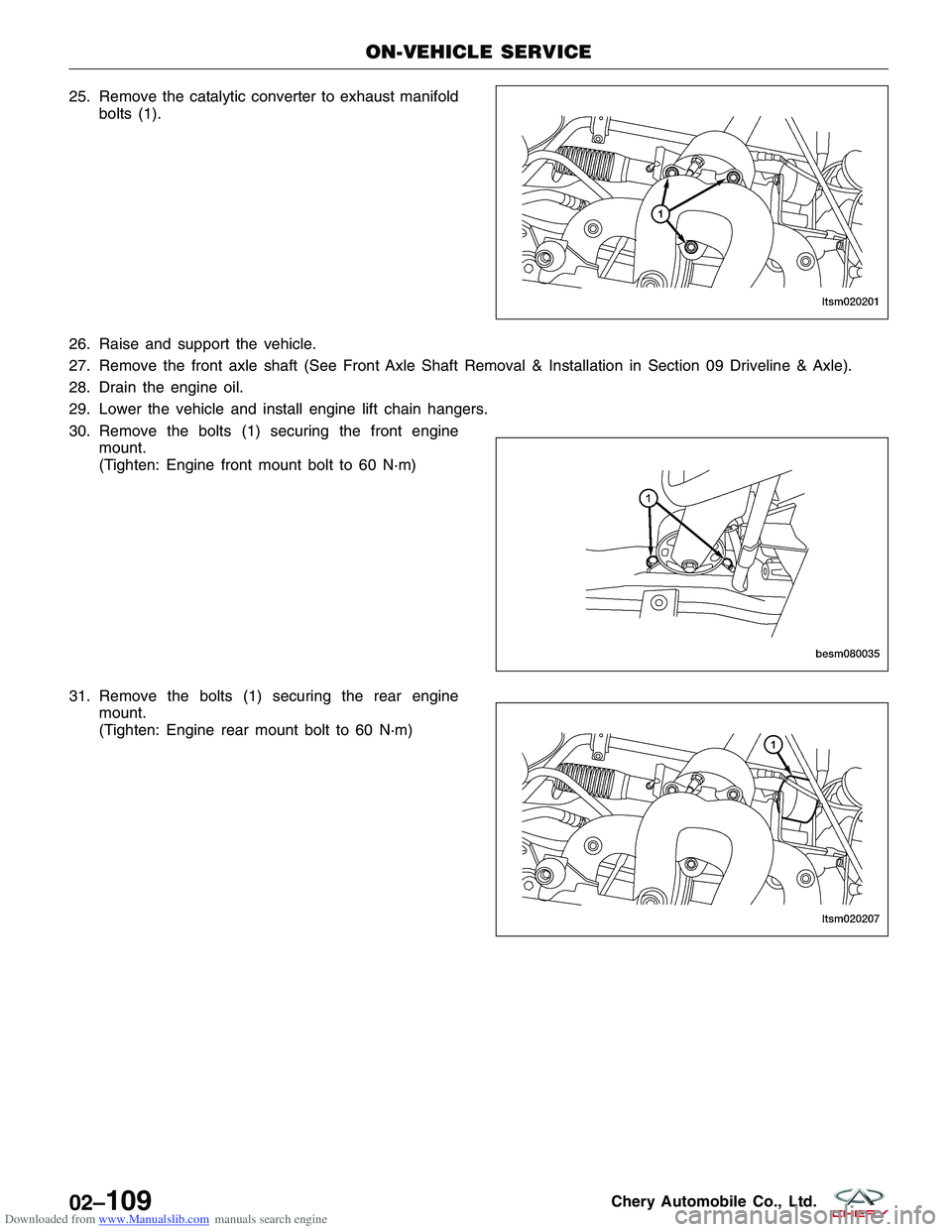

Downloaded from www.Manualslib.com manuals search engine 25. Remove the catalytic converter to exhaust manifoldbolts (1).

26. Raise and support the vehicle.

27. Remove the front axle shaft (See Front Axle Shaft Removal & Installation in Section 09 Driveline & Axle).

28. Drain the engine oil.

29. Lower the vehicle and install engine lift chain hangers.

30. Remove the bolts (1) securing the front engine mount.

(Tighten: Engine front mount bolt to 60 N·m)

31. Remove the bolts (1) securing the rear engine mount.

(Tighten: Engine rear mount bolt to 60 N·m)

ON-VEHICLE SERVICE

LTSM020201

BESM080035 LTSM020207

02–109Chery Automobile Co., Ltd.

Page 139 of 1903

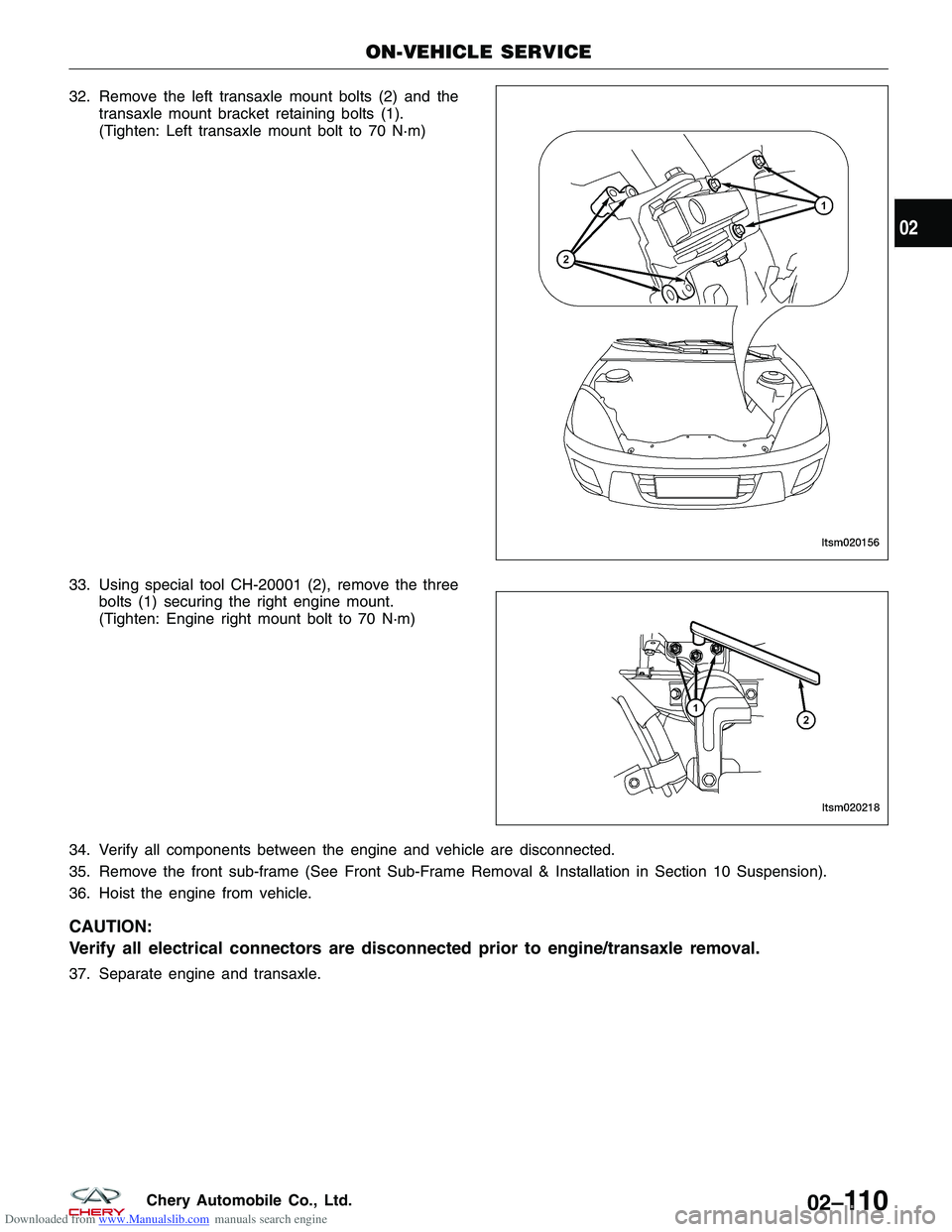

Downloaded from www.Manualslib.com manuals search engine 32. Remove the left transaxle mount bolts (2) and thetransaxle mount bracket retaining bolts (1).

(Tighten: Left transaxle mount bolt to 70 N·m)

33. Using special tool CH-20001 (2), remove the three bolts (1) securing the right engine mount.

(Tighten: Engine right mount bolt to 70 N·m)

34. Verify all components between the engine and vehicle are disconnected.

35. Remove the front sub-frame (See Front Sub-Frame Removal & Installation in Section 10 Suspension).

36. Hoist the engine from vehicle.

CAUTION:

Verify all electrical connectors are disconnected prior to engine/transaxle removal.

37. Separate engine and transaxle.

ON-VEHICLE SERVICE

LTSM020156

LTSM020218

02

02–11 0Chery Automobile Co., Ltd.

Page 145 of 1903

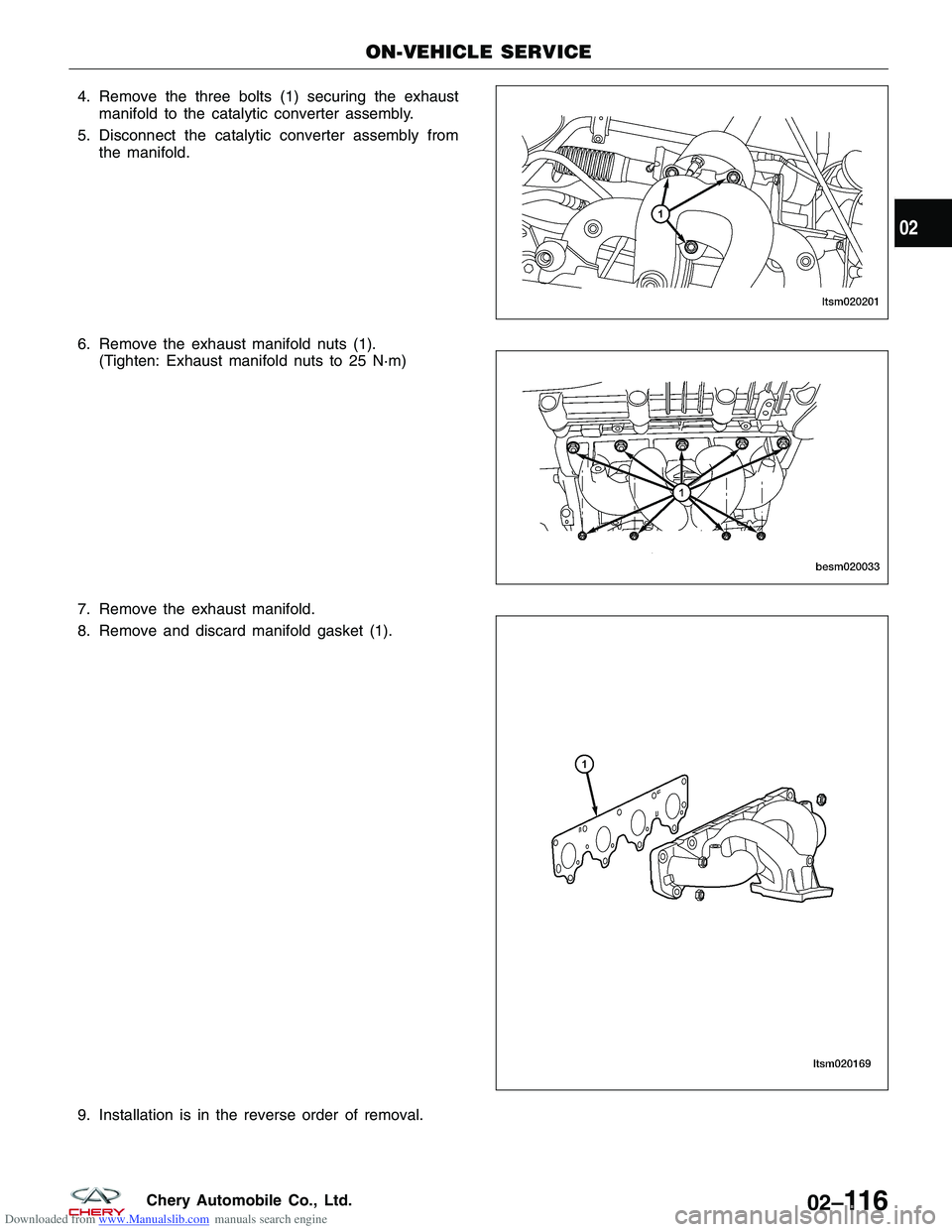

Downloaded from www.Manualslib.com manuals search engine 4. Remove the three bolts (1) securing the exhaustmanifold to the catalytic converter assembly.

5. Disconnect the catalytic converter assembly from the manifold.

6. Remove the exhaust manifold nuts (1). (Tighten: Exhaust manifold nuts to 25 N·m)

7. Remove the exhaust manifold.

8. Remove and discard manifold gasket (1).

9. Installation is in the reverse order of removal.

ON-VEHICLE SERVICE

LTSM020201

BESM020033

LTSM020169

02

02–11 6Chery Automobile Co., Ltd.

Page 147 of 1903

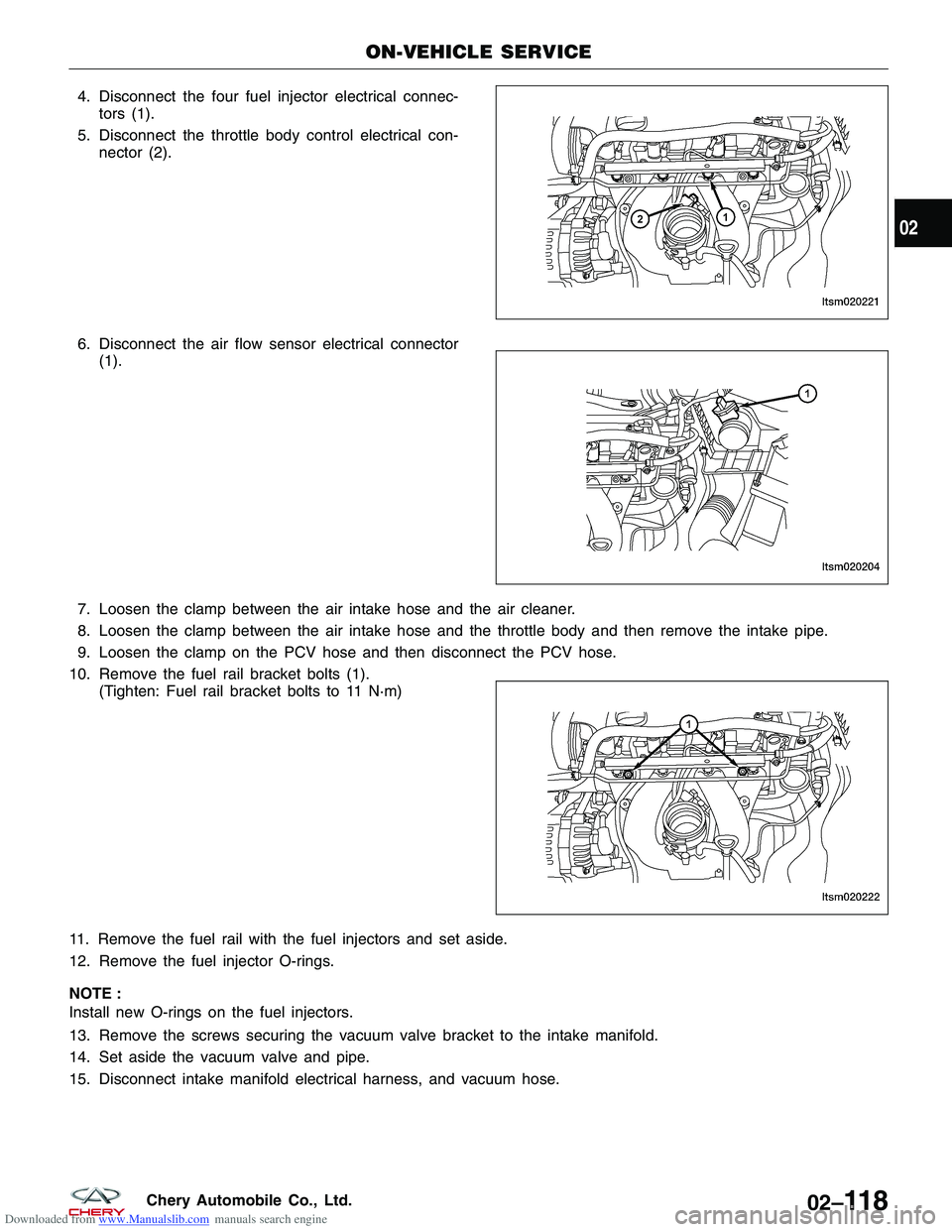

Downloaded from www.Manualslib.com manuals search engine 4. Disconnect the four fuel injector electrical connec-tors (1).

5. Disconnect the throttle body control electrical con- nector (2).

6. Disconnect the air flow sensor electrical connector (1).

7. Loosen the clamp between the air intake hose and the air cleaner.

8. Loosen the clamp between the air intake hose and the throttle body and then remove the intake pipe.

9. Loosen the clamp on the PCV hose and then disconnect the PCV hose.

10. Remove the fuel rail bracket bolts (1). (Tighten: Fuel rail bracket bolts to 11 N·m)

11. Remove the fuel rail with the fuel injectors and set aside.

12. Remove the fuel injector O-rings.

NOTE :

Install new O-rings on the fuel injectors.

13. Remove the screws securing the vacuum valve bracket to the intake manifold.

14. Set aside the vacuum valve and pipe.

15. Disconnect intake manifold electrical harness, and vacuum hose.

ON-VEHICLE SERVICE

LTSM020221

LTSM020204

LTSM020222

02

02–11 8Chery Automobile Co., Ltd.

Page 148 of 1903

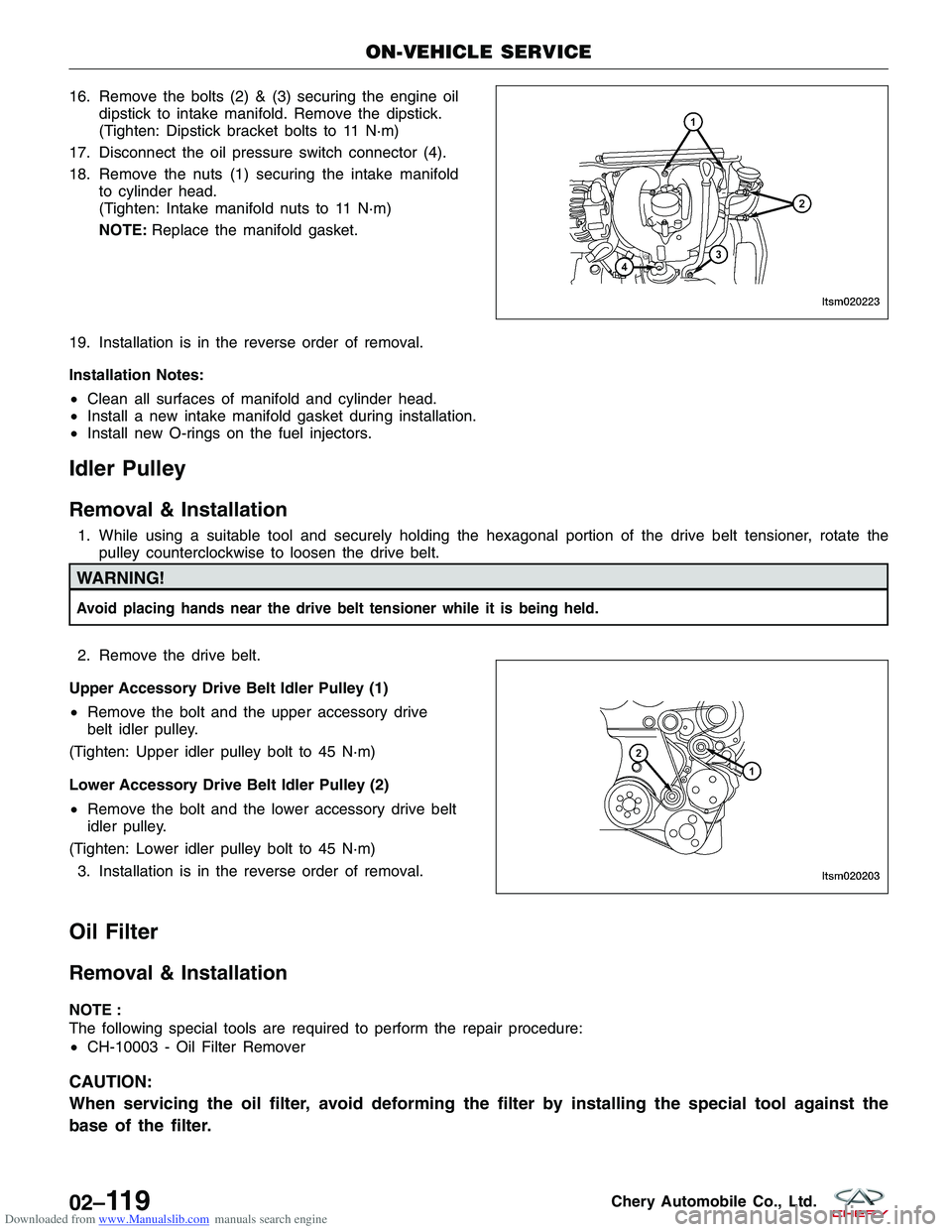

Downloaded from www.Manualslib.com manuals search engine 16. Remove the bolts (2) & (3) securing the engine oildipstick to intake manifold. Remove the dipstick.

(Tighten: Dipstick bracket bolts to 11 N·m)

17. Disconnect the oil pressure switch connector (4).

18. Remove the nuts (1) securing the intake manifold to cylinder head.

(Tighten: Intake manifold nuts to 11 N·m)

NOTE: Replace the manifold gasket.

19. Installation is in the reverse order of removal.

Installation Notes:

• Clean all surfaces of manifold and cylinder head.

• Install a new intake manifold gasket during installation.

• Install new O-rings on the fuel injectors.

Idler Pulley

Removal & Installation

1. While using a suitable tool and securely holding the hexagonal portion of the drive belt tensioner, rotate the

pulley counterclockwise to loosen the drive belt.

WARNING!

Avoid placing hands near the drive belt tensioner while it is being held.

2. Remove the drive belt.

Upper Accessory Drive Belt Idler Pulley (1)

• Remove the bolt and the upper accessory drive

belt idler pulley.

(Tighten: Upper idler pulley bolt to 45 N·m)

Lower Accessory Drive Belt Idler Pulley (2)

• Remove the bolt and the lower accessory drive belt

idler pulley.

(Tighten: Lower idler pulley bolt to 45 N·m) 3. Installation is in the reverse order of removal.

Oil Filter

Removal & Installation

NOTE :

The following special tools are required to perform the repair procedure:

• CH-10003 - Oil Filter Remover

CAUTION:

When servicing the oil filter, avoid deforming the filter by installing the special tool against the

base of the filter.

ON-VEHICLE SERVICE

LTSM020223

LTSM020203

02–11 9Chery Automobile Co., Ltd.

Page 198 of 1903

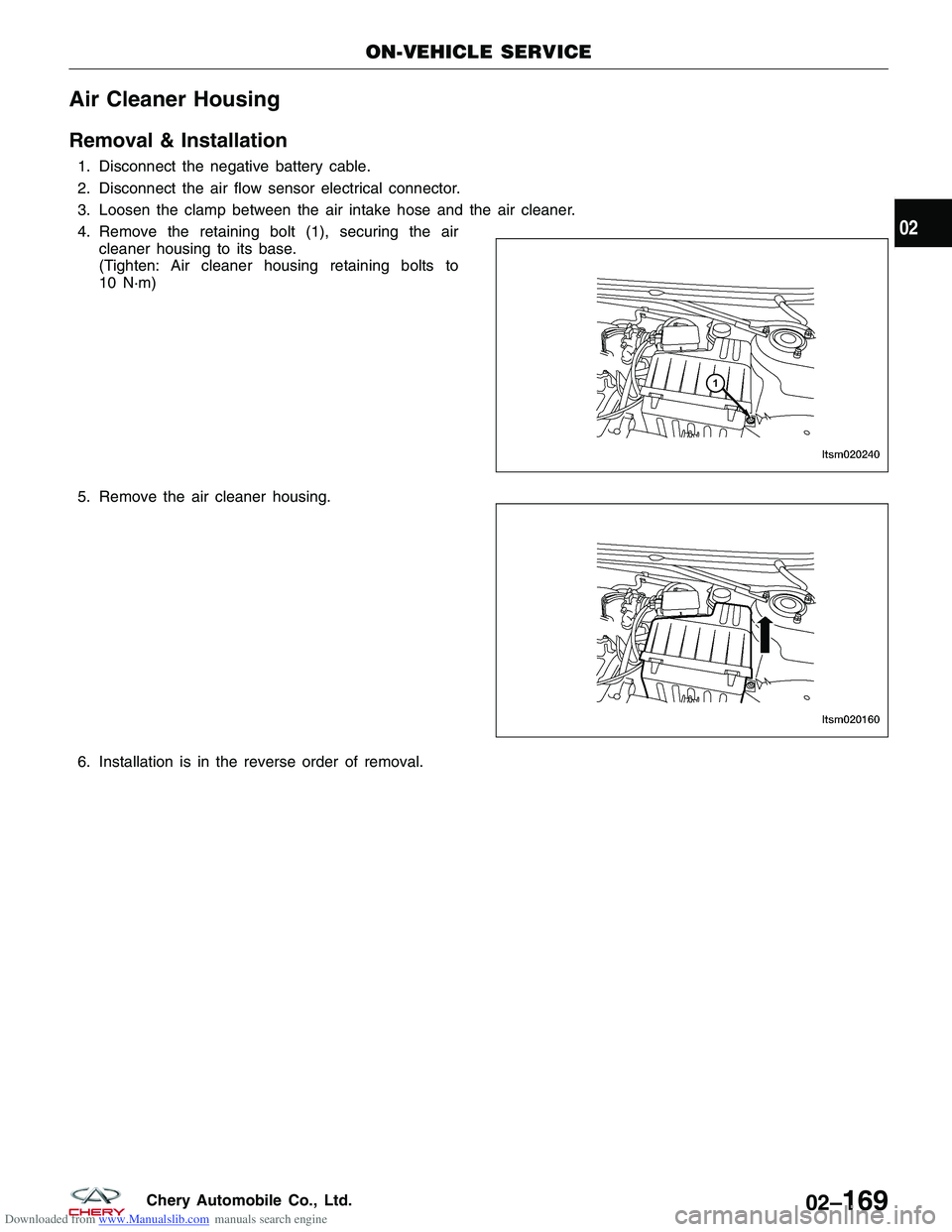

Downloaded from www.Manualslib.com manuals search engine Air Cleaner Housing

Removal & Installation

1. Disconnect the negative battery cable.

2. Disconnect the air flow sensor electrical connector.

3. Loosen the clamp between the air intake hose and the air cleaner.

4. Remove the retaining bolt (1), securing the aircleaner housing to its base.

(Tighten: Air cleaner housing retaining bolts to

10 N·m)

5. Remove the air cleaner housing.

6. Installation is in the reverse order of removal.

ON-VEHICLE SERVICE

LTSM020240

LTSM020160

02

02–169Chery Automobile Co., Ltd.

Page 211 of 1903

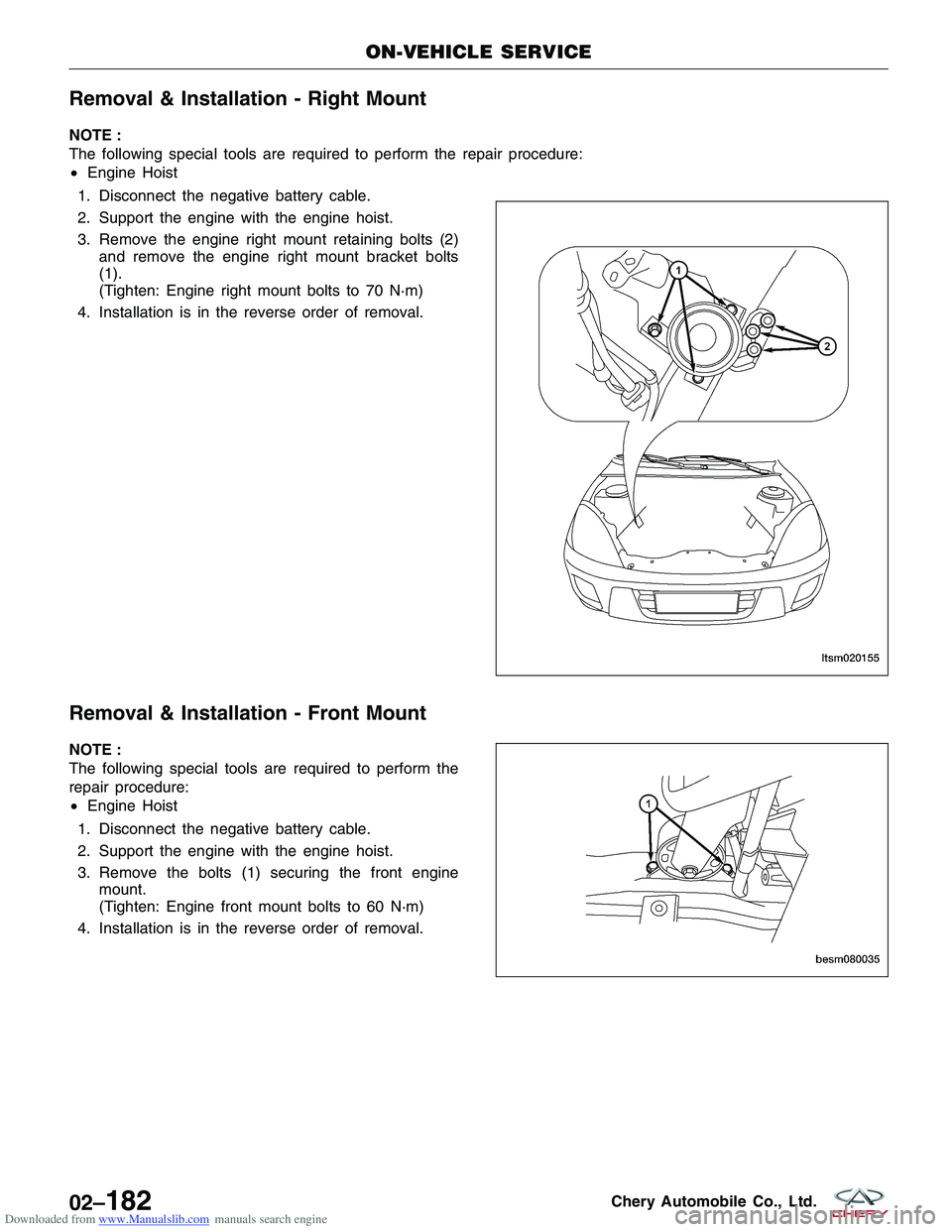

Downloaded from www.Manualslib.com manuals search engine Removal & Installation - Right Mount

NOTE :

The following special tools are required to perform the repair procedure:

•Engine Hoist

1. Disconnect the negative battery cable.

2. Support the engine with the engine hoist.

3. Remove the engine right mount retaining bolts (2) and remove the engine right mount bracket bolts

(1).

(Tighten: Engine right mount bolts to 70 N·m)

4. Installation is in the reverse order of removal.

Removal & Installation - Front Mount

NOTE :

The following special tools are required to perform the

repair procedure:

• Engine Hoist

1. Disconnect the negative battery cable.

2. Support the engine with the engine hoist.

3. Remove the bolts (1) securing the front engine mount.

(Tighten: Engine front mount bolts to 60 N·m)

4. Installation is in the reverse order of removal.

ON-VEHICLE SERVICE

LTSM020155

BESM080035

02–182Chery Automobile Co., Ltd.

Page 216 of 1903

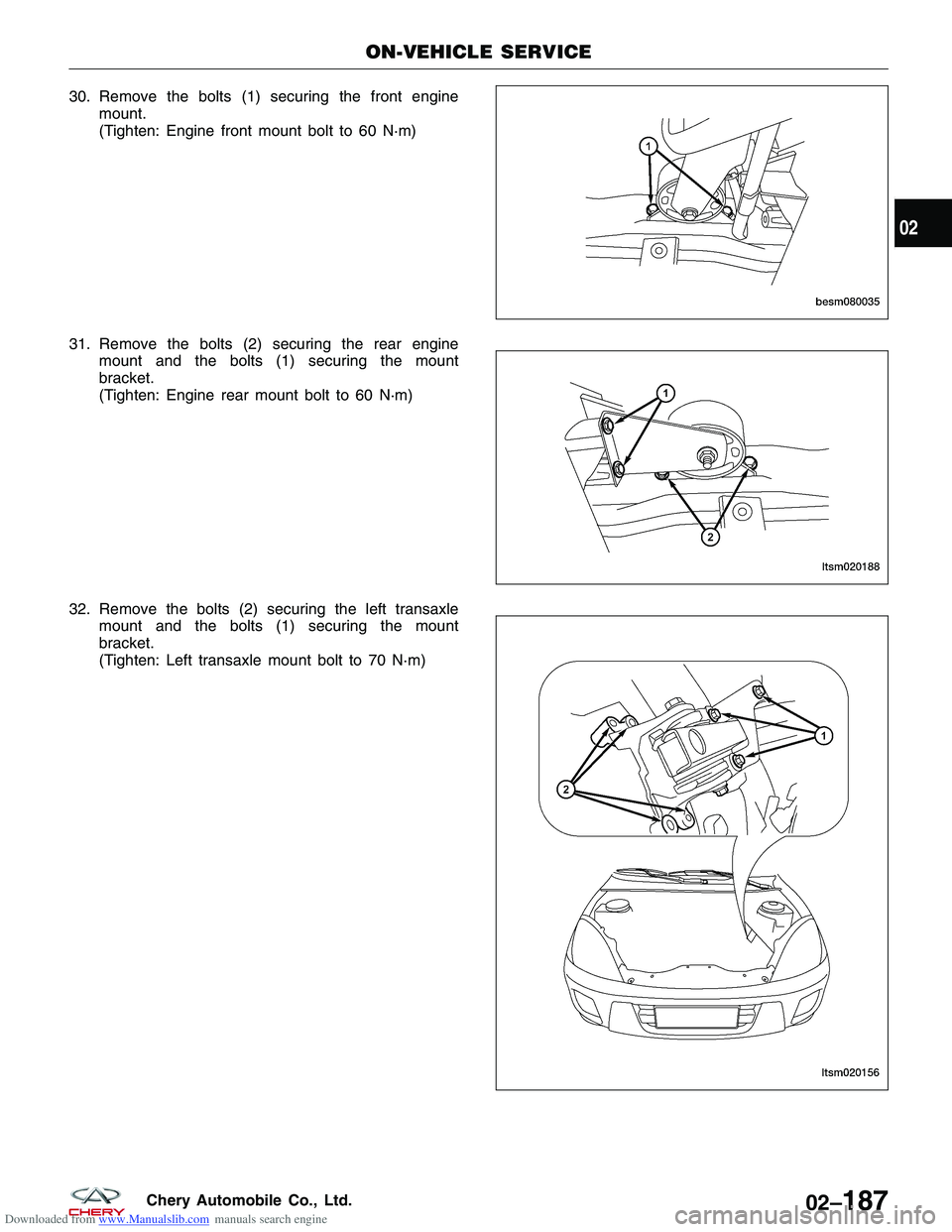

Downloaded from www.Manualslib.com manuals search engine 30. Remove the bolts (1) securing the front enginemount.

(Tighten: Engine front mount bolt to 60 N·m)

31. Remove the bolts (2) securing the rear engine mount and the bolts (1) securing the mount

bracket.

(Tighten: Engine rear mount bolt to 60 N·m)

32. Remove the bolts (2) securing the left transaxle mount and the bolts (1) securing the mount

bracket.

(Tighten: Left transaxle mount bolt to 70 N·m)

ON-VEHICLE SERVICE

BESM080035

LTSM020188

LTSM020156

02

02–187Chery Automobile Co., Ltd.

Page 217 of 1903

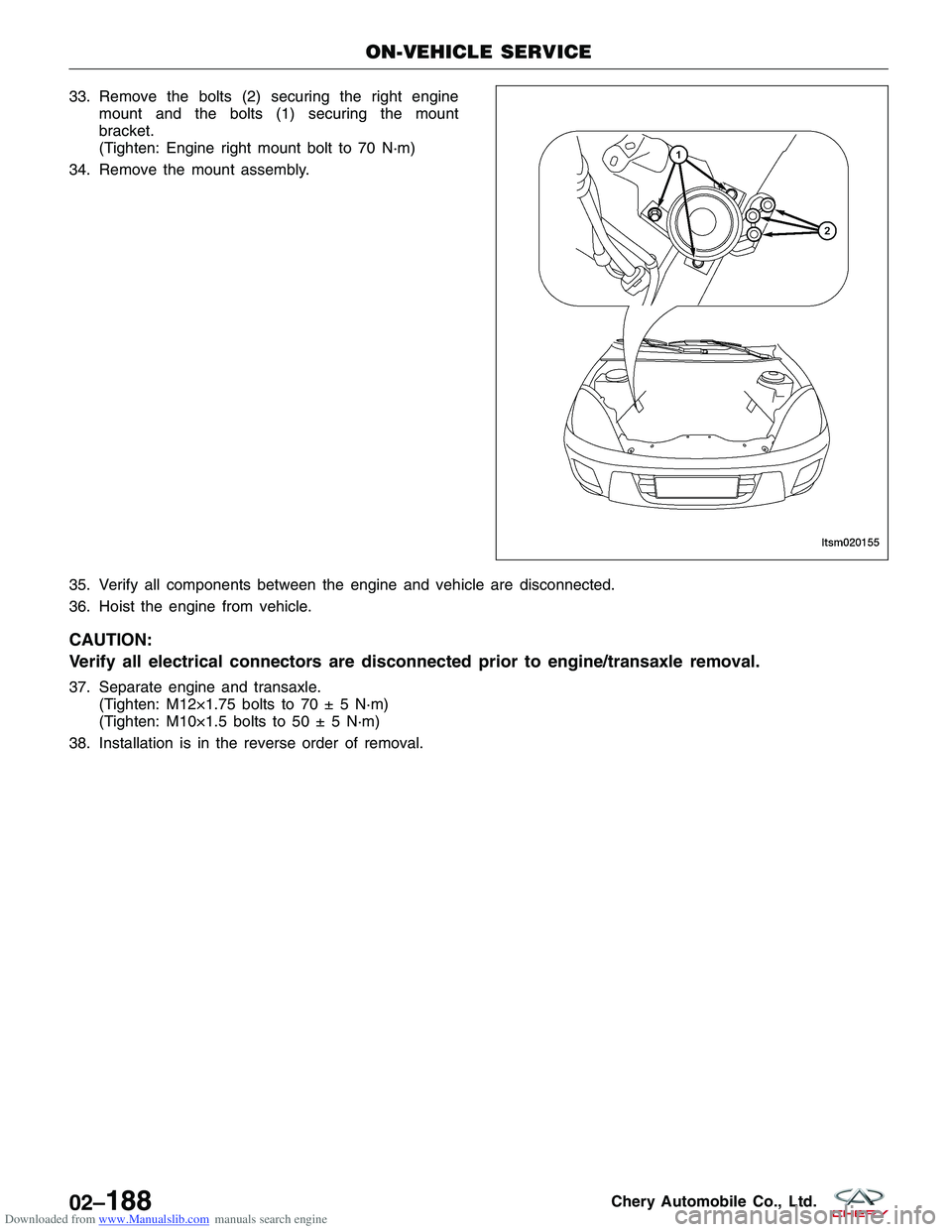

Downloaded from www.Manualslib.com manuals search engine 33. Remove the bolts (2) securing the right enginemount and the bolts (1) securing the mount

bracket.

(Tighten: Engine right mount bolt to 70 N·m)

34. Remove the mount assembly.

35. Verify all components between the engine and vehicle are disconnected.

36. Hoist the engine from vehicle.

CAUTION:

Verify all electrical connectors are disconnected prior to engine/transaxle removal.

37. Separate engine and transaxle. (Tighten: M12×1.75 bolts to 70 ± 5 N·m)

(Tighten: M10×1.5 bolts to 50 ± 5 N·m)

38. Installation is in the reverse order of removal.

ON-VEHICLE SERVICE

LTSM020155

02–188Chery Automobile Co., Ltd.