sensor CHERY TIGGO 2009 Service Repair Manual

[x] Cancel search | Manufacturer: CHERY, Model Year: 2009, Model line: TIGGO, Model: CHERY TIGGO 2009Pages: 1903, PDF Size: 33.38 MB

Page 818 of 1903

Downloaded from www.Manualslib.com manuals search engine The oxygen sensors are equipped with a heating element that keeps the sensors at proper operating temperature

during all operating modes. Maintaining correct sensor temperature at all times allows the system to enter into closed

loop operation sooner. Also, it allows the system to remain in closed loop operation during periods of extended idle.

Upstream Oxygen Sensor

The input from the upstream heated oxygen sensor tells the Engine Control Module (ECM) the oxygen content of the

exhaust gas. Based on this input, the ECM fine tunes the air-fuel ratio by adjusting injector pulse width.

Downstream Oxygen Sensor

The downstream heated oxygen sensor signal is used to detect catalytic convertor deterioration. As the convertor

deteriorates, the signal from the downstream sensor begins to match the upstream sensor signal except for a slight

time delay. By comparing the downstream heated oxygen sensor signal to the signal from the upstream sensor, the

ECM calculates catalytic convertor efficiency. This calculation is also used to establish the upstream O2 goal voltage

(switching point).

Removal & Installation - Upstream Oxygen Sensor

1. Disconnect the negative battery cable.

2. Disconnect the oxygen sensor electrical connector.

CAUTION:

Remove the oxygen sensor after the exhaust pipe has cooled.

3. Remove the upstream oxygen sensor (1).(Tighten: Upstream oxygen sensor to 45 N·m)

4. Installation is in the reverse order of removal.

Installation Notes:

• Before installing the oxygen sensor, coat the threads with rust inhibiting lubricant.

ON-VEHICLE SERVICE

LTSM030004

03–534Chery Automobile Co., Ltd.

Page 819 of 1903

Downloaded from www.Manualslib.com manuals search engine Removal & Installation - Downstream Oxygen Sensor

1. Disconnect the negative battery cable.

2. Disconnect the oxygen sensor electrical connector.

CAUTION:

Remove the oxygen sensor after the exhaust pipe has cooled.

3. Remove the downstream oxygen sensor (1).(Tighten: Downstream oxygen sensor to 45 N·m)

4. Installation is in the reverse order of removal.

Installation Notes:

• Before installing the oxygen sensor, coat the threads with rust inhibiting lubricant.

ON-VEHICLE SERVICE

LTSM030008

03

03–535Chery Automobile Co., Ltd.

Page 820 of 1903

Downloaded from www.Manualslib.com manuals search engine Camshaft Position (CMP) Sensor

Description

The Camshaft Position (CMP) sensor senses the protrusion of inlet valve cam sprocket to identify a particular cyl-

inder. The CMP sensor senses the piston position. When the Crankshaft Position (CKP) sensor becomes inoperative,

the CMP sensor provides various controls of engine parts instead, utilizing timing of cylinder identification signals.

The sensor consists of a permanent magnet and Hall IC.

Operation

When engine is running, the high and low parts of the teeth cause the gap with the sensor to change. The changing

gap cause the magnetic field near the sensor to change. Due to the changing magnetic field, the voltage from the

sensor changes. The Engine Control Module (ECM) detects the voltage signal and identify piston position and cyl-

inder timing.

Removal & Installation

1. Disconnect the negative battery cable.

2. Disconnect camshaft position sensor electrical connector from the wiring harness connector.

3. Remove the camshaft position sensor retaining bolt(1).

(Tighten: Camshaft position sensor retaining bolt to

10 N·m)

4. Remove camshaft position sensor.

5. Pull sensor up out of the cylinder head cover.

6. Installation is in the reverse order of the removal.

ON-VEHICLE SERVICE

LTSM030005

03–536Chery Automobile Co., Ltd.

Page 821 of 1903

Downloaded from www.Manualslib.com manuals search engine Air Flow Sensor

Description

The air flow sensor is placed in the air intake hose. The air flow sensor measures the intake flow rate by measuring

a part of the entire intake flow. The air flow sensor converts the amount of air drawn into the engine into a voltage

signal. The Engine Control Module (ECM) needs to know intake air volume to calculate engine load. This is neces-

sary to determine how much fuel to inject.

Operation

The air flow sensor controls the temperature of the hot wire to a certain amount. The heat generated by the hot wire

is reduced as the intake air flows around it. The more air, the greater the heat loss. Therefore, the electric current

supplied to the hot wire is changed to maintain the temperature of the hot wire as air flow increases. The ECM

detects the air flow by means of this voltage signal change.

Removal & Installation

1. Disconnect the negative battery cable.

2. Disconnect air flow sensor electrical connectorfrom the wiring harness connector.

3. Remove the air flow sensor retaining bolts (1). (Tighten: Air flow sensor retaining bolt to 8 N·m)

4. Remove the air flow sensor.

5. Installation is in the reverse order of removal.

ON-VEHICLE SERVICE

LTSM030006

03

03–537Chery Automobile Co., Ltd.

Page 822 of 1903

Downloaded from www.Manualslib.com manuals search engine Throttle Control Actuator

Description

The throttle body is located on the intake manifold. The throttle body meters air into the intake manifold.

Throttle control actuator consists of throttle control valve, throttle position sensor, idle air control motor, etc.

Operation

Filtered air from the air cleaner enters the intake manifold through the throttle body. A throttle valve (plate) is used to

supply air for idle and driving conditions. The throttle position sensor is part the throttle body. The throttle position

sensor signal is used by the ECM to determine throttle position. The ECM controls the throttle control to meter air

into the engine. This regulates engine power. The vehicle is in sense a “Drive by Wire” system.

Removal & Installation

1. Remove the engine cover.

2. Disconnect the negative battery cable.

3. Disconnect the throttle position sensor and idle air control motor electrical connect on the throttle control actua-tor.

4. Remove the accelerator cable on the throttle control actuator.

5. Remove three hoses on the throttle control actuator.

6. Remove four throttle control actuator mounting bolts (1).

(Tighten: Throttle control actuator bolts to 10 N·m)

7. Remove the throttle control actuator and gasket carefully.

8. Installation is in the reverse order of removal.

NOTE :

Replace a new throttle control actuator gasket when installing.

ON-VEHICLE SERVICE

LTSM030010

03–538Chery Automobile Co., Ltd.

Page 824 of 1903

Downloaded from www.Manualslib.com manuals search engine Throttle Position Sensor (TPS)

Description

The 4-wire throttle position sensor (TPS) is mounted on the throttle body and is connected to the throttle valve.

Operation

The TPS is a 4-wire variable resistor that provides the Engine Control Module (ECM) with an input signal that rep-

resents the throttle valve position of the throttle body. The sensor is connected to the throttle valve shaft. As the

position of the throttle valve changes, the resistance (output voltage) of the TPS changes.

Removal & Installation

1. Disconnect the negative battery cable.

2. Disconnect throttle position sensor electrical con-nector clamp from the wiring harness connector.

3. Remove the throttle position sensor retaining bolts (1).

4. Remove the throttle position sensor.

5. Installation is in the reverse order of removal.

ON-VEHICLE SERVICE

LTSM030027

03–540Chery Automobile Co., Ltd.

Page 826 of 1903

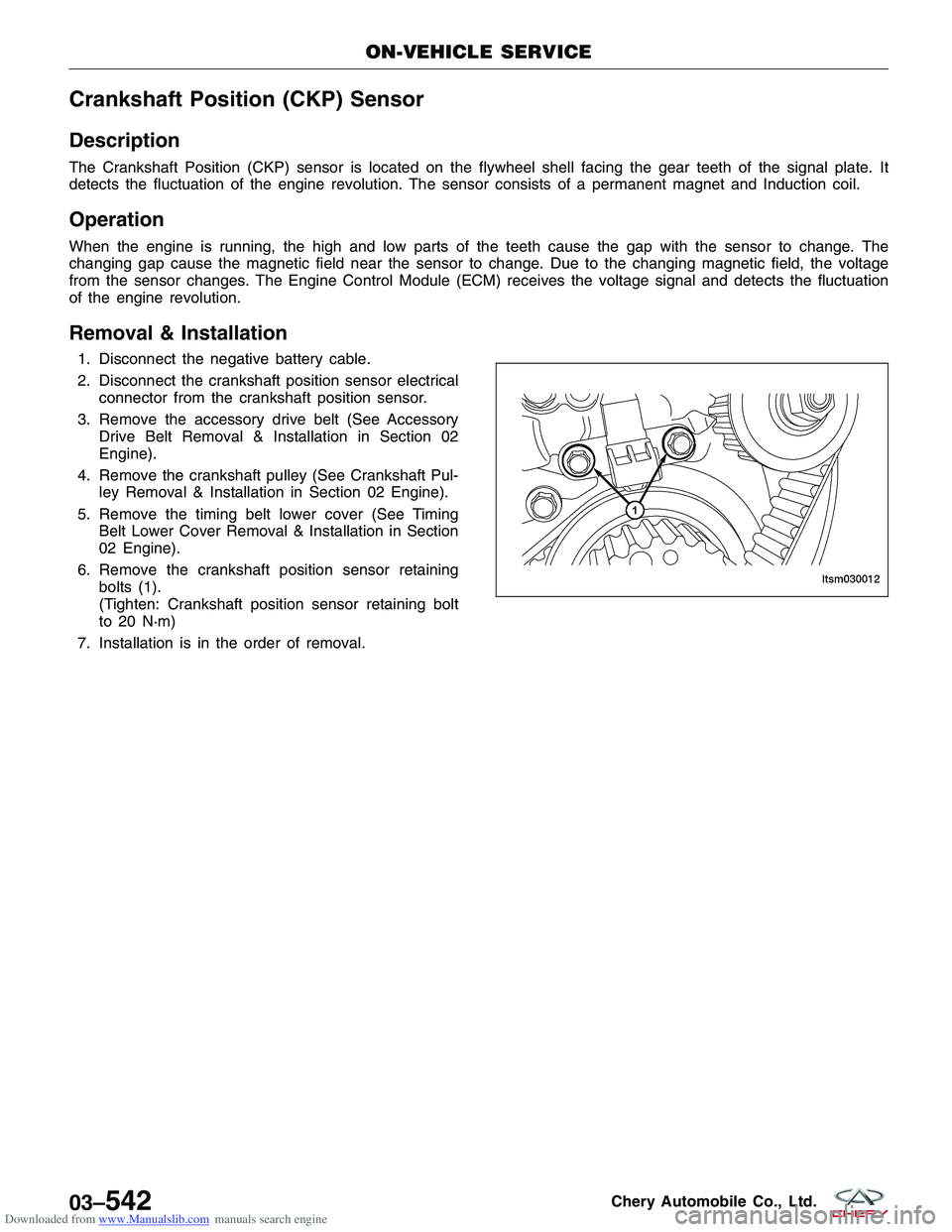

Downloaded from www.Manualslib.com manuals search engine Crankshaft Position (CKP) Sensor

Description

The Crankshaft Position (CKP) sensor is located on the flywheel shell facing the gear teeth of the signal plate. It

detects the fluctuation of the engine revolution. The sensor consists of a permanent magnet and Induction coil.

Operation

When the engine is running, the high and low parts of the teeth cause the gap with the sensor to change. The

changing gap cause the magnetic field near the sensor to change. Due to the changing magnetic field, the voltage

from the sensor changes. The Engine Control Module (ECM) receives the voltage signal and detects the fluctuation

of the engine revolution.

Removal & Installation

1. Disconnect the negative battery cable.

2. Disconnect the crankshaft position sensor electricalconnector from the crankshaft position sensor.

3. Remove the accessory drive belt (See Accessory Drive Belt Removal & Installation in Section 02

Engine).

4. Remove the crankshaft pulley (See Crankshaft Pul- ley Removal & Installation in Section 02 Engine).

5. Remove the timing belt lower cover (See Timing Belt Lower Cover Removal & Installation in Section

02 Engine).

6. Remove the crankshaft position sensor retaining bolts (1).

(Tighten: Crankshaft position sensor retaining bolt

to 20 N·m)

7. Installation is in the order of removal.

ON-VEHICLE SERVICE

LTSM030012

03–542Chery Automobile Co., Ltd.

Page 828 of 1903

Downloaded from www.Manualslib.com manuals search engine Symptom Diagnostic Tests

General Troubleshooting Checks

•Confirm the engine trouble light is working properly.

• Confirm that there are no DTCs recorded with the X-431 Scan Tool.

• Confirm that the customer’s complaint is current, and the conditions that are causing the failure are present.

Visual Inspection

•Check the fuel system for any fuel leakage.

• Check the vacuum system for any broken, kinked or incorrectly linked vacuum pipes or hoses.

• Check the intake air pipe for being jammed, leaking, or damaged.

• Check the ignition system for any broken or aging spark plug wires and verify the engine firing order is correct.

• Check the engine ground cable and verify a clean and tight connection.

• Check the sensors and actuators electrical connectors and verify good contact and tight connection.

NOTE :

Repair any of the above conditions first before continuing with symptom diagnostics.

Diagnostic Help

• Confirm there are no current engine DTCs.

• Confirm that the failure exists and the customer complaint can be verified.

• Inspect the engine following the above steps and verify all engine features are operating properly.

• While servicing the vehicle, verify the service record, vehicle maintenance, engine compression pressures,

mechanical ignition timing and fuel conditions.

• If replacing the Engine Control Module (ECM), carry out the validation test. If the failure no longer exists, the

failure is in the ECM; if the failure still exists, reinstall the original ECM and repeat the diagnostic test.

Symptom Diagnostic Test List

SYMPTOM DEFINITION

Engine Cranks Normal But Will Not Start

Engine Will Not Crank

Hard Start / Long Crank Time

Fast Idle

Lack / Loss Of Power

Back Fires

Engine Poor Driveability

Low Idle / Stalls During Deceleration

Idle Speed Slow Return To Normal Idle

ELECTRONIC ENGINE CONTROLS - 2.4L ENGINE SYMPTOM DIAGNOSIS

03–544Chery Automobile Co., Ltd.

Page 833 of 1903

Downloaded from www.Manualslib.com manuals search engine Hard Start / Long Crank / Erratic Start / Erratic Crank

The following conditions apply to this symptom:

•The engine cranks for an extended period of time.

• The engine starts hard during a long cranking time.

1.PRELIMINARY CHECKS

• Confirm that the correct starting procedure was used by the customer before proceeding with diagnosis.

• Carry out the following preliminary checks:

� Vacuum leaks

� Fuel quality (concerns such as correct octane, contamination, winter/summer blend)

� Intake air system (tubes)

� Air cleaner (restrictions)

� Battery condition and starter current draw.

Are all checks OK?

Ye s>>Go to the next step.

No

>>Repair as necessary.

Verify the symptom no longer exists.

2.CHECK ECM DTC

• With scan tool X-431, select view DTC and data stream in ECM.

Are there any DTCs present?

Ye s>>See the Diagnostic Trouble Code (DTC) List.

Go to the specific diagnostic test to troubleshoot the DTC.

No

>>Go to the next step.

3.CHECK SECONDARY IGNITION SYSTEM

• Perform the following to test the secondary ignition system:

� Disconnect the injector fuse.

� Remove any of the 4 spark plugs.

� Connect the spark plug to spark plug wire.

� Ground the spark plug on the cylinder block.

� Crank the engine to test the secondary ignition system with the spark plugs removed.

Is a strong blue spark visible at each spark plug while cranking the engine?

Ye s>>Go to the next step.

No

>>Check Camshaft Position (CMP) sensor signal at ECM.

If CMP sensor is OK, check the following:

� Crankshaft Position (CKP) sensor malfunction

� Faulty spark plug wires

� Faulty spark plugs

ELECTRONIC ENGINE CONTROLS - 2.4L ENGINE SYMPTOM DIAGNOSIS

03

03–549Chery Automobile Co., Ltd.

Page 835 of 1903

Downloaded from www.Manualslib.com manuals search engine 8.CHECK EVAPORATIVE EMISSIONS (EVAP) SYSTEM

• Disconnect the canister control valve (1) hose.

• Place a stiff piece of paper over the hose end and

start the engine.

Does vacuum hold the paper?

Ye s>>Check for a vacuum leak in EVAP system

(refer to EVAP system) and refer to EVAP control cir-

cuit relative DTC.

No

>>Go to the next step.

9.CHECK INTAKE AIR SYSTEM

• Check for MAP/MAF sensor.

Is there any contamination?

Ye s>>Install a new MAF/IAT or MAP/IAT sensor.

No

>>See Diagnostic Help for additional information.

ELECTRONIC ENGINE CONTROLS - 2.4L ENGINE SYMPTOM DIAGNOSIS

VISMD030007

03

03–551Chery Automobile Co., Ltd.