ABS CHERY TIGGO 2009 Service Owner's Guide

[x] Cancel search | Manufacturer: CHERY, Model Year: 2009, Model line: TIGGO, Model: CHERY TIGGO 2009Pages: 1903, PDF Size: 33.38 MB

Page 1292 of 1903

Downloaded from www.Manualslib.com manuals search engine The Tiggo 4WD is the first 4WD vehicle produced by Chery. The 4WD system is equipped with a QR523T transaxle

manufactured by Chery.

An active torque transfer system is used, and an interactive torque management system (ITM) is equipped to make

it possible to intelligently distribute the drive force for the front wheels and rear wheels according to different road

conditions. For example, on a smooth road, the vehicle utilizes front-wheel drive. When road conditions worsen, the

ITM will automatically switch to 4WD. The use of ITM allows the Tiggo vehicle to be more economical and more

efficient than the common 4WD system.

Operation

The intelligent 4WD system is controlled by an interactive torque management system (ITM) module. The ITM mod-

ule communicates with the Engine Control Module (ECM) and the Antilock Brake System (ABS) controller through the

CAN network. The ITM module collects data from sensors on the vehicle body to determine the condition of the drive

wheels. Based on the sensor inputs, the ITM module controls the ITM controller. The ITM controller will then distrib-

ute a portion of the torque to the rear drive axle as needed. The ITM controller works as an electromagnetic clutch.

Different torque can be transferred by changing the electric current of the ITM controller. The ITM controller will be

able to distribute the torque of the front drive axle and the rear drive axle at different ratios according to the various

dynamic conditions of the vehicle.

Specification

Transaxle Specifications

MODEL TYPE DISTANCEBETWEENCENTERS (mm) MAX

INPUT

TORQUE (N·m) GEAR / SPEED RATIO

1st 2nd 3rd 4th 5th Reverse Final

Drive

QR523T Front-

Wheel Drive

Transaxle 78 195 3.583 1.947 1.379 1.303 0.821 3.364 4.3125

1 - Transaxle

2 - Drive Line

3 - Rear Axle4 - Power Transfer

5 - ITM Controller

GENERAL INFORMATION

LTSM160027

09–18Chery Automobile Co., Ltd.

Page 1297 of 1903

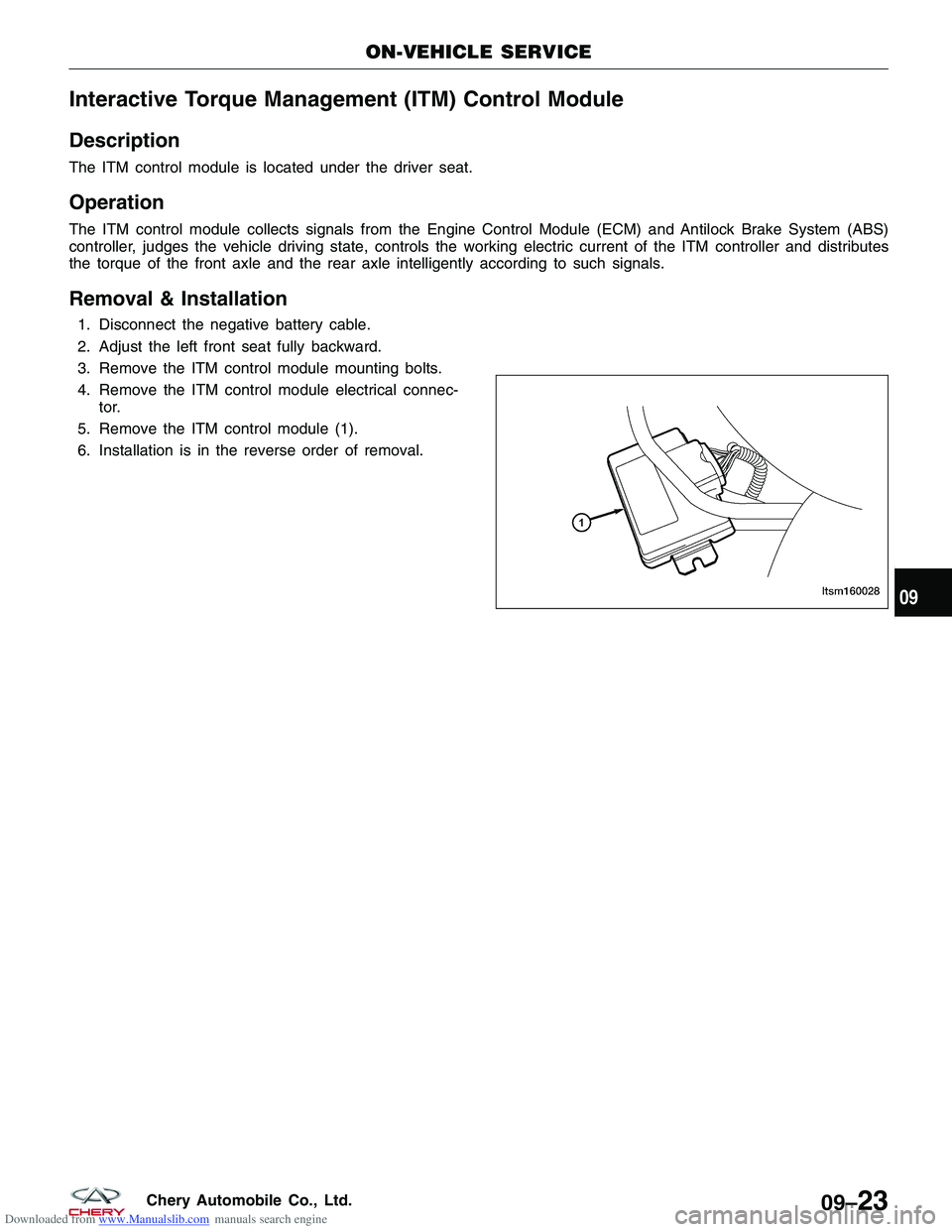

Downloaded from www.Manualslib.com manuals search engine Interactive Torque Management (ITM) Control Module

Description

The ITM control module is located under the driver seat.

Operation

The ITM control module collects signals from the Engine Control Module (ECM) and Antilock Brake System (ABS)

controller, judges the vehicle driving state, controls the working electric current of the ITM controller and distributes

the torque of the front axle and the rear axle intelligently according to such signals.

Removal & Installation

1. Disconnect the negative battery cable.

2. Adjust the left front seat fully backward.

3. Remove the ITM control module mounting bolts.

4. Remove the ITM control module electrical connec-tor.

5. Remove the ITM control module (1).

6. Installation is in the reverse order of removal.

ON-VEHICLE SERVICE

LTSM16002809

09–23Chery Automobile Co., Ltd.

Page 1303 of 1903

Downloaded from www.Manualslib.com manuals search engine GENERAL INFORMATION

Description

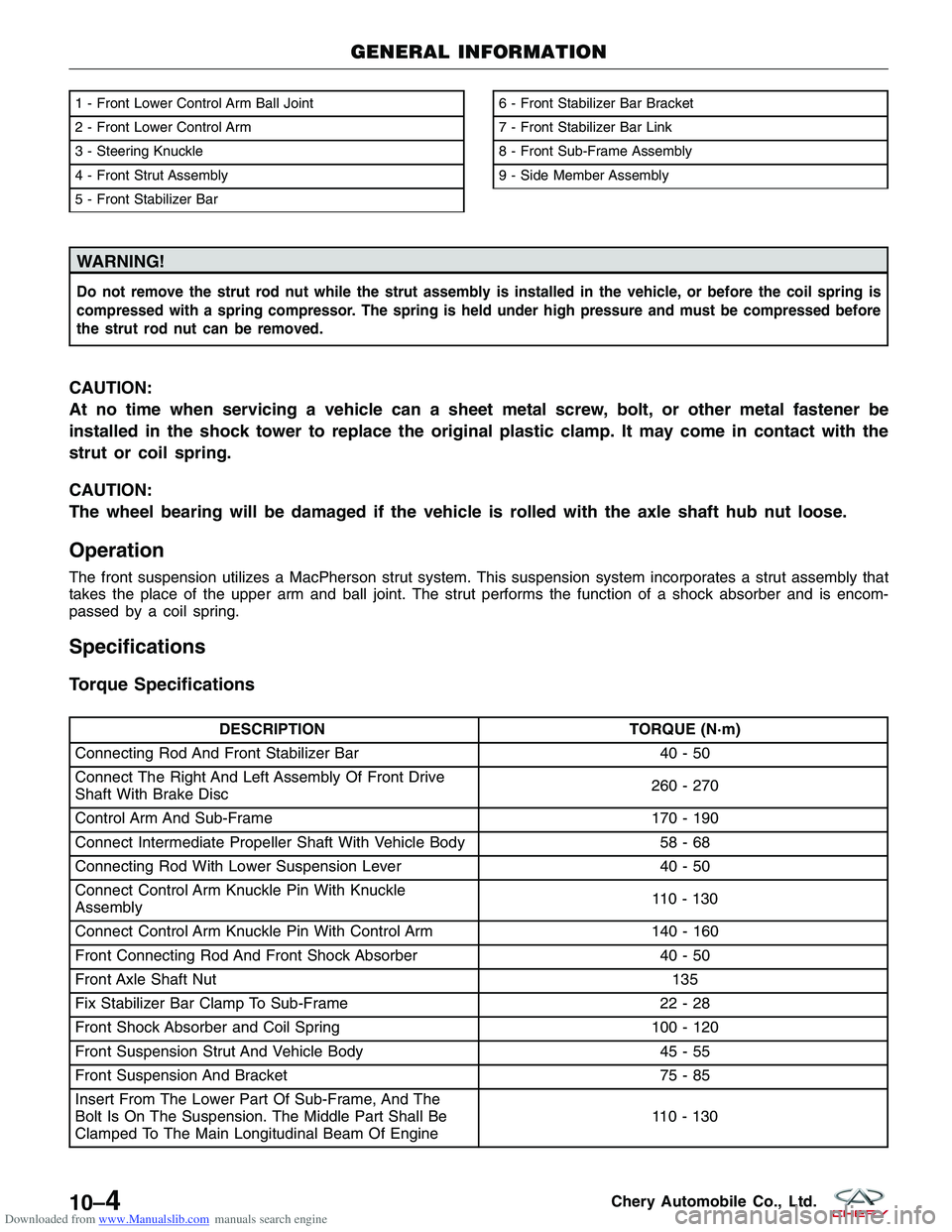

The front suspension system incorporates a strut assembly that takes the place of the upper control arm and upper

ball joint. The strut carries out the function of a shock absorber and is encompassed by a coil spring. The strut

assembly supports the weight of the vehicle and is also the pivot point for the steering knuckle. This system uses a

lower control arm and ball joint for the lower pivot point of the steering knuckle.

10–2Chery Automobile Co., Ltd.

Page 1305 of 1903

Downloaded from www.Manualslib.com manuals search engine WARNING!

Do not remove the strut rod nut while the strut assembly is installed in the vehicle, or before the coil spring is

compressed with a spring compressor. The spring is held under high pressure and must be compressed before

the strut rod nut can be removed.

CAUTION:

At no time when servicing a vehicle can a sheet metal screw, bolt, or other metal fastener be

installed in the shock tower to replace the original plastic clamp. It may come in contact with the

strut or coil spring.

CAUTION:

The wheel bearing will be damaged if the vehicle is rolled with the axle shaft hub nut loose.

Operation

The front suspension utilizes a MacPherson strut system. This suspension system incorporates a strut assembly that

takes the place of the upper arm and ball joint. The strut performs the function of a shock absorber and is encom-

passed by a coil spring.

Specifications

Torque Specifications

DESCRIPTIONTORQUE (N·m)

Connecting Rod And Front Stabilizer Bar 40 - 50

Connect The Right And Left Assembly Of Front Drive

Shaft With Brake Disc 260 - 270

Control Arm And Sub-Frame 170 - 190

Connect Intermediate Propeller Shaft With Vehicle Body 58 - 68

Connecting Rod With Lower Suspension Lever 40 - 50

Connect Control Arm Knuckle Pin With Knuckle

Assembly 110 - 130

Connect Control Arm Knuckle Pin With Control Arm 140 - 160

Front Connecting Rod And Front Shock Absorber 40 - 50

Front Axle Shaft Nut 135

Fix Stabilizer Bar Clamp To Sub-Frame 22 - 28

Front Shock Absorber and Coil Spring 100 - 120

Front Suspension Strut And Vehicle Body 45 - 55

Front Suspension And Bracket 75 - 85

Insert From The Lower Part Of Sub-Frame, And The

Bolt Is On The Suspension. The Middle Part Shall Be

Clamped To The Main Longitudinal Beam Of Engine 110 - 130

1 - Front Lower Control Arm Ball Joint

2 - Front Lower Control Arm

3 - Steering Knuckle

4 - Front Strut Assembly

5 - Front Stabilizer Bar6 - Front Stabilizer Bar Bracket

7 - Front Stabilizer Bar Link

8 - Front Sub-Frame Assembly

9 - Side Member Assembly

GENERAL INFORMATION

LTSM100008

10–4Chery Automobile Co., Ltd.

Page 1314 of 1903

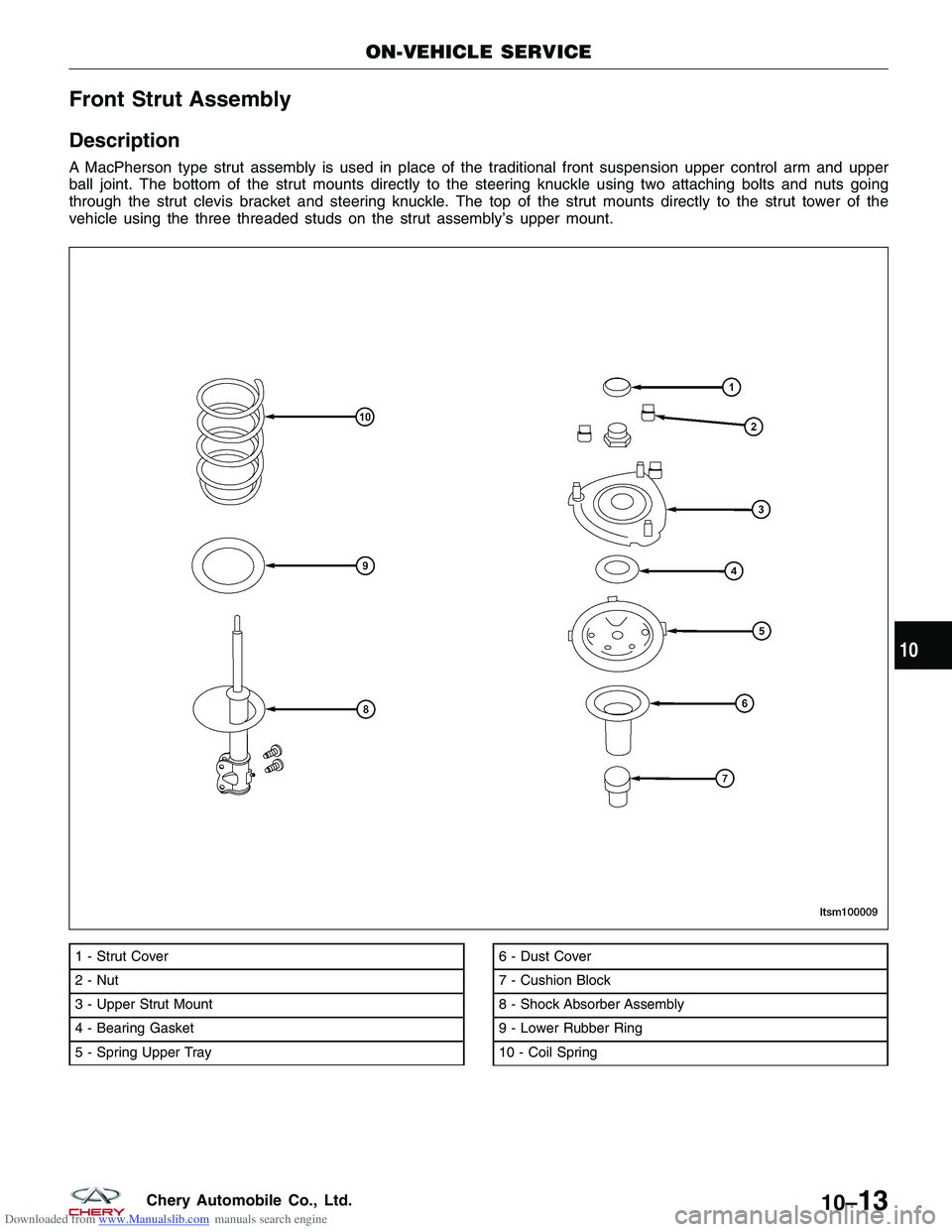

Downloaded from www.Manualslib.com manuals search engine Front Strut Assembly

Description

A MacPherson type strut assembly is used in place of the traditional front suspension upper control arm and upper

ball joint. The bottom of the strut mounts directly to the steering knuckle using two attaching bolts and nuts going

through the strut clevis bracket and steering knuckle. The top of the strut mounts directly to the strut tower of the

vehicle using the three threaded studs on the strut assembly’s upper mount.

1 - Strut Cover

2 - Nut

3 - Upper Strut Mount

4 - Bearing Gasket

5 - Spring Upper Tray6 - Dust Cover

7 - Cushion Block

8 - Shock Absorber Assembly

9 - Lower Rubber Ring

10 - Coil Spring

ON-VEHICLE SERVICE

LTSM100009

10

10–13Chery Automobile Co., Ltd.

Page 1315 of 1903

Downloaded from www.Manualslib.com manuals search engine Operation

The strut assembly cushions the ride of the vehicle, controlling vibration, jounce and rebound of the suspension. The

coil spring controls ride quality and maintains proper ride height. The spring isolators isolate the coil spring at the top

and bottom from coming into metal-to-metal contact with the upper mounting seat and the strut. The strut dampens

jounce and rebound motions of the coil spring and suspension.

Diagnosis & Testing

Before removing the front strut, perform the following to test the front strut functionality:

•Adjust the tire pressure to all tires to proper specifications.

• Push and shake the front of the vehicle three or four times with identical force every time

• During the pushing and recoiling, the resistance and recoil times of the vehicle should be equal.

• If the strut (shock absorber) functions properly, the vehicle will recoil several times and then stop recoiling after

the pushing force is removed.

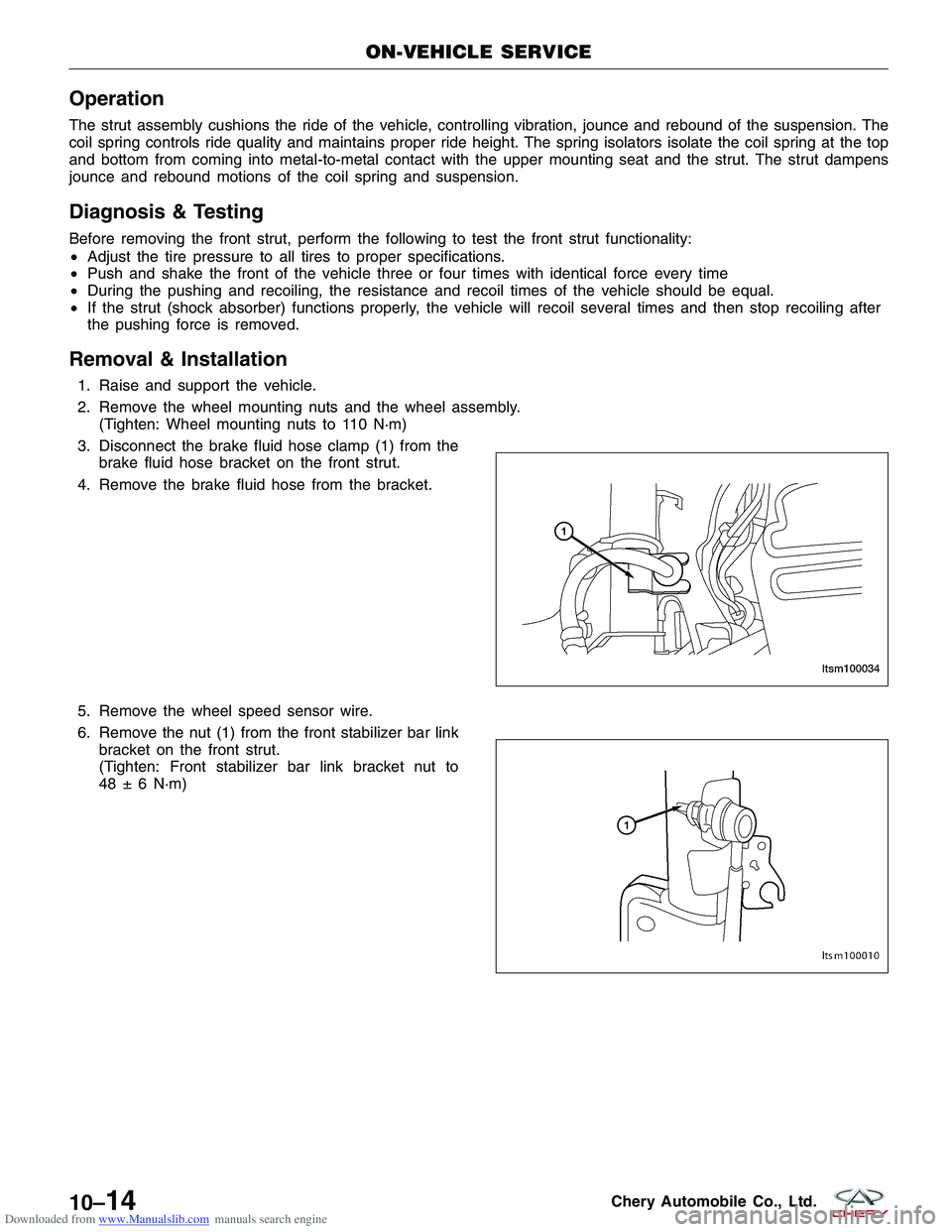

Removal & Installation

1. Raise and support the vehicle.

2. Remove the wheel mounting nuts and the wheel assembly.

(Tighten: Wheel mounting nuts to 110 N·m)

3. Disconnect the brake fluid hose clamp (1) from the brake fluid hose bracket on the front strut.

4. Remove the brake fluid hose from the bracket.

5. Remove the wheel speed sensor wire.

6. Remove the nut (1) from the front stabilizer bar link bracket on the front strut.

(Tighten: Front stabilizer bar link bracket nut to

48 ± 6 N·m)

ON-VEHICLE SERVICE

LTSM100034

LTSM100010

10–14Chery Automobile Co., Ltd.

Page 1317 of 1903

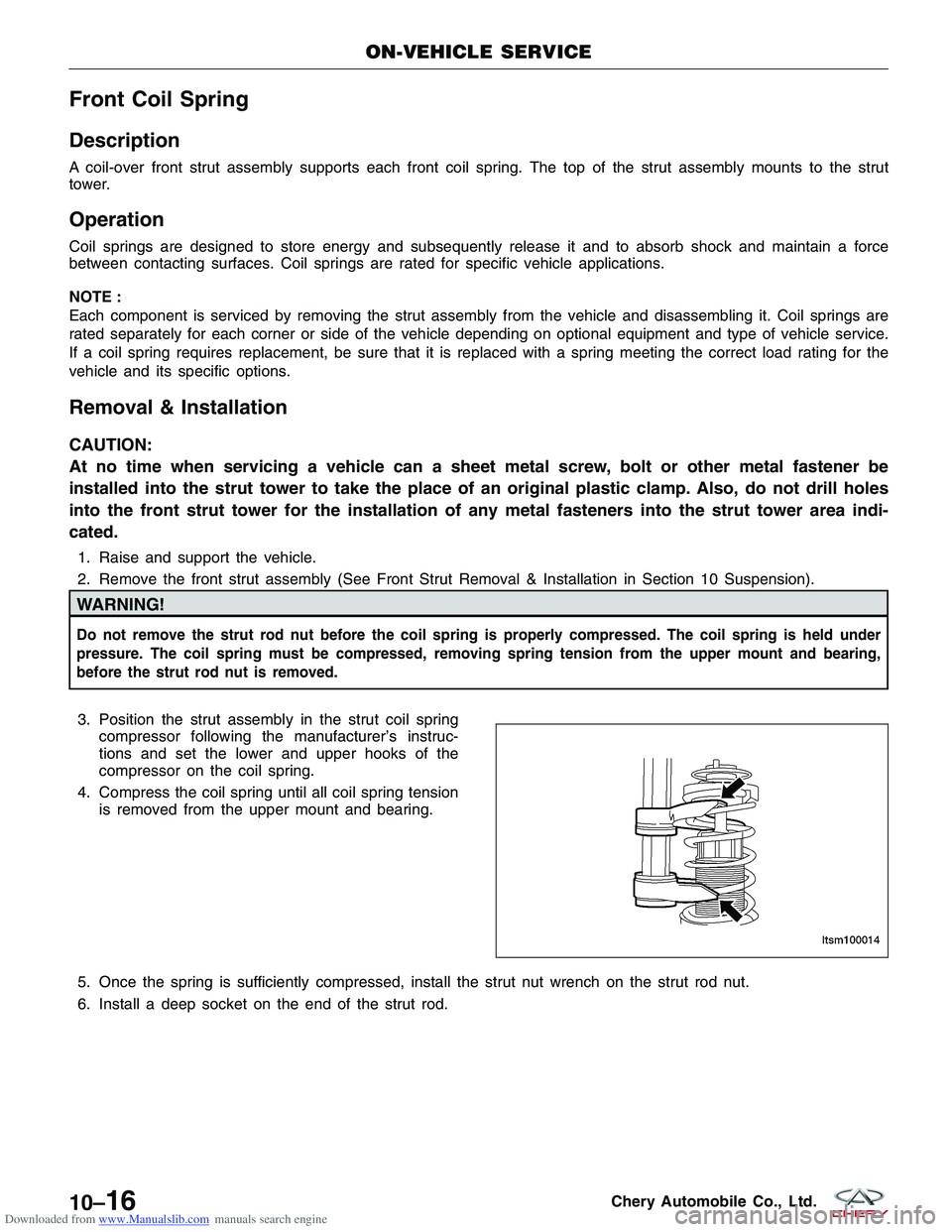

Downloaded from www.Manualslib.com manuals search engine Front Coil Spring

Description

A coil-over front strut assembly supports each front coil spring. The top of the strut assembly mounts to the strut

tower.

Operation

Coil springs are designed to store energy and subsequently release it and to absorb shock and maintain a force

between contacting surfaces. Coil springs are rated for specific vehicle applications.

NOTE :

Each component is serviced by removing the strut assembly from the vehicle and disassembling it. Coil springs are

rated separately for each corner or side of the vehicle depending on optional equipment and type of vehicle service.

If a coil spring requires replacement, be sure that it is replaced with a spring meeting the correct load rating for the

vehicle and its specific options.

Removal & Installation

CAUTION:

At no time when servicing a vehicle can a sheet metal screw, bolt or other metal fastener be

installed into the strut tower to take the place of an original plastic clamp. Also, do not drill holes

into the front strut tower for the installation of any metal fasteners into the strut tower area indi-

cated.

1. Raise and support the vehicle.

2. Remove the front strut assembly (See Front Strut Removal & Installation in Section 10 Suspension).

WARNING!

Do not remove the strut rod nut before the coil spring is properly compressed. The coil spring is held under

pressure. The coil spring must be compressed, removing spring tension from the upper mount and bearing,

before the strut rod nut is removed.

3. Position the strut assembly in the strut coil springcompressor following the manufacturer’s instruc-

tions and set the lower and upper hooks of the

compressor on the coil spring.

4. Compress the coil spring until all coil spring tension is removed from the upper mount and bearing.

5. Once the spring is sufficiently compressed, install the strut nut wrench on the strut rod nut.

6. Install a deep socket on the end of the strut rod.

ON-VEHICLE SERVICE

LTSM100014

10–16Chery Automobile Co., Ltd.

Page 1326 of 1903

Downloaded from www.Manualslib.com manuals search engine REAR SUSPENSION

GENERAL INFORMATION10-26

Description 10-26

Operation 10-27

Specifications 10-28

DIAGNOSIS & TESTING10-29

Vehicle Inspection 10-29

Vibration At High Speed 10-29

ON-VEHICLE SERVICE10-30

Rear Lower Control Arm 10-30

Removal & Installation 10-30

Rear Upper Control Arm 10-31

Removal & Installation 10-31 Rear Stabilizer Bar Link

10-32

Removal & Installation 10-32

Rear Shock Absorber 10-32

Description 10-32

Operation 10-32

Removal & Installation 10-32

Rear Shock Absorber Inspection 10-33

Rear Coil Spring 10-33

Description 10-33

Operation 10-34

Removal & Installation 10-34

Rear Trailing Arm Assembly 10-35

Removal & Installation 10-35

10

10–25Chery Automobile Co., Ltd.

Page 1329 of 1903

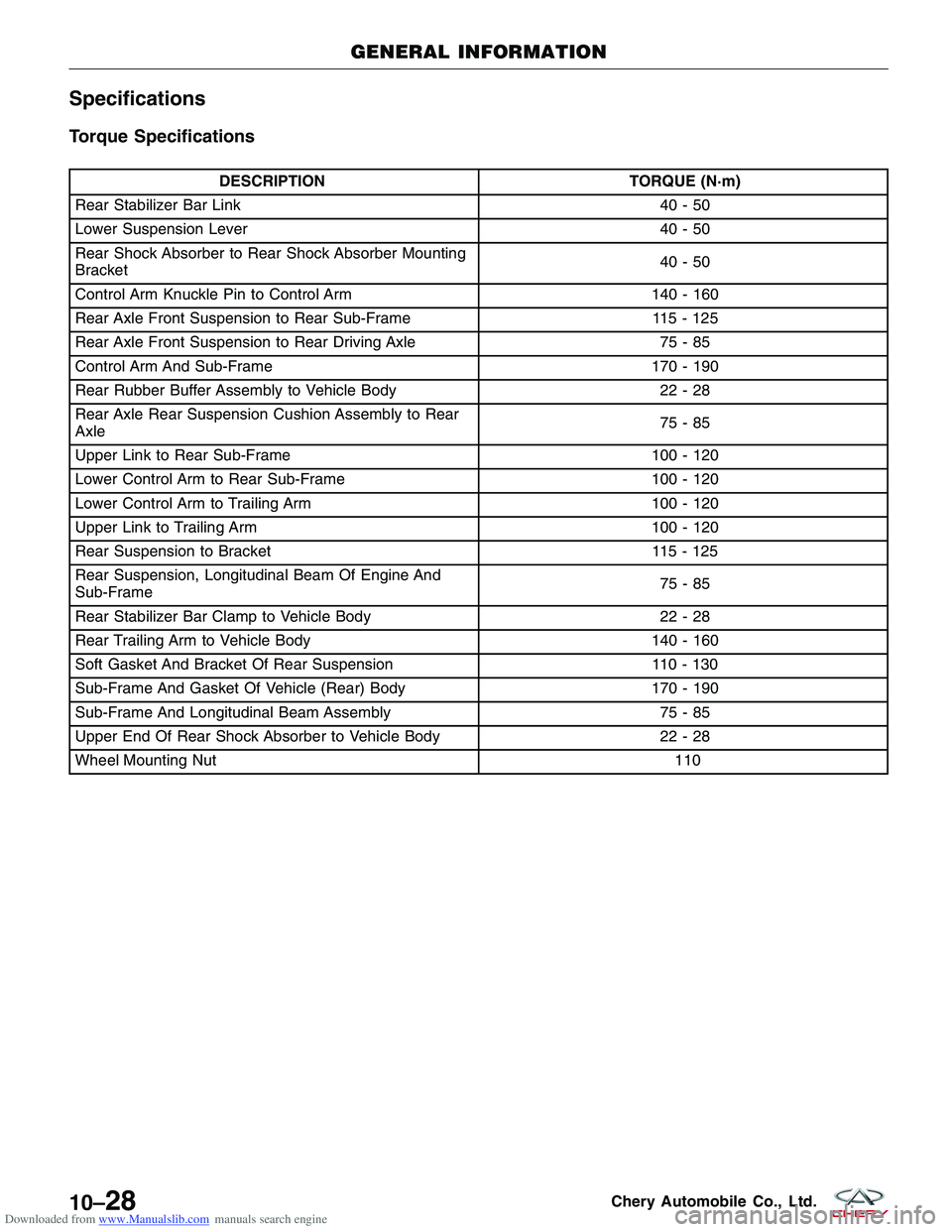

Downloaded from www.Manualslib.com manuals search engine Specifications

Torque Specifications

DESCRIPTIONTORQUE (N·m)

Rear Stabilizer Bar Link 40 - 50

Lower Suspension Lever 40 - 50

Rear Shock Absorber to Rear Shock Absorber Mounting

Bracket 40-50

Control Arm Knuckle Pin to Control Arm 140 - 160

Rear Axle Front Suspension to Rear Sub-Frame 115 - 125

Rear Axle Front Suspension to Rear Driving Axle 75 - 85

Control Arm And Sub-Frame 170 - 190

Rear Rubber Buffer Assembly to Vehicle Body 22 - 28

Rear Axle Rear Suspension Cushion Assembly to Rear

Axle 75-85

Upper Link to Rear Sub-Frame 100 - 120

Lower Control Arm to Rear Sub-Frame 100 - 120

Lower Control Arm to Trailing Arm 100 - 120

Upper Link to Trailing Arm 100 - 120

Rear Suspension to Bracket 115 - 125

Rear Suspension, Longitudinal Beam Of Engine And

Sub-Frame 75-85

Rear Stabilizer Bar Clamp to Vehicle Body 22 - 28

Rear Trailing Arm to Vehicle Body 140 - 160

Soft Gasket And Bracket Of Rear Suspension 110 - 130

Sub-Frame And Gasket Of Vehicle (Rear) Body 170 - 190

Sub-Frame And Longitudinal Beam Assembly 75 - 85

Upper End Of Rear Shock Absorber to Vehicle Body 22 - 28

Wheel Mounting Nut \

11

0

GENERAL INFORMATION

10–28Chery Automobile Co., Ltd.

Page 1333 of 1903

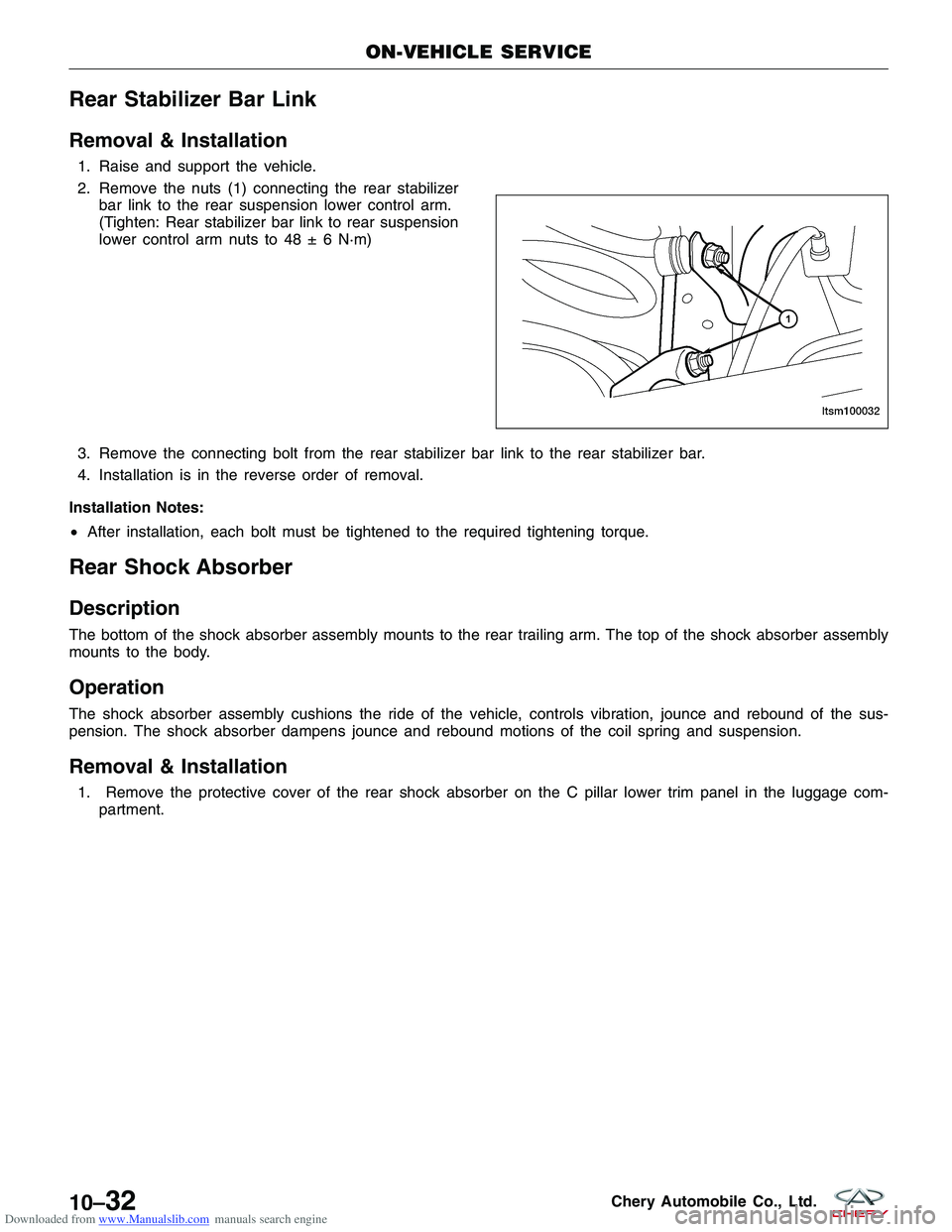

Downloaded from www.Manualslib.com manuals search engine Rear Stabilizer Bar Link

Removal & Installation

1. Raise and support the vehicle.

2. Remove the nuts (1) connecting the rear stabilizerbar link to the rear suspension lower control arm.

(Tighten: Rear stabilizer bar link to rear suspension

lower control arm nuts to 48 ± 6 N·m)

3. Remove the connecting bolt from the rear stabilizer bar link to the rear stabilizer bar.

4. Installation is in the reverse order of removal.

Installation Notes:

• After installation, each bolt must be tightened to the required tightening torque.

Rear Shock Absorber

Description

The bottom of the shock absorber assembly mounts to the rear trailing arm. The top of the shock absorber assembly

mounts to the body.

Operation

The shock absorber assembly cushions the ride of the vehicle, controls vibration, jounce and rebound of the sus-

pension. The shock absorber dampens jounce and rebound motions of the coil spring and suspension.

Removal & Installation

1. Remove the protective cover of the rear shock absorber on the C pillar lower trim panel in the luggage com-

partment.

ON-VEHICLE SERVICE

LTSM100032

10–32Chery Automobile Co., Ltd.