check engine CHERY TIGGO 2009 Service Repair Manual

[x] Cancel search | Manufacturer: CHERY, Model Year: 2009, Model line: TIGGO, Model: CHERY TIGGO 2009Pages: 1903, PDF Size: 33.38 MB

Page 1807 of 1903

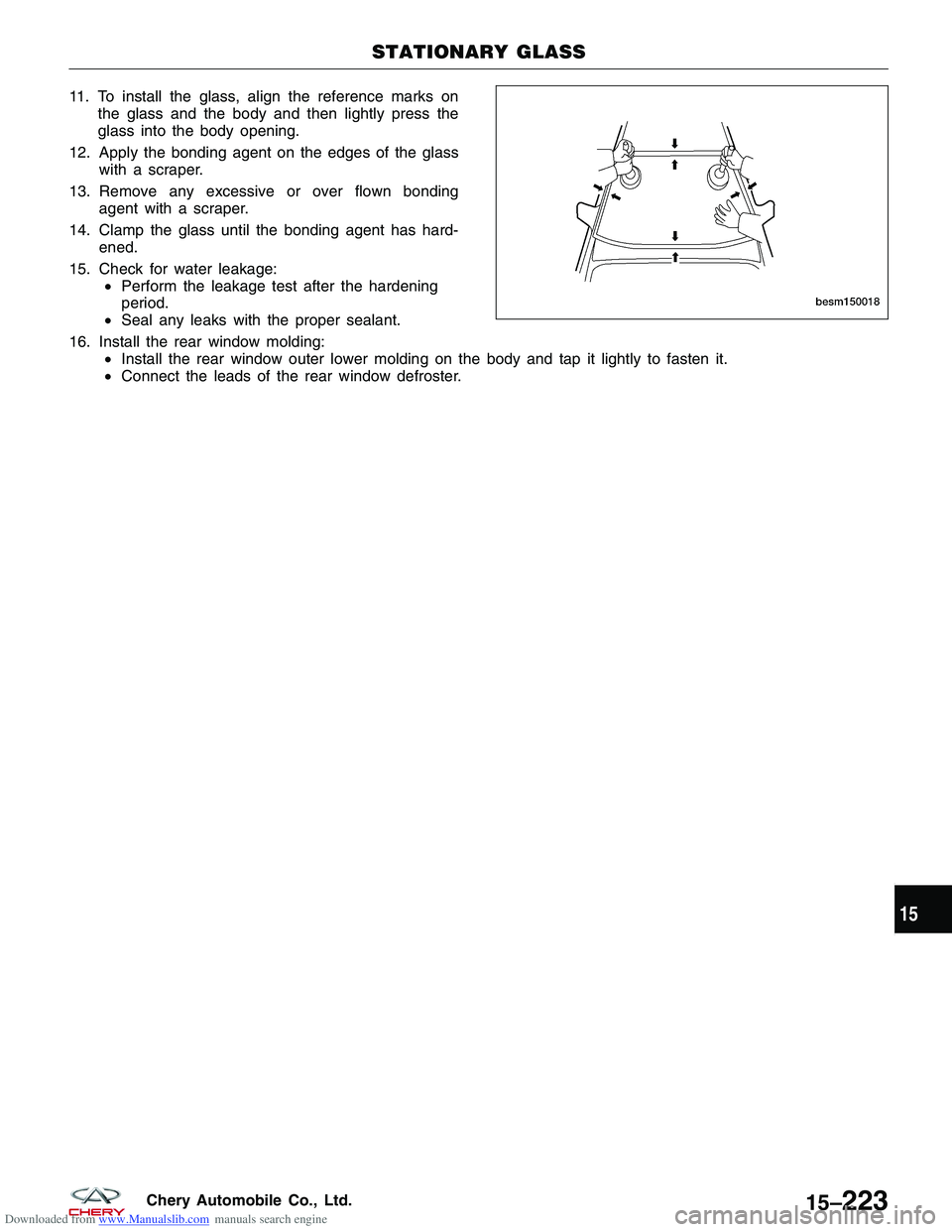

Downloaded from www.Manualslib.com manuals search engine 11. To install the glass, align the reference marks onthe glass and the body and then lightly press the

glass into the body opening.

12. Apply the bonding agent on the edges of the glass with a scraper.

13. Remove any excessive or over flown bonding agent with a scraper.

14. Clamp the glass until the bonding agent has hard- ened.

15. Check for water leakage: •Perform the leakage test after the hardening

period.

• Seal any leaks with the proper sealant.

16. Install the rear window molding: •Install the rear window outer lower molding on the body and tap it lightly to fasten it.

• Connect the leads of the rear window defroster.

STATIONARY GLASS

BESM150018

15

15–223Chery Automobile Co., Ltd.

Page 1813 of 1903

Downloaded from www.Manualslib.com manuals search engine ON-VEHICLE SERVICE

Sunroof Glass

Removal & Installation

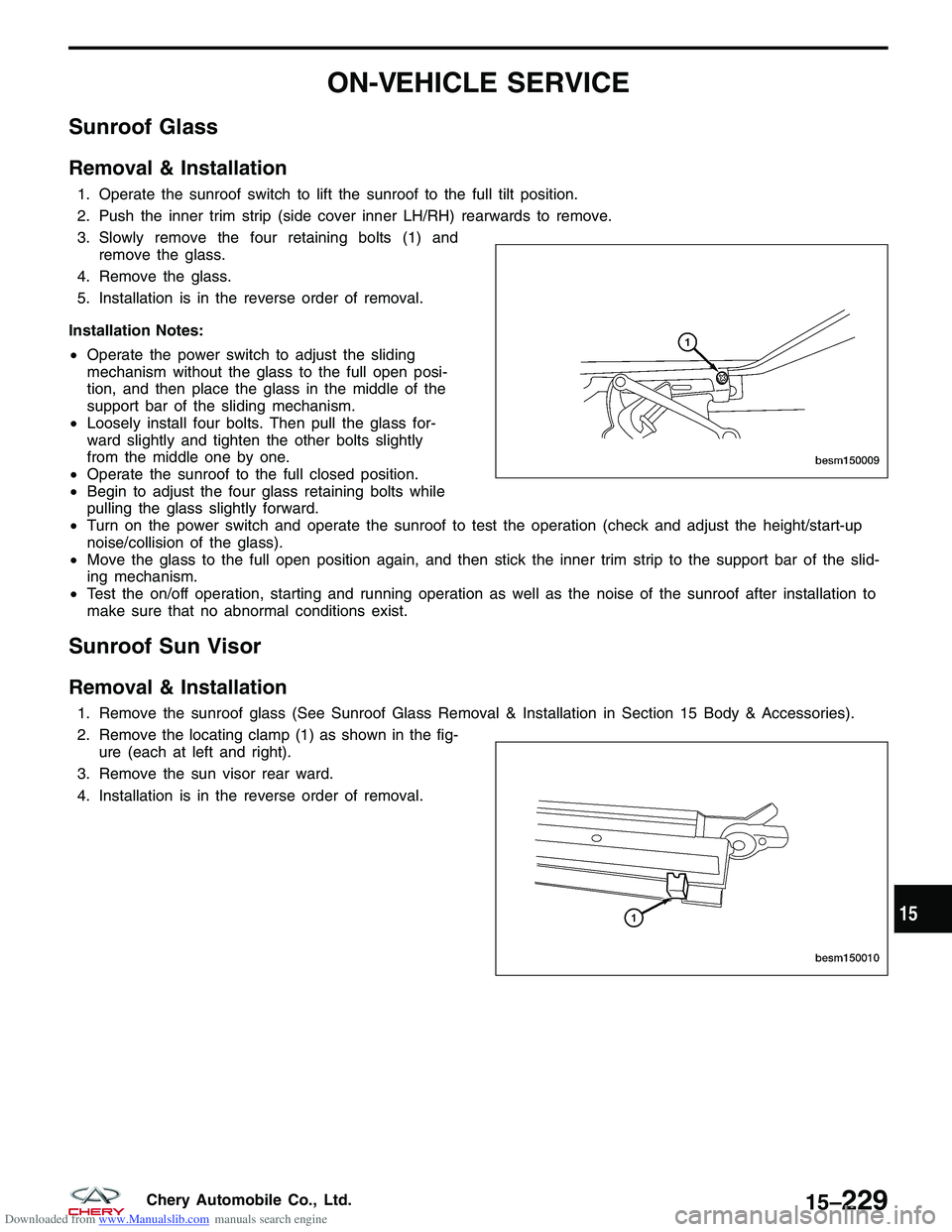

1. Operate the sunroof switch to lift the sunroof to the full tilt position.

2. Push the inner trim strip (side cover inner LH/RH) rearwards to remove.

3. Slowly remove the four retaining bolts (1) andremove the glass.

4. Remove the glass.

5. Installation is in the reverse order of removal.

Installation Notes:

• Operate the power switch to adjust the sliding

mechanism without the glass to the full open posi-

tion, and then place the glass in the middle of the

support bar of the sliding mechanism.

• Loosely install four bolts. Then pull the glass for-

ward slightly and tighten the other bolts slightly

from the middle one by one.

• Operate the sunroof to the full closed position.

• Begin to adjust the four glass retaining bolts while

pulling the glass slightly forward.

• Turn on the power switch and operate the sunroof to test the operation (check and adjust the height/start-up

noise/collision of the glass).

• Move the glass to the full open position again, and then stick the inner trim strip to the support bar of the slid-

ing mechanism.

• Test the on/off operation, starting and running operation as well as the noise of the sunroof after installation to

make sure that no abnormal conditions exist.

Sunroof Sun Visor

Removal & Installation

1. Remove the sunroof glass (See Sunroof Glass Removal & Installation in Section 15 Body & Accessories).

2. Remove the locating clamp (1) as shown in the fig-

ure (each at left and right).

3. Remove the sun visor rear ward.

4. Installation is in the reverse order of removal.

BESM150009

BESM150010

15

15–229Chery Automobile Co., Ltd.

Page 1831 of 1903

Downloaded from www.Manualslib.com manuals search engine ELECTRICAL TROUBLESHOOTING

Troubleshooting Wiring Problems

When troubleshooting wiring problems there are six steps which can aid in the procedure. The steps are listed and

explained below. Always check for non-factory equipped components added to the vehicle before doing any diagno-

sis. If the vehicle is equipped with these items, disconnect them to verify these add-on items are not the cause of the

problem.

Perform the following when troubleshooting a wiring problem:1. Verify the problem.

2. Verify any related symptoms (do this by performing operational checks on components that are in the same circuit).

3. Analyze the symptoms (use the wiring diagrams to determine what the circuit is doing, where the problem most likely is occurring and where the diagnosis will continue).

4. Isolate the problem area.

5. Repair the problem area.

6. Verify the proper operation (for this step, check for proper operation of all items on the repaired circuit).

Testing For Voltage

1. Connect the ground lead of a voltmeter to a known good ground.

2. Connect the other lead of the voltmeter to the selected test point. The vehicle ignition may need to be turned ON to check voltage. Refer to the appropriate test procedure.

Testing For Continuity

1. Remove the fuse for the circuit being checked or, disconnect the battery.

2. Connect one lead of the ohmmeter to one side of the circuit being tested.

3. Connect the other lead to the other end of the circuit being tested (low or no resistance means good continuity).

Testing For A Short To Ground

1. Remove the fuse and disconnect all items involved with the fuse.

2. Connect a test light or a voltmeter across the terminals of the fuse.

3. Starting at the fuse block, wiggle the wiring harness about six to eight inches apart and watch the voltmeter/testlight.

4. If the voltmeter registers voltage or the test light glows, there is a short to ground in that general area of the wiring harness.

Intermittent and Poor Connections

Most intermittent electrical problems are caused by faulty electrical connections or wiring. It is also possible for a

sticking component or relay to cause a problem. Before condemning a component or wiring assembly, check the

following items:

1. Connectors are fully seated

2. Spread terminals, or terminal push out

3. Terminals in the wiring assembly are fully seated into the connector/component and locked into position

4. Dirt or corrosion on the terminals (any amount of corrosion or dirt could cause an intermittent problem)

5. Damaged connector/component casing exposing the item to dirt or moisture

6. Wire insulation that has rubbed through causing a short to ground

7. Some or all of the wiring strands broken inside of the insulation

8. Wiring broken inside of the insulation

16

16–5Chery Automobile Co., Ltd.

Page 1833 of 1903

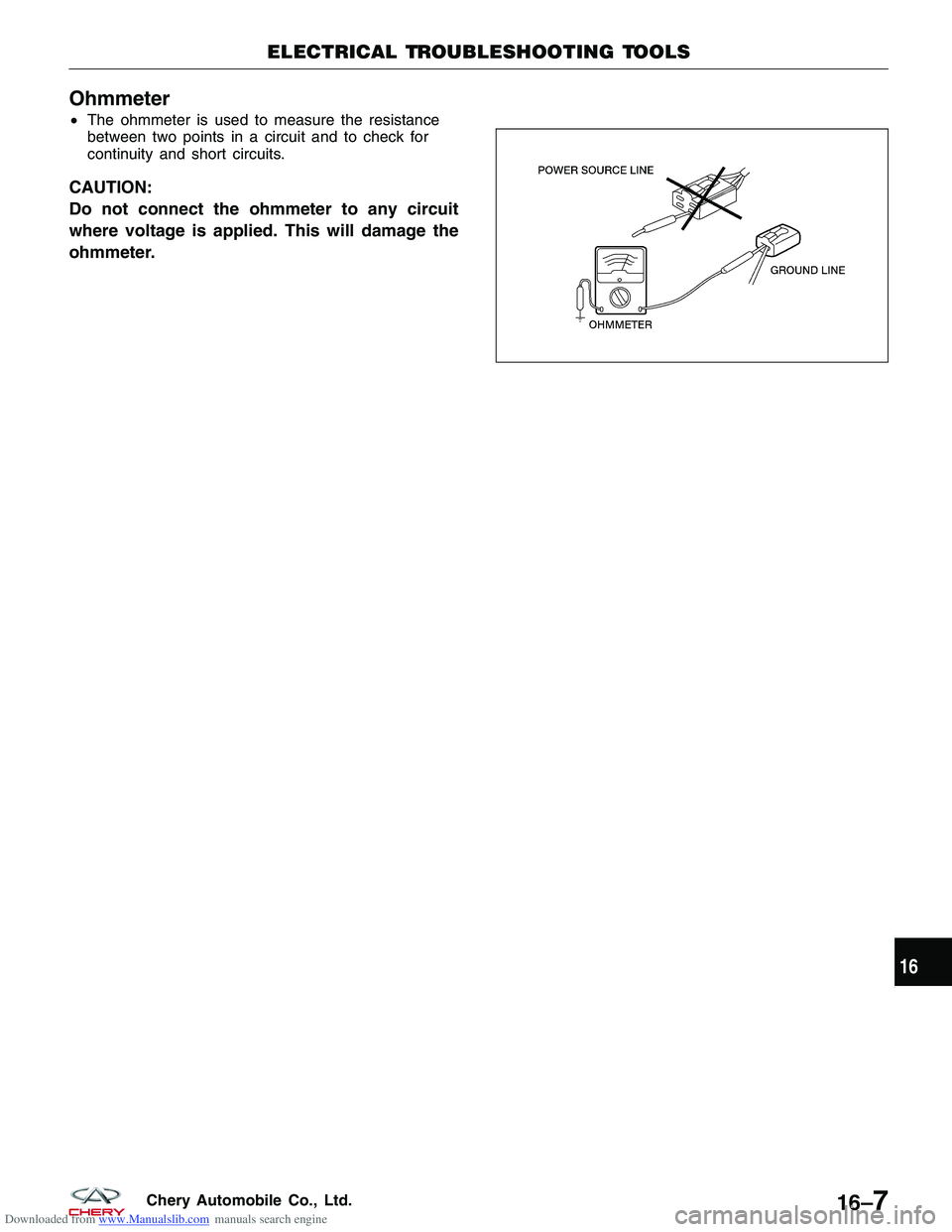

Downloaded from www.Manualslib.com manuals search engine Ohmmeter

•The ohmmeter is used to measure the resistance

between two points in a circuit and to check for

continuity and short circuits.

CAUTION:

Do not connect the ohmmeter to any circuit

where voltage is applied. This will damage the

ohmmeter.

ELECTRICAL TROUBLESHOOTING TOOLS

BESM010028

16

16–7Chery Automobile Co., Ltd.

Page 1834 of 1903

Downloaded from www.Manualslib.com manuals search engine ELECTRICAL REPAIR

Wire Repair

NOTE :

When splicing a wire, it is important that the correct gage be used.1. Remove one-half (1/2) inch of insulation from each wire that needs to be spliced.

2. Place a piece of adhesive lined heat shrink tubing on one side of the wire. Make sure the tubing will be long enough to cover and seal the entire repair area.

3. Place the strands of wire overlapping each other inside of the splice clip.

4. Using a crimping tool, crimp the splice clip and wires together.

NOTE :

Do not use acid core solder when making wiring repairs. 5. Solder the connection together using a soldering iron and rosin core type solder only.

6. Center the heat shrink tubing over the joint and heat using a heat gun. Heat the joint until the tubing is tightly sealed and sealant comes out of both ends of the tubing.

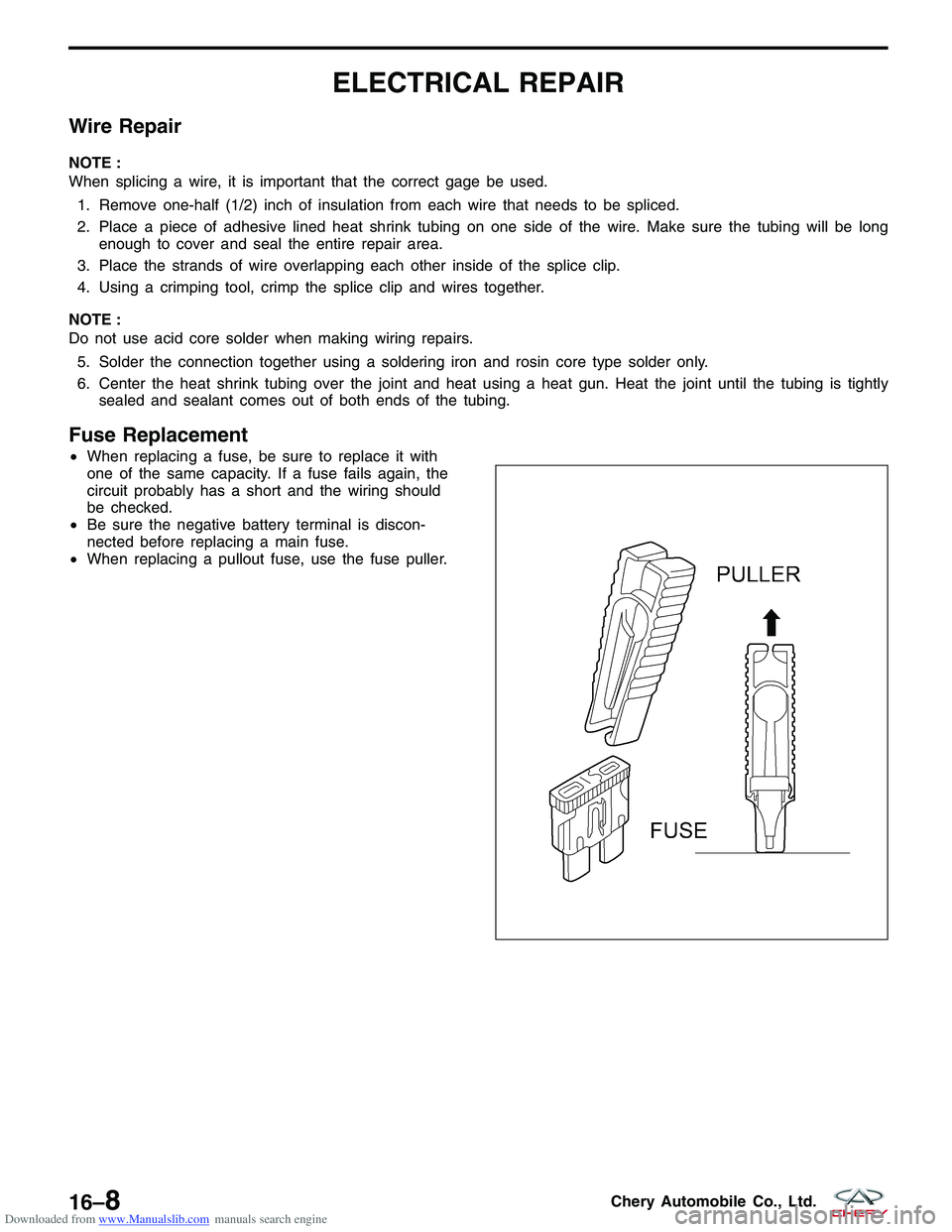

Fuse Replacement

•When replacing a fuse, be sure to replace it with

one of the same capacity. If a fuse fails again, the

circuit probably has a short and the wiring should

be checked.

• Be sure the negative battery terminal is discon-

nected before replacing a main fuse.

• When replacing a pullout fuse, use the fuse puller.

BESM010025

16–8Chery Automobile Co., Ltd.

Page 1837 of 1903

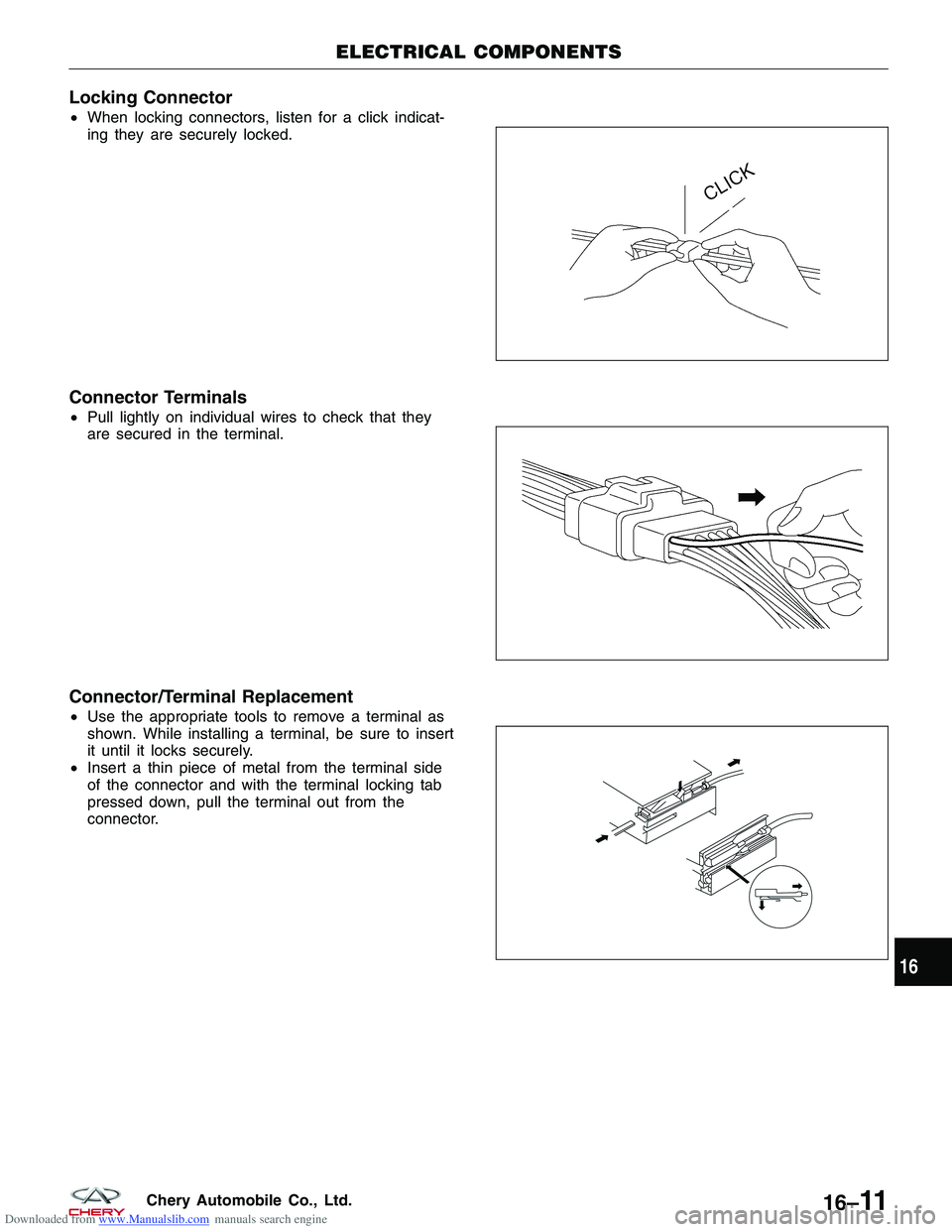

Downloaded from www.Manualslib.com manuals search engine Locking Connector

•When locking connectors, listen for a click indicat-

ing they are securely locked.

Connector Terminals

•Pull lightly on individual wires to check that they

are secured in the terminal.

Connector/Terminal Replacement

•Use the appropriate tools to remove a terminal as

shown. While installing a terminal, be sure to insert

it until it locks securely.

• Insert a thin piece of metal from the terminal side

of the connector and with the terminal locking tab

pressed down, pull the terminal out from the

connector.

ELECTRICAL COMPONENTS

BESM010020

BESM010023

BESM010029

16

16–11Chery Automobile Co., Ltd.