service CHERY TIGGO 2009 Service Manual Online

[x] Cancel search | Manufacturer: CHERY, Model Year: 2009, Model line: TIGGO, Model: CHERY TIGGO 2009Pages: 1903, PDF Size: 33.38 MB

Page 148 of 1903

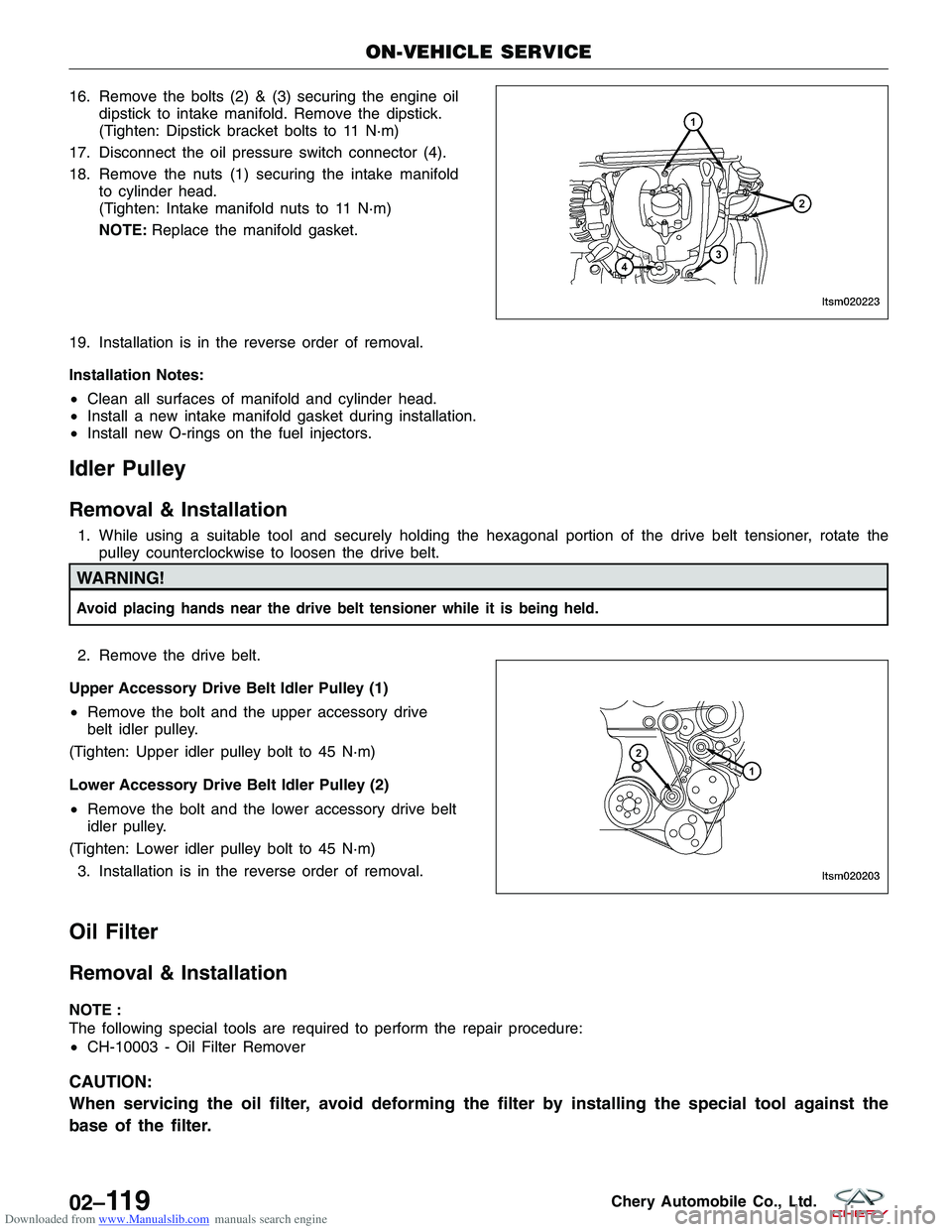

Downloaded from www.Manualslib.com manuals search engine 16. Remove the bolts (2) & (3) securing the engine oildipstick to intake manifold. Remove the dipstick.

(Tighten: Dipstick bracket bolts to 11 N·m)

17. Disconnect the oil pressure switch connector (4).

18. Remove the nuts (1) securing the intake manifold to cylinder head.

(Tighten: Intake manifold nuts to 11 N·m)

NOTE: Replace the manifold gasket.

19. Installation is in the reverse order of removal.

Installation Notes:

• Clean all surfaces of manifold and cylinder head.

• Install a new intake manifold gasket during installation.

• Install new O-rings on the fuel injectors.

Idler Pulley

Removal & Installation

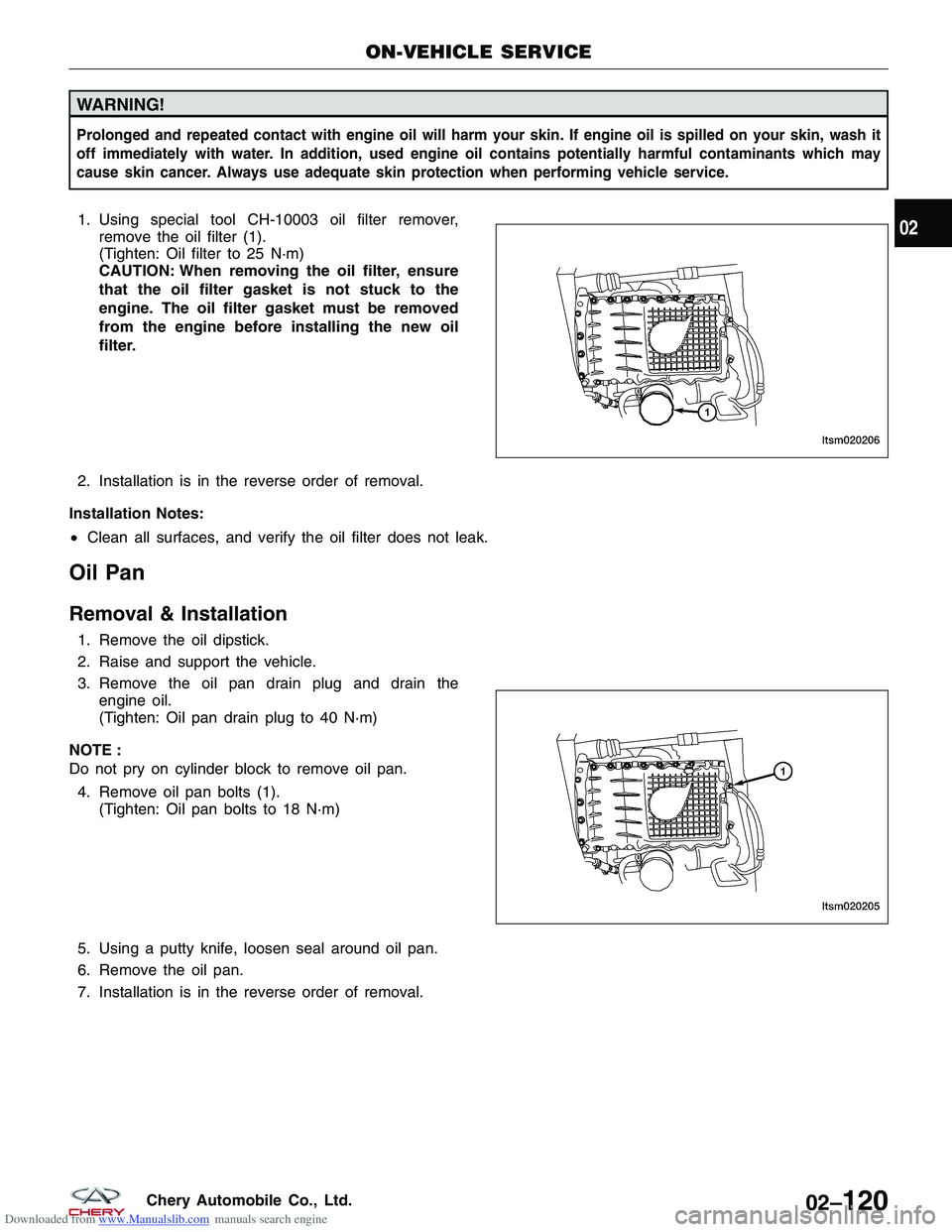

1. While using a suitable tool and securely holding the hexagonal portion of the drive belt tensioner, rotate the

pulley counterclockwise to loosen the drive belt.

WARNING!

Avoid placing hands near the drive belt tensioner while it is being held.

2. Remove the drive belt.

Upper Accessory Drive Belt Idler Pulley (1)

• Remove the bolt and the upper accessory drive

belt idler pulley.

(Tighten: Upper idler pulley bolt to 45 N·m)

Lower Accessory Drive Belt Idler Pulley (2)

• Remove the bolt and the lower accessory drive belt

idler pulley.

(Tighten: Lower idler pulley bolt to 45 N·m) 3. Installation is in the reverse order of removal.

Oil Filter

Removal & Installation

NOTE :

The following special tools are required to perform the repair procedure:

• CH-10003 - Oil Filter Remover

CAUTION:

When servicing the oil filter, avoid deforming the filter by installing the special tool against the

base of the filter.

ON-VEHICLE SERVICE

LTSM020223

LTSM020203

02–11 9Chery Automobile Co., Ltd.

Page 149 of 1903

Downloaded from www.Manualslib.com manuals search engine WARNING!

Prolonged and repeated contact with engine oil will harm your skin. If engine oil is spilled on your skin, wash it

off immediately with water. In addition, used engine oil contains potentially harmful contaminants which may

cause skin cancer. Always use adequate skin protection when performing vehicle service.

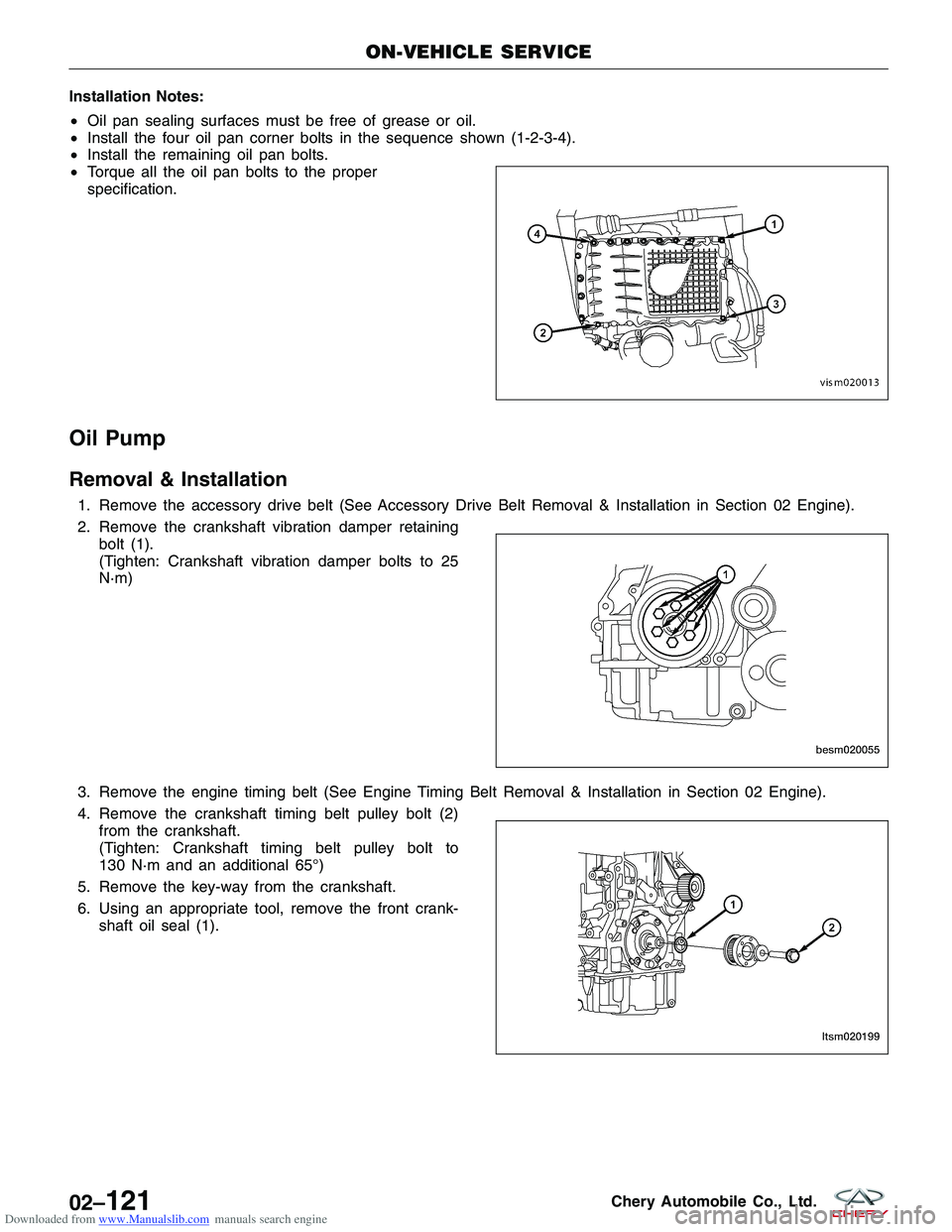

1. Using special tool CH-10003 oil filter remover,remove the oil filter (1).

(Tighten: Oil filter to 25 N·m)

CAUTION: When removing the oil filter, ensure

that the oil filter gasket is not stuck to the

engine. The oil filter gasket must be removed

from the engine before installing the new oil

filter.

2. Installation is in the reverse order of removal.

Installation Notes:

• Clean all surfaces, and verify the oil filter does not leak.

Oil Pan

Removal & Installation

1. Remove the oil dipstick.

2. Raise and support the vehicle.

3. Remove the oil pan drain plug and drain the

engine oil.

(Tighten: Oil pan drain plug to 40 N·m)

NOTE :

Do not pry on cylinder block to remove oil pan. 4. Remove oil pan bolts (1). (Tighten: Oil pan bolts to 18 N·m)

5. Using a putty knife, loosen seal around oil pan.

6. Remove the oil pan.

7. Installation is in the reverse order of removal.

ON-VEHICLE SERVICE

LTSM020206

LTSM020205

02

02–120Chery Automobile Co., Ltd.

Page 150 of 1903

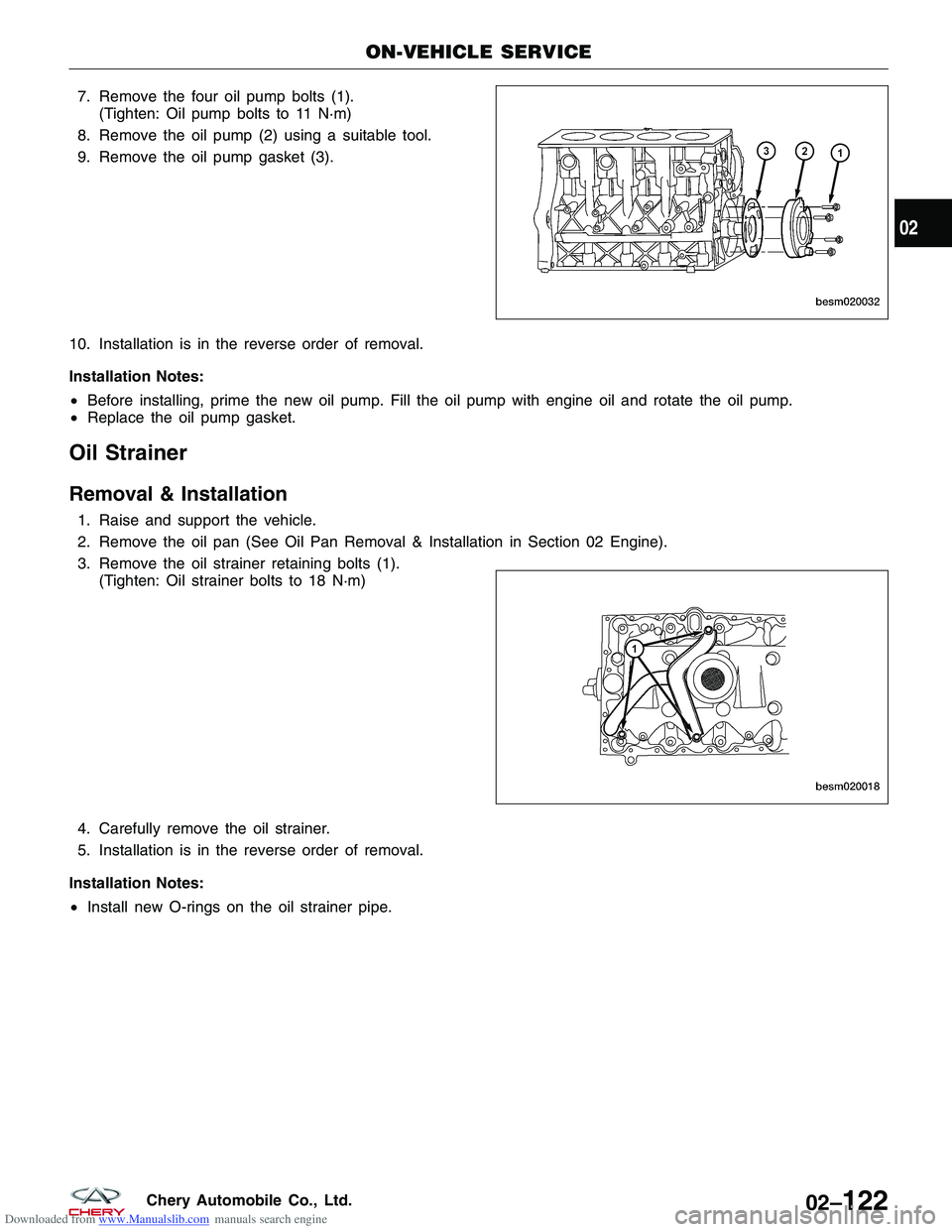

Downloaded from www.Manualslib.com manuals search engine Installation Notes:

•Oil pan sealing surfaces must be free of grease or oil.

• Install the four oil pan corner bolts in the sequence shown (1-2-3-4).

• Install the remaining oil pan bolts.

• Torque all the oil pan bolts to the proper

specification.

Oil Pump

Removal & Installation

1. Remove the accessory drive belt (See Accessory Drive Belt Removal & Installation in Section 02 Engine).

2. Remove the crankshaft vibration damper retaining

bolt (1).

(Tighten: Crankshaft vibration damper bolts to 25

N·m)

3. Remove the engine timing belt (See Engine Timing Belt Removal & Installation in Section 02 Engine).

4. Remove the crankshaft timing belt pulley bolt (2) from the crankshaft.

(Tighten: Crankshaft timing belt pulley bolt to

130 N·m and an additional 65°)

5. Remove the key-way from the crankshaft.

6. Using an appropriate tool, remove the front crank- shaft oil seal (1).

ON-VEHICLE SERVICE

VISM020013

BESM020055 LTSM020199

02–121Chery Automobile Co., Ltd.

Page 151 of 1903

Downloaded from www.Manualslib.com manuals search engine 7. Remove the four oil pump bolts (1).(Tighten: Oil pump bolts to 11 N·m)

8. Remove the oil pump (2) using a suitable tool.

9. Remove the oil pump gasket (3).

10. Installation is in the reverse order of removal.

Installation Notes:

• Before installing, prime the new oil pump. Fill the oil pump with engine oil and rotate the oil pump.

• Replace the oil pump gasket.

Oil Strainer

Removal & Installation

1. Raise and support the vehicle.

2. Remove the oil pan (See Oil Pan Removal & Installation in Section 02 Engine).

3. Remove the oil strainer retaining bolts (1).

(Tighten: Oil strainer bolts to 18 N·m)

4. Carefully remove the oil strainer.

5. Installation is in the reverse order of removal.

Installation Notes:

• Install new O-rings on the oil strainer pipe.

ON-VEHICLE SERVICE

BESM020032

BESM020018

02

02–122Chery Automobile Co., Ltd.

Page 154 of 1903

Downloaded from www.Manualslib.com manuals search engine Inspection

NOTE :

All measurements should be taken with the engine block at room temperature, 21°C.

Engine Block

•Clean cylinder block thoroughly and check all core hole plugs for evidence of leaking.

• Examine block and cylinder bores for cracks or fractures.

• Check block deck surfaces for flatness. Deck surface must be within service limit of 0.050 mm.

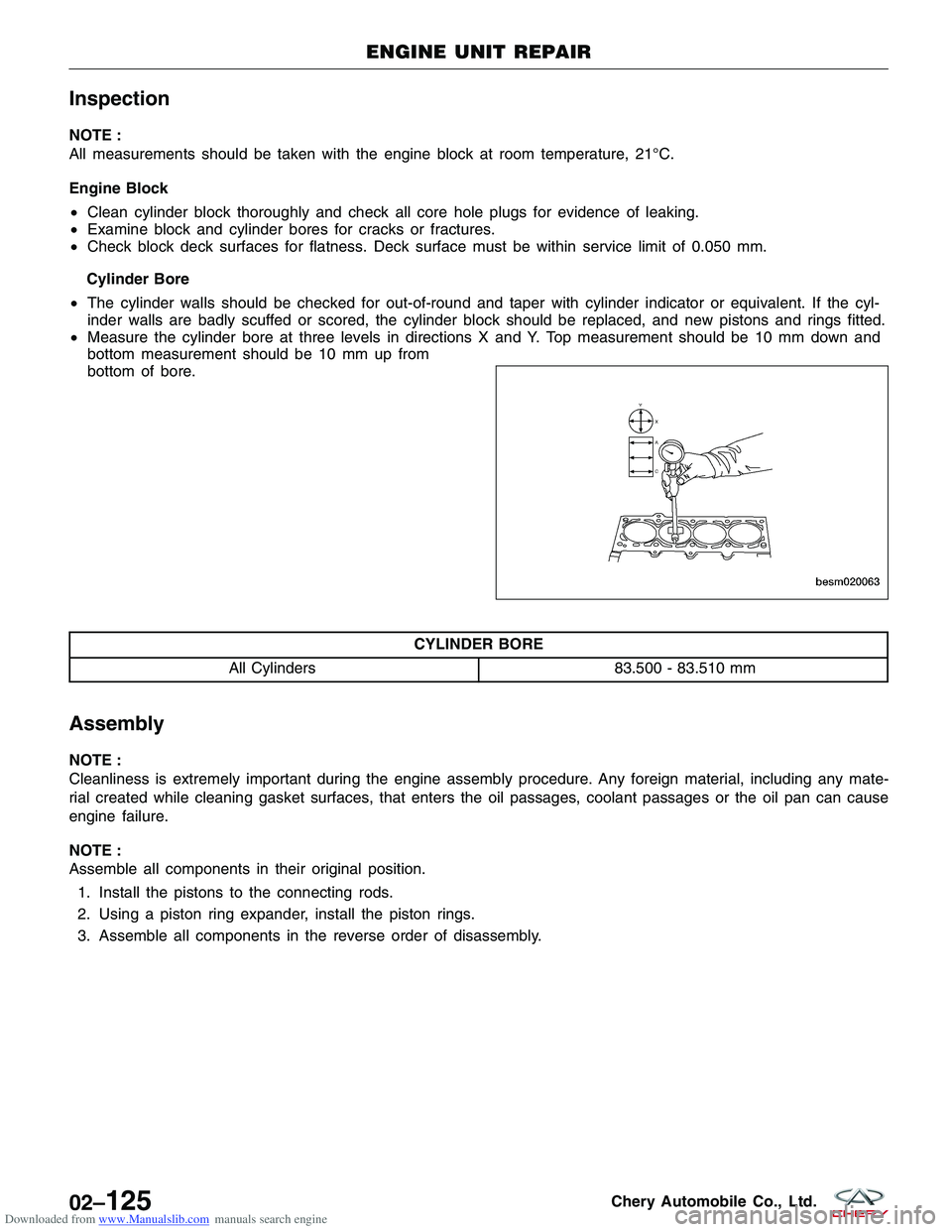

Cylinder Bore

• The cylinder walls should be checked for out-of-round and taper with cylinder indicator or equivalent. If the cyl-

inder walls are badly scuffed or scored, the cylinder block should be replaced, and new pistons and rings fitted.

• Measure the cylinder bore at three levels in directions X and Y. Top measurement should be 10 mm down and

bottom measurement should be 10 mm up from

bottom of bore.

CYLINDER BORE

All Cylinders 83.500 - 83.510 mm

Assembly

NOTE :

Cleanliness is extremely important during the engine assembly procedure. Any foreign material, including any mate-

rial created while cleaning gasket surfaces, that enters the oil passages, coolant passages or the oil pan can cause

engine failure.

NOTE :

Assemble all components in their original position.

1. Install the pistons to the connecting rods.

2. Using a piston ring expander, install the piston rings.

3. Assemble all components in the reverse order of disassembly.

ENGINE UNIT REPAIR

BESM020063

02–125Chery Automobile Co., Ltd.

Page 178 of 1903

Downloaded from www.Manualslib.com manuals search engine 2.4L ENGINE MECHANICAL

GENERAL INFORMATION02-151

Description 02-151

Operation 02-151

Specifications 02-151

Special Tools 02-154

Lubrication System 02-160

DIAGNOSIS & TESTING02-163

Engine Performance Diagnostics 02-163

Engine Mechanical Diagnostics 02-164

Cylinder Compression Pressure Test 02-165

Cylinder Head Gasket Test 02-166

Engine Oil Pressure Test 02-166

ON-VEHICLE SERVICE02-167

Accessory Drive Belt 02-167

Removal & Installation 02-167

Air Cleaner Element 02-168

Removal & Installation 02-168

Air Cleaner Housing 02-169

Removal & Installation 02-169

Cylinder Head Cover 02-170

Removal & Installation 02-170

Camshaft 02-171

Removal & Installation 02-171

Cylinder Head 02-175

Removal & Installation 02-175

Front Crankshaft Oil Seal 02-177

Removal & Installation 02-177

Rear Crankshaft Oil Seal 02-179

Removal & Installation 02-179

Engine Mounts 02-181

Removal & Installation - Left Mount 02-181

Removal & Installation - Right Mount 02-182

Removal & Installation - Front Mount 02-182

Removal & Installation - Rear Mount 02-183

Engine Assembly 02-183

Removal & Installation 02-183

Engine Timing Belt 02-189

Removal & Installation 02-189

Inspection 02-194

Timing Belt Automatic Tensioner 02-196

Removal & Installation 02-196

Inspection 02-197

Upper Balance Shaft Timing Belt 02-198

Removal & Installation 02-198Exhaust Manifold

02-200

Removal & Installation 02-200

Intake Manifold 02-201

Removal & Installation 02-201

Upper Balance Shaft 02-204

Removal & Installation 02-204

Upper Balance Shaft Bearing

Replacement 02-207

Lower Balance Shaft 02-208

Removal & Installation 02-208

Lower Balance Shaft Bearing

Replacement 02-211

Oil Filter 02-212

Removal & Installation 02-212

Oil Pan 02-213

Removal & Installation 02-213

Oil Pump 02-215

Removal & Installation 02-215

Oil Strainer 02-216

Removal & Installation 02-216

ENGINE UNIT REPAIR02-217

Engine Block 02-217

Specifications 02-217

Disassembly 02-218

Inspection 02-220

Assembly 02-220

Pistons 02-221

Specifications 02-221

Disassembly 02-222

Inspection 02-224

Assembly 02-226

Connecting Rods 02-229

Specifications 02-229

Disassembly 02-229

Inspection 02-230

Assembly 02-231

Crankshaft 02-233

Specifications 02-233

Disassembly 02-234

Inspection 02-236

Assembly 02-237

02–149Chery Automobile Co., Ltd.

Page 196 of 1903

Downloaded from www.Manualslib.com manuals search engine ON-VEHICLE SERVICE

Accessory Drive Belt

Removal & Installation

WARNING!

Inspect the drive belt only when the engine is stopped.

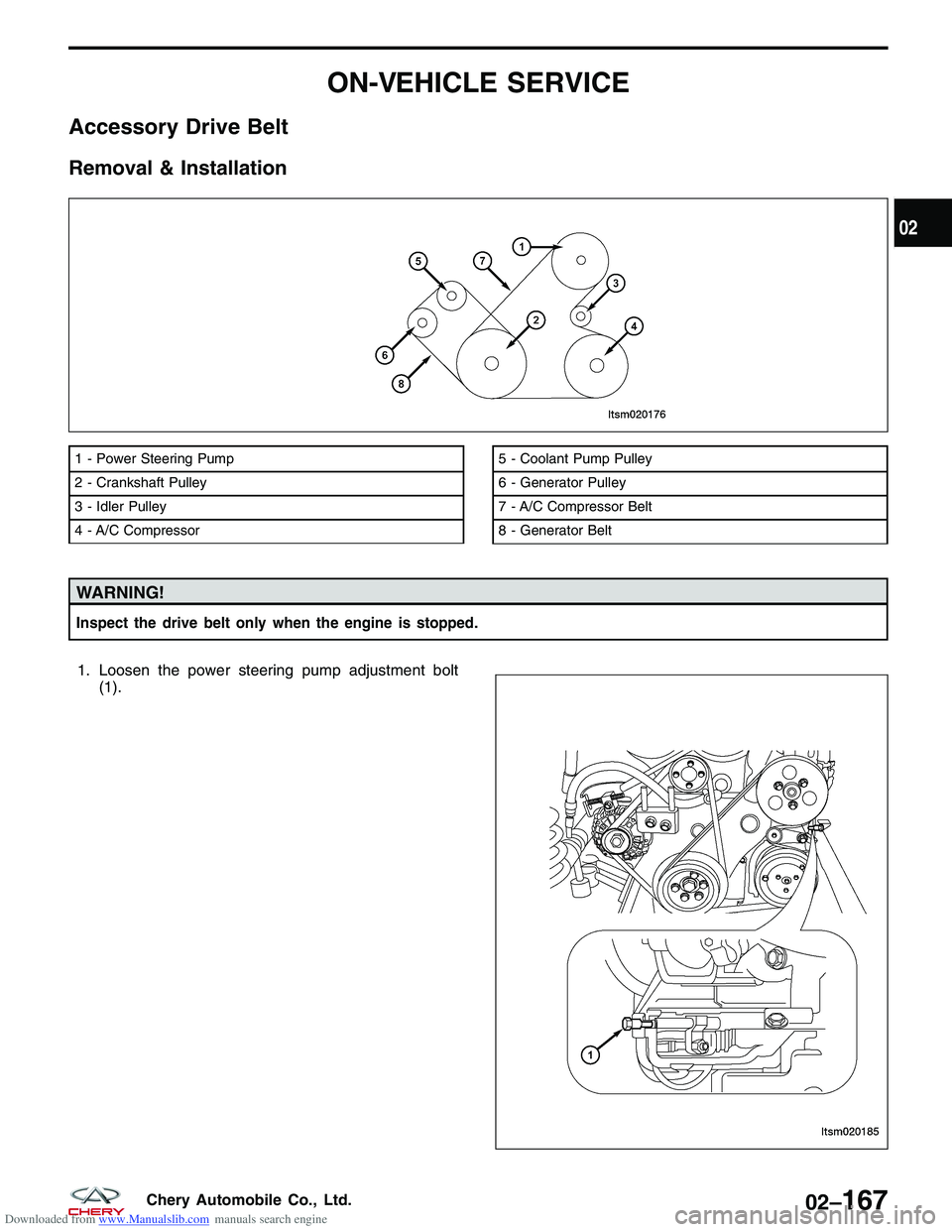

1. Loosen the power steering pump adjustment bolt(1).

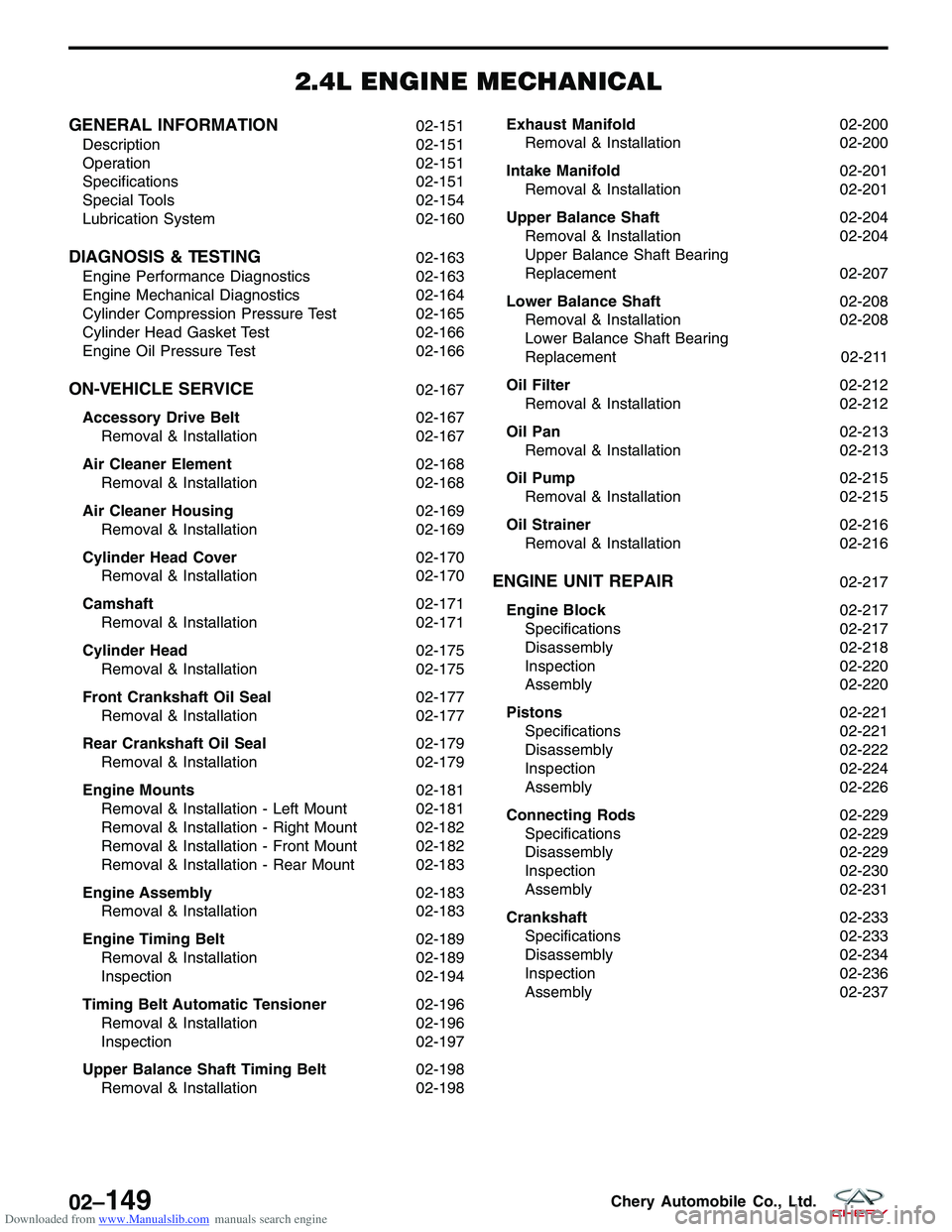

1 - Power Steering Pump

2 - Crankshaft Pulley

3 - Idler Pulley

4 - A/C Compressor5 - Coolant Pump Pulley

6 - Generator Pulley

7 - A/C Compressor Belt

8 - Generator Belt

LTSM020176

LTSM020185

02

02–167Chery Automobile Co., Ltd.

Page 197 of 1903

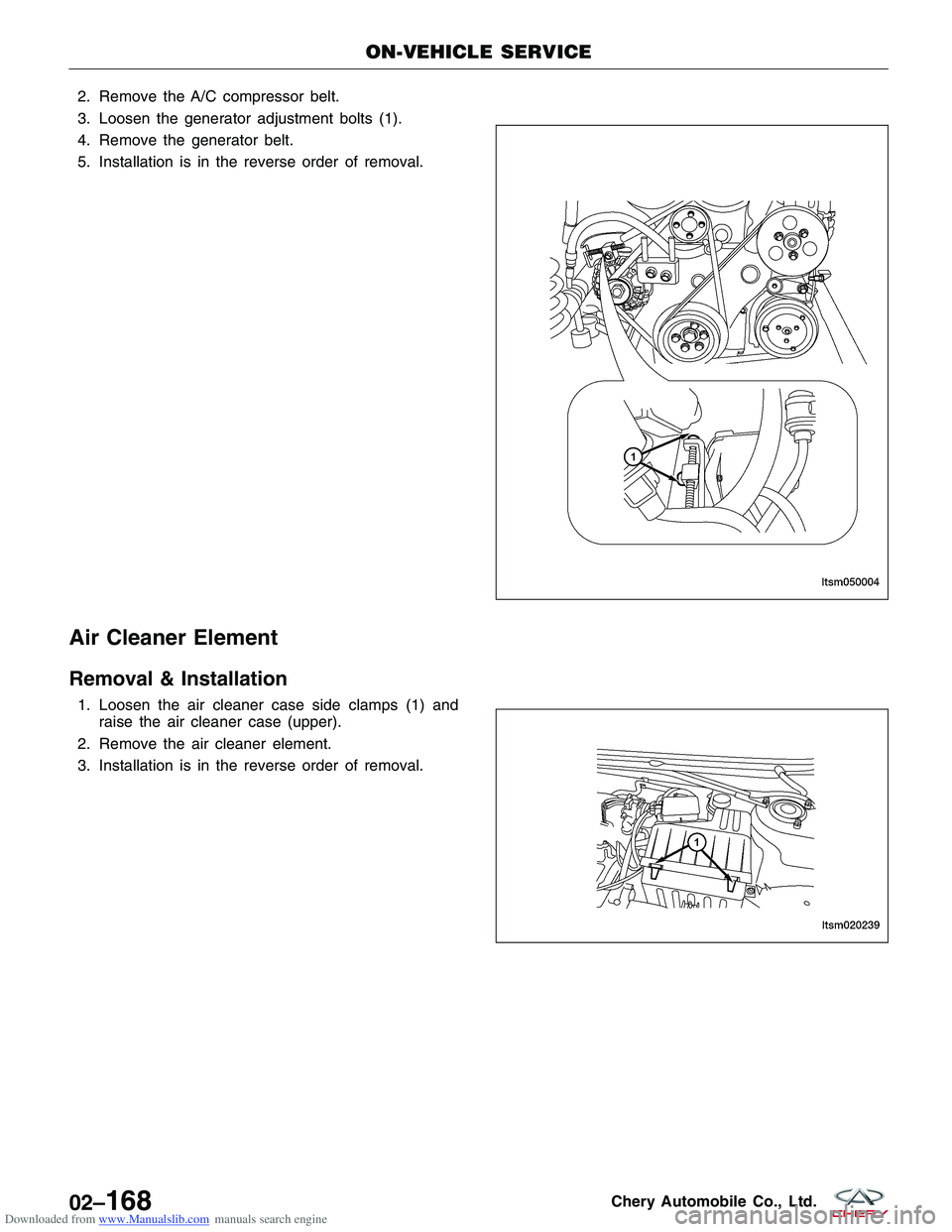

Downloaded from www.Manualslib.com manuals search engine 2. Remove the A/C compressor belt.

3. Loosen the generator adjustment bolts (1).

4. Remove the generator belt.

5. Installation is in the reverse order of removal.

Air Cleaner Element

Removal & Installation

1. Loosen the air cleaner case side clamps (1) andraise the air cleaner case (upper).

2. Remove the air cleaner element.

3. Installation is in the reverse order of removal.

ON-VEHICLE SERVICE

LTSM050004

LTSM020239

02–168Chery Automobile Co., Ltd.

Page 198 of 1903

Downloaded from www.Manualslib.com manuals search engine Air Cleaner Housing

Removal & Installation

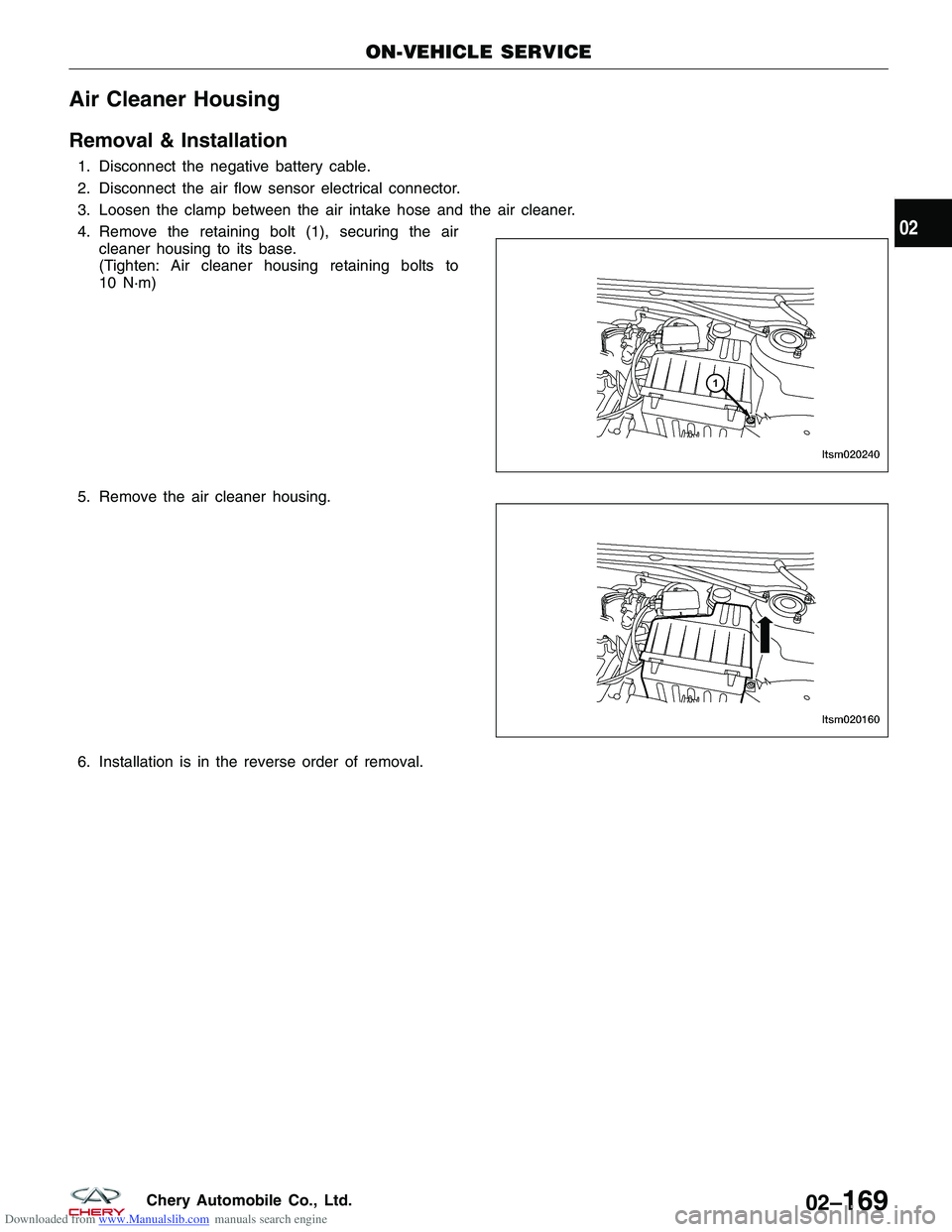

1. Disconnect the negative battery cable.

2. Disconnect the air flow sensor electrical connector.

3. Loosen the clamp between the air intake hose and the air cleaner.

4. Remove the retaining bolt (1), securing the aircleaner housing to its base.

(Tighten: Air cleaner housing retaining bolts to

10 N·m)

5. Remove the air cleaner housing.

6. Installation is in the reverse order of removal.

ON-VEHICLE SERVICE

LTSM020240

LTSM020160

02

02–169Chery Automobile Co., Ltd.

Page 199 of 1903

Downloaded from www.Manualslib.com manuals search engine Cylinder Head Cover

Removal & Installation

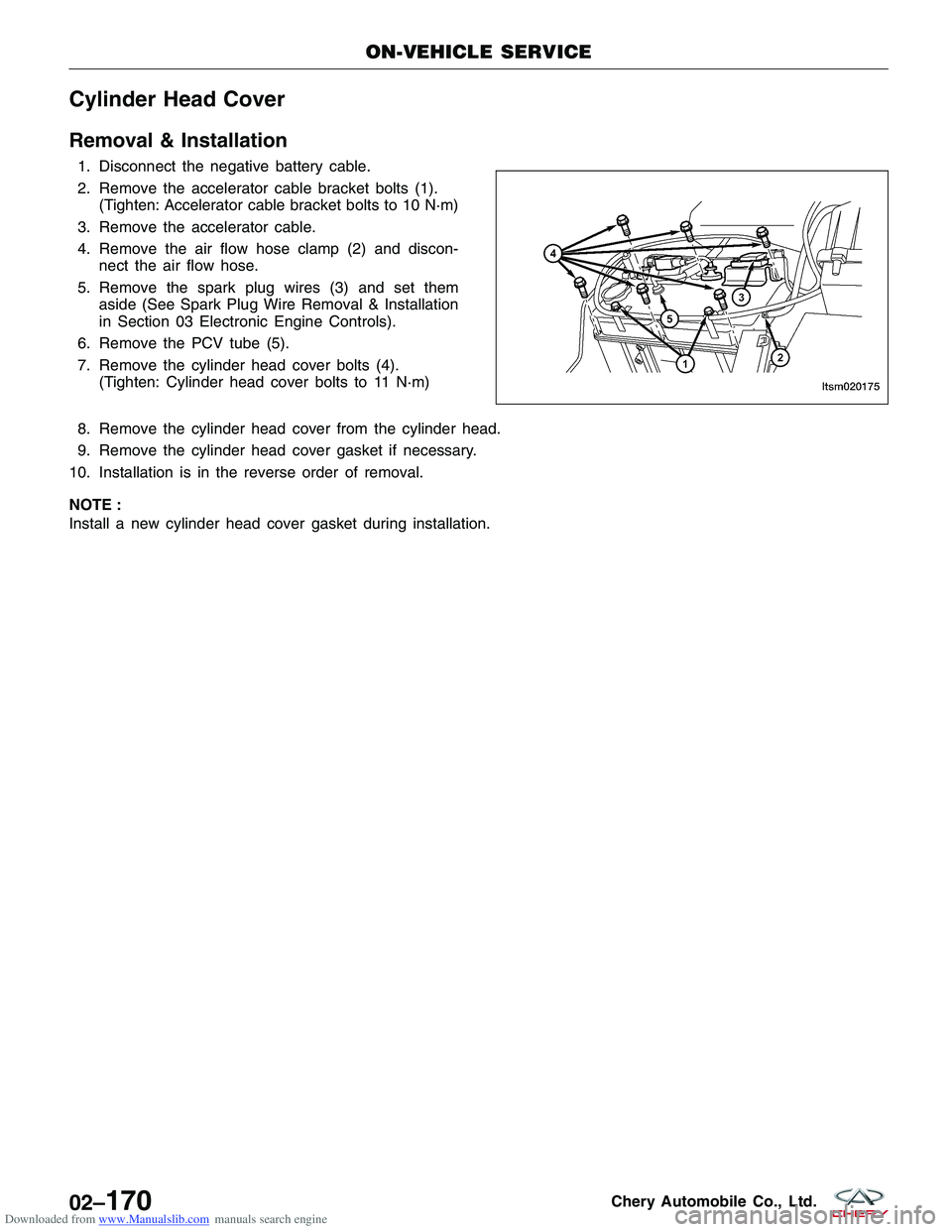

1. Disconnect the negative battery cable.

2. Remove the accelerator cable bracket bolts (1).(Tighten: Accelerator cable bracket bolts to 10 N·m)

3. Remove the accelerator cable.

4. Remove the air flow hose clamp (2) and discon- nect the air flow hose.

5. Remove the spark plug wires (3) and set them aside (See Spark Plug Wire Removal & Installation

in Section 03 Electronic Engine Controls).

6. Remove the PCV tube (5).

7. Remove the cylinder head cover bolts (4). (Tighten: Cylinder head cover bolts to 11 N·m)

8. Remove the cylinder head cover from the cylinder head.

9. Remove the cylinder head cover gasket if necessary.

10. Installation is in the reverse order of removal.

NOTE :

Install a new cylinder head cover gasket during installation.

ON-VEHICLE SERVICE

LTSM020175

02–170Chery Automobile Co., Ltd.