service CHERY TIGGO 2009 Service Workshop Manual

[x] Cancel search | Manufacturer: CHERY, Model Year: 2009, Model line: TIGGO, Model: CHERY TIGGO 2009Pages: 1903, PDF Size: 33.38 MB

Page 81 of 1903

Downloaded from www.Manualslib.com manuals search engine 8. Installation is in the reverse order of removal.

Inspection

NOTE :

All measurements should be taken with the engine block at room temperature, 21°C.

Engine Block

•Clean cylinder block thoroughly and check all core hole plugs for evidence of leaking.

• Examine block and cylinder bores for cracks or fractures.

• Check block deck surfaces for flatness. Deck surface must be within service limit of 0.050 mm.

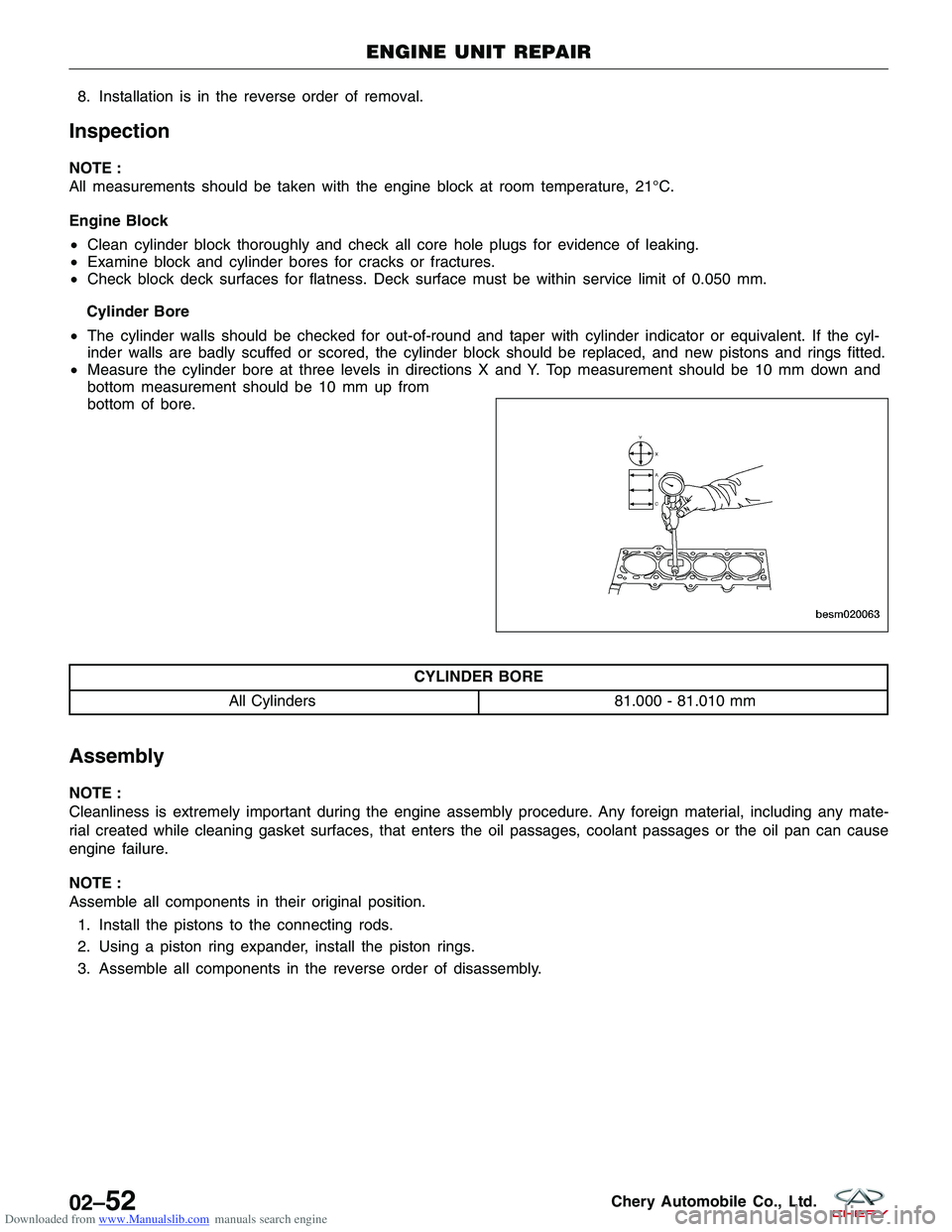

Cylinder Bore

• The cylinder walls should be checked for out-of-round and taper with cylinder indicator or equivalent. If the cyl-

inder walls are badly scuffed or scored, the cylinder block should be replaced, and new pistons and rings fitted.

• Measure the cylinder bore at three levels in directions X and Y. Top measurement should be 10 mm down and

bottom measurement should be 10 mm up from

bottom of bore.

CYLINDER BORE

All Cylinders 81.000 - 81.010 mm

Assembly

NOTE :

Cleanliness is extremely important during the engine assembly procedure. Any foreign material, including any mate-

rial created while cleaning gasket surfaces, that enters the oil passages, coolant passages or the oil pan can cause

engine failure.

NOTE :

Assemble all components in their original position.

1. Install the pistons to the connecting rods.

2. Using a piston ring expander, install the piston rings.

3. Assemble all components in the reverse order of disassembly.

ENGINE UNIT REPAIR

BESM020063

02–52Chery Automobile Co., Ltd.

Page 105 of 1903

Downloaded from www.Manualslib.com manuals search engine 2.0L ENGINE MECHANICAL

GENERAL INFORMATION02-77

Description 02-77

Operation 02-77

Specifications 02-77

Special Tools 02-81

Lubrication System 02-84

DIAGNOSIS & TESTING02-87

Engine Performance Diagnostics 02-87

Engine Mechanical Diagnostics 02-88

Cylinder Compression Pressure Test 02-90

Cylinder Head Gasket Test 02-90

ON-VEHICLE SERVICE02-91

Accessory Drive Belt 02-91

Removal & Installation 02-91

Air Cleaner Element 02-92

Removal & Installation 02-92

Air Cleaner Housing 02-93

Removal & Installation 02-93

Cylinder Head Cover 02-93

Removal & Installation 02-93

Camshaft 02-94

Removal & Installation 02-94

Cylinder Head 02-97

Removal & Installation 02-97

Front Crankshaft Oil Seal 02-99

Removal & Installation 02-99

Rear Crankshaft Oil Seal 02-100

Removal & Installation 02-100

Engine Mounts 02-103

Removal & Installation - Left Mount 02-103

Removal & Installation - Right Mount 02-104

Removal & Installation - Front Mount 02-104

Removal & Installation - Rear Mount 02-105

Engine Assembly 02-105

Removal & Installation 02-105

Engine Timing Belt 02-112

Removal & Installation 02-112

Exhaust Manifold 02-115

Removal & Installation 02-115

Intake Manifold 02-117

Removal & Installation 02-117

Idler Pulley 02-119

Removal & Installation 02-119

Oil Filter 02-119

Removal & Installation 02-119Oil Pan

02-120

Removal & Installation 02-120

Oil Pump 02-121

Removal & Installation 02-121

Oil Strainer 02-122

Removal & Installation 02-122

ENGINE UNIT REPAIR02-123

Engine Block 02-123

Specifications 02-123

Disassembly 02-123

Inspection 02-125

Assembly 02-125

Pistons 02-126

Specifications 02-126

Disassembly 02-127

Inspection 02-128

Assembly 02-130

Connecting Rods 02-131

Specifications 02-131

Disassembly 02-131

Inspection 02-132

Assembly 02-132

Crankshaft 02-133

Specifications 02-133

Disassembly 02-133

Inspection 02-134

Assembly 02-135

CYLINDER HEAD UNIT REPAIR02-136

Cylinder Head 02-136

Specifications 02-136

Disassembly 02-136

Inspection 02-138

Assembly 02-138

Camshaft 02-139

Specifications 02-139

Disassembly 02-140

Inspection 02-140

Assembly 02-142

Valve & Valve Guides 02-143

Specifications 02-143

Disassembly 02-143

Inspection 02-144

Assembly 02-145

Valve Springs 02-146

Specifications 02-146

Disassembly 02-146

Inspection 02-147

Assembly 02-148

02–76Chery Automobile Co., Ltd.

Page 120 of 1903

Downloaded from www.Manualslib.com manuals search engine ON-VEHICLE SERVICE

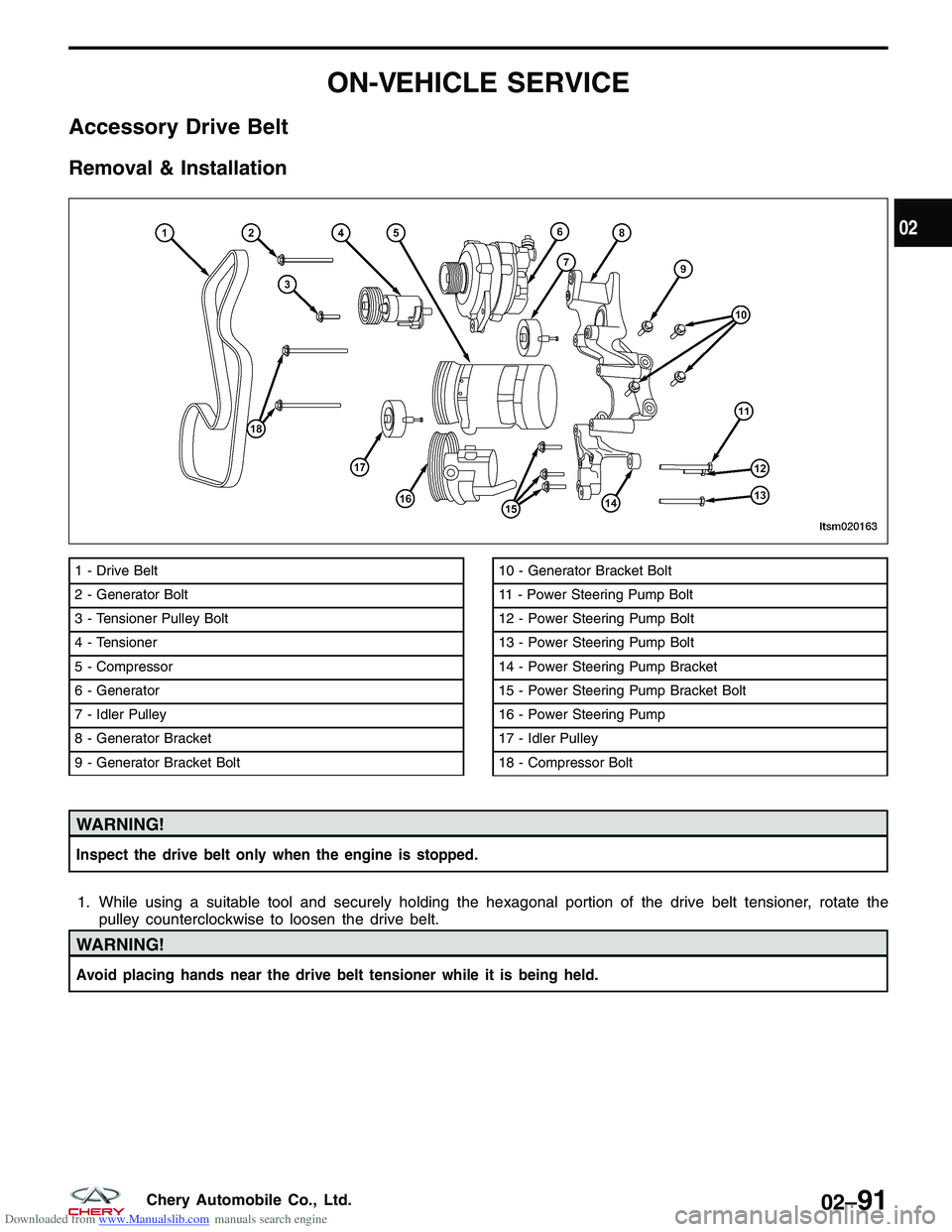

Accessory Drive Belt

Removal & Installation

WARNING!

Inspect the drive belt only when the engine is stopped.

1. While using a suitable tool and securely holding the hexagonal portion of the drive belt tensioner, rotate thepulley counterclockwise to loosen the drive belt.

WARNING!

Avoid placing hands near the drive belt tensioner while it is being held.

1 - Drive Belt

2 - Generator Bolt

3 - Tensioner Pulley Bolt

4 - Tensioner

5 - Compressor

6 - Generator

7 - Idler Pulley

8 - Generator Bracket

9 - Generator Bracket Bolt10 - Generator Bracket Bolt

11 - Power Steering Pump Bolt

12 - Power Steering Pump Bolt

13 - Power Steering Pump Bolt

14 - Power Steering Pump Bracket

15 - Power Steering Pump Bracket Bolt

16 - Power Steering Pump

17 - Idler Pulley

18 - Compressor Bolt

LTSM020163

02

02–91Chery Automobile Co., Ltd.

Page 121 of 1903

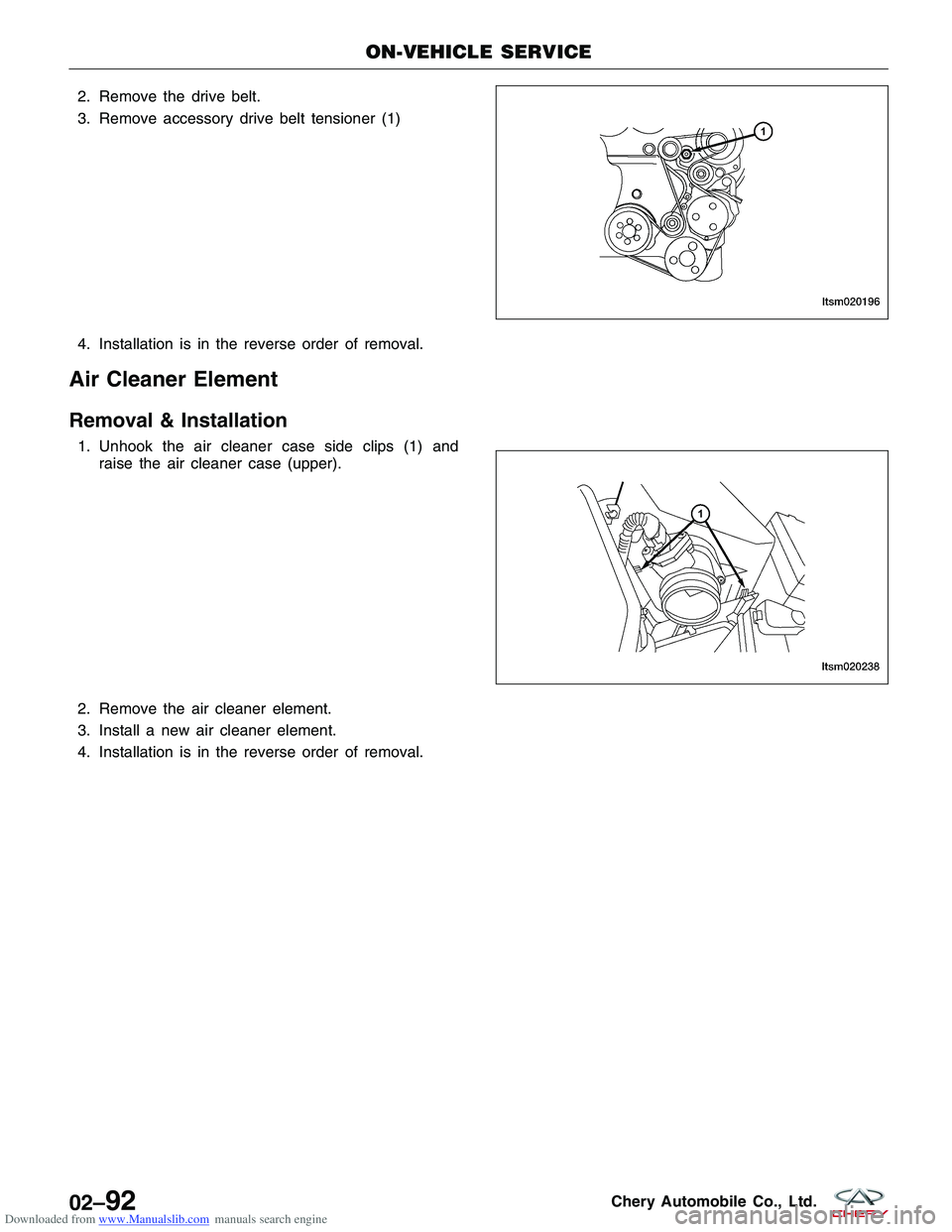

Downloaded from www.Manualslib.com manuals search engine 2. Remove the drive belt.

3. Remove accessory drive belt tensioner (1)

4. Installation is in the reverse order of removal.

Air Cleaner Element

Removal & Installation

1. Unhook the air cleaner case side clips (1) andraise the air cleaner case (upper).

2. Remove the air cleaner element.

3. Install a new air cleaner element.

4. Installation is in the reverse order of removal.

ON-VEHICLE SERVICE

LTSM020196

LTSM020238

02–92Chery Automobile Co., Ltd.

Page 122 of 1903

Downloaded from www.Manualslib.com manuals search engine Air Cleaner Housing

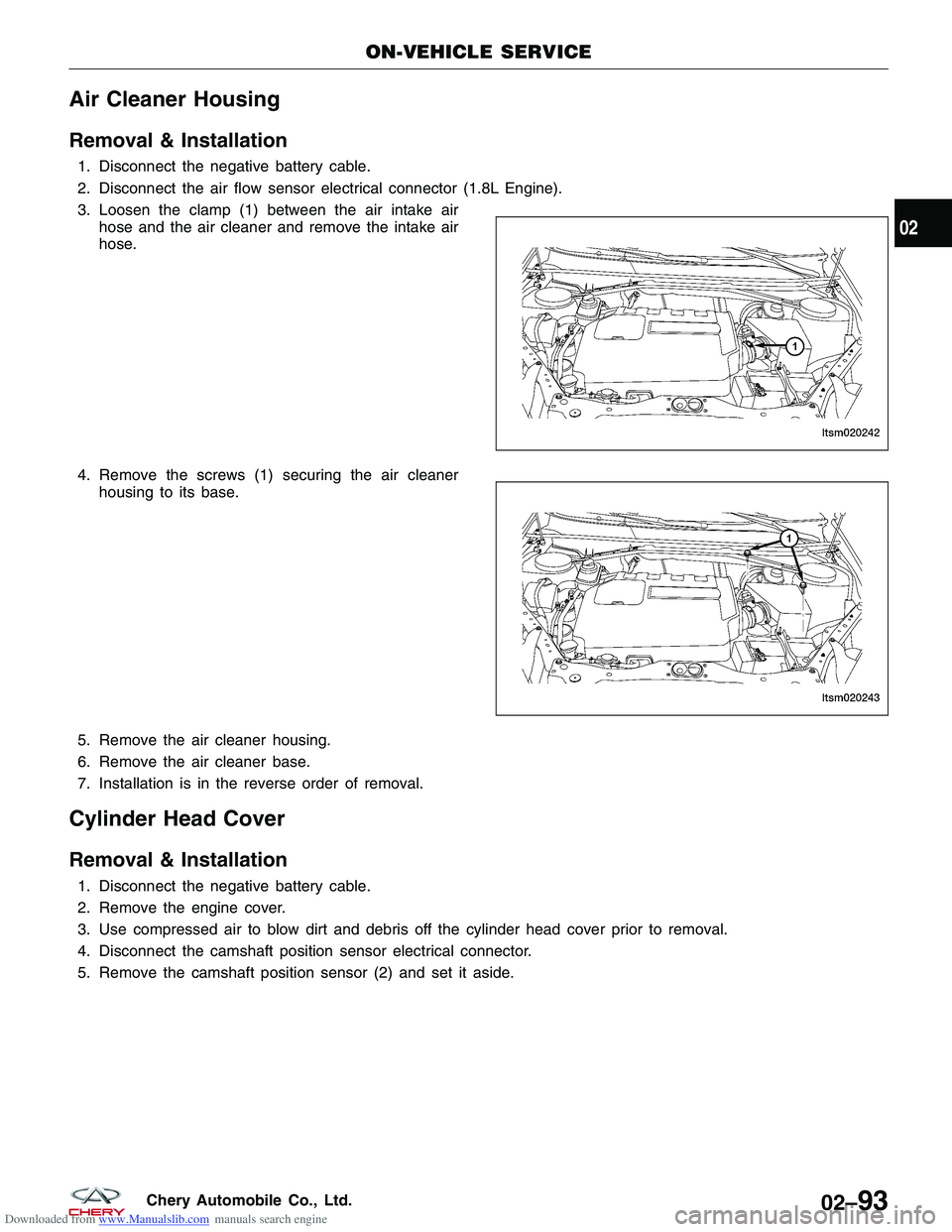

Removal & Installation

1. Disconnect the negative battery cable.

2. Disconnect the air flow sensor electrical connector (1.8L Engine).

3. Loosen the clamp (1) between the air intake airhose and the air cleaner and remove the intake air

hose.

4. Remove the screws (1) securing the air cleaner housing to its base.

5. Remove the air cleaner housing.

6. Remove the air cleaner base.

7. Installation is in the reverse order of removal.

Cylinder Head Cover

Removal & Installation

1. Disconnect the negative battery cable.

2. Remove the engine cover.

3. Use compressed air to blow dirt and debris off the cylinder head cover prior to removal.

4. Disconnect the camshaft position sensor electrical connector.

5. Remove the camshaft position sensor (2) and set it aside.

ON-VEHICLE SERVICE

LTSM020242

LTSM020243

02

02–93Chery Automobile Co., Ltd.

Page 123 of 1903

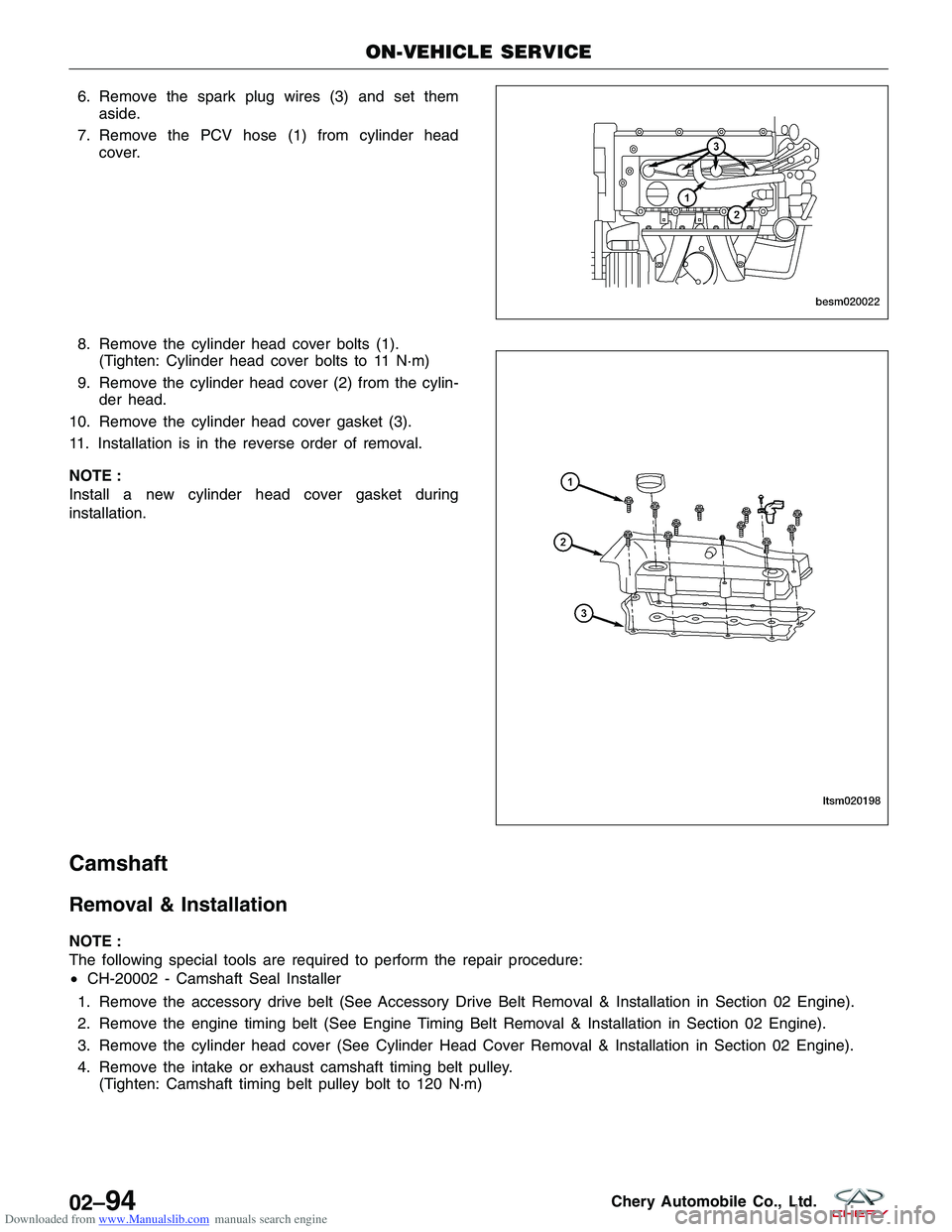

Downloaded from www.Manualslib.com manuals search engine 6. Remove the spark plug wires (3) and set themaside.

7. Remove the PCV hose (1) from cylinder head cover.

8. Remove the cylinder head cover bolts (1). (Tighten: Cylinder head cover bolts to 11 N·m)

9. Remove the cylinder head cover (2) from the cylin- der head.

10. Remove the cylinder head cover gasket (3).

11. Installation is in the reverse order of removal.

NOTE :

Install a new cylinder head cover gasket during

installation.

Camshaft

Removal & Installation

NOTE :

The following special tools are required to perform the repair procedure:

• CH-20002 - Camshaft Seal Installer

1. Remove the accessory drive belt (See Accessory Drive Belt Removal & Installation in Section 02 Engine).

2. Remove the engine timing belt (See Engine Timing Belt Removal & Installation in Section 02 Engine).

3. Remove the cylinder head cover (See Cylinder Head Cover Removal & Installation in Section 02 Engine).

4. Remove the intake or exhaust camshaft timing belt pulley. (Tighten: Camshaft timing belt pulley bolt to 120 N·m)

ON-VEHICLE SERVICE

BESM020022

LTSM020198

02–94Chery Automobile Co., Ltd.

Page 124 of 1903

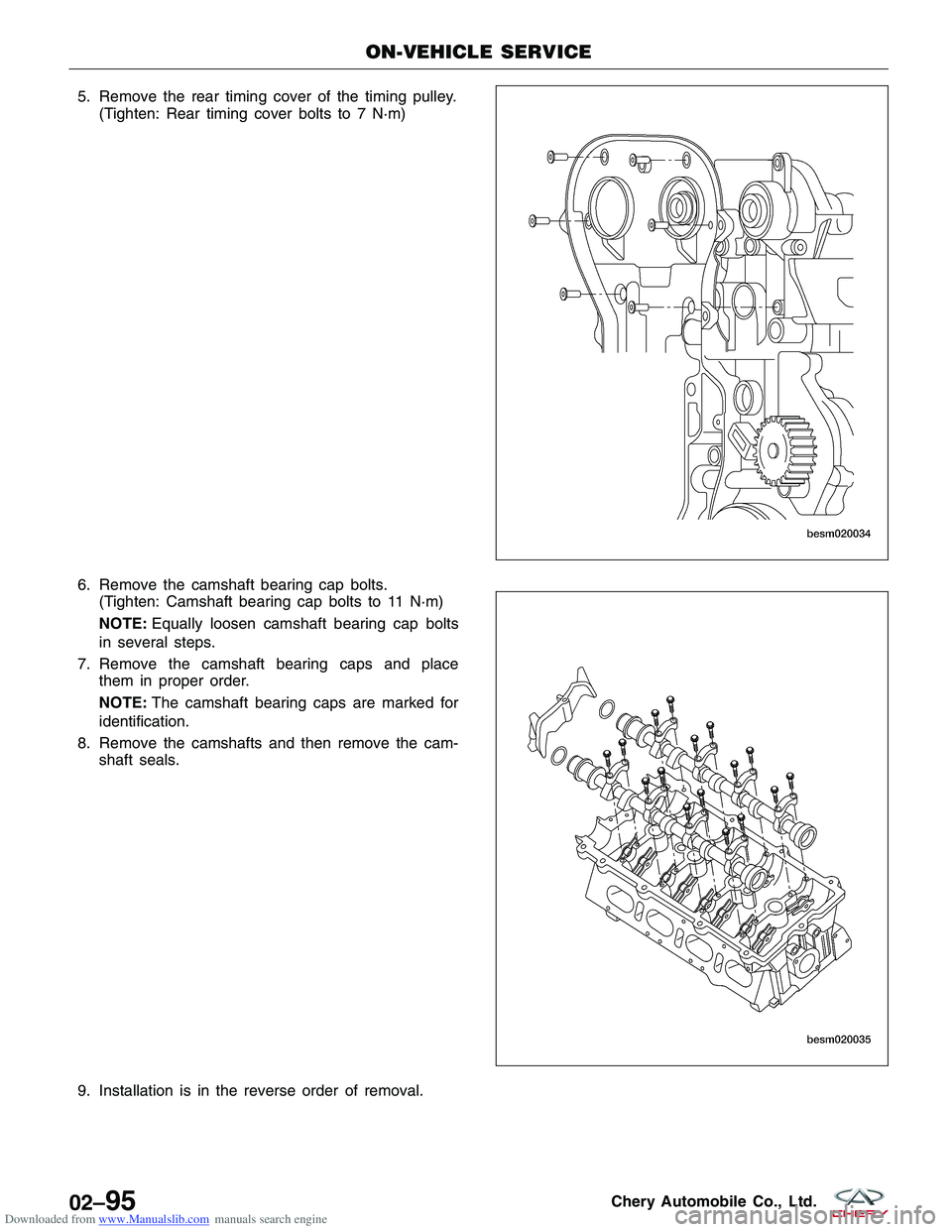

Downloaded from www.Manualslib.com manuals search engine 5. Remove the rear timing cover of the timing pulley.(Tighten: Rear timing cover bolts to 7 N·m)

6. Remove the camshaft bearing cap bolts. (Tighten: Camshaft bearing cap bolts to 11 N·m)

NOTE: Equally loosen camshaft bearing cap bolts

in several steps.

7. Remove the camshaft bearing caps and place them in proper order.

NOTE: The camshaft bearing caps are marked for

identification.

8. Remove the camshafts and then remove the cam- shaft seals.

9. Installation is in the reverse order of removal.

ON-VEHICLE SERVICE

BESM020034

BESM020035

02–95Chery Automobile Co., Ltd.

Page 125 of 1903

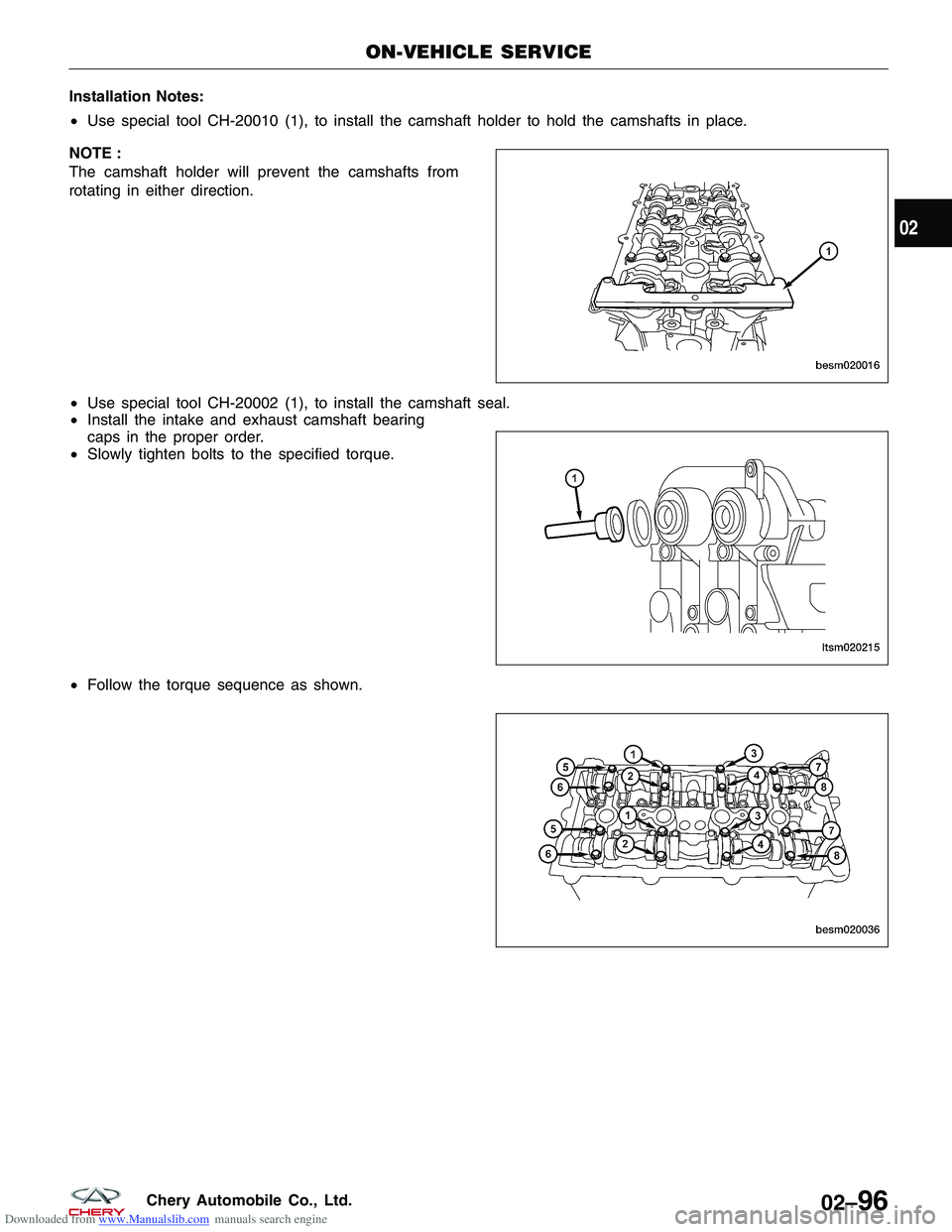

Downloaded from www.Manualslib.com manuals search engine Installation Notes:

•Use special tool CH-20010 (1), to install the camshaft holder to hold the camshafts in place.

NOTE :

The camshaft holder will prevent the camshafts from

rotating in either direction.

• Use special tool CH-20002 (1), to install the camshaft seal.

• Install the intake and exhaust camshaft bearing

caps in the proper order.

• Slowly tighten bolts to the specified torque.

• Follow the torque sequence as shown.

ON-VEHICLE SERVICE

BESM020016

LTSM020215

BESM020036

02

02–96Chery Automobile Co., Ltd.

Page 126 of 1903

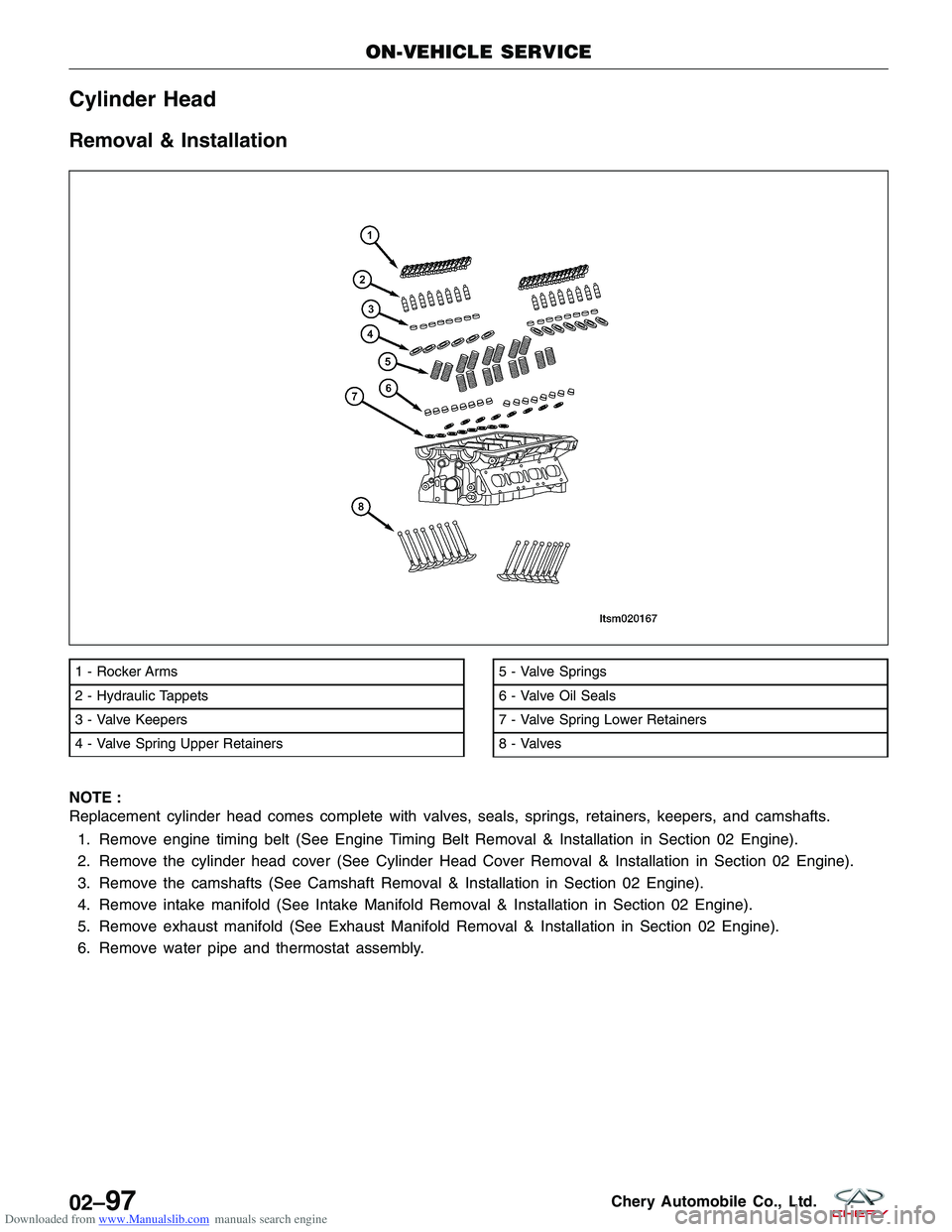

Downloaded from www.Manualslib.com manuals search engine Cylinder Head

Removal & Installation

NOTE :

Replacement cylinder head comes complete with valves, seals, springs, retainers, keepers, and camshafts.1. Remove engine timing belt (See Engine Timing Belt Removal & Installation in Section 02 Engine).

2. Remove the cylinder head cover (See Cylinder Head Cover Removal & Installation in Section 02 Engine).

3. Remove the camshafts (See Camshaft Removal & Installation in Section 02 Engine).

4. Remove intake manifold (See Intake Manifold Removal & Installation in Section 02 Engine).

5. Remove exhaust manifold (See Exhaust Manifold Removal & Installation in Section 02 Engine).

6. Remove water pipe and thermostat assembly.

1 - Rocker Arms

2 - Hydraulic Tappets

3 - Valve Keepers

4 - Valve Spring Upper Retainers5 - Valve Springs

6 - Valve Oil Seals

7 - Valve Spring Lower Retainers

8 - Valves

ON-VEHICLE SERVICE

LTSM020167

02–97Chery Automobile Co., Ltd.

Page 127 of 1903

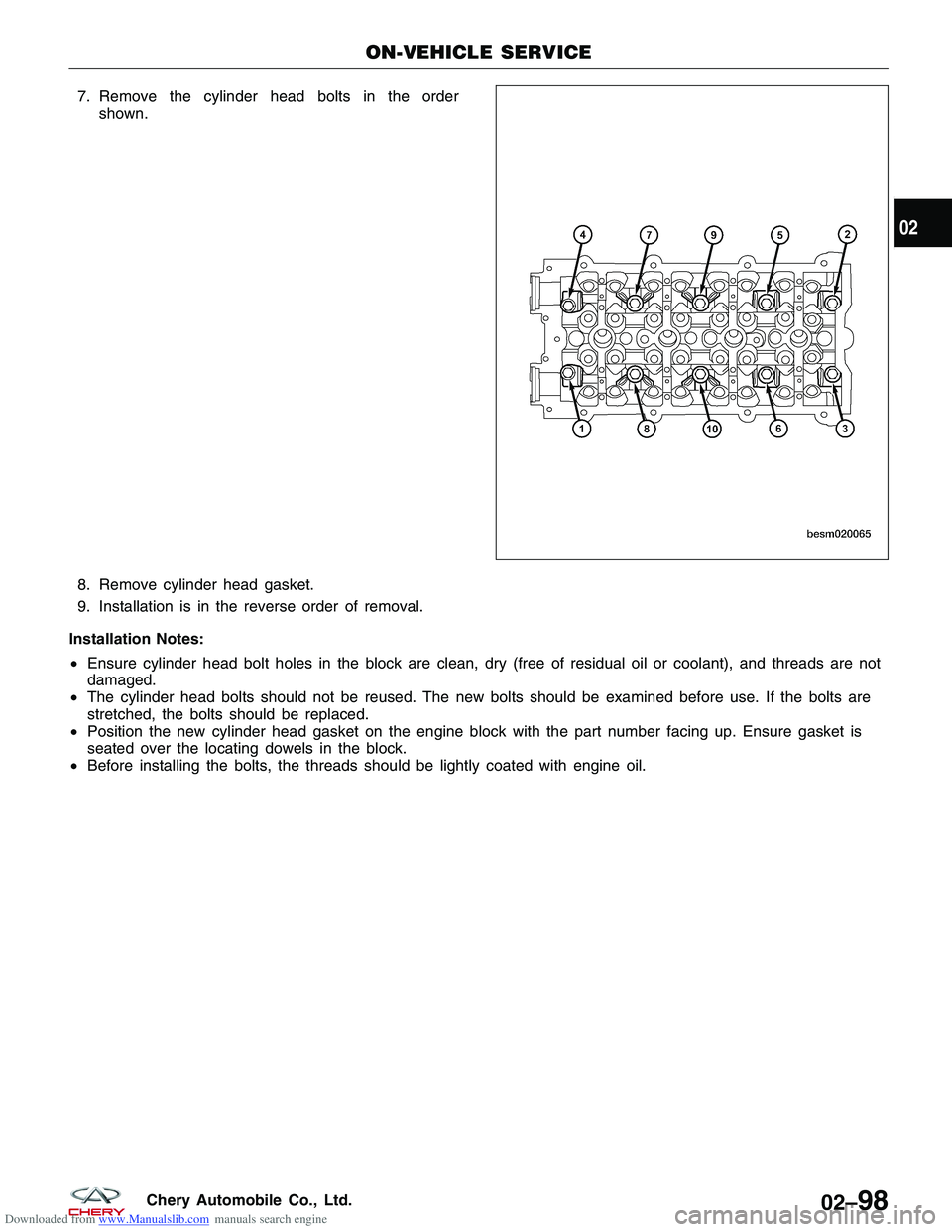

Downloaded from www.Manualslib.com manuals search engine 7. Remove the cylinder head bolts in the ordershown.

8. Remove cylinder head gasket.

9. Installation is in the reverse order of removal.

Installation Notes:

• Ensure cylinder head bolt holes in the block are clean, dry (free of residual oil or coolant), and threads are not

damaged.

• The cylinder head bolts should not be reused. The new bolts should be examined before use. If the bolts are

stretched, the bolts should be replaced.

• Position the new cylinder head gasket on the engine block with the part number facing up. Ensure gasket is

seated over the locating dowels in the block.

• Before installing the bolts, the threads should be lightly coated with engine oil.

ON-VEHICLE SERVICE

BESM020065

02

02–98Chery Automobile Co., Ltd.