lock CHEVROLET ASTRO 1998 2.G Repair Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1998, Model line: ASTRO, Model: CHEVROLET ASTRO 1998 2.GPages: 414, PDF Size: 21.46 MB

Page 302 of 414

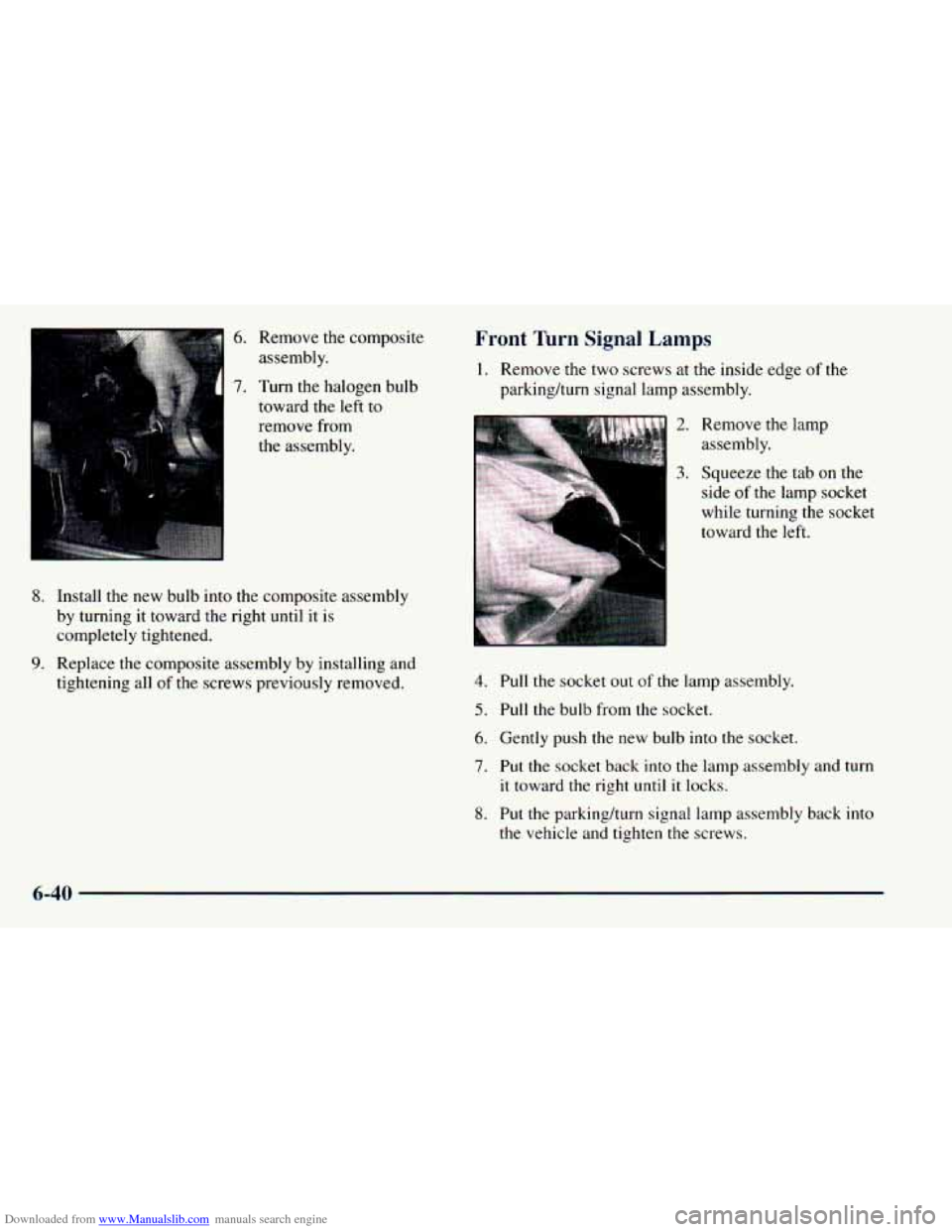

Downloaded from www.Manualslib.com manuals search engine 6. Remove the composite

assembly.

7. Turn the halogen bulb

toward the left

to

remove from

the assembly.

8. Install the new bulb into the composite assembly

by turning it toward the right until it is

completely tightened.

tightening all

of the screws previously removed.

9. Replace the composite assembly by installing and

Front Turn Signal Lamps

1. Remove the two screws at the inside edge of the

parkingkurn signal lamp assembly.

4.

5.

6.

7.

8.

.. .

2.

3.

Remove the lamp

assembly.

Squeeze the tab

on the

side of the lamp socket

while turning the socket

toward

the left.

Pull the socket out

of the lamp assembly.

Pull the bulb from the socket.

Gently push the new bulb into the socket.

Put the socket back into the lamp assembly and turn

it toward the right until it locks.

Put

the parkinghrn signal lamp assembly back into

the vehicle and tighten the screws.

6-40

Page 304 of 414

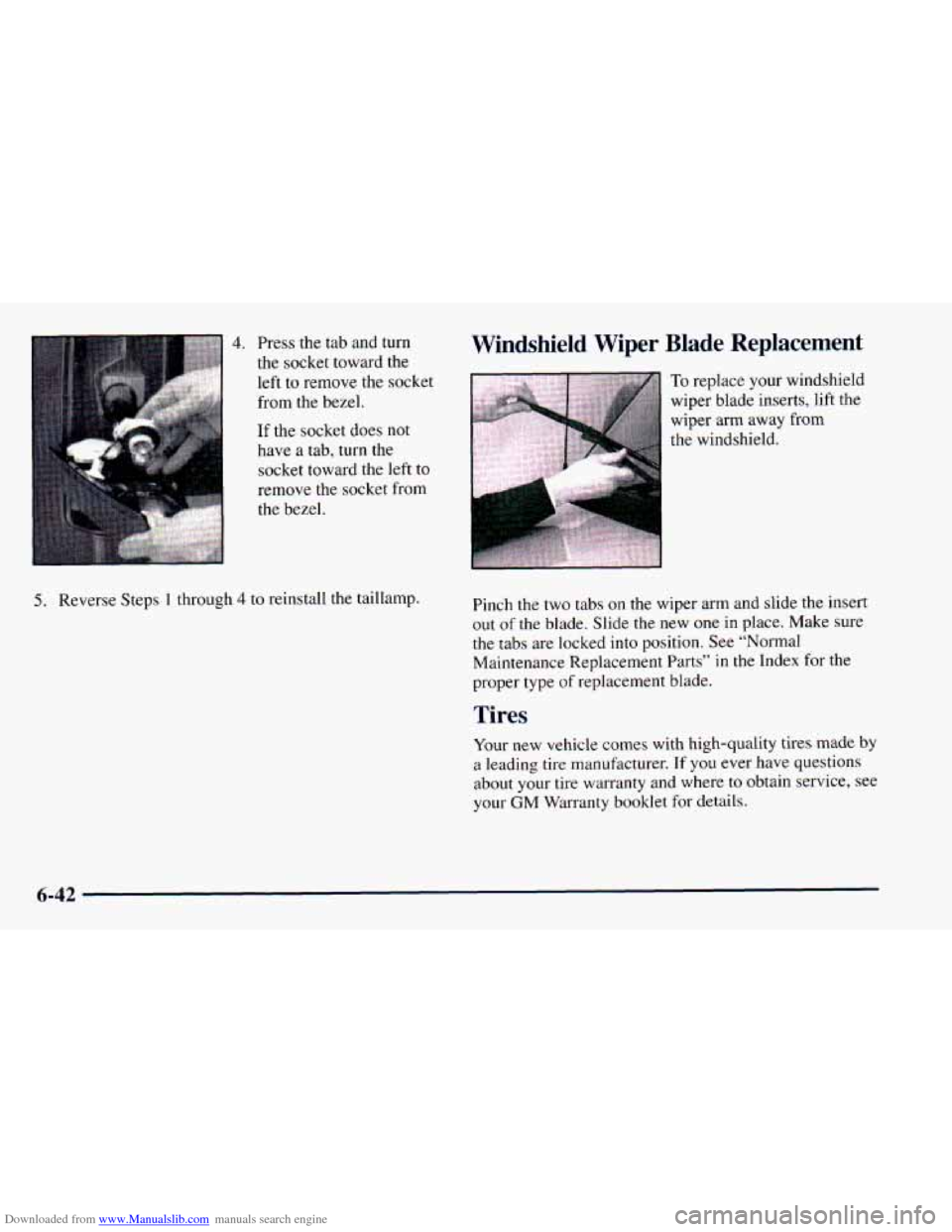

Downloaded from www.Manualslib.com manuals search engine 5. Reverse Steps 1 through 4 to reinstall the taillamp.

Pinch the two tabs on the wiper arm and slide the insert

out

of the blade, Slide the new one in place. Make sure

the tabs are locked into position. See “Normal

Maintenance Replacement Parts”

in the Index for the

proper type

of replacement blade.

Tires

Your new vehicle comes with high-quality tires made by

a leading tire manufacturer. If you ever have questions

about your tire warranty and where

to obtain service, see

your

GM Warranty booklet for details.

6-42

Page 323 of 414

Downloaded from www.Manualslib.com manuals search engine 11

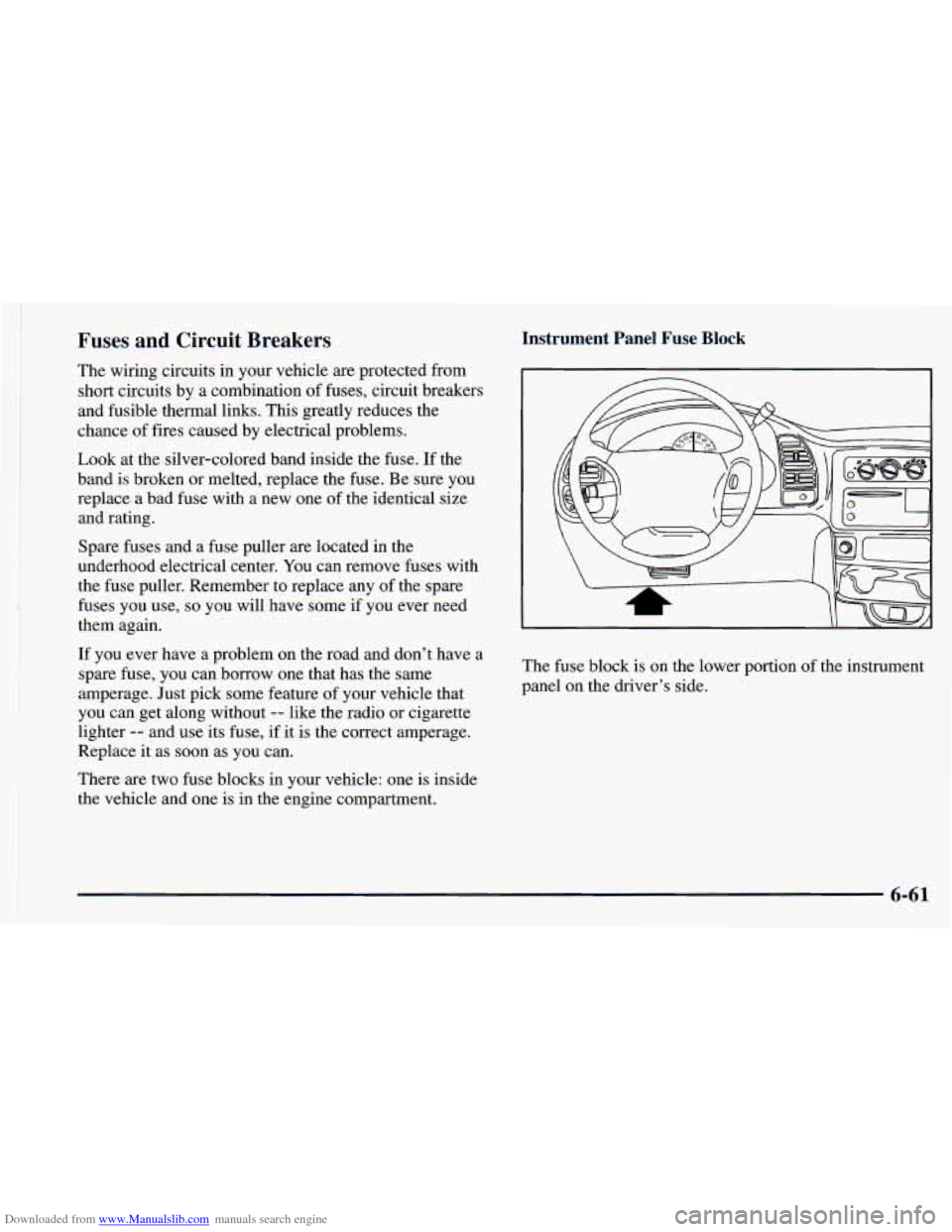

Fuses and Circuit Breakers

The wiring circuits in your vehicle are protected from

short circuits by a combination of fuses, circuit breakers

and fusible thermal links. This greatly reduces the

chance of fires caused by electrical problems.

Look at the silver-colored band inside the fuse. If the

band is broken or melted, replace the fuse. Be sure you

replace a bad fuse with a new one of the identical size

and rating.

Spare fuses and a fuse puller are located in the

underhood electrical center.

You can remove fuses with

the fuse puller. Remember to replace any of the spare

fuses you use,

so you will have some if you ever need

them again.

If you ever have a problem on the road and don’t have a

spare fuse, you can borrow one that has the same

amperage. Just pick some feature of your vehicle that

you can get along without

-- like the radio or cigarette

lighter

-- and use its fuse, if it is the correct amperage.

Replace

it as soon as you can.

There are two fuse blocks in your vehicle: one is inside

the vehicle and one is in the engine compartment.

Instrument Panel Fuse Block

The fuse block is on the lower portion of the instrument

panel on the driver’s side.

6-61

Page 325 of 414

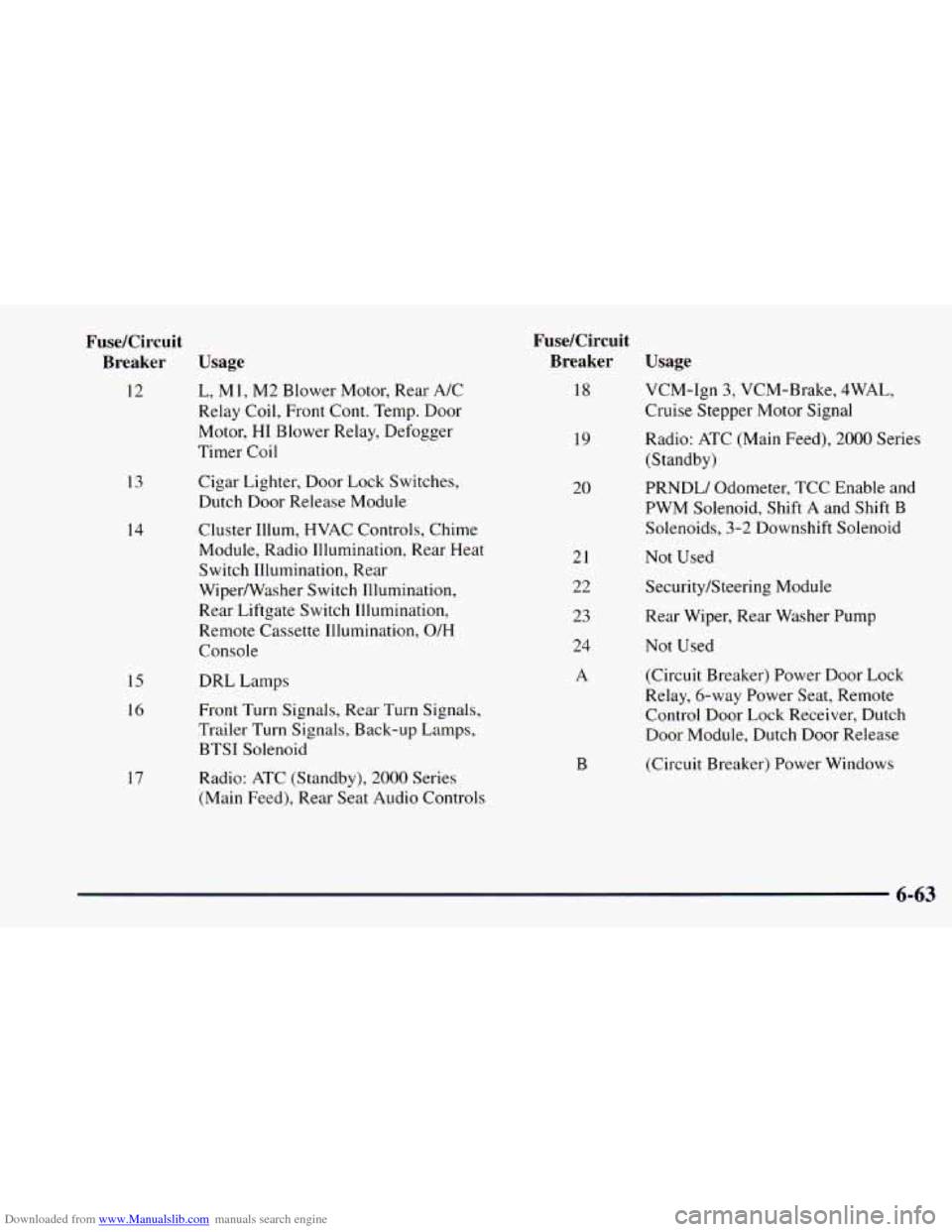

Downloaded from www.Manualslib.com manuals search engine FuseKircuit Breaker Usage

12

13

14

15

16

17

L, M 1, M2 Blower Motor, Rear A/C

Relay Coil, Front Cont. Temp. Door

Motor,

HI Blower Relay, Defogger

Timer Coil

Cigar Lighter, Door Lock Switches,

Dutch Door Release Module

Cluster Illum, HVAC Controls, Chime

Module, Radio Illumination, Rear Heat

Switch Illumination, Rear

Wiper/Washer Switch Illumination,

Rear Liftgate Switch Illumination,

Remote Cassette Illumination, O/H

Console

DRL Lamps

Front Turn Signals, Rear Turn Signals,

Trailer Turn Signals, Back-up Lamps,

BTSI Solenoid

Radio: ATC (Standby), 2000 Series

(Main Feed), Rear Seat Audio Controls 19

20

FuseKircuit

Breaker Usage

18 VCM-Ign 3, VCM-Brake, LCWAL,

Cruise Stepper Motor Signal

Radio: ATC (Main Feed),

2000 Series

(Standby)

PRNDL/ Odometer, TCC Enable and

PWM Solenoid, Shift A and Shift B

Solenoids, 3-2 Downshift Solenoid

21

22

23

24

A

B Not Used

Security/Steering Module

Rear Wiper, Rear Washer Pump

Not Used (Circuit Breaker) Power Door

Lock

Relay, 6-way Power Seat, Remote

Control Door Lock Receiver, Dutch

Door Module, Dutch Door Release

(Circuit Breaker) Power Windows

6-63

Page 326 of 414

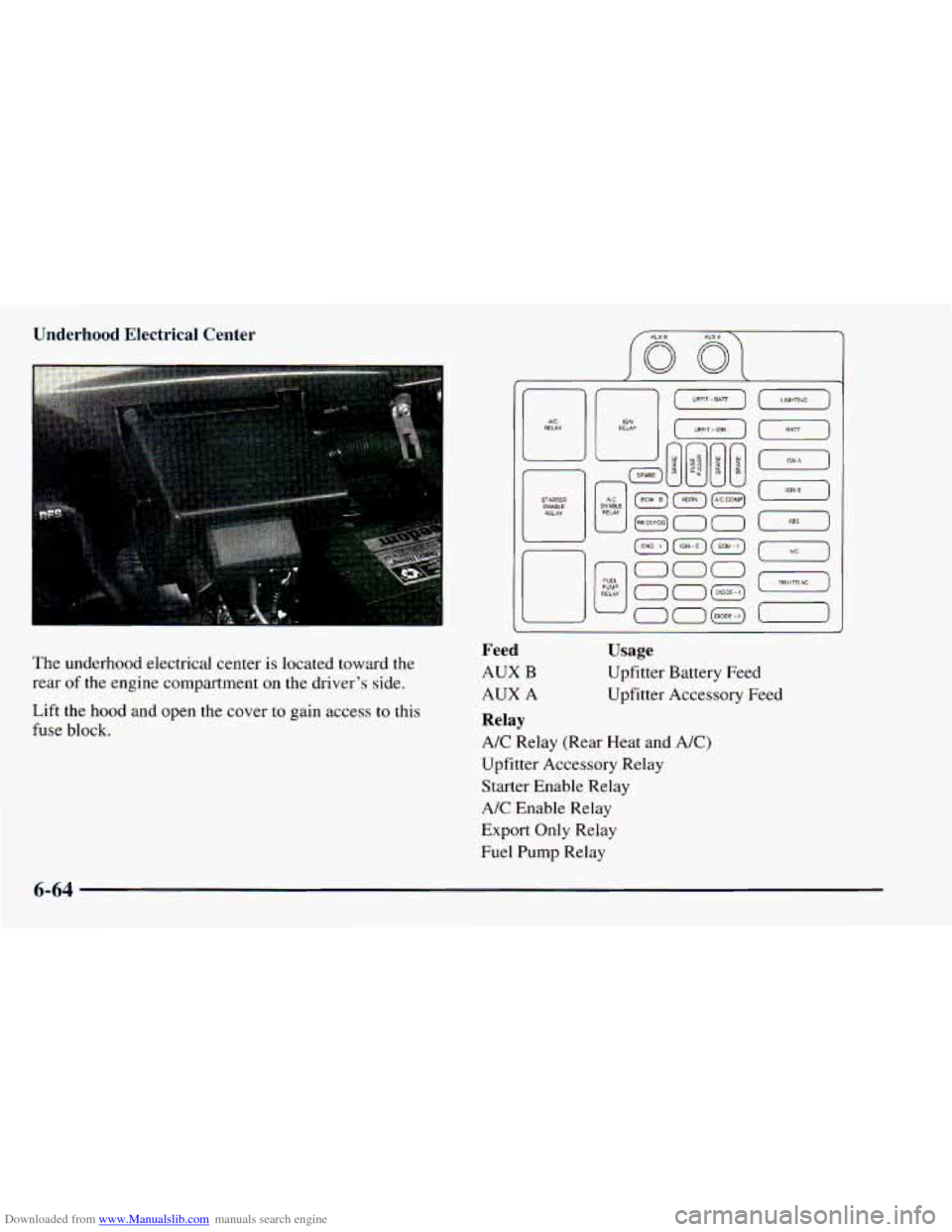

Downloaded from www.Manualslib.com manuals search engine Underhood Electrical Center

c

SThRTER ENABLE ENABLE =CLAY

(,,,) (-) (COLI-

I

I

[ LIGHTING 1

(7)

(T)

(-)

(-)

The underhood electrical center is located toward the

rear

of the engine compartment on the driver’s side.

Lift the hood and open

the cover to gain access to this

fuse block.

Feed Usage

AUX B Upfitter Battery Feed

AUX A Upfitter Accessory Feed

Relay

A/C Relay (Rear Heat and A/C)

Upfitter Accessory Relay

Starter Enable Relay

A/C Enable Relay

Export Only Relay

Fuel Pump Relay

6-64

Page 330 of 414

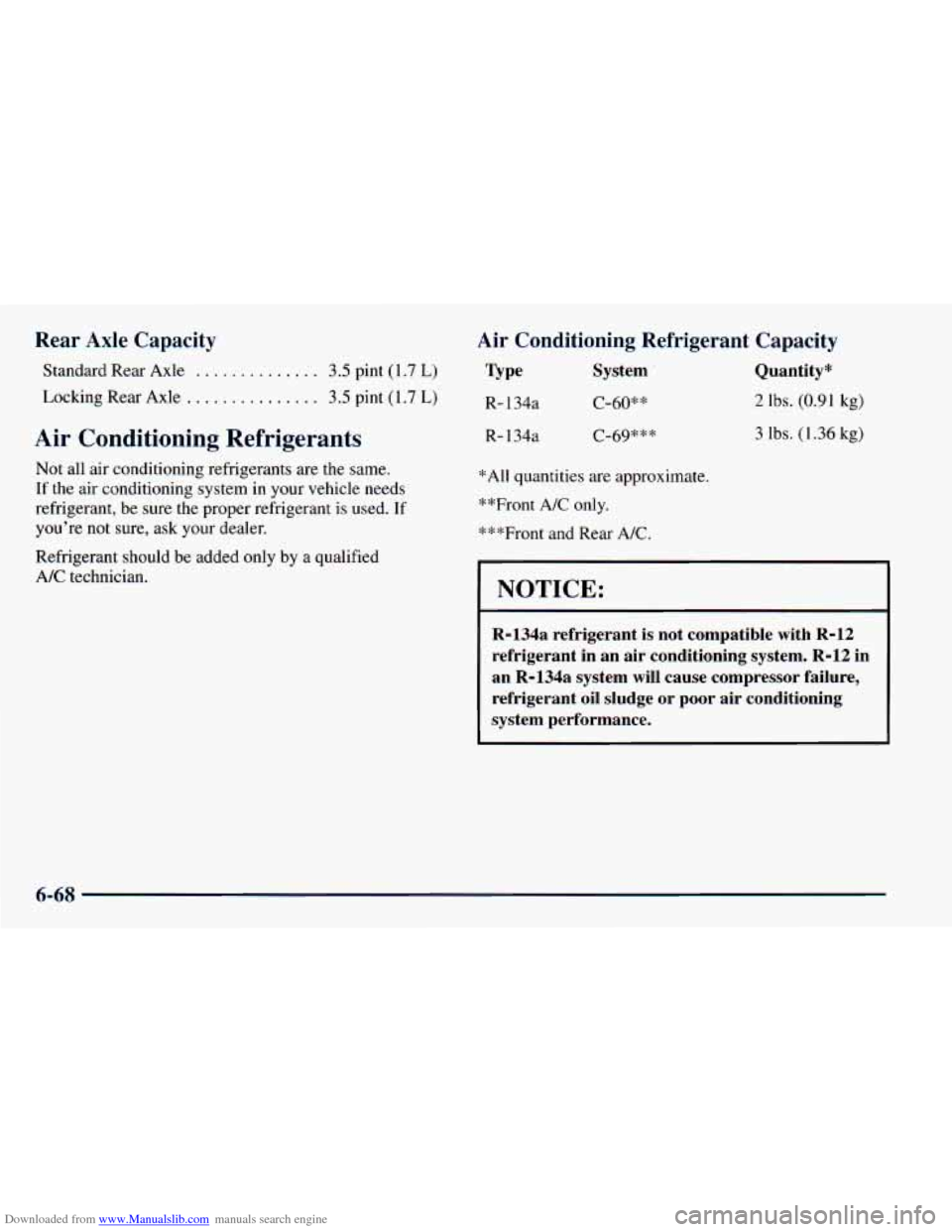

Downloaded from www.Manualslib.com manuals search engine Rear Axle Capacity

Standard Rear Axle . . . . . . . . . . . . . . 3.5 pint (1.7 L)

Locking Rear Axle . . . . . . . . . . . 3.5 pint (1.7 L)

Air Conditioning Refrigerants

Not all air conditioning refrigerants are the same.

If the air conditioning system in your vehicle needs

refrigerant, be sure the proper refrigerant is used. If

you’re not sure, ask your dealer.

Refrigerant should be added only by a qualified

NC technician.

Air Conditioning Refrigerant Capacity

mPe

R- 134a

R- 134a

System

C-60**

C-69***

*All quantities are approximate.

**Front

A/C only.

***Front and Rear A/C.

Quantity*

2 lbs. (0.91 kg)

3 lbs,

(1.36 kg)

NOTICE:

R-134a refrigerant is not compatible with R-12

refrigerant in an air conditioning system. R-12 in

an R-134a system

will cause compressor failure,

refrigerant oil sludge

or poor air conditioning

system performance.

6-68

Page 342 of 414

Downloaded from www.Manualslib.com manuals search engine Short TripKity Maintenance Schedule

The services shown in this schedule up to 100,000 miles

(166 000 km) should be performed after 100,000 miles

(166 000 km) at the same intervals. The services shown

at 150,000 miles

(240 000 km) should be performed at

the same interval after 150,000 miles (240 000 km).

See “Owner Checks and Services’’ and “Periodic

Maintenance Inspections” following.

Footnotes

The U.S. Envlronmental Protection Agency or the

California Air Resources Board has determined that the

failure to perform this maintenance item will

not nullify

the emission warranty or limit recall liability prior to the

completion

of the vehicle’s useful life. We, however,

urge that all recommended maintenance services be

performed at the indicated intervals and the maintenance

be recorded.

# Lubricate the front suspension, ball joints and kingpin

bushings, steering linkage and transfer case shift linkage,

parking brake cable guides, and brake pedal springs.

+ A good time to check your brakes is during tire

rotation. See “Brake System Inspection” under “Periodic

Maintenance Inspections” in Part

C of this schedule.

** Drive axle service (see “Recommended Fluids and

Lubricants”

in the Index for proper lubricant to use):

0

0

0

Locking Differential -- Drain fluid and refill at first

engine oil change. At subsequent oil changes, check

fluid level and add fluid as needed. If driving

in

dusty areas or towing a trailer, drain fluid and refill

every 15,000 miles

(25 000 km).

Standard Differential

-- Check fluid level and add

fluid as needed at every oil change. If driving in

dusty areas or towing a trailer, drain fluid and refill

every 15,000 miles

(25 000 km).

More frequent lubrication may be required for

heavy-duty use.

7-8

Page 363 of 414

Downloaded from www.Manualslib.com manuals search engine Long TripMighway Maintenance Schedule

The services shown in this schedule up to 100,000 miles

(166 000 km) should be performed after 100,000 miles

(166 000 km) at the same intervals. The services shown

at

150,000 miles (240 000 km) should be performed at

the same interval after

150,000 miles (240 000 km).

See “Owner Checks and Services” and “Periodic

Maintenance Inspections” following.

Footnotes

The U.S. Environmental Protection Agency or the

California Air Resources Board has determined that the

failure to perform this maintenance item will

not nullify

the emission warranty or limit recall liability prior to the

completion

of the vehicle’s useful life. We, however,

urge that all recommended maintenance services be

performed at

the indicated intervals and the maintenance

be recorded.

## Lubricate the front suspension, ball joints and

kingpin bushings, steering linkage and transfer case

shift linkage, parking brake cable guides, and brake

pedal springs.

+ A good time to check your brakes is during tire

rotation. See “Brake System Inspection” under “Periodic

Maintenance Inspections”

in Part C of this schedule.

#’* Drive axle service (see “Recommended Fluids and

Lubricants”

in the Index for proper lubricant to use):

0 Locking Differential -- Drain fluid and refill at first

engine

oil change. At subsequent oil changes, check

fluid

level and add fluid as needed.

fluid as needed at every engine oil change.

0 Standard Differential -- Check fluid level and add

7-29

Page 376 of 414

Downloaded from www.Manualslib.com manuals search engine At Least Twice a Year Automatic lkansmission Check

Restraint System Check

Make sure the safety belt reminder light and all your

belts, buckles, latch plates, retractors and anchorages are

working properly. If your vehicle has a built-in child

restraint, also periodically make sure the harness straps,

latch plates, buckle, clip, retractors and anchorages are

working properly. Look for any other loose or damaged

safety belt and built-in child restraint system parts. If

you see anything that might keep a safety belt or built-in

child restraint system from doing its

job, have it

repaired. Have any torn or frayed safety belts or harness

straps replaced.

Also look for

any opened or broken air bag coverings,

and have them repaired or replaced. (The air bag system

does

not need regular maintenance.)

Wiper Blade Check

Inspect wiper blades for wear or cracking. Replace blade

inserts that appear worn or damaged or that streak or

miss areas

of the windshield. Also see “Wiper Blades,

Cleaning” in the Index. Check the transmission fluid

level; add if needed.

See

“Automatic Transmission’’ in the Index. A fluid loss

may indicate a problem. Check the system and repair

if needed.

At Least Once a Year

Key Lock Cylinders Service

Lubricate the key lock cylinders with the lubricant

specified in Part

D.

Body Lubrication Service

Lubricate all body door hinges, the body hood, fuel

door and rear compartment hinges, latches and locks

including interior glove box and console doors, and any

moving seat hardware. Lubricate the hood safety lever

pivot and prop rod pivot. Part

D tells you what to use.

More frequent lubrication may be required when

exposed to a corrosive environment.

7-42

Page 377 of 414

Downloaded from www.Manualslib.com manuals search engine Starter Switch Check

I A CAUTION: I

When you are doing this check, the vehicle could

move suddenly.

If it does, you or others could be

injured. Follow the steps below.

1. Before you start, be sure you have enough room

around the vehicle.

2. Firmly apply both the parking brake (see “Parking

Brake” in the Index if necessary) and the

regular brake.

NOTE: Do not use the accelerator pedal, and be

ready to turn off the engine immediately

if it starts.

3. Try to start the engine in each gear. The starter

should work only

in PARK (P) or NEUTRAL (N).

If the starter works in any other position, your

vehicle needs service.

Brake-Transmission Shift Interlock (BTSI) Check

A CAUTION:

When you are doing this check, the vehicle could

move suddenly.

If it does, you or others could be

injured. Follow the steps below.

1. Before you start, be sure you have enough

room around the vehicle. It should be parked

on a level surface.

2.

3.

Firmly apply the parking brake (see “Parking Brake”

in the Index if necessary).

NOTE: Be ready to apply the regular brake

immediately if the vehicle begins to move.

With the engine

off, turn the key to the RUN position,

but don’t start

the engine. Without applying the regular

brake,

try to move the shift lever out of PARK (P) with

normal effort. If the shift lever moves out of

PARK (P), your vehicle’s

BTSI needs service.

7-43