maintenance CHEVROLET CAMARO 1967 1.G Chassis User Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1967, Model line: CAMARO, Model: CHEVROLET CAMARO 1967 1.GPages: 659, PDF Size: 114.24 MB

Page 217 of 659

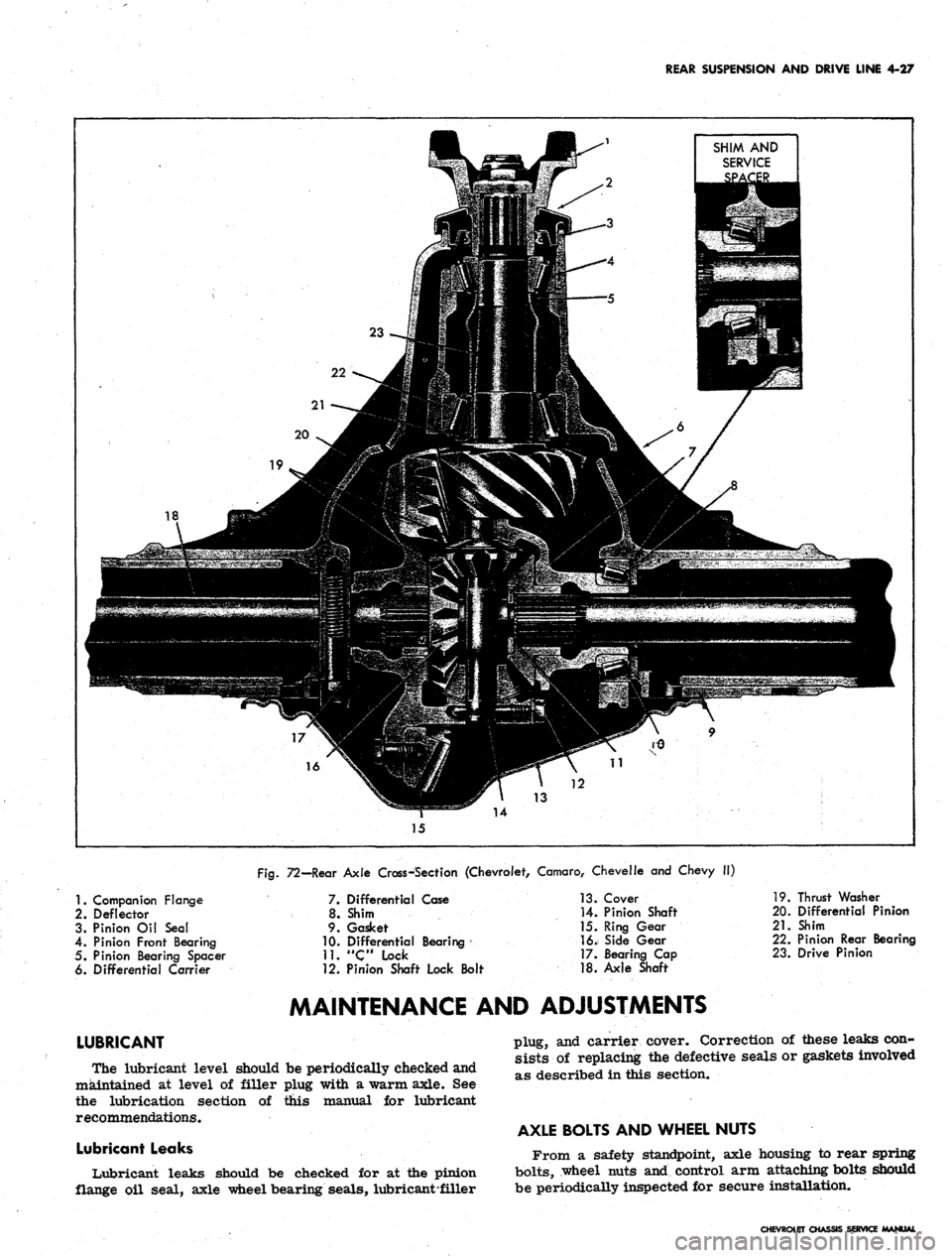

REAR SUSPENSION AND DRIVE LINE 4-27

SHIM AND

SERVICE

12

14

Fig.

72—Rear Axle Cross-Section (Chevrolet, Camaro, Chevelle and Chevy II)

1.

Companion Flange

2.

Deflector

3. Pinion Oil Seal

4.

Pinion Front Bearing

5. Pinion Bearing Spacer

6. Differential Carrier

LUBRICANT

7. Differential Case

8. Shim

9. Gasket

10.

Differential Bearing

11.

"Clock

12. Pinion Shaft Lock Bolt

13.

Cover

14.

Pinion Shaft

15.

Ring Gear

16.

Side Gear

17.

Bearing Cap

18.

Axle Shaft

19.

Thrust Washer

20.

Differential Pinion

21.

Shim

22.

Pinion Rear Bearing

23.

Drive Pinion

MAINTENANCE AND ADJUSTMENTS

The lubricant level should be periodically checked and

maintained at level of filler plug with a warm axle. See

the lubrication section of this manual for lubricant

recommendations.

Lubricant Leaks

Lubricant leaks should be checked for at the pinion

flange oil seal, axle wheel bearing seals, lubricant-filler

plug, and carrier cover. Correction of these leaks con-

sists of replacing the defective seals or gaskets involved

as described in this section.

AXLE BOLTS AND WHEEL NUTS

From a safety standpoint, axle housing to rear spring

bolts,

wheel nuts and control arm attaching bolts should

be periodically inspected for secure installation.

CHEVROLET CHASSIS SERVICE MANUAL

Page 227 of 659

REAR SUSPENSION AND DRIVE LINE 4-37

9. Connect spring end link bolts as outlined under

Spring--Installation, in this section.

10.

Remove filler plug, located on right side of cover,

and fill -with hypoid lubricant to level of filler hole.

11.

Lower vehicle and road test for leaks, noise and

general performance.

POSITRACTION DIFFERENTIAL UNIT

The optionally available Positraction differential unit

is installed in the conventional carrier to replace the

standard differential unit.

Service procedures for the Positraction equipped axle

are the same as on a conventional axle except for the.

operations listed below.

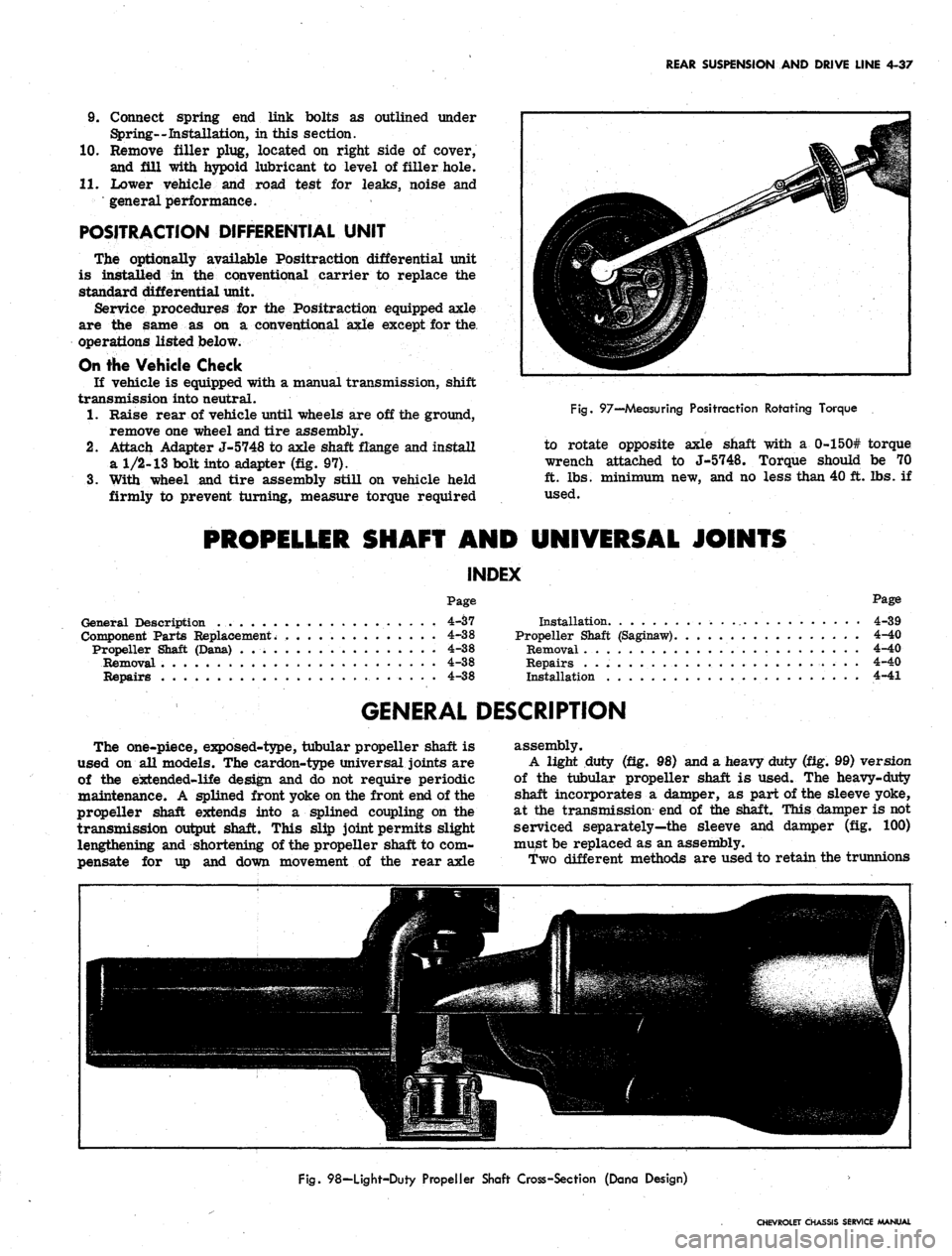

On the Vehicle Check

If vehicle is equipped with a manual transmission, shift

transmission into neutral.

1.

Raise rear of vehicle until wheels are off the ground,

remove one wheel and tire assembly.

2.

Attach Adapter J-5748 to axle shaft flange and install

a

1/2-13

bolt into adapter (fig. 97).

3.

With wheel and tire assembly still on vehicle held

firmly to prevent turning, measure torque required

Fig.

97—Measuring Positraction Rotating Torque

to rotate opposite axle shaft with a 0-150# torque

wrench attached to J-5748. Torque should be 70

ft.

lbs. minimum new, and no less than 40 ft. lbs. if

used.

PROPELLER SHAFT AND UNIVERSAL JOINTS

INDEX

Page

Page

General Description 4-37

Component Parts Replacement. 4-38

Propeller Shaft (Dana) 4-38

Removal 4-38

Repairs 4-38

Installation 4-39

Propeller Shaft (Saginaw) 4-40

Removal 4-40

Repairs 4-40

Installation 4-41

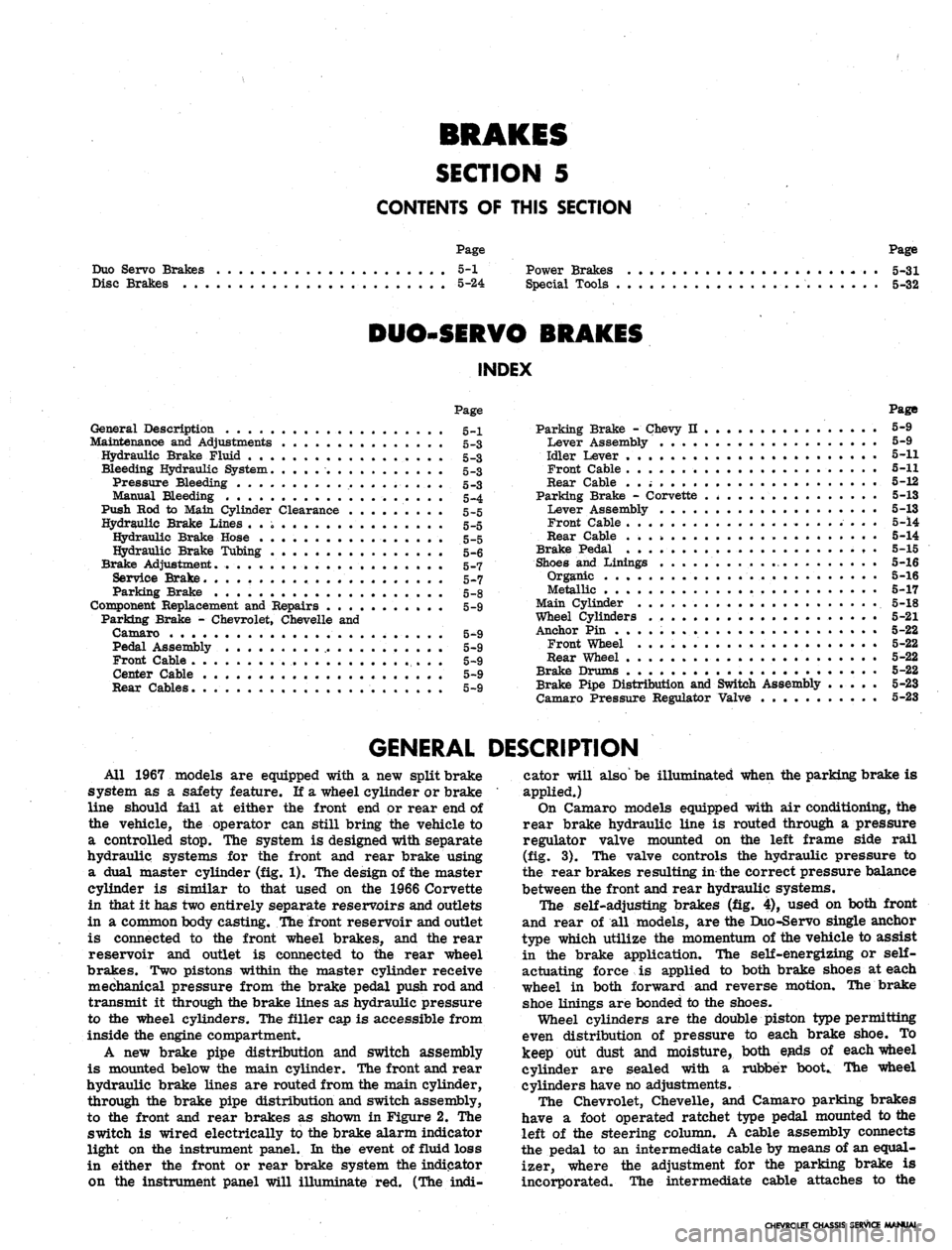

GENERAL DESCRIPTION

The one-piece, exposed-type, tubular propeller shaft is

used on all models. The cardon-type universal joints are

of the extended-life design and do not require periodic

maintenance. A splined front yoke on the front end of the

propeller shaft extends into a splined coupling on the

transmission output shaft. This slip joint permits slight

lengthening and shortening of the propeller shaft to com-

pensate for up and down movement of the rear axle

assembly.

A light duty (fig. 98) and a heavy duty (fig. 99) version

of the tubular propeller shaft is used. The heavy-duty

shaft incorporates a damper, as part of the sleeve yoke,

at the transmission end of the shaft. This damper is not

serviced separately—the sleeve and damper (fig. 100)

must be replaced as an assembly.

Two different methods are used to retain the trunnions

Fig.

98—Light-Duty Propeller Shaft Cross-Section (Dana Design)

CHEVROLET CHASSIS SERVICE MANUAL

Page 234 of 659

BRAKES

SECTION 5

CONTENTS OF THIS SECTION

Duo Servo Brakes

Disc Brakes

Page

5-1 Power Brakes

5-24 Special Tools

Page

5-31

5-32

DUO-SERVO BRAKES

INDEX

Page

General Description 5-1

Maintenance and Adjustments 5-3

Hydraulic Brake Fluid .. . 5-3

Bleeding Hydraulic System 5-3

Pressure Bleeding 5-3

Manual Bleeding 5_4

Push Rod to Main Cylinder Clearance 5-5

Hydraulic Brake Lines 5-5

Hydraulic Brake Hose 5-5

Hydraulic Brake Tubing 5-6

Brake Adjustment. .................... 5-7

Service Brake 5-7

Parking Brake 5-8

Component Replacement and Repairs 5-9

Parking Brake - Chevrolet, Chevelle and

Camaro 5^9

Pedal Assembly 5-9

Front Cable ,. . . 5-9

Center Cable 5-9

Rear Cables. . 5-9

Parking Brake - Chevy n 5-9

Lever Assembly 5-9

Idler Lever 5-11

Front Cable 5-11

Rear Cable . . ; 5-12

Parking Brake - Corvette 5-13

Lever Assembly . . . . 5-13

Front Cable 5-14

Rear Cable . . 5-14

Brake Pedal 5-15

Shoes and Linings 5-16

Organic 5-16

Metallic 5-17

Main Cylinder 5-18

Wheel Cylinders 5-21

Anchor Pin 5-22

Front Wheel 5-22

Rear Wheel 5-22

Brake Drums • 5-22

Brake Pipe Distribution and Switch Assembly . . . . . 5-23

Camaro Pressure Regulator Valve 5-23

GENERAL DESCRIPTION

All 1967 models are equipped with a new split brake

system as a safety feature. If a wheel cylinder or brake

line should fail at either the front end or rear end of

the vehicle, the operator can still bring the vehicle to

a controlled stop. The system is designed with separate

hydraulic systems for the front and rear brake using

a dual master cylinder (fig. 1). The design of the master

cylinder is similar to that used on the 1966 Corvette

in that it has two entirely separate reservoirs and outlets

in a common body casting. The front reservoir and outlet

is connected to the front wheel brakes, and the rear

reservoir and outlet is connected to the rear wheel

brakes. Two pistons within the master cylinder receive

mechanical pressure from the brake pedal push rod and

transmit it through the brake lines as hydraulic pressure

to the wheel cylinders. The filler cap is accessible from

inside the engine compartment.

A new brake pipe distribution and switch assembly

is mounted below the main cylinder. The front and rear

hydraulic brake lines are routed from the main cylinder,

through the brake pipe distribution and switch assembly,

to the front and rear brakes as shown in Figure 2. The

switch is wired electrically to the brake alarm indicator

light on the instrument panel. In the event of fluid loss

in either the front or rear brake system the indicator

on the instrument panel will illuminate red. (The indi-

cator will also' be illuminated when the parking brake is

applied.)

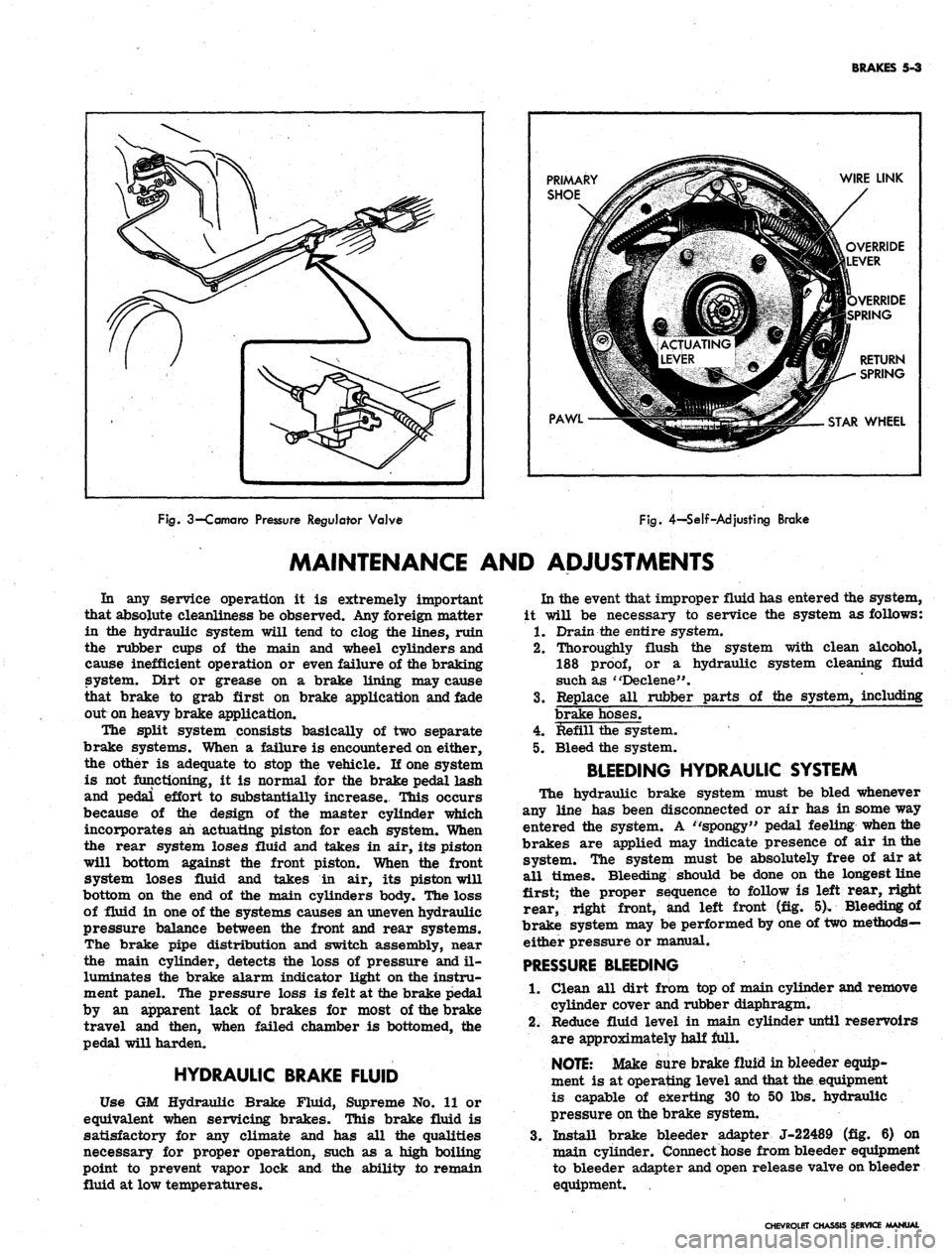

On Camaro models equipped with air conditioning, the

rear brake hydraulic line is routed through a pressure

regulator valve mounted on the left frame side rail

(fig. 3). The valve controls the hydraulic pressure to

the rear brakes resulting in the correct pressure balance

between the front and rear hydraulic systems.

The self-adjusting brakes (fig. 4), used on both front

and rear of all models, are the Duo-Servo single anchor

type which utilize the momentum of the vehicle to assist

in the brake application. The self-energizing or

self-

actuating force is applied to both brake shoes at each

wheel in both forward and reverse motion. The brake

shoe linings are bonded to the shoes.

Wheel cylinders are the double piston type permitting

even distribution of pressure to each brake shoe. To

keep out dust and moisture, both ejads of each wheel

cylinder are sealed with a rubber booC The wheel

cylinders have no adjustments.

The Chevrolet, Chevelle, and Camaro parking brakes

have a foot operated ratchet type pedal mounted to the

left of the steering column. A cable assembly connects

the pedal to an intermediate cable by means of an equal-

izer, where the adjustment for the parking brake is

incorporated. The intermediate cable attaches to the

CHEVROLET CHASSIS SERVICE MANUAL

Page 236 of 659

BRAKES

5-3

PRIMARY

SHOE

PAWL

WIRE LINK

OVERRIDE

LEVER

VERRIDE

SPRING

RETURN

SPRING

STAR

WHEEL

Fig.

3—Camaro

Pressure

Regulator

Valve

Fig.

4-Self-Adjusting

Brake

MAINTENANCE AND ADJUSTMENTS

In any service operation it is extremely important

that absolute cleanliness be observed. Any foreign matter

in the hydraulic system will tend to clog the lines, ruin

the rubber cups of the main and wheel cylinders and

cause inefficient operation or even failure of the braking

system. Dirt or grease on a brake lining may cause

that brake to grab first on brake application and fade

out on heavy brake application.

The split system consists basically of two separate

brake systems. When a failure is encountered on either,

the other is adequate to stop the vehicle. If one system

is not functioning, it is normal for the brake pedal lash

and pedal effort to substantially increase. This occurs

because of the design of the master cylinder which

incorporates ah actuating piston for each system. When

the rear system loses fluid and takes in air, its piston

will bottom against the front piston. When the front

system loses fluid and takes in air, its piston will

bottom on the end of the main cylinders body. The loss

of fluid in one of the systems causes an uneven hydraulic

pressure balance between the front and rear systems.

The brake pipe distribution and switch assembly, near

the main cylinder, detects the loss of pressure and il-

luminates the brake alarm indicator light on the instru-

ment panel. The pressure loss is felt at the brake pedal

by an apparent lack of brakes for most of the brake

travel and then, when failed chamber is bottomed, the

pedal will harden.

HYDRAULIC BRAKE FLUID

Use GM Hydraulic Brake Fluid, Supreme No. 11 or

equivalent when servicing brakes. This brake fluid is

satisfactory for any climate and has all the qualities

necessary for proper operation, such as a high boiling

point to prevent vapor lock and the ability to remain

fluid at low temperatures.

In the event that improper fluid has entered the system,

it will be necessary to service the system as follows:

1.

Drain the entire system.

2.

Thoroughly flush the system with clean alcohol,

188

proof,

or a hydraulic system cleaning fluid

such as "Declene".

3.

Replace all rubber parts of the system, including

brake hoses.

4.

Refill the system.

5. Bleed the system.

BLEEDING HYDRAULIC SYSTEM

The hydraulic brake system must be bled whenever

any line has been disconnected or air has in some way

entered the system. A ''spongy" pedal feeling when the

brakes are applied may indicate presence of air in the

system. The system must be absolutely free of air at

all times. Bleeding should be done on the longest line

first; the proper sequence to follow is left rear, right

rear, right front, and left front (fig. 5). Bleeding of

brake system may be performed by one of two methods—

either pressure or manual.

PRESSURE

BLEEDING

1.

Clean all dirt from top of main cylinder and remove

cylinder cover and rubber diaphragm.

2.

Reduce fluid level in main cylinder until reservoirs

are approximately half full.

NOTE:

Make sure brake fluid in bleeder equip-

ment is at operating level and that the. equipment

is capable of exerting 30 to 50 lbs. hydraulic

pressure on the brake system.

3.

Install brake bleeder adapter J-22489 (fig. 6) on

main cylinder. Connect hose from bleeder equipment

to bleeder adapter and open release valve on bleeder

equipment.

CHEVROLET CHASSIS SERVICE MANUAL

Page 242 of 659

BRAKES 5-9

COMPONENT REPLACEMENT AND REPAIRS

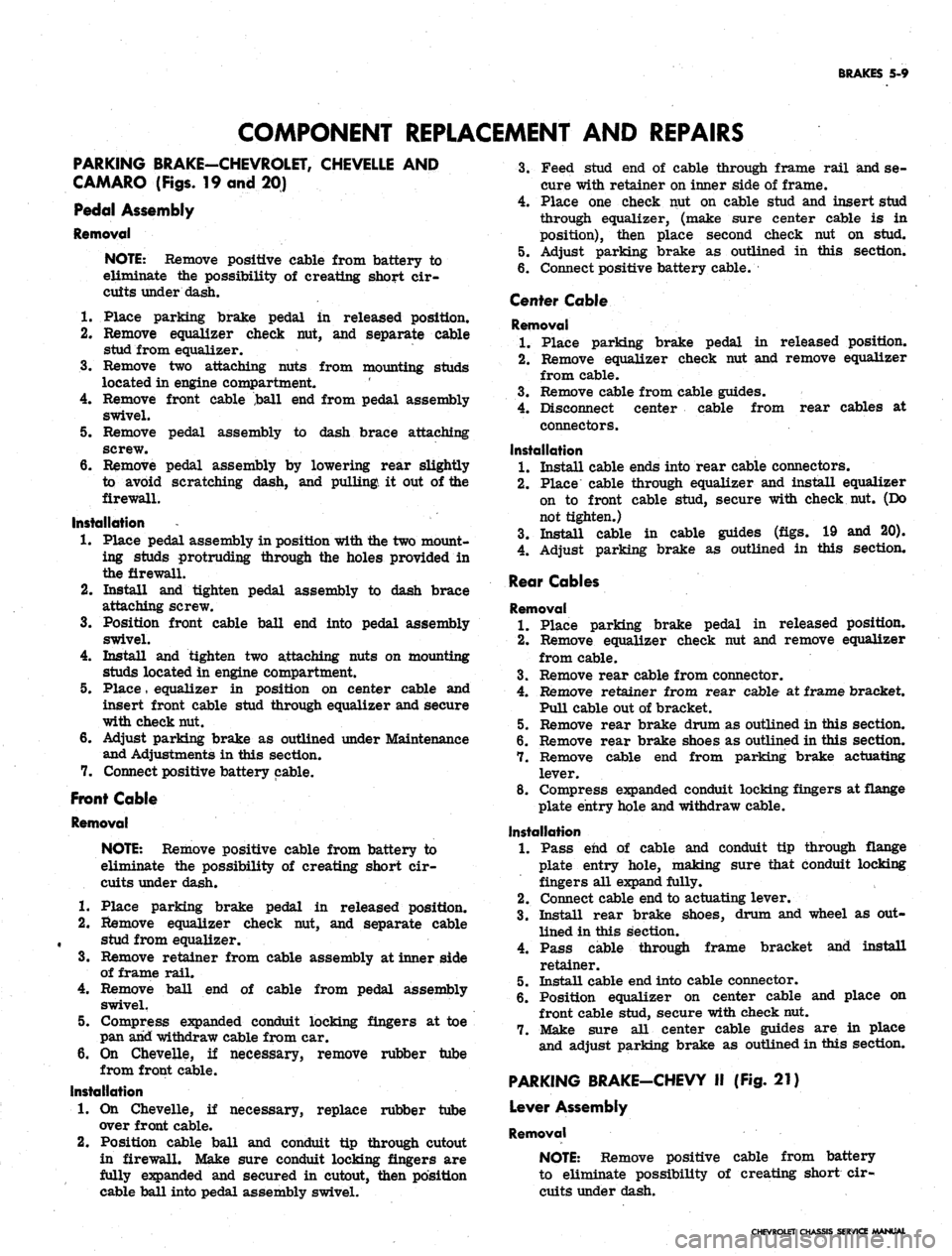

PARKING BRAKE-CHEVROLET, CHEVELLE AND

CAMARO (Figs. 19 and 20)

Pedal Assembly

Removal

NOTE:

Remove positive cable from battery to

eliminate the possibility of creating short cir-

cuits under dash.

1.

Place parking brake pedal in released position.

2.

Remove equalizer check nut, and separate cable

stud from equalizer.

3.

Remove two attaching nuts from mounting studs

located in engine compartment.

4.

Remove front cable .ball end from pedal assembly

swivel.

5. Remove pedal assembly to dash brace attaching

screw.

6. Remove pedal assembly by lowering rear slightly

to avoid scratching dash, and pulling, it out of the

firewall.

Installation

1.

Place pedal assembly in position with the two mount-

ing studs protruding through the holes provided in

the firewall.

2.

Install and tighten pedal assembly to dash brace

attaching screw.

3.

Position front cable ball end into pedal assembly

swivel.

4.

Install and tighten two attaching nuts on mounting

studs located in engine compartment.

5. Place

,

equalizer in position on center cable and

insert front cable stud through equalizer and secure

with check nut.

6. Adjust parking brake as outlined under Maintenance

and Adjustments in this section.

7. Connect positive battery cable.

Front Cable

Removal

NOTE:

Remove positive cable from battery to

eliminate the possibility of creating short cir-

cuits under dash.

1.

Place parking brake pedal in released position.

2.

Remove equalizer check nut, and separate cable

, stud from equalizer.

3.

Remove retainer from cable assembly at inner side

of frame rail.

4.

Remove ball end of cable from pedal assembly

swivel.

5. Compress expanded conduit locking fingers at toe

pan arid withdraw cable from car.

6. On Chevelle, if necessary, remove rubber tube

from front cable.

Installation

1.

On Chevelle, if necessary, replace rubber tube

over front cable.

2.

Position cable ball and conduit tip through cutout

in firewall. Make sure conduit locking fingers are

fully expanded and secured in cutout, then position

cable ball into pedal assembly swivel.

3.

Feed stud end of cable through frame rail and se-

cure with retainer on inner side of frame.

4.

Place one check nut on cable stud and insert stud

through equalizer, (make sure center cable is in

position), then place second check nut on stud.

5. Adjust parking brake as outlined in this section.

6. Connect positive battery cable.

Center Cable

Removal

1.

Place parking brake pedal in released position.

2.

Remove equalizer check nut and remove equalizer

from cable.

3.

Remove cable from cable guides.

4.

Disconnect center cable from rear cables at

connectors.

Installation

1.

Install cable ends into rear cable connectors.

2.

Place cable through equalizer and install equalizer

on to front cable stud, secure with check nut. (Do

not tighten.)

3.

Install cable in cable guides (figs. 19 and 20),

4.

Adjust parking brake as outlined in this section.

Rear Cables

Removal

1.

Place parking brake pedal in released position.

2.

Remove equalizer check nut and remove equalizer

from cable.

3.

Remove rear cable from connector.

4.

Remove retainer from rear cable at frame bracket.

Pull cable out of bracket.

5. Remove rear brake drum as outlined in this section.

6. Remove rear brake shoes as outlined in this section.

7. Remove cable end from parking brake actuating

lever.

8. Compress expanded conduit locking fingers at flange

plate entry hole and withdraw cable.

Installation

1.

Pass end of cable and conduit tip through flange

plate entry hole, making sure that conduit locking

fingers all expand fully.

2.

Connect cable end to actuating lever.

3.

Install rear brake shoes, drum and wheel as out-

lined in this section.

4.

Pass cable through frame bracket and install

retainer.

5. Install cable end into cable connector.

6. Position equalizer on center cable and place on

front cable stud, secure with check nut.

7. Make sure all center cable guides are in place

and adjust parking brake as outlined in this section.

PARKING BRAKE-CHEVY II (Fig. 21)

Lever Assembly

Removal

NOTE:

Remove positive cable from battery

to eliminate possibility of creating short cir-

cuits under dash.

CHEVROLET CHASSIS SERVICE MANUAL

Page 244 of 659

BRAKES 5-11

VIEW A

VIEWB

CAMARO

Fig.

20—Parking Brake System—Camano

1.

Place parking brake lever in released position.

2.

Remove return spring at equalizer.

3.

Remove equalizer check nut, and separate cable

stud from equalizer.

4.

Remove clevis pin clip and pin from idler lever

assembly.

5. Remove two lever dash attaching screws, and remove

lever assembly from vehicle.

Installation

1.

Place lever assembly into position and secure with

the two lever to dash attaching screws.

2.

Place idler lever in position with lever assembly,

align holes and install clevis pin and clip.

3.

Position equalizer on front cable stud and secure

with check nut.

4.

Install return spring at equalizer.

5. Adjust parking brake as outlined under Maintenance

and Adjustments in this section.

6. Connect positive battery cable.

Idler Lever

Removal

NOTE:

Remove positive cable from battery

to eliminate possibility of creating short cir-

cuits under dash.

1.

Place parking brake lever in released' position.

2.

Eemove return spring at equalizer.

3.

Remove equalizer check nut, and separate cable stud

from equalizer.

4.

Remove clevis pin clip and pin from idler lever

assembly.

5. Remove cable ball from idler lever.

6. Remove pivot pin clip and pivot pin, then remove

idler lever from vehicle.

Installation

1.

Place, idler lever into position and secure with

the pivot pin and clip.

2.

Connect cable ball to idler lever.

3.

Place idler lever in position with lever assembly,

align holes and install clevis pin and clip.

4.

Position equalizer on front cable stud and secure

with check nut.

5. Install return spring at equalizer.

6. Adjust parking brake as outlined under Maintenance

and Adjustments in this section.

7. Connect positive battery cable.

Front Cable

Removal

NOTE:

Remove positive cable from battery

to eliminate possibility of creating short cir-

cuits under dash.

1.

Place parking brake lever in released position.

CHEVROLET CHASSIS SERVICE MANUAL

Page 247 of 659

BRAKES 5-14

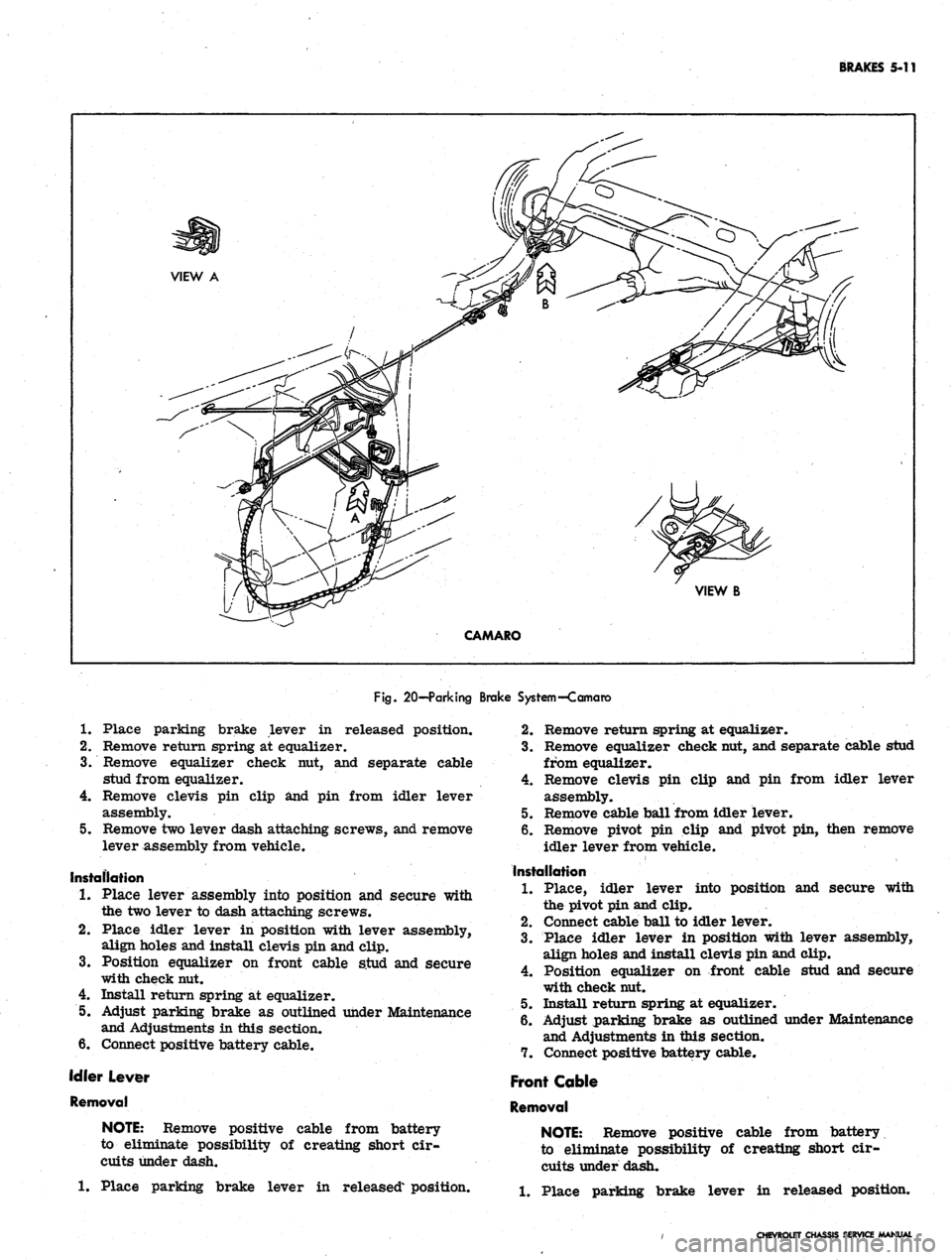

Fig.

23—Removing or Installing Cover Lower Mounting Screws

Fig.

24—Removing or Installing Trim Seal

8. Remove front cable from lever assembly using long

nose pliers as shown in Figure 25. Remove lever

from vehicle.

Installation

1.^

Install front cable in lever assembly using long

nose pliers as shown in Figure 25. Slide slack

cable through hole and place lever assembly in

position.

2.

Place forward mounting bracket in position and

secure plate and lever assembly to underbody with

four mounting bolts.

3.

Secure parking brake alarm switch to side of lever

assembly with washer and screw (fig. 24).

4.

Install trim seal on lever (fig. 24).

5. Insert the end of the trim seal into the slot in the

cover and slide the cover forward and down into

position.

6. Place the retainer in position. Secure retainer and

cover to underbody with six screws. It is necessary

to push the seat cushion down as shown in Figure 23

to gain access to the lower mounting screw hole on

each side.

7. Under vehicle, insert front cable stud through equal-

izer assembly and secure with nut.

8. Install return spring.

9. Adjust parking brake as outlined under Maintenance

and Adjustments in this section.

Front Cable

Removal

1.

Perform the complete parking brake lever removal

procedure above.

2.

Under vehicle, remove nut, washer, and bolt se-

. curing pulley to pulley bracket (fig. 22).

3.

Remove seal grommet from underbody cable hole.

4.

Pull front cable out of vehicle.

Installation

1.

Install seal grommet around front cable.

2.

Slide front cable into position through cable hole

and work seal grommet into installed position.

3.

Under vehicle, loop front cable around pulley wheel

and secure pulley wheel to bracket with bolt, washer,

and nut (fig..22).

4.

Perform the complete parking brake lever installa-

tion procedure above.

Removal

1.

Remove the cable clip retainers on the back side of

the frame rail from each of the rear brake cable

ends.

2.

Disconnect the cable at the rear wheel flange plate.

3.

Remove the cable ball out of the recess in .the brake

lever assembly clevis.

4.

Disconnect the cables at the equalizer connector and

remove the cables.

Installation

1.

Attach the rear cable balls on the rear cable ends

to the rear wheel recess in the brake lever assembly

clevis.

2.

Attach the cable assembly to the rear wheel flange

plate.

3.

Connect the cable assemblies along the frame rail

area.

4.

Insert the cable end through the equalizer and attach

to the equalizer connector.

5. Adjust as outlined under Maintenance and

Adjustments.

6. Lubricate the cables and all moving parts for

trouble-free operation—see Lubrication, Section 0.

Fig.

25—Removing or Installing Front Cable

CHEVROLET CHASSIS SERVICE MANUAL

Page 250 of 659

BRAKES 5-17

mended shoe and lining assemblies. Otherwise,

serious fade or failure may occur.

1.

Inspect new linings and make certain there are no

nicks or burrs on bonding material on shoe edge

where contact is made with brake flange plate or

on any of the contact surfaces.

NOTE: Keep hands clean while handling brake

shoes.

Do not permit oil or grease to come in

contact with linings.

2.

If working on rear brakes, lubricate parking brake

cable.

3.

On rear brakes only, lubricate fulcrum end of park-

ing brake lever and the bolt with brake lube, then

attach lever to secondary shoe with bolt, spring

washer, lock washer and nut. Make sure that lever

moves freely.

4.

Before installation make certain the adjusting screw

is clean and lubricated properly.

NOTE: Loose adjustment may occur from an

adjusting screw that is not properly operating.

If the lubrication in the adjusting screw as-

sembly is contaminated or destroyed, the ad-

justing screw should be thoroughly cleaned and

lubricated.

5.

Connect brake shoes together with adjusting screw

spring, then place adjusting screw, socket and nut

in position.

CAUTION: Make sure the proper adjusting

screw is used ("L" for left side of vehicle,

"R"

for right side of vehicle). The star wheel

should only be installed with the star wheel

nearest to the secondary shoe and the adjusting

screw spring inserted to prevent interference

with the star wheel.

6. On rear wheels connect parking brake cable to lever.

7.

Secure the primary brake shoe (short lining—faces

forward) first with the hold-down pin and spring

using a pair of pliers. Engages shoes with the wheel

cylinder connecting links.

8. Install and secure the actuator assembly and second-

ary brake shoe with the hold-down pin and spring

using a pair of needle nose pliers. On rear wheels

position parking brake strut and strut spring.

9. Install guide plate over anchor pin.

10.

Install the wire link.

NOTE: Do not hook the wire link over the

anchor pin stud with the regular spring hook

tool. This may damage the cylinder boot seals.

Fasten the wire link to the actuator assembly ;

first, then place over the anchor pin stud by

hand while holding the adjuster assembly in the

full down position.

11.

Install actuator return spring.

NOTE: Do not pry actuator lever to install re-

turn spring. Ease it in place using the end of a

screw driver or other suitable flat tool.

12.

If old brake pull back (return) springs are nicked,

distorted or if strength is doubtful, install new

springs.

13.

Hook springs in shoes using Tool J-8049 by in-

stalling the primary spring from the shoe over the

anchor pin and then spring from secondary shoe

over the wire link end.

14.

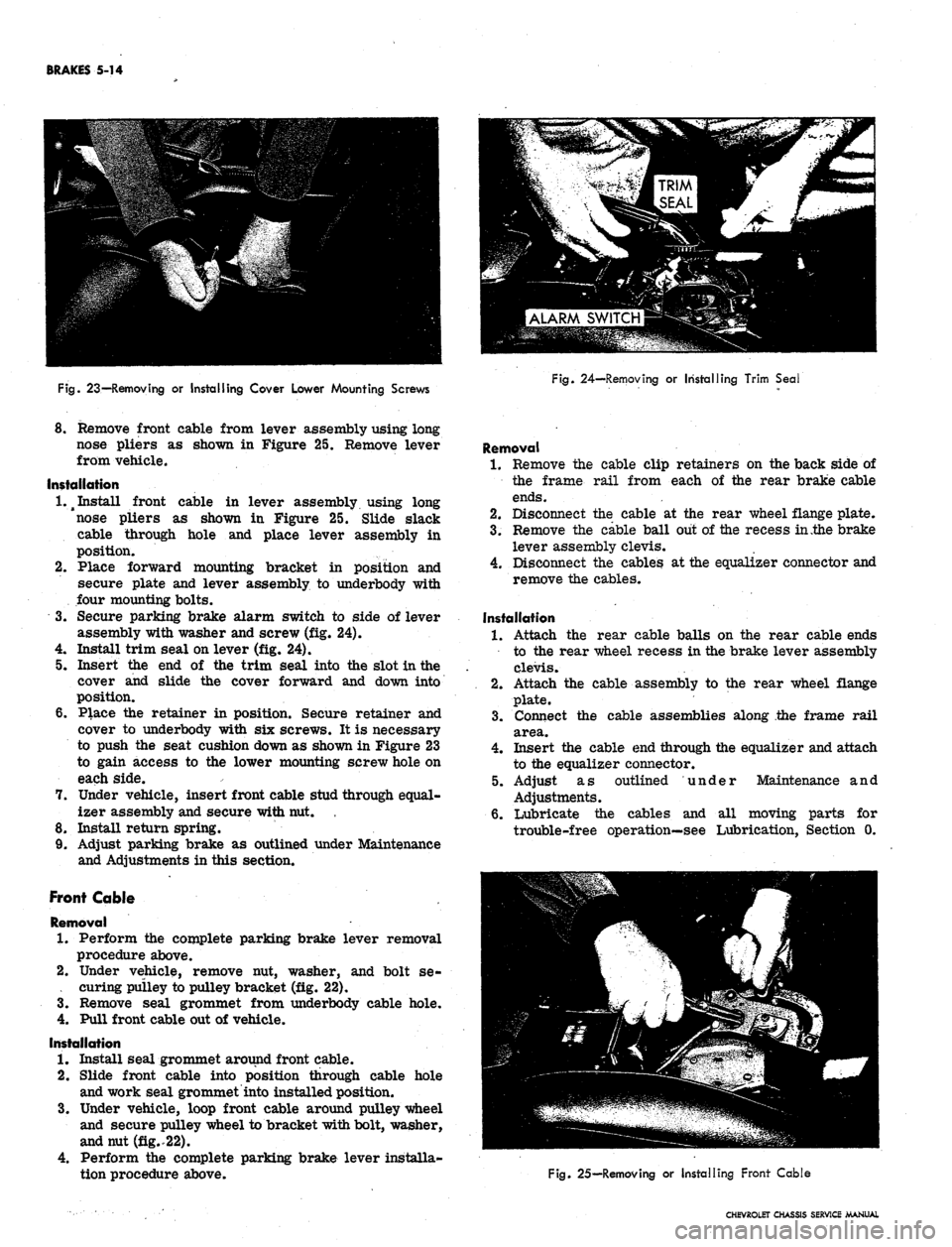

Pry shoes away from backing plate and lubricate

shoe contact surfaces with a thin coating of brake

lube (fig. 29).

CAUTION:

facings.

Be careful to keep lubricant off

Fig.

29—Backing Plate Contact Surfaces

15.

After completing installation, make certain the actu-

ator lever functions easily by hand operating the

self-adjusting feature (fig. 30).

1.6. Follow the above procedure for all wheels.

17.

Adjust the service brakes and parking brake as

outlined under "Maintenance and Adjustments" in

this section.

Metallic Linings

Metallic brake linings which use special heat resistant

brake springs are available as an option. Service opera-

tions are the same as for standard brakes; however,

when new linings are installed, the linings should be

seated as described below.

NOTE: Brake shoes with metallic linings re-

quire specially finished brake drums (honed to a

20 micro-inch finish). Metallic linings are not

recommended for service replacement on ve-

hicles with standard brake drums that have not

been honed to specified finish.

Seating Metallic Linings

After the brakes have been adjusted, the following

recommended "lining seating" is as follows:

1.

Make six to eight stops from 30 MPH with moderate

pedal pressure to aid in seating and to mbdulate

any tendency to dive.

CHEVROLET CHASSIS SERVICE MANUAL

Page 257 of 659

BRAKES

5-24

DISC BRAKES

INDEX

Page

General Description

. 5-24

Maintenance

and

Adjustments

5-24

Bleeding Hydraulic System

5-24

Parking Brake Adjustment

-

Corvette

5-24

Component Replacement

and

Repairs

5-25

Page

Brake Shoes

. . . . . 5-25

Brake Caliper

5-26

Brake Disc

5-29

Main Cylinder.

5-30

Parking Brake Shoes

-

Corvette

5-30

GENERAL DESCRIPTION

Four wheel disc brakes

are

standard equipment

on

the

1967

Corvette,

as in 1966. The

Corvette

may

also

be equipped with heavy duty disc brakes which include

new front calipers, shoes, linings,

and

rear pressure

regulator valve. This heavy duty option

is

used

in

conjunction with

a

vacuum power unit. Front wheel disc

brakes

are

installed

as

optional equipment

on

Chevrolet,

Chevelle, Camaro,

and

Chevy

II

models.

The disc brake,

(fig. 35),

consists

of a

fixed caliper,

rotating disc, splash shield,

and

mounting bracket.

The

caliper assembly contains four pistons and two shoe

and

lining assemblies with

the

lining riveted

to the

steel

shoes.

A

seal

and

dust boot

are

installed

on

each piston,

with

a

piston spring

in the

caliper cylinder bore beneath

each piston.

A

retaining pin extends through each caliper

half

and

both shoes

to

hold

the

shoes and linings

in

posi-

tion

in the

caliper.

On

Corvette heavy duty disc brakes,

two retaining cotter pins

are

used

at

each end

of the

caliper

to

secure

the

shoes

and

linings. Machined

sur-

faces within

the

caliper prevent

the

shoe

and

lining

assembly from rotating with

the

brake disc when pres-

sure

is

applied.

The disc, which

has a

series

of air

vent louvers

to

provide cooling,

is

mounted

on the

front wheel-hub.

The caliper straddles

the

disc and mounts

on a

mounting

bracket attached

to the

steering knuckle with

two

bolts.

The Corvette heavy duty option includes

a

pressure

regulator valve mounted

in the

rear brake line just

below

the

main cylinder. Chevrolet, Chevelle, Camaro,

and Chevy

n

models with disc brakes have

a

pressure

regulator valve mounted

in the

front brake line just

below

the

main cylinder. The valve controls

the

hydraulic

pressure

to the

front

or

rear brakes,

as

applicable,

resulting,

in the

correct pressure balance between

the

front

and

rear hydraulic systems. This valve guards

against premature .lock-up

of

front

or

rear wheels when

brakes

are

applied.

Maintenance, adjustment,

and

service operations which

are

not

included

in

this section

are the

same

as for

the Duo-Servo type brakes.

MAINTENANCE

AND

ADJUSTMENTS

BLEEDING HYDRAULIC SYSTEM

The operation

of

bleeding

the

disc brake hydraulic

system

is the

same

as for

Duo-Servo system outlined

in

the

front

of

this section. Note

the

exceptions below

and refer

to

bleeding procedures under Duo-Servo

brakes.

1.

When pressure bleeding equipment

is

used,

the

correct pressure setting

for

bleeding disc brakes

is 10-2.0

lbs. on

Corvette,

and 40 lbs. on all

other

models.

2.

The

front calipers contain

one

bleeder valve.

The

rear calipers

on

Corvette contain two bleeder valves

(one inboard

and one

outboard) which necessitates

the removal

of the

rear wheels

for

bleeding.

3.

Tapping

the

caliper with

a

rawhide mallet

as the

fluid

is

flowing

out may

assist

in

obtaining

a

good

bleeding

job.

4.

On

Chevrolet, Chevelle, Camaro

and

Chevy

II, the

spring loaded

end of the

pressure regulator valve

(fig.

36)

must

be

held (valve

in

open position) while

bleeding. This

is

done

by

depressing

and

holding

in

the

plunger

in the

end

of

the valve either

by

hand,

by taping,

or by

clamping.

PARKING BRAKE-CORVETTE

Adjustment

1.

Raise rear

end of

vehicle

and

place

on

jack stands.

2.

Remove rear wheels.

3/

Loosen brake cables

at the

equalizer until

the

park-

ing brake levers move freely

to the "off"

position

with slack

in the

cables.

4.

Turn

the

disc until

the

adjusting screw can

be

seen

through

the

hole

in the

disc.

5. Insert

an

adjusting tool

or

screw driver through

the

hole

in the

disc

and

tighten

the

adjusting screw

by

moving your hand away from

the

floor

on

both

the

left and right sides

(fig. 37).

6. Tighten until

the

disc will

not

move, then back

off

ten

(10)

notches.

7. Apply

the

parking brake four

(4)

notches from inside

the

car.

8. Tighten

the

brake cables

at the

equalizer

to

produce

a light drag with

the

wheels mounted.

9. Fully release

the

parking brake handle

and

rotate

the rear wheels.

No

drag should be evident with

the

handle released.

CHEVROLET CHASSIS SERVICE MANUAL

Page 262 of 659

BRAKES 5-29

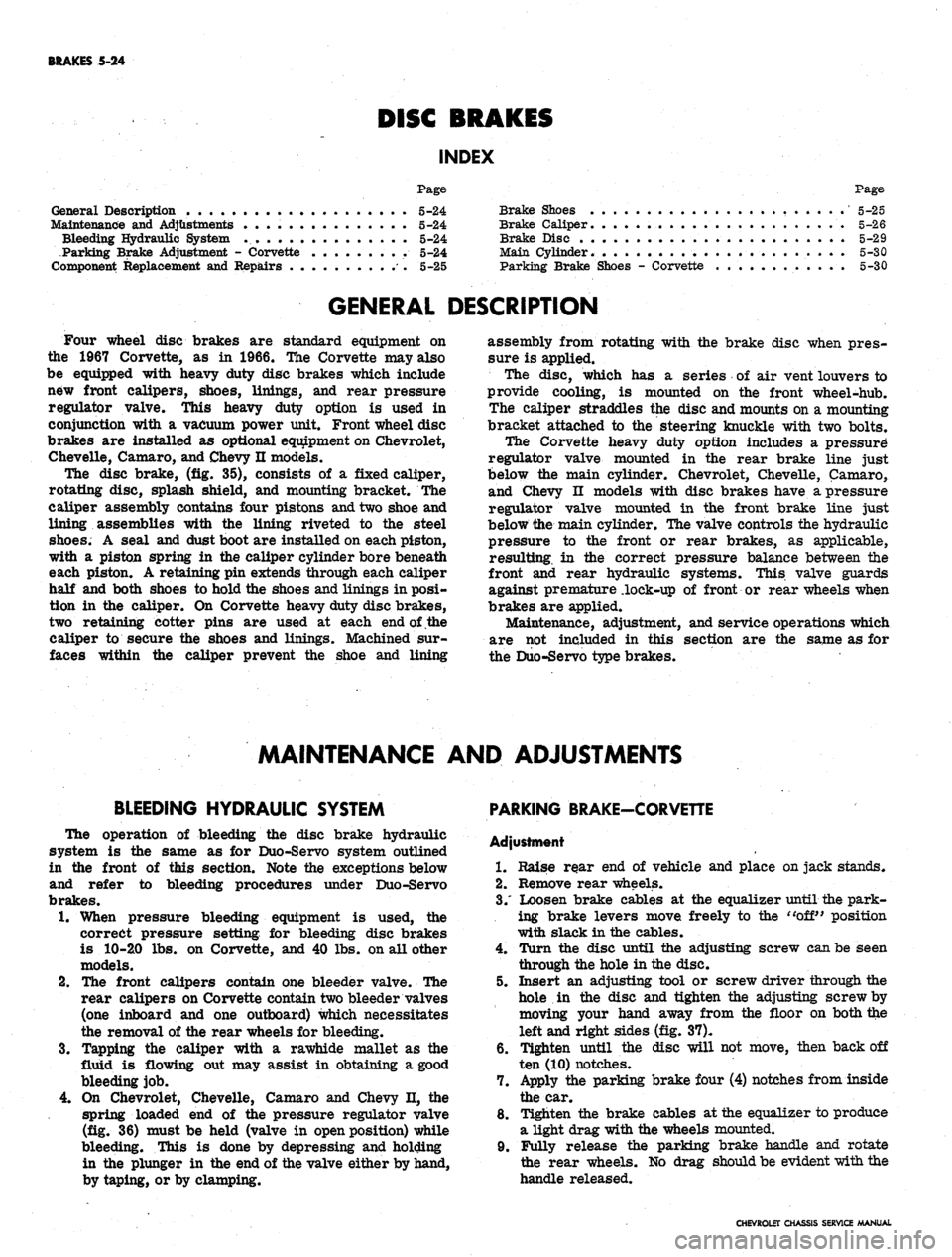

Fig.

42—Installing Caliper on Disc

Check that the hose does not touch other parts at

any time during suspension or geometry travel.

If contact does occur, remove the U-shaped retainer

and rotate the end of the hose in the support bracket

one or two points in a direction which will eliminate

hose contact. Reinstall the retainer and recheck

for hose contact. If it is satisfactory, place the

steel tube connector in the hose fitting and tighten

securely.

If rear brake caliper is being serviced, connect

brake line to caliper.

Bleed brakes as outlined in this section.

Install wheels and lower vehicle.

BRAKE DISC

Servicing of the disc brakes is extremely critical

due to tolerances required in machining of the brake

disc to insure proper brake operation. In manufacturing

the brake disc, tolerances of the rubbing surfaces for

flatness is .001 and for parallelism is .0005, while

lateral runout of the faces must not exceed .004 total.

The maintenance of these close controls of the shape of

the rubbing surfaces is necessary to prevent brake

roughness. In addition, the surface finish must be non-

directional and maintained at 30-50 micro-inches. This

control of the rubbing surface finish is necessary to

avoid pulls and erratic performance and promote long

lining life and equal lining wear of both left and right

brakes.

tight scoring of the disc surfaces not exceeding .015

in depth, which may result from normal use, is not

detrimental to brake operation.

When the total disc thickness is less than .965 for the

1"

thick disc or 1.215 for the 1-1/4" thick disc, it should

be replaced. Disc thicknesses less than this can permit

the shoes to come out of contact with the shoe abutments

and cause malfunction.

Because performance is not impaired by surface im-

perfection not exceeding .015 deep, refinishing of the

rubbing surface is not necessary.

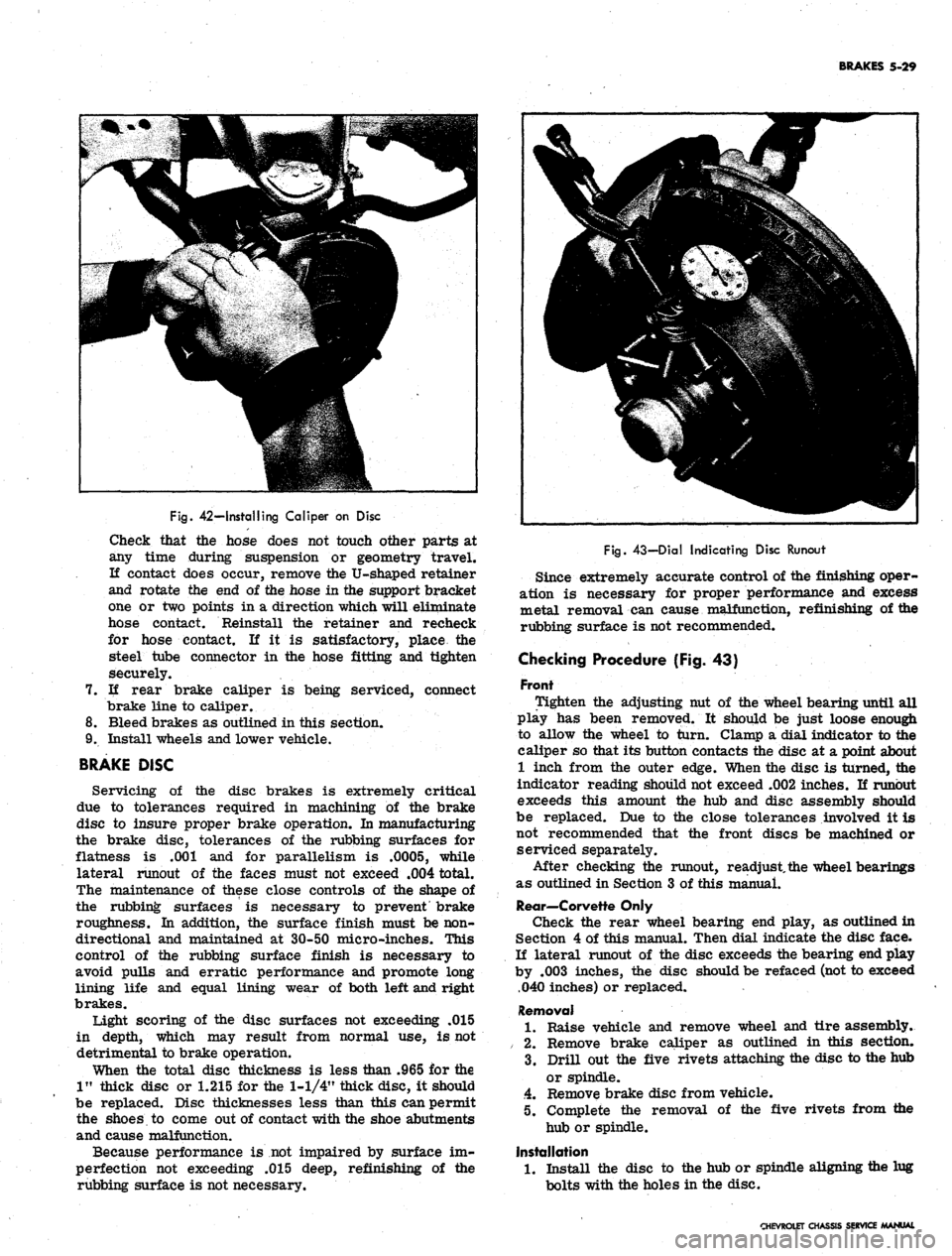

Fig.

43—Dial Indicating Disc Runout

Since extremely accurate control of the finishing oper-

ation is necessary for proper performance and excess

metal removal can cause malfunction, refinishing of the

rubbing surface is not recommended.

Checking Procedure (Fig. 43)

Front

Tighten the adjusting nut of the wheel bearing until all

play has been removed. It should be just loose enough

to allow the wheel to turn. Clamp a dial indicator to the

caliper so that its button contacts the disc at a point about

1 inch from the outer edge. When the disc is turned, the

indicator reading should not exceed .002 inches. If runout

exceeds this amount the hub and disc assembly should

be replaced. Due to the close tolerances involved it is

not recommended that the front discs be machined or

serviced separately.

After checking the runout, readjust, the wheel bearings

as outlined in Section 3 of this manual.

Rear—Corvette Only

Check the rear wheel bearing end play, as outlined in

Section 4 of this manual. Then dial indicate the disc face.

If lateral runout of the disc exceeds the bearing end play

by .003 inches, the disc should be refaced (not to exceed

.040 inches) or replaced.

Removal

1.

Raise vehicle and remove wheel and tire assembly.

/ 2. Remove brake caliper as outlined in this section.

3.

Drill out the five rivets attaching the disc to the hub

or spindle.

4.

Remove brake disc from vehicle.

5. Complete the removal of the five rivets from the

hub or spindle.

Installation

1.

Install the disc to the hub or spindle aligning the lug

bolts with the holes in the disc.

CHEVROLET CHASSIS SERVICE MANUAL