wheel alignment CHEVROLET CAMARO 1967 1.G Chassis User Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1967, Model line: CAMARO, Model: CHEVROLET CAMARO 1967 1.GPages: 659, PDF Size: 114.24 MB

Page 371 of 659

CLUTCH AND TRANSMISSIONS 7-12

DIAGNOSIS-OVERDRIVE

MECHANICAL

Any one of the following general complaints may be due

to non-standard mechanical conditions in the overdrive

unit:

1.

Does not drive unless locked up manually.

2.

Does not engage, or lock-up does not release.

3.

Engages with a severe jolt, or noise.

4.

Free-wheels at speeds over 30 mph.

These^ troubles may be diagnosed and remedied as de-

scribed in the following paragraphs.

1.

Does not drive unless locked up manually.

a. Occasionally, the unit may not drive the car for-

ward in direct drive, unless locked up by pulling

the dash control. This may be caused by one or

more broken rollers in the roller clutch, the

remedy for which is the replacement of the entire

set of rollers.

b.

This may also be caused by sticking of the roller

retainer upon the cam. This retainer must move

freely to push the rollers into engaging position,

under the pressure of the two actuating springs.

c. Sometimes this is due to slight indentations, worn

in the cam faces by the rollers spinning, remedied

by replacement of the cam.

2.

Does not engage, or lock-up does not release

.. a. Dash control improperly connected—-Unless the

overdrive dash control wire is connected to the

lockup lever on the left side of the overdrive

housing in such a manner as to move the lever

all the way back when the dash control knob is

pushed in, it may hold the shift rail in such a po-

sition as to interlock the pawl against full engage-

ment resulting in a buzzing noise when overdrive

engagement is attempted.

To correctly make this connection, loosen bind-

ing post at lever, pull dash control knob out 1/4",

move lever all the way to the rear, and tighten

binding post.

b.

Transmission and overdrive improperly aligned—

The same symptoms as above may also result

from misalignment, at assembly, of the overdrive

housing to the transmission case, resulting in

binding of the overdrive shift rail, so that the re-

tractor spring cannot move the rail fully forward,

when the dash control knob is pushed in, and the

transmission is not in reverse. Under such con-

ditions, the unit may remain fully locked up.

To test for this, be sure that the transmission

is not in reverse; disconnect the dash control

wire from the lockup lever, and feel the lever for

free forward movement. If the lever can be

moved forward more than 1/4", it indicates that

misalignment probably exists. To correct this,

Jposen the capscrews between the overdrive hous-

ing and transmission case, and tap the adpater

plate and overdrive housing until a position is

found where the rail shifts freely; tighten cap-

screws.

c. Kickdown switch improperly adjusted—The posi-

tion of the kickdown switch should be adjusted,

by means of the two large nuts which clamp the

switch shank, so the switch plunger travels 3/16"

before the throttle lever touches its stop.

Occasionally the large nuts which clamp the

switch through the switch bracket are tightened

sufficiently to bend the switch shank, thus pre-

venting free motion of the switch stem. This may

usually be remedied by loosening the upper of the

two nuts.

d. Improper installation of solenoid—If car cannot

be rolled backward under any circumstances and

there is no relay click when the ignition is turned

on, it probably indicates that the solenoid has

been installed directly, without twisting into the

bayonet lock between solenoid stem and pawl, thus

jamming the pawl permanently into overdrive en-

gagement. If the car will occasionally roll back-

wards, but not always, (and there is no relay click

when the ignition switch is turned on) it may indi-

cate that, upon installation, the bayonet lock was

caught, and the solenoid forcibly twisted into

alignment with the attaching flange, thus shearing

off the internal keying of the solenoid. Under

these circumstances, the end of the solenoid stem

may not catch in the pawl, and upon release of the

solenoid, the pawl will not be withdrawn promptly

from engagement, but simply drift out. If the

solenoid stem end has its two flats exactly facing

the two solenoid flange holes, it will not withdraw

the pawl properly. If the stem can be rotated

when grasped by a pair of pliers, it indicates that

the internal keying has been sheared.

e. Improper positioning of blocker ring—Occasion-

ally, either in assembly at the factory, or in

service operations in the field, the internal parts

of the overdrive unit may have been rotated with

the solenoid pawl removed, causing the blocker

ring to rotate, so that its two lugs are not located

with respect to- the pawl as shown in Figure 12B.

In other words, the solid portion of the blocker

ring may be in alignment with the pawl, which will

prevent fill} engagement of the pawl with the sun

gear control plate/

To test for this condition, remove solenoid

cover, pull dash control knob out, roll car 2 ft.

forward. Push dash control in, turn ignition

switch on. Then ground the "KD" terminal of

relay, and watch movement of center stem of

solenoid. It should not move more than 1/8" when

the solenoid clicks. Then, with the relay terminal

still grounded, shift into low gear, and roll car

forward by hand. Solenoid stem should then move

an additional 3/8", as the pawl engages fully.

These two tests indicate proper blocker action.

Unless both tests are met, the blocker ring is

probably not in the correct position.

3.

Engages with a severe jolt or noise

Insufficient blocker ring friction may cause the ring

to lose its grip on the hub of the sun gear control

plate. Check the fit and tension of the ring as de-

scribed under "Cleaning and Inspection".

4.

Free-wheels at speeds over 30 MPH

If cam roller retainer spring tension is weak the unit

will free wheel at all times. Check spring action as

described under "Cleaning and Inspection".

CHEVROLET CHASSIS SERVICE MANUAL

Page 383 of 659

CLUTCH AND TRANSMISSIONS 7-24

is at the full mark on the dip stick, it is just slightly be-

low the planetary gear unit. If additional oil is added,

bringing the oil level above the full mark, the planetary

unit will run in the oil, foaming and aerating the oil. This

aerated oil carried through the various oil pressure pas-

sages (low servo, reverse servo, clutch apply, converter,

etc.) may cause malfunction of the transmission assem-

bly, resulting in cavitation noise in the converter and

improper band or clutch application. Overheating may

also occur.

If the transmission is found consistently low on oil, a

thorough inspection should be made to find and correct

all external oil leaks.

PERIODIC OIL CHANGE

The transmission oil should be changed periodically as

recommended in Section 0, and whenever transmission is

to be removed from the vehicle for repairs.

1.

Run engine for one minute in neutral prior to chang-

ing.

2.

Be sure vehicle is level or raise from the rear only.

3.

Remove the oil pan drain plug and allow oil to drain

thoroughly into a pan or can.

Replace drain plug and refill with approximately two

quarts of oil specified in Section 0.

NOTE: To refill the transmission, remove dip

stick from oil filler tube and refill transmission

with oil specified in Section 0 using filler tube

and funnel J-4264. Then, after shifting into all

ranges at idle speed to fill all oil passages, the

engine should be run at 800-1000 rpm with the

transmission in Neutral until the oil warms up,

then add oil as required to raise the fluid level

to the full mark on the dip stick. Refill capacity

is approximately 2 qts.

4.

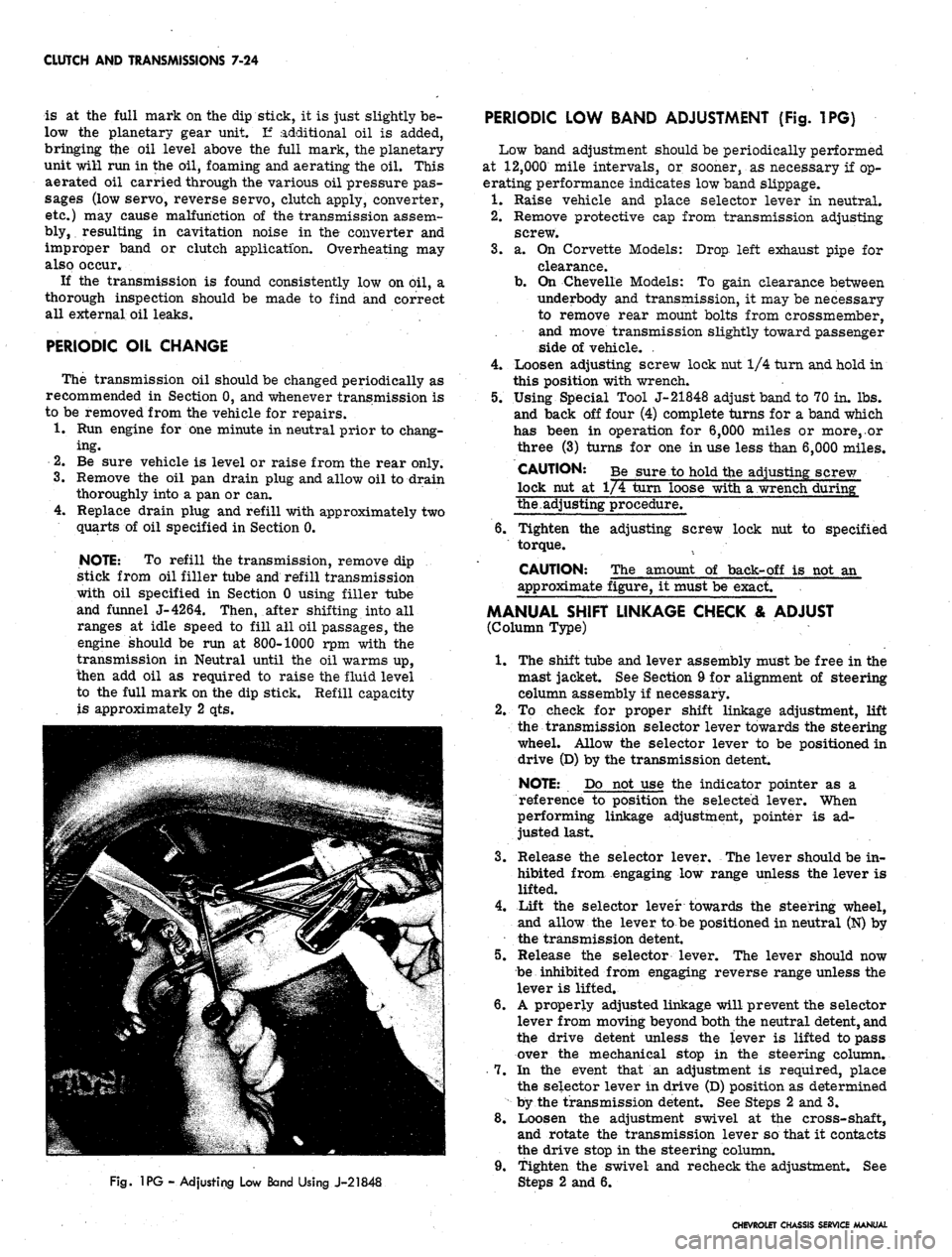

Fig.

1PG - Adjusting Low Band Using J-21848

PERIODIC LOW BAND ADJUSTMENT (Fig. 1PG)

Low band adjustment should be periodically performed

at 12,000 mile intervals, or sooner, as necessary if op-

erating performance indicates low band slippage.

1.

Raise vehicle and place selector lever in neutral.

2.

Remove protective cap from transmission adjusting

screw.

3.

a. On Corvette Models: Drop left exhaust pipe for

clearance.

b.

On Chevelle Models: To gain clearance between

underbody and transmission, it may be necessary

to remove rear mount bolts from crossmember,

and move transmission slightly toward passenger

side of vehicle. .

4.

Loosen adjusting screw lock nut 1/4 turn and hold in

this position with wrench.

5.

Using Special Tool J-21848 adjust band to 70 in. lbs.

and back off four (4) complete turns for a band which

has been in operation for 6,000 miles or more,.or

three (3) turns for one in use less than 6,000 miles.

CAUTION: Be sure to hold the adjusting screw

lock nut at 1/4 turn loose with a wrench during"

the.adjusting procedure.

6. Tighten the adjusting screw lock nut to specified

torque.

CAUTION: The amount of back-off is not an

approximate figure, it must be exact.

MANUAL SHIFT LINKAGE CHECK & ADJUST

(Column Type)

1.

The shift tube and lever assembly must be free in the

mast jacket. See Section 9 for alignment of steering

column assembly if necessary.

2.

To check for proper shift linkage adjustment, lift

the transmission selector lever towards the steering

wheel. Allow the selector lever to be positioned in

drive (D) by the transmission detent.

NOTE: Do not use the indicator pointer as a

reference to position the selected lever. When

performing linkage adjustment, pointer is ad-

justed last.

3.

Release the selector lever. The lever should be in-

hibited from engaging low range unless the lever is

lifted.

4.

Lift the selector lever towards the steering wheel,

and allow the lever to be positioned in neutral (N) by

the transmission detent.

5.

Release the selector lever. The lever should now

be inhibited from engaging reverse range unless the

lever is lifted.

6. A properly adjusted linkage will prevent the selector

lever from moving beyond both the neutral detent, and

the drive detent unless the lever is lifted to pass

over the mechanical stop in the steering column.

7.

In the event that an adjustment is required, place

the selector lever in drive (D) position as determined

by the transmission detent. See Steps 2 and 3.

8. Loosen the adjustment swivel at the cross-shaft,

and rotate the transmission lever so that it contacts

the drive stop in the steering column.

9. Tighten the swivel and recheck the adjustment. See

2 and 6.

CHEVROLET CHASSIS SERVICE MANUAL

Page 396 of 659

CLUTCH AND TRANSMISSIONS 7-37

LI.

- LI Range can be selected at any vehicle speed,

and the transmission will shift to second gear

and remain in second until vehicle speed is re-

duced to approximately 40 MPH, .depending on

axle ratio. LI Range position prevents the trans-

mission from shifting out of first gear.

It is very important that any communication concerning

the Turbo Hydra-Matic always contain the transmission

serial number and that all transmission parts returned

to Chevrolet Motor Division always be tagged with the

transmission serial number.

MAINTENANCE AND ADJUSTMENTS

TRANSMISSION FLUID

Transmission fluid level should be checked with trans-

mission warm and selector lever in "P" Park position,

every time engine oil level is checked or as specified in

Section 0 when engine oil is changed.

CAUTION: Since the Turbo Hydra-Matic trans-

mission is very sensitive to oil level, special

precautions should be taken when checking the

oil level, to insure against an overfifE

Transmission fluid should be changed as specified in

Section 0.

FLUID LEVEL INDICATOR

The fluid level indicator is located in the filler pipe at

the right rear corner of the engine. To bring the fluid

level from the add mark to the full mark add 1 pint.

Fluid level should be to the full mark with transmission

at normal operating temperature. With cold fluid the

level should be at the add mark or slightly below.

SHIFT CONTROL LINKAGE ADJUSTMENT

Adjust linkage as shown below and in Figure 2.

1.

The shift tube and lever assembly must be free in the

mast jacket See Section 9 for alignment of steering

column assembly if necessary.

2.

To check for proper shift linkage adjustment, lift the

transmission selector lever towards the steering

wheel. Allow the selector lever to be positioned in

drive (D) by the transmission detent.

NOTE: Do not use the indicator pointer as a

reference to position the selector lever. When

performing linkage adjustment, pointer is ad-

justed last.

3.

Release the selector lever. The lever should be in-

hibited from engaging low range unless the lever is

lifted.

4.

Lift the selector lever towards the steering wheel,

and allow the lever to be positioned in neutral (N) by

the transmission detent.

5.

Release the selector lever. The lever should now be

inhibited from engaging reverse range unless the

lever is lifted.

6. A properly adjusted linkage will prevent the selector

lever from moving beyond both the neutral detent,

and the drive detent unless the lever is lifted to pass

over the mechanical stop in the steering column.

See schematic diagram.

7.

In the event that an adjustment is required, place the

selector lever in drive (D) position as determined by

the transmission detent. See Steps 2 and 3.

8. Loosen the adjustment swivel at the cross-shaft, and

rotate the transmission lever so that it contacts the

drive stop in the steering column.

9. Tighten the swivel and recheck the adjustment. See

Steps 2 and 6. -

l(h Readjust indicator needle if necessary to agree with

the transmission detent" positions. See Section 9.

11.

Readjust neutral safety switch if necessary to pro-

vide the correct relationship to the transmission de-

tent positions. See Section 12.

12.

When properly adjusted the following conditions must

be met by manual operation of the steering column

shift lever:

a. From reverse to drive position travel, the trans-

mission detent feel must be noted and related to

indicated position on dial.

b.

When in drive and reverse positions, pull lever

rearward (towards steering wheel) and then re-

lease. It must drop back into position with no

restrictions.

NEUTRAL SAFETY SWITCH ADJUSTMENT

The neutral safety switch must be adjusted so that the

car will start in the park or neutral position, but will not

start in the other positions. For replacement refer to

Section 12 of this Manual.

DRAINING AND REFILLING TRANSMISSION

Drain oil immediately after operation before it has had

an opportunity to cool.

To drain oil proceed as follows:

1.

Remove bottom pan attaching screws, pan, and gas-

ket.

2.

Remove oil strainer. Remove "O" ring seal from

pick-up pipe and discard.

3.

Discard strainer if dirty.

4.

Install new "O" ring seal on pick-up pipe and install

strainer and pipe assembly.

5.

Thoroughly clean bottom pan.

6.. Affix new gasket to bottom pan with petroleum jelly.

7.

Install bottom pan with attaching screws and torque

to specifications;

8. If only the pan has been removed, pour approximately

7-1/2 pints of fluid into the transmission. If the

valve body has also been removed use 9-1/2 pints.

After a complete overhaul approximately 19 pints

are required. Be sure container, spout, or funnel is

clean.

9. Start engine and let idle (carburetor off fast idle

step).

Place selector lever in P position and apply

hand brake.

10.

With transmission warm (approximately 150°F), add

fluid to bring level to full mark on indicator.

CAUTION: Do not overfill. Foaming will re-

sult.

CHEVROLET CHASSIS SERVICE MANUAL

Page 430 of 659

FUEL TANK

AND

EXHAUST SYSTEMS

8-24

EXHAUST SYSTEMS

INDEX

Page

General Description. ..........

8-24

Service Operations

8-24

Muffler Assembly.

8-24

Side Mounted Exhaust.

. . . 8-25

GENERAL DESCRIPTION

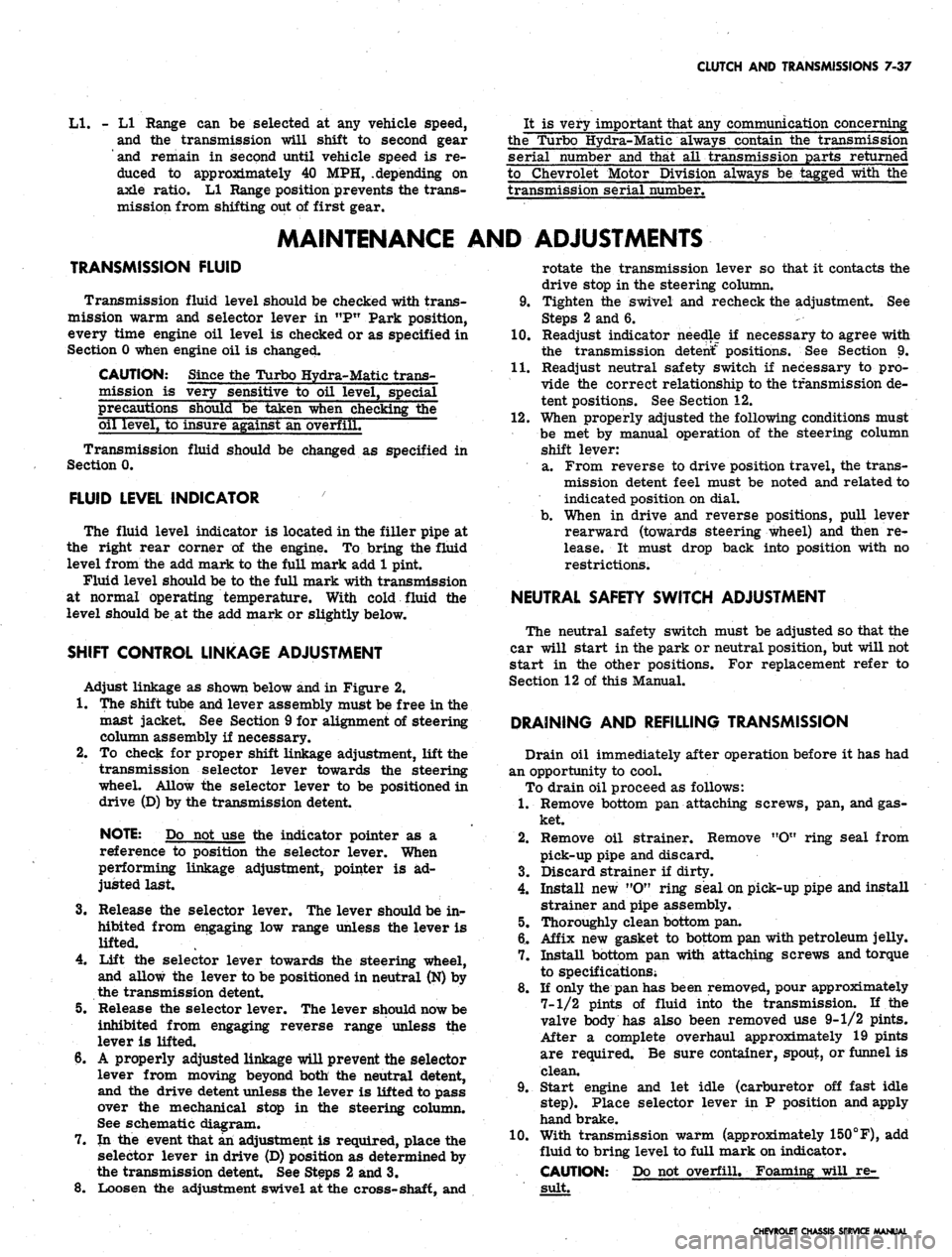

Fig.

30—Standard Dual

All Corvettes

are

equipped with dual exhaust systems

(fig.

30).

Each exhaust assembly

is

connected

to its own

exhaust manifold

and

carries

the

exhaust gases

to the

rear, discharging them

on

each side

of

the rear bumpers.

The dual exhaust system includes

two

front

and

rear

exhaust pipe sections, mufflers, tail pipes and attaching

hardware.

The

system

is

suspended

on

brackets with

insulators

for

rattle free operation. Adjustment

is

only

required

at the

rear muffler bracket.

In addition

to the

regular dual system

an

optional side

mounted, off-road exhaust system

is

available

as an

RPO

(fig.

31).

Extending between front

and

rear wheels,

the

dual units

are

mounted outboard

of the

frame side rails

at

the

rocker panel level,

and

completely replaces

the

regular dual assemblies*

Flow characteristics

are

improved and back pressures

reduced

by

the more direct exhaust routing and

by the use

of chambered pipes

for

sound muffling

in

place

of con-

ventional mufflers.

SERVICE OPERATIONS

Proper relationship

of

parts

is

necessary

in the ex-

haust system

for

carefree operation. Annoying rattles

are usually

a

result

of

incorrect alignment

of

the exhaust

system

due to

incorrect clearances.

MUFFLER ASSEMBLY

Replacement (Also Rear Exhaust

and

Tail Pipes)

Remove

"U"

bolt attachments

at

both rear tail pipe

shields.

2.

crossmember

1.

Separate

the

exhaust system

at the

tube

by

loosening the

"IT"

bolt nuts.

3.

Remove both rear muffler brackets from

the

frame

and slide

the

muffler system forward.

CAUTION: Before cutting

the

rear exhaust

pipe, measure service muffler exhaust pipe

end

and make certain

to

allow

1 1/2" for

engage-

ment

of the

rear exhaust pipe into service

muf-

fler pipe.

CHEVROLET CHASSIS SERVICE MANUAL

Page 441 of 659

SECTION

9

STEERING

CONTENTS

OF

THIS SECTION

Standard Steering

9-1

Power Steering

9-33

Special Tools

9-40

STANDARD STEERING

INDEX

Page

General Description 9.x

Maintenance and Adjustments 9.1

Adjustments

........................

9-2

Steering Gear 9-2

Steering Wheel Alignment and Higji

Point Centering. . . . 9-4

Toe-in Adjustment 9-4

Corvette Steering Ratio . . . . 9-4

Component Replacement and Repairs . . . . 9-4

Steering Wheel . . . 9-4

Regular Production 9-4

Simulated Wood . . . . 9-5

Corvette Telescoping 9-5

Steering Coupling . 9-6

Steering Gear . 9-9

Sector Shaft Seal Replacement 9-10

Steering Column 9-10

Removal 9-10

Disassembly—Syncromesh Column 9-12

Page

Assembly—Syncromesh Column . . 9-14

Disassembly—Column Mounted Powerglide

Lever or Floor Shift Column 9-16

Assembly-^Column Mounted Powerglide

Lever or Floor Shift Column g_x7

Disassembly—Tilt Column 9-19

Assembly—Tilt Column 9-21

Disassembly—Standard Corvette Column 9-23

Assembly—Standard Corvette Column 9-25

Disassembly—Corvette Telescoping Column .... 9.26

Assembly—Corvette Telescoping Column 9-27

Installation 9.27

Steering Linkage 9.29

Tie

Rods.

. 9-29

Relay Rod . . 9-31

Idler Arm . . . . 9-31

Pitman Arm. . 9-32

Steering Arms • • • • 9-32

Steering Damper 9-32

GENERAL DESCRIPTION

The regular production steering gear

is the

recirculat-

ing ball type. This gear provides

for

ease

of

handling

by

transmitting forces from worm

to

sector gear through

ball bearings.

The

steering linkage

is of

the relay type,

and extended interval lubrication design, with the pitman

arm connected

to one end of

the relay

rod. The

other

end

of

the

relay

rod is

connected

to an

idler

arm

which

is

connected

to the

frame side rail opposite

the

steering

gear.

Two

adjustable

tie

rods connect

the

relay

rod to

the steering arms.

All passenger

car

models

for 1967 are

equipped with

new energy absorbing steering columns.

The

mast jacket,

shift tube,

and

steering shaft

are

designed

to

collapse

under various front impact conditions.

All new

columns

are

of

this design, including

the

tilt option and telescope

option.

MAINTENANCE

AND

ADJUSTMENTS

The manual steering gear

is

filled

at the

factory with

a

water resistant grease. Seasonal change

of

this lubrica-

tion

is

unnecessary and

the

housing should

not be

drained.

The steering gear lubricant level should

be

checked every

36,000 miles. Whenever required, additions should

be

made using

a

water resistant

EP

chassis lubricant.

Check and fill steering gear

as

follows:

1.

Remove lower

and

outboard cover retaining screws

(fig.

1).

2.

Insert filling device

in

lower screw hole.

3.

Inject lubricant until

it

appears

in

outboard screw

hole; gear

is now

filled

to

correct level.

The steering linkage should

be

lubricated with water

resistant

EP

chassis lubricant every 6,000 miles

or six

months, whichever occurs first. Lubrication points

and

additional information

on the

chassis lubricant

to be

used

can

be

found

in

Section

0 --

General Information

and

Lubrication.

CHEVROLET CHASSIS SERVICE MANUAL

Page 442 of 659

STEERING 9-2

Fig.

1—Cover

Attaching Bolts—Chevy li Shown

ADJUSTMENTS

STEERING

GEAR

Before any adjustments are made to the steering gear

in an attempt to correct such conditions as shimmy,

loose or hard steering etc., a careful check should be

made of front end alignment, shock absorbers, wheel

balance and tire pressure for possible cause.

Correct adjustment of the steering gear is very im-

portant. Perform adjustments following the sequence

listed below,

1.

Remove pitman arm nut and mark relation of pitman

arm position to sector shaft. Remove pitman arm

with Tool J- 6632 as shown in Figure 2.

2.

Loosen the pitman shaft lash adjuster screw locknut

and turn the adjuster screw a few turns in a counter-

clockwise direction (fig. 3). This removes the load

Fig. 2—Removing Pitman Arm

imposed on the worm bearings by the close meshing

of rack and sector teeth. Turn steering wheel gently

in one direction until stopped by gear, then back away

about one turn.

CAUTION: Do not turn steering wheel hard

against stops when steering relay rod is discon-

nected as damage to ball guides may result.

3.

All except Corvette and telescopic columns:

a. Disconnect steering column harness at chassis

wiring connector plug.

b.

Remove horn cap or ornament and using an inch

pound torque wrench and socket on steering wheel

nut, measure torque required to keep the wheel

in motion.

LASH ADJUSTER

SCREW

LOCK NUT

WORM BEARING

ADJUSTER

\

WORM

ADJUSTER

Fig.

3—Steering Gear Adjustment Points

CHEVROLET CHASSIS SERVICE MANUAL

Page 443 of 659

STEERING 9-3

Fig.

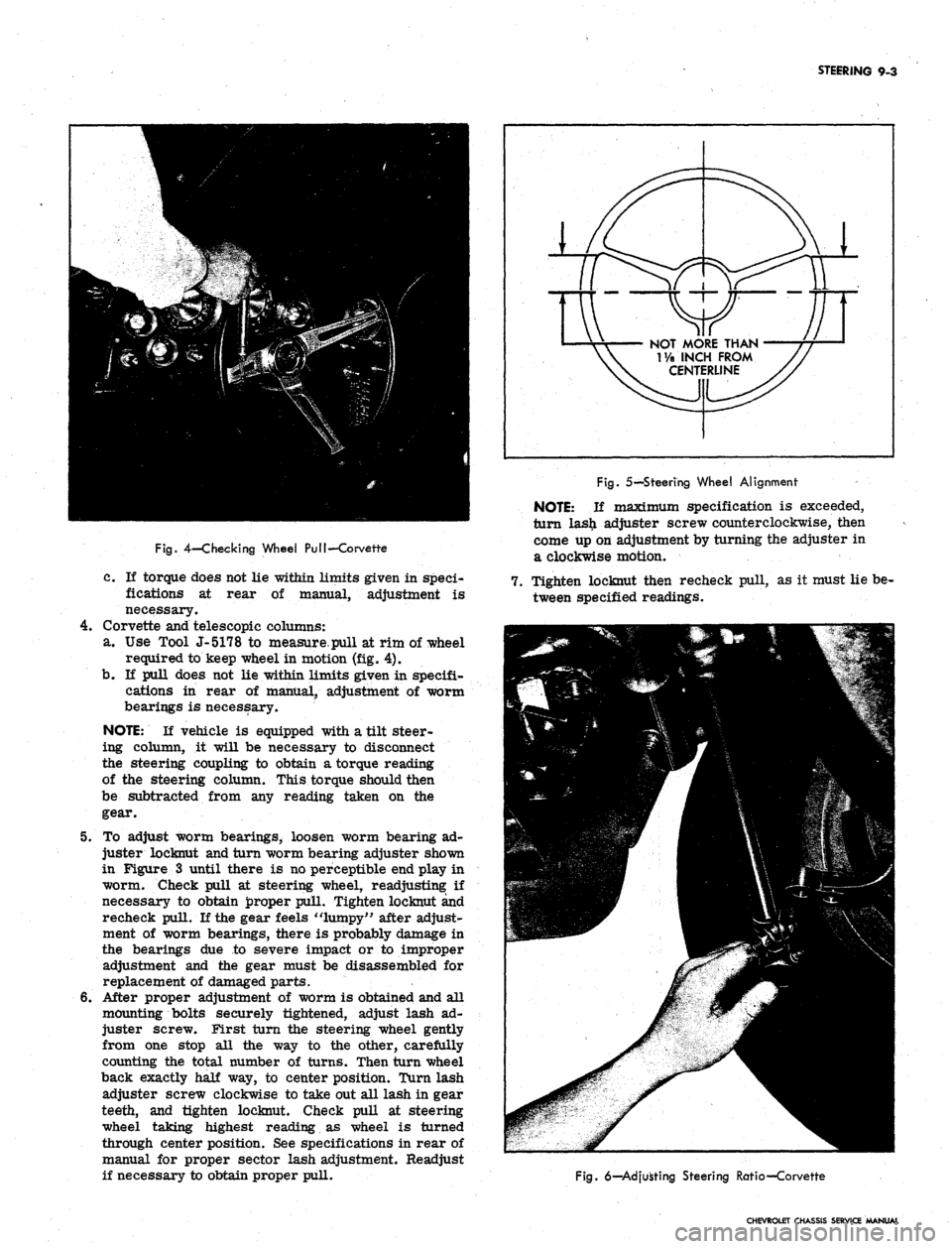

4-Checking Wheel PuI!-Corvette

c. If torque does not lie within limits given in speci-

fications at rear of manual, adjustment is

necessary.

4.

Corvette and telescopic columns:

a. Use Tool J-5178 to measure.pull at rim of wheel

required to keep wheel in motion (fig. 4).

b.

If pull does not lie within limits given in specifi-

cations in rear of manual, adjustment of worm

bearings is necessary.

NOTE:

If vehicle is equipped with a tilt steer-

ing column, it will be necessary to disconnect

the steering coupling to obtain a torque reading

of the steering column. This torque should then

be subtracted from any reading taken on the

gear.

5. To adjust worm bearings, loosen worm bearing ad-

juster locknut and turn worm bearing adjuster shown

in Figure 3 until there is no perceptible end play in

worm. Check pull at steering wheel, readjusting: if

necessary to obtain proper pull. Tighten locknut and

recheck pull. If the gear feels "lumpy" after adjust-

ment of worm bearings, there is probably damage in

the bearings due to severe impact or to improper

adjustment and the gear must be disassembled for

replacement of damaged parts.

6. After proper adjustment of worm is obtained and all

mounting bolts securely tightened, adjust lash ad-

juster screw. First turn the steering wheel gently

from one stop all the way to the other, carefully

counting the total number of turns. Then turn wheel

back exactly half way, to center position. Turn lash

adjuster screw clockwise to take out all lash in gear

teeth, and tighten locknut. Check pull at steering

wheel taking highest reading as wheel is turned

through center position. See specifications in rear of

manual for proper sector lash adjustment. Readjust

if necessary to obtain proper pull.

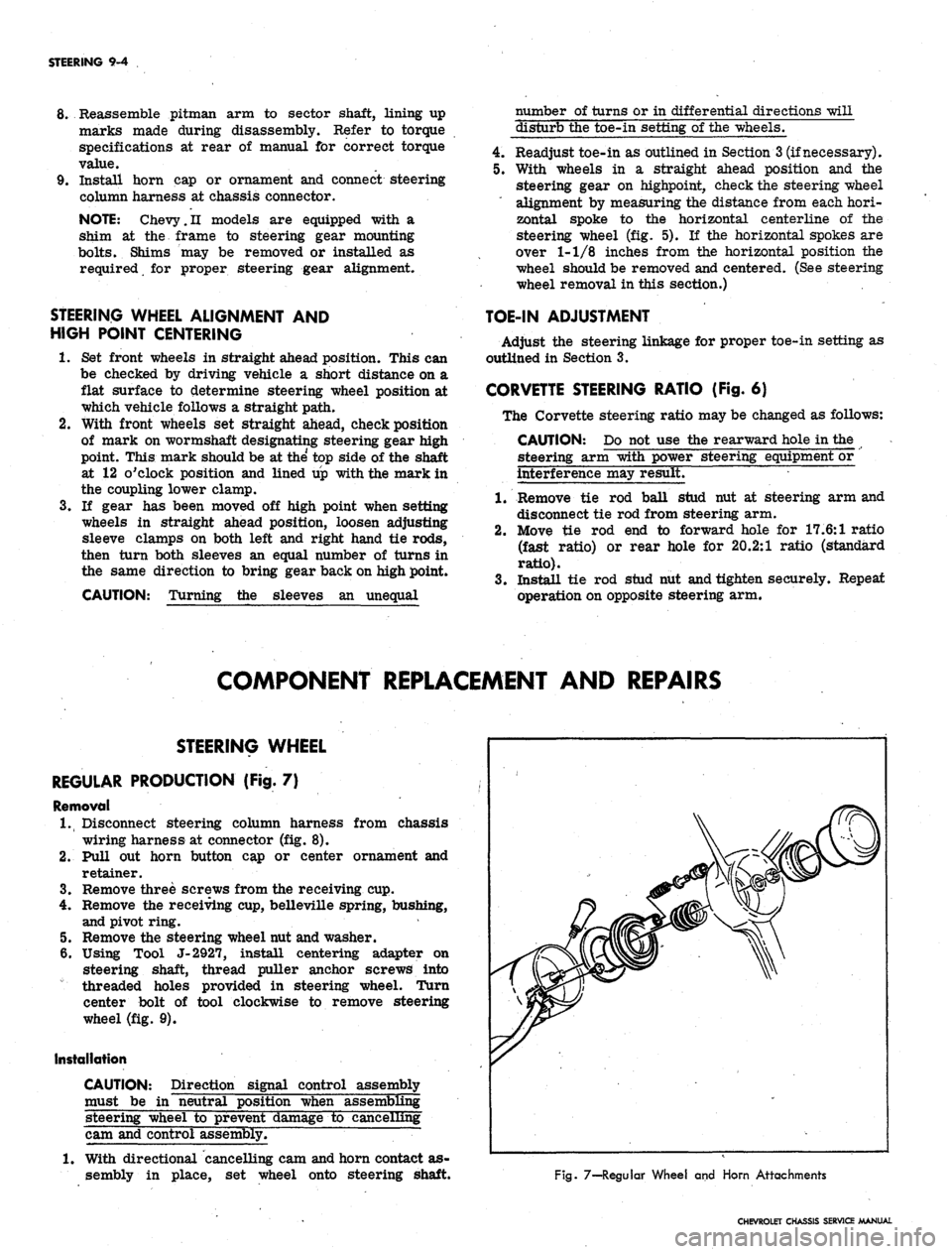

NOT MORE THAN

T/a INCH FROM

CENTERLINE

Fig.

5—Steering Wheel Alignment

NOTE:

If maximum specification is exceeded,

turn las£ adjuster screw counterclockwise, then

come up on adjustment by turning the adjuster in

a clockwise motion.

7. Tighten locknut then recheck pull, as it must lie be-

tween specified readings.

Fig.

6—Adjusting Steering Ratio—Corvette

CHEVROLET CHASSIS SERVICE MANUAL

Page 444 of 659

STEERING 9-4

8. Reassemble pitman arm to sector shaft, lining up

marks made during disassembly. Refer to torque

specifications at rear of manual for correct torque

value.

9. Install horn cap or ornament and connect steering

column harness at chassis connector.

NOTE:

Chevy.n models are equipped with a

shim at the frame to steering gear mounting

bolts.

Shims may be removed or installed as

required for proper steering gear alignment.

STEERING WHEEL ALIGNMENT AND

HIGH POINT CENTERING

1.

Set front wheels in straight ahead position. This can

be checked by driving vehicle a short distance on a

flat surface to determine steering wheel position at

which vehicle follows a straight path.

2.

With front wheels set straight ahead, check position

of mark on wormshaft designating steering gear high

point. This mark should be at the top side of the shaft

at 12 o'clock position and lined up with the mark in

the coupling lower clamp.

3.

If gear has been moved off high point when setting

wheels in straight ahead position, loosen adjusting

sleeve clamps on both left and right hand tie rods,

then turn both sleeves an equal number of turns in

the same direction to bring gear back on high point.

CAUTION: Turning the sleeves an unequal

number of turns or in differential directions will

disturb the toe-in setting of the wheels.

4.

Readjust toe-in as outlined in Section 3 (if necessary).

5. With wheels in a straight ahead position and the

steering gear on highpoint, check the steering wheel

alignment by measuring the distance from each hori-

zontal spoke to the horizontal centerline of the

steering wheel (fig. 5). If the horizontal spokes are

over 1-1/8 inches from the horizontal position the

wheel should be removed and centered. (See steering

wheel removal in this section.)

TOE-IN ADJUSTMENT

Adjust the steering linkage for proper toe-in setting as

outlined in Section 3.

CORVETTE STEERING RATIO (Fig. 6)

The Corvette steering ratio may be changed as follows:

CAUTION: Do not use the rearward hole in the

steering arm with power steering equipment or

interference may result.

1.

Remove tie rod ball stud nut at steering arm and

disconnect tie rod from steering arm.

2.

Move tie rod end to forward hole for 17.6:1 ratio

(fast ratio) or rear hole for 20.2:1 ratio (standard

ratio).

3.

Install tie rod stud nut and tighten securely. Repeat

operation on opposite steering arm.

COMPONENT REPLACEMENT AND REPAIRS

STEERING WHEEL

REGULAR PRODUCTION (Fig. 7)

Removal

1.

Disconnect steering column harness from chassis

wiring harness at connector (fig. 8).

2.

Pull out horn button cap or center ornament and

retainer.

3.

Remove three screws from the receiving cup.

4.

Remove the receiving cup, belleville spring, bushing,

and pivot ring.

5. Remove the steering wheel nut and washer.

6. Using Tool J-2927, install centering adapter on

steering shaft, thread puller anchor screws into

threaded holes provided in steering wheel. Turn

center bolt of tool clockwise to remove steering

wheel (fig. 9).

Installation

CAUTION: Direction signal control assembly

must be in "neutral position when assembling

steering wheel to prevent damage to cancelling

cam and control assembly.

1.

With directional cancelling cam and horn contact as-

sembly in place, set wheel onto steering shaft.

Fig. 7—-Regular Wheel and Horn Attachments

CHEVROLET CHASSIS SERVICE MANUAL

Page 469 of 659

STEERING 9-29

column mounting bracket, and place bracket in cor-

rect position on underside of instrument panel.

Loosely install bracket using bracket to column

mounting screws and bracket to instrument panel

washers and bolts.

NOTE: Steering shaft to gear clamp must be

tightened before column attaching bolts are

torqued. Refer to "Steering Gear-Chevy n",

installation procedure, for correct Chevy II

steering column alignment procedure.

5.

Camaro only (fig. 60):

Lay wedge shim in position on instrument panel

column mounting bracket and place bracket in cor-

rect position on underside of instrument panel.

Loosely install bracket using bracket to column

mounting screws, nuts, and washer and bolt as shown

in Figure 60.

6. Corvette only (fig. 61):

Loosely secure column mounting bracket to sup-

port plate and instrument panel with washers and

bolts.

7.

Secure flanged end of column to steering coupling

with lockwashers and nuts. On Chevy n, connect col-

umn to steering gear with clamp, clamp bolt, and

nut. On Corvette, slide steering shaft flange into

lower coupling

half,

and install upper clamp bolt

loosely; also secure support, seal and clamp loosely

at dash on engine side.

8. Tighten instrument panel mounting bracket bolts and

nuts.

Refer to torque specifications at rear of manual

for correct torque values.

9. Chevrolet only (fig. 15):

Place upper and lower mast jacket covers in po-

sition and secure covers together and to instrument

panel using nuts and screws as shown in Figure 15.

10.

Chevy H only (fig. 18):

Place lower mast jacket cover in position under

mast jacket and secure to upper cover with screws.

11.

CheveUe only (fig. 15):

Place mast jacket trim cover in position over col-

Fig.

61—Instrument Panel Mounting Bracket and

Support Plqte—Corvette

umn on underside of instrument panel and secure

with screws.

12.

Corvette only (fig. 14):

Slide escutcheon into position at instrument panel

and secure with screws. Place upper end lower

covers in position and secure with screws.

13.

On Chevrolet and CheveUe models with column

mounted powerglide controls, secure transmission

shift indicator pointer into position with set screw

(fig. 15). ,

14.

Chevrolet only (fig. 19):

a. Secure seal and cover to dash panel with screws.

b.

Place clamp assembly in position and install

clamp screw.

c. Install dash panel trim cover with mounting

screws.

15.

Chevelle only (fig. 20):

a. Secure seal and inner and outer covers to dash

panel with screws.

b.

Secure inner and outer covers together with

screws.

c. Install trim cover to dash panel with two

retainers.

16.

Chevy H only (fig. 21):

a. Secure seal, retainer, and clamp to dash panel

with screws.

b.

Install clamp screw.

c. Slide collar into position. Pinch and staple upper

tabs together.

17.

Camaro only (fig. 22):

a. Secure seal, upper cover, and lower cover to

dash panel with screws.

b.

Secure upper and lower cover together with

screws.

c. Fold rubber boot over securely against dash panel

to conceal covers.

18.

Corvette only (fig. 23):

a. Secure seal and support assembly to dash panel

on engine compartment side.

b.

Tighten clamp, washer, and clamp bolt on engine

compartment side.

19.

Connect transmission linkage to lower shift tube

levers in engine compartment, if column is so

equipped. Adjust levers as outlined in Section 7.

20.

Install steering wheel as outlined in this section.

21.

Connect directional signal, horn, back-up lamp, and

neutral start switch at wiring harness plugs. Adjust

back-up lamp, neutral start switch as outlined in

Section 12.

22.

Adjust steering gear and align and center steering

wheel as outlined in this section.

STEERING LINKAGE (Fig. 62)

TIE RODS

There are two tie rod assemblies used on all models.

Each assembly is of three piece construction, consisting

of a sleeve and two tie rod ends. The ends are threaded

into the sleeve and locked with clamps. Right and left

hand threads are provided to facilitate toe-in adjustment

and steering gear centering.

The tie rod ends are self-adjusting for wear and re-

quire no attention in service other than periodic lubrica-

tion and occasional inspection to see that ball studs are

tight. Replacement of tie rod ends should be made when

CHEVROLET CHASSIS SERVICE MANUAL

Page 471 of 659

STEERING 9-31

Fig.

63—Freeing Ball Stud

rod threads with EP Chassis lube and install ends on

tie rod making sure both ends are threaded ah equal

distance from the tie rod.

2.

Make sure that threads on ball stud and in ball stud

nuts are perfectly clean and smooth. Install neoprene

seals on ball studs.

NOTE: If threads are not clean and smooth,

ball studs may turn in tie rod ends when at-

tempting to tighten nut.

3.

Install ball studs in steering arms and relay rod.

4.

Install ball stud nut, and install cotter pins. Lubri-

cate tie rod ends.

5.

Adjust toe-in as described in Section 3.

NOTE: Before locking clamp bolts on the rods,

make sure that the tie rod ends are in alignment

with their ball studs (each ball joint is in the

center of its travel). If the tie rod is not in

alignment with the studs, binding will result.

RELAY ROD-ALL MODELS EXCEPT CORVETTE

Removal

1.

Remove inner ends of tie rods from relay rod as

described under Tie Rod - Removal.

2.

Remove cotter pin and nut from relay rod ball stud

attachment at pitman arm.

3.

Detach relay rod from pitman arm. Shift steering

linkage as required to free pitman arm from relay

rod.

4.

Remove cotter pin and nut from idler arm and re-

move relay rod from idler arm.

Installation

1.

Install relay rod to idler arm, making certain idler

stud seal is in place, then install and tighten nut.

Advance nut just enough to align castellation with

cotter pin hole and install pin.

2.

Raise end of rod and install on pitman arm. Secure

with nut and cotter pin.

3.

Install tie rod ends to relay rod as previously

described under Tie Rods. Lubricate tie rod ends.

4.

Adjust toe-in (see Section 3) and align steering wheel

as described previously in this section under Steer-

ing Wheel Alignment and High Point Centering.

RELAY ROD-CORVETTE

Removal

1.

Remove steering damper from relay rod as outlined

under Steering Damper-Removal. Remove anchor

bracket from relay rod by disconnecting two mount-

ing bolts.

2.

Remove inner ends of tie rods from relay rod as

described under Tie Rod--Removal.

3.

Remove cotter pin from end of relay rod at pitman

arm ball stud attachment, and remove stud nut.

4.

Tap brJl stud out of pitman arm and lower relay rod.

5.

Remove cotter key and nut from idler arm and re-

move relay rod from idler arm. Remove washer and

seal from idler arm.

Installation

1.

Place relay rod on idler arm stud, making certain

idler stud seal and washer are in place, then install

and tighten nut. Advance nut just enough to align

castellation with cotter pin hole and install pin.

2.

Install new seal and clamp over ball at end of pitman

arm.

3.

Install inner spring seat and spring to relay rod.

4.

Raise end of rod and install on pitman arm.

5.

Install spring seat, spring, and end plug.

6. Tighten end plug until springs are compressed and

plug bottoms, then back off 3/4 turn plug amount

necessary to insert cotter pin. Insert cotter pin to

lock adjustment.

7.

Install tie rod ends to relay rod as previously de-

scribed under Tie Rods.

8. Lubricate tie rod ends and pitman arm to relay rod

ball joint.

9. Install steering damper bracket and tighten bolts.

Install damper as outlined under Steering Damper--

Installation.

10.

Adjust toe-in and align steering wheel as described

previously in this section.

IDLER ARM

Chevrolet, Chevelle, Comoro, and Corvette (Fig. 62)

Removal

1.

Remove idler arm to frame nut, washer, and bolt.

No washer is used on Corvette.

2.

Remove cotter pin and nut from idler arm to relay

rod ball stud.

3.

Remove relay rod from idler arm by tapping relay

rod with a hammer using a heavy hammer as a

backing.

4.

Remove idler arm.

Installation

1.

On Chevrolet, place seal in position on idler arm

stud; position stud up through frame, and secure with

lock washer and nut.

2.

On Chevelle, Camaro, and Corvette, position idler

CHEVROLET CHASSIS SERVICE MANUAL