ECO mode CHEVROLET CAMARO 1967 1.G Chassis Owner's Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1967, Model line: CAMARO, Model: CHEVROLET CAMARO 1967 1.GPages: 659, PDF Size: 114.24 MB

Page 513 of 659

SECTION 12

ELECTRICAL-BODY AND CHASSIS

CONTENTS

OF

THIS

SECTION

Page

Page

System 12-1

Instruments and Gauges 12-21

Directional Signal 12r40

Windshield Wipers and Washers 12-44

Wiring Diagrams 12-56

Special Tools 12-60

LIGHTING SYSTEM

INDEX

Page

General Description

!2-i

Maintenance and Adjustments

•.................. 12-2

Headlamp Adjustment......................

12-3

Headlamp Panel Travel Adjustment.

12-5

Service Operations.

. . .. 12-5

Front Lighting

12-5

Headlamp

. 12_5

Parking Lamp

12-5

Fender Lamp

. 12_^

Headlamp Panel

12-8

Headlamp Panel Motor

^2-9

Rear Lighting

l2-10

Tail, Stop and Directional Lamps

12-10

Page

Backing Lamps

12-14

License Plate Lamp

12-14

Automatic Transmission Quadrant Lamp

12-14

Seat Separator Console Lamps

. 12-15

Lighting Switch

. . 12-15

Wiper Switch.

12-15

Stoplight Switch

12-15

Dimmer Switch

12-15

Backing Lamp Switches

12-15

Neutral Safety Switches

12-17

Parking Brake Alarm Switch

................. 12-19

Instrument Panel Compartment Lamp/Switch

12-19

Cirgarette Lighter

12-19

GENERAL DESCRIPTION

.

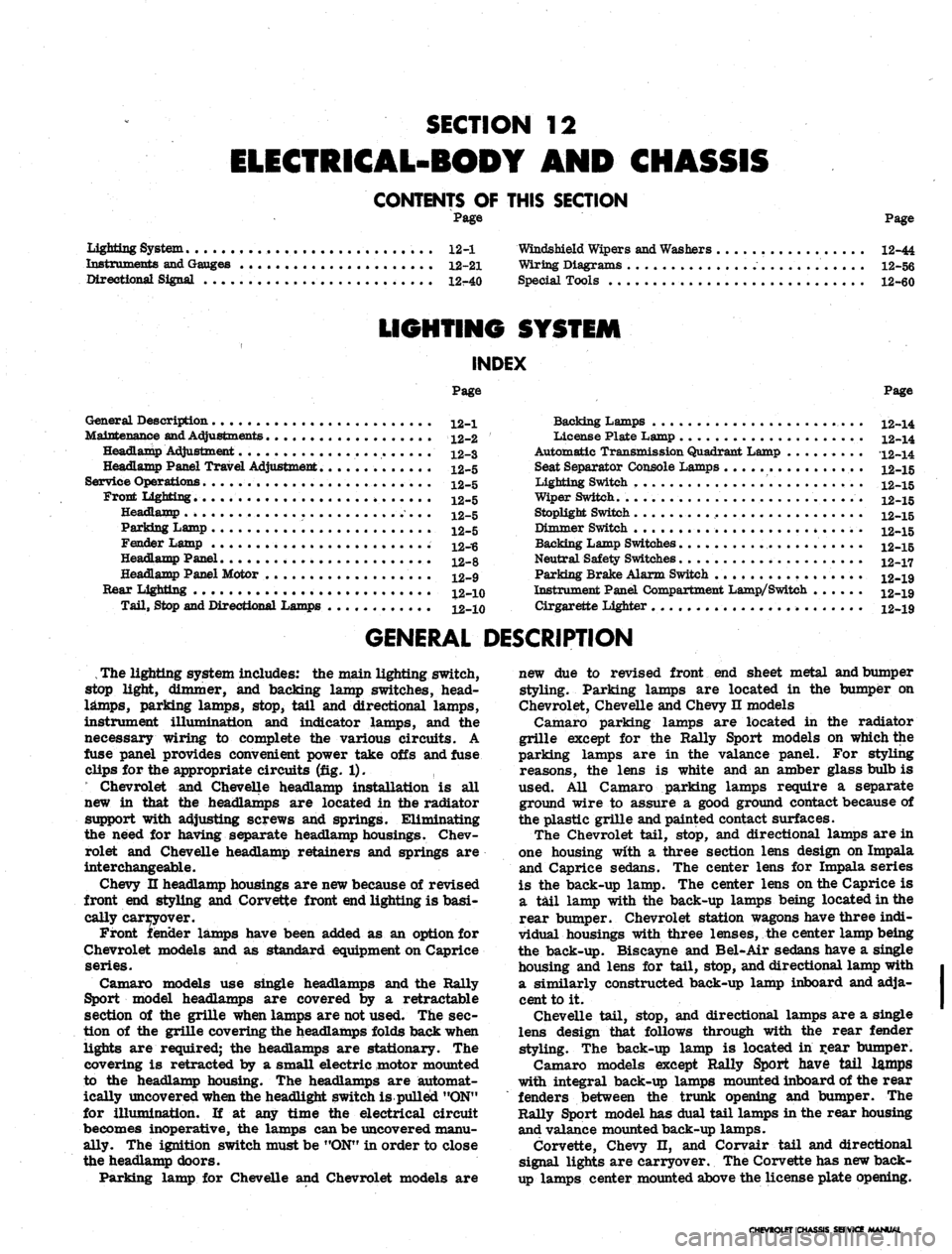

The lighting system includes: the main lighting switch,

stop light, dimmer, and backing lamp switches, head-

lamps, parking lamps, stop, tail and directional lamps,

instrument illumination and indicator lamps, and the

necessary wiring to complete the various circuits. A

fuse panel provides convenient power take offs and fuse

clips for the appropriate circuits (fig. 1).

Chevrolet and Chevelle headlamp installation is all

new in that the headlamps are located in the radiator

support with adjusting screws and springs. Eliminating

the need for having separate headlamp housings. Chev-

rolet and Chevelle headlamp retainers and springs are

interchangeable.

Chevy n headlamp housings are new because of revised

front end styling and Corvette front end lighting is basi-

cally carryover.

Front fender lamps have been added as an option for

Chevrolet models and as standard equipment on Caprice

series.

Camaro models use single headlamps and the Rally

Sport model headlamps are covered by a retractable

section of the grille when lamps are not used. The sec-

tion of the grille covering the headlamps folds back when

lights are required; the headlamps are stationary. The

covering is retracted by a small electric motor mounted

to the headlamp housing. The headlamps are automat-

ically uncovered when the headlight switch is pulled "ON"

for illumination. If at any time the electrical circuit

becomes inoperative, the lamps can be uncovered manu-

ally. The ignition switch must be

"ON"

in order to close

the headlamp doors.

Parking lamp for Chevelle and Chevrolet models are

new due to revised front end sheet metal and bumper

styling. Parking lamps are located in the bumper on

Chevrolet, Chevelle and Chevy n models

Camaro parking lamps are located in the radiator

grille except for the Rally Sport models on which the

parking lamps are in the valance panel. For styling

reasons, the lens is white and an amber glass bulb is

used. All Camaro parking lamps require a separate

ground wire to assure a good ground contact because of

the plastic grille and painted contact surfaces.

The Chevrolet tail, stop, and directional lamps are in

one housing with a three section lens design on Impala

and Caprice sedans. The center lens for Impala series

is the back-up lamp. The center lens on the Caprice is

a tail lamp with the back-up lamps being located in the

rear bumper. Chevrolet station wagons have three indi-

vidual housings with three lenses, the center lamp being

the back-up. Biscayne and Bel-Air sedans have a single

housing and lens for tail, stop, and directional lamp with

a similarly constructed back-up lamp inboard and adja-

cent to it.

Chevelle tail, stop, and directional lamps are a single

lens design that follows through with the rear fender

styling. The back-up lamp is located in r.ear bumper.

Camaro models except Rally Sport have tail lamps

with integral back-up lamps mounted inboard of the rear

fenders between the trunk opening and bumper. The

Rally Sport model has dual tail lamps in the rear housing

and valance mounted back-up lamps.

Corvette, Chevy n, and Corvair tail and directional

signal lights are carryover. The Corvette has new back-

up lamps center mounted above the license plate opening.

CHEVROLET CHASSIS SERVICE

Page 514 of 659

ELECTRICAL-BODY AND CHASSIS 12-2

FJg.

1 - Fuse Panel Assembly

All power window and tailgate circuits require the igni-

tion switch to be "ON" to open or close the windows un-

like past model designs which were operated independ-

ently of the ignition switch.

The windshield wiper and washer switch is new in that

washer button in the center of the knob has been deleted

and its function will be accomplished by pushing the knob.

A set screw is used to retain the knob to the shaft.

In addition to fuses, the wiring harness incorporates

fusible links to protect the wiring. Links are used rather

than a fuse in wiring circuits that are not normally fused,

such as the ignition circuit. Fusible links in the Chevro-

let wiring are four gauge sizes smaller than the cable it

is designed to protect. The links are marked on the

insulation with wire gauge size because of the heavy insu-

lation which makes the link appear a heavier gauge than it

actually is.

Engine compartment wiring harness incorporate sev-

eral fusible links. Each link is identified with its gauge

size.

A fusible link is a length of special wire (normally

four wire gauges smaller than the circuit it is protecting)

used in wiring circuits that are not normally fused, such

as the ignition circuit. The same size wire with a spe-

cial hypalon insulation must be used when replacing a

fusible link.

The links are:

1.

The pigtail lead at the battery positive cable (except

Corvette) is a 14 gauge, brown fusible link protecting

the 10 gange battery charging circuit. This wire is

an integral part of the battery cable assembly and

servicing requires replacing the complete battery

cable assembly. On Corvette models this link is

installed as a molded splice at the solenoid "Bat"

terminal and servicing requires splicing in a new

link.

2.

A 16 gauge black fusible link is located at horn relay

to protect all unfused wiring of 12 gauge or larger.

It is a serviceable piece with an in-line connector

and is not integral with the wiring harness.

3.

The generator warning light and field circuitry (16

gauge wire) is protected by a fusible link (20 gauge

orange wire) used in the "battery feed to voltage

regulator #3 terminal" wire. The link is installed

as a molded splice in the generator and forward lamp

harness and is serviced by splicing in a new 20 gauge

wire as required.

4.

The ammeter circuit on all models is protected by

two orange, 20 gauge wire fusible links installed as

molded splices in the circuit at the junction block or

the solenoid "Bat" terminal (Corvette only) and at the

horn relay. Each link is serviced by splicing in a

new 20 gauge wire as required.

The wiring harnesses use a standarized. color code

common to all Chevrolet vehicles. Under the color code,

the color of the wire designates a particular circuit. The

harness title indicates the type of harness, single of mul-

tiple wire, and also describe the location of the harness.

The body harness is a flat, solid wire assembly and is

routed through the vehicle near the center of the body.

Composite wiring diagrams (figs. 104 thru 124) are in-

cluded at the end of this section.

MAINTENANCE AND ADJUSTMENTS

Maintenance of the lighting units and wiring system

consists of an occasional check to see that all wiring

connections are tight and clean, that the lighting units are

tightly mounted to provide good ground and that the head-

lamps are properly adjusted. Loose or corroded con-

nections may cause a discharged battery, difficult start-

ing, dim lights, and possible damage to generator and

regulator. Wire harnesses must be replaced if insulation

becomes burned, cracked, or deteriorated. Whenever it

is necessary to splice a wire or repair one that is bro-

ken, always use solder to bond the splice. Always use

rosin flux solder on electrical connections. Use insulat-

ing tape to cover all splices or bare wires.

When replacing wires, it is important that the correct

size be used. Never replace a wire with one of a smaller

size.

Each harness and wire must be held securely in place

by clips or other holding devices to prevent chafing or

CHEVROLET CHASSIS SERVICE MANUAL

Page 515 of 659

ELECTRICAL-BODY AND CHASSIS 12-3

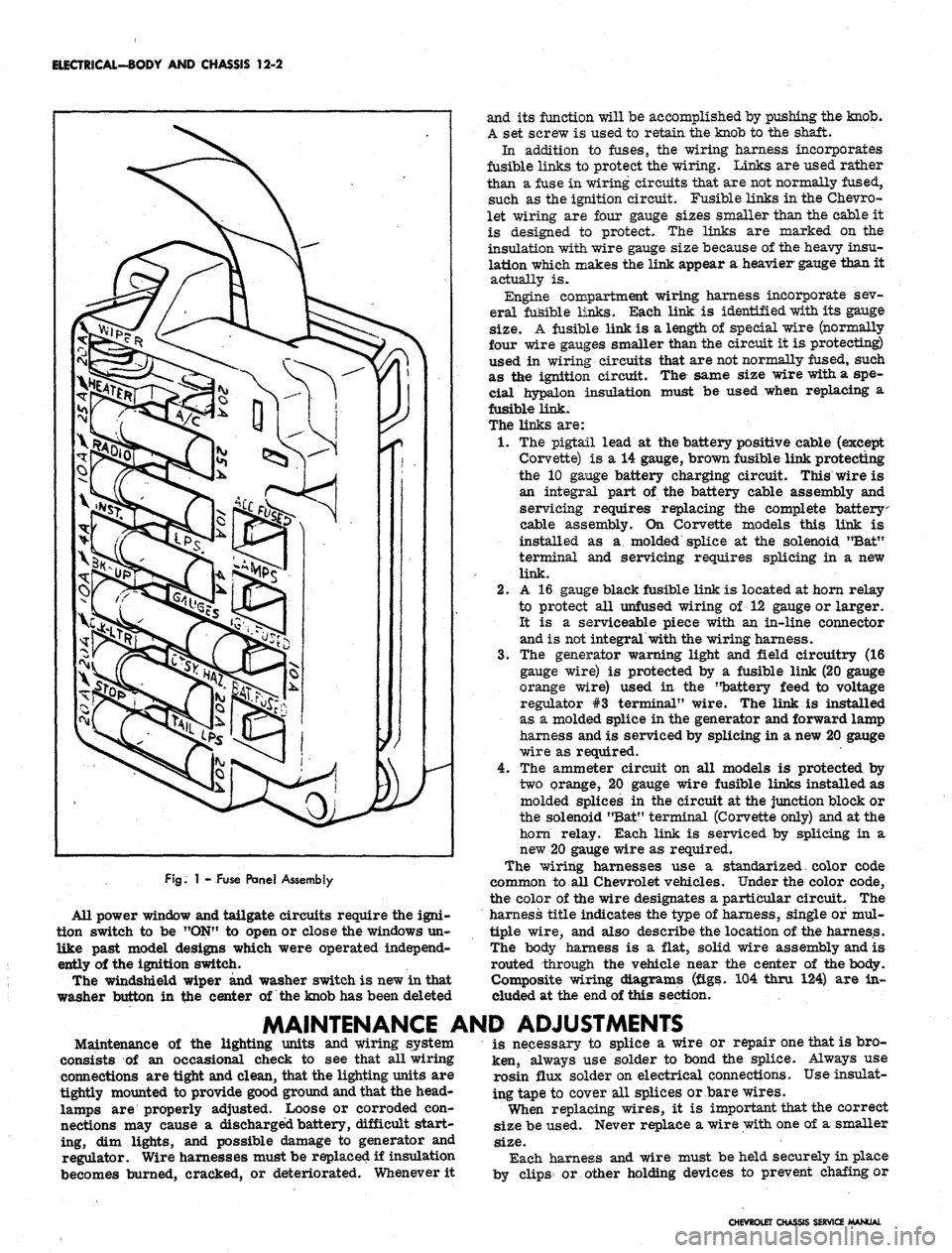

Fig.

2 - T-3 Safety Aimer

wearing away the insulation due to vibration.

By referring to the wiring diagrams, circuits may be

tested for continuous circuit or shorts with a conventional

test lamp or low reading volt meter.

HEADLAMP ADJUSTMENT-

T-3 HEADLAMPS

CAUTION: Check and tighten radiator support

grille retaining bolts prior to attempting head-

lamp aiming. Distorted grille or supports in

this area will hinder proper aiming of head-

lamps. On Corvette models make sure head-

lamp panel is adjusted properly - refer to

"Headlamp Panel Travel Adjustment".

When aiming headlamps, vehicle should be filled to ca-

pacity with gas, oil, and water but no load. Tires should

be uniformly inflated to recommended pressure.

the T-3 Safety Aimer-Type B (fig. 2), is used for the

headlamp aiming description that follows. An adapter is

required with the Type B T-3 Aimer when adjusting the 7

inch headlamp used on the Chevy n vehicle.

1.

Drive vehicle onto selected aiming area. Bounce

vehicle several times and allow to settle.

2.

Remove headlamp bezels.

3.

Mount the T-3 Aimers on either the No. 1 or No. 2

pair of headlamps so that "the points of the headlamps

engage the smooth inner ring of the aimers.

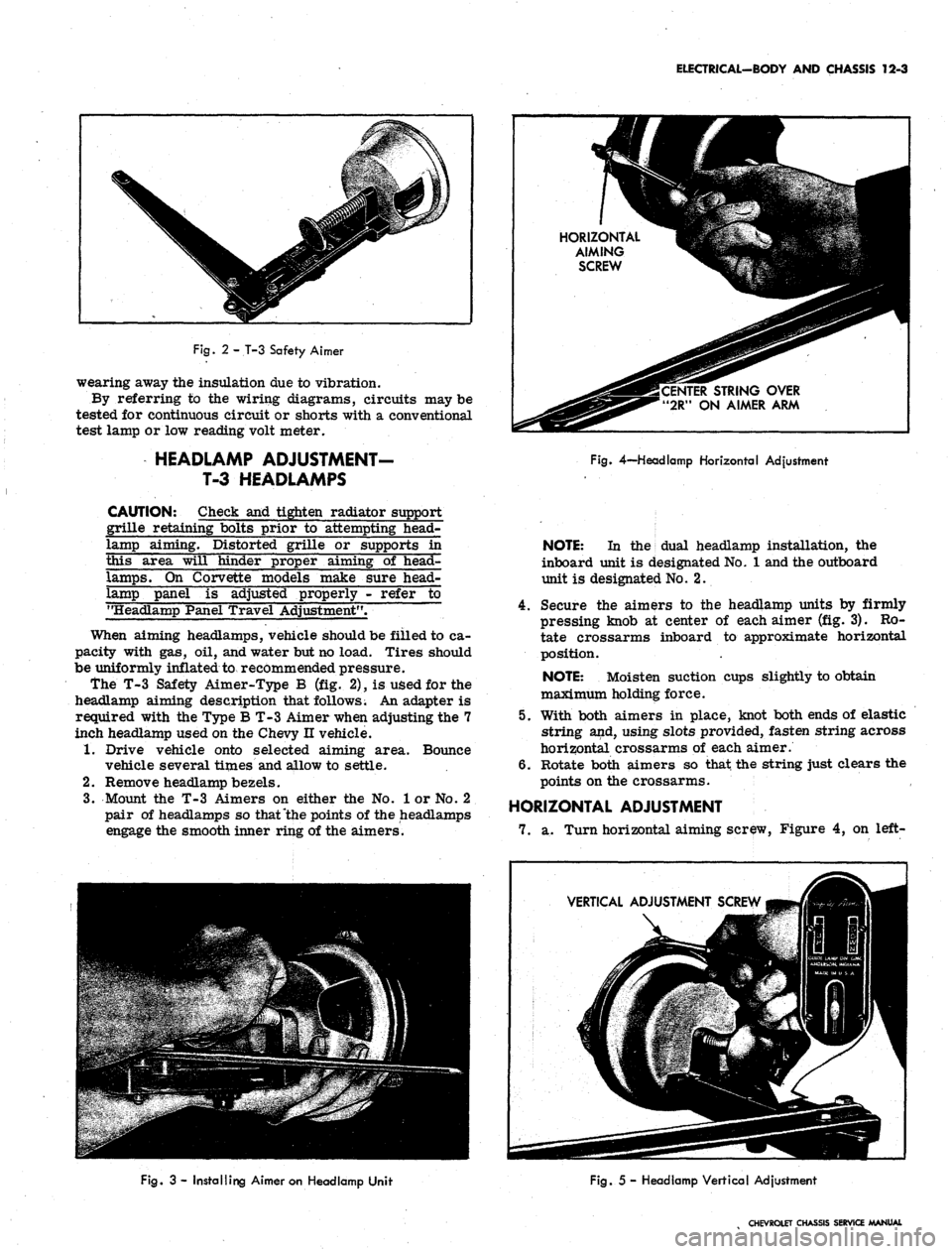

HORIZONTAL

AIMING

SCREW

STRING OVER

"2R" ON AIMER ARM

Fig.

4—-Headlamp Horizontal Adjustment

NOTE:

In the dual headlamp installation, the

inboard unit is designated No. 1 and the outboard

unit is designated No. 2.

4.

Secure the aimers to the headlamp units by firmly

pressing knob at center of each aimer (fig. 3). Ro-

tate crossarms inboard to approximate horizontal

position.

NOTE:

Moisten suction cups slightly to obtain

maximum holding force.

5. With both aimers in place, knot both ends of elastic

string and, using slots provided, fasten string across

horizontal crossarms of each aimer.

6. Rotate both aimers so that the string just clears the

points on the crossarms.

HORIZONTAL ADJUSTMENT

7. a. Turn horizontal aiming screw, Figure 4, on left-

VERTICAL ADJUSTMENT SCREW

Fig.

3 - Installing Aimer on Headlamp Unit

Fig.

5 - Headlamp Vertical Adjustment

CHEVROLET CHASSIS SERVICE MANUAL

Page 533 of 659

ELECTRICAL-BODY AND CHASSIS 12-21

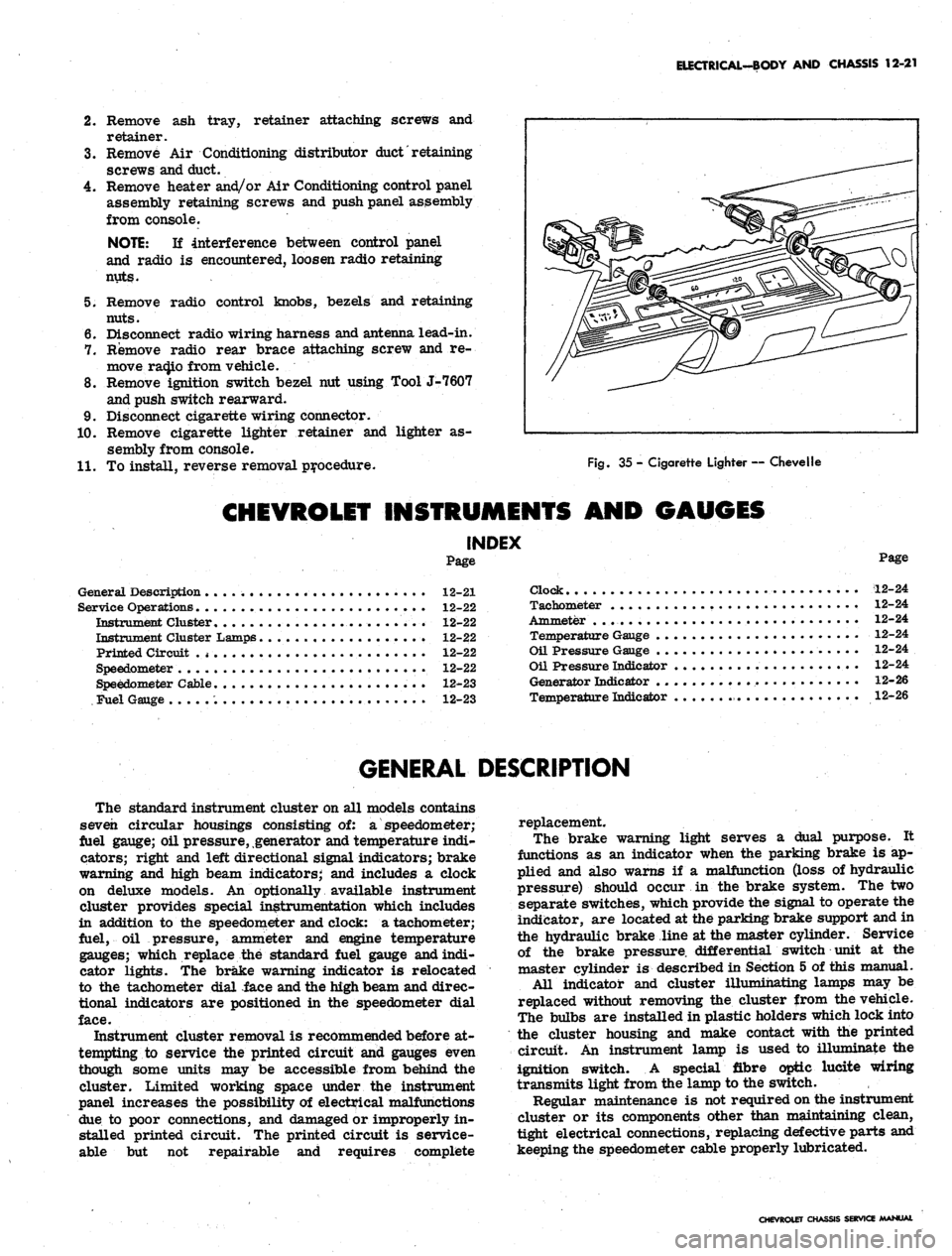

2.

Remove ash tray, retainer attaching screws and

retainer.

3.

Remove Air Conditioning distributor

duct'

retaining

screws and duct.

4.

Remove heater and/or Air Conditioning control panel

assembly retaining screws and push panel assembly

from console.

NOTE:

If interference between control panel

and radio is encountered, loosen radio retaining

nuts.

5. Remove radio control knobs, bezels and retaining

nuts.

6. Disconnect radio wiring harness and antenna lead-in.

7. Remove radio rear brace attaching screw and re-

move ra(Jio from vehicle.

8. Remove ignition switch bezel nut using Tool J-7607

and push switch rearward.

9. Disconnect cigarette wiring connector.

10.

Remove cigarette lighter retainer and lighter as-

sembly from console.

11.

To install, reverse removal procedure.

Fig.

35 - Cigarette Lighter — Chevelle

CHEVROLET INSTRUMENTS AND GAUGES

INDEX

Page

General Description 12-21

Service Operations 12-22

Instrument Cluster........................ 12-22

Instrument Cluster Lamps 12-22

Printed Circuit .

* •

12-22

Speedometer 12-22

Speedometer Cable 12-23

Fuel Gauge 12-23

Page

Clock 12-24

Tachometer 12-24

Ammeter . . 12-24

Temperature Gauge 12-24

Oil Pressure Gauge 12-24

Oil Pressure Indicator 12-24

Generator Indicator 12-26

Temperature Indicator 12-26

GENERAL DESCRIPTION

The standard instrument cluster on all models contains

seven circular housings consisting of: a speedometer;

fuel gauge; oil pressure, generator and temperature indi-

cators; right and left directional signal indicators; brake

warning and high beam indicators; and includes a clock

on deluxe models. An optionally available instrument

cluster provides special instrumentation which includes

in addition to the speedometer and clock: a tachometer;

fuel, oil pressure, ammeter and engine temperature

gauges; which replace the standard fuel gauge and indi-

cator lights. The brake warning indicator is relocated

to the tachometer dial face and the high beam and direc-

tional indicators are positioned in the speedometer dial

face.

Instrument cluster removal is recommended before at-

tempting to service the printed circuit and gauges even

though some units may be accessible from behind the

cluster. Limited working space under the instrument

panel increases the possibility of electrical malfunctions

due to poor connections, and damaged or improperly in-

stalled printed circuit. The printed circuit is service-

able but not repairable and requires complete

replacement.

The brake warning light serves a dual purpose. It

functions as an indicator when the parking brake is ap-

plied and also warns if a malfunction (loss of hydraulic

pressure) should occur in the brake system. The two

separate switches, which provide the signal to operate the

indicator, are located at the parking brake support and in

the hydraulic brake line at the master cylinder. Service

of the brake pressure, differential switch unit at the

master cylinder is described in Section 5 of this manual.

All indicator and cluster illumihating lamps may be

replaced without removing the cluster from the vehicle.

The bulbs are installed in plastic holders which lock into

the cluster housing and make contact with the printed

circuit. An instrument lamp is used to illuminate the

ignition switch. A special fibre optic lucite wiring

transmits light from the lamp to the switch.

Regular maintenance is not required on the instrument

cluster or its components other than maintaining clean,

tight electrical connections, replacing defective parts and

keeping the speedometer cable properly lubricated.

CHEVROLET CHASSIS SERVICE MANUAL

Page 539 of 659

ELECTRICAL-BODY AND CHASSIS 12-27

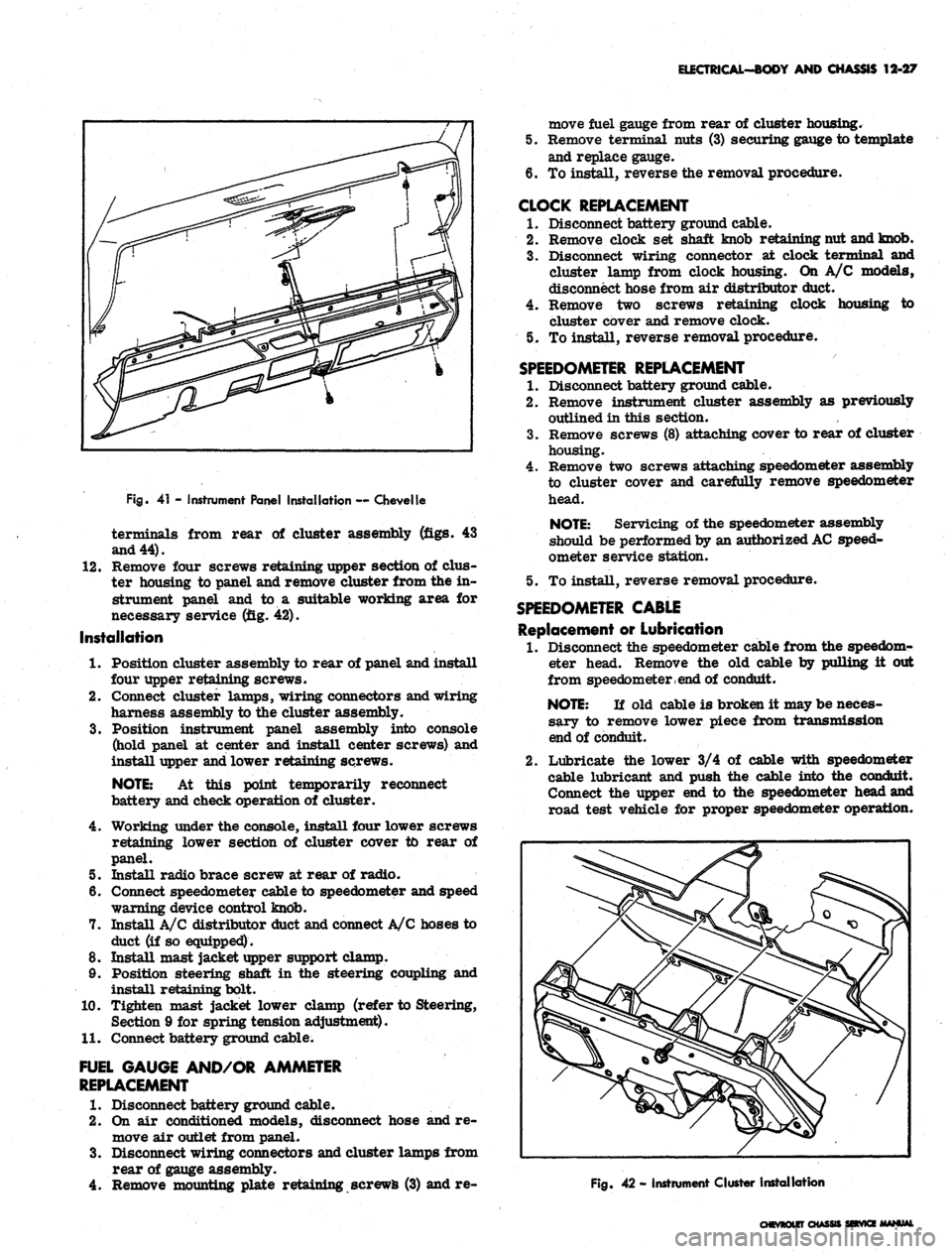

Fig.

41 - Instrument Panel Installation — Chevelle

terminals from rear of cluster assembly (figs. 43

and 44).

12.

Remove four screws retaining upper section of dus-

ter housing to panel and remove cluster from the in-

strument panel and to a suitable working area for

necessary service (fig. 42).

Installation

1.

Position cluster assembly to rear of panel and install

four upper retaining screws.

2.

Connect cluster lamps, wiring connectors and wiring

harness assembly to the cluster assembly.

3.

Position instrument panel assembly into console

(hold panel at center and install center screws) and

install upper and lower retaining screws.

NOTE:

At this point temporarily reconnect

battery and check operation of cluster.

4.

Working under the console, install four lower screws

retaining lower section of cluster cover to rear of

panel.

5. Install radio brace screw at rear of radio.

6. Connect speedometer cable to speedometer and speed

warning device control knob.

7. Install A/C distributor duct and connect A/C hoses to

duct (if so equipped).

8. Install mast jacket upper support clamp.

9. Position steering shaft in the steering coupling and

install retaining bolt.

10.

Tighten mast jacket lower clamp (refer to Steering,

Section 9 for spring tension adjustment).

11.

Connect battery ground cable.

FUEL GAUGE AND/OR AMMETER

REPLACEMENT

1.

Disconnect battery ground cable.

2.

On air conditioned models, disconnect hose and re-

move air outlet from panel.

3.

Disconnect wiring connectors and cluster lamps from

rear of gauge assembly.

4.

Remove mounting plate retaining screws (3) and re-

move fuel gauge from rear of cluster housing.

5. Remove terminal nuts (3) securing gauge to template

and replace gauge.

6. To install, reverse the removal procedure.

CLOCK REPLACEMENT

1.

Disconnect battery ground cable.

2.

Remove clock set shaft knob retaining nut and knob.

3.

Disconnect wiring connector at clock terminal and

cluster lamp from clock housing. On A/C models,

disconnect hose from air distributor duct.

4.

Remove two screws retaining clock housing to

cluster cover and remove clock.

5. To install, reverse removal procedure.

SPEEDOMETER REPLACEMENT

1.

Disconnect battery ground cable.

2.

Remove instrument cluster assembly as previously

outlined in this section.

3.

Remove screws (8) attaching cover to rear of cluster

housing.

4.

Remove two screws attaching speedometer assembly

to cluster cover and carefully remove speedometer

head.

NOTE:

Servicing of the speedometer assembly

should be performed by an authorized

AC

speed-

ometer service station.

5. To install, reverse removal procedure.

SPEEDOMETER CABLE

Replacement or Lubrication

1.

Disconnect the speedometer cable from the speedom-

eter head. Remove the old cable by pulling it out

from speedometer

, end

of conduit.

NOTE:

If old cable is broken it may be neces-

sary to remove lower piece from transmission

end of conduit.

2.

Lubricate the lower 3/4 of cable with speedometer

cable lubricant and push the cable into the conduit.

Connect the upper end to the speedometer head and

road test vehicle for proper speedometer operation.

Fig.

42 - Instrument Cluster Installation

CHEVROLET CHASSIS SEtVKE MANUAL

Page 648 of 659

SPECIFICATIONS

21

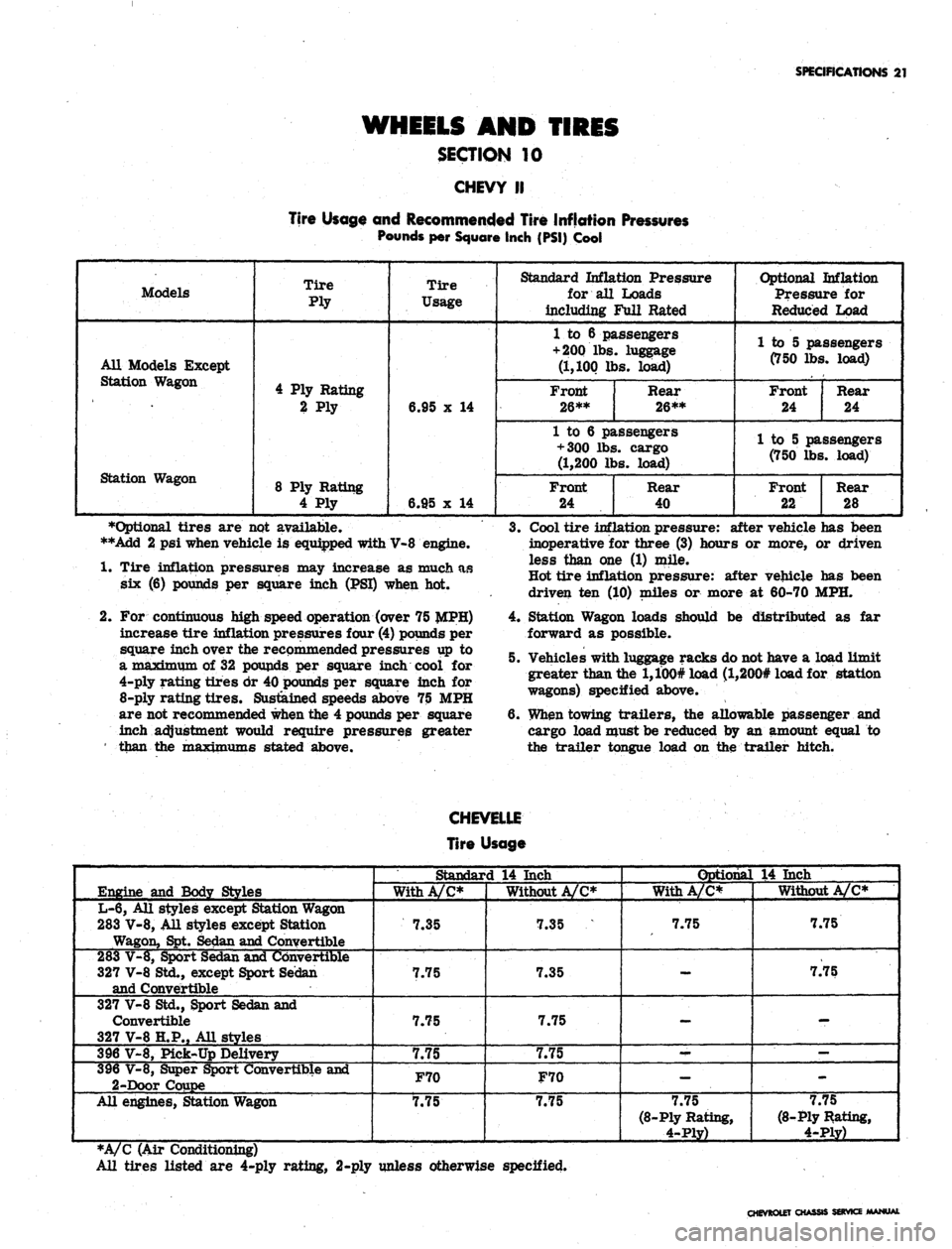

WHEELS AND TIRES

SECTION 10

CHEVY II

Tire Usage and Recommended Tire Inflation Pressures

Pounds per Square Inch (PSI) Cool

Models

All Models Except

Station Wagon

Station Wagon

Tire

Ply

4 Ply Rating

2 Ply

8 Ply Rating

4 Ply

Tire

Usage

6.95 x 14

6.95 x 14

Standard Inflation Pressure

for all Loads

including Full Rated

1 to 6 passengers

+ 200

lbs. luggage

(1,100 lbs. load)

Front

26**

Rear

26**

1 to 6 passengers

+ 300 lbs. cargo

(1,200 lbs. load)

Front

24

Rear

40

Optional Inflation

Pressure for

Reduced Load

1 to 5 passengers

(750 lbs. load)

Front

24

Rear

24

1 to 5 passengers

(750 lbs. load)

Front

22

Rear

28

•Optional tires are not available.

**Add 2 psi when vehicle is equipped with V-8 engine.

1.

Tire inflation pressures may increase as much as

six (6) pounds per square inch (PSI) when hot.

2.

For continuous high speed operation (over 75

increase tire inflation pressures four (4) pounds per

square inch over the recommended pressures up to

a maximum of 32 pounds per square inch cool for

4-ply rating tires dr 40 pounds per square inch for

8-ply

rating tires. Sustained speeds above 75 MPH

are not recommended when the 4 pounds per square

inch adjustment would require pressures greater

' than the TpaxiTP^Tns stated above.

3.

Cool tire inflation pressure: after vehicle has been

inoperative for three (3) hours or more, or driven

less than one (1) mile.

Hot tire inflation pressure: after vehicle has been

driven ten (10) miles or more at 60-70 MPH.

4.

Station Wagon loads should be distributed as far

forward as possible.

5. Vehicles with luggage racks do not have a load limit

greater than the l,100# load (l,200# load for station

wagons) specified above.

6. When towing trailers, the allowable passenger and

cargo load must be reduced by an amount equal to

the trailer tongue load on the trailer hitch.

CHEVELLE

Tire Usage

Engine and Body Styles

L-6, All styles except Station Wagon

283 V-8, All styles except Station

Wagon, Spt. Sedan and Convertible

283 V-8, Sport Sedan and Convertible

327 V-8 Std., except Sport Sedan

and Convertible

327 V-8 Std., Sport Sedan and

Convertible

327 V-8 H.P., All styles

396 V-8, Pick-Up Delivery

396 V-8, Super Sport Convertible and

2-Door Coupe

All engines, Station Wagon

Standard 14 Inch

With A/C*

7.35

7.75

7.75

7.75

F70

7.75

Without A/C*

7.35

7.35

7.75

7.75

F70

7.75

Optional 14 Inch

With A/C*

7.75

—

-

--

-

7.75

(8-Ply Rating,

4-Ply)

Without A/C*

7.75

7.75

-

—

-

7.75

(8-Ply Rating,

4-Ply)

*A/C (Air Conditioning)

All tires listed are 4-ply rating, 2-ply unless otherwise specified.

CHEVROLET CHASSIS SERVICE MANW

Page 649 of 659

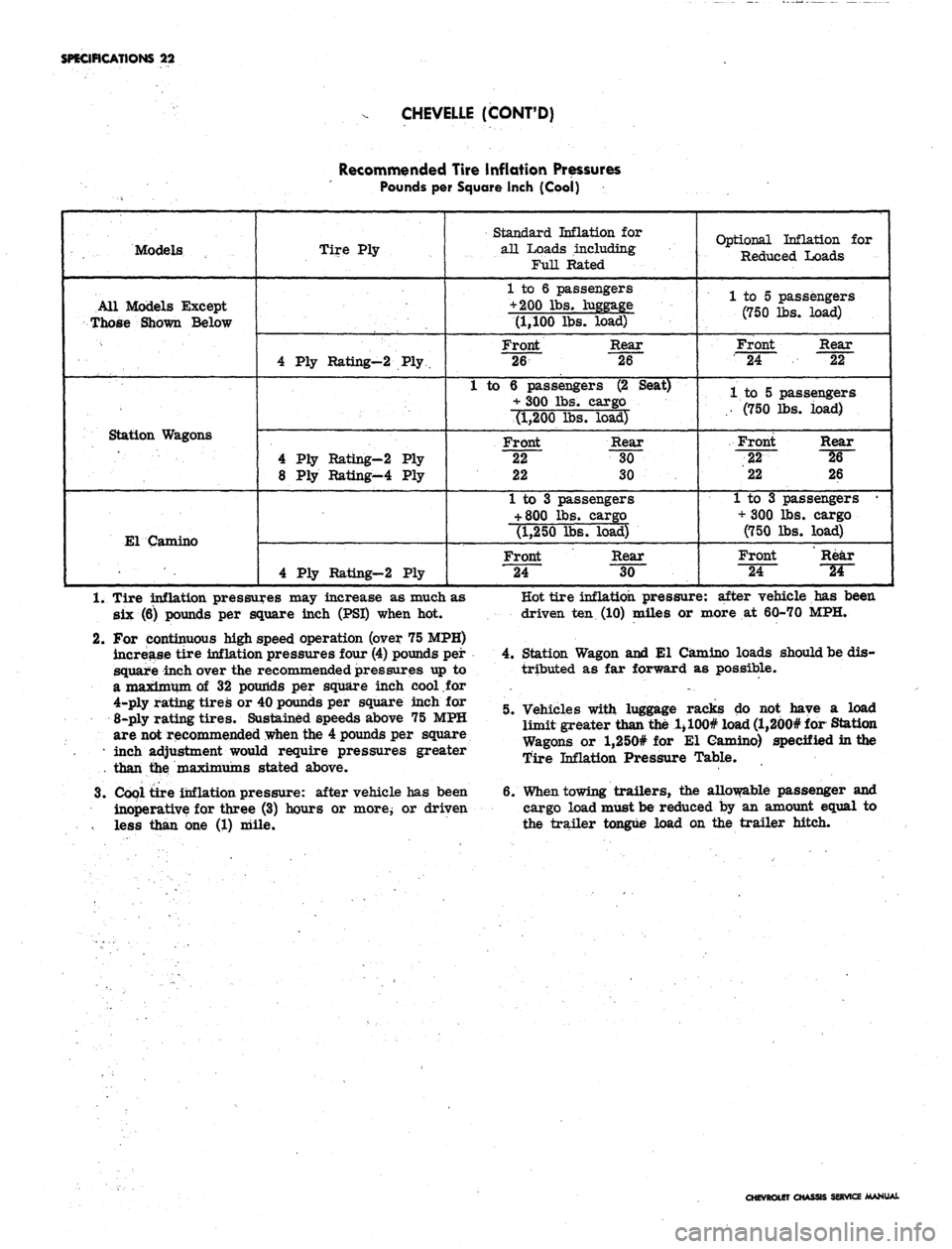

SPECIFICATIONS

22

CHEVELLE (CONT'D)

Recommended Tire inflation Pressures

Pounds per Square Inch (Cool)

Models

All Models Except

Those Shown Below

Station Wagons

El Camino

Tire Ply

4 Ply Rating-2 Ply

4 Ply Rating-2 Ply

8 Ply Rating-4 Ply

4 Ply Rating-2 Ply

Standard Inflation for

all Loads including

FuH Rated

1 to 6 passengers

+ 200 lbs. luggage

(1,100 lbs. load)

Front Rear

26 26

1 to 6 passengers (2 Seat)

+ 300 lbs. cargo

(1,200 lbs. load)

Front Rear

22 30

22 30

1 to 3 passengers

+

800 lbs. cargo

(1,250 lbs. load)

Front Rear

24 30

Optional Inflation for

Reduced Loads

1 to 5 passengers

(750 lbs. load)

Front Rear

24 22

1 to 5 passengers

.. (750 lbs. load)

Front Rear

22 ^6~

22 26

1 to 3 passengers •

+ 300 lbs. cargo

(750 lbs. load)

Front Rear

"24~

~W~

1.

Tire inflation pressures may increase as much as

six (6) pounds per square inch (PSI) when hot.

2.

For continuous high speed operation (over 75 MPH)

increase tire inflation pressures four (4) pounds per

square inch over the recommended pressures up to

a maximum of 32 pounds per square inch cool for

4-ply rating tires or 40 pounds per square inch for

8-ply rating tires. Sustained speeds above 75 MPH

are not recommended when the 4 pounds per square

• inch adjustment would require pressures greater

than the maximums stated above.

3.

Cool tire inflation pressure: after vehicle has been

inoperative for three (3) hours or more; or driven

less than one (1) mile.

Hot tire inflation pressure: after vehicle has been

driven ten (10) miles or more at 60-70 MPH.

4.

Station Wagon and El Camino loads should be dis-

tributed as far forward as possible.

5. Vehicles with luggage racks do not have a load

limit greater than the 1 > 100# load (l,200# for Station

Wagons or l,250# for El Camino) specified in the

Tire Inflation Pressure Table.

6. When towing trailers, the allowable passenger and

cargo load must be reduced by an amount equal to

the trailer tongue load on the trailer hitch.

OLETO

SERVICE MANUAL

Page 650 of 659

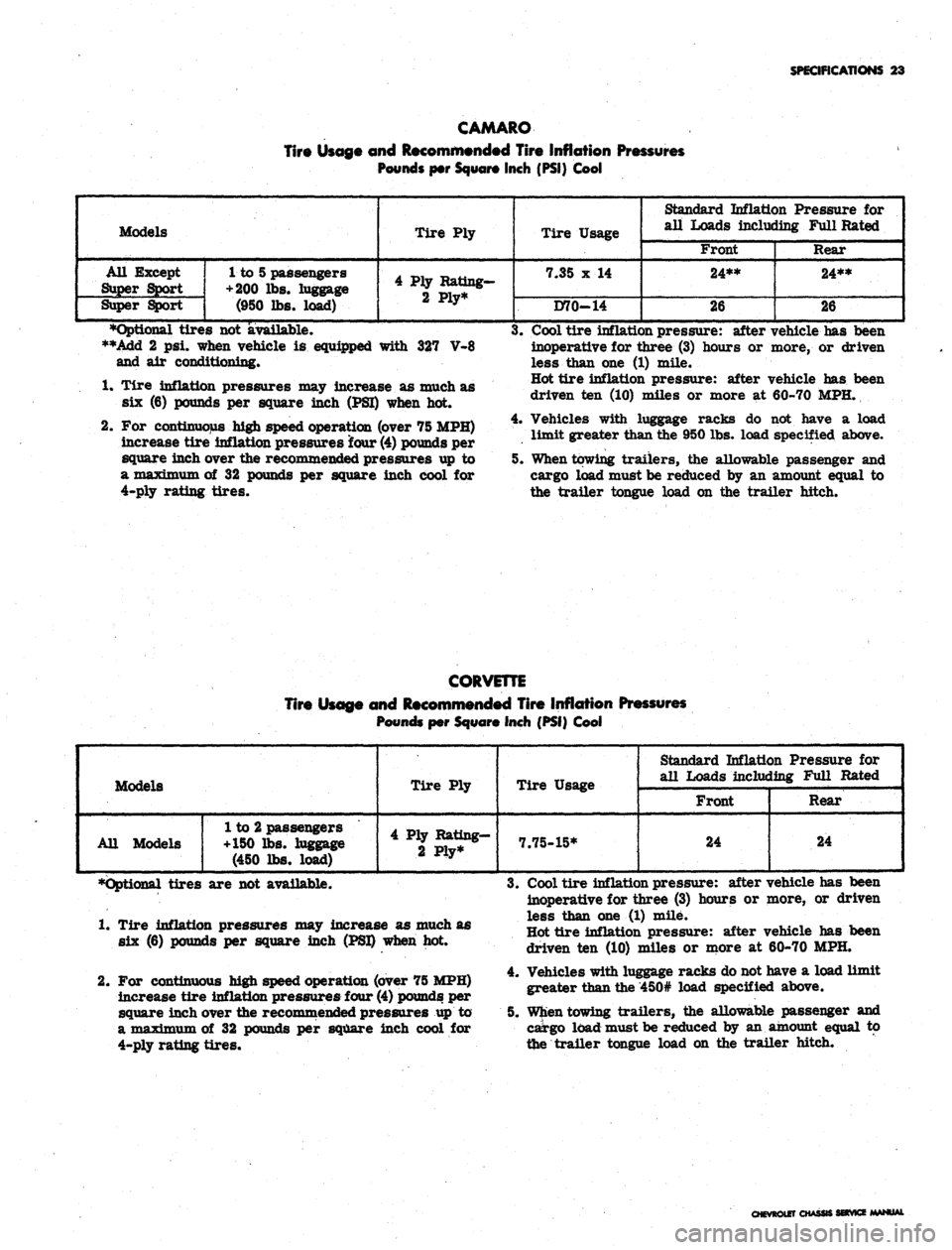

SPECIFICATIONS 23

CAMARO

Tire Usage and Recommended Tire Inflation Pressures

Pounds per Square Inch (PSI) Cool

Models

All Except

Super Sport

Super Sport

1 to 5 passengers

+ 200

lbs. luggage

(950 lbs. load)

Tire Ply

4 Ply Rating-

2 Ply*

Tire Usage

7.35 x 14

D70-14

Standard Inflation Pressure for

all Loads including Full Rated

Front

24**

26

Rear

24**

26

•Optional tires not available.

**Add 2 psi. when vehicle is equipped with 327 V-8

and air conditioning*

1.

Tire inflation pressures may increase as much as

six (6) pounds per square inch (PSI) when hot.

2.

For continuous high speed operation (over 75 MPH)

increase tire inflation pressures four

(4)

pounds per

square inch over the recommended pressures up to

a maximum of 32 pounds per square inch cool for

4-ply rating tires.

3.

Cool tire inflation pressure: after vehicle has been

inoperative for three (3) hours or more, or driven

less than one (1) mile.

Hot tire inflation pressure: after vehicle has been

driven ten (10) miles or more at 60-70 MPH.

4.

Vehicles with luggage racks do not have a load

limit greater than the 950 lbs. load specified above.

5. When towing trailers, the allowable passenger and

cargo load must be reduced by an amount equal to

the trailer tongue load on the trailer hitch.

CORVETTE

Tire Usage and Recommended Tire Inflation Pressures

Pounds per Square Inch (PSI) Cool

Models

All Models

1 to 2 passengers

+150 lbs. luggage

(450 lbs. load)

Tire Ply

4 Ply Rating-

2 Ply*

Tire Usage

7.75-15*

Standard Inflation Pressure for

all Loads including Full Rated

Front

24

Rear

24

•Optional tires are not available.

1.

Tire inflation pressures may increase as much as

six (6) pounds per square inch (PSI) when hot.

2.

For continuous high speed operation (over 75 MPH)

increase tire inflation pressures four

(4)

pounds per

square inch over the recommended pressures up to

a maximum of 32 pounds per square inch cool for

4-ply rating tires.

3.

Cool tire inflation pressure: after vehicle has been

inoperative for three (3) hours or more, or driven

less than one (1) mile.

Hot tire inflation pressure: after vehicle has been

driven ten (10) miles or more at 60-70 MPH.

4.

Vehicles with luggage racks do not have a load limit

greater than the 450# load specified above.

5. When towing trailers, the allowable passenger and

cargo load must be reduced by an amount equal to

the trailer tongue load on the trailer hitch.

CHEVROLET CHASSIS SERVICE MANUAL

Page 651 of 659

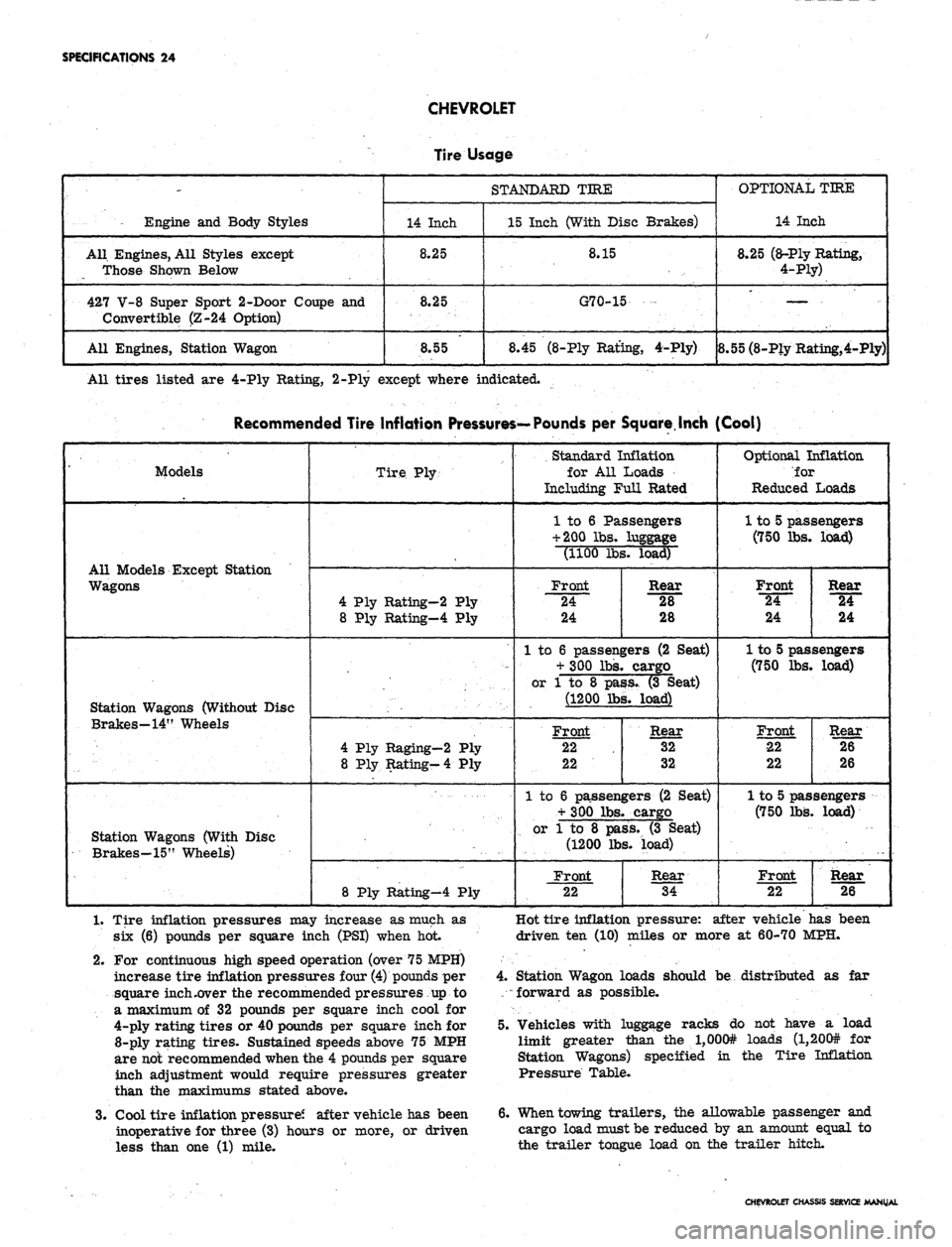

SPECIFICATIONS 24

CHEVROLET

Engine and Body Styles

All. Engines, All Styles except

Those Shown Below

427 V-8 Super Sport 2-Door Coupe and

Convertible (Z-24 Option)

All Engines, Station Wagon

Tire

14 Inch

8.25

8.25

8.55

Usage

STANDARD TIRE

15 Inch (With Disc

8.15

G70-15

8.45 (8-Ply Rating,

Brakes)

4-Ply)

OPTIONAL TIRE

14 Inch

8.25 (a-Ply Rating,

4-Ply)

. —. ...

8.55 (8-Ply Rating,4-Ply)

All tires listed are 4-Ply Rating, 2-Ply except where indicated.

Recommended Tire Inflation Pressures—Pounds per Square.Inch (Cool)

' Models

All Models Except Station

Wagons

Station Wagons (Without Disc

Brakes—14" Wheels

Station Wagons (With Disc

Brakes-15" Wheels)

Tire Ply-

4 Ply Rating-2 Ply

8 Ply Rating-4 Ply

4 Ply Raging—2 Ply

8 Ply Rating-4 Ply

8 Ply Rating-4 Ply

Standard Inflation

for All Loads

Including Full Rated

1 to 6 Passengers

+ 200 lbs. luggage

(1100 lbs. load)

Front

24

24

Rear

28

28

1 to 6 passengers (2 Seat)

+ 300 lbs. cargo

or 1 to 8 pass. (3 Seat)

(1200 lbs. load)

Front

22

22

Rear

32

32

1 to 6 passengers (2 Seat)

+ 300 lbs. cargo

or 1 to 8 pass. (3 Seat)

(1200 lbs. load)

Front

22

Rear

34

Optional Inflation

ior

Reduced Loads

1 to 5 passengers

(750 lbs. load)

Front

"24~

24

Rear

24

24

1 to 5 passengers

(750 lbs. load)

Front

22

22

Rear

26

26

1 to 5 passengers

(750 lbs. load)

Front

22

Rear

26

1.

Tire inflation pressures may increase as much as

six (6) pounds per square inch (PSI) when hot

2.

For continuous high speed operation (over 75 MPH)

increase tire inflation pressures four (4) pounds per

square inch .over the recommended pressures up to

a maximum of 32 pounds per square inch cool for

4-ply rating tires or 40 pounds per square inch for

8-ply rating tires. Sustained speeds above 75 MPH

are not recommended when the 4 pounds per square

inch adjustment would require pressures greater

than the maximums stated above.

3.

Cool tire inflation pressure? after vehicle has been

inoperative for three (3) hours or more, or driven

less than one (1) mile.

Hot tire inflation pressure: after vehicle has been

driven ten (10) miles or more at 60-70 MPH.

4.

Station Wagon loads should be distributed as far

forward as possible.

5. Vehicles with luggage racks do not have a load

limit greater than the l,000# loads (l,200# for

Station Wagons) specified in the Tire Inflation

Pressure Table.

6. When towing trailers, the allowable passenger and

cargo load must be reduced by an amount equal to

the trailer tongue load on the trailer hitch.

CHEVROLET CHASSIS SERVICE MANUAL