battery CHEVROLET CAMARO 1967 1.G Chassis Repair Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1967, Model line: CAMARO, Model: CHEVROLET CAMARO 1967 1.GPages: 659, PDF Size: 114.24 MB

Page 343 of 659

ENGINE-ELECTRICAL 6Y-18

IGNITION SYSTEMS

INDEX

Page

General Description . 6Y-18

Maintenance and Adjustments 6Y-19

Breaker Point System 6Y-19

Breakerless System . . 6Y-X9

Ignition Coil Check 6Y-19

Spark Plugs 6Y-19

Service Operations , 6Y-19

Distributor Contact Points . 6Y-19

Cleaning 6Y-19

Replacement 6Y-20

Setting Dwell Angle 6Y-21

Distributor Condenser 6Y-22

Performance Diagnosis. 6Y-22

Replacement . . 6Y-23

Distributor

Breaker Point Type 6Y-23

Removal. . 6Y-23

Disassembly • 6Y-23

Page

Cleaning and Inspection .....'.., 6Y-25

Assembly . 6Y-25

Installation 6Y-26

Breakerless i 6Y-27

Removal . 6Y-27

Disassembly and Assembly 6Y-27

Installation 6Y-27

Off-Engine Test. . 6Y-27

Coil Replacement 6Y-27

Pulse Amplifier. 6Y-28

Disassembly .6Y-4S8

Component Checks

!

6Y-28

Assembly 6Y-29

Ignition Switch Replacement 6Y-29

Spark Plugs 6Y-30

Cleaning and Regapping I ....... 6Y-30

Installation . 6Y-31

GENERAL DESCRIPTION

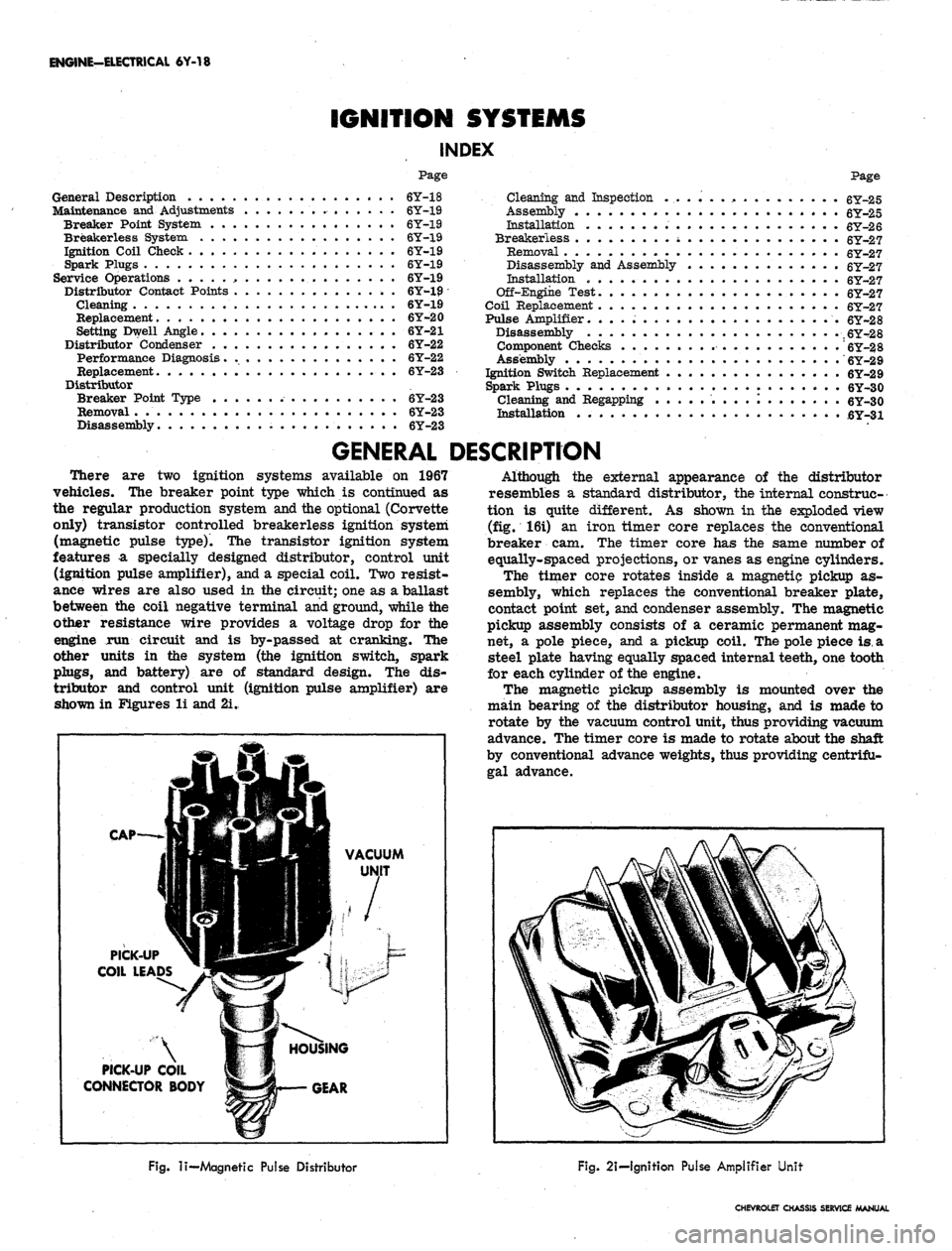

There are two ignition systems available on 1967

vehicles. The breaker point type which is continued as

the regular production system and the optional (Corvette

only) transistor controlled breakerless ignition system

(magnetic pulse type). The transistor ignition system

features a specially designed distributor, control unit

(ignition pulse amplifier), and a special coil. Two resist-

ance wires are also used in the circuit; one as a ballast

between the coil negative terminal and ground, while the

other resistance wire provides a voltage drop for the

engine run circuit and is by-passed at cranking. The

other units in the system (the ignition switch, spark

plugs,

and battery) are of standard design. The dis-

tributor and control unit (ignition pulse amplifier) are

shown in Figures li and 2i.

CAP-

VACUUM

PICK-UP

COIL LEADS

PICK-UP COIL

CONNECTOR BODY

Although the external appearance of the distributor

resembles a standard distributor, the internal construc-

tion is quite different. As shown in the exploded view

(fig. 16i) an iron timer core replaces the conventional

breaker cam. The timer core has the same number of

equally-spaced projections, or vanes as engine cylinders.

The timer core rotates inside a magnetic pickup as-

sembly, which replaces the conventional breaker plate,

contact point set, and condenser assembly. The magnetic

pickup assembly consists of a ceramic permanent mag-

net, a pole piece, and a pickup coil. The pole piece

is.

a

steel plate having equally spaced internal teeth, one tooth

for each cylinder of the engine.

The magnetic pickup assembly is mounted over the

main bearing of the distributor housing, and is made to

rotate by the vacuum control unit, thus providing vacuum

advance. The timer core is made to rotate about the shaft

by conventional advance weights, thus providing centrifu-

gal advance.

Fig.

li—

Magnetic Pulse Distributor

Fig.

2i-lgnition Pulse Amplifier Unit

CHEVROLET CHASSIS SERVICE MANUAL

Page 344 of 659

MAINTENANCE AND ADJUSTMENTS

ENGINE-ELECTRICAL 6Y-19

PERIODIC MAINTENANCE

BREAKER POINT SYSTEM

The distributor breaker points and spark plugs are the

only ignition system components that require periodic

service. The remainder of the ignition system requires

only periodic inspection to check operation of the units,

tightness of the electrical connections, and condition of

the wiring. When checking the coil, test with a reputable

tester.

Breaker type distributors are equipped with cam lubri-

cator and should have the wick replaced at the same time

contact point set is replaced. It is not necessary to

lubricate the breaker cam when using a cam lubricator.

Do not attempt to lubricate the wick - Replace when

necessary. When installing a new wick, adjust its posi-

tion so the end of the wick just touches the lobe of the

breaker cam.

Distributor shaft lubrication is accomplished by a

reservoir of lube around the mainshaft in the distributor

body.

BREAKERLESS SYSTEM

Since there are no moving parts in the ignition pulse

amplifier unit mounted forward of the radiator bulkhead,

and the distributor shaft and bushings have permanent

type lubrication, no periodic maintenance is therefore

required for the breakerless ignition system. The dis-

tributor lower bushing is lubricated by engine oil through

a splash hole in the distributor housing, and a housing

cavity next to the upper bushing contains a supply of

lubricant which will last between overhaul periods. At

time of overhaul, the upper bushing may be lubricated

by removing the plastic seal and then adding SAE 20 oil

to the packing in the cavity. A new plastic seal will be

required since the old one will be damaged during

removal.

Tachometer readings for test purposes can be made on

the primary circuit of the breakerless ignition system in

the same manner as on the conventional ignition system,

however before attempting to connect a test tachometer

into the primary circuit check with your instrument

supplier to insure that satisfactory readings can be

obtained and the breakerless system will not be damaged

by the tachometer that is to be used,

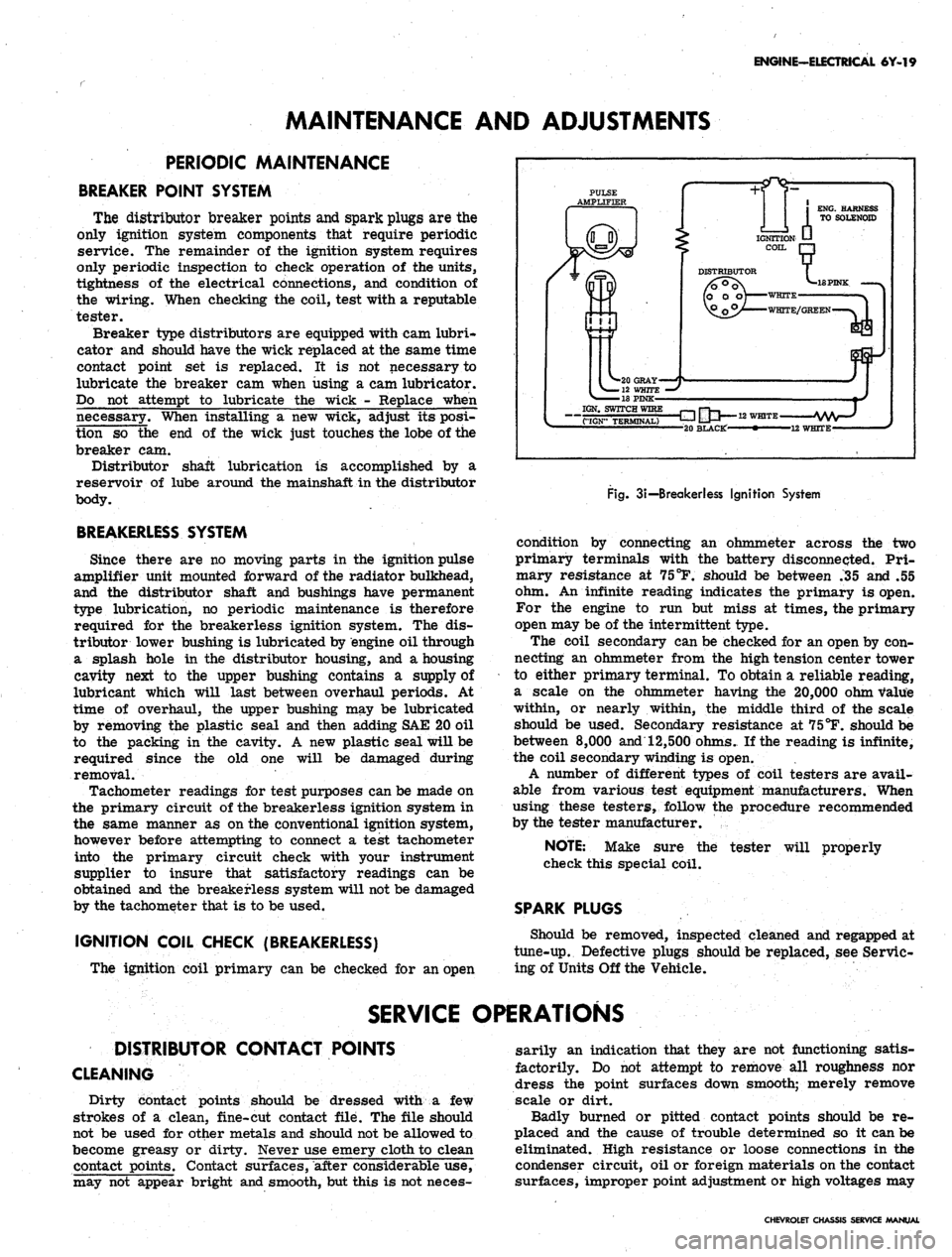

IGNITION COIL CHECK (BREAKERLESS)

The ignition coil primary can be checked for an open

PULSE

AMPLIFIER

IGN. SWITCH WIRE

"("IGN" TERMINAL)

-E3 IJU

12

WHITE-

-20 BLACKf' • 12 WHITE-

Fig.

3i—

Breakerless Ignition System

condition by connecting an ohmmeter across the two

primary terminals with the battery disconnected. Pri-

mary resistance at 75

°F.

should be between .35 and .55

ohm. An infinite reading indicates the primary is open.

For the engine to run but miss at times, the primary

open may be of the intermittent type.

The coil secondary can be checked for an open by con-

necting an ohmmeter from the high tension center tower

to either primary terminal. To obtain a reliable reading,

a scale on the ohmmeter having the 20,000 ohm value

within, or nearly within, the middle third of the scale

should be used. Secondary resistance at 75°F. should be

between

8,000

and 12,500 ohms. If the reading is infinite,

the coil secondary winding is open.

A number of different types of coil testers are avail-

able from various test equipment manufacturers. When

using these testers, follow the procedure recommended

by the tester manufacturer.

tester will properly

NOTE:

Make sure the

check this special coil.

SPARK PLUGS

Should be removed, inspected cleaned and regapped at

tune-up. Defective plugs should be replaced, see Servic-

ing of Units Off the Vehicle.

SERVICE OPERATIONS

DISTRIBUTOR CONTACT POINTS

CLEANING

Dirty contact points should be dressed with a few

strokes of a clean, fine-cut contact file. The file should

not be used for other metals and should not be allowed to

become greasy or dirty. Never use emery cloth to clean

contact points. Contact surfaces, after considerable use,

may not appear bright and smooth, but this is not neces-

sarily an indication that they are not functioning satis-

factorily. Do not attempt to remove all roughness nor

dress the point surfaces down smooth; merely remove

scale or dirt.

Badly burned or pitted contact points should be re-

placed and the cause of trouble determined so it can be

eliminated. High resistance or loose connections in the

condenser circuit, oil or foreign materials on the contact

surfaces, improper point adjustment or high voltages may

CHEVROLET CHASSIS SERVICE MANUAL

Page 354 of 659

ENGINE-ELECTRICAL 6Y-29

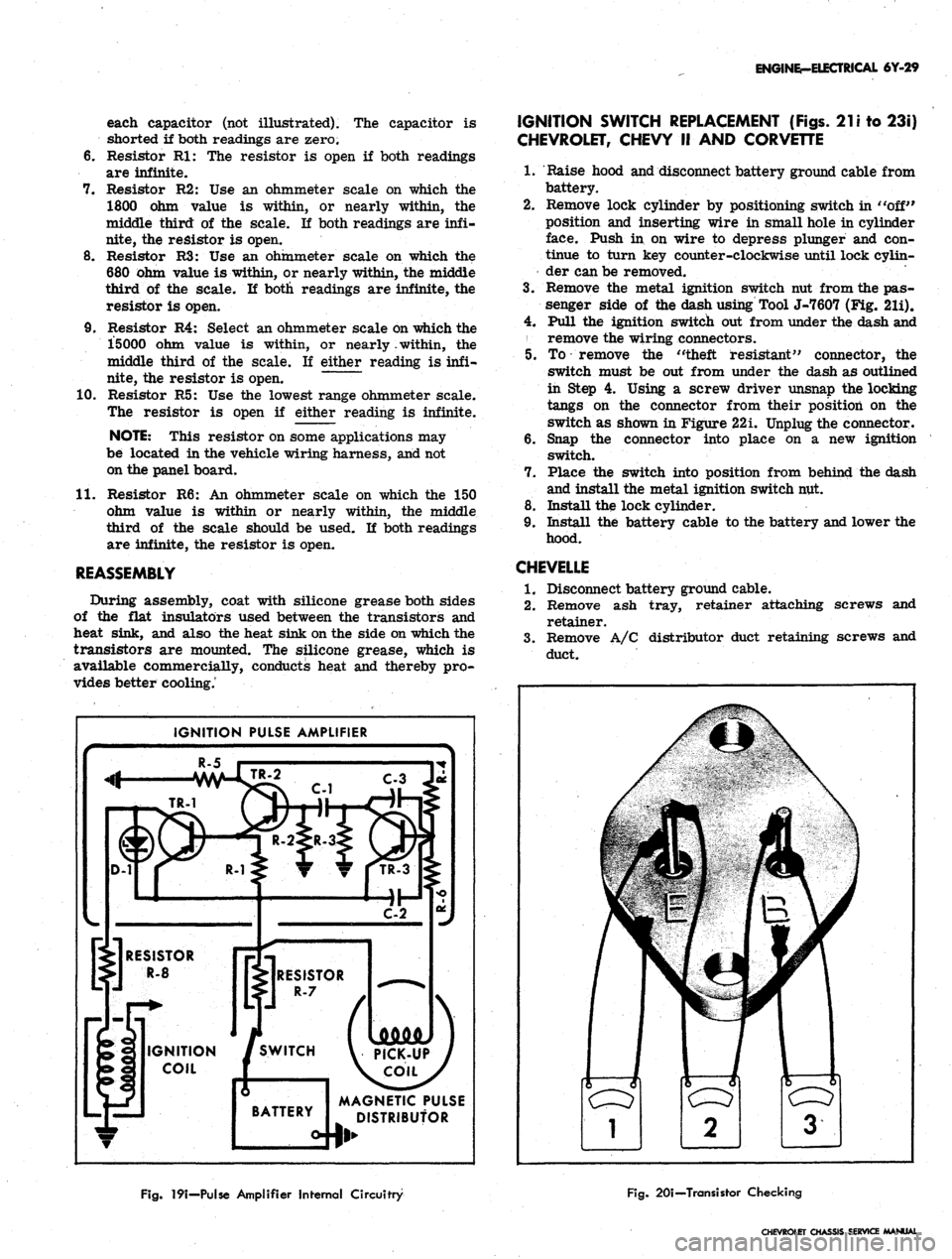

each capacitor (not illustrated). The capacitor is

shorted if both readings are zero.

6. Resistor Rl: The resistor is open if both readings

are infinite.

7. Resistor R2: Use an ohmmeter scale on which the

1800 ohm value is within, or nearly within, the

middle third of the scale. If both readings are infi-

nite, the resistor is open.

8. Resistor R3: Use an ohmmeter scale on which the

680 Ohm value is within, or nearly within, the middle

third of the scale. If both readings are infinite, the

resistor is open.

9. Resistor R4: Select an ohmmeter scale on which the

15000 ohm value is within, or nearly .within, the

middle third of the scale. If either reading is infi-

nite, the resistor is open. ~

10.

Resistor R5: Use the lowest range ohmmeter scale.

The resistor is open if either reading is infinite.

NOTE:

This resistor on some applications may

be located in the vehicle wiring harness, and not

on the panel board.

11.

Resistor R6: An ohmmeter scale on which the 150

ohm value is within or nearly within, the middle

third of the scale should be used. If both readings

are infinite, the resistor is open.

REASSEMBLY

During assembly, coat with silicone grease both sides

of the flat insulators used between the transistors and

heat sink, and also the heat sink on the side on which the

transistors are mounted. The silicone grease, which is

available commercially, conducts heat and thereby pro-

vides better cooling.'

IGNITION PULSE AMPLIFIER

R-5

C-3 Ju

MAGNETIC PULSE

DISTRIBUTOR

IGNITION SWITCH REPLACEMENT (Figs.

21

i to 23i)

CHEVROLET, CHEVY II AND CORVETTE

1.

Raise hood and disconnect battery ground cable from

battery.

2.

Remove lock cylinder by positioning switch in "off"

position and inserting wire in small hole in cylinder

face. Push in on wire to depress plunger and con-

tinue to turn key counter-clockwise until lock cylin-

der can be removed.

3.

Remove the metal ignition switch nut from the pas-

senger side of the dash using Tool J-7607 (Fig. 21i).

4.

Pull the ignition switch out from under the dash and

remove the wiring connectors.

5. To remove the "theft resistant" connector, the

switch must be out from under the dash as outlined

in Step 4. Using a screw driver unsnap the locking

tangs on the connector from their position on the

switch as shown in Figure 22i. Unplug the connector.

6. Snap the connector into place on a new ignition

switch.

7. Place the switch into position from behind the dash

and install the metal ignition switch nut.

8. Install the lock cylinder.

9. Install the battery cable to the battery and lower the

hood.

CHEVELLE

1.

Disconnect battery ground cable.

2.

Remove ash tray, retainer attaching screws and

retainer.

3.

Remove A/C distributor duct retaining screws and

duct.

Fig.

19i—Pulse Amplifier Internal Circuitry

Fig.

20i—Transistor Checking

CHEVROLET Oi

Page 357 of 659

ENGINE-ELECTRICAL 6Y-32

STARTER CIRCUIT

INDEX

Page

General Description 6Y-32

Maintenance and Adjustments . '. . 6Y-32

Resistance Checks 6Y-32

Starting Motor and Solenoid Check 6Y-33

Page

Service Operations 6Y-33

Starter Motor 6Y-33

Removal and Installation 6Y-33

GENERAL DESCRIPTION

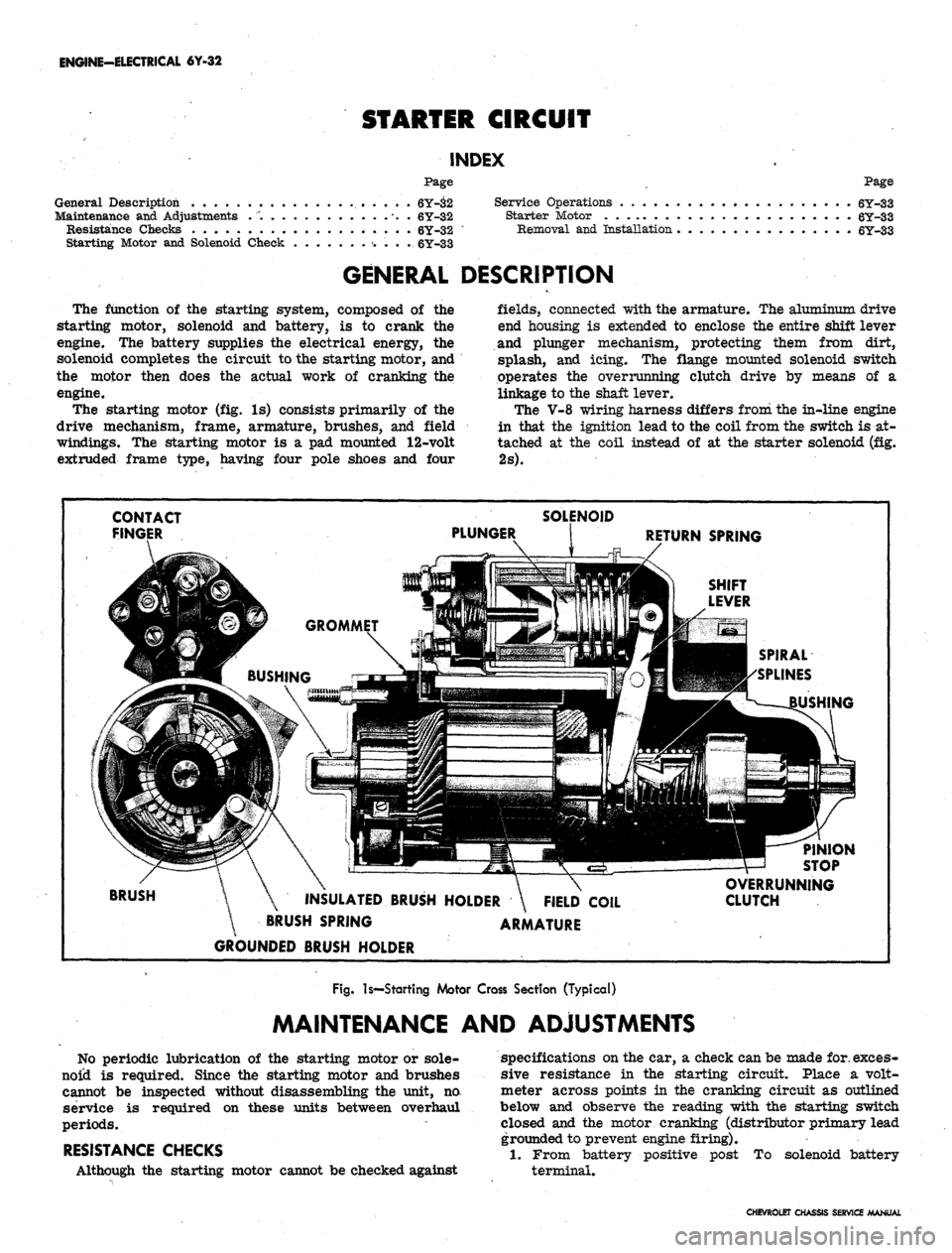

The function of the starting system, composed of the

starting motor, solenoid and battery, is to crank the

engine. The battery supplies the electrical energy, the

solenoid completes the circuit to the starting motor, and

the motor then does the actual work of cranking the

engine.

The starting motor (fig. Is) consists primarily of the

drive mechanism, frame, armature, brushes, and field

windings. The starting motor is a pad mounted 12-volt

extruded frame type, having four pole shoes and four

fields,

connected with the armature. The aluminum drive

end housing is extended to enclose the entire shift lever

and plunger mechanism, protecting them from dirt,

splash, and icing. The flange mounted solenoid switch

operates the overrunning clutch drive by means of a

linkage to the shaft lever.

The V-8 wiring harness differs from the in-line engine

in that the ignition lead to the coil from the switch is at-

tached at the coil instead of at the starter solenoid (fig.

2s).

CONTACT

FINGER

PINION

STOP

BRUSH

INSULATED BRUSH HOLDER \ FIELD COIL

BRUSH SPRING ARMATURE

GROUNDED BRUSH HOLDER

OVERRUNNING

CLUTCH

Fig.

Is—Starting Motor Cross Section (Typical)

MAINTENANCE AND ADJUSTMENTS

No periodic lubrication of the starting motor or sole-

noid is required. Since the starting motor and brushes

cannot be inspected without disassembling the unit, no.

service is required on these units between overhaul

periods.

RESISTANCE CHECKS

Although the starting motor cannot be checked against

specifications on the car, a check can be made for. exces-

sive resistance in the starting circuit. Place a volt-

meter across points in the cranking circuit as outlined

below and observe the reading with the starting switch

closed and the motor cranking (distributor primary lead

grounded to prevent engine firing).

1.

From battery positive post To solenoid battery

terminal.

CHEVROLET CHASSIS SERVICE MANUAL

Page 358 of 659

ENGINE-ELECTRICAL 6Y-33

O

V-8 ENGINE

STARTING MOTOR

Fig.

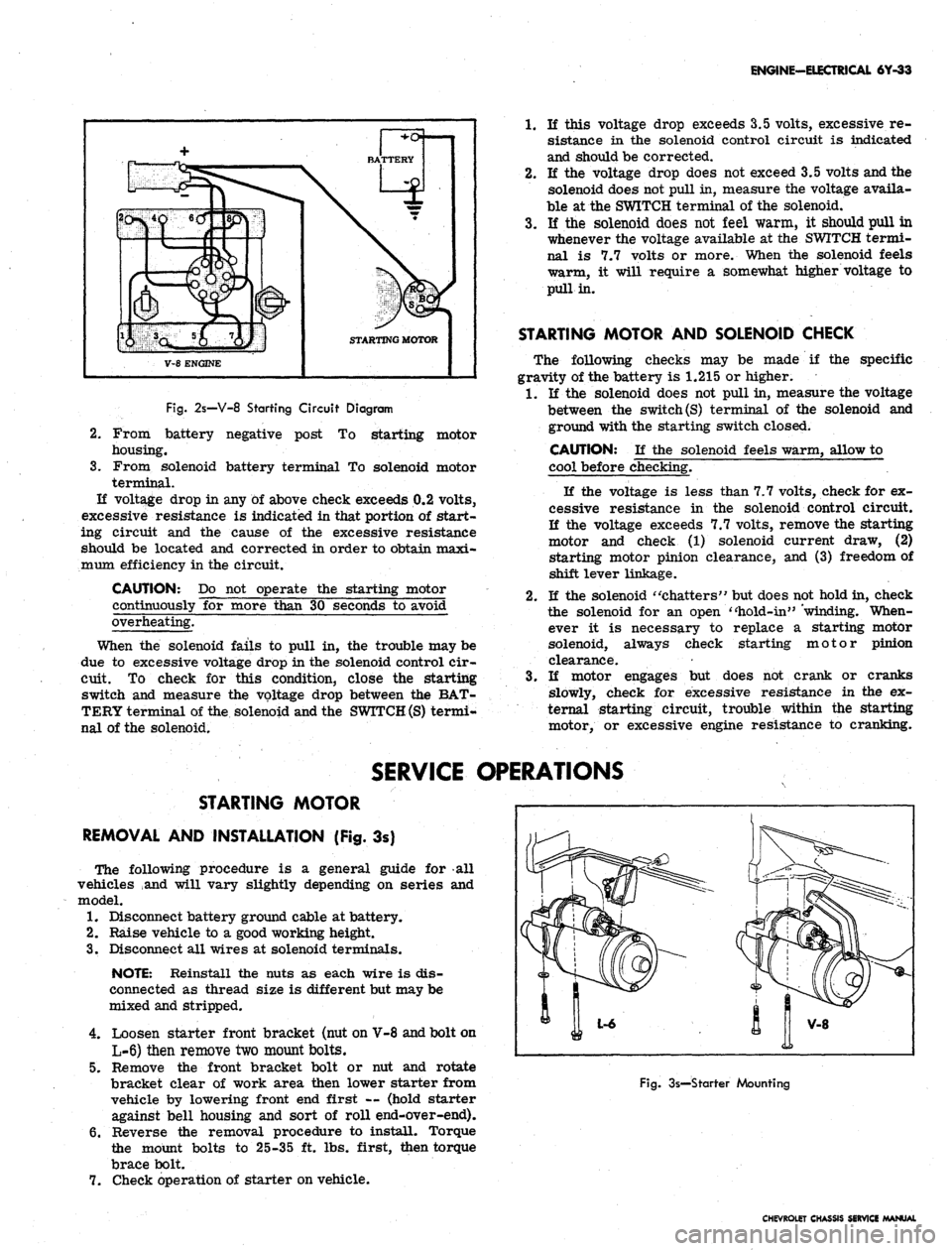

2s—V-8 Starting Circuit Diagram

2.

3.

From battery negative post

To

starting motor

housing.

From solenoid battery terminal

To

solenoid motor

terminal.

If voltage drop

in

any

of

above check exceeds 0.2 volts,

excessive resistance

is

indicated in that portion

of

start-

ing circuit

and the

cause

of the

excessive resistance

should

be

located

and

corrected

in

order to obtain maxi-

mum efficiency in the circuit.

CAUTION:

Do not

operate

the

starting motor

continuously

for

more than

30

seconds

to

avoid

overheating.

When

the

solenoid fails

to

pull

in, the

trouble may be

due

to

excessive voltage drop in the solenoid control cir-

cuit.

To

check

for

this condition, close

the

starting

switch

and

measure

the

voltage drop between

the

BAT-

TERY terminal of the solenoid and the

SWITCH (S)

termi-

nal

of

the solenoid.

1.

If

this voltage drop exceeds 3.5 volts, excessive

re-

sistance

in the

solenoid control circuit

is

indicated

and should be corrected.

2.

If the

voltage drop does not exceed 3.5 volts and the

solenoid does not pull in, measure the voltage availa-

ble

at

the SWITCH terminal

of

the solenoid.

3.

If the

solenoid does

not

feel warm,

it

should pull

in

whenever the voltage available

at

the SWITCH termi-

nal

is 7.7

volts

or

more. When

the

solenoid feels

warm,

it

will require

a

somewhat higher voltage

to

pull in.

STARTING MOTOR AND SOLENOID CHECK

The following checks

may be

made

if the

specific

gravity of the battery

is

1.215

or

higher.

1.

If the

solenoid does

not

pull in, measure the voltage

between

the

switch

(S)

terminal

of the

solenoid

and

ground with the starting switch closed.

CAUTION:

If the

solenoid feels warm, allow

to

cool before checking.

If

the

voltage

is

less than 7.7 volts, check for ex-

cessive resistance

in the

solenoid control circuit.

If

the

voltage exceeds 7.7 volts, remove the starting

motor

and

check

(1)

solenoid current draw,

(2)

starting motor pinion clearance,

and (3)

freedom of

shift lever linkage.

2.

If

the solenoid "chatters" but does not hold in, check

the solenoid

for an

open "hold-in" 'winding. When-

ever

it is

necessary

to

replace

a

starting motor

solenoid, always check starting motor pinion

clearance.

3.

If

motor engages

but

does

not

crank

or

cranks

slowly, check

for

excessive resistance

in the ex-

ternal starting circuit, trouble within

the

starting

motor,

or

excessive engine resistance

to

cranking.

SERVICE OPERATIONS

STARTING MOTOR

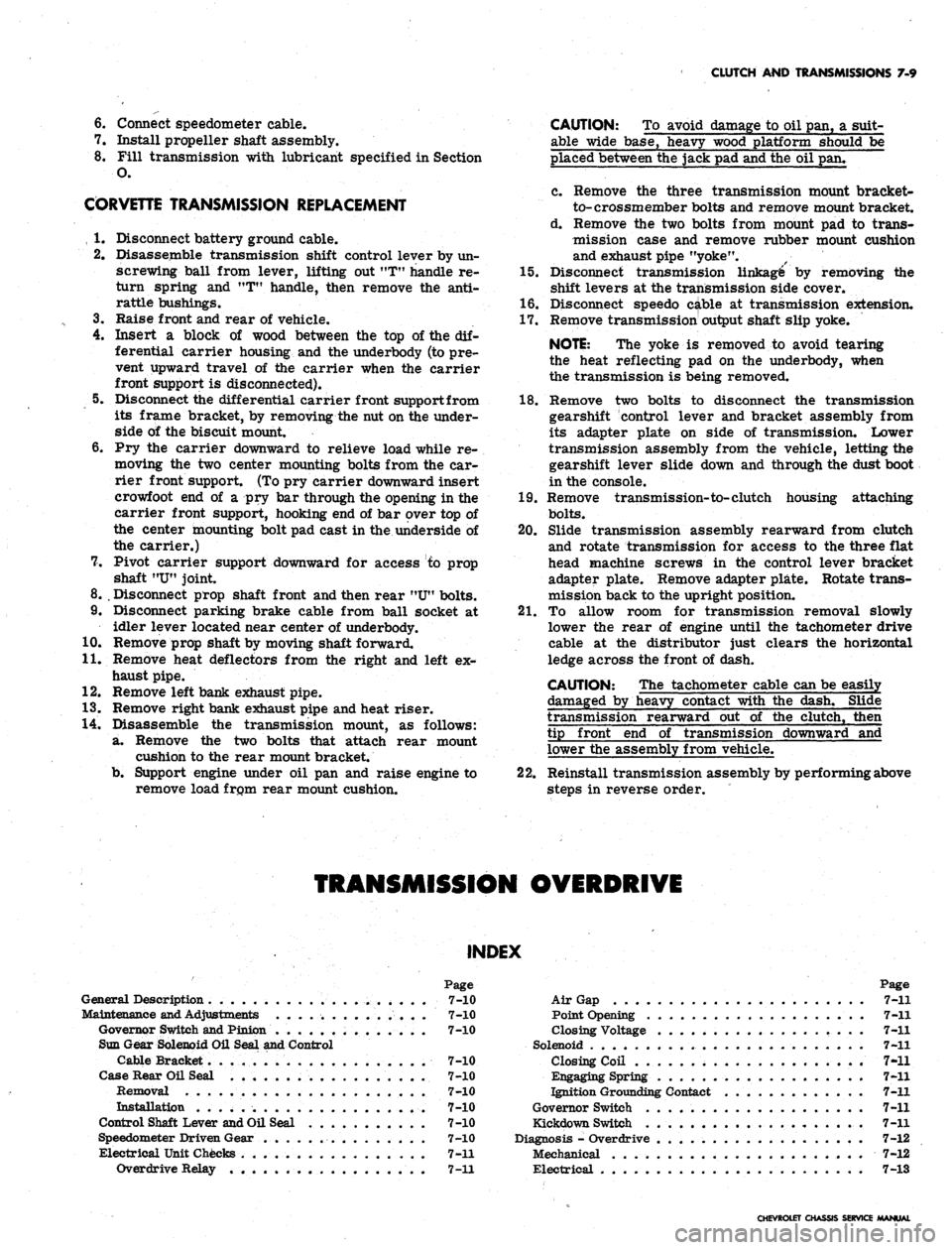

REMOVAL AND INSTALLATION (Fig.

3s)

The following procedure

is a

general guide

for all

vehicles

and

will vary slightly depending

on

series

and

model.

1.

Disconnect battery ground cable at battery.

2.

Raise vehicle

to a

good working height.

3.

Disconnect all wires

at

solenoid terminals.

NOTE: Reinstall

the

nuts

as

each wire

is

dis-

connected

as

thread size

is

different but may be

mixed and stripped.

4.

Loosen starter front bracket (nut on V-8 and bolt on

L-6) then remove two mount bolts.

5.

Remove

the

front bracket bolt

or nut and

rotate

bracket clear

of

work area then lower starter from

vehicle

by

lowering front end first

—

(hold starter

against bell housing

and

sort

of

roll end-over-end).

6. Reverse

the

removal procedure

to

install. Torque

the mount bolts

to

25-35

ft.

lbs. first, then torque

brace bolt.

7.

Check operation

of

starter on vehicle.

Fig.

3s—Starter Mounting

CHEVROLET CHASSIS SERVICE MANUAL

Page 368 of 659

CLUTCH AND TRANSMISSIONS 7-9

6. Connect speedometer cable.

7. Install propeller shaft assembly.

8. Fill transmission with lubricant specified in Section

O.

CORVETTE TRANSMISSION REPLACEMENT

, 1. Disconnect battery ground cable.

2.

Pisassemble transmission shift control lever by un-

screwing ball from lever, lifting out

"T"

handle re-

turn spring and "T" handle, then remove the anti-

rattle bushings.

3.

Raise front and rear of vehicle.

4.

Insert a block of wood between the top of the dif-

ferential carrier housing and the underbody (to pre-

vent upward travel of the carrier when the carrier

front support is disconnected).

5. Disconnect the differential carrier front supportfrom

its frame bracket, by removing the nut on the under-

side of the biscuit mount.

6. Pry the carrier downward to relieve load while re-

moving the two center mounting bolts from the car-

rier front support. (To pry carrier downward insert

crowfoot end of a pry bar through the opening in the

carrier front support, hooking end of bar over top of

the center mounting bolt pad cast in the underside of

the carrier.)

7. Pivot carrier support downward for access to prop

shaft "U" joint.

8.

.

Disconnect prop shaft front and then rear "U" bolts.

9. Disconnect parking brake cable from ball socket at

idler lever located near center of underbody.

10.

Remove prop shaft by moving shaft forward.

11.

Remove heat deflectors from the right and left ex-

haust pipe.

12.

Remove left bank exhaust pipe.

13.

Remove right bank exhaust pipe and heat riser.

14.

Disassemble the transmission mount, as follows:

a. Remove the two bolts that attach rear mount

cushion to the rear mount bracket.

b.

Support engine under oil pan and raise engine to

remove load from rear mount cushion.

CAUTION: To avoid damage to oil pan, a suit-

able wide base, heavy wood platform should be

placed between the jack pad and the oil pan.

c. Remove the three transmission mount bracket-

to-

crossm ember bolts and remove mount bracket.

d. Remove the two bolts from mount pad to trans-

mission case and remove rubber mount cushion

and exhaust pipe "yoke".

15.

Disconnect transmission linkage by removing the

shift levers at the transmission side cover.

16.

Disconnect speedo cable at transmission extension.

17.

Remove transmission output shaft slip yoke.

NOTE:

The yoke is removed to avoid tearing

the heat reflecting pad on the underbody, when

the transmission is being removed.

18.

Remove two bolts to disconnect the transmission

gearshift control lever and bracket assembly from

its adapter plate on side of transmission. Lower

transmission assembly from the vehicle, letting the

gearshift lever slide down and through the dust boot

in the console.

19.

Remove transmission-to-clutch housing attaching

bolts.

20.

Slide transmission assembly rearward from clutch

and rotate transmission for access to the three flat

head machine screws in the control lever bracket

adapter plate. Remove adapter plate. Rotate trans-

mission back to the upright position.

21.

To allow room for transmission removal slowly

lower the rear of engine until the tachometer drive

cable at the distributor just clears the horizontal

ledge across the front of dash.

CAUTION: The tachometer cable can be easily

damaged by heavy contact with the dash. Slide

transmission rearward out of the clutch, then

tip front end of transmission downward and

lower the assembly from vehicle.

22.

Reinstall transmission assembly by performing above

steps in reverse order.

TRANSMISSION OVERDRIVE

INDEX

Page

General

Description 7-10

Maintenance

and Adjustments 7—10

Governor

Switch and Pinion .............. 7-10

Sun

Gear Solenoid Oil Seal and Control

Cable

Bracket 7-10

Case

Rear Oil Seal 7-10

Removal

7-10

Installation

. . . . . 7-10

Control

Shaft Lever and Oil Seal 7-10

Speedometer

Driven Gear 7-10

Electrical

Unit Checks 7-11

Overdrive

Relay . 7-11

Page

Air

Gap 7-11

Point

Opening 7-11

Closing

Voltage 7-11

Solenoid

. 7-11

Closing

Coil 7-11

Engaging

Spring . - 7-11

Ignition

Grounding Contact . 7-11

Governor

Switch 7-11

Kickdown

Switch 7-11

Diagnosis

- Overdrive 7-12

Mechanical

. 7-12

Electrical

7-13

CHEVROLET CHASSIS SERVICE MANUAL

Page 370 of 659

CLUTCH AND TRANSMISSIONS 7-11

UPPER ARMATURE STOP

(BEND TO ADJUST POINT OPENING)

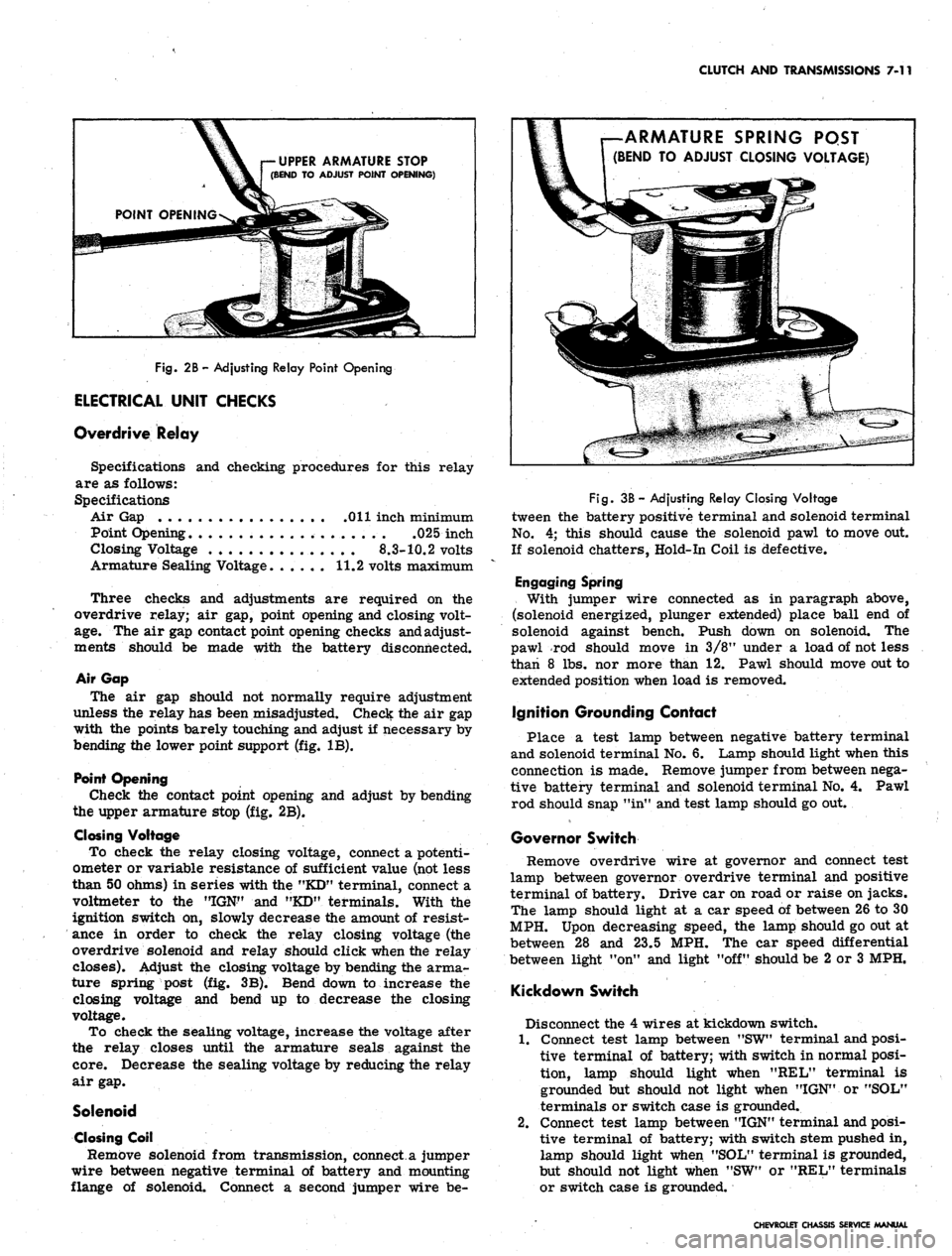

Fig.

2B-Adjusting Relay Point Opening

ELECTRICAL UNIT CHECKS

Overdrive Relay

Specifications and checking procedures for this relay

are as follows:

Specifications

Air Gap Oil inch minimum

Point Opening .025 inch

Closing Voltage

8.3-10.2

volts

Armature Sealing Voltage. ..... 11.2 volts maximum

Three checks and adjustments are required on the

overdrive relay; air gap, point opening and closing volt-

age.

The air gap contact point opening checks and adjust-

ments should be made with the battery disconnected.

Air Gap

The air gap should not normally require adjustment

unless the relay has been misadjusted. Check the air gap

with the points barely touching and adjust if necessary by

bending the lower point support (fig, IB).

Point Opening

Check the contact point opening and adjust by bending

the upper armature stop (fig. 2B).

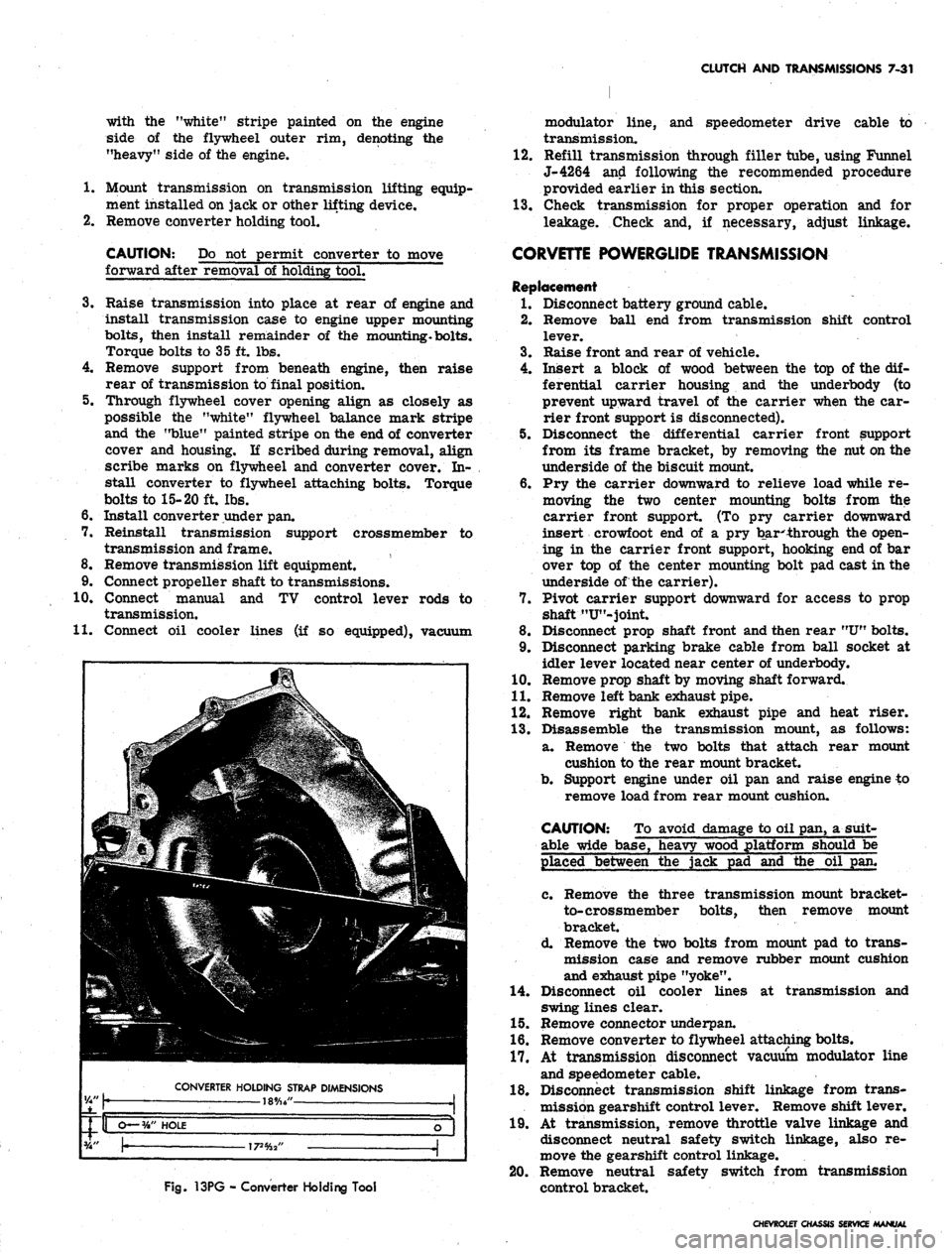

Closing Voltage

To check the relay closing voltage, connect a potenti-

ometer or variable resistance of sufficient value (not less

than 50 ohms) in series with the "KD" terminal, connect a

voltmeter to the "IGN" and "KD" terminals. With the

ignition switch on, slowly decrease the amount of resist-

ance in order to check the relay closing voltage (the

overdrive solenoid and relay should click when the relay

closes). Adjust the closing voltage by bending the arma-

ture spring post (fig. 3B). Bend down to increase the

closing voltage and bend up to decrease the closing

voltage.

To check the sealing voltage, increase the voltage after

the relay closes until the armature seals against the

core.

Decrease the sealing voltage by reducing the relay

air gap.

Solenoid

Closing Coil

Remove solenoid from transmission, connect a jumper

wire between negative terminal of battery and mounting

flange of solenoid. Connect a second jumper wire be-

ARMATURE SPRING PQST

(BEND TO ADJUST CLOSING VOLTAGE)

Fig.

3B - Adjusting Relay Closing Voltage

tween the battery positive terminal and solenoid terminal

No.

4; this should cause the solenoid pawl to move out.

If solenoid chatters, Hold-In Coil is defective.

Engaging Spring

With jumper wire connected as in paragraph above,

(solenoid energized, plunger extended) place ball end of

solenoid against bench. Push down on solenoid. The

pawl rod should move in 3/8M under a load of not less

than 8 lbs. nor more than 12. Pawl should move out to

extended position when load is removed.

Ignition Grounding Contact

Place a test lamp between negative battery terminal

and solenoid terminal No. 6. Lamp should light when this

connection is made. Remove jumper from between nega-

tive battery terminal and solenoid terminal No. 4. Pawl

rod should snap "in" and test lamp should go out.

Governor Switch

Remove overdrive wire at governor and connect test

lamp between governor overdrive terminal and positive

terminal of battery. Drive car on road or raise on jacks.

The lamp should light at a car speed of between 26 to 30

MPH. Upon decreasing speed, the lamp should go out at

between 28 and 23.5 MPH. The car speed differential

between light "on" and light "off" should be 2 or 3 MPH.

Kickdown Switch

Disconnect the 4 wires at kickdown switch.

1.

Connect test lamp between "SW" terminal and posi-

tive terminal of battery; with switch in normal posi-

tion, lamp should light when "REL" terminal is

grounded but should not light when "IGN" or "SOL"

terminals or switch case is grounded.

2.

Connect test lamp between "IGN" terminal and posi-

tive terminal of battery; with switch stem pushed in,

lamp should light when "SOL" terminal is grounded,

but should not light when "SW" or "REL" terminals

or switch case is grounded.

CHEVROLET CHASSIS SERVICE MANUAL

Page 390 of 659

CLUTCH AND TRANSMISSIONS 7-31

with the "white" stripe painted on the engine

side of the flywheel outer rim, denoting the

"heavy" side of the engine.

1.

Mount transmission on transmission lifting equip-

ment installed on jack or other lifting device.

2.

Remove converter holding tool.

CAUTION: Do not permit converter to move

forward after removal of holding tool.

3.

Raise transmission into place at rear of engine and

install transmission case to engine upper mounting

bolts,

then install remainder of the mounting*bolts.

Torque bolts to 35 ft. lbs.

4.

Remove support from beneath engine, then raise

rear of transmission to final position.

5. Through flywheel cover opening align as closely as

possible the "white" flywheel balance mark stripe

and the "blue" painted stripe on the end of converter

cover and housing. If scribed during removal, align

scribe marks on flywheel and converter cover. In-

stall converter to flywheel attaching bolts. Torque

bolts to 15-20 ft. lbs.

6. Install converter under pan.

7. Reinstall transmission support crossmember to

transmission and frame.

8. Remove transmission lift equipment.

9. Connect propeller shaft to transmissions.

10.

Connect manual and TV control lever rods to

transmission.

11.

Connect oil cooler lines (if so equipped), vacuum

Fig.

13PG - Converter Holding Tool

modulato:* line, and speedometer drive cable to

transmission.

12.

Refill transmission through filler tube, using Funnel

J-4264 and following the recommended procedure

provided earlier in this section.

13.

Check transmission for proper operation and for

leakage. Check and, if necessary, adjust linkage.

CORVETTE POWERGLIDE TRANSMISSION

Replacement

1.

Disconnect battery ground cable.

2.

Remove ball end from transmission shift control

lever.

3.

Raise front and rear of vehicle.

4.

Insert a block of wood between the top of the dif-

ferential carrier housing and the underbody (to

prevent upward travel of the carrier when the car-

rier front support is disconnected).

5. Disconnect the differential carrier front support

from its frame bracket, by removing the nut on the

underside of the biscuit mount.

6. Pry the carrier downward to relieve load while re-

moving the two center mounting bolts from the

carrier front support. (To pry carrier downward

insert crowfoot end of a pry bar**hrough the open-

ing in the carrier front support, hooking end of bar

over top of the center mounting bolt pad cast in the

underside of the carrier).

7. Pivot carrier support downward for access to prop

shaft "U"-joint.

8. Disconnect prop shaft front and then rear

"U"

bolts.

9. Disconnect parking brake cable from ball socket at

idler lever located near center of underbody.

10.

Remove prop shaft by moving shaft forward.

11.

Remove left bank exhaust pipe.

12.

Remove right bank exhaust pipe and heat riser.

13.

Disassemble the transmission mount, as follows:

a. Remove the two bolts that attach rear mount

cushion to the rear mount bracket.

b.

Support engine under oil pan and raise engine to

remove load from rear mount cushion.

CAUTION: To avoid damage to oil pan, a suit-

able wide base, heavy wood platform should be

placed between the jack pad and the oil pan.

c. Remove the three transmission mount bracket-

to-crossmember bolts, then remove mount

bracket.

d. Remove the two bolts from mount pad to trans-

mission case and remove rubber mount cushion

and exhaust pipe "yoke".

14.

Disconnect oil cooler lines at transmission and

swing lines clear.

15.

Remove connector underpan.

16.

Remove converter to flywheel attaching bolts.

17.

At transmission disconnect vacuum modulator line

and speedometer cable.

18.

Disconnect transmission shift linkage from trans-

mission gearshift control lever. Remove shift lever.

19.

At transmission, remove throttle valve linkage and

disconnect neutral safety switch linkage, also re-

move the gearshift control linkage.

20.

Remove neutral safety switch from transmission

control bracket.

CHEVROLET CHASSIS SERVICE

Page 399 of 659

CLUTCH AND TRANSMISSIONS 7-40

pipes.

If

care

is

taken

in

removing control valve

body

the six (6)

check balls will stay

in

place above

the spacer plate.

CAUTION:

Do not

drop manual valve.

5. Remove

the

governor pipes

and

manual valve from

control valve body.

Installation

Installation

of the

control valve body

is the

reverse

of

the removal.

GOVERNOR

Removal

.

1.

Remove governor cover attaching screws, cover,

and

gasket.

2.

Discard gasket.

3.

Withdraw governor assembly from case.

Installation

Installation

of the

governor assembly

is the

reverse

of

the removal.

Use a new

gasket under

the

governor

cover.

MODULATOR AND MODULATOR VALVE

Removal

1.

Remove modulator assembly attaching screw

and

retainer.

2.

Remove modulator assembly from case. Discard

"O"

ring seal.

3.

Remove modulator valve from case.

Installation

Installation

of the

modulator assembly

and

modulator

valve

is the

reverse

of the

removal.

Use a new

"O" ring

seal

on the

modulator assembly.

PARKING LINKAGE

Removal

1.

Remove bottom

pan and oil

strainer.

2.

Unthread

jam nut

holding detent lever

to

manual

shaft.

3.

Remove manual shaft retaining

pin

from case.

4.

Remove manual shaft

and jam nut

from case.

NOTE:

DO NOT

remove manual shaft seal

un-

less replacement

is

required.

5. Remove parking actuator

rod and

detent lever

as-

sembly.

6. Remove parking pawl bracket attaching screws

and

bracket.

7. Remove parking pawl return spring.

NOTE:

The

following steps should

not be com-

pleted unless part replacement

is

required.

8. Remove parking pawl shaft retainer.

9.

Remove parking pawl shaft,

cup

plug, parking pawl

shaft, and parking pawl.

Installation

Installation

of the

parking linkage

is the

reverse

of the

removal.

Use new

seal

and cup

plug,

if

removed,

and

new bottom

pan

gasket.

REAR SEAL

Removal

1.

Remove propeller shaft.

2.

Pry

seal

out

with screw driver.

Installation

1.

Using Tool J-5154

or

J-21359 install

new

seal.

2.

Re-install propeller shaft.

OTHER SERVICE WITH TRANSMISSION IN VEHICLE

The following operations when done

as

single opera-

tions

and not as

part

of a

general overhaul should,

as a

practical matter,

be

performed with

the

transmission

in

the.

vehicle. Refer

to the

"Transmission Disassembly

and Reassembly" section

of the

Overhaul Manual

for

service procedures.

a. Oil

filler pipe

and

"O"

ring seal.

b.

Oil pan

and

gasket.

c. Down shift solenoid

or

connector.

d. Valve body spacer plate, gasket

and

check balls.

e. Front accumulator piston.

f.

Rear servo

and

rear accumulator assembly.

g.

Rear band apply checking with Tool J-21370.

Ji.

Front servo assembly.

i. Speedo driven gear.

j.

Case extension

or

gasket.

k.

Strainer

and

"O"

ring.

TRANSMISSION REPLACEMENT

Before raising

the car,

disconnect

the

battery

and re-

lease

the

parking brake.

1.

Remove propeller shaft.

8.

2.

Disconnect speedometer cable, electrical lead to case

9.

connector, vacuum line

at

modulator,

and oil

cooler

10.

pipes.

3.

Disconnect shift control linkage.

4.

Support transmission with suitable transmission jack.

11.

5. Disconnect rear mount from frame crossmember.

6. Remove

two

bolts

at

each

end of

frame crossmember

12.

and remove crossmember.

7. Remove

oil

cooler lines, vacuum modulator line,

speedo cable,

and

detent solenoid connector wire

at

transmission.

Remove converter under

pan.

Remove converter

to

flywheel bolts.

Loosen exhaust pipe

to

manifold bolts approximately

1/4

inch,

and

lower transmission until jack

is

barely

supporting

it.

Remove transmission

to

engine mounting bolts

and

remove

oil

filler tube

at

transmission.

Raise transmission

to its

normal position, support

engine with jack

and

slide transmission rearward

from engine

and

lower

it

away from vehicle.

CHEVROLET CHASSIS SERVICE MANUAL

Page 424 of 659

FUEL TANK

AND

EXHAUST SYSTEMS

8-18

CORVETTE

FUEL TANK

INDEX

Page

General Description.

. 8-18

Service Operations

8-18

Fuel Tank

8-18

Gauge Sending Unit

8-20

Fuel Lines.

8-20

GENERAL DESCRIPTION

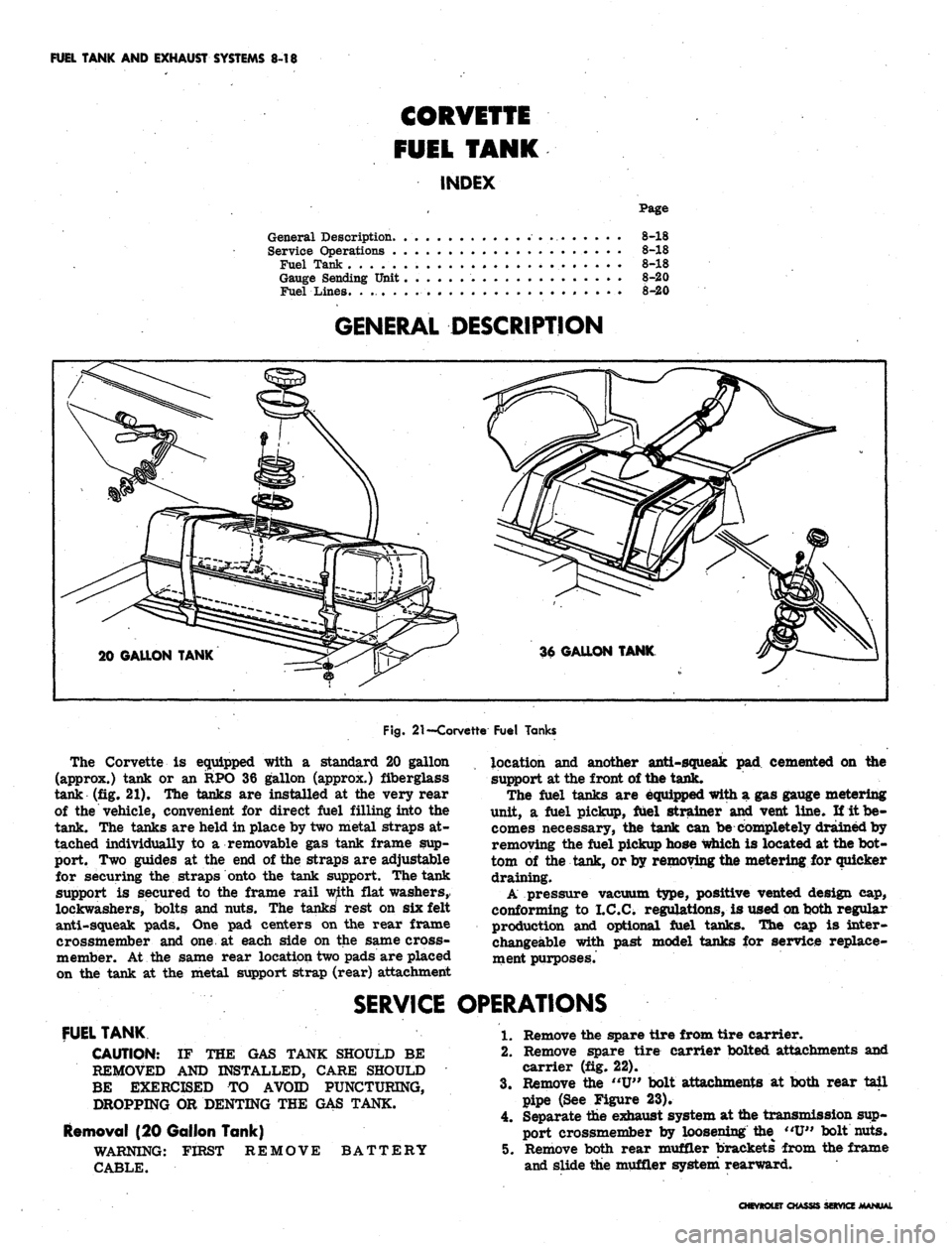

20 GALLON TANK

Fig.

21

—Corvette Fuel Tanks

The Corvette

is

equipped with

a

standard

20

gallon

(approx.) tank

or an RPO 36

gallon (approx.) fiberglass

tank

(fig. 21). The

tanks

are

installed

at the

very rear

of

the

vehicle, convenient

for

direct fuel filling into

the

tank.

The

tanks

are

held

in

place

by

two metal straps

at-

tached individually

to a

removable

gas

tank frame

sup-

port.

Two

guides

at the end of

the straps

are

adjustable

for securing

the

straps onto

the

tank support. The tank

support

is

secured

to the

frame rail with flat washers,

lockwashers, bolts

and

nuts.

The

tanks' rest

on six

felt

anti-squeak pads.

One pad

centers

on the

rear frame

crossmember

and one at

each side

on the

same cross-

member.

At the

same rear location two pads

are

placed

on

the

tank

at the

metal support strap (rear) attachment

location

and

another anti-squeak

pad

cemented

on the

support

at

the front

of

the tank.

The fuel tanks

are

equipped with

a gas

gauge metering

unit,

a

fuel pickup, fuel strainer

and

vent line.

If it be-

comes necessary,

the

tank

can be

completely drained

by

removing

the

fuel pickup hose which

is

located

at

the

bot-

tom

of the

tank,

or

by removing the metering

for

quicker

draining.

A pressure vacuum type, positive vented design

cap,

conforming

to

I.C.C. regulations,

is

used on both regular

production

and

optional fuel tanks.

The cap is

inter-

changeable with past model tanks

for

service replace-

ment purposes.

SERVICE OPERATIONS

FUEL TANK

CAUTION:

IF THE GAS

TANK SHOULD

BE

REMOVED

AND

INSTALLED, CARE SHOULD

BE EXERCISED

TO

AVOID PUNCTURING,

DROPPING

OR

DENTING

THE GAS

TANK.

Removal

(20

Gallon Tank)

WARNING: FIRST REMOVE BATTERY

CABLE.

1.

Remove

the

spare tire from tire carrier.

2.

Remove spare tire carrier bolted attachments

and

carrier

(fig. 22).

3.

Remove

the "U"

bolt attachments

at

both rear tail

pipe

(See

Figure

23).

4.

Separate

the

exhaust system

at

the transmission sup-

port crossmember

by

loosening

the "U"

bolt nuts.

5. Remove both rear muffler brackets from

the

frame

and slide

the

muffler system rearward.

CHEVROLET CHASSIS SERVICE MANUAL