battery CHEVROLET CAMARO 1967 1.G Chassis Service Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1967, Model line: CAMARO, Model: CHEVROLET CAMARO 1967 1.GPages: 659, PDF Size: 114.24 MB

Page 282 of 659

ENGINE 6-17

Fig.

5L

-

Engine Blocked for Pan Removal

NOTE: Do not install rocker arm cover.

11.

Start engine and allow warm up then retorque cylin-

der head

as

outlined in Step 4 and readjust valves as

outlined under Engine Tune Up.

OIL PAN

Removal

Chevrolet

and Camaro

1.

Disconnect battery positive cable.

2.

Remove through bolts from engine front mounts.

3.

Drain radiator, then disconnect upper and lower ra-

diator hoses at radiator.

4.

Remove fan blade as outlined in Section 6K.

5.

Raise vehicle then drain engine oil.

6. Disconnect and remove* starter.

7.

On

vehicles equipped with automatic transmission,

disconnect transmission cooler lines at transmission

and remove converter housing underpan.

8. Disconnect steering

rod at

idler lever then swing

steering linkage for oil pan clearance.

9. Rotate crankshaft until timing mark

on

torsional

damper is at 6:00 o'clock position.

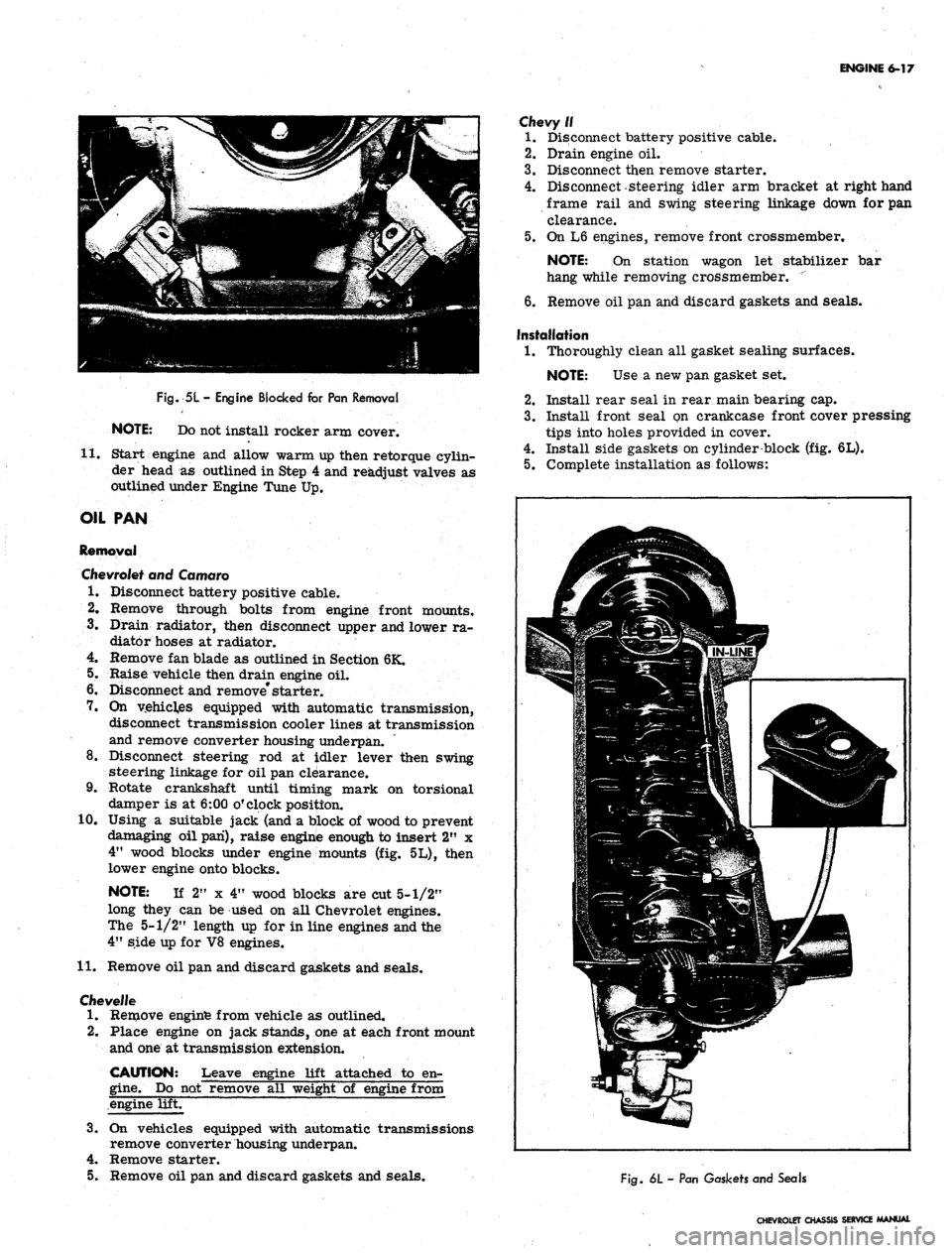

10.

Using

a

suitable jack (and a block of wood to prevent

damaging oil pan), raise engine enough to insert 2"

x

4"

wood blocks under engine mounts (fig. 5L), then

lower engine onto blocks.

NOTE:

If

2"

x

4" wood blocks are cut 5-1/2"

long they can be used on all Chevrolet engines.

The 5-1/2" length up for in line engines and the

4"

side up for V8 engines.

11.

Remove oil pan and discard gaskets and seals.

Cfievel/e

1.

Remove enginfe from vehicle as outlined.

2.

Place engine on jack stands, one at each front mount

and one at transmission extension.

CAUTION: Leave engine lift attached

to

en-

gine.

Do not remove all weight

of

engine from

engine lift.

3.

On

vehicles equipped with automatic transmissions

remove converter housing underpan.

4.

Remove starter.

5.

Remove oil pan and discard gaskets and seals.

Chevy//

1.

Disconnect battery positive cable.

2.

Drain engine oil.

3.

Disconnect then remove starter.

4.

Disconnect-steering idler arm bracket at right hand

frame rail and swing steering linkage down for pan

clearance.

5.

On L6 engines, remove front crossmember.

NOTE:

On

station wagon

let

stabilizer

bar

hang while removing crossmember.

"

6. Remove oil pan and discard gaskets and seals.

Installation

1.

Thoroughly clean all gasket sealing surfaces.

NOTE: Use

a

new pan gasket set.

2.

Install rear seal in rear main bearing cap.

3.

Install front Seal on crankcase front cover pressing

tips into holes provided in cover.

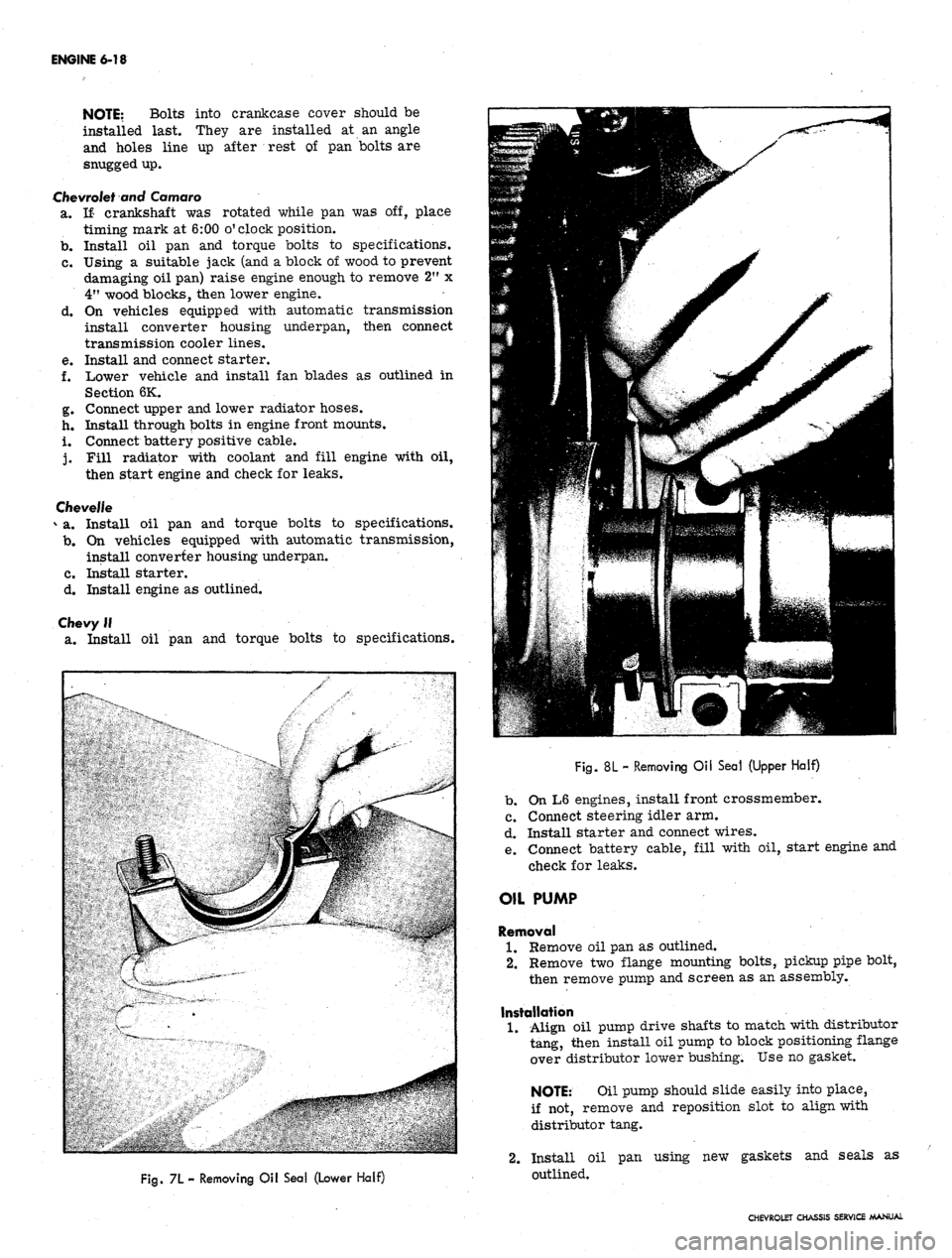

4.

Install side gaskets on cylinder block (fig. 6L).

5.

Complete installation as follows:

Life

1

i

If ^

jfp^;.^3p

>\~^^ \s3^^r' -'••'•'-^^Hll

|^=-5p|:*iil^

mm

Fig.

6L

-

Pan Gaskets and Seals

CHEVROLET CHASSIS SERVICE MANUAL

Page 283 of 659

ENGINE 6-18

NOTE:

Bolts into crankcase cover should be

installed last. They are installed at an angle

and holes line up after rest of pan bolts are

snugged up.

Chevrolet and Camaro

a. If crankshaft was rotated while pan was off, place

timing mark at 6:00 o'clock position.

b.

Install oil pan and torque bolts to specifications.

c. Using a suitable jack (and a block of wood to prevent

damaging oil pan) raise engine enough to remove 2" x

4"

wood blocks, then lower engine.

d. On vehicles equipped with automatic transmission

install converter housing underpan, then connect

transmission cooler lines.

e. Install and connect starter.

f. Lower vehicle and install fan blades as outlined in

Section 6K.

g. Connect upper and lower radiator hoses.

h. Install through bolts in engine front mounts.

i. Connect battery positive cable.

j.

Fill radiator with coolant and fill engine with oil,

then start engine and check for leaks.

Chevelie

* a. Install oil pan and torque bolts to specifications.

b.

On vehicles equipped with automatic transmission,

install converter housing underpan.

c. Install starter.

d. Install engine as outlined.

Chevy II

a. Install oil pan and torque bolts to specifications.

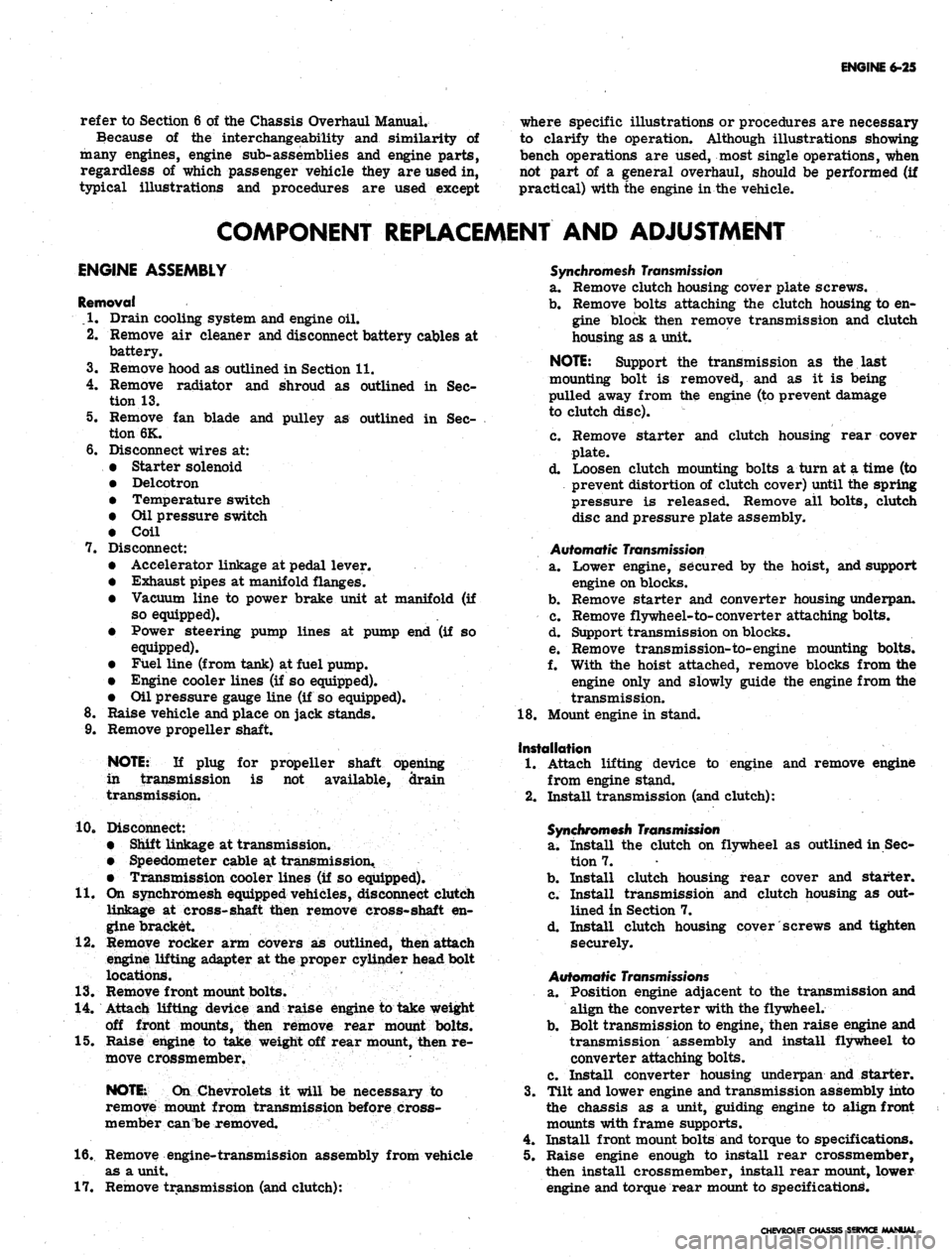

Fig.

7L- Removing Oil Sea! (Lower Half)

Fig.

8L - Removing Oil Seal (Upper Half)

b.

On L6 engines, install front crossmember.

c. Connect steering idler arm.

d. Install starter and connect wires.

e. Connect battery cable, fill with oil, start engine and

check for leaks.

OIL PUMP

Removal

1.

Remove oil pan as outlined.

2.

Remove two flange mounting bolts, pickup pipe bolt,

then remove pump and screen as an assembly.

Installation

1.

Align oil pump drive shafts to match with distributor

tang, then install oil pump to block positioning flange

over distributor lower bushing. Use no gasket.

NOTE:

Oil pump should slide easily into place,

if not, remove and reposition slot to align with

distributor tang.

2.

Install oil pan using new gaskets and seals as

outlined.

CHEVROLET CHASSIS SERVICE MANUAL

Page 290 of 659

ENGINE 6-25

refer to Section 6 of the Chassis Overhaul Manual.

Because of the interchangeability and similarity of

many engines, engine sub-assemblies and engine parts,

regardless of which passenger vehicle they are used in,

typical illustrations and procedures are used except

where specific illustrations or procedures are necessary

to clarify the operation. Although illustrations showing

bench operations are used, most single operations, when

not part of a general overhaul, should be performed (if

practical) with the engine in the vehicle.

COMPONENT REPLACEMENT AND ADJUSTMENT

ENGINE ASSEMBLY

Removal

• .1. Drain cooling system and engine oil.

2.

Remove air cleaner and disconnect battery cables at

battery.

3.

Remove hood as outlined in Section 11.

4.

Remove radiator and shroud as outlined in Sec-

tion 13.

5. Remove fan blade and pulley as outlined in Sec-

tion 6K.

6. Disconnect wires at:

• Starter solenoid

• Delcotron

• Temperature switch

• Oil pressure switch

• Coil

7. Disconnect:

• Accelerator linkage at pedal lever.

• Exhaust pipes at manifold flanges.

• Vacuum line to power brake unit at manifold (if

so equipped),

• Power steering pump lines at pump end (if so

equipped).

• Fuel line (from tank) at fuel pump.

• Engine cooler lines (if so equipped).

• Oil pressure gauge line (if so equipped).

8. Raise vehicle and place on jack stands.

9. Remove propeller shaft.

NOTE:

If plug for propeller shaft opening

in transmission is not available, drain

transmission.

10.

Disconnect:

• Shift linkage at transmission.

• Speedometer cable at transmission.

• Transmission cooler lines (if so equipped).

11.

On synchromesh equipped vehicles, disconnect clutch

linkage at cross-shaft then remove cross-shaft en-

gine bracket.

12.

Remove rocker arm covers as outlined, then attach

engine lifting adapter at the proper cylinder head bolt

locations.

13.

Remove front mount bolts.

14.

Attach lifting device and raise engine to take weight

off front mounts, then remove rear mount bolts.

15.

Raise engine to take weight off rear mount, then re-

move crossmember.

NOTE:

On Chevrolets it will be necessary to

remove mount from transmission before cross-

member can be removed.

16.

Remove engine-transmission assembly from vehicle

as a unit.

17.

Remove transmission (and clutch):

Synchromesh Transmission

a. Remove clutch housing cover plate screws.

b.

Remove bolts attaching the clutch housing to en-

gine block then remove transmission and clutch

housing as a unit.

NOTE:

Support the transmission as the last

mounting bolt is removed, and as it is being

pulled away from the engine (to prevent damage

to clutch disc).

c. Remove starter and clutch housing rear cover

plate.

d. Loosen clutch mounting bolts a turn at a time (to

prevent distortion of clutch cover) until the spring

pressure is released. Remove all bolts, clutch

disc and pressure plate assembly.

Automatic

Transmission

a. Lower engine, secured by the hoist, and support

engine on blocks.

b.

Remove starter and converter housing underpan.

c. Remove flywheel-to-converter attaching bolts.

d. Support transmission on blocks.

e. Remove transmission-to-engine mounting bolts.

f. With the hoist attached, remove blocks from the

engine only and slowly guide the engine from the

transmission.

18.

Mount engine in stand.

Installation

1.

Attach lifting device to engine and remove engine

from engine stand.

2.

Install transmission (and clutch):

Synchromesh Transmission

a. Install the clutch on flywheel as outlined in Sec-

tion 7.

b.

Install clutch housing rear cover and starter.

c. Install transmission and clutch housing as out-

lined in Section 7.

d. Install clutch housing cover screws and tighten

securely.

Automatic

Transmissions

a. Position engine adjacent to the transmission and

align the converter with the flywheel.

b.

Bolt transmission to engine, then raise engine and

transmission assembly and install flywheel to

converter attaching bolts.

c. Install converter housing underpan and starter.

3.

Tilt and lower engine and transmission assembly into

the chassis as a unit, guiding engine to align front

mounts with frame supports.

4.

Install front mount bolts and torque to specifications.

5. Raise engine enough to install rear crossmember,

then install crossmember, install rear mount, lower

engine and torque rear mount to specifications.

CHEVROLET CHASSIS SERVICE MANUAL

Page 291 of 659

ENGINE 6-26

6. Remove lifting device and lifting adapter then install

rocker arm covers as outlined.

7.

On synchromesh equipped vehicles, install clutch

cross-shaft engine bracket, then adjust and connect

clutch as outlined in Section 7.

8. Connect:

• Speedometer cable.

• Shift linkage at transmission.

• Transmission cooler lines (if so equipped).

9. Install propeller shaft.

10.

Remove jack stands and lower vehicle.

11.

Connect: \ '

Power steering pump lines (if so equipped).

Vacuum line to power brake unit (if so equipped).

Exhaust pipes at manifold flanges.

Accelerator linkage at pedal lever.

Fuel line at fuel pump.

Engine cooler lines (if so equipped).

Oil pressure gauge lines (if so equipped).

12.

Connect wires at:

Coil

Oil pressure switch

Temperature switch

Delcotron

Starter solenoid

13.

Install pulley, fan blade and fan belt as outlined in

Section 6K.

14.

Install radiator and shroud as outlined in Section 13.

15.

Install and adjust hood as outlined in Section 11.

16.

Connect battery cables.

17.

Fill with coolant, engine oil and transmission oil,

then start engine and check for leaks.

18.

Perform necessary adjustments and install air

cleaner.

INTAKE MANIFOLD

Removal

1.

Drain radiator and remove air cleaner.

2.

Disconnect:

Battery cables at battery.

Upper radiator and heater hose at manifold.

Accelerator linkage at pedal lever.

Fuel line at carburetor. ;

Wires at temperature sending switch and coil

(both sides).

Power brake hose at carburetor base.

Spark advance hose at distributor.

Crankcase ventilation hoses (as required).

3.

Remove distributor cap and mark rotor position with

chalk. Remove distributor clamp and distributor,

then position distributor cap rearward clear of

manifold.

4.

Remove coil.

5.

Remove manifold-to-head attaching bolts, then re^

move manifold, (with carburetor on) from engine and

discard gaskets and seals.

6. If manifold is to be replaced,,transfer:

Carburetor and carburetor mounting studs.

Temperature sending switch.

Water outlet and thermostat (use new gasket).

Heater hose adapter.

Choke coil.

Installation

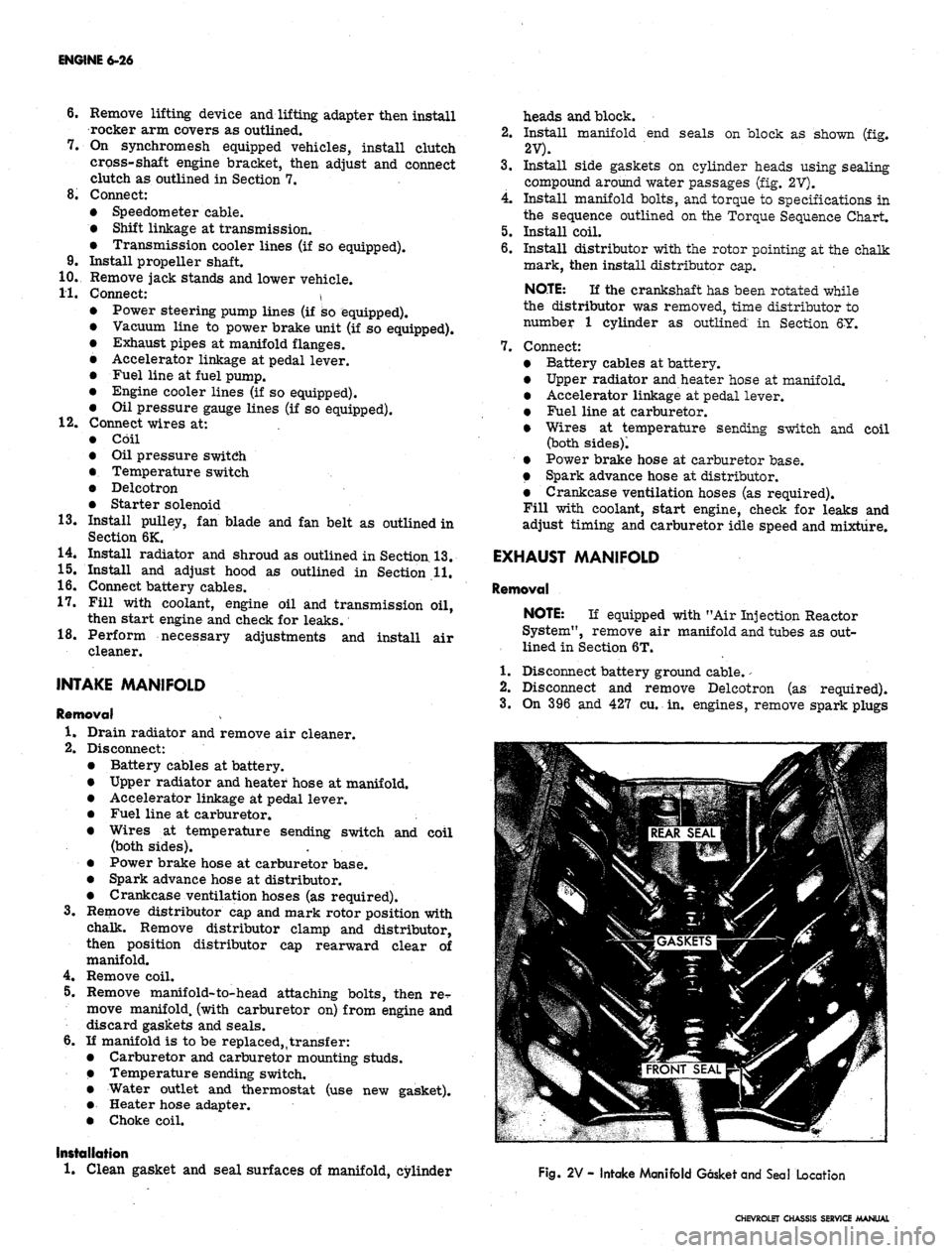

1.

Clean gasket and seal surfaces of manifold, cylinder

heads and block.

2.

Install manifold end seals on block as shown (fig.

2V).

3.

Install side gaskets on cylinder heads using sealing

compound around water passages (fig. 2V).

4.

Install manifold bolts, and torque to specifications in

the sequence outlined on the Torque Sequence Chart.

5.

Install coil.

6. Install distributor with the rotor pointing at the chalk

mark, then install distributor cap.

NOTE:

If the crankshaft has been rotated while

the distributor was removed, time distributor to

number 1 cylinder as outlined in Section 6Y.

7.

Connect:

Battery cables at battery.

Upper radiator and heater hose at manifold.

Accelerator linkage at pedal lever.

Fuel line at carburetor.

Wires at temperature sending switch and coil

(both sides)!

Power brake hose at carburetor base.

Spark advance hose at distributor.

Crankcase ventilation hoses (as required).

Fill with coolant, start engine, check for leaks and

adjust timing and carburetor idle speed and mixture.

EXHAUST MANIFOLD

Removal

NOTE:

If equipped with "Air Injection Reactor

System", remove air manifold and tubes as out-

lined in Section 6T.

1.

Disconnect battery ground cable.

-

2.

Disconnect and remove Delcotron (as required).

3.

On 396 and 427 cu. in. engines, remove spark plugs

Fig. 2V - Intake Manifold Gasket and Seal Location

CHEVROLET CHASSIS SERVICE MANUAL

Page 292 of 659

ENGINE 6-27

and spark plug shields.

4.

Remove exhaust manifold flange nuts, then lower ex-

haust pipe assembly (hang exhaust pipe from frame

with wire).

5.

Bend french lock tabs (fig. 3V), remove end bolts

then remove center bolts and remove manifold from

engine.

NOTE: A 9/16 thin-wall 6 point socket, sharp-

ened at the leading edge, then started on the head

of the bolt and tapped in place with a hammer,

simplifies bending of french locks.

Installation

1.

Clean mating surfaces on manifold and head, then

install manifold in position and install center bolts.

2.

Install end bolts with french locks under them.

3.

Torque center bolts to specifications, then torque end

bolts to specifications, and bend french lock tabs to

lock end bolts.

4.

Using a new flange gasket install exhaust pipe to

manifold flange.

5.

On 396 and 427 cu. in. engines, clean and install

spark plugs using new gaskets. (Torque spark plugs

to specifications.)

6. Install and connect Delcotron.

7.

Connect the battery ground cable.

8. Start engine and check for leaks.

ROCKER ARM COVER

Removal

1.

Remove air cleaner.

2.

Disconnect crankcase ventilation hoses (as required).

3.

Disconnect temperature wire from rocker arm cover

clips.

4.

Remove rocker arm cover.

CAUTION: DO NOT pry rocker arm cover

loose. Gaskets adhering to cylinder head and

Installation

1.

.Clean gasket surfaces on cylinder head and rocker

arm cover with degreaser then, using a new gasket,

install rocker arm cover and torque bolts to

specifications. .

2.

Connect crankcase ventilation hoses (if disconnected).

3.

Connect temperature wire at rocker arm cover clips.

4.

Install air cleaner.

VALVE MECHANISM

Removal

1.

Remove rocker arm covers as outlined.

2.

Remove rocker arm nuts, rocker arm balls, rocker

arms and push rods.

NOTE: Place rocker arms, rocker arm balls

and push rods in a rack so they may be rein-

stalled in the same location.

Installation and Adjustment

NOTE: Whenever new rocker arms and/or

rocker arm balls are being installed, coat bear-

ing surfaces of rocker arms and rocker arm

balls with Molykote or its equivalent.

1.

Install push rods; Be sure push rods seat in lifter

socket.

2.

Install rocker arms, rocker arm balls and rocker

arm nuts.

3.

Adjust valves when lifter is on base circle of cam-

shaft lobe as follows:

With Hydraulic Valve

Lifters

2L.

Crank engine until

mark on torsional damper

lines up with center or "0M mark on the timing

tab and the engine is in the number 1 firing posi-

tion. This may be determined by placing fingers

on the number 1 cylinder valve as the mark on the

rocker arm cover may be sheared by bumpii

end of rocker arm cover rearward with palm

hand or a rubber mallet.

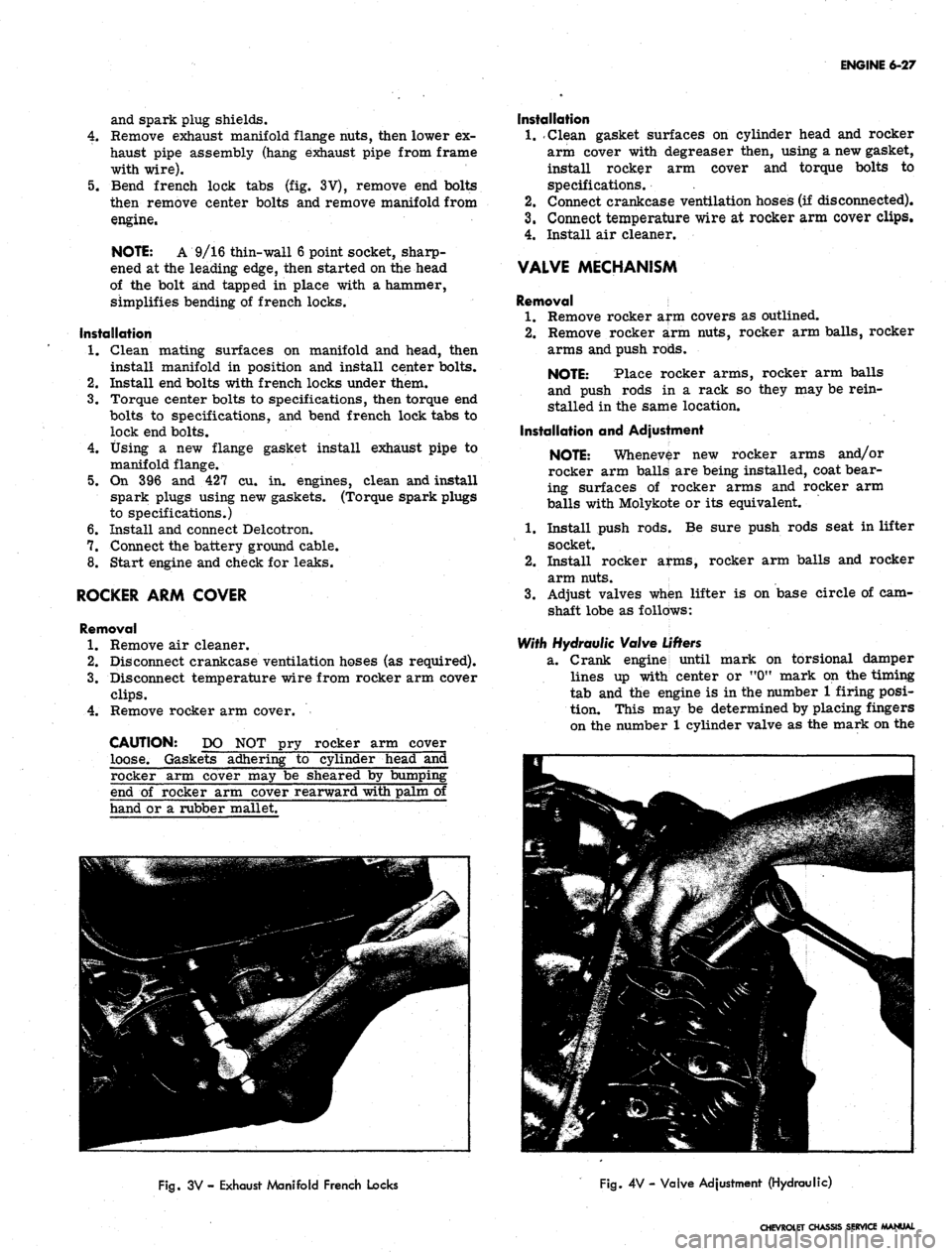

Fig.

3V - Exhaust Manifold French Locks

Fig.

4V - Valve Adjustment (Hydraulic)

CHEVROLET CHASSIS SERVICE MANUAL

Page 295 of 659

ENGINE 6-30

c". Install the valve locks and release the compres-

sor tool making sure the locks seat properly in

the upper groove of the valve stem.

NOTE: Grease may be used to hold the locks

in place while releasing the compressor tool.

396 and 427

cu.

in.

Engines

a. Install new valve stem oil seal (coated with oil)

in position over valve guide.

b.

Set the valve spring and damper and valve cap in

place.

c. Compress the spring with Tool J-5892 and install

the valve locks, then release the compressor tool,

making sure the locks seat properly in the groove

of the valve stem.

NOTE: Grease may be used to hold the locks

in place while releasing the compressor tool.

7.

Install spark ,plug, using a new gasket, and torque to

specifications. -

8. Install and adjust valve mechanism as outlined.

CYLINDER HEAD ASSEMBLY

Removal

1.

Remove intake manifold as outlined.

2.

Remove exhaust manifolds as outlined.

3.

Remove valve mechanism as outlined.

4.

Drain cooling system (block).

5.

Remove cylinder head bolts, cylinder head and gas-

ket. Place cylinder head on two blocks of wood to

prevent damage.

Installation

CAUTION: The gasket surfaces on both the

head and the block must be clean of any foreign

ttter and free of nicks or heavy scratches.

Under bolt threads in the block and threads on

Pie cylinder head bolt must be cleaned. (Dirt

will affect bolt torqueT)

1.

On engines using a STEEL gasket, coat both sides of

a new gasket with a good sealer, spread the sealer

thin and even. One method of applying the sealer that

will assure the proper- coat is with the use of a paint

roller. Too much sealer may hold the beads of the

gasket away from the head or block.

CAUTION: Use no sealer on engines using a

composition STEEL ASBESTOS gasket.

2.

Place the gasket in position over the dowel pins with

the bead up.

3.

Carefully guide cylinder head into place over dowel

pins and gasket.

4.

Coat threads of cylinder head bolts with sealing

compound and install finger tight.

5.

Tighten cylinder head bolts a little at a time in the

sequence shown on the torque sequence chart until

the specified torque is reached.

6. Install the exhaust manifold as outlined.

7.

Install the intake manifold as outlined.

8. Install and adjust the valve mechanism as outlined.

OIL

PAN

Removal

Chevrolet

and Camaro

1.

Disconnect battery positive cable.

2.

Disconnect distributor cap from distributor (to pr-e-

vent breaking distributor cap when engine is raised).

3.

Drain radiator, then disconnect lower radiator hose

at water pump and remove oil dip stick and tube

(where necessary). '

4.

Remove fan blade.

5.

Raise vehicle then drain engine oil;

6. Remove through bolts from engine front mounts.

Disconnect and remove starter.

7.

On vehicles equipped with automatic transmissions,

remove converter housing underpan.

8. Disconnect steering rod at idler lever then swing

steering linkage 4pwn for oil pan clearance.

9. Rotate crankshaft untii timing mark on torsional

damper is at 6:00 o'clock position.

10.

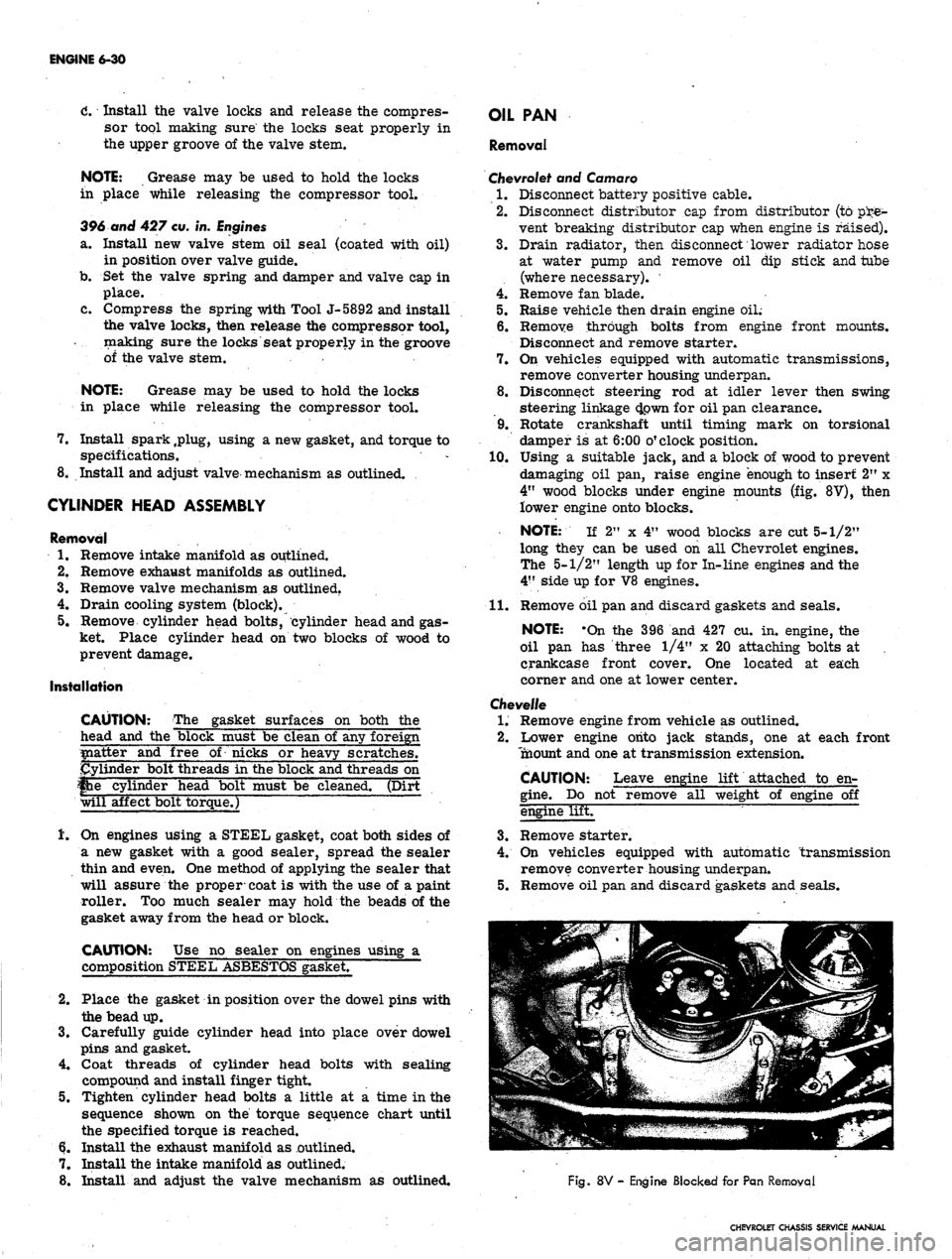

Using a suitable jack, and a block of wood to prevent

damaging oil pan, raise engine "enough to insert 2" x

4"

wood blocks under engine mounts (fig. 8V), then

lower engine onto blocks.

NOTE: If 2" x 4" wood blocks are cut 5-1/2"

long they can be used on all Chevrolet engines.

The 5-1/2" length up for In-line engines and the

4"

side up for V8 engines.

11.

Remove oil pan and discard gaskets and seals.

NOTE: -On the 396 and 427 cu. in. engine, the

oil pan has three 1/4" x 20 attaching bolts at ,

crankcase front cover. One located at each

corner and one at lower center.

Chevelle

1.

Remove engine from vehicle as outlined.

2.

Lower engine onto jack stands, one at each front

Tnaount and one at transmission extension.

CAUTION: Leave engine lift attached to en-

gine.

Do not remove all weight of engine off

engine lifET

3.

Remove starter.

4.

On vehicles equipped with automatic transmission

remove converter housing underpan.

5.

Remove oil pan and discard gaskets and seals.

Fig.

8V - Engine Blocked for Pan Removal

CHEVROLET CHASSIS SERVICE MANUAL

Page 296 of 659

ENGINE 6-31

Chevy II

1.

Disconnect battery positive cable.

2.

Drain engine oil.

3.

Disconnect and remove starter.

4 Disconnect steering idler arm bracket at right hand

frame rail and swing steering linkage down for pan

clearance.

5.

Disconnect* exhaust pipes at manifolds and allow

pipes to hang free.

6. Remove oil pan and discard gaskets and seals.

Corvette

1.

Disconnect battery positive cable then remove oil

dipstick and tube.

2.

Raise and support vehicle then drain engine oil.

3.

Remove starter and flywheel underpan.

4.

Disconnect steering linkage idler at frame and lower

the linkage.

5.

Remove oil pan and discard gaskets and seals.

6. On Hi-Performance engines, the oil baffle must

be removed before additional operations can be

performed.

NOTE: On the 427 cu. in. engine, the oil pan

has three 1/4" x 20 attaching bolts at crankcase

front cqver. One located at each corner and one

at lower center.

Installation

1.

Thoroughly clean all gasket sealing surfaces.

NOTE: Use a new pan. gasket set.

2.

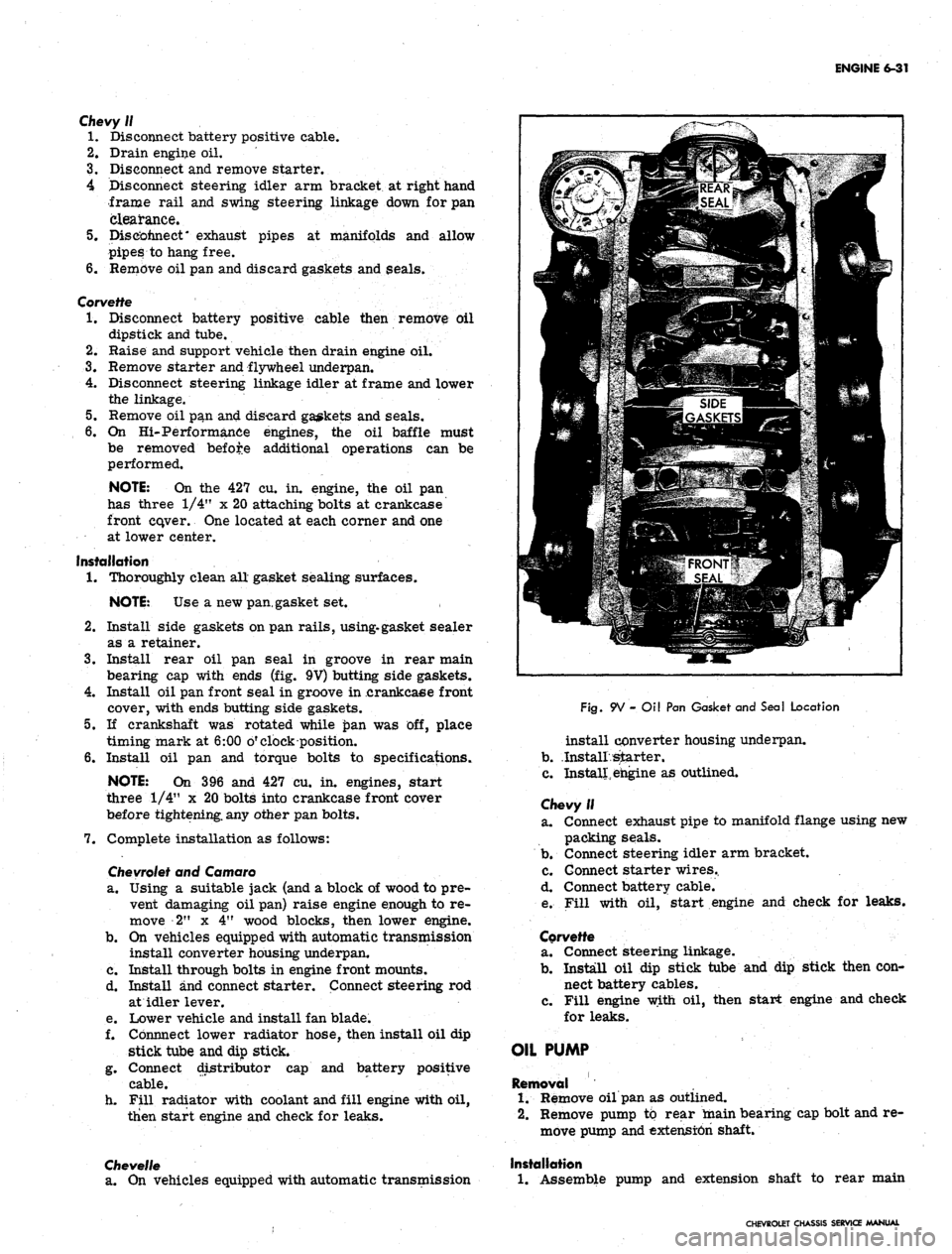

Install side gaskets on pan rails, using.gasket sealer

as a retainer.

3.

Install rear oil pan seal in groove in rear main

bearing cap with ends (fig. 9V) butting side gaskets.

4.

Install oil pan front seal in groove in .crankcaee front

cover, with ends butting side gaskets.

5.

If crankshaft was rotated while £>an was off, place

timing mark at 6:00 o'clock position.

6. Install oil pan and torque bolts to specifications.

NOTE: On 396 and 427 cu. in. engines, start

three 1/4" x 20 bolts into crankcase front cover

before tightening, any other pan bolts.

7.

Complete installation as follows:

Chevrolet

and Camaro

a. Using a suitable jack (and a block of wood to pre-

vent damaging oil pan) raise engine enough to re-

move 2" x 4" wood blocks, then lower engine.

b.

On vehicles equipped with automatic transmission

install converter housing underpan.

c. Install through bolts in engine front mounts.

d. Install and connect starter. Connect steering rod

at idler lever.

e. Lower vehicle and install fan blade.

f. Cbnnnect lower radiator hose, then install oil dip

stick tube and dip stick.

g. Connect distributor cap and battery positive

cable.

h. Fill radiator with coolant and fill engine with oil,

then start engine and check for leaks.

Chevelle

a. On vehicles equipped with automatic transmission

Fig.

9V - Oil Pan Gasket and Seal Location

install converter housing underpan.

b.

.Install starter.

c. Install, engine as outlined.

Chevy II

a. Connect exhaust pipe to manifold flange using new

packing seals.

b.

Connect steering idler arm bracket.

c. Connect starter wires..

d. Connect battery cable.

e. Fill with oil, start engine and check for leaks.

Corvette

a. Connect steering linkage.

b.

Install oil dip stick tube and dip stick then con-

nect battery cables.

c. Fill engine with oil, then start engine and check

for leaks.

OIL PUMP

Removal

1.

Remove oil pan as outlined.

2.

Remove pump to rear main bearing cap bolt and re-

move pump and extension shaft.

Installation

1.

Assemble pump and extension shaft to rear main

CHEVROLET CHASSIS SERVICE MANUAL

Page 313 of 659

ENGINE FUEL 6M-5

3.

Disconnect choke rod or choke cable.

4.

Disconnect accelerator linkage.

5.

If equipped with Automatic transmission, discon-

nect TV linkage.

6. Remove carburetor attaching nuts and/or bolts and

remove carburetor.

Test Before Installation -

It is good shop practice to fill the carburetor bowl

before installing the carburetor. This reduces the strain

on the starting motor and battery and reduces the pos-

sibility of backfiring while attempting to start the engine.

A fuel pump clamped to the bench, a small supply of fuel

and the necessary fittings enable the carburetor to be

filled1 and the operation of the float and'intake needle and

seat to be checked. Operate the throttle several times

and check the discharge from the pump jets before in-

stalling the carburetor.

Installation

1.

Be certain throttle body and intake manifold sealing

surfaces are clean.

2.

Install new carburetor to manifold flange gasket (if

required).

3.

Install carburetor over manifold studs.

4.

Start vacuum and fuel lines at carburetor.

5.

Install attaching nuts and/or bolts and tighten

securely.

6. Tighten fuel and vacuum lines.

7.

Connect and adjust accelerator and TV linkage.

8. Connect choke tube or choke rod.

9. Adjust idle speed and mixture, then install air

cleaner. #

Fuel Filter Maintenance

1.

Disconnect fuel line connection at inlet fuel filter

nut.

2.

Remove inlet fuel filter nut from carburetor with a

1"

box wrench or socket.

3.

Remove filter element and spring (fig. 4c).

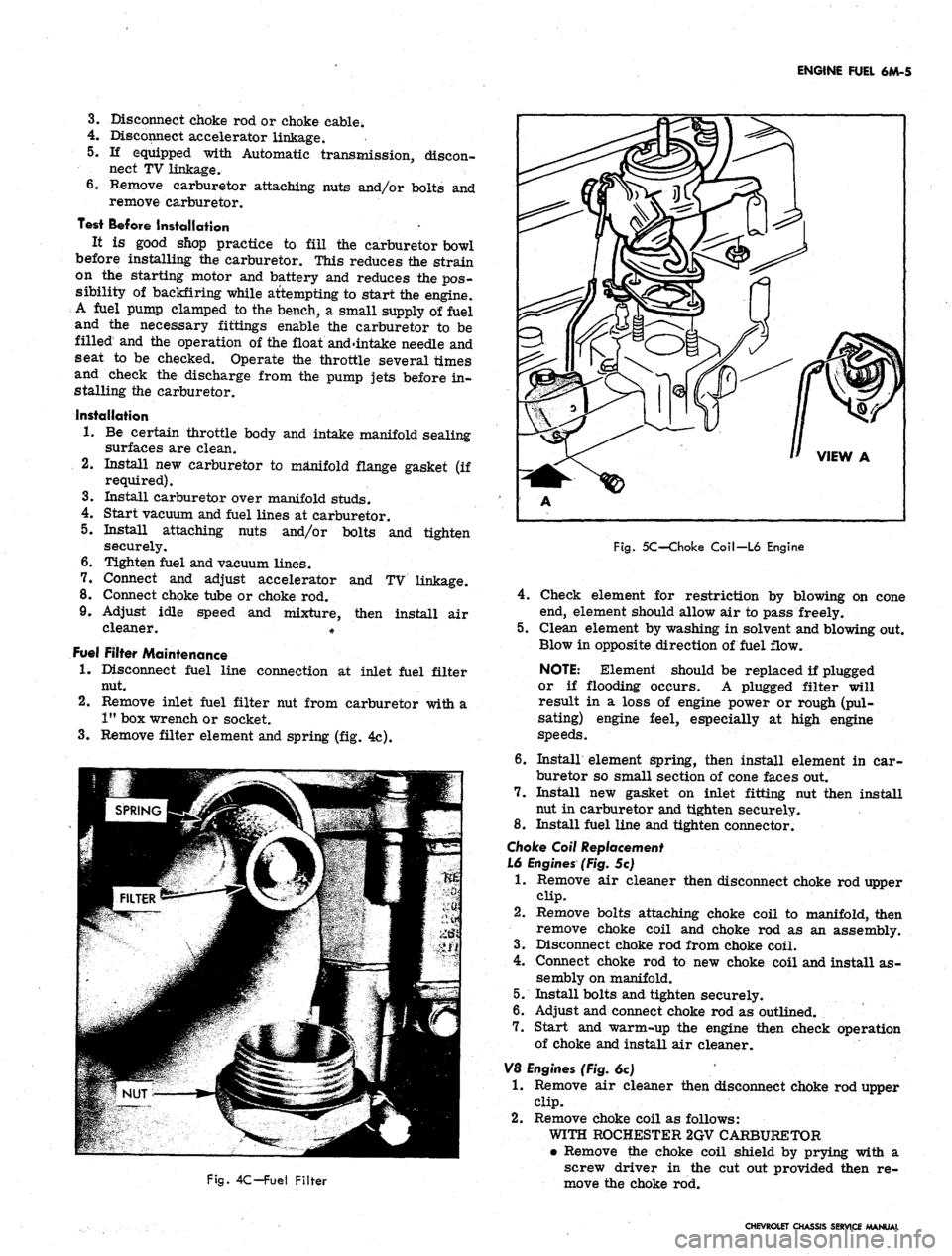

Fig. 5C-Choke Coil-L6 Engine

4.

Fig. 4C-Fuel Filter

Check element for restriction by blowing on cone

end, element should allow air to pass freely.

5.

Clean element by washing in solvent and blowing out.

Blow in opposite direction of fuel flow.

NOTE: Element should be replaced if plugged

or if flooding ocpurs. A plugged filter will

result in a loss of engine power or rough (pul-

sating) engine feel, especially at high engine

speeds.

6. Install element spring, then install element in car-

buretor so small section of cone faces out.

7.

Install new gasket on inlet fitting nut then install

nut in carburetor and tighten securely.

8. Install fuel line and tighten connector.

Choke Coil Replacement

L6 Engines (Fig. 5c)

1.

Remove air cleaner then disconnect choke rod upper

clip.

2.

Remove bolts attaching choke coil to manifold, then

remove choke coil and choke rod as an assembly.

3.

Disconnect choke rod from choke coil.

4.

Connect choke rod to new choke coil and install as-

sembly on manifold.

5.

Install bolts and tighten securely.

6. Adjust and connect choke rod as outlined.

7.

Start and warm-up the engine then check operation

of choke and install air cleaner.

V8 Engines (Fig. 6c)

1.

Remove air cleaner then disconnect choke rod upper

clip.

2.

Remove choke coil as follows:

WITH ROCHESTER 2GV CARBURETOR

• Remove the choke coil shield by prying with a

screw driver in the cut out provided then re-

move the choke rod.

CHEVROLET CHASSIS SERVICE MANUAL

Page 326 of 659

SECTION 6Y

ENGINE ELECTRICAL

CONTENTS

OF

THIS SECTION

Page

System

6Y-19

6Y-32

6Y-34

BATTERY

INDEX

Page

General Description 6Y_i

Types of Batteries 6Y-1

Dry Charged Batteries 6Y-2

Activating Dry Charged Batteries 6Y-2

Wet Charged Batteries 6Y 2

Periodic Service 6Y-3

Common Causes of Failure 6Y-3

Delco Eye 6Y_3

Electrolyte Level

AY

3

Water Usage ] \ 6Y_3

Cleaning 6Y_4

Cables 6Y_4

Carrier and Holddown 6Y-4

Page

Safety Precautions 6Y-4

Charging Procedures . . gY_4

Slow Charging gY-4

Fast Charging . * 6Y-4

Emergency Boost Charging 6Y-4

Test Procedures QY-S

Visual Inspection 6Y-5

Instrument 6Y-5

Full Charge Hydrometer Test. 6Y-5

Specific Gravity Readings 6Y-5

Cell Comparison Test . 6Y-5

Installing Battery 6Y-5

GENERAL DESCRIPTION

The battery (fig. lb) is made up of a number of separ-

ate elements, each located in an individual cell in a hard

rubber case. Each element consists of an assembly of

positive plates and negative plates containing dissimilar

active materials and kept apart by separators. Hie ele-

ments are immersed in an electrolyte composed of dilute

sulfuric acid. Plate straps located on the top of each ele-

ment connect all the positive plates and all the negative

plates into groups. The elements are connected in series

electrically by connectors that pass directly through the

case partitions between cells. The battery top is a one-

piece cover of hard rubber construction. Tfte cell con-

nectors, by-passing through the cell partitions, connect

the elements along the shortest practical path (fig. 2b).

With the length of the electrical circuit inside the

Battery reduced to a minimum, the internal voltage drop

is decreased resulting in improved performance, par-

ticularly during engine cranking at low temperatures.

The hard, smooth one-piece cover greatly reduces the

tendency for corrosion to form on the top of the Battery.

The cover is bonded to the case with sealing compound

that forms an air tight seal between the cover and case.

Protection for the Battery charging circuit (10 gage

wire) is provided by a pigtail lead which is a fusible Hnk

off the battery positive cable (14 gage wire). This lead is

an integral part of the Battery cable assembly and serv-

icing requires replacing the complete cable assembly.

TYPES

OF

BATTERIES

There are two types of Batteries—the "dry charge"

type and the "wet charge" type. The difference in types

depends on the method of manufacture.

ONE PIECE

CELL COVER

VENT PLUG

ELECTROLYTE LEVEL

INDICATOR

HOLD-DOWN SLOT

Fig.

lb—Battery

CHEVROLET CHASSIS SERVICE MANUAL

Page 327 of 659

ENGINE-ELECTRICAL 6Y-2

PARTITION

PLATE

STRAP

CONNECTOR

Fig.

2b—Internal View of Two Cells Showing Connector

through Partition

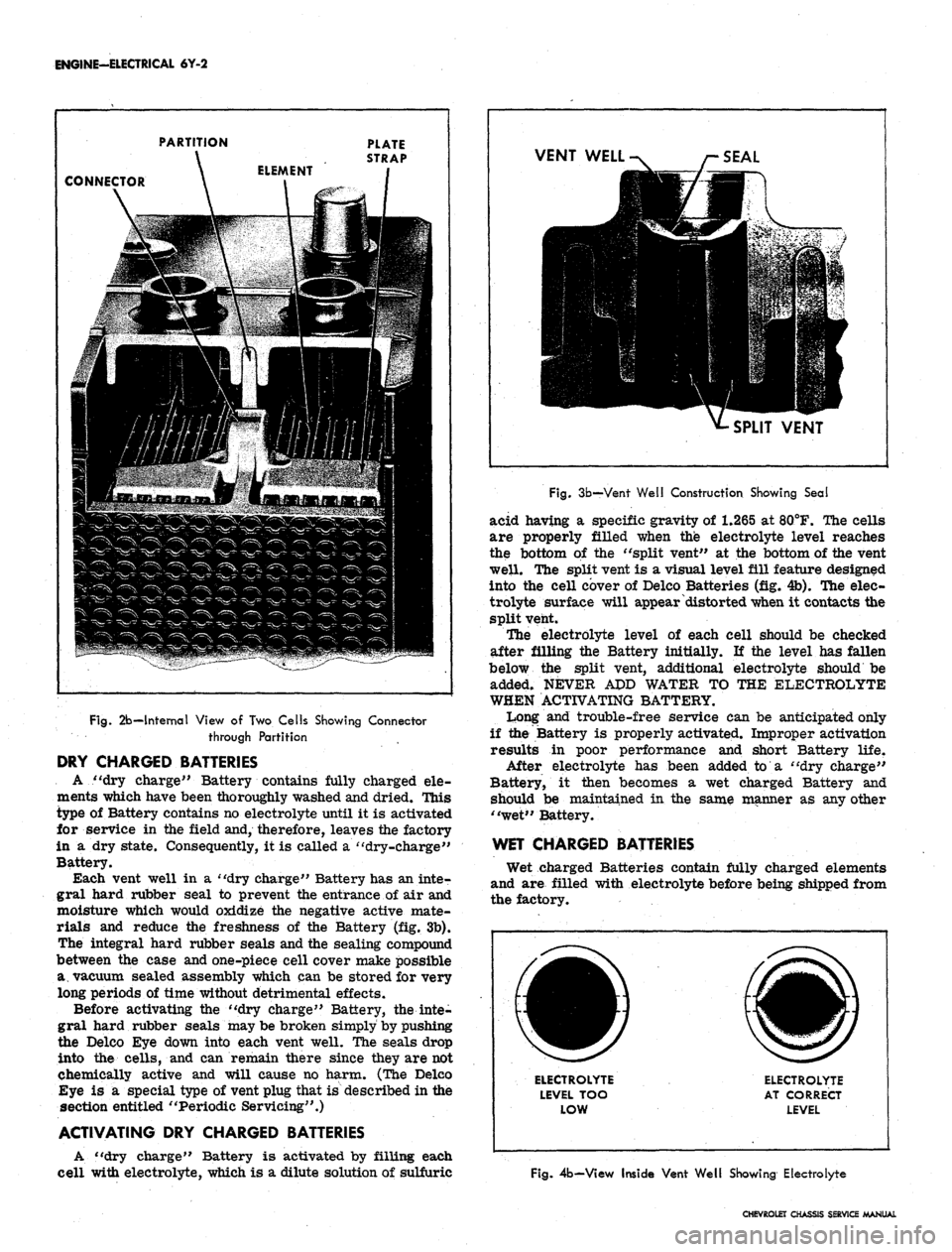

DRY CHARGED BATTERIES

A "dry charge" Battery contains fully charged ele-

ments which have been thoroughly washed and dried. Hiis

type of Battery contains no electrolyte until it is activated

for service in the field and, therefore, leaves the factory

in a dry state. Consequently, it is called a "dry-charge"

Battery.

Each vent well in a "dry charge" Battery has an inte-

gral hard rubber seal to prevent the entrance of air and

moisture which would oxidize the negative active mate-

rials and reduce the freshness of the Battery (fig. 3b).

The integral hard rubber seals and the sealing compound

between the case and one-piece cell cover make possible

a. vacuum sealed assembly which can be stored for very

long periods of time without detrimental effects.

Before activating the "dry charge" Battery, the inte-

gral hard rubber seals may be broken simply by pushing

the Delco Eye down into each vent well. The seals drop

into the cells, and can remain there since they are not

chemically active and will cause no harm. (The Delco

Eye is a special type of vent plug that is described in the

section entitled "Periodic Servicing".)

ACTIVATING DRY CHARGED BATTERIES

A "dry charge" Battery is activated by filling each

cell with electrolyte, which is a dilute solution of sulfuric

VENT WELL

SEAL

SPLIT VENT

Fig. 3b—Vent Well Construction Showing Seal

acid having a specific gravity of 1.265 at 80°F. The cells

are properly filled when the electrolyte level reaches

the bottom of the "split vent" at the bottom of the vent

well. The split vent is a visual level fill feature designed

into the cell cover of Delco Batteries (fig. 4b). The elec-

trolyte surface will appear distorted when it contacts the

split vent.

The electrolyte level of each cell should be checked

after filling the Battery initially. If the level has fallen

below the split vent, additional electrolyte should be

added. NEVER APD WATER TO THE ELECTROLYTE

WHEN ACTIVATING BATTERY.

Ir?ong and trouble-free service can be anticipated only

if the Battery is properly activated. Improper activation

results in poor performance and short Battery life.

After electrolyte has been added to a "dry charge"

Battery, it then becomes a wet charged Battery and

should be maintained in the same manner as any other

"wet" Battery.

WET CHARGED BATTERIES

Wet charged Batteries contain fully charged elements

and are filled with electrolyte before being shipped from

the factory.

ELECTROLYTE

LEVEL TOO

LOW

ELECTROLYTE

AT CORRECT

LEVEL

Fig. 4b-View Inside Vent Well Showing Electrolyte

CHEVROLET CHASSIS SERVICE MANUAL