torque CHEVROLET CAMARO 1967 1.G Chassis Manual Online

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1967, Model line: CAMARO, Model: CHEVROLET CAMARO 1967 1.GPages: 659, PDF Size: 114.24 MB

Page 309 of 659

SECTION 6M

ENGINE FUEL

CONTENTS OF THIS SECTION

Page

Carburetors 6M-1 Fuel Pumps .

Air Cleaners 6M-7 Special Tools

Page

6M-10

6M-12

CARBURETORS

INDEX

Page

General Description 6M-1

Service Procedures 6M-1

Preliminary Checks 6M-1

Idle Speed and Mixture Adjustment ........... 6M-1

Fast Idle Adjustment .................. 6M-3

Choke Adjustment 6M-3

Float Adjustment 6M-4

Page

Additional Adjustments 6M-4

Removal 6M-4

Test Before Installation 6M-5

Installation 6M-5

Fuel Filter Maintenance 6M-5

Choke Coil Replacement 6M-5

Throttle Linkage Adjustment . . 6M-6

GENERAL DESCRIPTION

Various carburetors (fig. lc) are used with Chevrolet,

Chevelle, Chevy II, Camaro and Corvette passenger

vehicles. These carburetors are designed to meet the

particular requirements of engines, transmissions and

vehicles, therefore carburetors that look alike are not

always interchangeable. (Refer to carburetor part num-

ber and/or specifications.)

Because many service procedures for the various

carburetors are similar, typical illustrations and pro-

cedures are used except where specific illustrations or

procedures are necessary to clarify the operation.

This section covers removal, installation and adjust-

ments (on engine) of carburetors. Also covered in this

section are maintenance procedures for choke coils,

throttle linkage and fuel filters. For carburetor .over-

haul procedures and additional adjustments (bench), re-

fer to Section 6M of the Overhaul Manual under the

carburetor being serviced.

Specifications for carburetors are located in the back

of this manual.

SERVICE PROCEDURES

Preliminary Checks

1.

Thoroughly warm-up engine. If the engine is cold,

allow to run for at least 15 minutes.

2.

Inspect torque of carburetor to intake manifold bolts

and intake manifold to cylinder head bolts to exclude

the possibility of air leaks.

3.

Inspect manifold heat control valve (if used) for free-

dom of action and correct spring tension.

Idle Speed and Mixture Adjustment (Except Air Injection

Reactor System)

NOTE:

This adjustment should be performed

with engine at operating temperature and park-

ing brake applied.

1.

Remove Air Cleaner.

2.

Connect tachometer and vacuum gauge to engine, then

set hand brake and shift transmission into neutral.

3.

As a preliminary adjustment, turn idle mixture

screws lightly to seat and back out 1-1/2 turns.

CAUTION: Do not turn idle mixture screw

tightly against seat or damage may result.

4.

With engine running (choke wide open) adjust idle

speed screw to specified idle speed, (automatic

transmission in drive, synchronized transmission in

neutral).

5. Adjust idle mixture screw to obtain highest steady

vacuum at specified idle speed.

NOTE:

On air conditioned vehicles, turn air

conditioning to the "on" position and hold the

hot idle compensator valve closed while adjust-

ing idle speed and idle mixture screws.

NOTE:

On Rochester BV carburetors the idle

mixture screw should be turned out 1/4 turn

from the "lean roll" position. The definition

of "lean roll" point is a 20 to 30 rpm drop

in engine speed obtained by leaning the idle

mixture.

6. Repeat Steps 4 and5 as needed for final adjustment.

NOTE:

If necessary, final adjustment of the \

carburetor may be made with the air cleaner

installed.

7. Turn engine off, remove gauges and install air

clearer.

CHEVROLET CHASSIS SERVICE MANUAL

Page 322 of 659

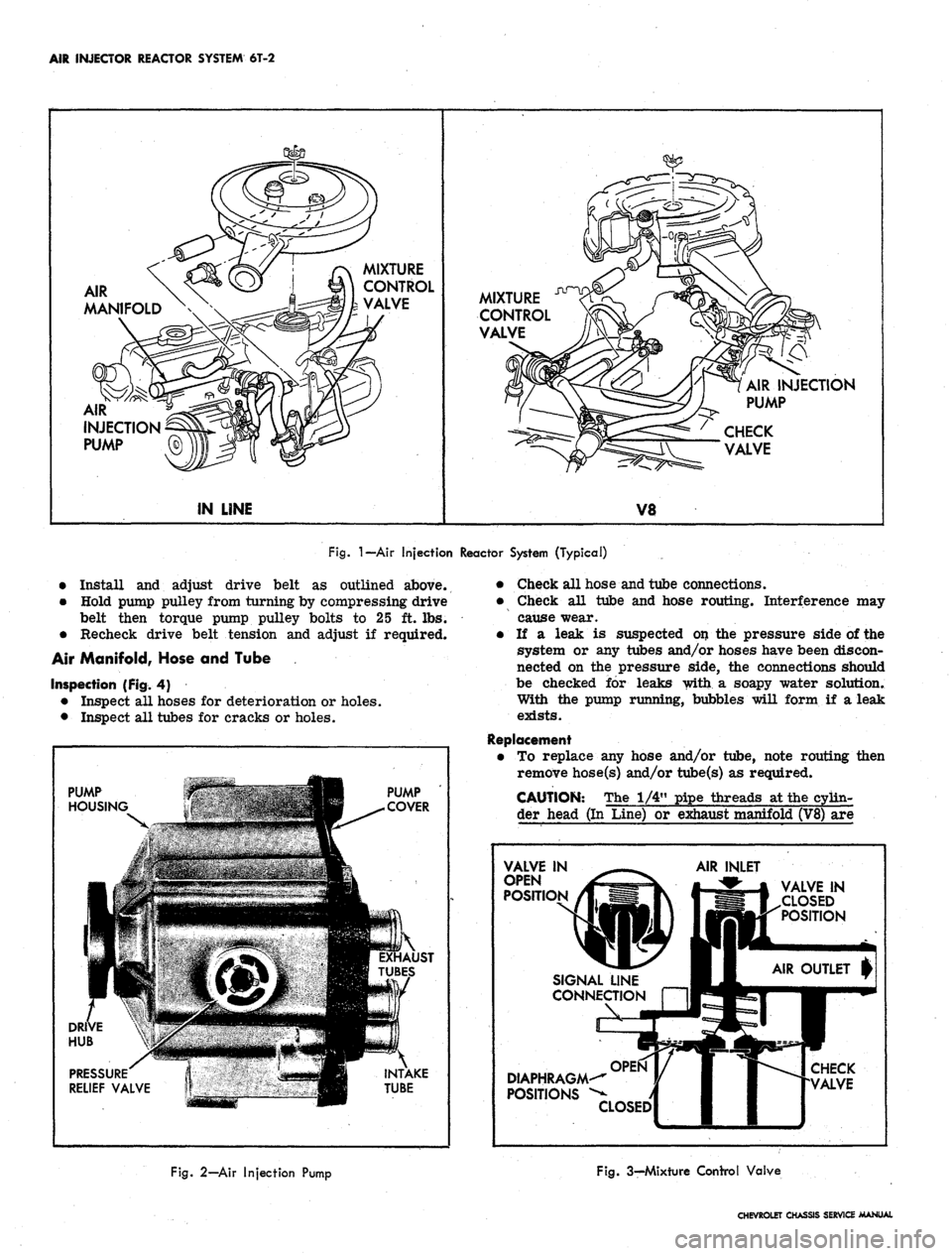

AIR INJECTOR REACTOR SYSTEM

6T-2

AIR

MANIFOLD

MIXTURE

CONTROL

VALVE

AIR

INJECTION

PUMP

IN LINE

MIXTURE

CONTROL

VALVE

AIR INJECTION

PUMP

CHECK

VALVE

V8

Fig.

I—Air

Injection Reactor System (Typical)

• Install

and

adjust drive belt

as

outlined above.

• Hold pump pulley from turning

by

compressing drive

belt then torque pump pulley bolts

to 25 ft. lbs.

• Recheck drive belt tension

and

adjust

if

required.

Air Manifold, Hose and Tube

Inspection (Fig. 4)

• Inspect

all

hoses

for

deterioration

or

holes.

• Inspect

all

tubes

for

cracks

or

holes.

PUMP

HOUSING

91

DRIVE V

HUB

PRESSURE

RELIEF VALVE

•H

PUMP

'

Mm ^

COVER

A.

J^HTEXHAUST

wBBE

TUBES

SB

^1 INTAKE

JH TUBE

• Check

all

hose and tube connections.

• Check

all

tube

and

hose routing. Interference

may

cause wear.

•

If a

leak

is

suspected

on the

pressure side

of the

system

or any

tubes and/or hoses have been discon-

nected

on the

pressure side,

the

connections should

be checked

for

leaks with

a

soapy water solution.

With

the

pump running, bubbles will form

if

aleak

exists.

Replacement

•

To

replace

any

hose and/or tube, note routing then

remove hose(s) and/or tube(s)

as

required.

CAUTION:

The 1/4"

pipe threads

at the

cylin-

der head

(In

Line)

or

exhaust manifold

(V8) are

VALVE

IN

OPEN

POSITION

INLET

VALVE

IN

CLOSED

POSITION

DIAPHRAGM

POSITIONS

SIGNAL

LINE

CONNECTION

ALVE

Fig.

2—Air Injection Pump

Fig.

3—Mixture Control Valve

CHEVROLET CHASSIS SERVICE MANUAL

Page 339 of 659

ENGINE-ELECTRICAL 6Y-14

VOLTMETER

WIRING HARNESS

CONNECTOR

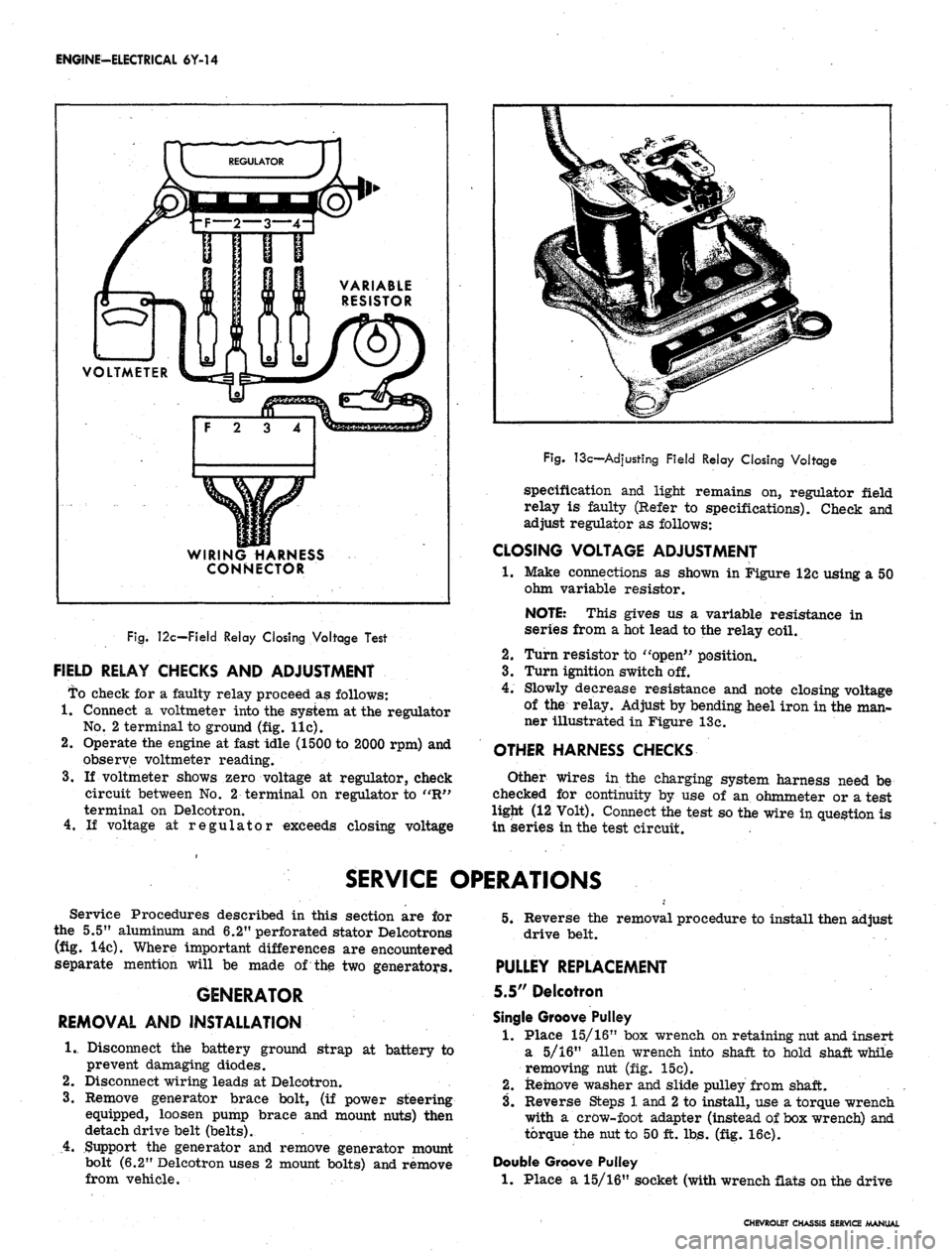

Fig.

12c—Field Relay Closing Voltage Test

FIELD RELAY CHECKS AND ADJUSTMENT

To check for a faulty relay proceed as follows:

1.

Connect a voltmeter into the system at the regulator

No.

2 terminal to ground (fig. lie).

2.

Operate the engine at fast idle (1500 to 2000 rpm) and

observe voltmeter reading.

3.

If voltmeter shows zero voltage at regulator, check

circuit between No. 2 terminal on regulator to "R"

terminal on Delcotron.

4.

If voltage at regulator exceeds closing voltage

Fig.

13c—Adjusting Field Relay Closing Voltage

specification and light remains on, regulator field

relay is faulty (Refer to specifications). Check and

adjust regulator as follows:

CLOSING VOLTAGE ADJUSTMENT

•1.

Make connections as shown in Figure 12c using a 50

ohm variable resistor.

NOTE: This gives us a variable resistance in

series from a hot lead to the relay coil.

2.

Turn resistor to "open" position.

3.

Turn ignition switch off.

4.

Slowly decrease resistance and note closing voltage

of the relay. Adjust by bending heel iron in the man-

ner illustrated in Figure 13c.

OTHER HARNESS CHECKS

Other wires in the charging system harness need be

checked for continuity by use of an ohmmeter or a test

ligjit (12 Volt). Connect the test so the wire in question is

in series in the test circuit.

SERVICE OPERATIONS

Service Procedures described in this section are for

the 5.5" aluminum and 6.2" perforated stator Delcotrons

(fig. 14c). Where important differences are encountered

separate mention will be made of the two generators.

GENERATOR

REMOVAL AND INSTALLATION

1.

Disconnect the battery ground strap at battery to

prevent damaging diodes.

2.

Disconnect wiring leads at Delcotron.

3.

Remove generator brace bolt, (if power steering

equipped, loosen pump brace and mount nuts) then

detach drive belt (belts).

4.

Support the generator and remove generator mount

bolt (6.2" Delcotron uses 2 mount bolts) and remove

from vehicle.

5.

Reverse the removal procedure to install then adjust

drive belt.

PULLEY REPLACEMENT

5.5" Delcotron

Single Groove Pulley

1.

Place 15/16" box wrench on retaining nut and insert

a 5/16" alien wrench into shaft to hold shaft while

removing nut (fig. 15c).

2.

Remove washer and slide pulley from shaft.

3.

Reverse Steps 1 and

2

to install, use a torque wrench

with a crow-foot adapter (instead of box wrench) and

torque the nut to 50 ft. lbs. (fig. 16c).

Double Groove Pulley

1.

Place a 15/16" socket (with wrench flats on the drive

CHEVROLET CHASSIS SERVICE MANUAL

Page 340 of 659

ENGINE-ELECTRICAL 6Y-15

L

RELAY

TERMINAL "F" TERMINAL

"BAT" \ ' /

TERMINAL

/ / /

GRD7

TERMINAL

5.5" SERIES ID DELCOTRON

"BAH"

TERMINAL

^Vs^^^^lijBii^^8C^3^SH|j^^^^^^sH^^Bf- y/

RELAY ^^^"^^^jWwIi^^^^ RELAY

6.2" SERIES 2D, TYPE 150 DELCOTRON

Fig.

14c—Delcotrons - Full View

end or use Adapter J-21501 and a box wrench) on re-

taining nut, insert a 5/16" alien wrench through

socket and adapter into hex on shaft to hold the shaft

while removing the nut.

2.

Remove washer and slide pulley from shaft.

3.

To install, slide pulley and washer on shaft and start

the nut.

4.

Use the socket and adapter with a torque wrench and

tighten-nut to 50 ft. lbs. torque.

BRUSH

REPLACEMENT

6.2"

Delcotron

1.

Remove two nuts retaining the blade connectors and

remove the connectors (fig. 17c). Slide the indicator

light relay wire from the terminal post.

2.

Remove two screws retaining the capacitor and brush

holder to rear end frame, Remove brush holder.

3.

To install brushes, push brushes into holder and

install pin to keep the brushes in holder.

4.

Attach brush assembly and condenser to the end

frame with hex-head stud on the .left side only.

Fig.

15c—Pulley Removal

Fig.

16c—Torqulng Pulley Nut

CHEVROLET CHASSIS SERVICE MANUAL

Page 356 of 659

ENGINE-ELECTRICAL

6Y-31

CAUTION: Before adjusting gap, me center

INSTALLATION

electrode flat. In adjusting the spark pluig Install the spark plugs in the engine with new gaskets

gap,

never bend the center electrode which and tighten to specifications. If torque wrench is not

extends through the porcelain center. Always available, tighten plugs finger tight and 1/2 turn more.

make adjustment by bending the ground or , Plugs are of a 14 millimeter size and care must be

side electrode. exercised when installing or the gap setting may be

changed.

CHEVROLET CHASSIS SERVICE MANUAL

Page 358 of 659

ENGINE-ELECTRICAL 6Y-33

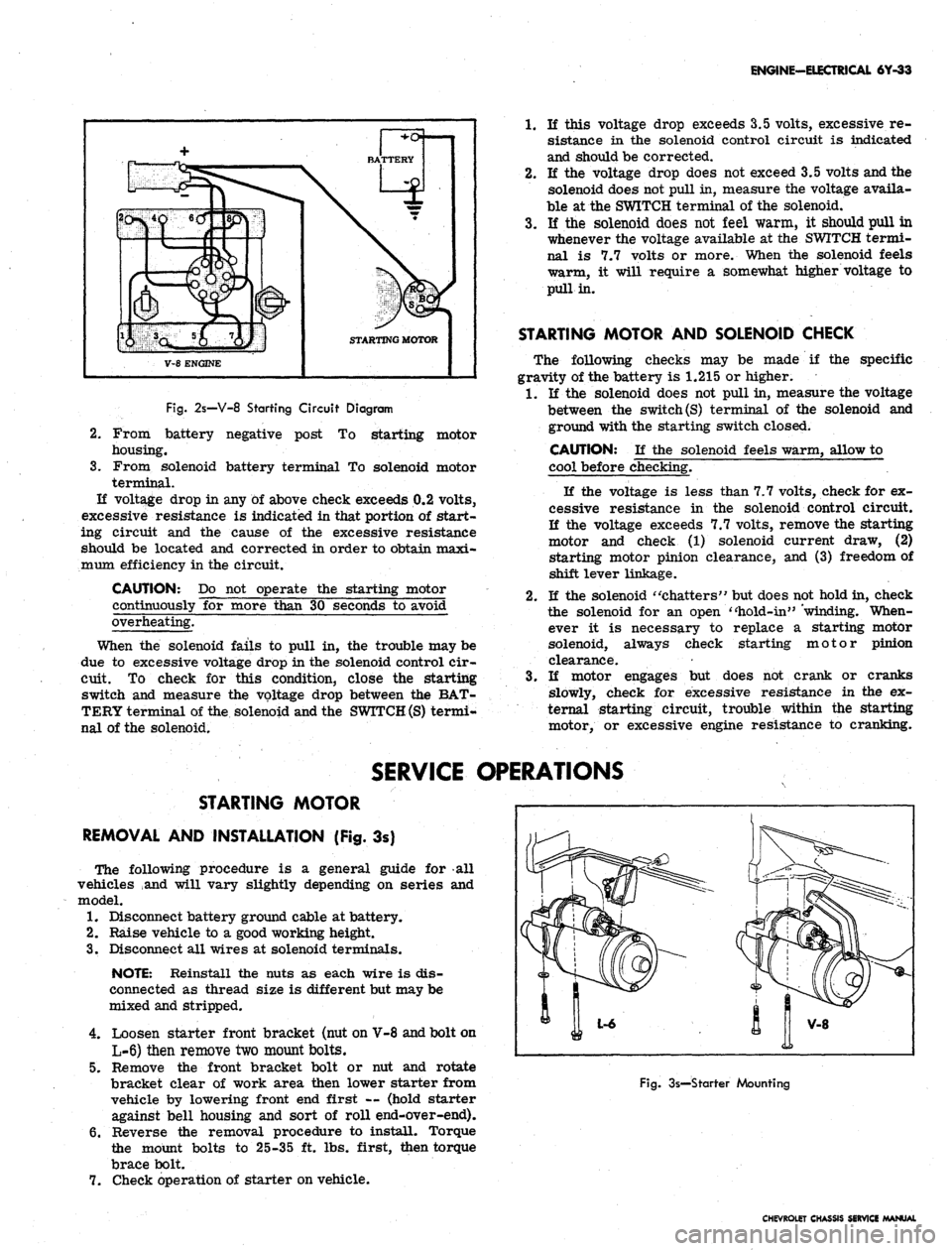

O

V-8 ENGINE

STARTING MOTOR

Fig.

2s—V-8 Starting Circuit Diagram

2.

3.

From battery negative post

To

starting motor

housing.

From solenoid battery terminal

To

solenoid motor

terminal.

If voltage drop

in

any

of

above check exceeds 0.2 volts,

excessive resistance

is

indicated in that portion

of

start-

ing circuit

and the

cause

of the

excessive resistance

should

be

located

and

corrected

in

order to obtain maxi-

mum efficiency in the circuit.

CAUTION:

Do not

operate

the

starting motor

continuously

for

more than

30

seconds

to

avoid

overheating.

When

the

solenoid fails

to

pull

in, the

trouble may be

due

to

excessive voltage drop in the solenoid control cir-

cuit.

To

check

for

this condition, close

the

starting

switch

and

measure

the

voltage drop between

the

BAT-

TERY terminal of the solenoid and the

SWITCH (S)

termi-

nal

of

the solenoid.

1.

If

this voltage drop exceeds 3.5 volts, excessive

re-

sistance

in the

solenoid control circuit

is

indicated

and should be corrected.

2.

If the

voltage drop does not exceed 3.5 volts and the

solenoid does not pull in, measure the voltage availa-

ble

at

the SWITCH terminal

of

the solenoid.

3.

If the

solenoid does

not

feel warm,

it

should pull

in

whenever the voltage available

at

the SWITCH termi-

nal

is 7.7

volts

or

more. When

the

solenoid feels

warm,

it

will require

a

somewhat higher voltage

to

pull in.

STARTING MOTOR AND SOLENOID CHECK

The following checks

may be

made

if the

specific

gravity of the battery

is

1.215

or

higher.

1.

If the

solenoid does

not

pull in, measure the voltage

between

the

switch

(S)

terminal

of the

solenoid

and

ground with the starting switch closed.

CAUTION:

If the

solenoid feels warm, allow

to

cool before checking.

If

the

voltage

is

less than 7.7 volts, check for ex-

cessive resistance

in the

solenoid control circuit.

If

the

voltage exceeds 7.7 volts, remove the starting

motor

and

check

(1)

solenoid current draw,

(2)

starting motor pinion clearance,

and (3)

freedom of

shift lever linkage.

2.

If

the solenoid "chatters" but does not hold in, check

the solenoid

for an

open "hold-in" 'winding. When-

ever

it is

necessary

to

replace

a

starting motor

solenoid, always check starting motor pinion

clearance.

3.

If

motor engages

but

does

not

crank

or

cranks

slowly, check

for

excessive resistance

in the ex-

ternal starting circuit, trouble within

the

starting

motor,

or

excessive engine resistance

to

cranking.

SERVICE OPERATIONS

STARTING MOTOR

REMOVAL AND INSTALLATION (Fig.

3s)

The following procedure

is a

general guide

for all

vehicles

and

will vary slightly depending

on

series

and

model.

1.

Disconnect battery ground cable at battery.

2.

Raise vehicle

to a

good working height.

3.

Disconnect all wires

at

solenoid terminals.

NOTE: Reinstall

the

nuts

as

each wire

is

dis-

connected

as

thread size

is

different but may be

mixed and stripped.

4.

Loosen starter front bracket (nut on V-8 and bolt on

L-6) then remove two mount bolts.

5.

Remove

the

front bracket bolt

or nut and

rotate

bracket clear

of

work area then lower starter from

vehicle

by

lowering front end first

—

(hold starter

against bell housing

and

sort

of

roll end-over-end).

6. Reverse

the

removal procedure

to

install. Torque

the mount bolts

to

25-35

ft.

lbs. first, then torque

brace bolt.

7.

Check operation

of

starter on vehicle.

Fig.

3s—Starter Mounting

CHEVROLET CHASSIS SERVICE MANUAL

Page 361 of 659

CLUTCH AND TRANSMISSIONS 7-2

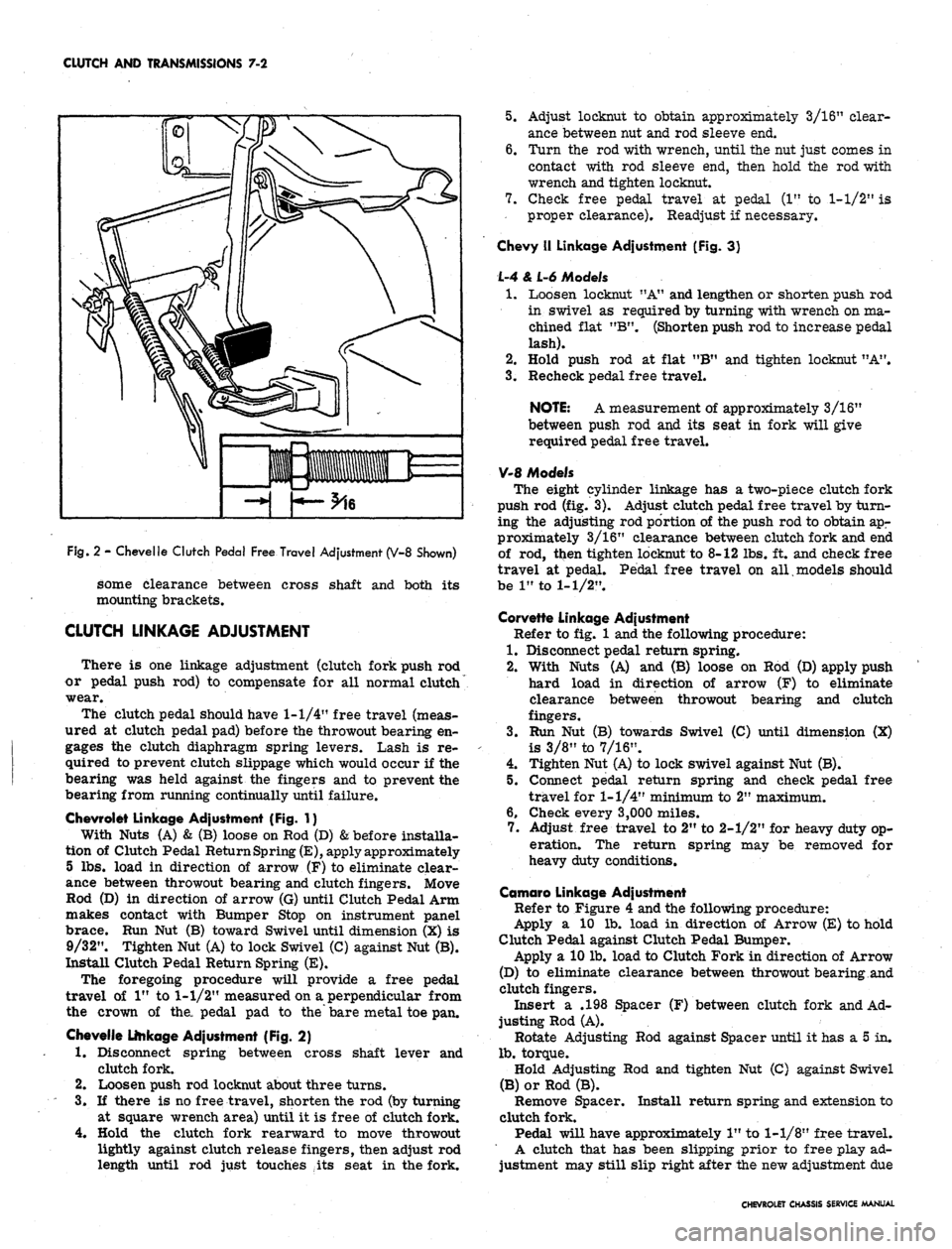

Fig.

2 - Chevelle Clutch Pedal Free Travel Adjustment (V-8 Shown)

some clearance between cross shaft and both its

mounting brackets.

CLUTCH LINKAGE ADJUSTMENT

There is one linkage adjustment (clutch fork push rod

or pedal push rod) to compensate for all normal clutch

wear.

The clutch pedal should have

1-1/4"

free travel (meas-

ured at clutch pedal pad) before the throwout bearing en-

gages the clutch diaphragm spring levers. Lash is re-

quired to prevent clutch slippage which would occur if the

bearing was held against the fingers and to prevent the

bearing from running continually until failure.

Chevrolet Linkage Adjustment (Fig. 1}

With Nuts (A) & (B) loose on Rod (D)

&

before installa-

tion of Clutch Pedal Return Spring

(E),

apply approximately

5 lbs. load in direction of arrow (F) to eliminate clear-

ance between throwout bearing and clutch fingers. Move

Rod (D) in direction of arrow (G) until Clutch Pedal Arm

makes contact with Bumper Stop on instrument panel

brace. Run Nut (B) toward Swivel until dimension (X) is

9/32". Tighten Nut (A) to lock Swivel (C) against Nut (B).

Install Clutch Pedal Return Spring (E).

The foregoing procedure will provide a free pedal

travel of 1" to

1-1/2"

measured on a perpendicular from

the crown of the, pedal pad to the bare metal toe pan.

Chevelle Linkage Adjustment (Fig. 2)

1.

Disconnect spring between cross shaft lever and

clutch fork.

2.

Loosen push rod locknut about three turns.

3.

If there is no free travel, shorten the rod (by turning

at square wrench area) until it is free of clutch fork.

4.

Hold the clutch fork rearward to move throwout

lightly against clutch release fingers, then adjust rod

length until rod just touches ,its seat in the fork.

5.

Adjust locknut to obtain approximately 3/16" clear-

ance between nut and rod sleeve end.

6. Turn the rod with wrench, until the nut just comes in

contact with rod sleeve end, then hold the rod with

wrench and tighten locknut.

7.

Check free pedal travel at pedal (1" to

1-1/2"

is

proper clearance). Readjust if necessary.

Chevy II Linkage Adjustment (Fig. 3}

L-4 & L-6 Models

1.

Loosen locknut "A" and lengthen or shorten push rod

in swivel as required by turning with wrench on ma-

chined flat "B". (Shorten push rod to increase pedal

lash).

2.

Hold push rod at flat "B" and tighten locknut "A".

3.

Recheck pedal free travel.

NOTE: A measurement of approximately 3/16"

between push rod and its seat in fork will give

required pedal free travel.

V-8 Models

The eight cylinder linkage has a two-piece clutch fork

push rod (fig. 3). Adjust clutch pedal free travel by turn-

ing the adjusting rod portion of the push rod to obtain apr

proximately 3/16" clearance between clutch fork and end

of rod, ttien tighten locknut to 8-12 lbs. ft. and check free

travel at pedal. Pedal free travel on all models should

be 1" to

1-1/2".

Corvette Linkage Adjustment

Refer to fig. 1 and the following procedure:

1.

Disconnect pedal return spring.

2.

With Nuts (A) and (B) loose on Rod (D) apply push

hard load in direction of arrow (F) to eliminate

clearance between throwout bearing and clutch

fingers.

3.

Run Nut (B) towards Swivel (C) until dimension (X)

is 3/8" to 7/16".

4.

Tighten Nut (A) to lock swivel against Nut (B).

5.

Connect pedal return spring and check pedal free

travel for

1-1/4"

minimum to 2" maximum.

6. Check every 3,000 miles.

7.

Adjust free travel to 2" to 2-1/2" for heavy duty op-

eration. The return spring may be removed for

heavy duty conditions.

Camaro Linkage Adjustment

Refer to Figure 4 and the following procedure:

Apply a 10 lb. load in direction of Arrow (E) to hold

Clutch Pedal against Clutch Pedal Bumper.

Apply a 10 lb. load to Clutch Fork in direction of Arrow

(D) to eliminate clearance between throwout bearing and

clutch fingers.

Insert a .198 Spacer (F) between clutch fork and Ad-

justing Rod (A).

Rotate Adjusting Rod against Spacer until it has a 5 in.

lb.

torque.

Hold Adjusting Rod and tighten Nut (C) against Swivel

(B) or Rod (B).

Remove Spacer. Install return spring and extension to

clutch fork.

Pedal will have approximately 1" to

1-1/8"

free travel.

A clutch that has been slipping prior to free play ad-

justment may still slip right after the new adjustment due

CHEVROLET CHASSIS SERVICE MANUAL

Page 367 of 659

CLUTCH AND TRANSMISSIONS 7-3

DETENT CAM

DETENT SPRING

DETENT CAM

2-3 SHIFT

FORK

DETENT CAM

PIVOT PIN

1ST & REV. 1ST& REV.

SHIFTER SHAFT SHIFT FORK

DETENT CAM

RETAINER RING

2-3 SHIFTER SHAFT

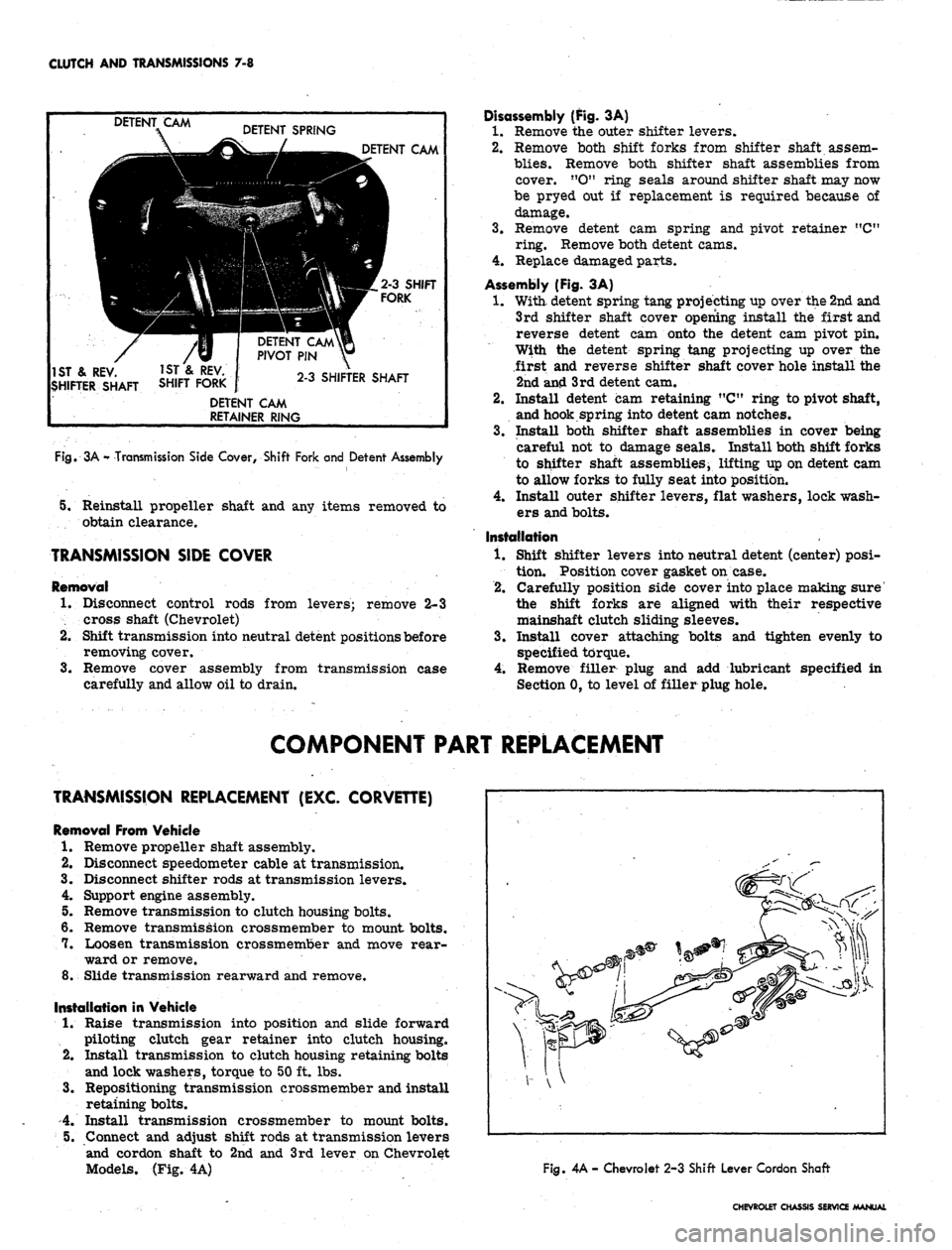

Fig. 3A

•*

Transmission Side Cover, Shift Fork and Detent Assembly

5. Reinstall propeller shaft and any items removed to

obtain clearance.

TRANSMISSION SIDE COVER

Removal •

1.

Disconnect control rods from levers; remove 2-3

cross shaft (Chevrolet)

2.

Shift transmission into neutral detent positions before

removing cover.

3.

Remove cover assembly from transmission case

carefully and allow oil to drain.

Disassembly (Fig. 3A)

1.

Remove the outer shifter levers.

2.

Remove both shift forks from shifter shaft assem-

blies.

Remove both shifter shaft assemblies from

cover. "OM ring seals around shifter shaft may now

be pryed out if replacement is required because of

damage.

3.

Remove detent cam spring and pivot retainer "C"

ring. Remove both detent cams.

4.

Replace damaged parts.

Assembly (Fig. 3A)

1.

With,

detent spring tang projecting up over the

2nd

and

3rd shifter shaft cover opening install the first and

reverse detent cam onto the detent cam pivot pin.

With the detent spring tang projecting up over the

first and reverse shifter shaft cover hole install the

2nd an£ 3rd detent cam.

2.

Install detent cam retaining "C" ring to pivot shaft,

and hook spring into detent cam notches.

3.

Install both shifter shaft assemblies in cover being

careful not to damage seals. Install both shift forks

to shifter shaft assemblies^ lifting up on detent cam

to allow forks to fully seat into position.

4.

Install outer shifter levers, flat washers, lock wash-

ers and bolts.

Installation

1.

Shift shifter levers into neutral detent (center) posi-

tion.

Position cover gasket on case.

2.

Carefully position side cover into place making sure'

the shift forks are aligned with their respective

mainshaft clutch sliding sleeves.

3.

Install cover attaching bolts and tighten evenly to

specified torque.

4.

Remove filler plug and add lubricant specified in

Section 0, to level of filler plug hole.

COMPONENT PART REPLACEMENT

TRANSMISSION REPLACEMENT (EXC. CORVETTE)

Removal From Vehicle

1.

Remove propeller shaft assembly.

2.

Disconnect speedometer cable at transmission.

3.

Disconnect shifter rods at transmission levers.

4.

Support engine assembly.

5. Remove transmission to clutch housing bolts.

6. Remove transmission crossmember to mount bolts.

7. Loosen transmission crossmember and move rear-

ward or remove.

8. Slide transmission rearward and remove.

Installation in Vehicle

1.

Raise transmission into position and slide forward

piloting clutch gear retainer into clutch housing.

2.

Install transmission to clutch housing retaining bolts

and lock washers, torque to 50 ft. lbs.

3.

Repositioning transmission crossmember and install

retaining bolts.

4.

Install transmission crossmember to mount bolts.

5. Connect and adjust shift rods at transmission levers

and cordon shaft to 2nd and 3rd lever on Chevrolet

Models. (Fig. 4A)

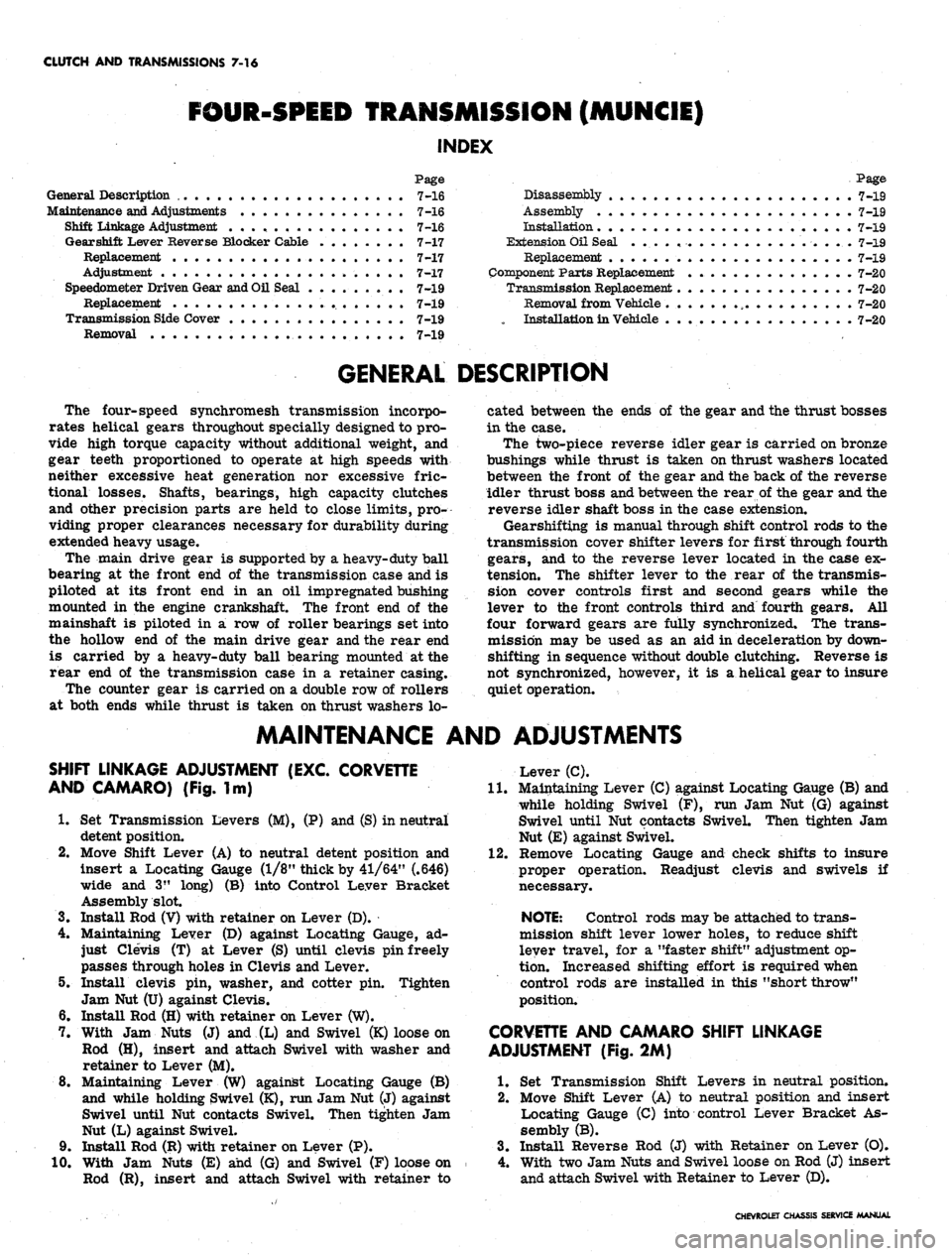

Fig. 4A - Chevrolet 2-3 Shift Lever Cordon Shaft

CHEVROLET CHASSIS SERVICE MANUAL

Page 373 of 659

CLUTCH AND TRANSMISSIONS 7-14

SPEED HEAVY DUTY TRANSMISSION

(WARNER MODEL T 16)

INDEX

General Description ......

Maintenance and Adjustments

Shift Linkage Adjustment

Side Cover ........

Removal .........

Disassembly

7-14

7-14

7-14

7-14

7-14

7-14

Assembly 7-14

Installation • 7-15

Other Maintenance

&

Adjustment

Operations See 3-Speed Saginaw Section

Transmission Replacement . . . See 3-Speed Saginaw Section

GENERAL DESCRIPTION

The Borg-Warner heavy duty three speed fully syn-

chronized (all forward gears) transmission incorporates

helical gears throughout specially designed to provide

high torque capacity, and gear teeth proportion to operate

at high speeds with neither excessive heat generation nor

excessive frictional losses. Shafts, bearings, high ca-

pacity clutches and other precision parts are held to

close limits providing proper clearances necessary for

durability during extended heavy usage.

The main drive gear is supported by a heavy duty ball

bearing at the front end of the transmission case and is

piloted at its front end in an oil impregnated bushing

mounted in the engine crankshaft. The front end of the

mainshaft is piloted in a row of roller bearings set into

the hollow end of the main drive gear and the rear end

is carried by a heavy duty ball bearing mounted in the

front of the extension housing.

The countergear is carried on a double row of rollers

at both ends while thrust is taken on thrust washers lo-

cated between the ends of the gear and the thrust bosses

in the case. An anti-rattle plate assembly at the front

of the countergear provides a constant spring tension be-

tween the counter and clutch gears to reduce torsional

vibrations. The reverse idler gear is carried on 25

roller bearings while thrust is taken on thrust washers

located between the ends of the gear and the thrust bosses

of the case.

Gear shifting is manual through shift control rods from

the shifter tube in the mast jacket to the rearward shift

lever of the side cover assembly for first and reverse

gear; and through a cross shaft assembly attached to the

forward side cover lever for second and third gear. All

three forward gears are fully synchronized. The syn-

chronizer assemblies consist of a clutch hub, clutch

sleeve, two clutch key springs and three energizer clutch

keys and are retained as an assembly on the main shaft

by a snap ring. The transmission may be used as an aid

in deceleration by downshifting in sequence without

double-clutching or any gear clashing. Reverse is not

synchronized, however, it is a helical gear to insure

quiet operation.

MAINTENANCE AND ADJUSTMENTS

Refer to similar procedures under the 3-speed Saginaw

Transmission Section for—Column Mounted Shift Linkage

Adjustment, Speedometer Driven Gear and Oil Seal Re-

placement, Extension Oil Seal Replacement and Trans-

mission Replacement. ~~

Camaro and Corvette Floor Shift Linkage Adjustment

(Fig.

lc)

1.

Set Lever (L), (K) in neutral position.

2.

Move Lever Assembly (A) and Levers (C), (D) to

neutral position and insert Locating Gauge (B) into

control Lever Bracket Assembly.

3.,

Install Rod (H) with Retainer (M) on Lever (L).

4.

With two Jam Nuts (G), (E) and Swivel (F) loose on

Rod (H) insert and attach Swivel with Retainer (N)

to Lever (D).

5.

Repeat steps 3 and 4 for Rod (J) and Levers (C

&

K).

6. Remove' Locating Gauge and check shift to insure

proper operation.

SIDE COVER ASSEMBLY

Removal

1.

Drain transmission and disconnect control rod and

cross shaft from side cover levers. *

2.

Remove nine cap screws securing the transmission

side cover assembly to transmission, case and re-

move cover assembly, shifting forks, and gasket.

Disassembly (Fig. 2C) '

1.

Remove shifting forks from shift lever assemblies.

2.

Remove nut and lock washer from each shift lever

shaft.

3.

Remove outer shift levers and lightly tap shift lever

shafts from assembly.

4.

Remove two steel balls, poppet spring, interlock pin

and interlock sleeve from cover.

5.

Remove "O" ring seals from shift lever shafts.

Assembly (Fig. 2C)

1.

Install new "O" ring seals to shift lever shafts.

2.

Install low and reverse shifter shaft and plate as-

sembly to cover.

3.

Place shifter shaft and plate assembly in neutral po-

sition, middle detent, and install interlock sleeve,

ball, poppet spring and interlock pin.

4.

Install remaining poppet ball and then install second

and third shifter shaft and plate assembly.

NOTE: Installation is easiest if shifter shaft

and plate assembly passes over ball in its neu-

tral position.

5.

Check clearance between end of interlock sleeve and

shifter shaft and plate cams when one plate is in

neutral and the other is shifted into gear position.

CHEVROLET CHASSIS SERVICE MANUAL

Page 375 of 659

CLUTCH AND TRANSMISSIONS 7-16

FOUR-SPEED TRANSMISSION (MUNCIE)

INDEX

Page

General Description 7-16

Maintenance and Adjustments 7-16

Shift Linkage Adjustment 7-16

Gearshift Lever Reverse Blocker Cable 7-17

Replacement . 7-17

Adjustment 7-17

Speedometer Driven Gear and Oil Seal 7-19

Replacement 7-19

Transmission Side Cover 7-19

Removal 7-19

Page

Disassembly 7-19

Assembly 7-19

Installation . 7-19

Extension Oil Seal ......... 7-19

Replacement 7-19

Component Parts Replacement 7-20

Transmission Replacement 7-20

Removal from Vehicle , 7-20

. Installation in Vehicle . . . 7-20

GENERAL DESCRIPTION

The four-speed synchromesh transmission incorpo-

rates helical gears throughout specially designed to pro-

vide high torque capacity without additional weight, and

gear teeth proportioned to operate at high speeds with

neither excessive heat generation nor excessive fric-

tional losses. Shafts, bearings, high capacity clutches

and other precision parts are held to close limits, pro-

viding proper clearances necessary for durability during

extended heavy usage.

The main drive gear is supported by a heavy-duty ball

bearing at the front end of the transmission case and is

piloted at its front end in an oil impregnated bushing

mounted in the engine crankshaft. The front end of the

mainshaft is piloted in a row of roller bearings set into

the hollow end of the main drive gear and the rear end

is carried by a heavy-duty ball bearing mounted at the

rear end of the transmission case in a retainer casing.

The counter gear is carried on a double row of rollers

at both ends while thrust is taken on thrust washers lo-

cated between the ends of the gear and the thrust bosses

in the case.

The two-piece reverse idler gear is carried on bronze

bushings while thrust is taken on thrust washers located

between the front of the gear and the back of the reverse

idler thrust boss and between the rear of the gear and the

reverse idler shaft boss in the case extension.

Gearshifting is manual through shift control rods to the

transmission cover shifter levers for first through fourth

gears,

and to the reverse lever located in the case ex-

tension. The shifter lever to the rear of the transmis-

sion cover controls first and second gears while the

lever to the front controls third and fourth gears. All

four forward gears are fully synchronized. The trans-

mission may be used as an aid in deceleration by down-

shifting in sequence without double clutching. Reverse is

not synchronized, however, it is a helical gear to insure

quiet operation.

MAINTENANCE AND ADJUSTMENTS

SHIFT LINKAGE ADJUSTMENT (EXC. CORVETTE

AND CAMARO) (Fig. 1m)

1.

Set Transmission Levers (M), (P) and (S) in neutral

detent position.

2.

Move Shift Lever (A) to neutral detent position and

insert a Locating Gauge (1/8" thick by 41/64" (.646)

wide and 3" long) (B) into Control Lever Bracket

Assembly slot.

3.

Install Rod (V) with retainer on Lever (D).

4.

Maintaining Lever (D) against Locating Gauge, ad-

just Clevis (T) at Lever (S) until clevis pin freely

passes through holes in Clevis and Lever.

5. Install clevis pin, washer, and cotter pin. Tighten

Jam Nut (U) against Clevis.

6. Install Rod (H) with retainer on Lever (W).

7. With Jam Nuts (J) and (L) and Swivel (K) loose on

Rod (H), insert and attach Swivel with washer and

retainer to Lever (M).

8. Maintaining Lever (W) against Locating Gauge (B)

and while holding Swivel (K), run Jam Nut (J) against

Swivel until Nut contacts Swivel. Then tighten Jam

Nut (L) against Swivel.

9. Install Rod (R) with retainer on Lever (P).

10.

With Jam Nuts (E) and (G) and Swivel (F) loose on

Rod (R), insert and attach Swivel with retainer to

Lever (C).

11.

Maintaining Lever (C) against Locating Gauge (B) and

while holding Swivel (F), run Jam Nut (G) against

Swivel until Nut contacts Swivel. Then tighten Jam

Nut (E) against Swivel.

12.

Remove Locating Gauge and check shifts to insure

proper operation. Readjust clevis and swivels if

necessary.

NOTE:

Control rods may be attached to trans-

mission shift lever lower holes, to reduce shift

lever travel, for a "faster shift" adjustment op-

tion.

Increased shifting effort is required when

control rods are installed in this "short throw"

position.

CORVETTE AND CAMARO SHIFT LINKAGE

ADJUSTMENT (Fig. 2M)

1.

Set Transmission Shift Levers in neutral position.

2.

Move Shift Lever (A) to neutral position and insert

Locating Gauge (C) into control Lever Bracket As-

sembly (B).

3.

Install Reverse Rod (J) with Retainer on Lever (O).

4.

With two Jam Nuts and Swivel loose on Rod (J) insert

and attach Swivel with Retainer to Lever (D).

CHEVROLET CHASSIS SERVICE MANUAL