torque CHEVROLET CAMARO 1967 1.G Chassis Workshop Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1967, Model line: CAMARO, Model: CHEVROLET CAMARO 1967 1.GPages: 659, PDF Size: 114.24 MB

Page 400 of 659

CLUTCH AND TRANSMISSIONS 7-41

CAUTION: Use converter holding ToolJ-5384

when lowering transmission or keep rear of

transmission lower than front so as not to lose

converter.

The installation of the transmission is the reverse of

the removal.

TURBO HYDRA-MATIC DIAGNOSIS PROCEDURE

Accurate diagnosis of transmission problems begins

with a thorough understanding of normal transmission

operation. In particular, knowing which units are in-

volved in the various speeds or shifts so that the specific

units or circuits involved in the problem can be isolated

and investigated further. Analytical diagnosis will pro-

tect the technician from come backs and certainly will

improve owner satisfaction.

An important and often overlooked aspect of diagnosis

is finding out specifically what the customer is com-

plaining of. For this purpose a short ride with the cus-

tomer will often prove beneficial. It may be found that

the condition the customer wants corrected is standard

and should not be altered.

The following sequence, based on field experience, pro-

vides the desired information quickly and in most cases

actually corrects the malfunction without requiring the

removal of the transmission. Details of the items listed

in this sequence are covered further in the text.

SEQUENCE FOR TURBO HYDRA-MATIC

DIAGNOSIS PROCEDURE

1.

Check oil level and condition.

2.

Check and correct detent switch.

3.

Check and correct vacuum line and fittings.

4.

Check and correct manual linkage.

OIL LEVEL AND CONDITION CHECK

Always check the oil level before road testing. Oil

must be visible on dip stick prior to operating the ve-

hicle. Erratic shifting, pump noise, or other malfunc-

tions can in some cases be traced to improper oil level.

Oil level should be checked with the selector lever in

the Park (P) position, engine running, and the vehicle on

level pavement.

Fluid level should be to the FULL mark with the trans-

mission at normal operating temperature (170°-190°

F.).

With warm fluid (room temperature), the level should be

at or slightly below the ADD mark.

If oil level was low, refer to Oil Leaks.

The condition of the oil is often an indication of whether

the transmission should be removed from the vehicle, or

to make further tests. When checking oil level, a burned

smell and discoloration indicate burned clutches or bands

and the transmission will have to be removed.

MANUAL LINKAGE

Manual linkage adjustment and the associated neutral

safety switch are important from a safety standpoint

The neutral safety switch should be adjusted so that the

engine will start in the Park and Neutral positions only.

With the selector lever in the Park position, the park-

ing pawl should freely engage and prevent the vehicle

from rolling. The pointer on the indicator quadrant

should line up properly with the range indicators in all

ranges.

OIL LEAKS

Before attempting to correct an oil leak, the actual

source of the leak must be determined. In many cases,

the source of the leak can be deceiving due to "wind flow"

around the engine and transmission.

The suspected area should be wiped clean of all oil be-

fore inspecting for the source of the leak. Red dye is

used in the transmission oil at the assembly plant and

will indicate if the oil leak is from the transmission.

. The use of a "black light"* to identify the oil at the

source of leak is also helpful. Comparing the oil from

the leak to that on the engine or transmission dip stick

(when viewed by black light) will determine the source

of the leak.

Oil leaks around the engine and transmission are gen-

erally carried toward the rear of the car by the air

stream. For example, a transmission "oil filler tube to

case leak" will sometimes appear as a leak at the rear of

the transmission. In determining the source of an oil

leak it is most helpful to keep the engine running.

POSSIBLE POINTS OF OIL LEAKS

• 1. TRANSMISSION OIL PAN LEAK

a. Attaching bolts not correctly torqued.

b.

Improperly installed or damaged pan gasket.

c. Oil pan gasket mounting face not flat.

2.

REAR EXTENSION LEAK

a. Attaching bolts not correctly torqued.

b.

Rear seal assembly — damaged or improperly

installed.

c. Gasket seal — (extension to case) damaged or

improperly installed.

d. Porous casting.

3.

CASE LEAK

a. Filler pipe "O" ring seal damaged or missing;

misposition of filler pipe bracket to engine —

"loading" one side of

"O"

ring.

b.

Modulator assembly "O" ring seal

—

damaged or

improperly installed.

c. Governor cover, gasket and bolts — damaged,

loose; case face leak.

d. Speedo gear

—

"O" ring damaged.

e. Manual shaft seal — damaged, improperly in-

stalled.

f. line pressure tap plug — stripped, shy sealer

compound.

g. Parking pawl shaft cup plug

—

damaged, improp-

erly installed.

h. Vent pipe (refer to Item 5).

i. Porous case.

4.

FRONT END LEAK

a. Front seal - damaged (check converter neck for

nicks,

etc., also for pump bushing moved for-

ward);

garter spring missing from pump to con-

verter seaL

b.

Pump attaching bolts and seals

—

damaged, miss-

ing, bolts loose.

CHEVROLET a

SERVICE

Page 404 of 659

CLUTCH AND TRANSMISSIONS 7-45

23

Fig.

5T - Aluminum Powerglide Special Tools

1. J-9506

2.

J-3289-01

3.

J-9549

4.

J-21867

5.

J-4264

6. J-3387

7.

J-9539

8. J-6839

9. J-9546

10.

J-7782

11.

J-5133

12.

J-4599

13.

J-9542

14.

J-9557

Holding Fixture Adapters

Holding Fixture (Use with J-3289-20 Base)

Converter Safety Strap

Transmission Pressure Gauge and Hose

Oil Filler Tube and Funnel

Pilot Stud Set

Front Pump Puller Bolts (Use with weights

from Slide Hammers J-6585)

Front Pump Seal Driver

Clutch Drum Bushing Remover and Installer

Clutch Spring Compressor Adapter Plate

Clutch Spring Compressor

Planet Pinion Assembly Tool Set

Reverse Piston Spring Compressor

Transmission Case Rear Bushing Remover and

Installer and Rear Pump Bushing Remover

15.

J-7079

16.

J-6582

17.

J-9543

18.

J-5778

19.

J-5154

20.

J-5403

21.

J-5814

22.

J-5853

23.

J-8039

24.

J-21848

J-8001

J-5492

J-6585

J-6585-3

J-9534

Handle

Rear Pump Bushing Installer

Vacuum

Modu

lator Wrench

Extension Bushing Remover and Installer

Extension Oil Seal Installer

Snap Ring Pliers

Speedometer Drive Gear Remover and

Installer

Torque Wrench

Snap Ring Pliers

Low Band Adjusting Tool

Dial Indicator (Not Illustrated)

Dial Indicator Support Strap (Not Illustrated)

Slide Hammers (Not Illustrated)

Slide Hammer Adapters (Not Illustrated)

Bushing Remover (Not Illustrated)

CHEVROLET CHASSIS SERVICE MANUAL

Page 406 of 659

CLUTCH AND TRANSMISSIONS 7-47

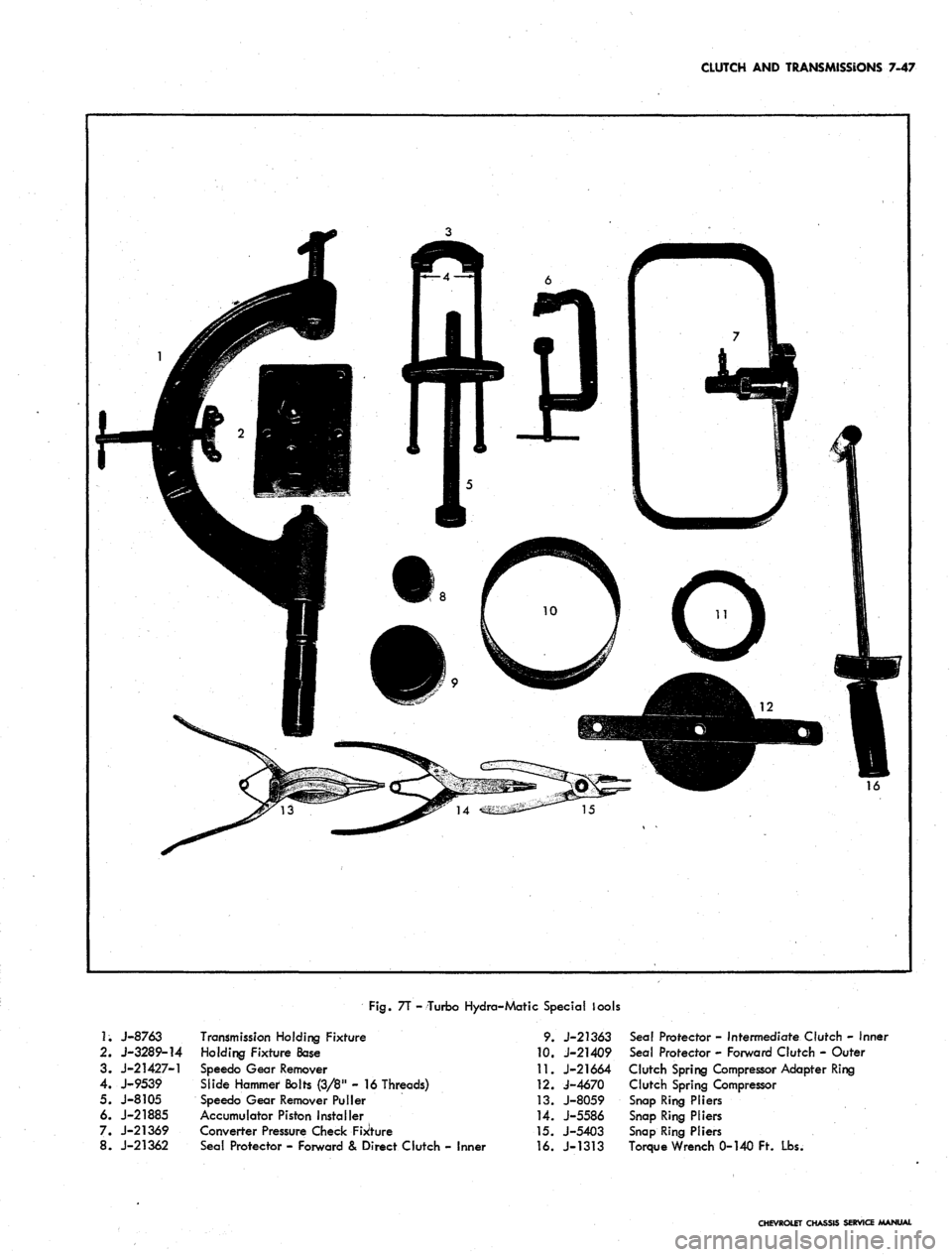

Fig.

7T - Turbo Hydro-Matic Special lools

1;

J-8763

2.

J-3289-14

3. J-21427-1

4.

J-9539

5. J-8105

6. J-21885

7. J-21369

8. J-21362

Transmission Holding Fixture

Holding Fixture Base

Speedo Gear Remover

Slide Hammer Bolts (3/8" - 16 Threads)

Speedo Gear Remover Puller

Accumulator Piston Installer

Converter Pressure Check Fixture

Seal Protector - Forward & Direct Clutch - Inner

9. J-21363

10.

J-21409

11.

J-21664

12.

J-4670

13.

J-8059

14.

J-5586

15.

J-5403

16.

J-1313

Seal Protector - Intermediate Clutch - Inner

Seal Protector - Forward Clutch - Outer

Clutch Spring Compressor Adapter Ring

Clutch Spring Compressor

Snap Ring Pliers

Snap Ring Pliers

Snap Ring Pliers

Torque Wrench 0-140 Ft. Lbs.

CHEVROLET CHASSIS SERVICE MANUAL

Page 411 of 659

FUEL TANK

AND

EXHAUST SYSTEMS

8-5

EXHAUST SYSTEMS

INDEX

Page

General Description

. . 8-5

Component Part Replacement

8-5

Muffler Assembly.

8-5

Exhaust Pipes.

8-5

Tail Pipes.

8-5

GENERAL DESCRIPTION

All exhaust systems used

on the 1967

Chevrolet

are

exhaust systems

(fig. 7) are

available

as

regular produc-

the split system type

in

which the. component parts

are

tion equipment

on the 427 cu. in.

displacement

V-8 en-

secured together with clamps.

The

single exhaust system gines

and as an

option

on the

other (except

283 cu. in.)

used

on L-6

engine models

(fig. 6)

consists

of an

exhaust

V-8

engines. These systems consist

of two

exhaust

pipe, muffler, tailpipe

and

attaching hardware.

On V-8

pipes, mufflers, tailpipes with resonators

and

attaching

engine single exhaust models

a

crossover pipe

is

added hardware.

All

exhaust systems

are

suspended on brackets

to connect

the

right exhaust manifold

to the

system. Dual with insulators

for

rattle free operation.

COMPONENT PART REPLACEMENT

Care should

be

taken

to

have

the

exhaust pipe, muffler

or tail pipe

in

proper relation with each other. Incorrect

alignment frequently causes annoying rattles

due to in-

correct clearances.

MUFFLER ASSEMBLY

Remove

and

Replace

1.

Remove "U" bolt clamp

at

center mounting.

2.

Remove

"U"

bolt clamp

at

forward

end of

muffler

pipe.

3.

Disengage muffler

at

exhaust

and

tail pipe

connections.

4.

Three-fourths inch clearance should

be

allowed

be-

tween

the

muffler bracket (hanger)

and

crossmember

at installation.

5. Install unit with

the

flat side

of the

muffler showing.

EXHAUST PIPE (CROSSOVER WITH

V-8

ENGINE)

Remove

and

Replace

1.

Remove

two

nuts, extension

and

packings-separate

pipe from manifold.

2.

3.

Disassemble

pipe.

"U"

damp from muffler

and

remove

Attach pipe

to

muffler, then secure

to

manifold. Note

clearances

for the

standard

and

automatic control

linkages, underbody

and

crossmember. Contact

of

exhaust pipe

to

engine panrail

is

permissible.

4.

Tighten nuts uniformly.

TAIL PIPE AND/OR RESONATOR

Remove

and

Replace

1.

Remove

"U"

clamp attachment

at

muffler.

2.

Remove screw attachment

at

tail pipe rear hanger

assembly.

3.

Remove tail pipe.

4.

Replace tail pipe

at

muffler, then install

at

hanger

Do

not

secure attachments until clearances have been

checked. Check position

of

hanger

so

that interplates

are parallel.

5. Torque nuts

7-9 ft. lbs. at

hanger

and 10-15 ft. lbs.

at muffler.

CHEVROLET CHASSIS

SEI

Page 442 of 659

STEERING 9-2

Fig.

1—Cover

Attaching Bolts—Chevy li Shown

ADJUSTMENTS

STEERING

GEAR

Before any adjustments are made to the steering gear

in an attempt to correct such conditions as shimmy,

loose or hard steering etc., a careful check should be

made of front end alignment, shock absorbers, wheel

balance and tire pressure for possible cause.

Correct adjustment of the steering gear is very im-

portant. Perform adjustments following the sequence

listed below,

1.

Remove pitman arm nut and mark relation of pitman

arm position to sector shaft. Remove pitman arm

with Tool J- 6632 as shown in Figure 2.

2.

Loosen the pitman shaft lash adjuster screw locknut

and turn the adjuster screw a few turns in a counter-

clockwise direction (fig. 3). This removes the load

Fig. 2—Removing Pitman Arm

imposed on the worm bearings by the close meshing

of rack and sector teeth. Turn steering wheel gently

in one direction until stopped by gear, then back away

about one turn.

CAUTION: Do not turn steering wheel hard

against stops when steering relay rod is discon-

nected as damage to ball guides may result.

3.

All except Corvette and telescopic columns:

a. Disconnect steering column harness at chassis

wiring connector plug.

b.

Remove horn cap or ornament and using an inch

pound torque wrench and socket on steering wheel

nut, measure torque required to keep the wheel

in motion.

LASH ADJUSTER

SCREW

LOCK NUT

WORM BEARING

ADJUSTER

\

WORM

ADJUSTER

Fig.

3—Steering Gear Adjustment Points

CHEVROLET CHASSIS SERVICE MANUAL

Page 443 of 659

STEERING 9-3

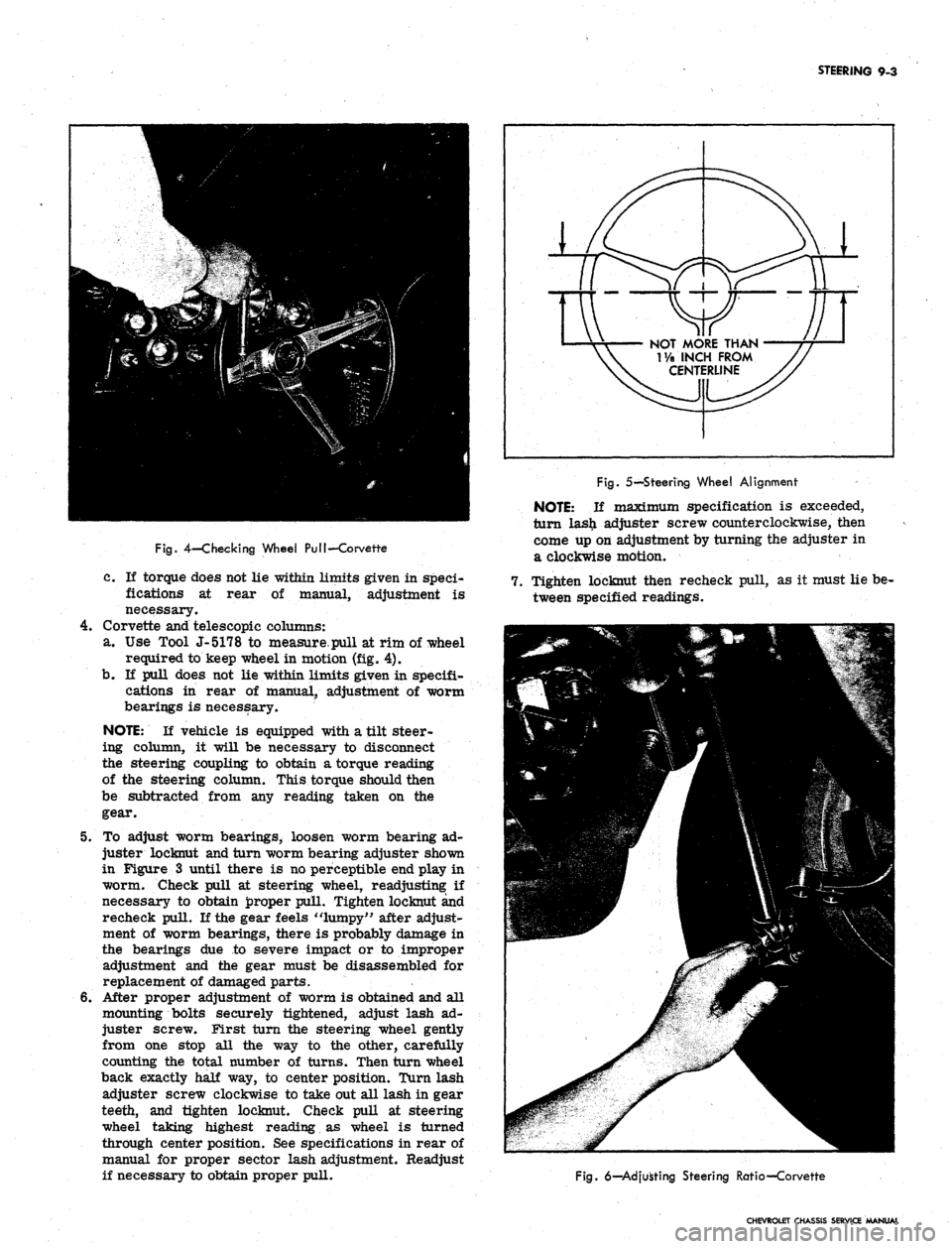

Fig.

4-Checking Wheel PuI!-Corvette

c. If torque does not lie within limits given in speci-

fications at rear of manual, adjustment is

necessary.

4.

Corvette and telescopic columns:

a. Use Tool J-5178 to measure.pull at rim of wheel

required to keep wheel in motion (fig. 4).

b.

If pull does not lie within limits given in specifi-

cations in rear of manual, adjustment of worm

bearings is necessary.

NOTE:

If vehicle is equipped with a tilt steer-

ing column, it will be necessary to disconnect

the steering coupling to obtain a torque reading

of the steering column. This torque should then

be subtracted from any reading taken on the

gear.

5. To adjust worm bearings, loosen worm bearing ad-

juster locknut and turn worm bearing adjuster shown

in Figure 3 until there is no perceptible end play in

worm. Check pull at steering wheel, readjusting: if

necessary to obtain proper pull. Tighten locknut and

recheck pull. If the gear feels "lumpy" after adjust-

ment of worm bearings, there is probably damage in

the bearings due to severe impact or to improper

adjustment and the gear must be disassembled for

replacement of damaged parts.

6. After proper adjustment of worm is obtained and all

mounting bolts securely tightened, adjust lash ad-

juster screw. First turn the steering wheel gently

from one stop all the way to the other, carefully

counting the total number of turns. Then turn wheel

back exactly half way, to center position. Turn lash

adjuster screw clockwise to take out all lash in gear

teeth, and tighten locknut. Check pull at steering

wheel taking highest reading as wheel is turned

through center position. See specifications in rear of

manual for proper sector lash adjustment. Readjust

if necessary to obtain proper pull.

NOT MORE THAN

T/a INCH FROM

CENTERLINE

Fig.

5—Steering Wheel Alignment

NOTE:

If maximum specification is exceeded,

turn las£ adjuster screw counterclockwise, then

come up on adjustment by turning the adjuster in

a clockwise motion.

7. Tighten locknut then recheck pull, as it must lie be-

tween specified readings.

Fig.

6—Adjusting Steering Ratio—Corvette

CHEVROLET CHASSIS SERVICE MANUAL

Page 444 of 659

STEERING 9-4

8. Reassemble pitman arm to sector shaft, lining up

marks made during disassembly. Refer to torque

specifications at rear of manual for correct torque

value.

9. Install horn cap or ornament and connect steering

column harness at chassis connector.

NOTE:

Chevy.n models are equipped with a

shim at the frame to steering gear mounting

bolts.

Shims may be removed or installed as

required for proper steering gear alignment.

STEERING WHEEL ALIGNMENT AND

HIGH POINT CENTERING

1.

Set front wheels in straight ahead position. This can

be checked by driving vehicle a short distance on a

flat surface to determine steering wheel position at

which vehicle follows a straight path.

2.

With front wheels set straight ahead, check position

of mark on wormshaft designating steering gear high

point. This mark should be at the top side of the shaft

at 12 o'clock position and lined up with the mark in

the coupling lower clamp.

3.

If gear has been moved off high point when setting

wheels in straight ahead position, loosen adjusting

sleeve clamps on both left and right hand tie rods,

then turn both sleeves an equal number of turns in

the same direction to bring gear back on high point.

CAUTION: Turning the sleeves an unequal

number of turns or in differential directions will

disturb the toe-in setting of the wheels.

4.

Readjust toe-in as outlined in Section 3 (if necessary).

5. With wheels in a straight ahead position and the

steering gear on highpoint, check the steering wheel

alignment by measuring the distance from each hori-

zontal spoke to the horizontal centerline of the

steering wheel (fig. 5). If the horizontal spokes are

over 1-1/8 inches from the horizontal position the

wheel should be removed and centered. (See steering

wheel removal in this section.)

TOE-IN ADJUSTMENT

Adjust the steering linkage for proper toe-in setting as

outlined in Section 3.

CORVETTE STEERING RATIO (Fig. 6)

The Corvette steering ratio may be changed as follows:

CAUTION: Do not use the rearward hole in the

steering arm with power steering equipment or

interference may result.

1.

Remove tie rod ball stud nut at steering arm and

disconnect tie rod from steering arm.

2.

Move tie rod end to forward hole for 17.6:1 ratio

(fast ratio) or rear hole for 20.2:1 ratio (standard

ratio).

3.

Install tie rod stud nut and tighten securely. Repeat

operation on opposite steering arm.

COMPONENT REPLACEMENT AND REPAIRS

STEERING WHEEL

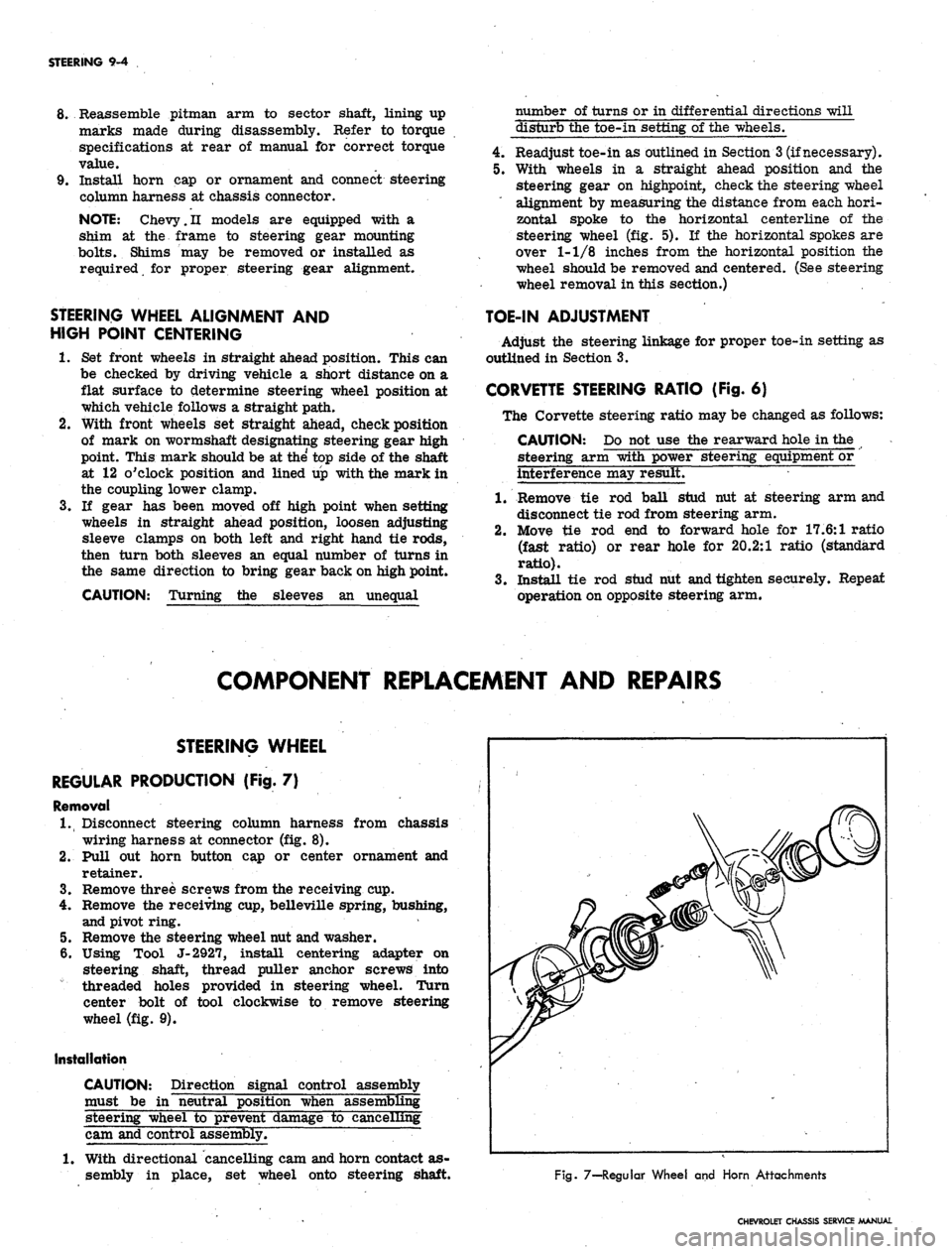

REGULAR PRODUCTION (Fig. 7)

Removal

1.

Disconnect steering column harness from chassis

wiring harness at connector (fig. 8).

2.

Pull out horn button cap or center ornament and

retainer.

3.

Remove three screws from the receiving cup.

4.

Remove the receiving cup, belleville spring, bushing,

and pivot ring.

5. Remove the steering wheel nut and washer.

6. Using Tool J-2927, install centering adapter on

steering shaft, thread puller anchor screws into

threaded holes provided in steering wheel. Turn

center bolt of tool clockwise to remove steering

wheel (fig. 9).

Installation

CAUTION: Direction signal control assembly

must be in "neutral position when assembling

steering wheel to prevent damage to cancelling

cam and control assembly.

1.

With directional cancelling cam and horn contact as-

sembly in place, set wheel onto steering shaft.

Fig. 7—-Regular Wheel and Horn Attachments

CHEVROLET CHASSIS SERVICE MANUAL

Page 445 of 659

STEERING 9-5

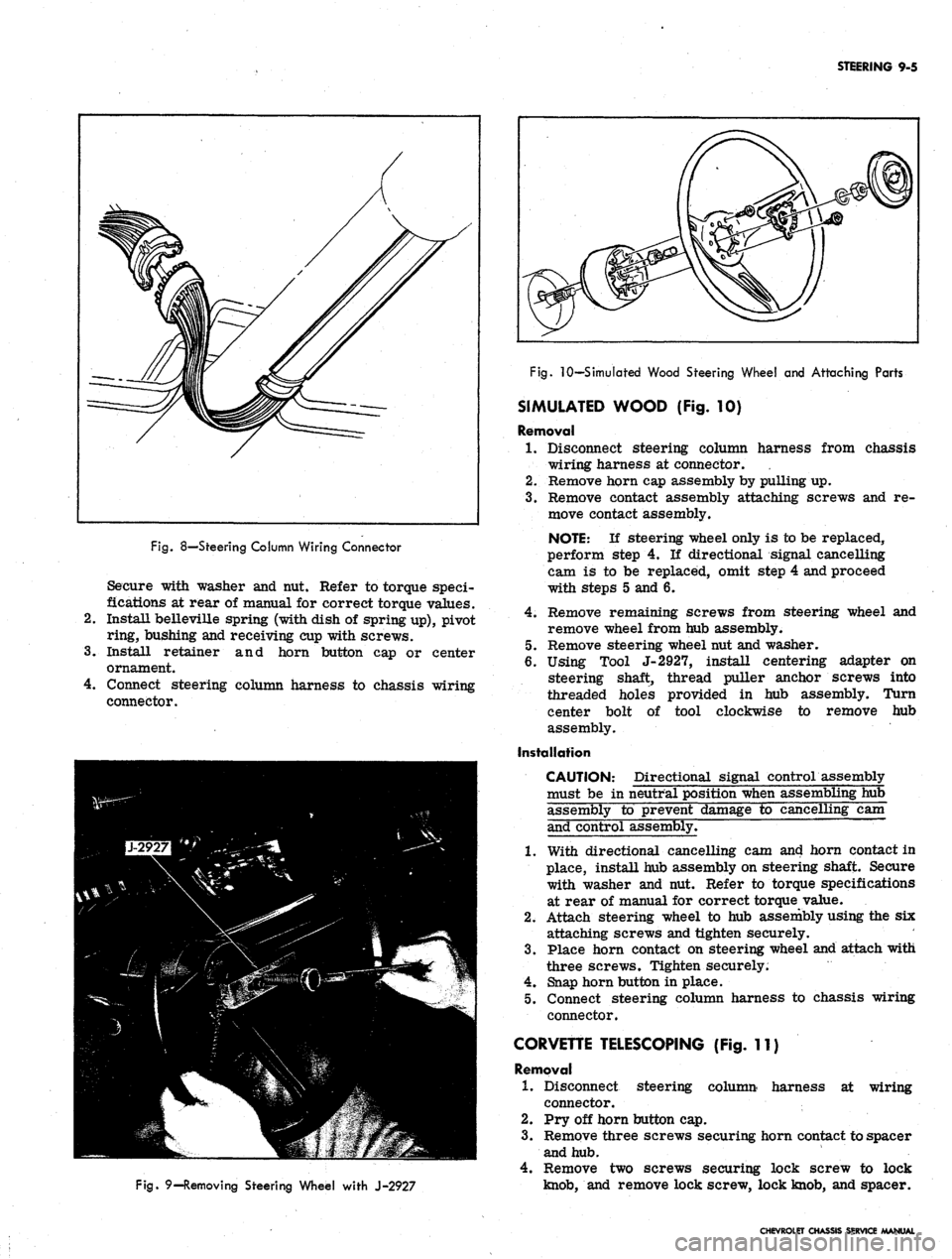

Fig.

8—Steering Column Wiring Connector

Secure with washer and nut. Refer to torque speci-

fications at rear of manual for correct torque values.

Install belleville spring (with dish of spring up), pivot

ring, bushing and receiving cup with screws.

Install retainer and horn button cap or center

ornament.

Connect steering column harness to chassis wiring

connector.

Fig.

9—Removing Steering Wheel with J-2927

Fig.

10—Simulated Wood Steering Wheel and Attaching Parts

SIMULATED WOOD (Fig. 10)

Removal

1.

Disconnect steering column harness from chassis

wiring harness at connector.

2.

Remove horn cap assembly by pulling up.

3.

Remove contact assembly attaching screws and re-

move contact assembly.

NOTE:

If steering wheel only is to be replaced,

perform step 4. If directional signal cancelling

cam is to be replaced, omit step 4 and proceed

with steps 5 and 6.

4.

Remove remaining screws from steering wheel and

remove wheel from hub assembly.

5. Remove steering wheel nut and washer.

6. Using Tool J-2927, install centering adapter on

steering shaft, thread puller anchor screws into

threaded holes provided in hub assembly. Turn

center bolt of tool clockwise to remove hub

assembly.

Installation

CAUTION: Directional signal control assembly

must be in neutral position when assembling hub

assembly to prevent damage to cancelling cam

and control assembly.

1.

With directional cancelling cam and horn contact in

place, install hub assembly on steering shaft. Secure

with washer and nut. Refer to torque specifications

at rear of manual for correct torque value.

2.

Attach steering wheel to hub assembly using the six

attaching screws and tighten securely.

3.

Place horn contact on steering wheel and attach with

three screws. Tighten securely.

4.

Snap horn button in place.

5. Connect steering column harness to chassis wiring

connector.

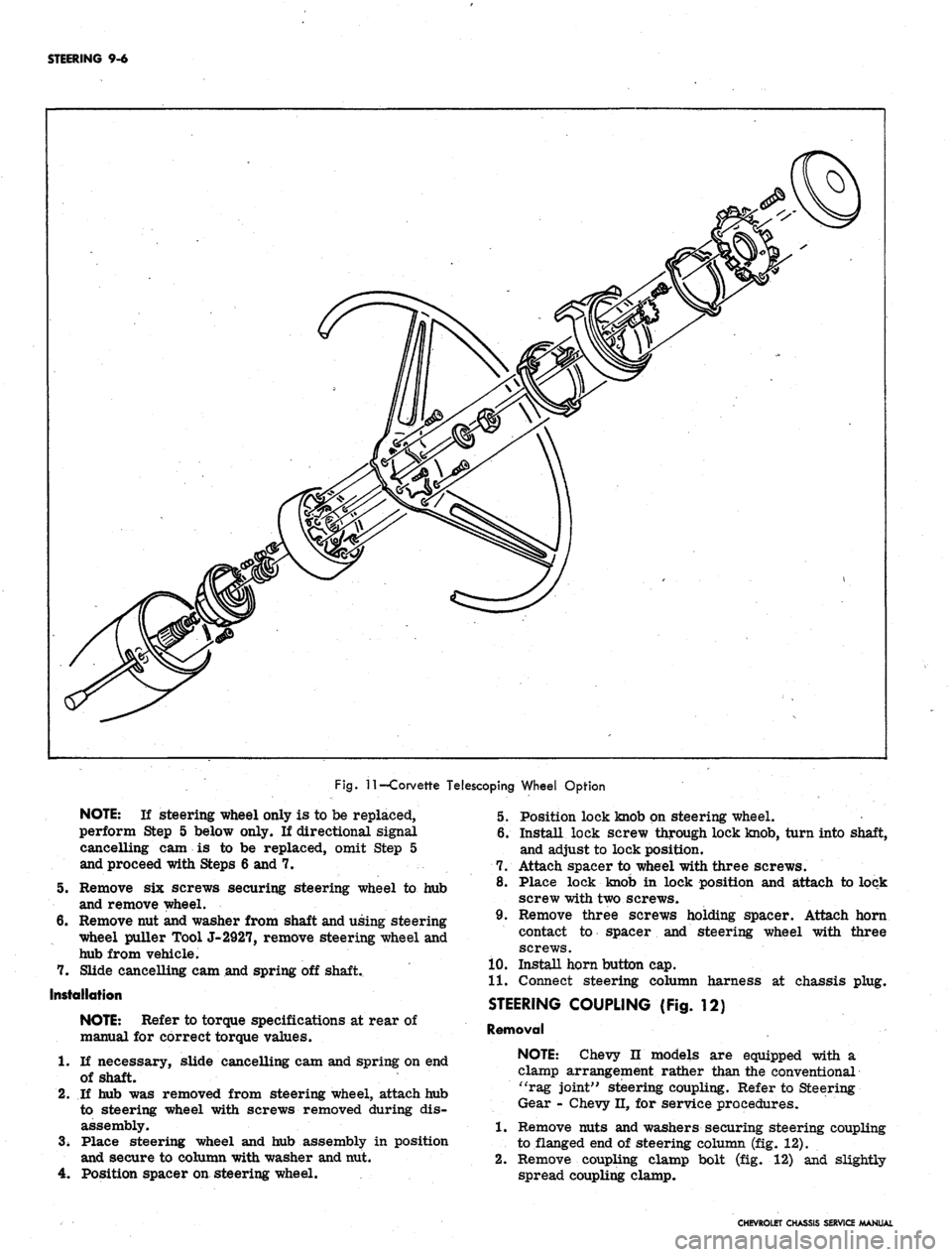

CORVETTE TELESCOPING (Fig. 11)

Removal

1.

Disconnect steering column harness at wiring

connector.

2.

Pry off horn button cap.

3.

Remove three screws securing horn contact to spacer

and hub.

4.

Remove two screws securing lock screw to lock

knob,

and remove lock screw, lock knob, and spacer.

CHEVROLET CHASSIS SERVICE MANUAL

Page 446 of 659

STEERING 9-6

Fig.

11

—Corvette Telescoping Wheel Option

5.

7.

NOTE:

If steering wheel only is to be replaced,

perform Step 5 below only. If directional signal

cancelling cam is to be replaced, omit Step 5

and proceed with Steps 6 and 7.

Remove six screws securing steering wheel to hub

and remove wheel.

Remove nut and washer from shaft and using steering

wheel puller Tool J-2927, remove steering wheel and

hub from vehicle.

Slide cancelling cam and spring off shaft.

Installation

NOTE:

Refer to torque specifications at rear of

manual for correct torque values.

1.

If necessary, slide cancelling cam and spring on end

of shaft.

2.

If hub was removed from steering wheel, attach hub

to steering wheel with screws removed during dis-

assembly.

3.

Place steering wheel and hub assembly in position

and secure to column with washer and nut.

4.

Position spacer on steering wheel.

5. Position lock knob on steering wheel.

6. Install lock screw through lock knob, turn into shaft,

and adjust to lock position.

7. Attach spacer to wheel with three screws.

8. Place lock knob in lock position and attach to lock

screw with two screws.

9. Remove three screws holding spacer. Attach horn

contact to spacer and steering wheel with three

screws.

10.

Install horn button cap.

11.

Connect steering column harness at chassis plug.

STEERING COUPLING (Fig. 12)

Removal

NOTE:

Chevy n models are equipped with a

clamp arrangement rather than the conventional

"rag joint" steering coupling. Refer to Steering

Gear - Chevy II, for service procedures.

1.

Remove nuts and washers securing steering coupling

to flanged end of steering column (fig. 12).

2.

Remove coupling clamp bolt (fig. 12) and slightly

spread coupling clamp.

CHEVROLET CHASSIS SERVICE MANUAL

Page 448 of 659

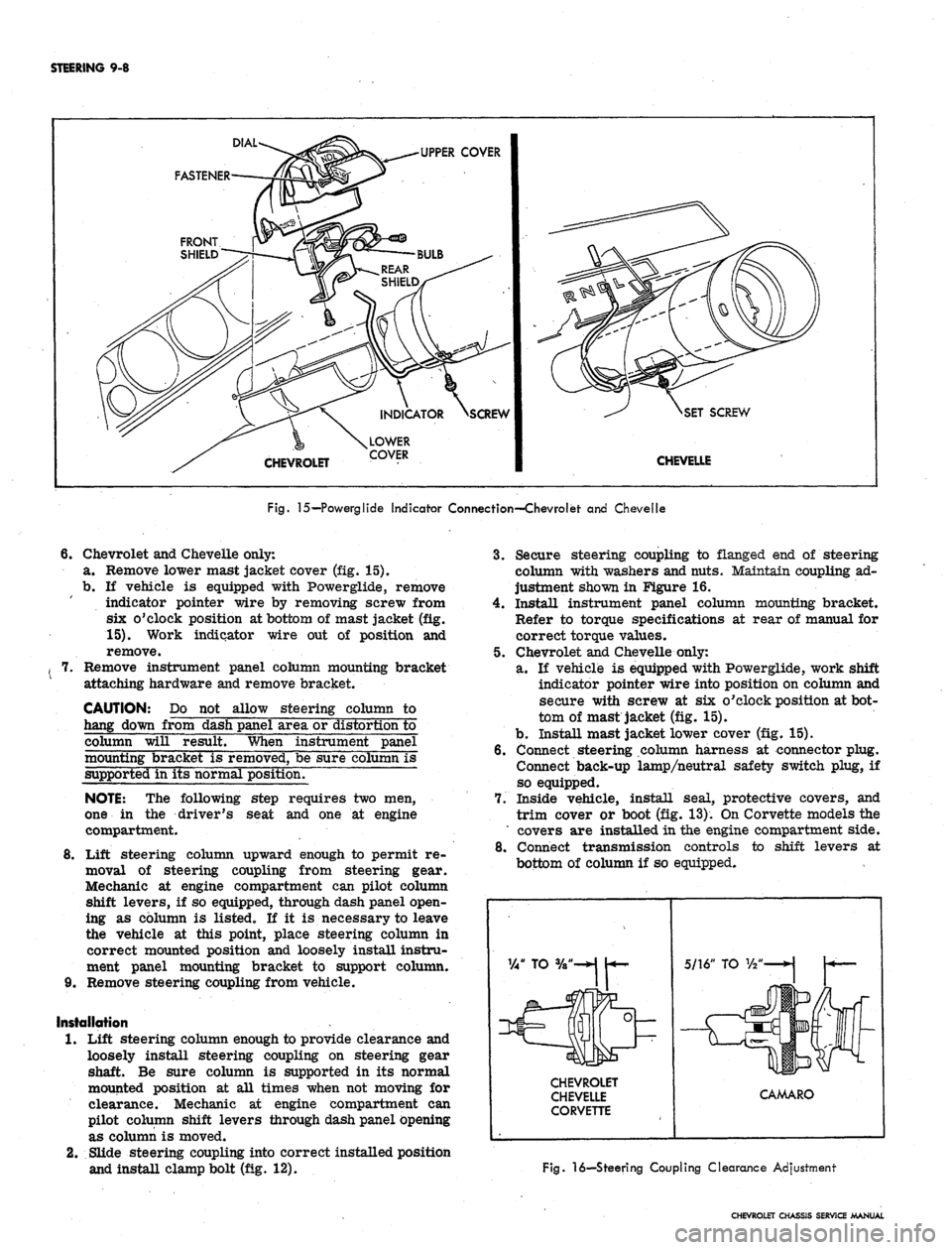

STEERING 9-8

DIAL

UPPER COVER

FASTENER

CHEVROLET

SCREW

CHEVELLE

Fig.

15—Powerglide Indicator Connection—Chevrolet and Chevelle

6.

Chevrolet and Chevelle only:

a. Remove lower mast jacket cover (fig. 15).

b.

If vehicle is equipped with Powerglide, remove

indicator pointer wire by removing screw from

six o'clock position at bottom of mast jacket (fig.

15).

Work indicator wire out of position and

remove.

Remove instrument panel column mounting bracket

attaching hardware and remove bracket.

CAUTION: Do not allow steering column to

hang down from dash panel area or distortion to

column will result. When instrument panel

mounting bracket is removed, be sure column is

supported in its normal position.

NOTE:

The following step requires two men,

one in the driver's seat and one at engine

compartment.

8

Lift steering column upward enough to permit re-

moval of steering coupling from steering gear.

Mechanic at engine compartment can pilot column

shift levers, if so equipped, through dash panel open-

ing as column is listed. If it is necessary to leave

the vehicle at this point, place steering column in

correct mounted position and loosely install instru-

ment panel mounting bracket to support column.

9. Remove steering coupling from vehicle.

Installation

1.

Lift steering column enough to provide clearance and

loosely install steering coupling on steering gear

shaft. Be sure column is supported in its normal

mounted position at all times when not moving for

clearance. Mechanic at engine compartment can

pilot column shift levers through dash panel opening

as column is moved.

2.

Slide steering coupling into correct installed position

and install clamp bolt (fig. 12).

3.

Secure steering coupling to flanged end of steering

column with washers and nuts. Maintain coupling ad-

justment shown in Figure 16.

4.

Install instrument panel column mounting bracket.

Refer to torque specifications at rear of manual for

correct torque values.

5. Chevrolet and Chevelle only:

a. If vehicle is equipped with Powerglide, work shift

indicator pointer wire into position on column and

secure with screw at six o'clock position at bot-

tom of mast jacket (fig. 15).

b.

Install mast jacket lower cover (fig. 15).

6. Connect steering column harness at connector plug.

Connect back-up lamp/neutral safety switch plug, if

so equipped.

7. Inside vehicle, install seal, protective covers, and

trim cover or boot (fig. 13). On Corvette models the

' covers are installed in the engine compartment side.

8. Connect transmission controls to shift levers at

bottom of column if so equipped.

CHEVROLET

CHEVELLE

CORVETTE

CAMARO

Fig.

16—Steering Coupling Clearance Adjustment

CHEVROLET CHASSIS SERVICE MANUAL