brakes CHEVROLET CAMARO 1967 1.G Chassis Workshop Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1967, Model line: CAMARO, Model: CHEVROLET CAMARO 1967 1.GPages: 659, PDF Size: 114.24 MB

Page 19 of 659

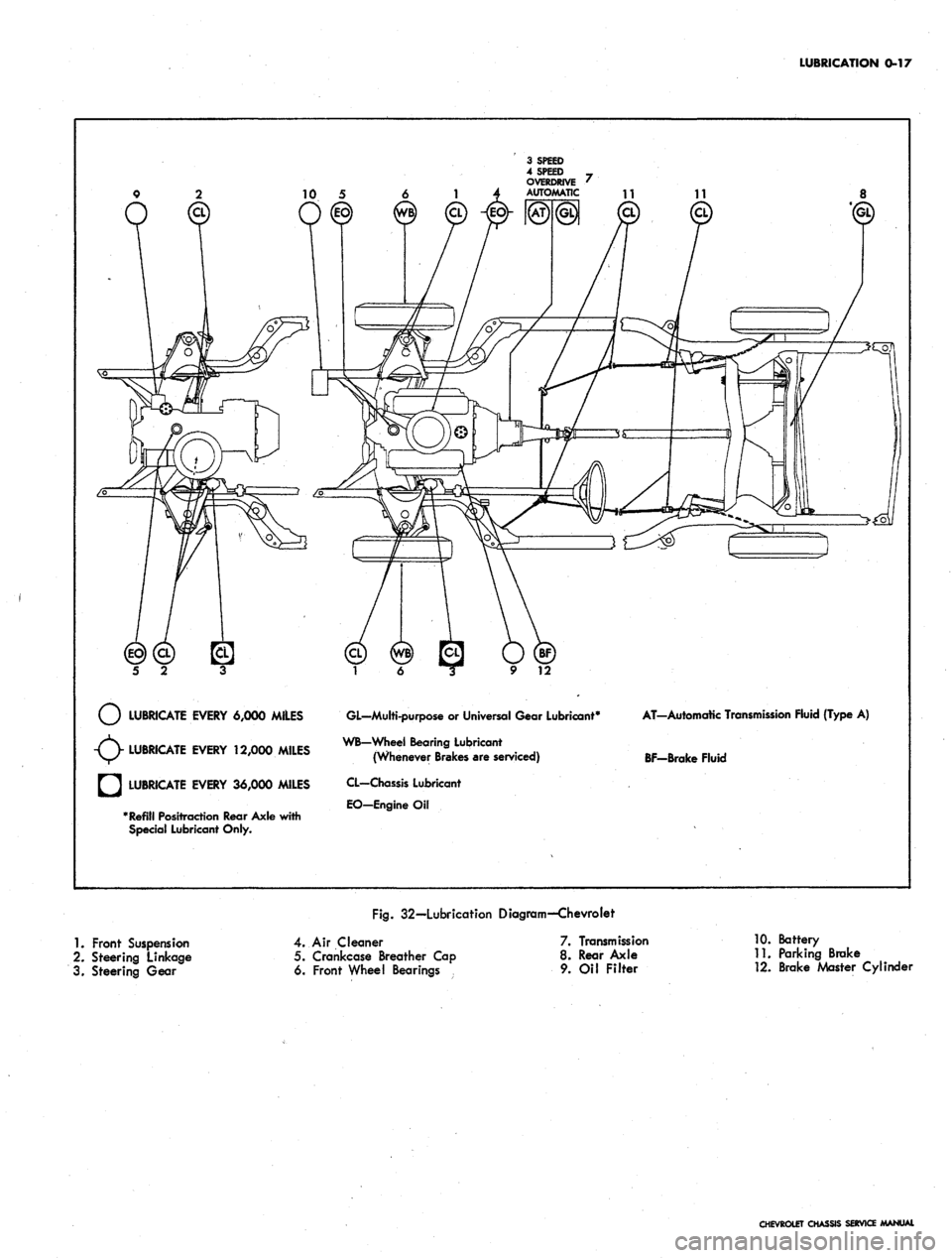

LUBRICATION 0-17

LUBRICATE EVERY 6,000 MILES

LUBRICATE EVERY 12,000 MILES

LUBRICATE EVERY 36,000 MILES

Refill Positraction Rear Axle with

Special Lubricant Only.

GL—Multi-purpose

or

Universal Gear Lubricant4

WB-Wheel Bearing Lubricant

(Whenever Brakes are serviced)

CL—Chassis Lubricant

EO-EngineOil

AT-Automatic Transmission Fluid {Type

A)

BF-Brake Fluid

Fig.

32—Lubrication Diagram—Chevrolet

1.

Front Suspension

2.

Steering Linkage

3. Steering Gear

4.

Air Cleaner

5. Crankcase Breather Cap

6. Front Wheel Bearings

7. Transmission

8. Rear Axle

9. Oil Filter

10.

Battery

11.

Parking Brake

12.

Brake Master Cylinder

CHEVROLET CHASSIS SERVICE MANUAL

Page 20 of 659

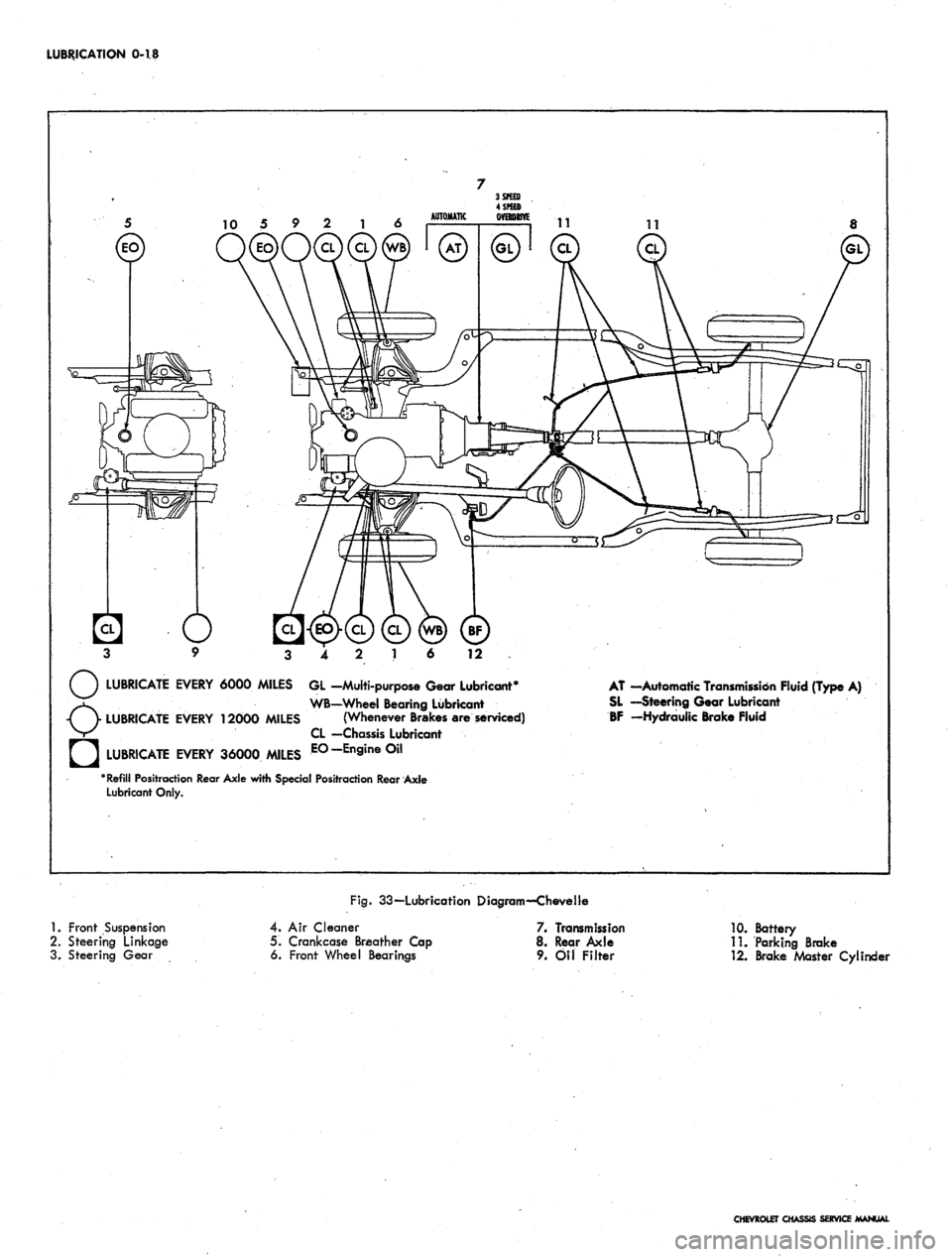

LUBRICATION 0-18

12

LUBRICATE EVERY 6000 MILES GL -Multi-purpose Gear Lubricant*

WB—Wheel Bearing Lubricant

LUBRICATE EVERY 12000 MILES (Whenever Brakes are serviced)

CL —Chassis Lubricant

LUBRICATE EVERY 36000 MILES E°-En9ine°il

"Refill Positraction Rear Axle with Special Positraction Rear Axle

Lubricant Only.

AT —Automatic Transmission Fluid (Type A)

SL —Steering Gear Lubricant

BF -Hydraulic Brake Fluid

1.

Front Suspension

2.

Steering Linkage

3. Steering Gear

Fig.

33—Lubrication Diagram—Chevelle

4.

Air Cleaner

5. Crankcase Breather Cap

6. Front Wheel Bearings

7. Transmission

8. Rear Axle

9. Oil Filter

10.

Battery

11.

Parking Brake

12.

Brake Master CylincU

CHEVROLET CHASSIS SERVICE MANUAL

Page 21 of 659

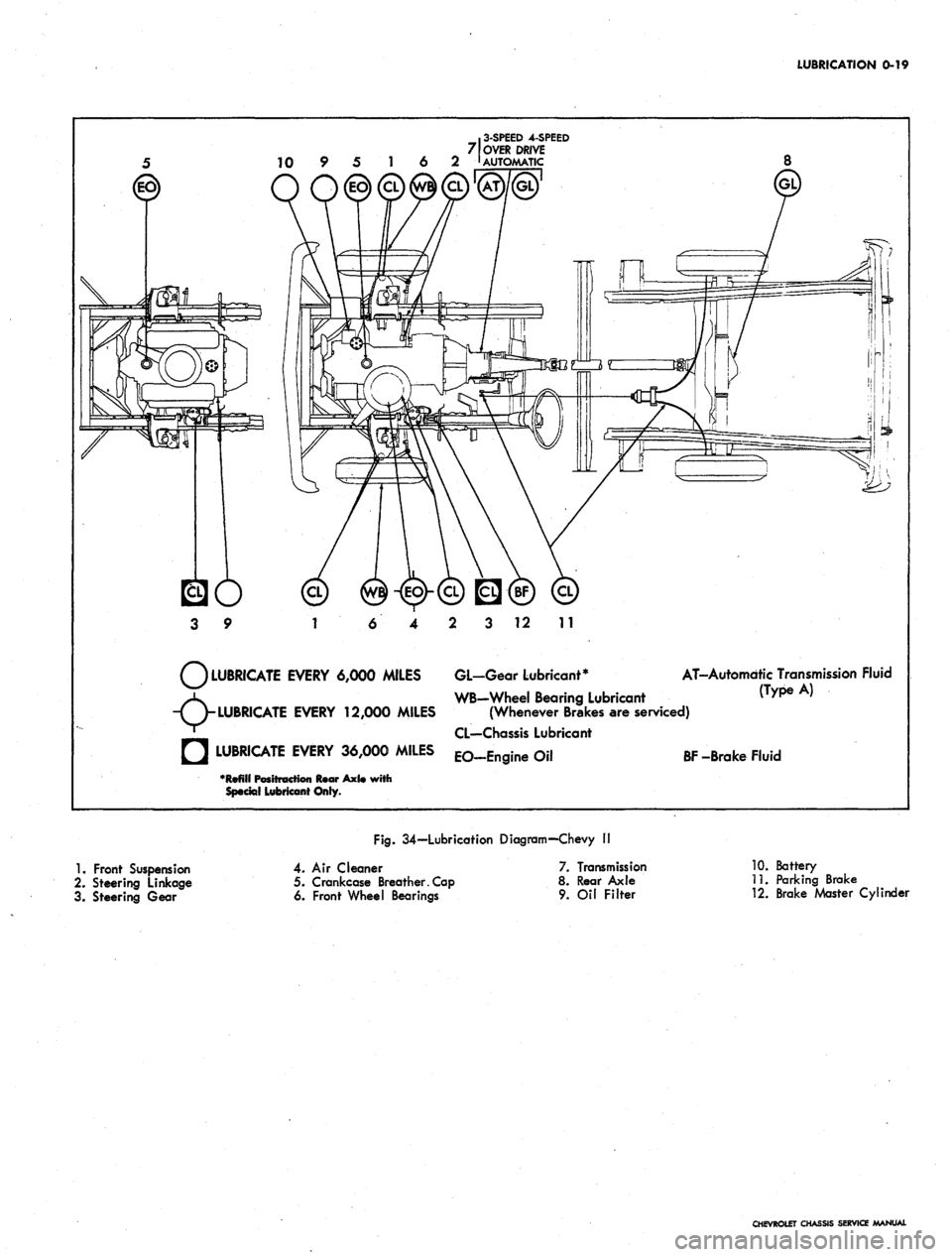

LUBRICATION

0-19

.

3-SPEED

4-SPEED

7 OVER DRIVE

10 9 5 1 6 2 '

AUTOMATIC

3 12 11

LUBRICATE EVERY 6,000 MILES GL-Gear Lubricant*

WB-Wheel Bearing Lubricant

(Wh Bk

AT-Automdtic Transmission Fluid

^ WB-Wheel Bearing Lubricant (Type A)

-TV

LUBRICATE

EVERY 12,000 MILES (Whenever Brakes are serviced)

' CL—Chassis Lubricant

• LUBRICATE EVERY 36,000 MILES EO_Engine Oil

BF

-Brake Fluid

•Refill Positt

Special Lubricant Only.

Axl«

with

1.

Front Suspension

2.

Steering Linkage

3. Steering Gear

Fig.

34—Lubrication Diagram—Chevy I!

4. Air Cleaner

5. Crankcase Breather. Cap

6. Front Wheel Bearings

7. Transmission

8. Rear Axle

9.

Oil Filter

10.

Battery

11.

Parking Brake

12.

Brake Master Cylinder

CHEVROLET CHASSIS SERVICE MANUAL

Page 22 of 659

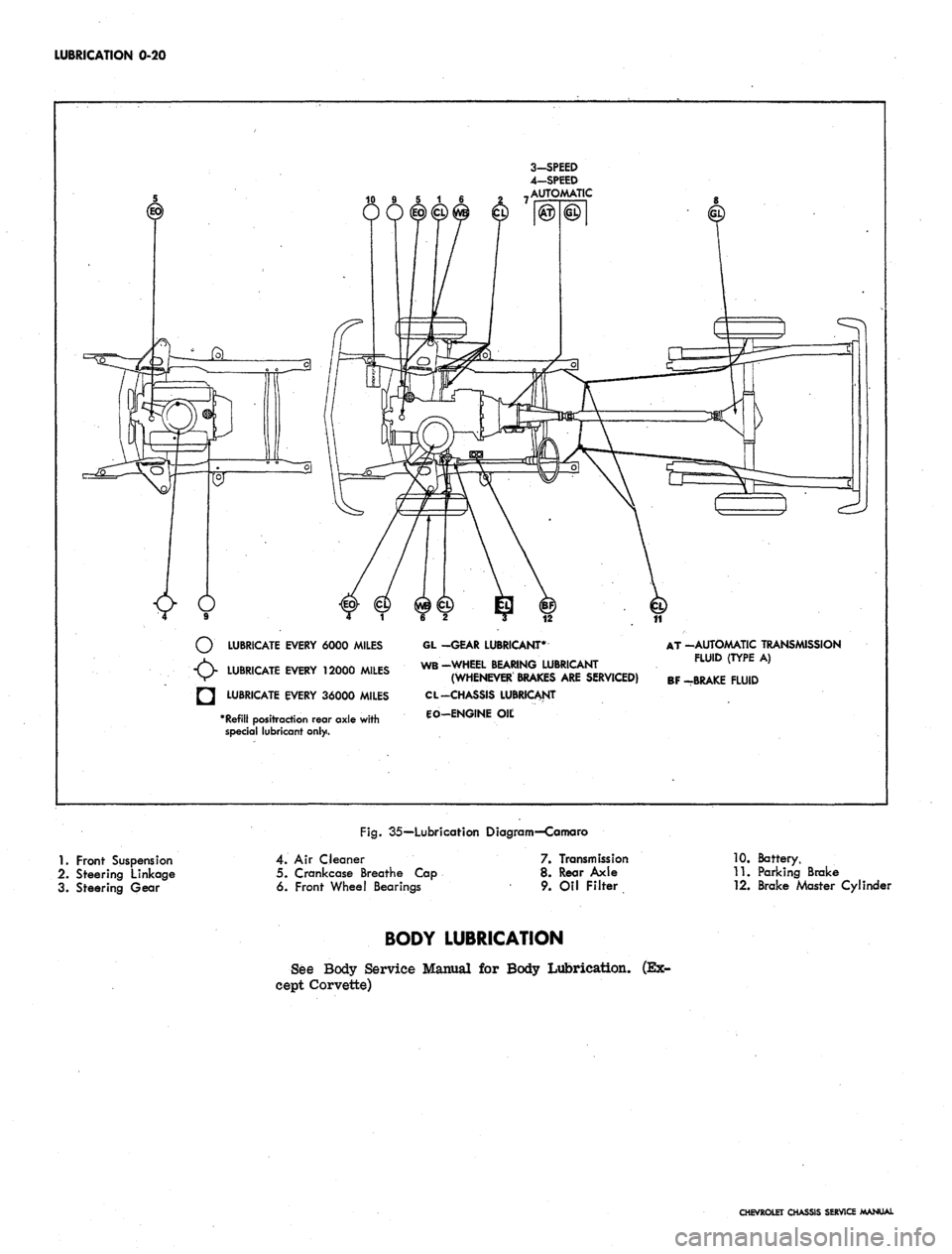

LUBRICATION 0-20

3-SPEED

4—SPEED

AUTOMATIC

LUBRICATE EVERY 6000 MILES

LUBRICATE EVERY 12000 MILES

LUBRICATE EVERY 36000 MILES

*

Refill

positraction rear axle with

special lubricant only.

GL -GEAR LUBRICANT*

WB-WHEEL BEARING LUBRICANT

(WHENEVER BRAKES

ARE

SERVICED)

CL -CHASSIS LUBRICANT

CO-ENGINE

Oil;

AT -AUTOMATIC TRANSMISSION

FLUID (TYPE

A)

BF -BRAKE FLUID

Fig.

35—Lubricafion Diagram—Camaro

1.

Front Suspension

2.

Steering Linkage

3. Steering Gear

4.

Air Cleaner

5. Crankcase Breathe Cap

6. Front Wheel Bearings

7. Transmission

8. Rear Axle

9. Oil Filter

10.

Battery,

11.

Parking Brake

12.

Brake Master Cylinder

BODY LUBRICATION

See Body Service Manual

for

Body Lubrication,

cept Corvette)

(Ex-

CHEVROLET CHASSIS SERVICE MANUAL

Page 23 of 659

LUBRICATION

0-21

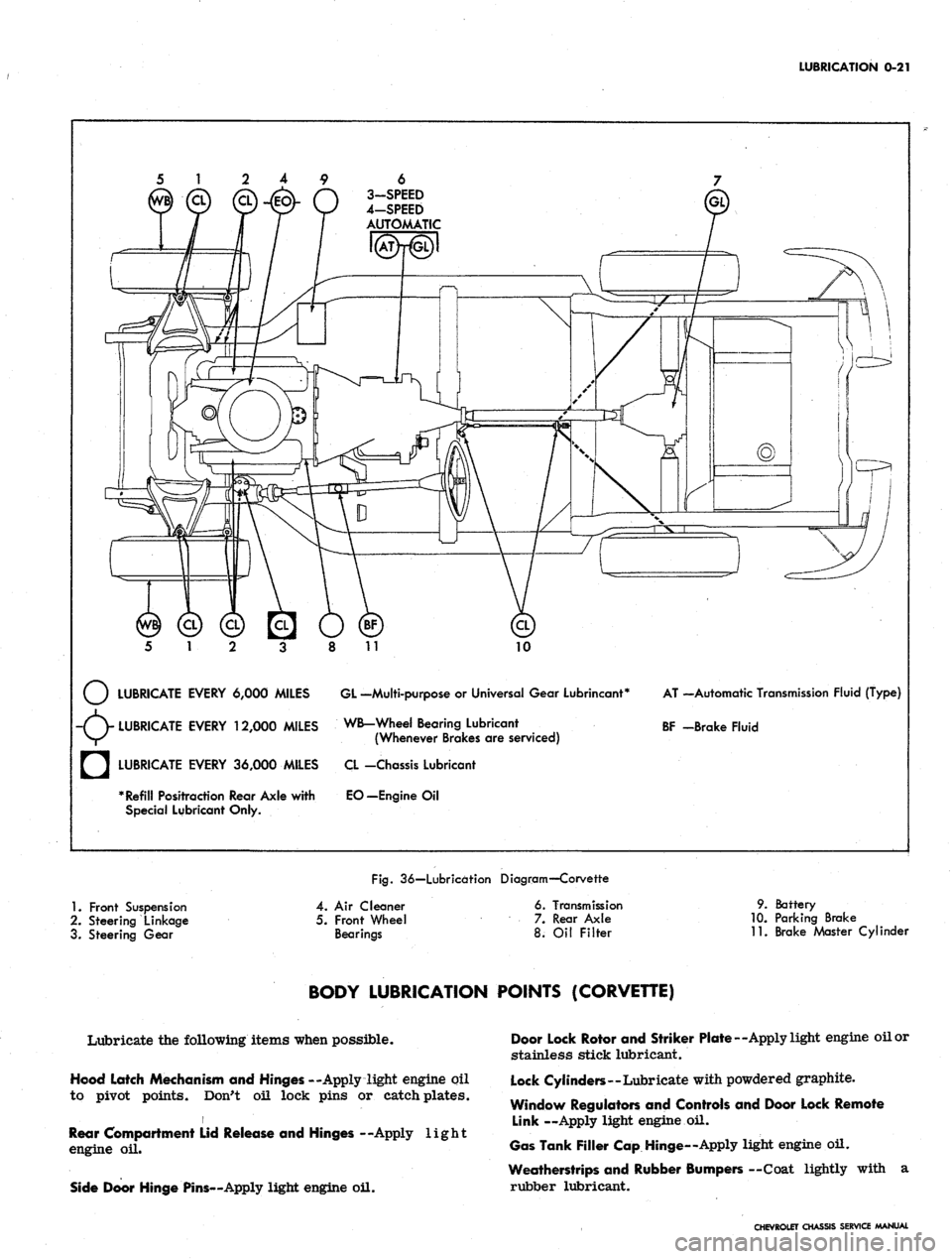

6

3-SPEED

4-SPEED

AUTOMATIC

10

LUBRICATE EVERY 6,000 MILES GL -Multi-purpose

or

Universal Gear Lubrincant*

-(V LUBRICATE EVERY 12,000 MILES WB-Wheel Bearing Lubricant

V/^ (Whenever Brakes

are

serviced)

AT —Automatic Transmission Fluid (Type)

BF -Brake Fluid

a

LUBRICATE EVERY 36,000 MILES

* Refill Positraction Rear Axle with

Special Lubricant Only.

CL -Chassis Lubricant

EO—Engine

Oil

Fig.

36—Lubrication Diagram—Corvette

1.

Front Suspension

2.

Steering Linkage

3. Steering Gear

4.

Air

Cleaner

5. Front Wheel

Bearings

6. Transmission

7. Rear Axle

8.

Oil

Filter

9. Battery

10.

Parking Brake

11.

Brake Master Cylinder

BODY LUBRICATION POINTS (CORVETTE)

Lubricate the following items when possible.

Hood Latch Mechanism and Hinges --Apply light engine oil

to pivot points. Don't oil lock pins or catch plates.

i

Rear Compartment Lid Release and Hinges --Apply light

engine

oil.

Side Door Hinge Pins—Apply light engine oil.

Door Lock Rotor and Striker Plate—Apply light engine oil or

stainless stick lubricant.

Lock Cylinders—Lubricate with powdered graphite.

Window Regulators and Controls and Door Lock Remote

Link —Apply light engine

oil.

Gas Tank Filler Cap Hinge—Apply light engine oil.

Weatherstrips and Rubber Bumpers —Coat lightly with

a

rubber lubricant.

CHEVROLET CHASSIS SERVICE MANUAL

Page 214 of 659

REAR SUSPENSION AND DRIVE LINE 4-24

4

i*

5

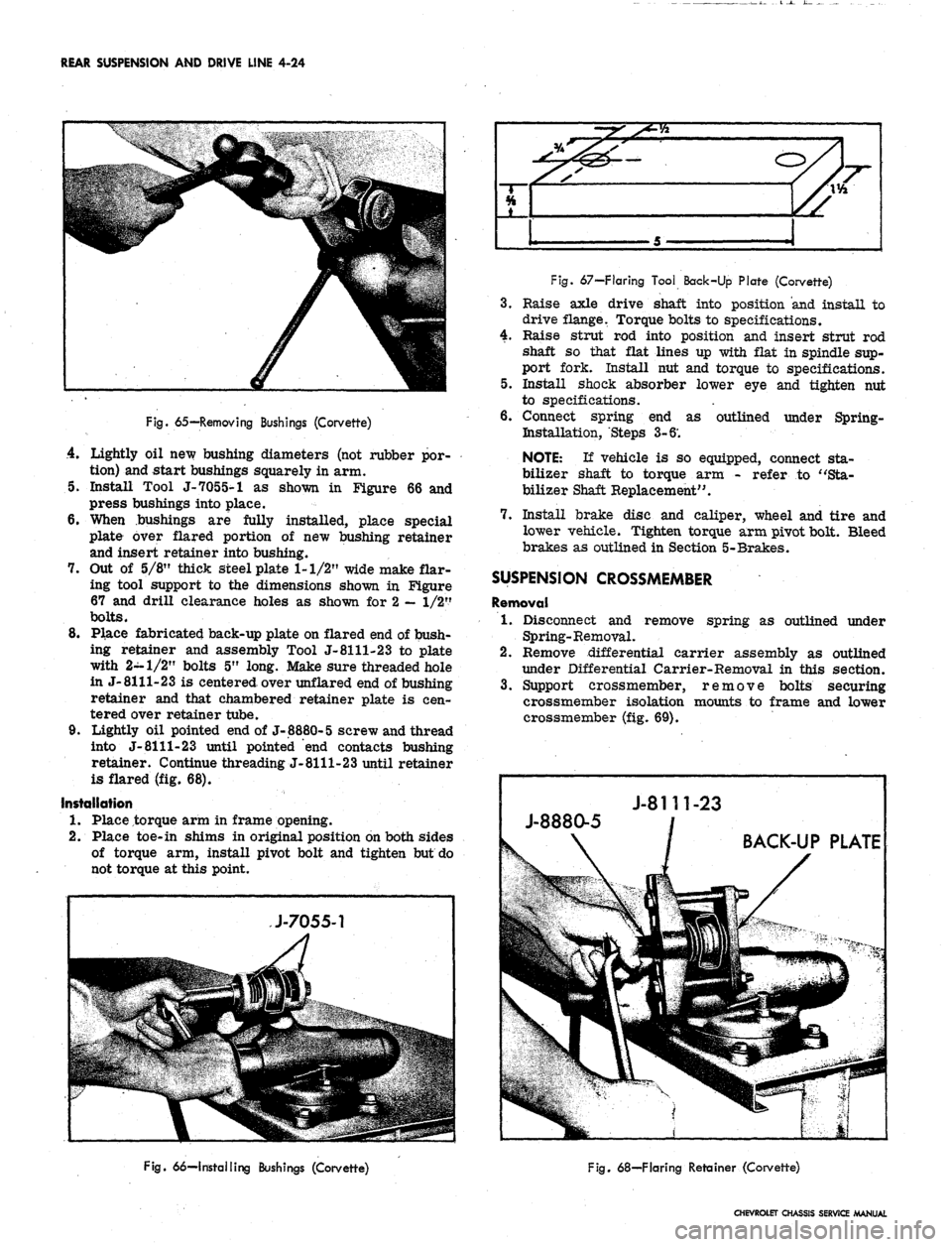

Fig.

65—Removing Bushings (Corvette)

4.

Lightly oil new bushing diameters (not rubber por-

tion) and start bushings squarely in arm.

5. Install Tool J-7055-1 as shown in Figure 66 and

press bushings into place.

6. When bushings are fully installed, place special

plate over flared portion of new bushing retainer

and insert retainer into bushing.

7. Out of 5/8" thick steel plate 1-1/2" wide make flar-

ing tool support to the dimensions shown in Figure

67 and drill clearance holes as shown for 2

—

1/2"

bolts.

8. Place fabricated back-up plate on flared end of bush-

ing retainer and assembly Tool J-8111-23 to plate

with 2-1/2" bolts 5" long. Make sure threaded hole

in J-8111-23 is centered over unflared end of bushing

retainer and that chambered retainer plate is cen-

tered over retainer tube.

9. Lightly oil pointed end of J-8880-5 screw and thread

into J-

8111-23

until pointed "end contacts bushing

retainer. Continue threading J-8111-23 until retainer

is flared (fig. 68).

Installation

1.

Place torque arm in frame opening.

2.

Place toe-in shims in original position on both sides

of torque arm, install pivot bolt and tighten but do

not torque at this point.

Fig.

67—Flaring Tool Back-Up Plate (Corvette)

3.

Raise axle drive shaft into position and install to

drive flange. Torque bolts to specifications.

4.

Raise strut rod into position and insert strut rod

shaft so that flat lines up with flat in spindle sup-

port fork. Install nut and torque to specifications.

5. Install shock absorber lower eye and tighten nut

to specifications.

6. Connect spring end as outlined under Spring-

Bistallation, Steps 3-6'.

NOTE:

If vehicle is so equipped, connect sta-

bilizer shaft to torque arm - refer to "Sta-

bilizer Shaft Replacement".

7. Install brake disc and caliper, wheel and tire and

lower vehicle. Tighten torque arm pivot bolt. Bleed

brakes as outlined in Section 5-Brakes.

SUSPENSION CROSSMEMBER

Removal

1.

Disconnect and remove spring as outlined under

Spring-Removal.

2.

Remove differential carrier assembly as outlined

under Differential Carrier-Removal in this section.

3.

Support crossmember, remove bolts securing

crossmember isolation mounts to frame and lower

crossmember (fig. 69).

Fig.

66—Installing Bushings (Corvette)

Fig.

68—Flaring Retainer (Corvette)

CHEVROLET CHASSIS SERVICE MANUAL

Page 220 of 659

REAR SUSPENSION AND DRIVE LINE 4-30

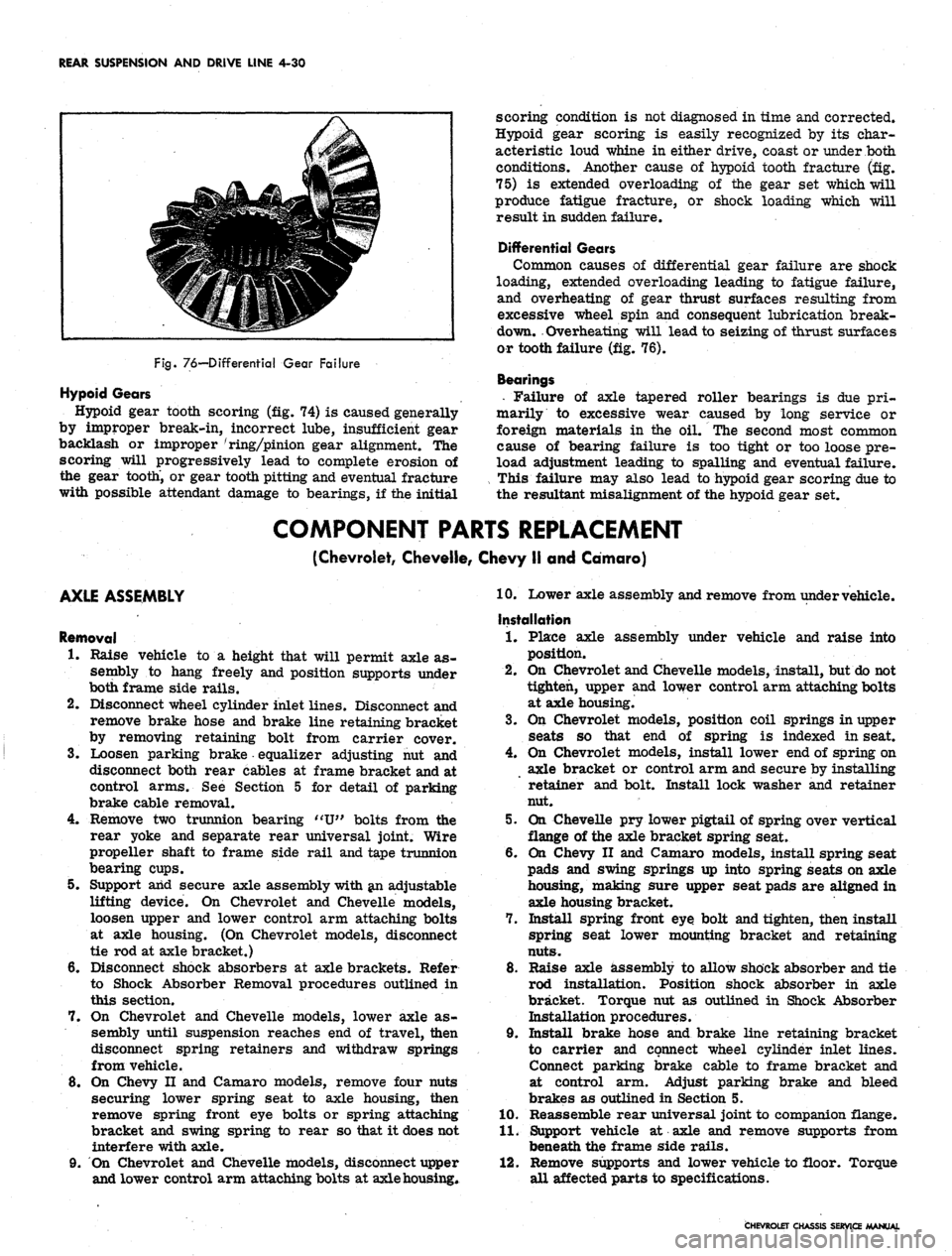

Fig.

76—Differential Gear Failure

Hypoid Gears

Hypoid gear tooth scoring (fig. 74) is caused generally

by improper break-in, incorrect lube, insufficient gear

backlash or improper 'ring/pinion gear alignment. The

scoring will progressively lead to complete erosion of

the gear tooth, or gear tooth pitting and eventual fracture

with possible attendant damage to bearings, if the initial

scoring condition is not diagnosed in time and corrected.

Hypoid gear scoring is easily recognized by its char-

acteristic loud whine in either drive, coast or under both

conditions. Another cause of hypoid tooth fracture (fig.

75) is extended overloading of the gear set which will

produce fatigue fracture, or shock loading which will

result in sudden failure.

Differential Gears

Common causes of differential gear failure are shock

loading, extended overloading leading to fatigue failure,

and overheating of gear thrust surfaces resulting from

excessive wheel spin and consequent lubrication break-

down. Overheating will lead to seizing of thrust surfaces

or tooth failure (fig. 76).

Bearings

• Failure of axle tapered roller bearings is due pri-

marily to excessive wear caused by long service or

foreign materials in the oil. The second most common

cause of bearing failure is too tight or too loose pre-

load adjustment leading to spalling and eventual failure.

This failure may also lead to hypoid gear scoring due to

the resultant misalignment of the hypoid gear set.

COMPONENT PARTS REPLACEMENT

(Chevrolet, Cheveile, Chevy II and Camaro)

AXLE ASSEMBLY

Removal

1.

Raise vehicle to a height that will permit axle as-

sembly to hang freely and position supports under

both frame side rails.

2.

Disconnect wheel cylinder inlet lines. Disconnect and

remove brake hose and brake line retaining bracket

by removing retaining bolt from carrier cover.

3.

Loosen parking brake equalizer adjusting nut and

disconnect both rear cables at frame bracket and at

control arms. See Section 5 for detail of parking

brake cable removal.

4.

Remove two trunnion bearing "U" bolts from the

rear yoke and separate rear universal joint. Wire

propeller shaft to frame side rail and tape trunnion

bearing cups.

5. Support arid secure axle assembly with an adjustable

lifting device. On Chevrolet and Cheveile models,

loosen upper and lower control arm attaching bolts

at axle housing. (On Chevrolet models, disconnect

tie rod at axle bracket.)

6. Disconnect shock absorbers at axle brackets. Refer

to Shock Absorber Removal procedures outlined in

this section.

7. On Chevrolet and Cheveile models, lower axle as-

sembly until suspension reaches end of travel, then

disconnect spring retainers and withdraw springs

from vehicle.

8. On Chevy II and Camaro models, remove four nuts

securing lower spring seat to axle housing, then

remove spring front eye bolts or spring attaching

bracket and swing spring to rear so that it does not

interfere with axle.

9. On Chevrolet and Cheveile models, disconnect upper

and lower control arm attaching bolts at axle housing*

10.

Lower axle assembly and remove from under vehicle.

Installation

1.

Place axle assembly under vehicle and raise into

position.

2.

On Chevrolet and Cheveile models, install, but do not

tighten, upper and lower control arm attaching bolts

at axle housing.

3.

On Chevrolet models, position coil springs in upper

seats so that end of spring is indexed in seat.

4.

On Chevrolet models, install lower end of spring on

axle bracket or control arm and secure by installing

retainer and bolt. Install lock washer and retainer

nut.

5. On Cheveile pry lower pigtail of spring over vertical

flange of the axle bracket spring seat.

6. On Chevy II and Camaro models, install spring seat

pads and swing springs up into spring seats on axle

housing, making sure upper seat pads are aligned in

axle housing bracket.

7. Install spring front eye bolt and tighten, then install

spring seat lower mounting bracket and retaining

nuts.

8. Raise axle assembly to allow shock absorber and tie

rod installation. Position shock absorber in axle

bracket. Torque nut as outlined in Shock Absorber

Installation procedures.

9. Install brake hose and brake line retaining bracket

to carrier and connect wheel cylinder inlet lines.

Connect parking brake cable to frame bracket and

at control arm. Adjust parking brake and bleed

brakes as outlined in Section 5.

10.

Reassemble rear universal joint to companion flange.

11.

Support vehicle at axle and remove supports from

beneath the frame side rails.

12.

Remove supports and lower vehicle to floor. Torque

all affected parts to specifications.

CHEVROLET CHASSIS SERVICE MANUAL

Page 222 of 659

REAR SUSPENSION AND DRIVE LINE 4-32

HP?

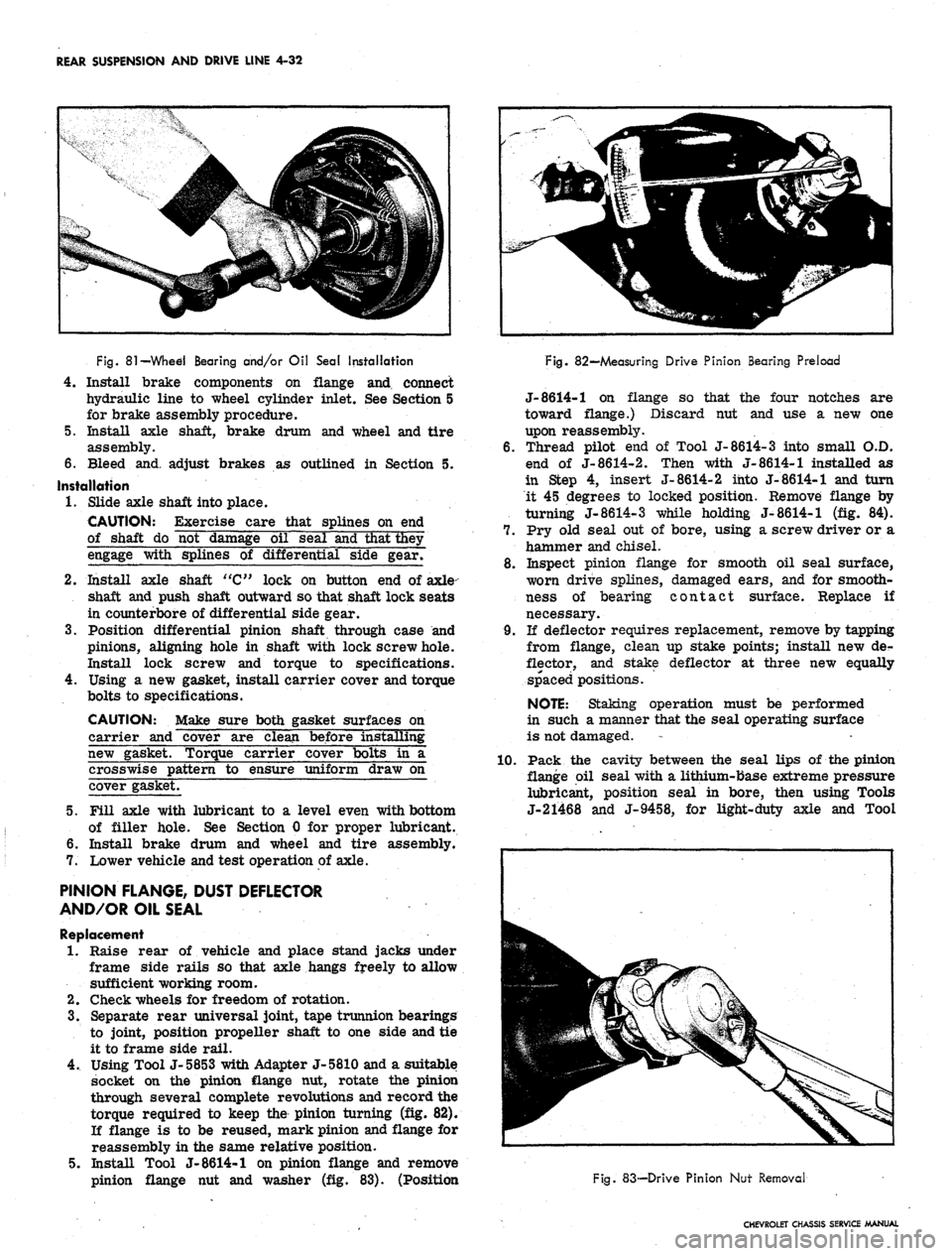

Fig.

81

—Whed Bearing and/or Oil Seal Installation

4.

Install brake components on flange and connect

hydraulic line to wheel cylinder inlet. See Section 5

for brake assembly procedure.

5. Install axle shaft, brake drum and wheel and tire

assembly.

6. Bleed and. adjust brakes as outlined in Section 5.

Installation

1.

Slide axle shaft into place.

CAUTION: Exercise care that splines on end

of shaft do not damage oil seal and that they

engage with splines of differential side gear/

2.

Install axle shaft "C" lock on button end of axle-

shaft and push shaft outward so that shaft lock seats

in counterbore of differential side gear.

3.

Position differential pinion shaft through case and

pinions, aligning hole in shaft with lock screw hole.

Install lock screw and torque to specifications.

4.

Using a new gasket, install carrier cover and torque

bolts to specifications.

CAUTION: Make sure both gasket surfaces on

carrier and cover are clean before installing

new gasket. Torque carrier cover bolts in a

crosswise pattern to ensure uniform draw on

cover gasket.

5. Fill axle with lubricant to a level even with bottom

of filler hole. See Section 0 for proper lubricant.

6. Install brake drum and wheel and tire assembly.

7. Lower vehicle and test operation of axle.

PINION FLANGE, DUST DEFLECTOR

AND/OR OIL SEAL

Replacement

1.

Raise rear of vehicle and place stand jacks under

frame side rails so that axle hangs freely to allow

sufficient working room.

2.

Check wheels for freedom of rotation.

3.

Separate rear universal joint, tape trunnion bearings

to joint, position propeller shaft to one side and tie

it to frame side rail.

4.

Using Tool J-5853 with Adapter J-5810 and a suitable

socket on the pinion flange nut, rotate the pinion

through several complete revolutions and record the

torque required to keep the pinion turning (fig. 82).

If flange is to be reused, mark pinion and flange for

reassembly in the same relative position.

5. Install Tool J-8614-1 on pinion flange and remove

pinion flange nut and washer (fig. 83). (Position

Fig. 82—Measuring Drive Pinion Bearing Preload

J-8614-1 on flange so that the four notches are

toward flange.) Discard nut and use a new one

upon reassembly.

6. Thread pilot end of Tool J-8614-3 into small O.D.

end of J-8614-2. Then with J-8614-1 installed as

in Step 4, insert J-8614-2 into J-8614-1 and turn

it 45 degrees to locked position. Remove flange by

turning J-8614-3 while holding J-8614-1 (fig. 84).

7. Pry old seal out of bore, using a screw driver or a

hammer and chisel.

8. Inspect pinion flange for smooth oil seal surface,

worn drive splines, damaged ears, and for smooth-

ness of bearing contact surface. Replace if

necessary.

9. If deflector requires replacement, remove by tapping

from flange, clean up stake points; install new de-

flector, and stake deflector at three new equally

spaced positions.

NOTE:

Staking operation must be performed

in such a manner that the seal operating surface

is not damaged.

1.0. Pack the cavity between the seal lips of the pinion

flange oil seal with a lithium-base extreme pressure

lubricant, position seal in bore, then using Tools

J-21468 and J-9458, for light-duty axle and Tool

Fig. 83-—Drive Pinion Nut Removal

CHEVROLET CHASSIS SERVICE MANUAL

Page 234 of 659

BRAKES

SECTION 5

CONTENTS OF THIS SECTION

Duo Servo Brakes

Disc Brakes

Page

5-1 Power Brakes

5-24 Special Tools

Page

5-31

5-32

DUO-SERVO BRAKES

INDEX

Page

General Description 5-1

Maintenance and Adjustments 5-3

Hydraulic Brake Fluid .. . 5-3

Bleeding Hydraulic System 5-3

Pressure Bleeding 5-3

Manual Bleeding 5_4

Push Rod to Main Cylinder Clearance 5-5

Hydraulic Brake Lines 5-5

Hydraulic Brake Hose 5-5

Hydraulic Brake Tubing 5-6

Brake Adjustment. .................... 5-7

Service Brake 5-7

Parking Brake 5-8

Component Replacement and Repairs 5-9

Parking Brake - Chevrolet, Chevelle and

Camaro 5^9

Pedal Assembly 5-9

Front Cable ,. . . 5-9

Center Cable 5-9

Rear Cables. . 5-9

Parking Brake - Chevy n 5-9

Lever Assembly 5-9

Idler Lever 5-11

Front Cable 5-11

Rear Cable . . ; 5-12

Parking Brake - Corvette 5-13

Lever Assembly . . . . 5-13

Front Cable 5-14

Rear Cable . . 5-14

Brake Pedal 5-15

Shoes and Linings 5-16

Organic 5-16

Metallic 5-17

Main Cylinder 5-18

Wheel Cylinders 5-21

Anchor Pin 5-22

Front Wheel 5-22

Rear Wheel 5-22

Brake Drums • 5-22

Brake Pipe Distribution and Switch Assembly . . . . . 5-23

Camaro Pressure Regulator Valve 5-23

GENERAL DESCRIPTION

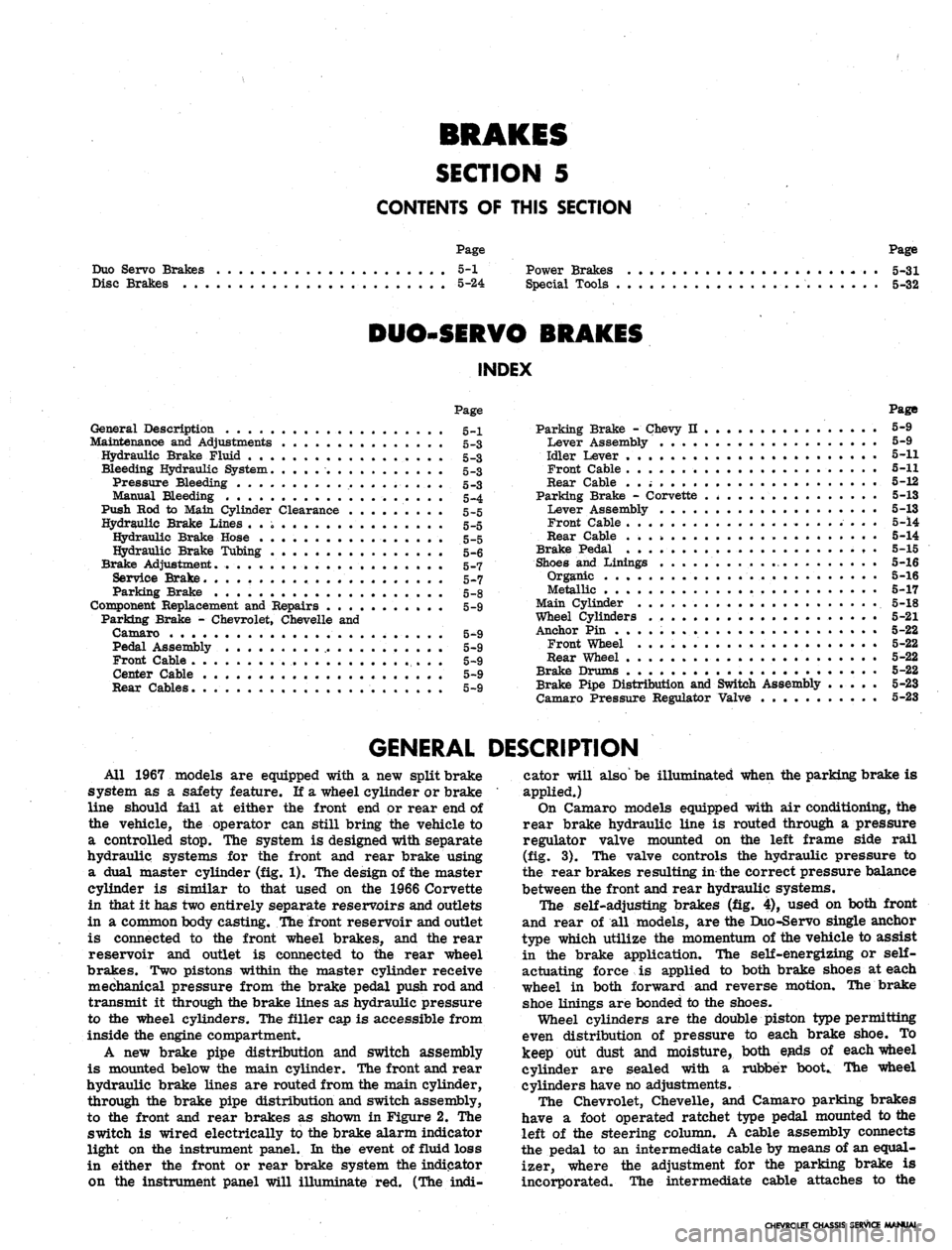

All 1967 models are equipped with a new split brake

system as a safety feature. If a wheel cylinder or brake

line should fail at either the front end or rear end of

the vehicle, the operator can still bring the vehicle to

a controlled stop. The system is designed with separate

hydraulic systems for the front and rear brake using

a dual master cylinder (fig. 1). The design of the master

cylinder is similar to that used on the 1966 Corvette

in that it has two entirely separate reservoirs and outlets

in a common body casting. The front reservoir and outlet

is connected to the front wheel brakes, and the rear

reservoir and outlet is connected to the rear wheel

brakes. Two pistons within the master cylinder receive

mechanical pressure from the brake pedal push rod and

transmit it through the brake lines as hydraulic pressure

to the wheel cylinders. The filler cap is accessible from

inside the engine compartment.

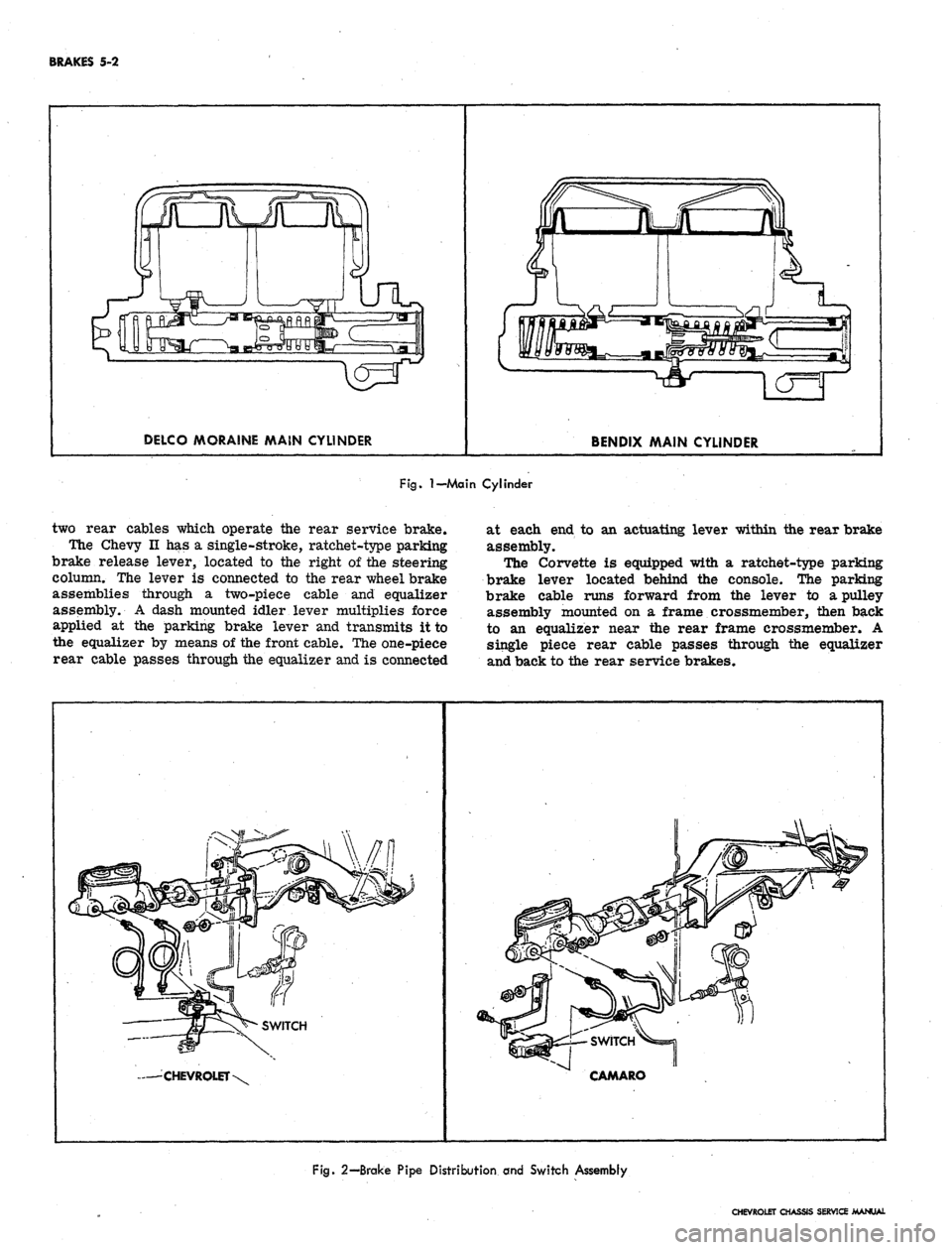

A new brake pipe distribution and switch assembly

is mounted below the main cylinder. The front and rear

hydraulic brake lines are routed from the main cylinder,

through the brake pipe distribution and switch assembly,

to the front and rear brakes as shown in Figure 2. The

switch is wired electrically to the brake alarm indicator

light on the instrument panel. In the event of fluid loss

in either the front or rear brake system the indicator

on the instrument panel will illuminate red. (The indi-

cator will also' be illuminated when the parking brake is

applied.)

On Camaro models equipped with air conditioning, the

rear brake hydraulic line is routed through a pressure

regulator valve mounted on the left frame side rail

(fig. 3). The valve controls the hydraulic pressure to

the rear brakes resulting in the correct pressure balance

between the front and rear hydraulic systems.

The self-adjusting brakes (fig. 4), used on both front

and rear of all models, are the Duo-Servo single anchor

type which utilize the momentum of the vehicle to assist

in the brake application. The self-energizing or

self-

actuating force is applied to both brake shoes at each

wheel in both forward and reverse motion. The brake

shoe linings are bonded to the shoes.

Wheel cylinders are the double piston type permitting

even distribution of pressure to each brake shoe. To

keep out dust and moisture, both ejads of each wheel

cylinder are sealed with a rubber booC The wheel

cylinders have no adjustments.

The Chevrolet, Chevelle, and Camaro parking brakes

have a foot operated ratchet type pedal mounted to the

left of the steering column. A cable assembly connects

the pedal to an intermediate cable by means of an equal-

izer, where the adjustment for the parking brake is

incorporated. The intermediate cable attaches to the

CHEVROLET CHASSIS SERVICE MANUAL

Page 235 of 659

BRAKES 5-2

DELCO MORAINE MAIN CYLINDER

BENDIX MAIN CYLINDER

Fig.

I—Main

Cylinder

two rear cables which operate the rear service brake.

The Chevy II has a single-stroke, ratchet-type parking

brake release lever, located to the right of the steering

column. The lever is connected to the rear wheel brake

assemblies through a two-piece cable and equalizer

assembly. A dash mounted idler lever multiplies force

applied at the parking brake lever and transmits it to

the equalizer by means of the front cable. The one-piece

rear cable passes through the equalizer and is connected

at each end to an actuating lever within the rear brake

assembly.

The Corvette is equipped with a ratchet-type parking

brake lever located behind the console. The parking

brake cable runs forward from the lever to a pulley

assembly mounted on a frame crossmember, then back

to an equalizer near the rear frame crossmember. A

single piece rear cable passes through the equalizer

and back to the rear service brakes.

— CHEVROLET

CAMARO

Fig.

2—Brake Pipe Distribution and Switch Assembly

CHEVROLET CHASSIS SERVICE MANUAL