engine CHEVROLET CAMARO 1967 1.G Chassis Workshop Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1967, Model line: CAMARO, Model: CHEVROLET CAMARO 1967 1.GPages: 659, PDF Size: 114.24 MB

Page 3 of 659

SECTION O

INFORMATION AND LUBRICATION

CONTENTS OF THIS SECTION

Page

General Information o-l

Lubrication 0-13

GENERAL INFORMATION

Model Identification and Vehicle Dimensions

Chevrolet

Chevelle

Chevy n

Corvette

Camaro

Page

0-1

0-1

0-2

0-2

0-3

0-3

Page

Unit and Serial Numbers o-3

Engine Number o-3

Vehicle Serial Number 0r3

Keys and Locks 0-4

Pushing,Towing and Lifting 0-7

Series

Biscayne

Bel Air

Tmpala.

Impala

Super Sport

Caprice

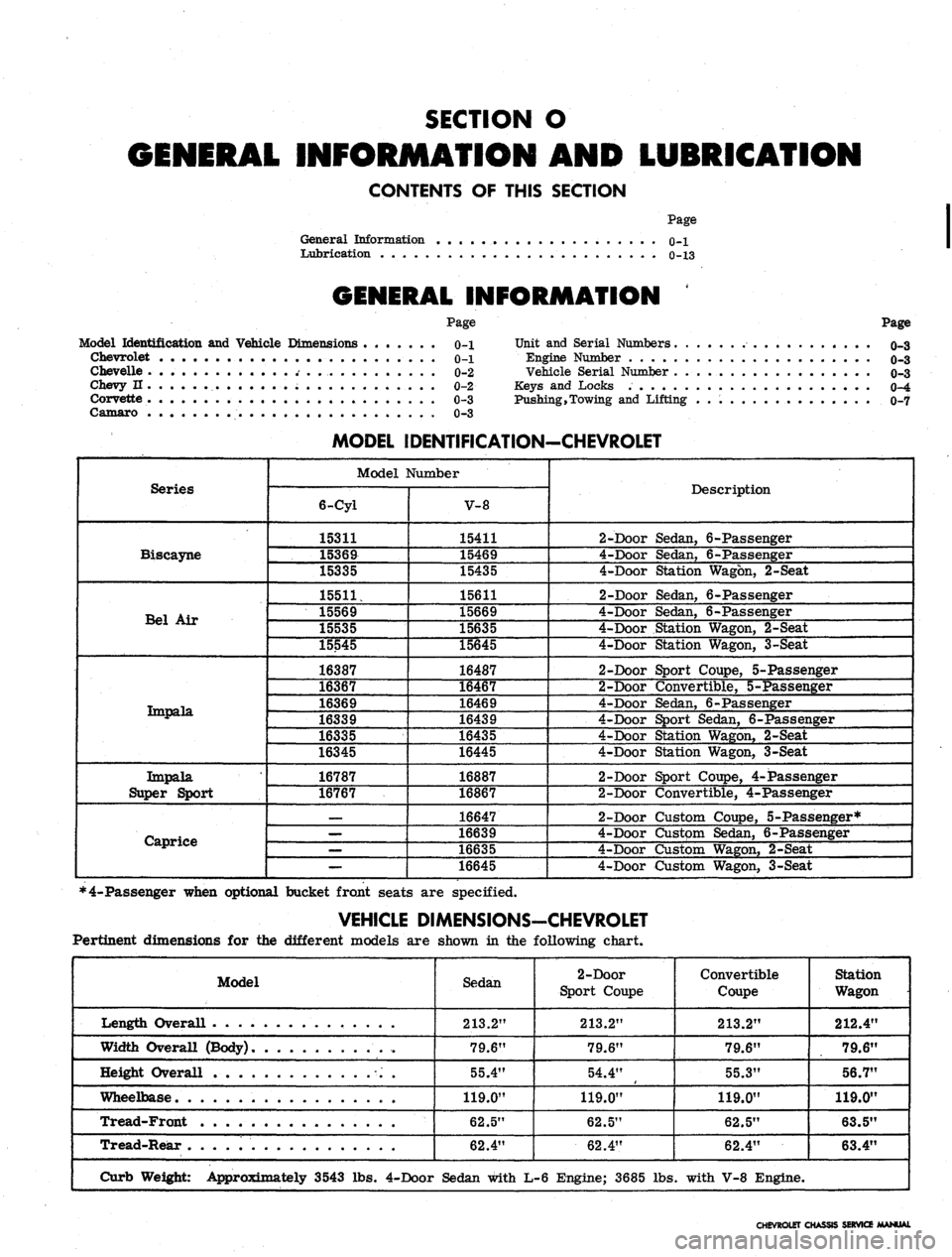

MODEL IDENTIFICATION-CHEVROLET

Model Number

6-Cyl

15311

15369

15335

15511,

15569

15535

15545

16387

16367

16369

16339

16335

16345

16787

16767

—

—

—

—

V-8

15411

15469

15435

15611

15669

15635

15645

16487

16467

16469

16439

16435

16445

16887

16867

16647

16639

16635

16645

Description

2-Door Sedan, 6-Passenger

4-Door Sedan, 6-Passenger

4-Door Station Wagon, 2-Seat

2-Door Sedan, 6-Passenger

4-Door Sedan, 6-Passenger

4-Door Station Wagon, 2-Seat

4-Door Station Wagon, 3-Seat

2-Door Sport Coupe, 5-Passenger

2-Door Convertible, 5-Passenger

4-Door Sedan, 6-Passenger

4-Door Sport Sedan, 6-Passenger

4-Door Station Wagon, 2-Seat

4-Door Station Wagon, 3-Seat

2-Door Sport Coupe, 4-Passenger

2-Door Convertible, 4-Passenger

2-Door Custom Coupe, 5-Passenger*

4-Door Custpm Sedan, 6-Passenger

4-Door Custom Wagon, 2-Seat

4-Door Custom Wagon, 3-Seat

*4-Passenger when optional bucket front seats are specified.

VEHICLE DIMENSIONS-CHEVROLET

Pertinent dimensions for the different models are shown in the following chart.

Model

Length Overall . .

Width Overall (Body)

Height Overall

Wheelbase

Tread-Front

Tread-Rear

Curb Weight: Approximately 3543 lbs.

Sedan

213.2"

79.6"

55.4"

119.0"

62.5"

62.4"

4-Door Sedan with

2-Door

Sport Coupe

213.2"

79.6"

54.4"

119.0"

62.5"

62.4"

L-6 Engine; 3685 lbs

Convertible

Coupe

213.2"

79.6"

55.3"

119.0"

62.5"

62.4"

. with V-8 Engine.

Station

Wagon

212.4"

79.6"

56.7"

119.0"

63.5"

63.4"

CHEVROLET CHASSIS SERVICE MANUAL

Page 4 of 659

GENERAL INFORMATION 0-2

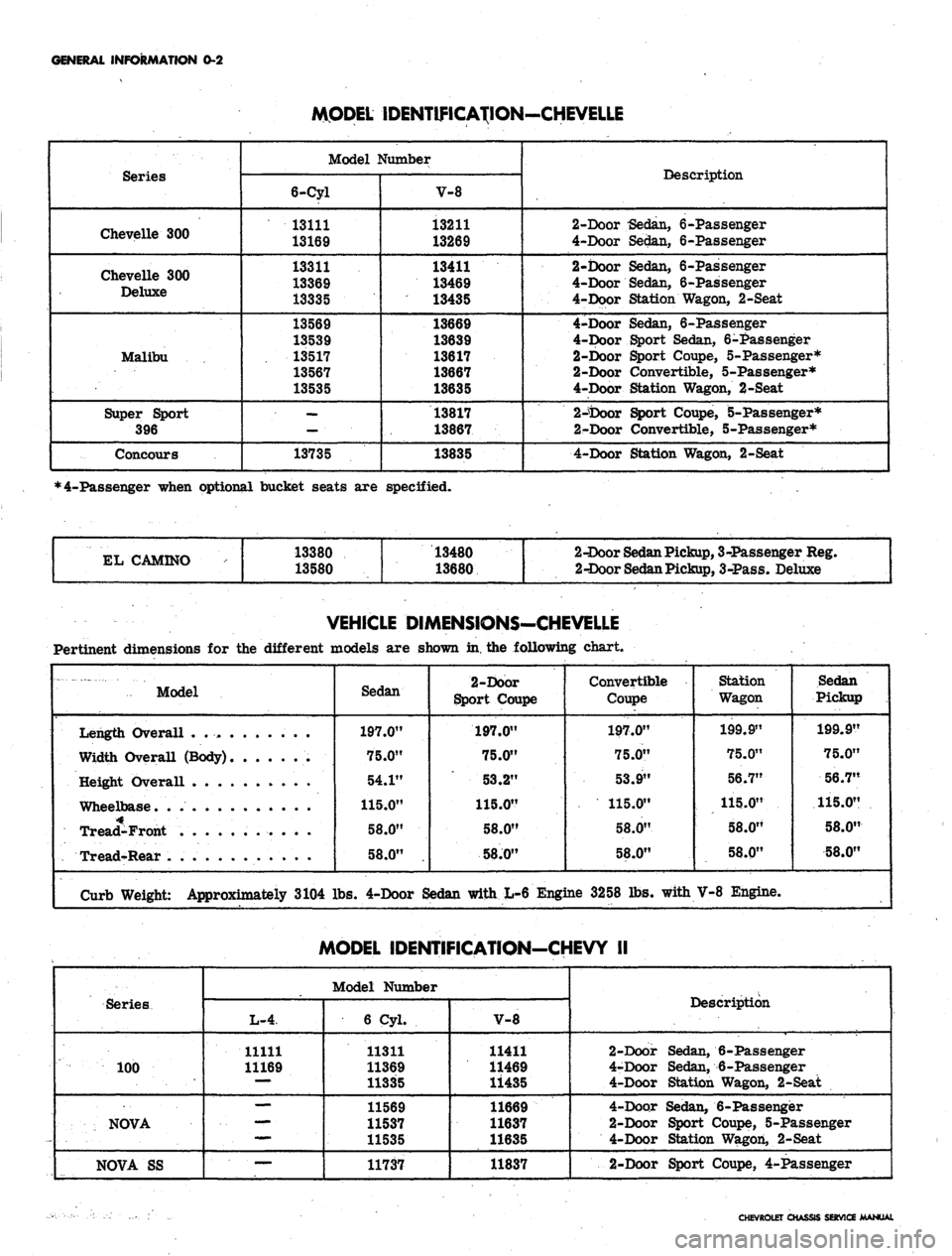

MODEL IDENTIFICATION-CHEVELLE

Series

Chevelle 300

Chevelle 300

Deluxe

Malibu

Super Sport

396

Concours

Model Number

6-Cyl

13111

13169

13311

13369

13335

13569

13539

13517

13567

13535

—

13735

V-8

13211

13269

13411

13469

13435

13669

13639

13617

13667

13635

13817

13867

13835

Description

2-Door -Sedan, 6-Passenger

4-Door Sedan, 6-Passenger

2-Door Sedan, 6-Passenger

4-Door Sedan, 6-Passenger

4-Door Station Wagon, 2-Seat

4-Door Sedan, 6-Passenger

4-Door Sport Sedan, 6-Passenger

2-Door Sport Coupe, 5-Passenger*

2-Door Convertible, 5-Passenger*

4-Door Station Wagon, 2-Seat

2-tooor Sport Coupe, 5-Passenger*

2-Door Convertible, 5-Passenger*

4-Door Station Wagon, 2-Seat

*4-Passenger when optional bucket seats are specified.

EL CAMINO

13380

13580

13480

13680

2-Door

Sedan

Pickup,

3-Passenger Reg.

2-Door

Sedan

Pickup,

3-Pass. Deluxe

VEHICLE DIMENSIONS-CHEVELLE

Pertinent dimensions for the different models are shown in, the following chart.

Model

Sedan

197.0"

75.0"

54.1"

115.0"

58.0"

58.0"

2-Door

Sport Coupe

197.0"

75.0"

53.2"

115.0"

58.0"

58J0"

Convertible

Coupe

197.0"

75.0"

53.9"

115.0"

58.0"

58.0"

Station

Wagon

199.9"

75.0"

56.7"

115.0"

58.0"

58.0"

Sedan

Pickup

199.9"

75.0"

56.7"

115.0"

58.0"

58.0"

Length Overall .

Width Overall (Body)

Height Overall . . .

Wheelbase. .

Tread-Front

Tread-Rear .

Curb Weight: Approximately 3104 lbs. 4-Door Sedan with L-6 Engine 3258 lbs. with V-8 Engine.

MODEL IDENTIFICATION-CHEVY II

Series

100

NOVA

NOVA SS

Model Number

L-4

11111

11169

mmm.

—

6 Cyl.

11311

11369

11335

11569

11537

11535

11737

V-8

11411

11469

11435

11669

11637

11635

11837

Description

2-Door Sedan, 6-Passenger

4-Door Sedan, 6-Passenger

4-Door Station Wagon, 2-Seat

4-Door Sedan, 6-Passenger

2-Door Sport Coupe, 5-Passenger

4-Door Station Wagon, 2-Seat

2-Door Sport Coupe, 4-Passenger

CHEVROLET CHASSIS SERVICE MANUAL

Page 5 of 659

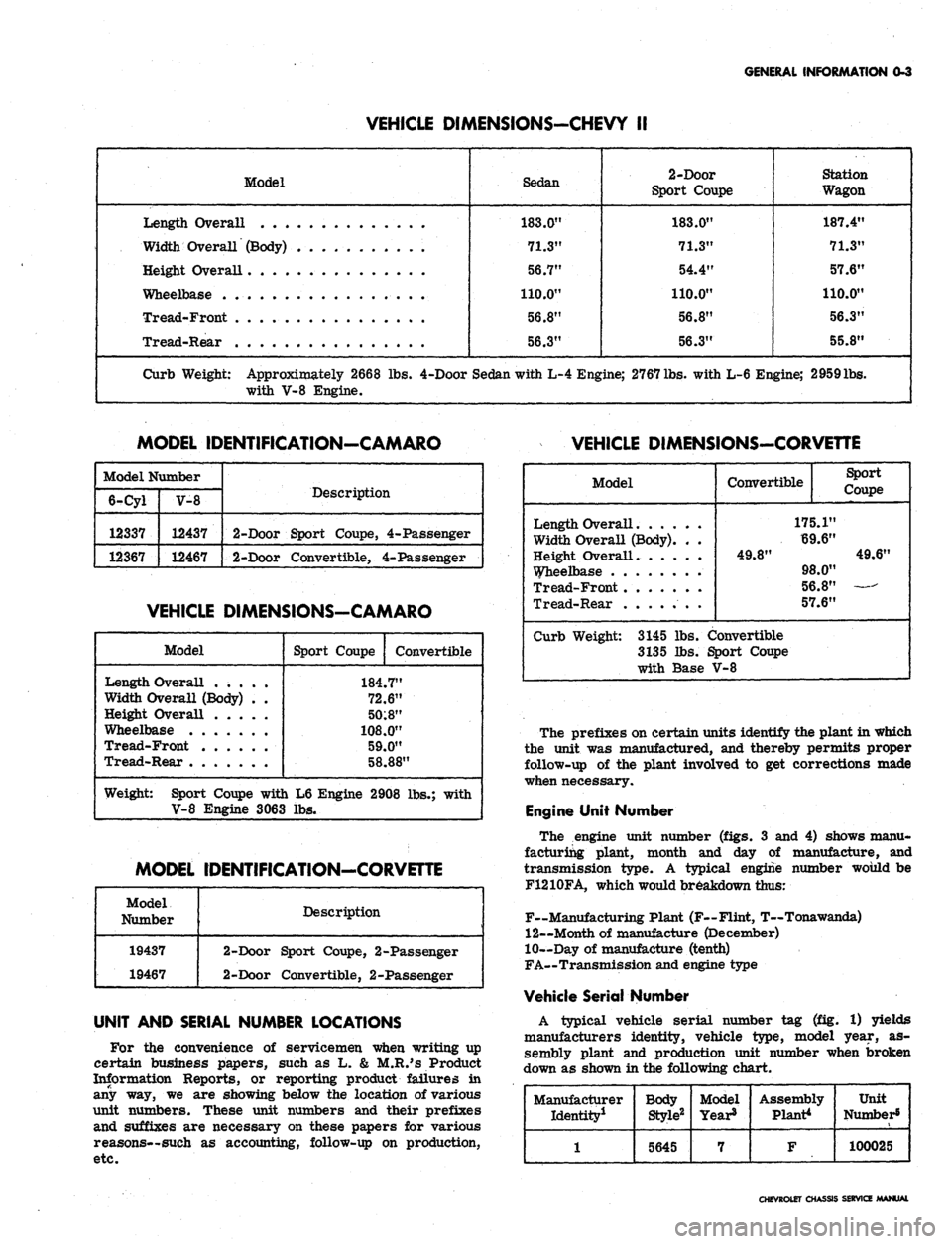

GENERAL INFORMATION 0-3

VEHICLE DIMENSIONS-CHEVY II

Model

Length Overall

Width Overall (Body) . . . .

Height Overall

Wheelbase

Tread-Front

Tread-Rear . . .

Sedan

183.0"

71.3"

56.7"

110.0"

56.8"

56.3"

2-Door

Sport Coupe

183.0"

71.3"

54.4"

110.0"

56.8"

56.3"

Station

Wagon

187.4"

71.3"

57.6"

110.0"

56.3"

55.8"

Curb Weight: Approximately 2668 lbs. 4-Door Sedan with L-4 Engine; 2767

lbs.

with L-6 Engine; 2959lbs.

with V-8 Engine.

MODEL IDENTIFICATION-CAMARO

VEHICLE DIMENSIONS-CORVEnE

Model Number

6-Cyl

12337

12367

V-8

12437

12467

Description

2-Door Sport Coupe, 4-Passenger

2-Door Convertible, 4-Passenger

VEHICLE DIMENSIONS-CAMARO

Model

Length Overall .....

Width Overall (Body) . .

Height Overall

Wheelbase

Tread-Front

Tread-Rear

Sport Coupe

Convertible

184.7"

72.6"

50:8"

108.0"

59.0"

58.88"

Weight: Sport Coupe with L6 Engine 2908 lbs.; with

V-8 Engine 3063 lbs.

MODEL IDENTIFICATION-CORVETTE

Model

Number

19437

19467

Description

2-Door Sport Coupe, 2-Passenger

2-Door Convertible, 2-Passenger

UNIT AND SERIAL NUMBER LOCATIONS

For the convenience of servicemen when writing up

certain business papers, such as L. & M.R.'s Product

Information Reports, or reporting product failures in

any way, we are showing below the location of various

unit numbers. These unit numbers and their prefixes

and suffixes are necessary on these papers for various

reasons—such as accounting, follow-up on production,

etc.

Model

Length Overall

Width Overall (Body). . .

Height Overall.

Wheelbase

Tread-Front

Tread-Rear .

Convertible

Sport

Coupe

175.1"

69.6"

49.8"

49.6"

98.0"

56.8"

57.6"

Curb Weight: 3145 lbs. Convertible

3135 lbs. Sport Coupe

with Base V-8

The prefixes on certain units identify the plant in which

the unit was manufactured, and thereby permits proper

follow-up of the plant involved to get corrections made

when necessary.

Engine Unit Number

The engine unit number (figs. 3 and 4) shows manu-

facturing plant, month and day of manufacture, and

transmission type. A typical engine number would be

F1210FA, which would breakdown thus:

F~Manufacturing Plant (F—Flint, T—Tonawanda)

12—Month of manufacture (December)

10—Day of manufacture (tenth)

FA—Transmission and engine type

Vehicle Serial Number

A typical vehicle serial number tag (fig. 1) yields

manufacturers identity, vehicle type, model year, as-

sembly plant and production unit number when broken

down as shown in the following chart.

Manufacturer

Identity1

1

Body

Style2

5645

Model

Year8

7

Assembly

Plant*

F

Unit

Number5

100025

CHEVROLET CHASSIS SERVICE /MANUAL

Page 6 of 659

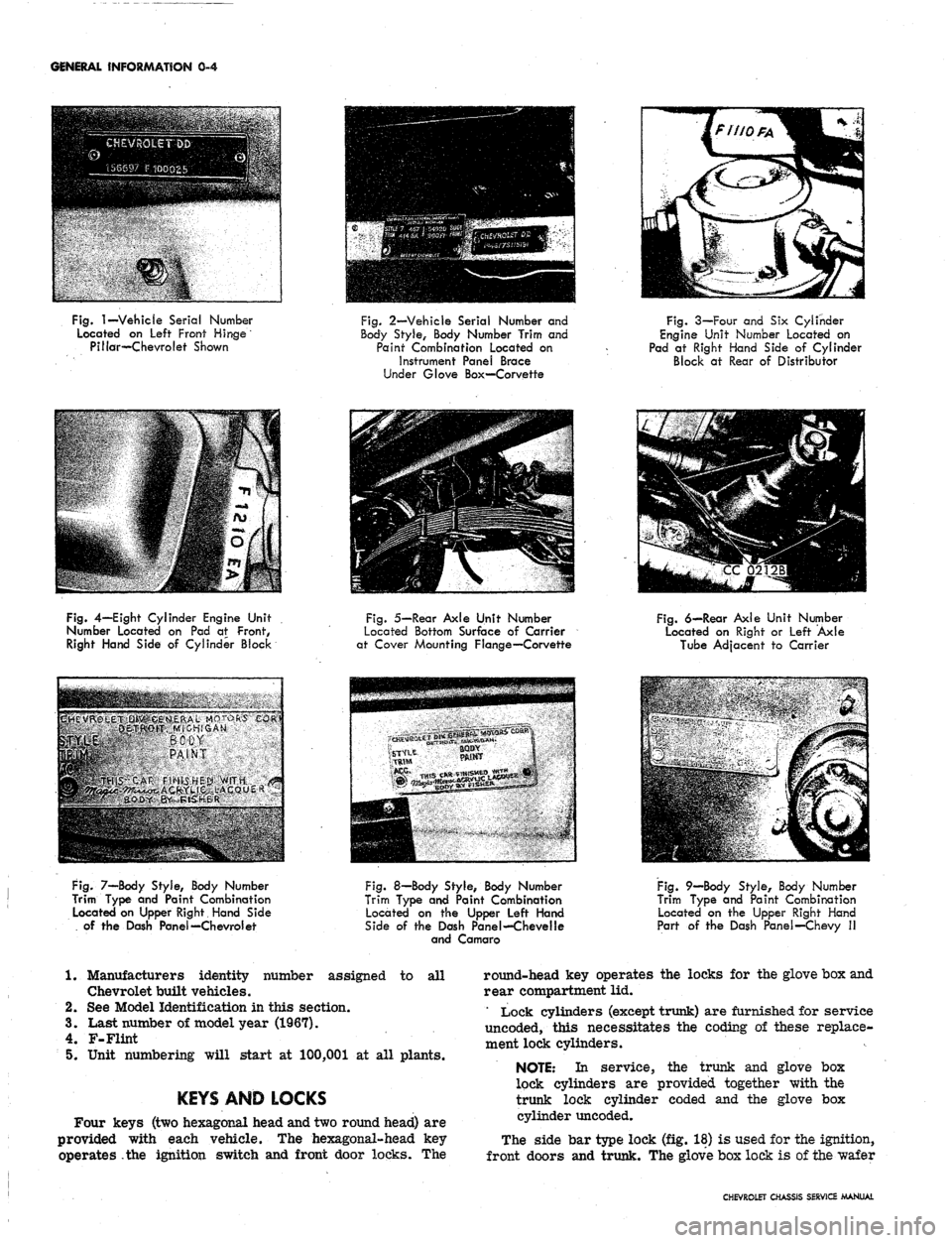

GENERAL INFORMATION 0-4

Fig.

1—Vehicle

Serial Number

Located on Left Front Hinge

Pillar—Chevrolet Shown

Fig.

2—Vehicle Serial Number and

Body Style, Body Number Trim and

Paint Combination Located on

Instrument Panel Brace

Under Glove Box—Corvette

Fig. 3—Four and Six Cylinder

Engine Unit Number Located on

Pad at Right Hand Side of Cylinder

Block at Rear of Distributor

Fig.

4—Eight Cylinder Engine Unit

Number Located on Pad at Front,

Right Hand Side of Cylinder Block

Fig.

5—Rear Axle Unit Number

Located Bottom Surface of Carrier

at Cover Mounting Flange—Corvette

Fig.

6—Rear Axle Unit Number

Located on Right or Left Axle

Tube Adjacent to Carrier

BSHfi^;^

PAINT

HRIKI5"tM>

fIHIsS

HE|St.>MfT*

^^ * *•'"

•<"'

Fig.

7—Body Style, Body Number

Trim Type and Paint Combination

Located on Upper Right Hand Side

of the Dash Panel—Chevrol et

Fig.

8—Body Style, Body Number

Trim Type and Paint Combination

Located on the Upper Left Hand

Side of the Dash Panel—Chevelle

and Camaro

Fig.

9—Body Style, Body Number

Trim Type and Paint Combination

Located on the Upper Right Hand

Part of the Dash Panel—Chevy II

1. Manufacturers identity number assigned to all

Chevrolet built vehicles.

2.

See Model Identification in this section.

3.

Last number of model year (1967).

4.

F-Flint

5.

Unit numbering will start at 100,001 at all plants.

KEYS AND LOCKS

Four keys (two hexagonal head and two round head) are

provided with each vehicle. The hexagonal-head key

operates the ignition switch and front door locks. The

round-head key operates the locks for the glove box and

rear compartment lid.

' Lock cylinders (except trunk) are furnished for service

uncoded, this necessitates the coding of these replace-

ment lock cylinders.

NOTE: In service, the trunk and glove box

lock cylinders are provided together with the

trunk lock cylinder coded and the glove box

cylinder uncoded.

The side bar type lock (fig. 18) is used for the ignition,

front doors and trunk. The glove box lock is of the wafer

CHEVROLET CHASSIS SERVICE MANUAL

Page 9 of 659

GENERAL INFORMATION 0-7

a vise using leather or wood on each side to prevent

damage to the cylinder,

7. Stake the retainer securely in place by staking the

cylinder metal over both edges of the retainer ends

using a suitable staking tool at right angles to the

top of the retainer and from the cast metal of the

cylinder over the retainer at each corner.

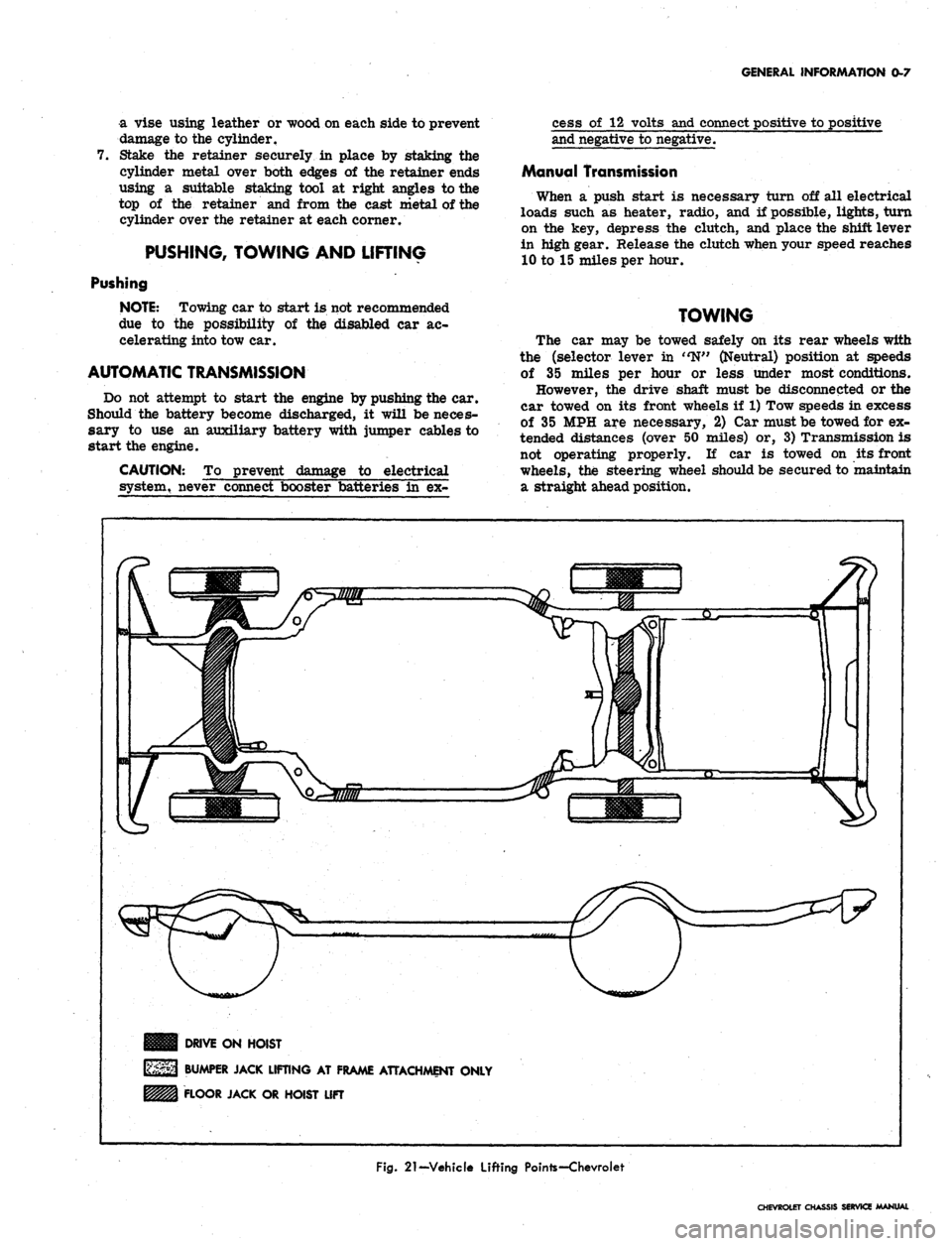

PUSHING, TOWING AND LIFTING

Pushing

NOTE:

Towing car to start is not recommended

due to the possibility of the disabled car ac-

celerating into tow car.

AUTOMATIC TRANSMISSION

Do not attempt to start the engine by pushing the car.

Should the battery become discharged, it will be neces-

sary to use an auxiliary battery with jumper cables to

start the engine.

CAUTION: To prevent damage to electrical

system, never connect booster batteries in ex-

cess of 12 volts and connect positive to positive

and negative to negative.

Manual Transmission

When a push start is necessary turn off all electrical

loads such as heater, radio, and if possible, lights, turn

on the key, depress the clutch, and place the shift lever

in high gear. Release the clutch when your speed reaches

10 to 15 miles per hour.

TOWING

The car may be towed safely on its rear wheels with

the (selector lever in "N" (Neutral) position at speeds

of 35 miles per hour or less under most conditions.

However, the drive shaft must be disconnected or the

car towed on its front wheels if 1) Tow speeds in excess

of 35 MPH are necessary, 2) Car must be towed for ex-

tended distances (over 50 miles) or, 3) Transmission is

not operating properly. If car is towed on its front

wheels, the steering wheel should be secured to maintain

a straight ahead position.

DRIVE ON HOIST

BUMPER JACK LIFTING AT FRAME ATTACHMENT ONLY

FLOOR JACK OR HOIST LIFT

Fig.

21-Vehicle Lifting Pointe-Chevroiet

CHEVROLET CHASSIS SERVICE MANUAL

Page 15 of 659

LUBRICATION 0-13

LUBRICATION

INDEX

Page

Engine Crankcase Oil . 0-13

Crankcase Capacities. . 0-13

Lubrication . ,

•

o-13

SAE Viscosity Oils 0-13

Types of Oils 0-14

Maintaining Oil Level 0-14

Oil and Filter Change Intervals 0-14

Oil.

. . ...:.. 0-14

Filter o-14

Crankcase Dilution . 0-14

Automatic Control Devices to Minimize

Crankcase Dilution 0-14

Crankcase Breather Cap 0-14

Crankcase Ventilation System 0-15

Valve Type 0-15

Fuel Filter 0-15

Air Cleaner . 0-15

Polyurethane Type 0-15

Oil Wetted Paper Element Type 0-15

Battery Terminal Washers 0-15

Page

Distributor 0-15

Rear Axle and 3-Speed and Overdrive

4-Speed Transmission 0-15

Recommended Lubricants 0-15

Multi-Purpose Gear Lubricants 0-15

Lubricant Additions 0-15

Lubricant Changes 0-15

Powerglide Transmission 0-15

Turbo Hydra-Matic 0-16

Front Wheel Bearings 0-16

Manual Steering Gear . . . . 0-16

Power Steering 0-16

Air Conditioning 0-16

Brake Master Cylinder. 0-16

Parking Brake 0-16

Clutch Cross-Shaft , 0-16

Chassis Lubrication 0-16

Lubrication Diagrams . . 0-19

Body Lubrication (Chevrolet, Chevelle, Chevy n, Camaro). 0-20

Body Lubrication Points (Corvette) . 0-21

The selection of the proper lubricant and its correct

application at regular intervals does much to increase the

life and operation of all moving parts of the vehicle.

Consequently, it is important that the correct grade of

oil or grease, as noted in the following pages, be used.

ENGINE CRANKCASE OIL

Crankcase Capacity

4 Cylinder 4 qt.

6 Cylinder 4 qt.

8 Cylinder (283) 4 qt.

8 Cylinder (327) 4 qt.

8 Cylinder (350) 4 qt.

8 Cylinder (396) 4 qt.

8 Cylinder (427) Chevrolet 4 qt.

8 Cylinder (427) Corvette 5 qt.

For 4 Cyl. Add .5 qt. with filter change;

1 qt. for 6 and 8 Cyl. engines.

Lubrication

Crankcase oil should be selected to give the best per-

formance under the climatic and driving conditions in the

territory in which the vehicle is driven.

During warm or hot weather, an oil which will provide

adequate lubrication under high operating temperatures

is required.

During the colder months of the year* an oil which will

permit easy starting at the lowest atmospheric tempera-

ture likely to be encountered, should be used.

When the crankcase is drained and refilled, the crank-

case oil should be selected, not on the basis of the exist-

ing temperature at the time of the change, but on the

lowest temperature anticipated for the period during

which the oil is to be used.

Unless the crankcase oil is selected on the basis of

viscosity or fluidity of the anticipated temperature, dif-

ficulty in starting will be experienced at each sudden

drop in temperature.

SAE Viscosity Oils

SAE Viscosity Numbers indicate only the viscosity or

body of the oil, that is, whether an oil is a light or a

heavy body oil, and do not consider or include other

properties or quality factors.

The lower SAE Viscosity Numbers, such as SAE 5W

and SAE 10W which represent the light body oils, are

recommended for use during cold weather to provide

easy starting and instant lubrication. The higher SAE

Viscosity Numbers such as SAE 20 and SAE 20W, which

represents heavier body oils, are recommended for use

during warm or hot weather to provide improved oil

economy and adequate lubrication under high operating

temperatures.

Oils are available which are designed to combine the

easy starting characteristics of the lower SAE Viscosity

Number with the warm weather operating characteristics

of the higher SAE Viscosity Number. These are termed

"multi-viscosity oils," SAE 5-10W, SAE 5W-20, SAE

10W-20W, and SAE 10W-30.

The following chart will serve as a guide for the

selection of the correct SAE Viscosity Number for use

under different atmospheric temperature ranges, and

suggests the appropriate SAE Viscosity Numbers when

multi-viscosity oils are used.

Lowest Anticipated

Temperature

During Time

Oil Will Be

in Crankcase

32°F.

0°F.

Below 0°F.

Recommended

SAE Viscosity

Oils

SAE 20 or 20W

SAE 10W

SAE 5W

Recommended

SAE

Multi-

Viscosity

Oils

SAE 10W-30 .

SAE 10W-30

SAE 5W-20

SAE 30 or 10W-30 is recommended when most of the

driving is at high speeds and/or at temperatures above

90

°F.

CHEVROLET CHASSIS SERVICE MANUAL

Page 16 of 659

LUBRICATION 0-14

SAE 5W-30 oils may be used during periods when

temperatures of 32° and below are to be expected.

Types of Oils

In service, crankcase oils may form sludge and varnish

and under some conditions, corrosive acids unless pro-

tected against oxidation.

To minimize the formation of these harmful products

and to assure the use of oil best suited for present day

operating conditions, automobile manufacturers have de-

veloped a series of sequence tests designed to evaluate

the ability of any oil to properly lubricate automobile

engines.

It is recommended that only those oils which are

certified by their suppliers as meeting or exceeding the

maximum severity requirements of these sequence tests

(or GM Standard 4745-M) be used in Chevrolet engines.

Certified sequence tested oils will be described as such

on their containers.

Maintaining Oil Level

The oil gauge rod is marked "Full" and "Add Oil."

These notations have broad arrows pointing to the level

lines.

The oil level should be maintained between the

two lines, neither going above the "Full" line nor under

the "Add Oil" line. DO NOT OVERFILL. After operating

vehicle allow a few minutes for oil to return to crankcase

before checking oil level.

Check the oil level frequently and add oil when

necessary.

Oil and Filter Change Intervals

NOTE:

Under prolonged dusty driving condi-

tions,

it is recommended that these operations

be performed more often.

OIL

To insure continuation of best performance, low main-

tenance cost and long engine life, it is necessary to

change the crankcase oil whenever it becomes contami-

nated with harmful foreign materials. Under normal

driving conditions draining the crankcase and refilling

with fresh oil every 60 days or every 6000 miles which-

ever occurs first, is recommended.

It is always advisable to drain the crankcase only after

the engine has become thoroughly warmed up or reached

normal operating temperature. The benefit of draining is,

to a large extent, lost if the crankcase is drained when

the engine is cold, as some of the suspended foreign

material will cling to the sides of the oil pan and will not

drain out readily with the cold, slower moving oil.

OIL FILTER

Change engine oil filter every 6000 miles or every 6

months, whichever occurs first.

NOTE:

For Vehicles in heavy duty operation

involving continuous start-stop or prolonged idl-

ing, engine oil should be changed after 2500-

3000 miles of operation. The filter should be

changed after 5000-6000 miles of operation.

Crankcase Dilution

Probably the most serious phase of engine oil deterio-

ration is that of crankcase dilution which is the thinning

of the oil by fuel vapor leaking by pistons and rings and

mixing with the oil and by condensation of water on the

cylinder walls and crankcase.

Leakage of fuel, or fuel vapors, into the oil pan occurs

mostly during the "warming up" period when the fuel is

not thoroughly vaporized and burned. Water vapor enters

the crankcase through normal engine ventilation and

through exhaust gas blow-by. When the engine is not

completely warmed up, these vapors condense, combine

with the condensed fuel and exhaust gases and form acid

compounds in the crankcase.

As long as the gases and internal walls of the crank-

case are hot enough to keep water vapor from con-

densing, no harm will result. However, when the engine

is run in low temperatures moisture will collect and

unite with the gases formed by combustion resulting in

an acid formation. The acid thus formed is likely to

cause serious etching or pitting which will manifest itself

in excessively rapid wear on piston pins, camshaft

bearings and other moving parts of the engine, oftentimes

causing the owner to blame the car manufacturer or the

lubricating oil when in reality the trouble may be traced

back to the character of fuel used, or a condition of the

engine such as excessive blowby or improper carburetor

adjustment.

Automatic Control Devices to Minimize

Crankcase Dilution

All engines are equipped with automatic devices which

aid greatly in minimizing the danger of crankcase

dUution.

The thermostat, mounted in the cylinder head water

outlet, restricts the flow of water to the radiator until a

predetermined temperature is reached, thus minimizing

the length of time required to reach efficient operating

temperature, reducing the time that engine temperatures

are conducive to vapor condensation.

A water by-pass is included in the cooling system,

utilizing a hole in the front of, the cylinder block. This

allows a limited circulation of coolant, bypassing the

thermostat until thermostat opening temperatures are

reached. This system provides a uniform coolant tem-

perature throughout the engine, eliminating localized

hot-spots, improving exhaust valve life, provides fast

warmrup of lubricating oil and fast temperature rise in

the coolant which provides fast heater operation in cold

weather.

A thermostatic heat control on the exhaust manifold

during the warming up period, automatically directs the

hot exhaust gases against the center of the intake mani-

fold, greatly aids in proper vaporization of the fuel.

An automatic choke reduces the danger of raw or

unvaporized fuel entering the combustion chamber and

leaking into the oil reservoir.

An.

efficient crankcase ventilating system drives off

fuel vapors and aids in the evaporation of the raw fuel

and water which may find its way into the oil pan.

CRANKCASE BREATHER CAP

Clean and re-oil at every oil change..

CHEVROLET CHASSIS SERVICE MANUAL

Page 17 of 659

LUBRICATION 0-15

CRANKCASE VENTILATION VALVE

VALVE TYPE

NOTE: Under prolonged dusty driving condi-

tions,

it is recommended that these operations

be performed more often. Every 12,000 miles

or 12 months the valve should be replaced.

Connecting hoses, fittings, flame arrestor and

crankcase breather cap (where used) should be

cleaned. At every oil change the system should

be tested for proper function and serviced, if

necessary.

FUEL FILTER

Replace filter element located in carburetor inlet if

flooding occurs, if engine surges during constant speed

operation (pulsating effect) or if poor performance is

experienced during acceleration or at higher speeds.

AIR CLEANER

NOTE: Under prolonged dusty driving condi-

tions,

it is recommended that these operations

be performed more often.

POLYURETHANE TYPE-

Every 12,000 miles clean element in solvent, squeeze

out solvent, then soak in engine oil and squeeze out

excess.

OIL WETTED PAPER ELEMENT TYPE-

First 12,000 miles inspect or test element; if satis-

factory, re-use element but recheck every 6,000 miles

until replaced. Element must not be washed, oiled,

tapped or cleaned with an air hose.

BATTERY TERMINAL WASHERS

Battery terminals have felt washers between top of

case and cable connections to minimize corrosive action

of battery acid. These felt washers should be saturated

with engine oil every 6,000 miles.

DISTRIBUTOR

4 and 6-Cylinder Engine—Remove distributor cap and

rotate lubricator 1/2 turn at 12,000 mile intervals. Re-

place at 24,000 mile intervals.

8-Cylinder Engine—Change cam lubricator end for end

at 12,000 mile intervals. Replace at 24,000 mile

intervals.

REAR AXLE AND 3-SPEED AND

OVERDRIVE, 4-SPEED TRANSMISSIONS

The passenger car operates under the most severe

lubrication conditions at high speed and requires a hypoid

lubricant which will meet this condition.

Recommended Lubricants

Standard Rear Axles—SAE 90 "Multi-Purpose" gear

lubricant.

Positraction Rear Axles—Use special Positraction

lubricant.

CAUTION: Straight Mineral Oil gear lubricants

must not be used in hypoid rear axles.

Transmissions—SAE 90 "Multi-Purpose" gear

lubricant.

The SAE 90 viscosity grade is recommended for year

round use. However, when extremely low temperatures

are encountered for protracted periods during the winter

months, the SAE 80 viscosity grade may be used.

"Multi-Purpose" Gear Lubricants

Gear lubricants that will satisfactorily lubricate hypoid

rear axles have been developed and are commonly re-

ferred to as ' 'Multi-Purpose" gear lubricants meeting

U.S.

Army Ord. Spec. MIL-L-2105B.

These lubricants can also be satisfactorily used in

manual transmissions.

CAUTION: With Positraction rear axles use

special Positraction lubricant.

"Multi-Purpose" gear lubricants must be manufac-

tured under carefully controlled conditions and the

lubricant manufacturer must be responsible for the

satisfactory performance of his product. His reputation

is the best indication of quality.

Lubricant Additions

The lubricant level in the axle and transmission hous-

ings should be checked periodically. (Every 6,000 miles.)

It is recommended that any additions required to bring

up the lubricant level be made using the same type lubri-

cant already in the housing.

When checking lubricant level in transmission or rear

axle the unit being cheeked should be at operating

temperature. With unit at operating temperature the

lubricant should be level with bottom of the filler plug

hole.

If the lubricant level is checked with the unit cold

the lubricant level should be 1/2 inch below the filler

plug hole.

Lubricant Changes

The rear axle lubricant does not require changing for

the life of the vehicle. If additions are needed, or when

refilling the axle after service procedures, use lubricants

described above.

POWERGLIDE TRANSMISSION

NOTE: Every 12,000 miles, it is recommended

that the Powerglide low band be adjusted as

specified in Section 7 of this manual.

Every 6,000 miles--Check fluid level on dipstick with

engine idling, selector lever in neutral position, parking

brake set and transmission at operating temperature. If

fluid level is below full mark on dip stick, adding a small

amount of Automatic Transmission Fluid, General Motors

Automatic Transmission Fluid (Part Numbers 1050568-

69,

70) is recommended. If this fluid is not obtainable,

use Automatic Transmission Fluid Type 'A' bearing the

mark AQ-ATF followed by a number and the suffix letter

'A'.

Recheck fluid level on dip stick and again add a

small amount of fluid if needed to bring level to full

mark. DO NOT OVERFILL.

CHEVROLET CHASSIS SERVICE MANUAL

Page 19 of 659

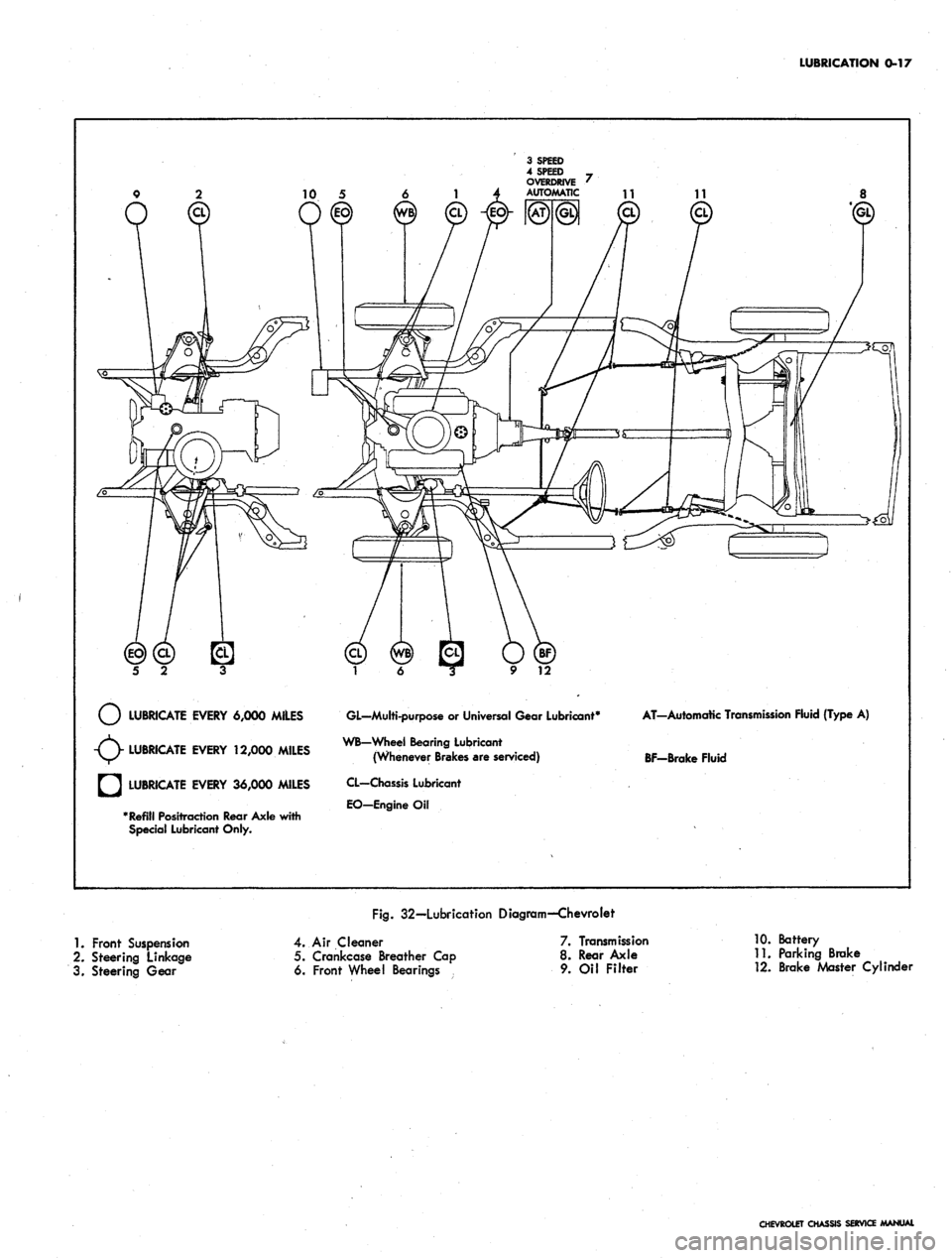

LUBRICATION 0-17

LUBRICATE EVERY 6,000 MILES

LUBRICATE EVERY 12,000 MILES

LUBRICATE EVERY 36,000 MILES

Refill Positraction Rear Axle with

Special Lubricant Only.

GL—Multi-purpose

or

Universal Gear Lubricant4

WB-Wheel Bearing Lubricant

(Whenever Brakes are serviced)

CL—Chassis Lubricant

EO-EngineOil

AT-Automatic Transmission Fluid {Type

A)

BF-Brake Fluid

Fig.

32—Lubrication Diagram—Chevrolet

1.

Front Suspension

2.

Steering Linkage

3. Steering Gear

4.

Air Cleaner

5. Crankcase Breather Cap

6. Front Wheel Bearings

7. Transmission

8. Rear Axle

9. Oil Filter

10.

Battery

11.

Parking Brake

12.

Brake Master Cylinder

CHEVROLET CHASSIS SERVICE MANUAL

Page 21 of 659

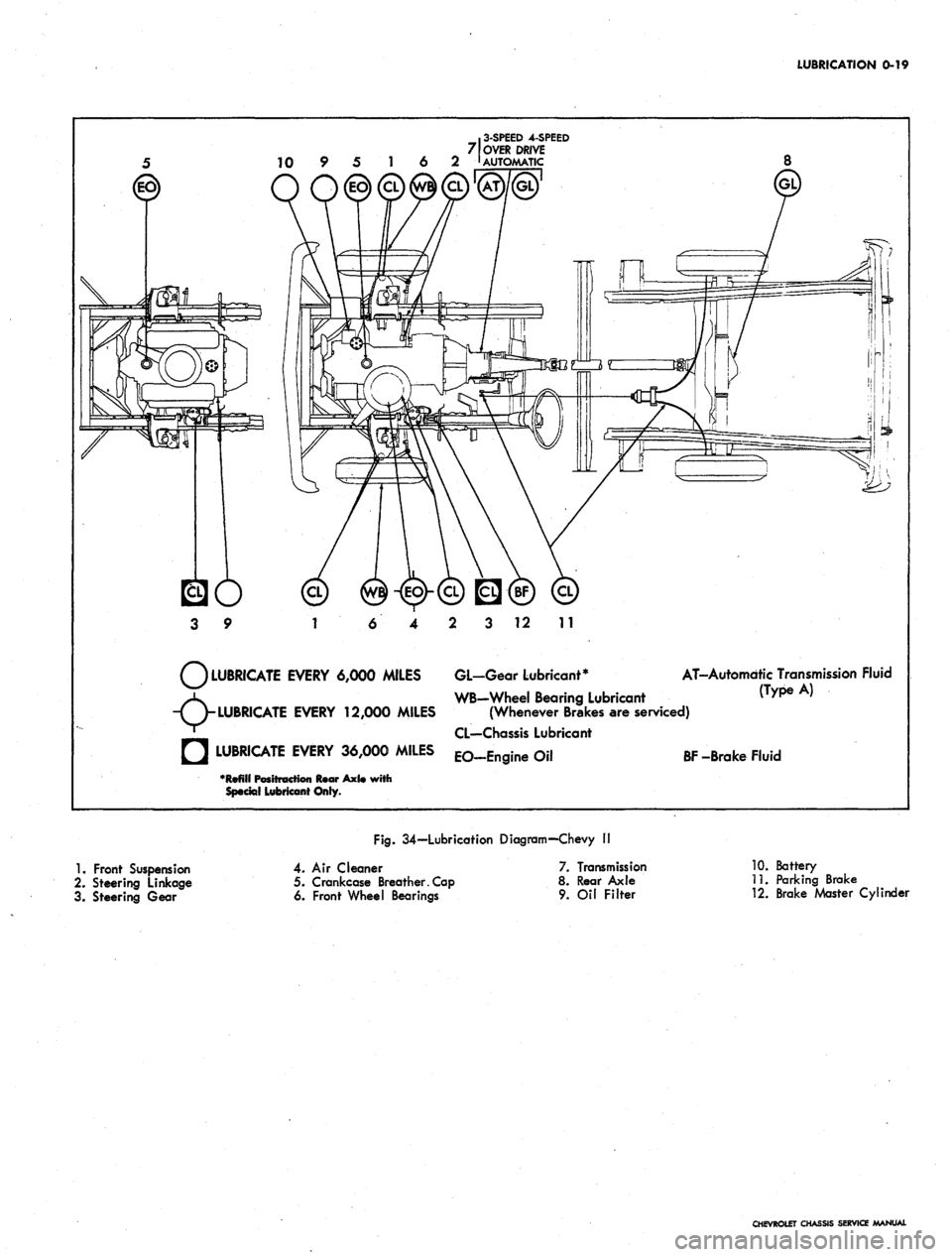

LUBRICATION

0-19

.

3-SPEED

4-SPEED

7 OVER DRIVE

10 9 5 1 6 2 '

AUTOMATIC

3 12 11

LUBRICATE EVERY 6,000 MILES GL-Gear Lubricant*

WB-Wheel Bearing Lubricant

(Wh Bk

AT-Automdtic Transmission Fluid

^ WB-Wheel Bearing Lubricant (Type A)

-TV

LUBRICATE

EVERY 12,000 MILES (Whenever Brakes are serviced)

' CL—Chassis Lubricant

• LUBRICATE EVERY 36,000 MILES EO_Engine Oil

BF

-Brake Fluid

•Refill Positt

Special Lubricant Only.

Axl«

with

1.

Front Suspension

2.

Steering Linkage

3. Steering Gear

Fig.

34—Lubrication Diagram—Chevy I!

4. Air Cleaner

5. Crankcase Breather. Cap

6. Front Wheel Bearings

7. Transmission

8. Rear Axle

9.

Oil Filter

10.

Battery

11.

Parking Brake

12.

Brake Master Cylinder

CHEVROLET CHASSIS SERVICE MANUAL