steering wheel adjustment CHEVROLET CAMARO 1967 1.G Chassis Workshop Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1967, Model line: CAMARO, Model: CHEVROLET CAMARO 1967 1.GPages: 659, PDF Size: 114.24 MB

Page 18 of 659

LUBRICATION 0-16

Every 12,000 miles (more frequently*, depending on

severity of service, if vehicle is used to pull trailers,

carry full loads during high ambient temperatures,

operate in mountainous terrain or operate under other

severe conditions--Remove fluid from the transmission

sump and add one and a half quarts of fresh fluid for

Camaro and Chevy II and two quarts for Chevrolet,

Chevelle, and Corvette. Operate transmission through all

ranges and check fluid level as described above.

•Except if vehicle is equipped with transmission pro-

vided in heavy duty service options. If so equipped,

drain converter and pump every 12,000 miles and add

approximately seven and a half quarts of fresh fluid

for Chevy II and nine quarts for Chevrolet and Chevelle.

TURBO HYDRA-MATIC

Lubrication. recommendations for the Turbo Hydra-

Matic are the same as outlined for the Powerglide

transmission except for fluid capacity and filter change

listed below.

After checking transmission fluid level it is important

that the dip stick be pushed all the way into the fill tube.

Every 12,000 miles — after removing fluid from the

transmission sump, approximately 7 1/2 pints of fresh

fluid will be required to return level to proper mark on

the dip stick.

Every 24,000 miles, or at every other fluid change--

the transmission sump strainer should be replaced.

FRONT WHEEL BEARINGS

It is necessary to remove the wheel and hub assembly

to lubricate the bearings. The bearing assemblies should

be cleaned before repacking with lubricant. Do not pack

the hub between the inner and outer bearing assemblies

or the hub caps, as this excessive lubrication results in

the lubricant working out into the brake drums and

linings.

Front wheels of all passenger car models are equipped

with tapered roller bearings and should be packed with a

high melting point water resistant front wheel bearing

lubricant whenever wheel and hub are removed.

CAUTION: "Long fibre" or "viscous" type

lubricant should not be used. Do not mix wheel

bearing lubricants. Be sure to thoroughly clean

bearings and hubs of all old lubricant before

repacking.

The proper adjustment of front wheel bearings is one

of the important service operations- that has a definite

bearing on safety. A car with improperly adjusted front

wheel bearings lacks steering stability, has a tendency to

wander or shimmy and may have increased tire wear.

The adjustment of these bearings is very critical. The

procedure is covered in Section 3 of this manual under

Front Wheel Bearings—Adjust,

MANUAL STEERING GEAR

Check lubricant level every 36,000 miles. If required,

add EP Chassis Lubricant.

POWER STEERING

On models equipped with power steering gear, check

fluid at operating temperature in pump reservoir. Add

GM Power Steering Fluid, or, if this is not available, use

Automatic Transmission Fluid "Type A" bearing the

mark AQ-ATF followed by a number and the suffix letter

'A'

to bring level to full mark on dip stick.

AIR CONDITIONING

After the first 6,000 miles, check all hose clamp

connections for proper tightness.

Every 6,000 miles check sight glass under the hood,

after the system has been in operation for several

minutes. Sight glass should be clear but may, during

milder weather, show traces of bubbles. Foam or dirt

indicate a leak which should be repaired immediately.

BRAKE MASTER CYLINDER

Check level every 6,000 miles and maintain 1/4" below

lowest edge of each filler opening with GM Hydraulic

Brake Fluid Supreme No. 11.

PARKING BRAKE

Every 6,000 miles, apply water resistant lube to park-

ing brake cable, cable guides and at all operating links

and levers.

CLUTCH CROSS-SHAFT

Periodic lubrication of the clutch cross shaft is not

required. At 36,000 miles or sooner, if necessary;

remove plug, install lube fitting and apply CHASSIS

LUBRICANT.

CHASSIS LUBRICATION

For chassis lubrication, consult the lubrication chart.

It shows the points to be lubricated and how often the

lubricant should be applied.

The term "chassis lubricant" as used in this manual,

describes a water resistant EP chassis grease designed

for application by commercial pressure gun equipment.

CHEVROLET CHASSIS SERVICE MANUAL

Page 165 of 659

SECTION

3

FRONT SUSPENSION

INDEX

Page

General Description

. . . . 3-1

Maintenance and Adjustments

3-3

Front Wheel Bearing Adjustment

3-3

Front End Alignment

3-5 .

Alignment Preliminary Steps ............

3-5

Caster

and

Camber Adjustments

. . 3-5

Chevelle, Caxnaro

and

Corvette

3-5

Chevrolet and Chevy

II 3-6

Steering Axis Inclination

3-6

Toe-in Adjustment

3-6

Cornering Wheel Relationship

3-6

Riding Heigit

and

Coil Spring Sag

3-7

Repair Procedures

3-8

Front Brake Drum (Chevrolet, Camaro, Chevelle,

Chevy E)

. . 3-8

Removal

3-8

Installation

3-8

Front Wheel Hub

3-8

Replacement

. . . . . 3-8

Replacement

of

Hub Wheel Bolts

3-8

Front Wheel Bearings

. . 3-8

Removal

3-8

Inspection

3-9

Repairs

. . 3-9

Replacement

of

Bearing Cups

3-9

Installation

3-9

Steering Knuckle

. . . 3-9

Removal

3-9

Installation

3-9

Shock Absorber

3-10

Chevrolet, Chevelle, Camaro

and

Corvette

3-10

Removal

, . 3-10

Installation

3-10

Chevy

It 3-11

Removal

3-11

Installation

3-11

Stabilizer

Bar 3-11

Removal

3-11

Installation

3-11

Strut Rod

3-11

Chevrolet and Chevy

II 3-11

Removal

3-11

Installation

3-12

Front Coil Springs

3-12

Chevrolet

3-12

Removal

3-12

Installation

3-13

Chevelle

and

Camaro

3-13

Removal

3-13

Installation

3-14

Chevy H

3-14

Removal

3-14

Spring Seat Disassembly and Assembly

3-15

Installation

3-15

Corvette

3-15

Lower Control Arm Spherical Joint

.' 3-16

Chevrolet, Chevelle, Camaro and

Corvette

3-16

Inspection

. 3-16

Chevrolet and Corvette

3-16

Removal

3-16

Installation

3-16

Page

Chevelle

and

Camaro

3-17

Removal

3-17

Installation

. . . . 3-17

Chevy

II 3-17

Inspection

. 3-17

Removal

3-17

Installation

3-17

Lube Fittings

3-18

Lower Control Arm

. . . . 3-18

Chevrolet

. 3-18

Removal

3-18

Installation

3-18

Chevelle and Camaro

3-18

Removal

3-18

Installation

3-18

Chevy H

3-18

Removal

3-18

Installation

3-19

Corvette

3-19

Removal

3-19

mstallation

3-19

Lower Control Arm Bushings

3-20

Chevrolet

3-20

Removal

3-20

Installation

3-20

Chevelle and Camaro

. 3-20

Removal

3-20

Installation

3-20

Chevy H

3-21

Removal

* 3-21

InstaEation

3-21

Cross Shaft and/or Bushings

. 3-21

Corvette

3-21

Removal

3-21

Installation

3-21

Upper Control Arm Spherical Joint

3-21

Chevrolet, Chevelle, Camaro and Corvette

..... 3-21

Inspection.

3-21

Replacement

3-21

Chevy

II 3-21

Inspection

3-21

Replacement

3-21

Lube Fittings

3-22

Upper Control Arm

3-22

Chevrolet, Chevelle, Camaro

and

Corvette

3-22

Removal

3-22

Installation

3-22

Chevy H

3-22

Removal

3-22

Installation

3-23

Upper Control Arm Cross Shaft

and/or Bushings

3-23

Chevrolet, Camaro and Chevelle

3-23

Removal

. 3-23

Installation

3-23

Chevy H

3-24

Removal

3-24

Installation

. . . 3-25

Corvette

3-25

Removal

3-25

Installation

3-25

Special Tools

3-26

Specifications

...'..'

At rear of Book

GENERAL DESCRIPTION

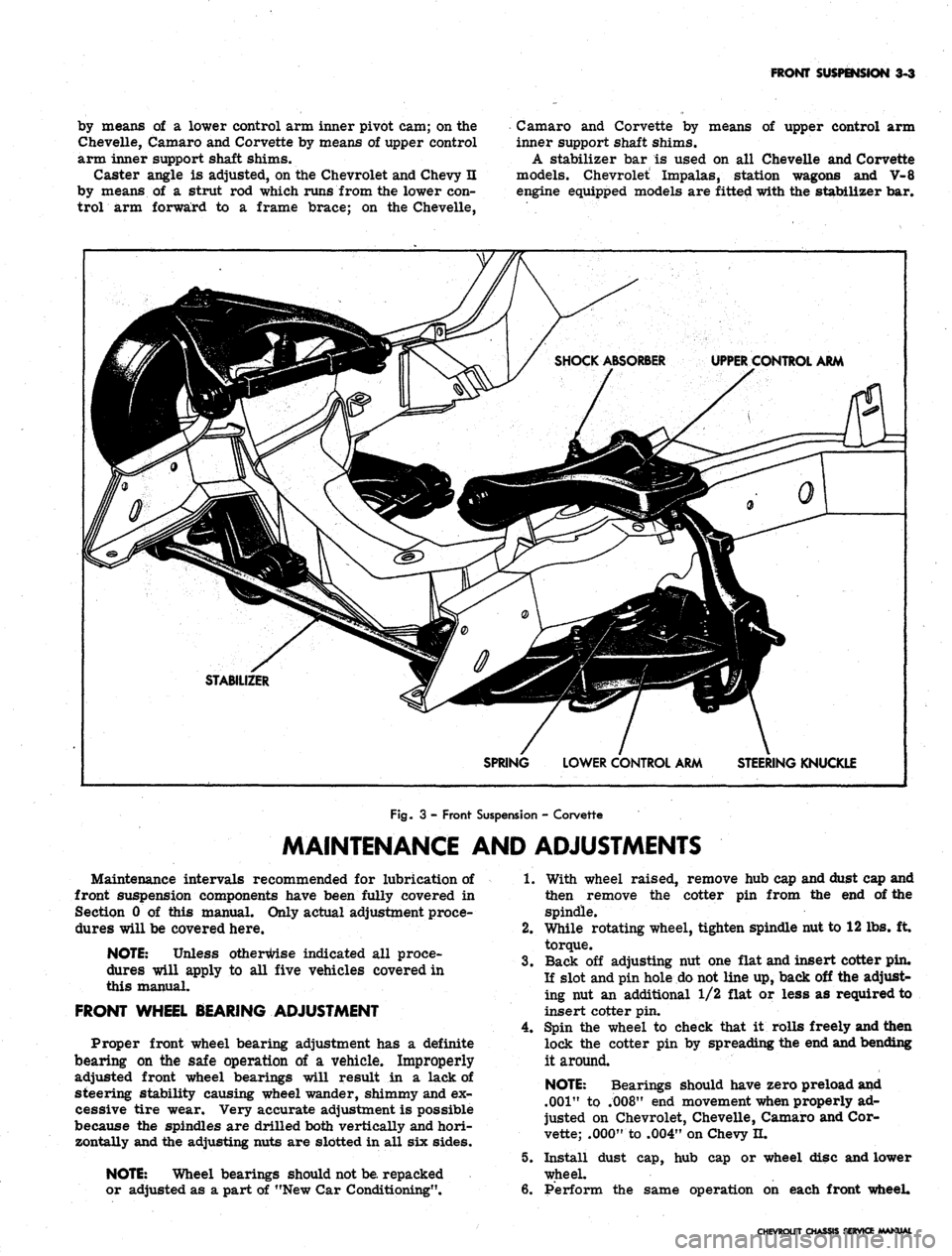

The 1967 Chevrolet, Chevelle, Camaro, Chevy n and

Corvette front suspension systems are basically similar,

being of the

S.L.A.

(short-long arm) type with independent

coil springs. In the Chevrolet, Chevelle, Camaro and

Corvette the springs ride on the lower control arms; in

the Chevy II the springs ride on the upper control arms.

Spherical joints connect the upper and lower arms to the

steering knuckle. Tapered roller wheel bearings are

used.

Camber angle is adjusted, on the Chevrolet and Chevy n

CHEVROLET CHASSIS SERVICE MANIM

Page 167 of 659

FRONT SUSPENSION 3-3

by means of a lower control arm inner pivot cam; on the

Chevelle, Camaro and Corvette by means of upper control

arm inner support shaft shims.

Caster angle is adjusted, on the Chevrolet and Chevy n

by means of a strut rod which runs from the lower con-

trol arm forward to a frame brace; on the Chevelle,

Camaro and Corvette by means of upper control arm

inner support shaft shims.

A stabilizer bar is used on all Chevelle and Corvette

models. Chevrolet Impalas, station wagons and V-8

engine equipped models are fitted with the stabilizer bar.

UPPER CONTROL ARM

STABILIZER

SPRING

LOWER CONTROL ARM

STEERING KNUCKLE

Fig.

3 - Front Suspension - Corvette

MAINTENANCE AND ADJUSTMENTS

Maintenance intervals recommended for lubrication of

front suspension components have been fully covered in

Section 0 of this manual. Only actual adjustment proce-

dures will be covered here.

NOTE:

Unless otherwise indicated all proce-

dures will apply to all five vehicles covered in

this manual.

FRONT WHEEL BEARING ADJUSTMENT

Proper front wheel bearing adjustment has a definite

bearing on the safe operation of a vehicle. Improperly

adjusted front wheel bearings will result in a lack of

steering stability causing wheel wander, shimmy and ex-

cessive tire wear. Very accurate adjustment is possible

because the spindles are drilled both vertically and hori-

zontally and the adjusting nuts are slotted in all six sides.

NOTE:

Wheel bearings should not

be.

repacked

or adjusted as a part of "New Car Conditioning".

1.

With wheel raised, remove hub cap and dust cap and

then remove the cotter pin from the end of the

spindle.

2.

While rotating wheel, tighten spindle nut to 12 lbs. ft

torque.

3.

Back off adjusting nut one flat and insert cotter pin.

If slot and pin hole do not line up, back off the adjust-

ing nut an additional 1/2 flat or less as required to

insert cotter pin.

4.

Spin the wheel to check that it rolls freely and then

lock the cotter pin by spreading the end and bending

it around.

NOTE:

Bearings should have zero preload and

.001"

to .008" end movement when properly ad-

justed on Chevrolet, Chevelle, Camaro and Cor-

vette; .000" to .004" on Chevy H.

5.

Install dust cap, hub cap or wheel disc and lower

wheel.

6. Perform the same operation on each front wheel.

CHEVROLET CHASSIS SERVICE MANUAL

Page 169 of 659

FRONT SUSPENSION 3-5

FRONT END ALIGNMENT

Front end alignment, that is alignment of the inter-

related steering components of the front suspension sys-

tem, must be correctly maintained to assure ease and

stability of steering and satisfactory tire life.

Alignment Preliminary Steps

Several different types of machines are available for

checking all the factors of front end alignment. The in-

structions furnished with each particular machine should

be followed. In all cases, however, checks should be

made with the vehicle level and at curb weight.

Since steering complaints are not always the result of

improper alignment a check should be made to see if any

of the following conditions exist. Any such conditions

should be corrected before proceeding further.

1.

Steering gear loose or improperly adjusted.

2.

Steering gear housing loose at frame.

3.

Excessive wear or play in spherical joints or steer-

ing shaft coupling.

4.

Tie rod or steering connections loose.

5.

Improper front spring heights.

6. Unbalanced or underinflated tires.

7.

Improperly adjusted wheel bearings.

8. Shock absorbers not operating properly.

Wheel alignment should always be made with the vehi-

cle rolled forward taking out any slack in the same man-

ner as when the vehicle is traveling forward.

Caster and Camber Adjustment

NOTE: Before adjusting caster and camber

angles, the front bumper should be raised and

quickly released to allow car to return to its

normal height.

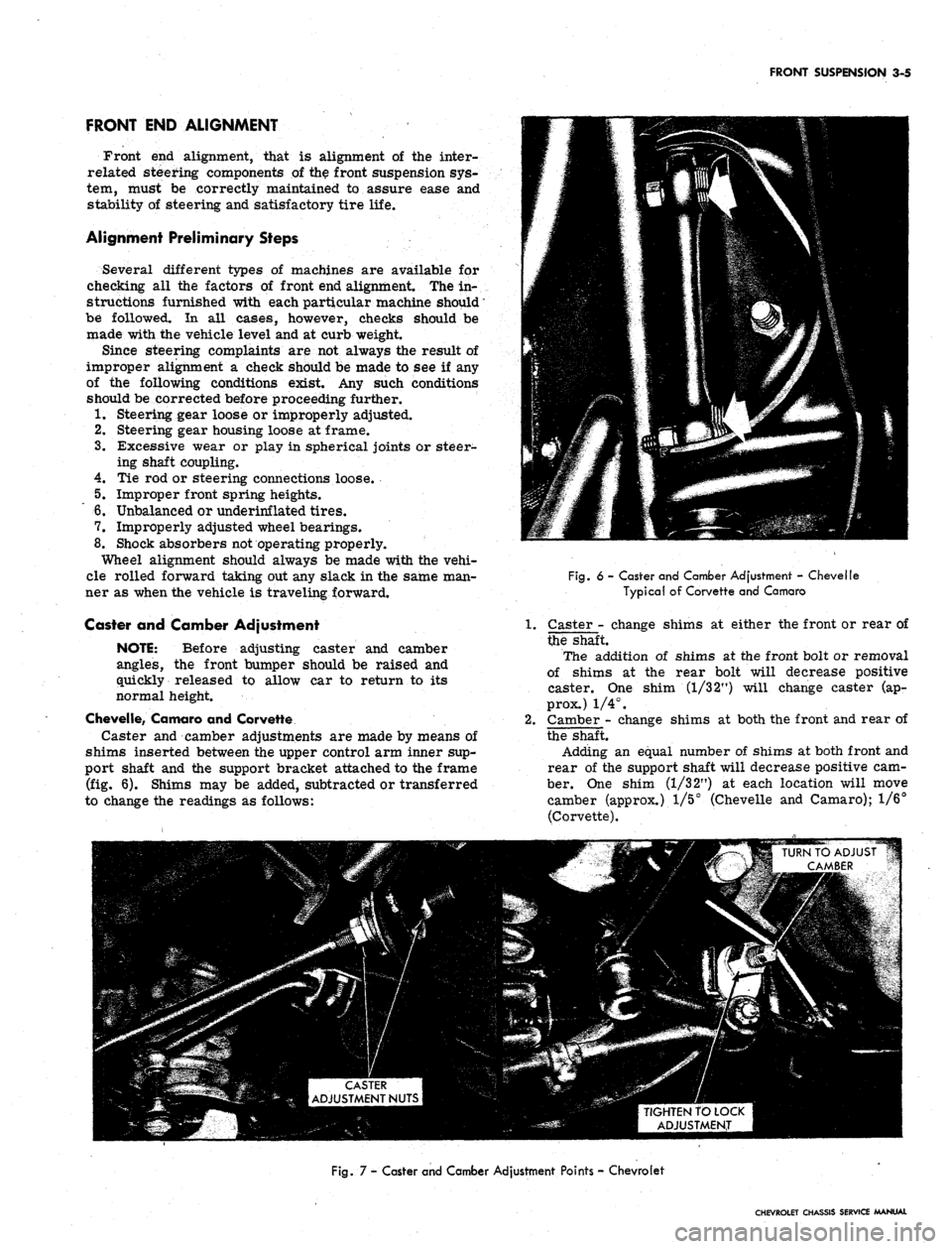

Chevelle, Camaro and Corvette

Caster and camber adjustments are made by means of

shims inserted between the upper control arm inner sup-

port shaft and the support bracket attached to the frame

(fig. 6). Shims may be added, subtracted or transferred

to change the readings as follows:

Fig.

6 - Caster and Camber Adjustment - Chevelle

Typical of Corvette and Camaro

Caster - change shims at either the front or rear of

the shaft.

The addition of shims at the front bolt or removal

of shims at the rear bolt will decrease positive

caster. One shim (1/3 2") will change caster (ap-

prox.) 1/4°.

Camber - change shims at both the front and rear of

the shaft.

Adding an equal number of shims at both front and

rear of the support shaft will decrease positive cam-

ber. One shim (1/32") at each location will move

camber (approx.) 1/5° (Chevelle and Camaro); 1/6°

(Corvette).

TIGHTEN TO LOCK

ADJUSTMENT

Fig.

7 - Caster and Camber Adjustment Points - Chevrolet

CHEVROLET CHASSIS SERVICE MANUAL

Page 170 of 659

FRONT SUSPENSION 3-6

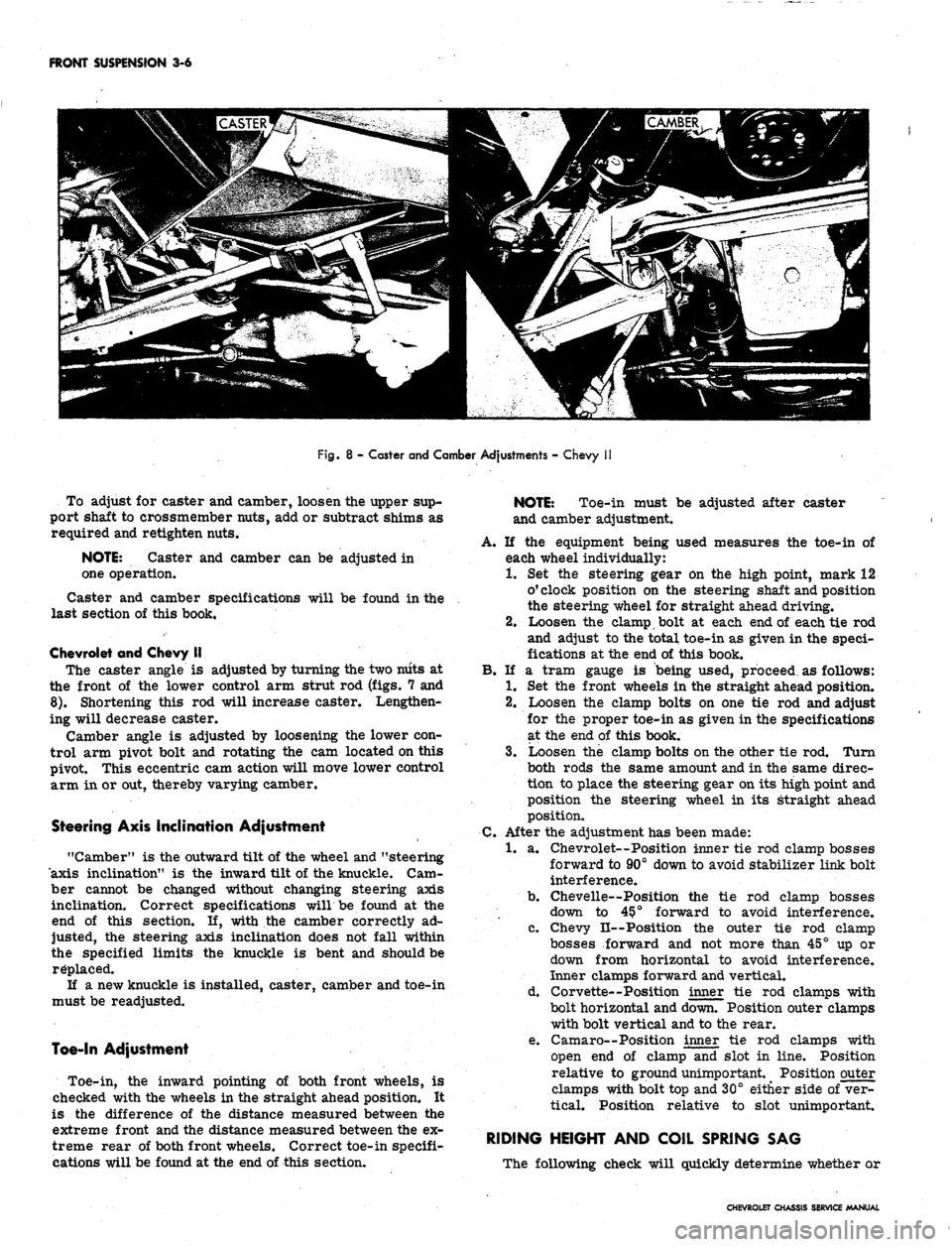

Fig.

8 - Caster and Camber Adjustments - Chevy

To adjust for caster and camber, loosen the upper sup-

port shaft to crossmember nuts, add or subtract shims as

required and retighten nuts.

NOTE:

Caster and camber can be adjusted in

one operation.

Caster and camber specifications will be found in the

last section of this book.

Chevrolet and Chevy II

The caster angle is adjusted by turning the two niits at

the front of the lower control arm strut rod (figs. 7 and

8).

Shortening this rod will increase caster. Lengthen-

ing will decrease caster.

Camber angle is adjusted by loosening the lower con-

trol arm pivot bolt and rotating the cam located on this

pivot. This eccentric cam action will move lower control

arm in or out, thereby varying camber.

Steering Axis Inclination Adjustment

"Camber" is the outward tilt of the wheel and "steering

axis inclination" is the inward tilt of the knuckle. Cam-

ber cannot be changed without changing steering axis

inclination. Correct specifications willbe found at the

end of this section. If, with the camber correctly ad-

justed, the steering axis inclination does not fall within

the specified limits the knuckle is bent and should be

replaced.

If a new knuckle is installed, caster, camber and toe-in

must be readjusted.

Toe-In Adjustment

Toe-in, the inward pointing of both front wheels, is

checked with the wheels in the straight ahead position. It

is the difference of the distance measured between the

extreme front and the distance measured between the ex-

treme rear of both front wheels. Correct toe-in specifi-

cations will be found at the end of this section.

NOTE:

Toe-in must be adjusted after caster

and camber adjustment.

A. If the equipment being used measures the toe-in of

each wheel individually:

1.

Set the steering gear on the high point, mark 12

o'clock position on the steering shaft and position

the steering wheel for straight ahead driving.

2.

Loosen the clamp bolt at each end of each tie rod

and adjust to the total toe-in as given in the speci-

fications at the end of this book.

B.

If a tram gauge is being used, proceed as follows:

1.

Set the front wheels in the straight ahead position.

2.

Loosen the clamp bolts on one tie rod and adjust

for the proper toe-in as given in the specifications

at the end of this book.

3.

Loosen the clamp bolts on the other tie rod. Turn

both rods the same amount and in the same direc-

tion to place the steering gear on its high point and

position the steering wheel in its straight ahead

position.

C.

After the adjustment has been made:

1.

a. Chevrolet—Position inner tie rod clamp bosses

forward to 90° down to avoid stabilizer link bolt

interference.

b.

Chevelle—Position the tie rod clamp bosses

down to 45?° forward to avoid interference.

c. Chevy II--Position the outer tie rod clamp

bosses forward and not more than 45° up or

down from horizontal to avoid interference.

Inner clamps forward and vertical.

d. Corvette--Position inner tie rod clamps with

bolt horizontal and down. Position outer clamps

with bolt vertical and to the rear.

e. Camaro—Position inner tie rod clamps with

open end of clamp and slot in line. Position

relative to ground unimportant. Position outer

clamps with bolt top and 30° either side of ver-

tical. Position relative to slot unimportant.

RIDING HEIGHT AND COIL SPRING SAG

The following check will quickly determine whether or

CHEVROLET CHASSIS SERVICE MANUAL

Page 173 of 659

FRONT SUSPENSION 3-9

Inspection

1.

Check bearings for cracked separators or worn or

pitted rollers and races.

2.

Check brake drum for

out-of-

round or scoring.

3.

Check fit of bearing outer cups in hub.

Repairs

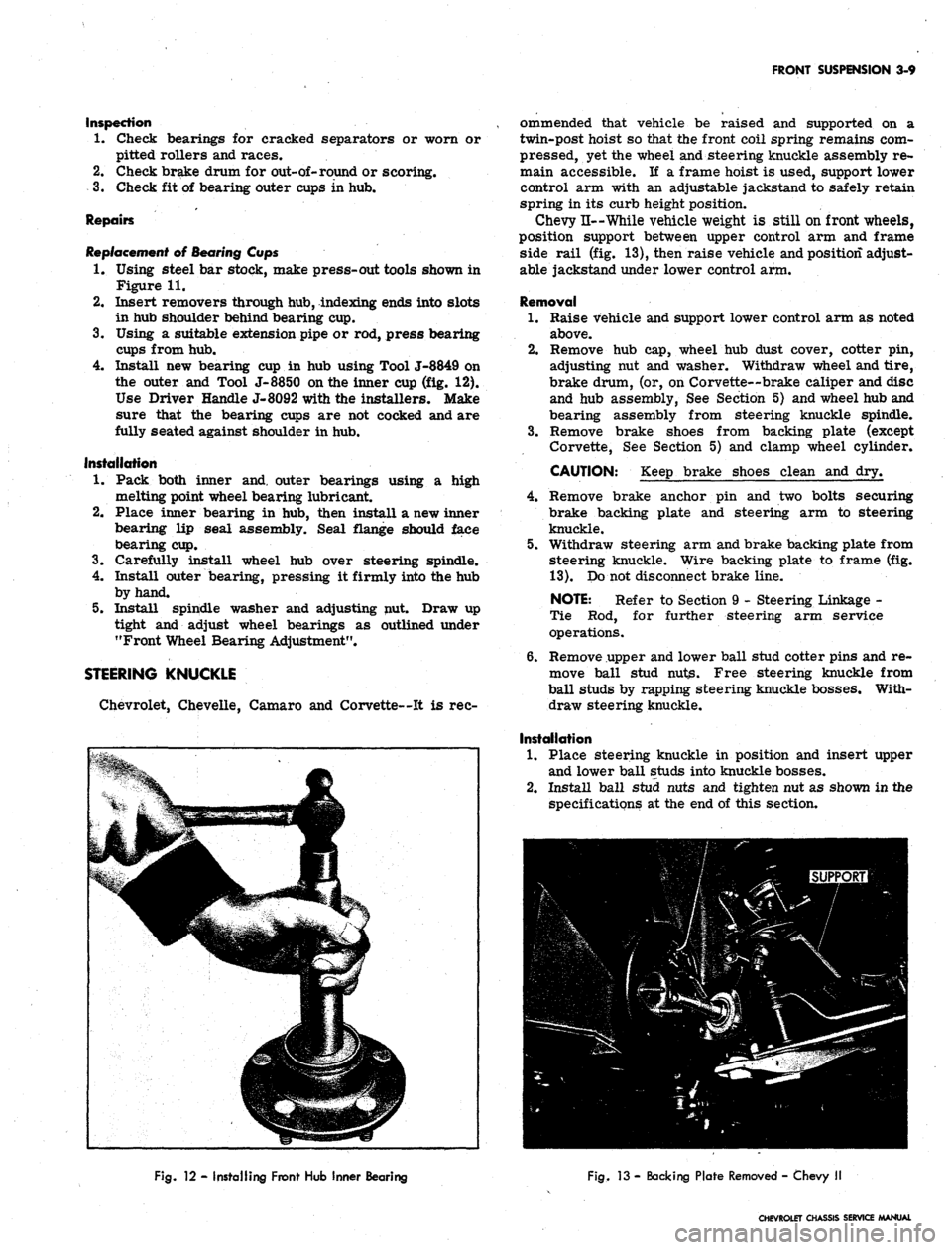

Replacement of Bearing Cups

1.

Using steel bar stock, make press-out tools shown in

Figure 11.

2.

Insert removers through hub, indexing ends into slots

in hub shoulder behind bearing cup.

3.

Using a suitable extension pipe or rod, press bearing

cups from hub.

4.

Install new bearing cup in hub using Tool J-8849 on

the outer and Tool J-8850 on the inner cup (fig. 12).

Use Driver Handle J-8092 with the installers. Make

sure that the bearing cups are not cocked and are

fully seated against shoulder in hub.

Installation

1.

Pack both inner and. outer bearings using a high

melting point wheel bearing lubricant.

2.

Place inner bearing in hub, then install a new inner

bearing lip seal assembly. Seal flange should face

bearing cup.

3.

Carefully install wheel hub over steering spindle.

4.

Install outer bearing, pressing it firmly into the hub

by hand.

5.

Install spindle washer and adjusting nut. Draw up

tight and adjust wheel bearings as outlined under

"Front Wheel Bearing Adjustment".

STEERING KNUCKLE

Chevrolet, Chevelle, Camaro and Corvette—It is rec-

ommended that vehicle be raised and supported on a

twin-post hoist so that the front coil spring remains com-

pressed, yet the wheel and steering knuckle assembly re-

main accessible. If a frame hoist is used, support lower

control arm with an adjustable jackstand to safely retain

spring in its curb height position.

Chevy n— While vehicle weight is still on front wheels,

position support between upper control arm and frame

side rail (fig. 13), then raise vehicle and position adjust-

able jackstand under lower control arm.

Removal

1.

Raise vehicle and support lower control arm as noted

above.

2.

Remove hub cap, wheel hub dust cover, cotter pin,

adjusting nut and washer. Withdraw wheel and tire,

brake drum, (or, on Corvette--brake caliper and disc

and hub assembly, See Section 5) and wheel hub and

bearing assembly from steering knuckle spindle.

3.

Remove brake shoes from backing plate (except

Corvette, See Section 5) and clamp wheel cylinder.

CAUTION: Keep brake shoes clean and dry.

4.

Remove brake anchor pin and two bolts securing

brake backing plate and steering arm to steering

knuckle.

5.

Withdraw steering arm and brake backing plate from

steering knuckle. Wire backing plate to frame (fig.

13).

Do not disconnect brake line.

NOTE: Refer to Section 9 - Steering Linkage -

Tie Rod, for further steering arm service

operations.

6. Remove upper and lower ball stud cotter pins and re-

move ball stud nuts. Free steering knuckle from

ball studs by rapping steering knuckle bosses. With-

draw steering knuckle.

Installation

1.

Place steering knuckle in position and insert upper

and lower ball studs into knuckle bosses.

2.

Install ball stud nuts and tighten nut as shown in the

specifications at the end of this section.

Fig.

12 - Installing Front Hub Inner Bearing

Fig.

13 - Backing Plate Removed - Chevy II

CHEVROLET CHASSIS SERVICE MANUAL

Page 174 of 659

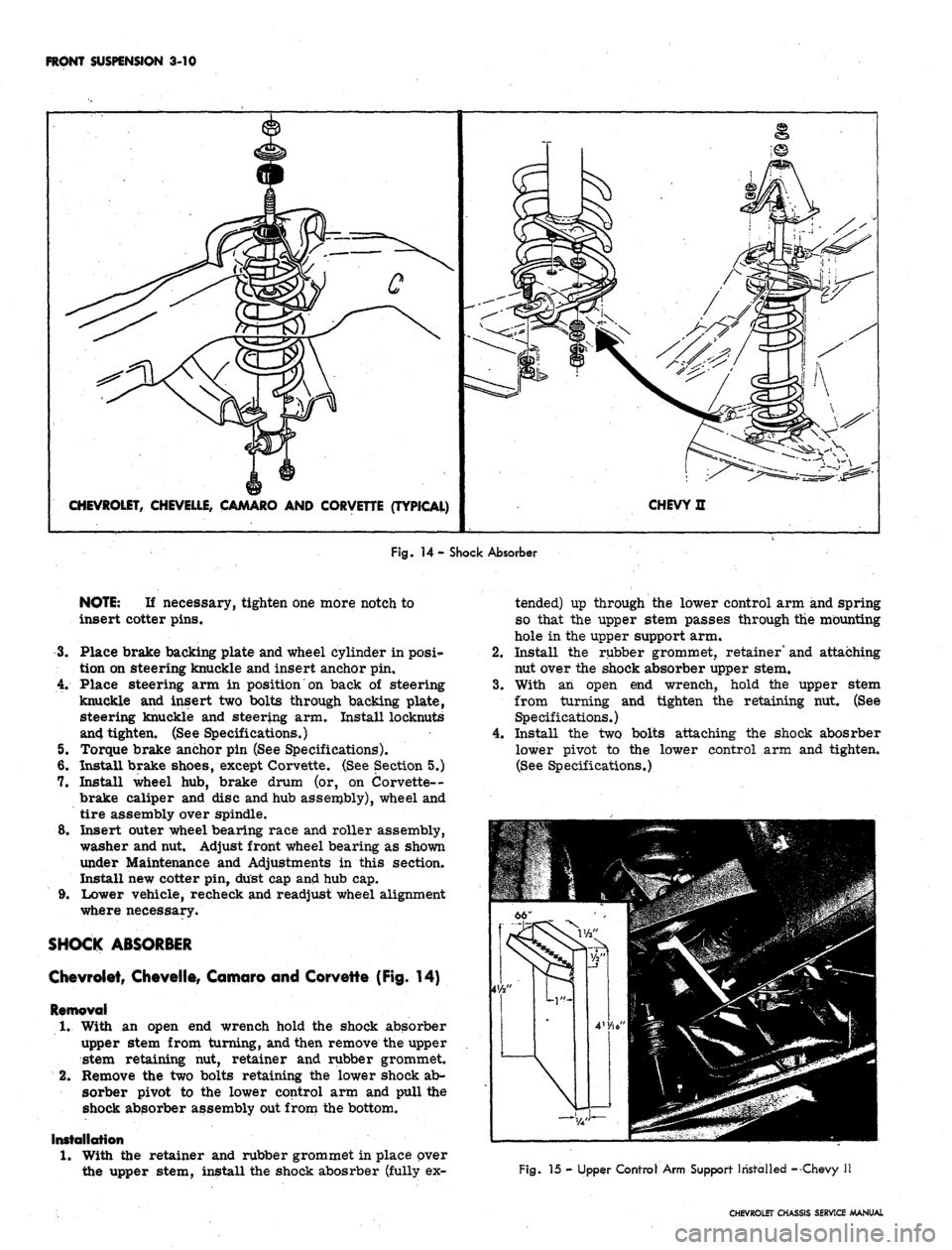

FRONT SUSPENSION 3-10

CHEVROLET, CHEVELLE, CAMARO AND CORVETTE (TYPICAL)

CHEVY H

Fig.

14- Shock Absorber

NOTE:

If necessary, tighten one more notch to

insert cotter pins.

3.

Place brake backing plate and wheel cylinder in posi*-

tion on steering knuckle and insert anchor pin.

4.

Place steering arm in position on back of steering

knuckle and insert two bolts through backing plate,

steering knuckle and steering arm. Install locknuts

and tighten. (See Specifications.)

5. Torque brake anchor pin (See Specifications).

6. Install brake shoes, except Corvette. (See Section 5.)

7. Install wheel hub, brake drum (or, on Corvette--

brake caliper and disc and hub assembly), wheel and

tire assembly over spindle.

8. Insert outer wheel bearing race and roller assembly,

washer and nut. Adjust front wheel bearing as shown

under Maintenance and Adjustments in this section.

Install new cotter pin, dust cap and hub cap.

9. Lower vehicle, recheck and readjust wheel alignment

where necessary.

SHOCK ABSORBER

Chevrolet, Chevelle, Comoro and Corvette (Fig. 14)

Removal

1.

With an open end wrench hold the shock absorber

upper stem from turning, and then remove the upper

stem retaining nut, retainer and rubber grommet.

2.

Remove the two bolts retaining the lower shock ab-

sorber pivot to the lower control arm and pull the

shock absorber assembly out from the bottom.

Installation

1.

With the retainer and rubber grommet in place over

the upper stem, install the shock abosrber (fully ex-

tended) up through the lower control arm and spring

so that the upper stem passes through the mounting

hole in the upper support arm.

2.

Install the rubber grommet, retainer' and attaching

nut over the shock absorber upper stem.

3.

With an open end wrench, hold the upper stem

from turning and tighten the retaining nut. (See

Specifications.)

4.

Install the two bolts attaching the shock abosrber

lower pivot to the lower control arm and tighten.

(See Specifications.)

Fig.

15 - Upper Control Arm Support Installed - Chevy II

CHEVROLET CHASSIS SERVICE MANUAL

Page 234 of 659

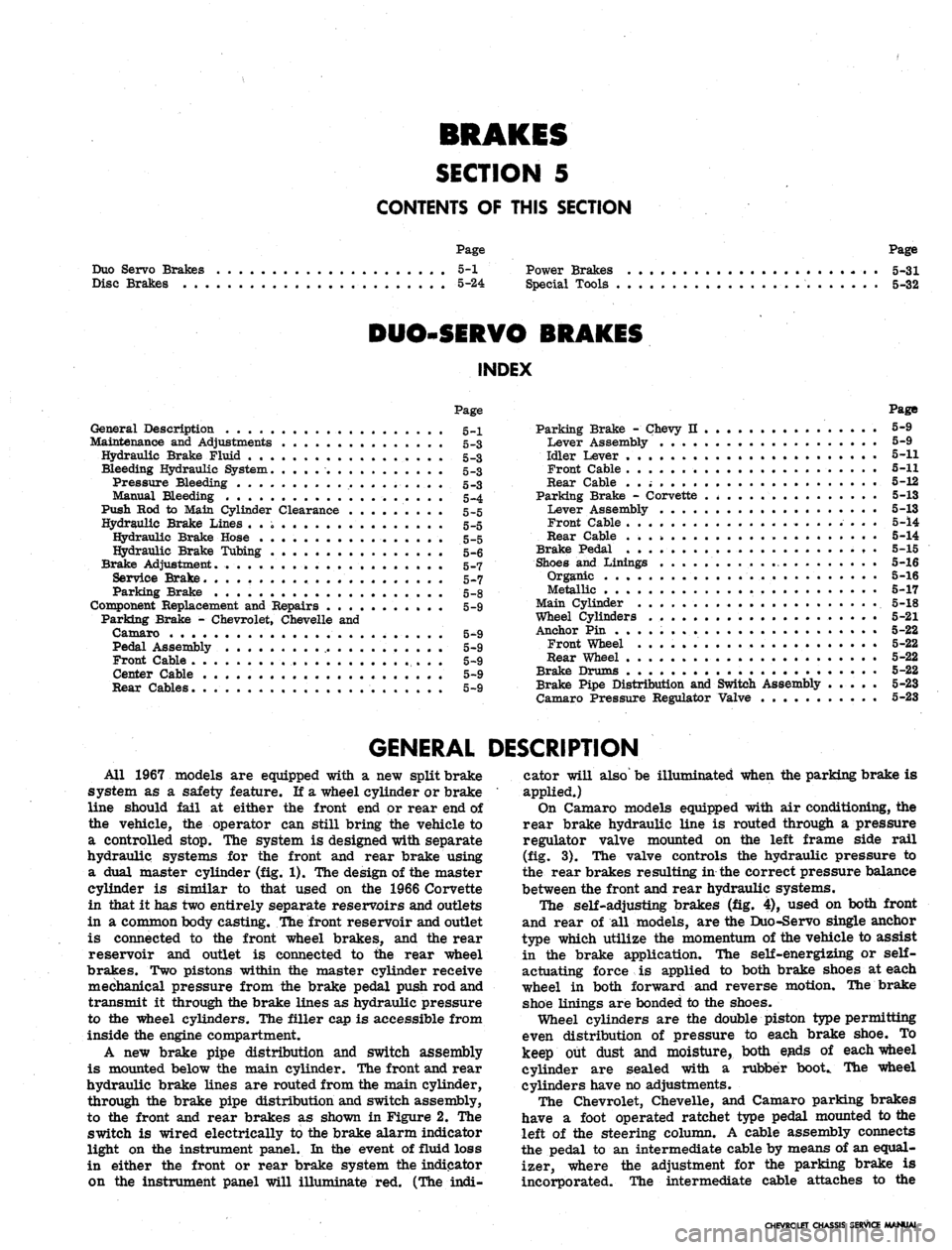

BRAKES

SECTION 5

CONTENTS OF THIS SECTION

Duo Servo Brakes

Disc Brakes

Page

5-1 Power Brakes

5-24 Special Tools

Page

5-31

5-32

DUO-SERVO BRAKES

INDEX

Page

General Description 5-1

Maintenance and Adjustments 5-3

Hydraulic Brake Fluid .. . 5-3

Bleeding Hydraulic System 5-3

Pressure Bleeding 5-3

Manual Bleeding 5_4

Push Rod to Main Cylinder Clearance 5-5

Hydraulic Brake Lines 5-5

Hydraulic Brake Hose 5-5

Hydraulic Brake Tubing 5-6

Brake Adjustment. .................... 5-7

Service Brake 5-7

Parking Brake 5-8

Component Replacement and Repairs 5-9

Parking Brake - Chevrolet, Chevelle and

Camaro 5^9

Pedal Assembly 5-9

Front Cable ,. . . 5-9

Center Cable 5-9

Rear Cables. . 5-9

Parking Brake - Chevy n 5-9

Lever Assembly 5-9

Idler Lever 5-11

Front Cable 5-11

Rear Cable . . ; 5-12

Parking Brake - Corvette 5-13

Lever Assembly . . . . 5-13

Front Cable 5-14

Rear Cable . . 5-14

Brake Pedal 5-15

Shoes and Linings 5-16

Organic 5-16

Metallic 5-17

Main Cylinder 5-18

Wheel Cylinders 5-21

Anchor Pin 5-22

Front Wheel 5-22

Rear Wheel 5-22

Brake Drums • 5-22

Brake Pipe Distribution and Switch Assembly . . . . . 5-23

Camaro Pressure Regulator Valve 5-23

GENERAL DESCRIPTION

All 1967 models are equipped with a new split brake

system as a safety feature. If a wheel cylinder or brake

line should fail at either the front end or rear end of

the vehicle, the operator can still bring the vehicle to

a controlled stop. The system is designed with separate

hydraulic systems for the front and rear brake using

a dual master cylinder (fig. 1). The design of the master

cylinder is similar to that used on the 1966 Corvette

in that it has two entirely separate reservoirs and outlets

in a common body casting. The front reservoir and outlet

is connected to the front wheel brakes, and the rear

reservoir and outlet is connected to the rear wheel

brakes. Two pistons within the master cylinder receive

mechanical pressure from the brake pedal push rod and

transmit it through the brake lines as hydraulic pressure

to the wheel cylinders. The filler cap is accessible from

inside the engine compartment.

A new brake pipe distribution and switch assembly

is mounted below the main cylinder. The front and rear

hydraulic brake lines are routed from the main cylinder,

through the brake pipe distribution and switch assembly,

to the front and rear brakes as shown in Figure 2. The

switch is wired electrically to the brake alarm indicator

light on the instrument panel. In the event of fluid loss

in either the front or rear brake system the indicator

on the instrument panel will illuminate red. (The indi-

cator will also' be illuminated when the parking brake is

applied.)

On Camaro models equipped with air conditioning, the

rear brake hydraulic line is routed through a pressure

regulator valve mounted on the left frame side rail

(fig. 3). The valve controls the hydraulic pressure to

the rear brakes resulting in the correct pressure balance

between the front and rear hydraulic systems.

The self-adjusting brakes (fig. 4), used on both front

and rear of all models, are the Duo-Servo single anchor

type which utilize the momentum of the vehicle to assist

in the brake application. The self-energizing or

self-

actuating force is applied to both brake shoes at each

wheel in both forward and reverse motion. The brake

shoe linings are bonded to the shoes.

Wheel cylinders are the double piston type permitting

even distribution of pressure to each brake shoe. To

keep out dust and moisture, both ejads of each wheel

cylinder are sealed with a rubber booC The wheel

cylinders have no adjustments.

The Chevrolet, Chevelle, and Camaro parking brakes

have a foot operated ratchet type pedal mounted to the

left of the steering column. A cable assembly connects

the pedal to an intermediate cable by means of an equal-

izer, where the adjustment for the parking brake is

incorporated. The intermediate cable attaches to the

CHEVROLET CHASSIS SERVICE MANUAL

Page 257 of 659

BRAKES

5-24

DISC BRAKES

INDEX

Page

General Description

. 5-24

Maintenance

and

Adjustments

5-24

Bleeding Hydraulic System

5-24

Parking Brake Adjustment

-

Corvette

5-24

Component Replacement

and

Repairs

5-25

Page

Brake Shoes

. . . . . 5-25

Brake Caliper

5-26

Brake Disc

5-29

Main Cylinder.

5-30

Parking Brake Shoes

-

Corvette

5-30

GENERAL DESCRIPTION

Four wheel disc brakes

are

standard equipment

on

the

1967

Corvette,

as in 1966. The

Corvette

may

also

be equipped with heavy duty disc brakes which include

new front calipers, shoes, linings,

and

rear pressure

regulator valve. This heavy duty option

is

used

in

conjunction with

a

vacuum power unit. Front wheel disc

brakes

are

installed

as

optional equipment

on

Chevrolet,

Chevelle, Camaro,

and

Chevy

II

models.

The disc brake,

(fig. 35),

consists

of a

fixed caliper,

rotating disc, splash shield,

and

mounting bracket.

The

caliper assembly contains four pistons and two shoe

and

lining assemblies with

the

lining riveted

to the

steel

shoes.

A

seal

and

dust boot

are

installed

on

each piston,

with

a

piston spring

in the

caliper cylinder bore beneath

each piston.

A

retaining pin extends through each caliper

half

and

both shoes

to

hold

the

shoes and linings

in

posi-

tion

in the

caliper.

On

Corvette heavy duty disc brakes,

two retaining cotter pins

are

used

at

each end

of the

caliper

to

secure

the

shoes

and

linings. Machined

sur-

faces within

the

caliper prevent

the

shoe

and

lining

assembly from rotating with

the

brake disc when pres-

sure

is

applied.

The disc, which

has a

series

of air

vent louvers

to

provide cooling,

is

mounted

on the

front wheel-hub.

The caliper straddles

the

disc and mounts

on a

mounting

bracket attached

to the

steering knuckle with

two

bolts.

The Corvette heavy duty option includes

a

pressure

regulator valve mounted

in the

rear brake line just

below

the

main cylinder. Chevrolet, Chevelle, Camaro,

and Chevy

n

models with disc brakes have

a

pressure

regulator valve mounted

in the

front brake line just

below

the

main cylinder. The valve controls

the

hydraulic

pressure

to the

front

or

rear brakes,

as

applicable,

resulting,

in the

correct pressure balance between

the

front

and

rear hydraulic systems. This valve guards

against premature .lock-up

of

front

or

rear wheels when

brakes

are

applied.

Maintenance, adjustment,

and

service operations which

are

not

included

in

this section

are the

same

as for

the Duo-Servo type brakes.

MAINTENANCE

AND

ADJUSTMENTS

BLEEDING HYDRAULIC SYSTEM

The operation

of

bleeding

the

disc brake hydraulic

system

is the

same

as for

Duo-Servo system outlined

in

the

front

of

this section. Note

the

exceptions below

and refer

to

bleeding procedures under Duo-Servo

brakes.

1.

When pressure bleeding equipment

is

used,

the

correct pressure setting

for

bleeding disc brakes

is 10-2.0

lbs. on

Corvette,

and 40 lbs. on all

other

models.

2.

The

front calipers contain

one

bleeder valve.

The

rear calipers

on

Corvette contain two bleeder valves

(one inboard

and one

outboard) which necessitates

the removal

of the

rear wheels

for

bleeding.

3.

Tapping

the

caliper with

a

rawhide mallet

as the

fluid

is

flowing

out may

assist

in

obtaining

a

good

bleeding

job.

4.

On

Chevrolet, Chevelle, Camaro

and

Chevy

II, the

spring loaded

end of the

pressure regulator valve

(fig.

36)

must

be

held (valve

in

open position) while

bleeding. This

is

done

by

depressing

and

holding

in

the

plunger

in the

end

of

the valve either

by

hand,

by taping,

or by

clamping.

PARKING BRAKE-CORVETTE

Adjustment

1.

Raise rear

end of

vehicle

and

place

on

jack stands.

2.

Remove rear wheels.

3/

Loosen brake cables

at the

equalizer until

the

park-

ing brake levers move freely

to the "off"

position

with slack

in the

cables.

4.

Turn

the

disc until

the

adjusting screw can

be

seen

through

the

hole

in the

disc.

5. Insert

an

adjusting tool

or

screw driver through

the

hole

in the

disc

and

tighten

the

adjusting screw

by

moving your hand away from

the

floor

on

both

the

left and right sides

(fig. 37).

6. Tighten until

the

disc will

not

move, then back

off

ten

(10)

notches.

7. Apply

the

parking brake four

(4)

notches from inside

the

car.

8. Tighten

the

brake cables

at the

equalizer

to

produce

a light drag with

the

wheels mounted.

9. Fully release

the

parking brake handle

and

rotate

the rear wheels.

No

drag should be evident with

the

handle released.

CHEVROLET CHASSIS SERVICE MANUAL

Page 277 of 659

ENGINE

6-12

ENGINE

MECHANICAL

IN LINE

INDEX

Page

General Description . „ 6-12

Component Replacement and Adjustment 6-12

.Engine Assembly 6-12

Removal 6-12

Installation 6-13

Manifold Assembly 6-14

Removal . 6-14

Installation 6-14

Rocker Arm Cover . 6-14

Removal 6-14

mstallation . . . 6-14

Valve Mechanism

......

1 6-14

Removal 6-14

Installation and Adjustment . 6-14

Valve Lifters

..............

6-15

Locating Noisy Lifters

„.;....

6-15

Removal

.'.*...•

6-15

Installation . 6-15

Valve Stem Oil Seal and/or Valve Spring . 6-16

Replacement . 6-16

Cylinder Head Assembly . 6-16

Removal 6-16

Installation . 6-16

Oil Pan . » 6-17

Removal . . . ; . . 6-17

Installation

.........

. 6-17

Oil Pump . 6-18

Page

Removal . 6-18

Installation . 6-18

Oil Seal (Rear Main) . 6-19

Replacement 6-19

Crankshaft Pulley and Hub 6-19

Removal 6-19

Installation 6-19

Torsional Damper 6-19

Removal 6-19

Installation 6-19

Crankcase Front Cover . 6-20

Removal . 6-20

Installation 6-20

•

Oil Seal (Front Cover) 6-20

Replacement 6-20

Camshaft 6-21

Measuring Lobe Lift . ... .

.-.••.-.

6-21

Removal 6-21

Installation 6-22

Timing Gears

..••••.............••• 6—22

Replacement

6-22

Flywheel

6-22

Removal

* 6-22

Installation

6-22

Engine

Mounts

6-23

Replacement

(Front)

6-23

Replacement

(Rear)

. 6-23

GENERAL DESCRIPTION

The

In

Line engines

(fig. 1L)

covered

in

this section

are

the 1H3 cu. in. L4, the 194,

230

and

250

cu. in. L6,

regardless

of

which passenger vehicle they

are

used

in.

This section covers

the

removal

and

installation

of en-

gine assemblies;

the

removal, installation

and

adjustment

of some sub-assemblies

and

replacement

of

some

com-

ponents.

For

service

to all

components

and

sub-assem-

blies (after removal)

and

removal

of

some sub-assem-

blies,

refer

to

Section

6 of the

Chassis Overhaul Manual.

Because

of the

interchangeability

and

similarity

of

many engine sub-assemblies

and

engine parts, regardless

of which passenger vehicle they

are

used

in,

typical illus-

trations

and

procedures

are

used except where specific

illustrations

or

procedures

are

necessary

to

clarify

the

operation. Although illustrations showing bench opera-

tions

are

used, most single operations, when

not

part

of a

general overhaul, should

be

performed

(if

practical) with

the engine

in the

vehicle.

COMPONENT REPLACEMENT

AND

ADJUSTMENT

ENGINE ASSEMBLY

Removal

1.

Drain cooling system

and

engine

oil.

2.

Remove

air

cleaner

and

disconnect battery cables

at 7.

battery.

3.

Remove hood

as

outlined

in

Section 11.

4.

Remove radiator

and

radiator shroud

as

outlined

in

Section 13.

5.

Remove

fan

blade

and

pulley

as

outlined

in

Section

6K.

6. Disconnect wires

at:

• Starter Solenoid

8.

• Delcotron

9.

Temperature Switch

Oil Pressure Switch

Coil

Disconnect:

Accelerator linkage

at

manifold bellerank.

Exhaust pipe

at

manifold flange.

.

Fuel line (from tank)

at

fuel pump.

Vacuum line

to

power brake unit

at

manifold

(if

so equipped).

• Power steering pump lines

at

pump

end (if so

equipped).

Raise vehicle

and

place

on

jack stands.

Remove propeller shaft.

CHEVROLET CHASSIS SERVICE MANUAL