hose CHEVROLET CAMARO 1982 Repair Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1982, Model line: CAMARO, Model: CHEVROLET CAMARO 1982Pages: 875, PDF Size: 88.64 MB

Page 760 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 760

GENERAL INFORMATION & MAINTENANCE

HOW TO USE THIS INFORMATION

The introductory part of this repair gui de is intended to help you learn more

about the inner workings of your Camaro while saving you money on its upkeep

and operation.

The beginning of the repair guide will likely be referred to the most, since that is

where you will find information for maintenance and tune-up. The other

information deals with the more complex systems of your vehicle. Systems

(from engine through brakes) are covered to the extent that the average do-it-

yourselfer can attempt. This repair guide will not explain such things as

rebuilding a differential because the ex pertise required and the special tools

necessary make this uneconomical. It will, however, give you detailed

instructions to help you change your own brake pads and shoes, replace spark

plugs, and perform many more jobs that can save you money and help avoid

expensive problems.

A secondary purpose of this repair guide is a reference for owners who want to

understand their vehicle and/or their mechanics better.

WHERE TO BEGIN

Before removing any bolts, read through t he entire procedure. This will give you

the overall view of what tools and supplies will be required. So read ahead and

plan ahead. Each operation should be approached logically and all procedures

thoroughly understood before attempting any work.

If repair of a component is not considered practical, we tell you how to remove

the part and then how to insta ll the new or rebuilt replacement. In this way, you

at least save labor costs.

AVOIDING TROUBLE

Many procedures in this repair guide r equire you to "label and disconnect ..." a

group of lines, hoses or wires. Don't be think you can remember where

everything goes - you won't. If you hook up va cuum or fuel lines incorrectly, the

vehicle may run poorly, if at all. If you hook up electrical wiring incorrectly, you

may instantly learn a very expensive lesson.

You don't need to know the proper name for each hose or line. A piece of

masking tape on the hose and a piece on its fitting will allow you to assign your

own label. As long as you remember your own code, the lines can be

reconnected by matching your tags. Re member that tape will dissolve in

gasoline or solvents; if a part is to be washed or cleaned, use another method

of identification. A permanent felt-tipped marker or a metal scribe can be very

handy for marking metal parts. Remove any tape or paper labels after

assembly.

Page 762 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 762

Loctite). If you're worried about getting so

mething together tight enough to hold,

but loose enough to avoid mechanical damage during assembly, one of these

products might offer substantial insurance. Before choosing a threadlocking

compound, read the label on the pa ckage and make sure the product is

compatible with the materials, fluids, etc. involved.

3. Crossthreading. This occu rs when a part such as a bolt is screwed into a

nut or casting at the wrong angle and forced. Cr ossthreading is more

likely to occur if access is diffic ult. It helps to clean and lubricate

fasteners, then to start threading the bolt, spark pl ug, etc. with your

fingers. If you encounter resistance, unscrew the part and start over

again at a different angle until it can be inserted and turned several t\

imes

without much effort. Keep in mind t hat many parts have tapered threads,

so that gentle turning will automatica lly bring the part you're threading to

the proper angle. Don't put a wrench on the part until it's been tightened

a couple of turns by hand. If you s uddenly encounter resistance, and the

part has not seated fully, don't force it. Pull it back out to make sure it's

clean and threading properly.

Be sure to take your time and be pati ent, and always plan ahead. Allow yourself

ample time to perform r epairs and maintenance.

TOOLS AND EQUIPMENT

Without the proper tools and equipment it is impossible to properly service your

vehicle. It would be virtually impossible to catalog every tool that you would

need to perform all of the oper ations in this repair guide. It would be unwise for

the amateur to rush out and buy an expens ive set of tools on the theory that

he/she may need one or more of them at some time.

The best approach is to proceed slowly, gathering a good quality set of those

tools that are used most frequently. Don't be misled by the low cost of bargain

tools. It is far better to spend a little more for better quality. Forged wrenches, 6

or 12-point sockets and fine tooth ratc hets are by far preferable to their less

expensive counterparts. As any good me chanic can tell you, there are few

worse experiences than trying to work on a vehicle with bad tools. Your

monetary savings will be far outweighed by frustration and mangled knuckles.

Begin accumulating those tools that are used most frequently: those associated

with routine maintenance and tune-up. In addition to the normal assortment of

screwdrivers and pliers, you should have the following tools:

• Wrenches/sockets and combination o pen end/box end wrenches in sizes 1/83/4 in. and/or 3mm-19mm 13/16 in. or 5/8 in. spark plug socket

(depending on plug type).

If possible, buy various length socket drive extensions. Universal-joint\

and

wobble extensions can be extremely usef ul, but be careful when using them, as

they can change the amount of torque applied to the socket.

Page 766 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 766

In addition to the above it

ems there are several others that are not absolutely

necessary, but handy to have around. These include an equivalent oil

absorbent gravel, like cat litter, and the usual supply of lubricants, antifreeze

and fluids. This is a basic list for rout ine maintenance, but only your personal

needs and desire can accurately determine your list of tools.

After performing a few projects on the vehi cle, you'll be amazed at the other

tools and non-tools on your workbench. Some useful household items are: a

large turkey baster or siphon, empty coff ee cans and ice trays (to store parts), a

ball of twine, electrical t ape for wiring, small rolls of colored tape for tagging

lines or hoses, markers and pens, a note pad, golf tees (for plugging vacuum

lines), metal coat hangers or a roll of mechanic's wire (to hold things out of the

way), dental pick or similar long, poi nted probe, a strong magnet, and a small

mirror (to see into rece sses and under manifolds).

Fig. 7: Although not always necessary, us ing specialized brake tools will save

time

Page 794 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 794

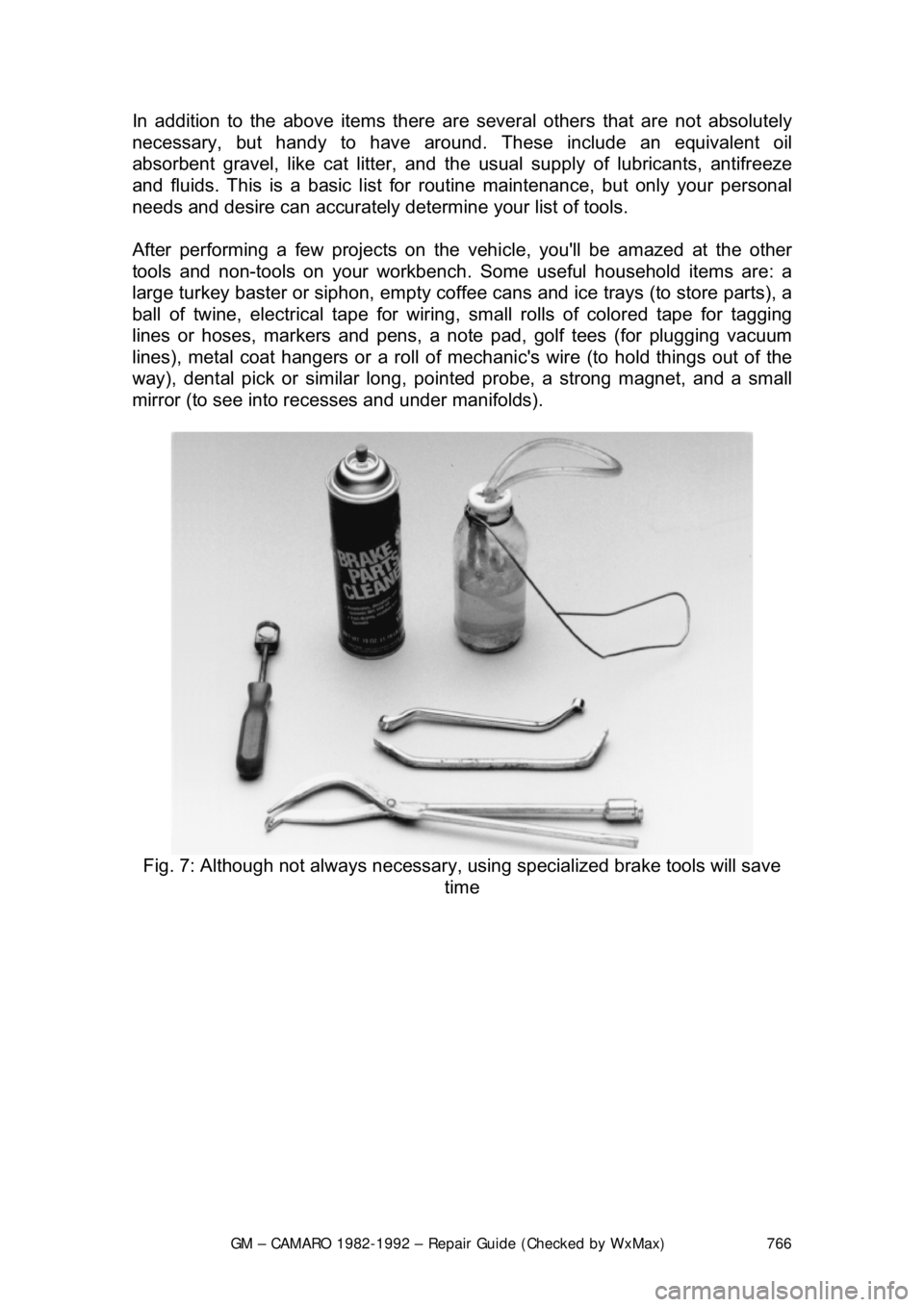

Fig. 5: Periodically remove all debris from the radiator fins

CAUTION - Do not remove a radiator cap wh ile the engine and radiator are still

hot. Danger of burns by scalding fluid and steam under pressure may result!

1. With a cool engine, slowly rotate t he radiator cap counterclockwise to the

detent without pressing down on the cap.

2. Wait until any remaini ng pressure is relieved by listening for a hissing

sound.

3. After all the pressure is relieved, press down on the cap and continue to

rotate the radiator cap counterclockwise.

4. With a suitable container to catc h the fluid under the radiator, open the

radiator drain cock.

5. If equipped, remove the engine blo ck drain plugs and the knock sensor,

located on either side of the engine block. This will help to drain the

coolant from the block.

6. Loosen or slide the recovery tank hos e clamp at the radiator filler neck

overflow tube and remove the hose. Holding the hose down to the drain

pan, allow the recovery tank to empty. Attach the hose to the filler neck

overflow and tighten the clamp.

7. Close the radiator drain cock and install the engine block drain plug and

knock sensor. Tighten the knock sensor to 14 ft. lbs. (19 Nm), the engine

block drain plug to 15 ft. lbs. (21 N m), and the drain cock to 13 inch lbs.

(1.5 Nm).

8. Add enough coolant mixture to fill the system to a level just below the

radiator neck. Fill the reservoir a ssembly to the "FULL COLD" mark.

Page 828 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 828

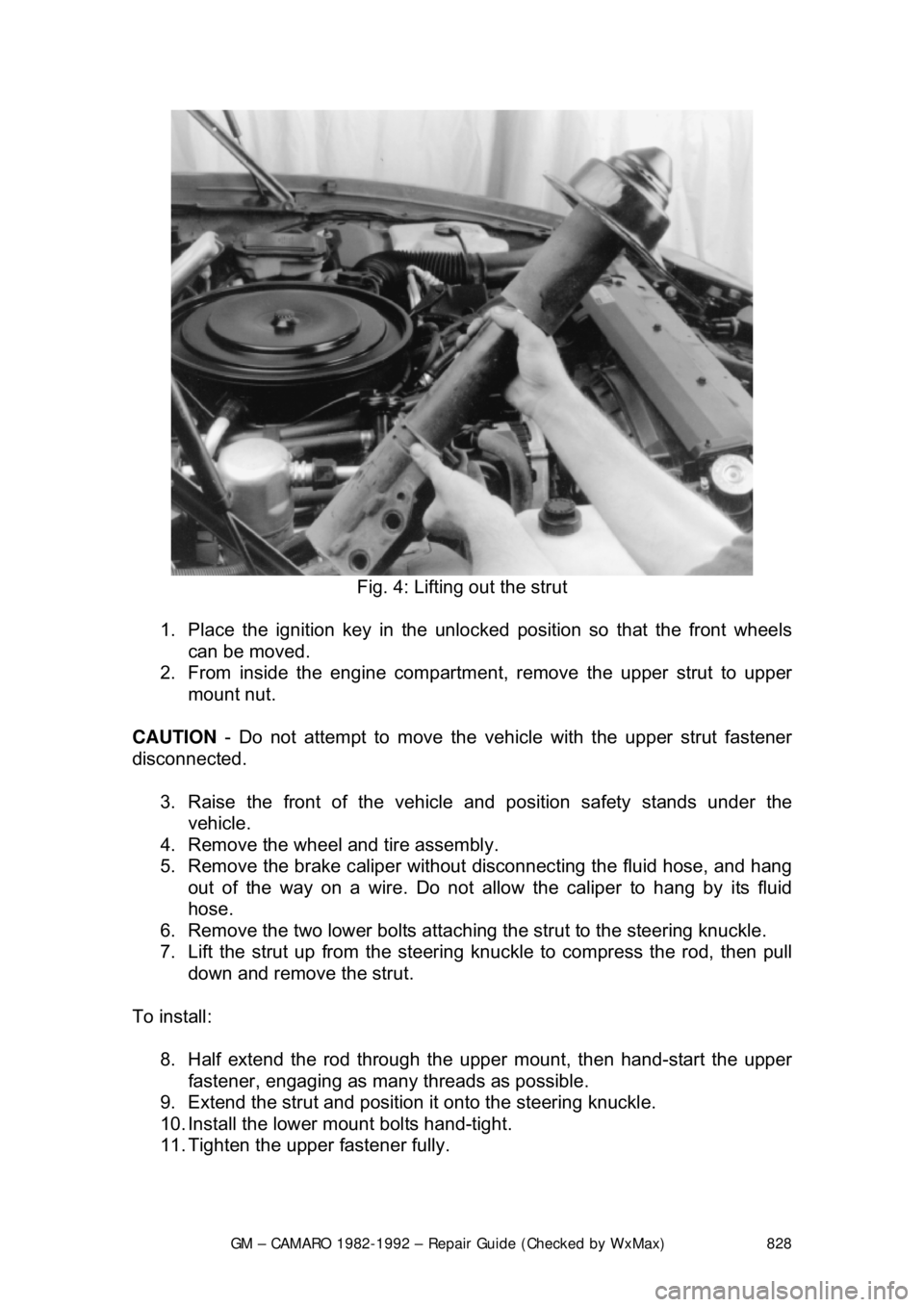

Fig. 4: Lifting out the strut

1. Place the ignition key in the unlock ed position so that the front wheels

can be moved.

2. From inside the engine compartm ent, remove the upper strut to upper

mount nut.

CAUTION - Do not attempt to move the ve hicle with the upper strut fastener

disconnected.

3. Raise the front of the vehicl e and position safety stands under the

vehicle.

4. Remove the wheel and tire assembly.

5. Remove the brake caliper without disconnecting the fluid hose, and hang

out of the way on a wire. Do not allo w the caliper to hang by its fluid

hose.

6. Remove the two lower bolts attachi ng the strut to the steering knuckle.

7. Lift the strut up from the steering k nuckle to compress the rod, then pull

down and remove the strut.

To install: 8. Half extend the rod through th e upper mount, then hand-start the upper

fastener, engaging as many threads as possible.

9. Extend the strut and position it onto the steering knuckle.

10. Install the lower mount bolts hand-tight.

11. Tighten the upper fastener fully.

Page 833 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 833

1. Siphon some brake fluid from the ma

ster cylinder. Raise and support the

vehicle.

2. Remove the wheel and tire. Remo ve the brake hose from the strut.

3. Remove the caliper and support on a wire. Refer to Brakes for

procedures, then remove the hub-and-disc.

4. Remove the splash shield. Disc onnect the tie rod from the steering

knuckle.

5. Support the lower control arm and disconnect the ball joint from the

steering knuckle using tool J-24292A.

6. Remove the 2 bolts securing the stru t to the steering knuckle and remove

the steering knuckle.

To install: 7. Place the steering knu ckle into position and install the 2 bolts securing

the strut to the st eering knuckle.

8. Support the lower control arm and c onnect the ball joint to the steering

knuckle.

9. Connect the tie rod to the steering knuckle. Install the splash shield.

10. Install the caliper.

11. Install the brake hose from the strut. Install the wheel and tire.

12. Lower the vehicle and refill the master cylinder with brake fluid.

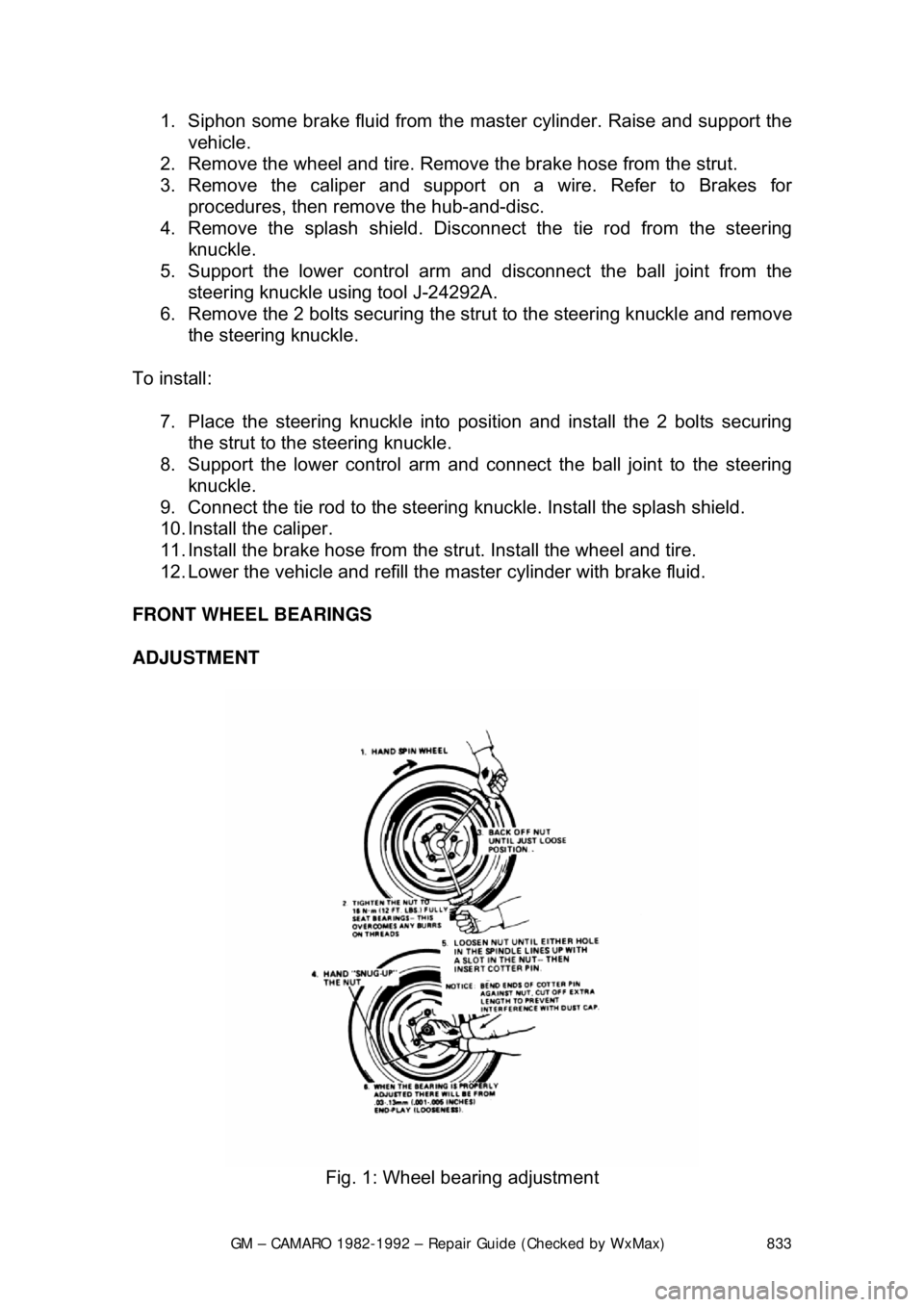

FRONT WHEEL BEARINGS

ADJUSTMENT

Fig. 1: Wheel bearing adjustment

Page 839 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 839

COIL SPRINGS

REMOVAL & INSTALLATION

1. Raise the car by the frame so that the rear axle can be independently

raised and lowered.

2. Support the rear axle with a floor jack.

3. If equipped with brake hose attaching brackets, disconnect the brackets

allowing the hoses to hang free. Do not disconnect the hoses. Perform

this step only if the hoses woul d otherwise be stretched and damaged

when the axle is lowered.

4. Disconnect the track bar from the axle.

5. Remove the lower shock absorber bol ts and lower the axle. Make sure

the axle is supported securely on t he floor jack and that there is no

chance of the axle slipping after the shock absorbers are disconnected.

On vehicles equipped with a 4-cylinder engine, remove the driveshaft.

6. Lower the axle and remove the coil spring. Do not lower the axle past th\

e limits of the brake lines or the lines will be damaged.

To install: 7. Position spring with the axle lowered.

8. On vehicles equipped with 4-cylinder engines, install the driveshaft.

9. Raise the axle and install the lower shock absorber bolts.

10. Connect the track bar to the axle.

11. Connect the brake hose attaching brackets, if removed.

12. Remove the support from the rear axle.

13. Lower the vehicle.

Page 843 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 843

TRACK BAR BRACE

REMOVAL & INSTALLATION

1. Raise the rear of the vehicle, pl ace jackstands under the rear axle, then

lower the jack so that the stands are supporting all of the weight.

2. Remove the heat shield screw s from the track bar brace.

3. Remove the three track bar brace-to-body brace screws.

4. Remove the track bar-to-body bra cket fasteners and remove the track

bar brace.

To install: 5. Place the track bar brace into position.

6. Install the track bar-to-body bracket fasteners.

7. Install the three track bar brace-to-body brace screws.

8. Install the heat shield scre ws to the track bar brace.

9. Lower the vehicle.

CONTROL ARM

REMOVAL & INSTALLATION

Remove/reinstall only one lower control ar m at a time. If both arms are removed

at the same time, the axle could roll or slip sideways, making reinstallation of

the arms very difficult.

1. Raise the rear of the vehicle, pl ace jackstands under the rear axle, then

lower the jack so that the stands are supporting all of the weight.

2. Remove the control arm attachi ng fasteners, then remove the control

arm.

3. Installation is a simple matter of bol ting the arm into place. Torque the 3

bolts at the body brace bracket to 35 ft. lbs. (47 Nm) and the nut at the

body bracket to 61 ft. lbs. (83 Nm).

TORQUE ARM

REMOVAL & INSTALLATION

The coil springs must be removed BEFORE the torque arm. If the torque arm is

removed first, vehicle damage will result. In order to proceed, the vehicle must

be supported in a manner whic h will allow the rear axle height to be adjusted

independently of the body height.

1. Remove the track bar mounting bolt at the axle assembly, then loosen

the track bar bolt at the body brace.

2. Disconnect the rear brake hose clip at the axle assembly, which will allow

additional drop of the axle.

3. Remove the lower attaching nuts from both rear shock absorbers.

4. Disconnect the shock absorbers from their lower attaching points.

Page 844 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 844

5. On models with four cylinder engines, remove the driveshaft.

6. Carefully lower the rear axle asse

mbly and remove the rear coil springs.

CAUTION - DO NOT overstretch the br ake hose when lowering the axle-

damage to the hose will result.

7. Remove the torque arm rear attaching bolts.

8. Remove the front torq ue arm outer bracket.

9. Remove the torque ar m from the vehicle.

To install: 10. Place the torque arm in position and loosely install the rear torque arm

bolts.

11. Install the front torque arm bracket and torque the nuts to 31 ft. lbs. (42

Nm).

12. Torque the rear torque arm nuts to 100 ft. lbs. (135 Nm).

13. Place the rear springs and insulators in position, then raise the rear axle

assembly until all of the weight is supported by the spring.

14. Attach the shock absorbers to the rear axle and torque the fasteners to

70 ft. lbs. (95 Nm).

15. Clean and reinstall the track bar mounting bolt at the axle. Torque the

bolt to 59 ft. lbs. (80 Nm).

16. Clean and reinstall the track bar-t o-body brace nut. Torque the nut to 78

ft. lbs. (105 Nm).

17. Install the brake line clip to the underbody.

18. On four cylinder models, reinstall the driveshaft.

19. Lower the vehicle.

Page 869 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 869

4. Remove Pitman arm using spec

ial tool J-6632 or its equal.

5. Remove the steering box to fram e bolts. Remove the steering box.

On vehicles with power steering, remo ve the fluid hoses and cap them to

prevent foreign material from entering the system.

To install:

6. Position the steering box and secure with the steering box-to-frame bolts.

7. Install the Pitman arm to the matchmarks made earlier.

8. Install the Pitman arm nut and washer.

9. Install the retaining bolts at the st eering coupling to steering shaft flange.

10. Install the coupling shield.

11. Connect the negative battery cable.

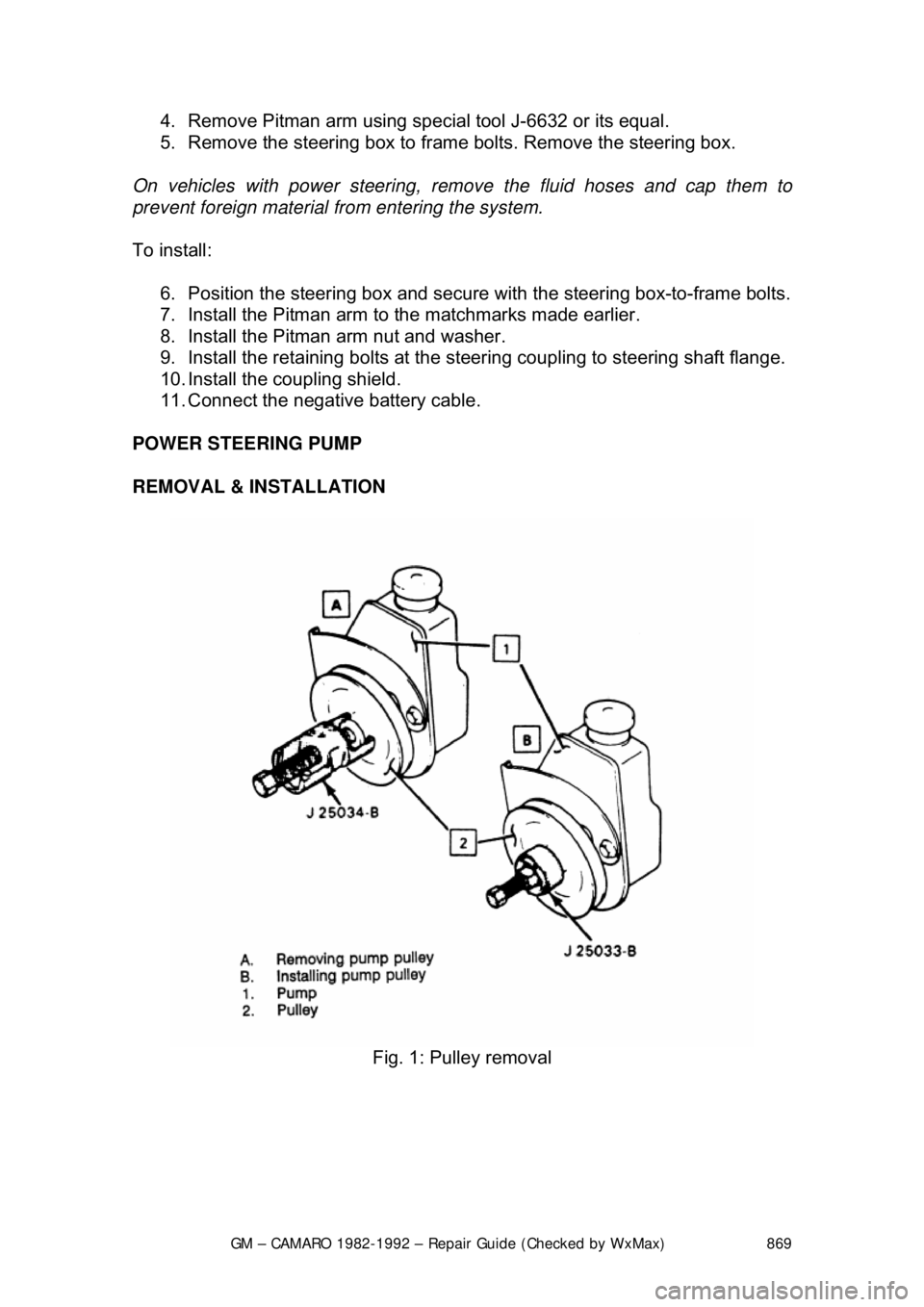

POWER STEERING PUMP

REMOVAL & INSTALLATION

Fig. 1: Pulley removal