automatic transmission CHEVROLET CAMARO 1982 Repair Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1982, Model line: CAMARO, Model: CHEVROLET CAMARO 1982Pages: 875, PDF Size: 88.64 MB

Page 661 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 661

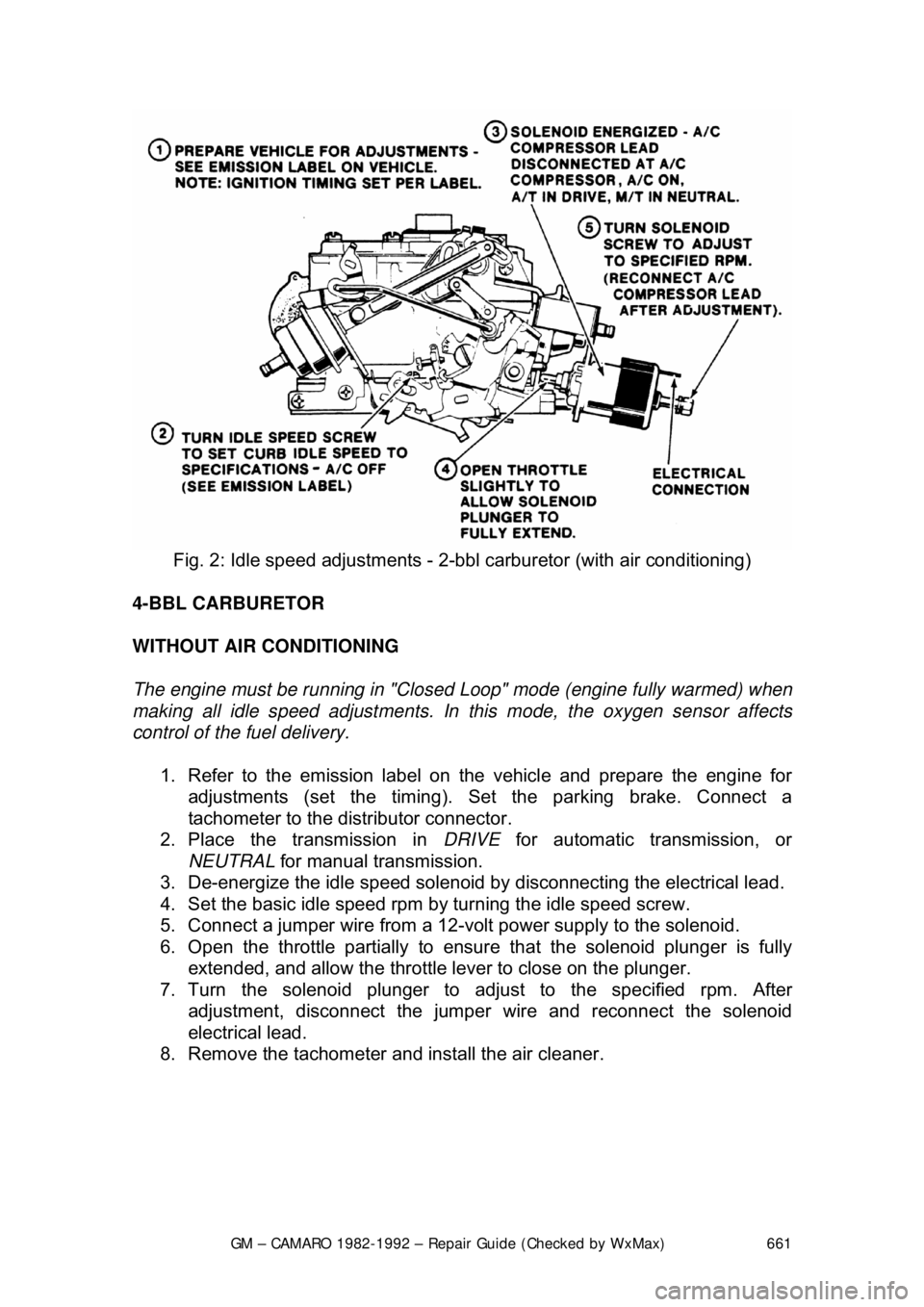

Fig. 2: Idle speed adjustm ents - 2-bbl carburetor (with air conditioning)

4-BBL CARBURETOR

WITHOUT AIR CONDITIONING

The engine must be running in "Closed Loop" mode (engine fully warmed) when

making all idle speed adjustments. In this mode, the oxygen sensor affects

control of the fuel delivery.

1. Refer to the emission label on the vehicle and prepare the engine for

adjustments (set the timing). Se t the parking brake. Connect a

tachometer to the dist ributor connector.

2. Place the transmission in DRIVE for automatic transmission, or

NEUTRAL for manual transmission.

3. De-energize the idle speed solenoid by disconnecting the electrical lead.

4. Set the basic idle speed rpm by turning the idle speed screw.

5. Connect a jumper wire from a 12-vo lt power supply to the solenoid.

6. Open the throttle partially to ensure that the solenoid plunger is fully

extended, and allow the throttle lever to close on the plunger.

7. Turn the solenoid plunger to adj ust to the specified rpm. After

adjustment, disconnect the jumper wire and reconnect the solenoid

electrical lead.

8. Remove the tachometer and install the air cleaner.

Page 662 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 662

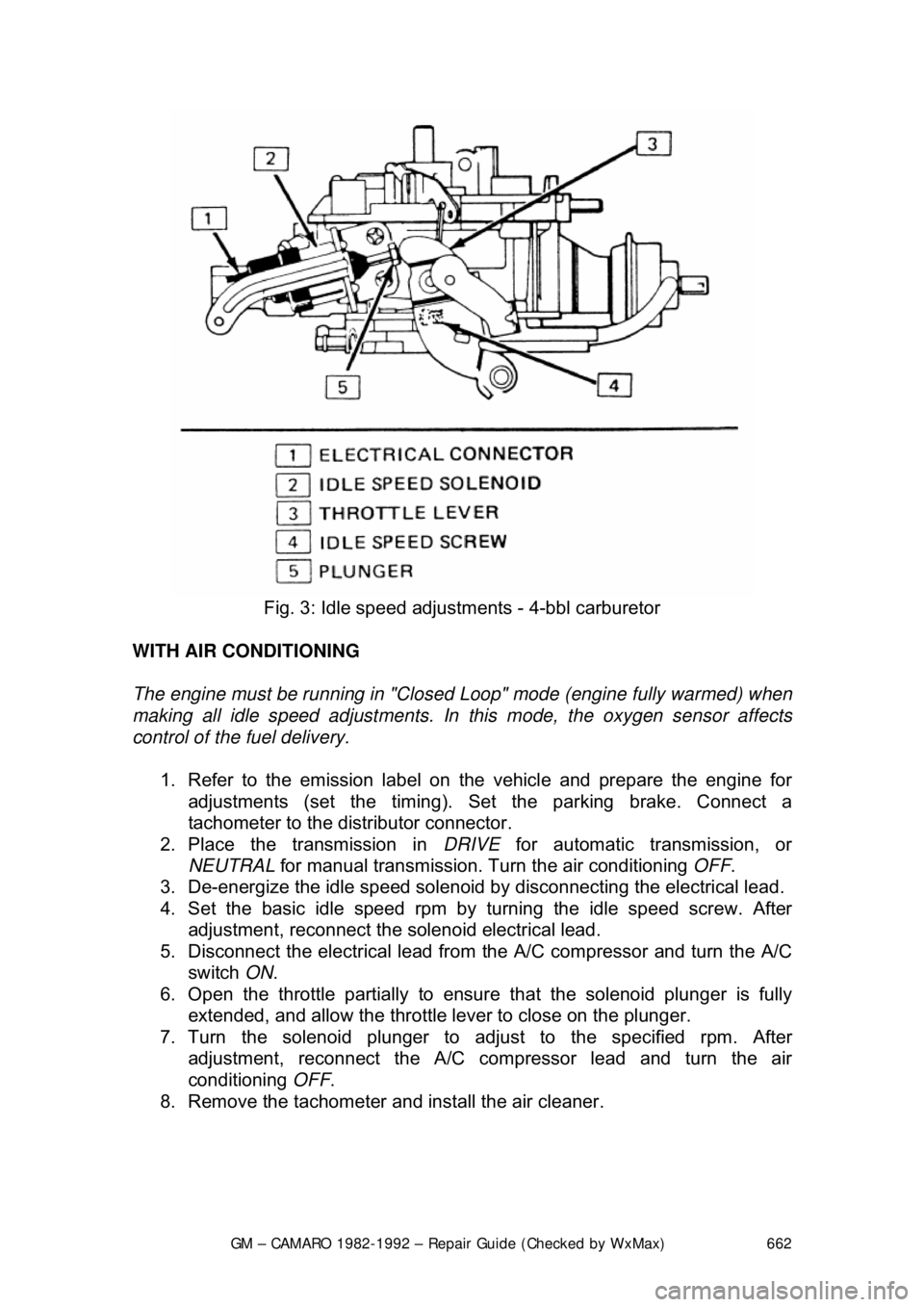

Fig. 3: Idle speed adjustm ents - 4-bbl carburetor

WITH AIR CONDITIONING

The engine must be running in "Closed Loop" mode (engine fully warmed) when

making all idle speed adjustments. In this mode, the oxygen sensor affects

control of the fuel delivery.

1. Refer to the emission label on the vehicle and prepare the engine for

adjustments (set the timing). Se t the parking brake. Connect a

tachometer to the dist ributor connector.

2. Place the transmission in DRIVE for automatic transmission, or

NEUTRAL for manual transmission. Tu rn the air conditioning OFF.

3. De-energize the idle speed solenoid by disconnecting the electrical lead.

4. Set the basic idle speed rpm by turning the idle speed screw. After

adjustment, reconnect the solenoid electrical lead.

5. Disconnect the electrical lead from the A/C compressor and turn the A/C

switch ON.

6. Open the throttle partially to ensure that the solenoid plunger is fully

extended, and allow the throttle lever to close on the plunger.

7. Turn the solenoid plunger to adj ust to the specified rpm. After

adjustment, reconnect the A/C co mpressor lead and turn the air

conditioning OFF.

8. Remove the tachometer and install the air cleaner.

Page 692 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 692

IDLE AIR VALVE

A cover is in place over t

he idle air bleed valve. Also , the access holes to the

idle mixture needles are s ealed with hardened plugs. This is done to seal the

factory settings, during original equipment production. These items are NOT to

be removed unless required for cleaning, part replacement, improper dwell

readings or if the System Performance Check indicates the carburetor is the

cause of the trouble.

ROCHESTER E4ME AND E4MC

1. With engine OFF, cover the internal bowl vents and inlet to bleed valve

and the carburetor air intakes with maski ng tape. This is done to prevent

metal chips from entering.

2. Carefully drill rivet head of idle air bleed cover, with 0.110 in. (2.8mm) drill bit.

3. Remove rivet head and all pieces of rivet.

4. Lift cover off air bleed valve and bl ow out any metal shavings, or use a

magnet to remove excess metal.

CAUTION - Always wear eye protection when using compressed air.

5. Remove masking tape.

6. Start engine and allow it to reac h normal operating temperature.

7. Disconnect the vacuum hose from t he canister purge valve and plug it.

8. While idling in D for automatic transmission or N for manual

transmission, slowly turn the valve c ounterclockwise or clockwise, until

the dwell reading varies within the 25-35 degree range, attempting to be

as close to 30 degrees as possible.

Perform this step carefully. The air bleed valve is very sensitive and should be

turned in

1/8 turn increments only.

9. If the dwell reading d oes not vary and is not within the 25-35 degree

range, it will be necessary to remove the plugs and to adjust the idle

mixture needles.

Page 716 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 716

INJECTOR REPLACEMENT

Use care in removing injectors to prev

ent damage to the electrical connector

pins on top of the injector, the fuel injector fuel filter and nozzle. The fuel injector

is serviced as a complete assembly on ly and should never be immersed in any

type of cleaner.

SINGLE INJECTOR UNITS 1. Relieve the fuel system pressure.

2. Remove the air cleaner.

3. Detach the injector connector by squeezing the two tabs together and

pulling straight up.

4. Remove the screws securing the fuel meter cover. Note the location of

any short screws for correct placement during reassembly.

CAUTION - DO NOT remove the four screws se curing the pressure regulator to

the fuel meter cover. The fuel pressure regulator includes a large spring under

heavy tension which could cause personal injury if released.

5. With the old fuel meter gasket in place to prevent damage to the casting,

use a prytool and fulcrum to pry the inje ctor carefully until it is free from

the fuel meter body.

6. Remove the injector.

7. Remove the large O-ring and steel back-up washer at the top of the

injector cavity in the fuel meter body.

8. Remove the small O-ring located at the bottom of the injector cavity.

To Install: 9. Lubricate the new, small O-ring with automatic transmission fluid; then,

push the new O-ring on the nozzle end of the injector up against the

injector fuel filter.

10. Install the steel backup washer in the recess of the fuel meter body.

Lubricate the new large O-ring with automatic transmission fluid, then

install the O-ring directly above t he backup washer, pressing the O-ring

down into the cavity recess. The O-ri ng is properly installed when it is

flush with the casting surface.

WARNING - Do not attempt to reverse this procedure and install the backup

washer and O-ring after the injector is located in the cavity. To do so will

prevent proper seating of the O-ring in th e cavity recess which could result in a

fuel leak and possible fire.

11. Install the injector by using a pushing/twisting mo tion to center the nozzle

O-ring in the bottom of the injector cavity and aligning the raised lug on

the injector base with the notch cast into the fuel meter body. Push down

on the injector making sure it is fully seated in the cavity. Injector

installation is correct when the lug is seated in the notch and the

electrical terminals are parallel to the throttle shaft.

Page 732 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 732

MINIMUM IDLE AND THROTTL

E VALVE SYNCHRONIZING

The throttle position of each throttle body must be balanced so that the throttle

plates are synchronized and open si multaneously. These adjustment

procedures must be followed AFTER performing the "Preliminary Adjustments".

1. Remove the air cleaner and plug the vacuum port on the rear TBI unit for

the thermostatic air cleaner.

2. Remove the tamper resistant pl ugs covering both unit throttle stop

screws, if necessary.

3. Block the drive wheels and apply the parking brake.

4. Connect a tachometer to measure rpm.

5. Start the engine and allo w the engine rpm to stabilize at normal operating

temperature.

6. Have a helper apply the brakes and place the transmission in DRIVE.

7. Plug the idle air pass ages of each throttle body with plugs (J-33047 or

equivalent). Make sure the plugs are seated fully in the passage so that

no air leaks exist. The engine rpm should decrease below curb idle

speed. If the engine rpm does not decreas e, check for a vacuum leak.

8. Remove the cap from the ported tube on the rear TBI unit and connect a

vacuum gauge or water manometer.

9. Adjust the rear unit throttle stop screw to obtain approximately

1/2 in. Hg

as read on the vacuum gauge, or 6 in. H

2O as read on the manometer. If

not able to adjust to this level, check that the front unit throttle stop is not

limiting throttle travel.

10. Remove the vacuum gauge or manometer from t he rear unit and install

the cap on the port ed vacuum tube.

11. Remove the cap from the ported va cuum tube on the front TBI unit and

install the gauge or manomet er as before. If the reading is not the same

as the rear unit, proceed as follows: a. Locate the throttle synchronizing screw and collar on the front TBI

unit. The screw may be welded to discourage tampering with this

adjustment. Break the weld, if ne cessary, and install a new screw

with a thread seali ng compound applied.

b. Adjust the screw to obtain approximately

1/2 in. Hg as read on the

vacuum gauge, or 6 in. H

2O on the manometer.

12. Remove the gauge or manometer fr om the ported tube and reinstall the

cap.

13. Adjust the rear throttle stop screw to obtain 475 rpm, with the

transmission in D and the parking brake applied. On manual

transmission models, leave the gear selector in N.

14. Turn the ignition OFF and pl ace automatic transmission in N.

15. Remove idle air passage plugs.

16. Start the engine. It may run at a high rpm but the engine speed should

decrease when the idle air control va lves close the air passages. Stop

the engine when the rpm decreases.

17. The throttle position sensor (TPS) voltage should be checked and adjusted, if necessary.

18. Connect the vacuum line to the TBI unit and install the air cleaner.

19. Reset the idle speed control motors by driving the vehicle to 45 mph.

Page 761 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 761

MAINTENANCE OR REPAIR?

Maintenance includes routine inspecti

ons, adjustments, and replacement of

parts which show signs of normal wear . Maintenance compensates for wear or

deterioration. Repair implies that someth ing has broken or is not working. A

need for a repair is often caused by lack of maintenance. for example: draining

and refilling automatic transmission fl uid is maintenance recommended at

specific intervals. Failure to do this can shorten the life of the

transmission/transaxle, requiring very expen sive repairs. While no maintenance

program can prevent items from eventually breaking or wearing out, a general

rule is true: MAINTENANCE IS CHEAPER THAN REPAIR.

Two basic mechanic's rules should be mentioned here. First, whenever the left

side of the vehicle or engine is refe rred to, it means the driver's side.

Conversely, the right side of the vehi cle means the passenger's side. Second,

screws and bolts are removed by turn ing counterclockwise, and tightened by

turning clockwise unless specifically noted.

Safety is always the most important rule. Constantly be aware of the dangers

involved in working on an automobile and take the proper precautions. Please

refer to the information in this se ction regarding SERVICING YOUR VEHICLE

SAFELY and the SAFETY NOTICE on the acknowledgment page.

AVOIDING THE MOST COMMON MISTAKES

Pay attention to the instructions prov ided. There are 3 common mistakes in

mechanical work:

1. Incorrect order of assembly, di sassembly or adjustment. When taking

something apart or putting it toget her, performing steps in the wrong

order usually just costs you ex tra time; however, it CAN break

something. Read the entire proc edure before beginning. Perform

everything in the order in which the instructions say you should, even if

you can't see a reason for it. When you' re taking apart something that is

very intricate, you might want to draw a picture of how it looks when

assembled in order to make sure you get everything back in its proper

position. When making adjustments, per form them in the proper order.

One adjustment possibly will affect another.

2. Overtorquing (or undertorquing). While it is more common for overtorquing to cause damage, undertorquing may allow a fastener to

vibrate loose causing serious dam age. Especially when dealing with

aluminum parts, pay attention to tor que specifications and utilize a torque

wrench in assembly. If a torque figure is not available, remember that if

you are using the right tool to perfo rm the job, you will probably not have

to strain yourself to get a fast ener tight enough. The pitch of most

threads is so slight that the te nsion you put on the wrench will be

multiplied many times in actual fo rce on what you are tightening.

There are many commercial products avai lable for ensuring that fasteners won't

come loose, even if they are not torqued just right (a very common brand is

Page 782 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 782

10. Refill the engine with the correct amount

of fresh oil. Please refer to the

Capacities chart at the end of this section.

11. Check the oil level on the dipstick. It is normal for the level to be a bit

above the full mark. Start the engine and allow it to idle for a few

minutes.

CAUTION - Do not run the engi ne above idle speed until it has built up oil

pressure, as indicated w hen the oil light goes out

12. Shut off the engine and allow the oil to flow back to the crankcase for a

minute, then recheck the oil level. C heck around the filter and drain plug

for any leaks, and correct as necessary.

MANUAL TRANSMISSIONS

FLUID RECOMMENDATIONS

• 1982-85 4-speed manual transmissi ons - SAE 80W/90 GL-5 gear

lubricant

• 1986-87 4-speed manual transmission - Dexron®®II automatic

transmission fluid

• 1982-84 5-speed manual transmissions - use SAE 80W/90 GL-5 gear

lubricant (SAE 80W GL-5 in Canada)

• 1985-92 5-speed manual transmissi ons - Dexron®II automatic

transmission fluid

LEVEL CHECK

The oil in the manual tr ansmission should be check ed every 12 months or

15,000 miles.

1. Raise the car and support on jackstands as close to level as possible. \

2. Remove the filler plug from the side of the transmission housing.

3. If lubricant begins to trickle out of the hole, there is enough and you need

not go any further. Otherwise, carefully insert your finger (watch out for

sharp threads) and check to see if the oil is up to the edge of the hol\

e.

4. If not, add oil through the hole until the level is at the edge of the hole.

Most lubricants come in a plasti c squeeze bottle with a nozzle; making

additions simple.

5. Install and tighten the filler plug.

DRAIN AND REFILL

The fluid in the manual transmission do es not require changing. If you do

choose to change the transmission fluid, the fluid can be drained out through

the lower drain plug hole on the side of the transmission. Fill the transmission

with the recommended lubricant to the bottom of the filler plug hole and install

the filler plug.

Page 783 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 783

AUTOMATIC TRANSMISSION

FLUID RECOMMENDATIONS

Use only Dexron®II Automati

c Transmission Fluid.

LEVEL CHECK

Fig. 1: Read automatic transmission flui d level on dipstick and add, as required

Check the automatic transmission fluid le vel at each oil change. Driving with too

much or too little transmission fluid ca n damage the transmission. The dipstick

can be found in the rear of the engine compartment. The fluid level should be

checked only when the transmission is at normal operating temperature. If your

Camaro has been driven at highway speeds fo r a long time, in city traffic in hot

weather, or pulling a trailer, wait for about 30 minutes for the fluid to cool down

so a correct reading can be read.

1. Park the car on a level surface, with the parking brake on. Start the

engine and let it idle for about 15 minutes. Move the transmission

through all the gears and then back to P.

2. Remove the dipstick and carefully touch the wet end of the dipstick to see if the fluid is cool, warm, or ho t. Wipe it clean and then reinsert it

firmly. Be sure that it has been pushed all the way in. Remove the

dipstick again and check the fluid leve l while holding it horizontally.

a. If fluid is cool (room temper ature), the level should be about

1/8-3/8

in. (3-10mm) below the ADD mark.

Page 784 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 784

b. If fluid is warm, the le

vel should be close to the ADD mark, either

above or below.

c. If fluid is too hot to touc h, the level should be at the FULL mark.

3. If the fluid level is low, add Dexr on®II automatic transmission fluid (ATF)

through the dipstick tube. This is eas ily done with the aid of a funnel.

Check the level often as you are f illing the transmission. Be extremely

careful not to overfill it. Overfilling will cause slippage, seal damage and

overheating. Approximately 1 pint (0.473L) of ATF will raise the fluid level

from one notch/line to the other.

If the fluid on the dipstick appears discolored (brown or black), or smells burnt,

serious transmission troubles, probably due to overheating, should be

suspected. The transmission should be inspected by a qualified technician to

locate the cause of the burnt fluid.

DRAIN AND REFILL

Please refer to the "PAN AND FILTER SERVICE" procedure listed in this

section.

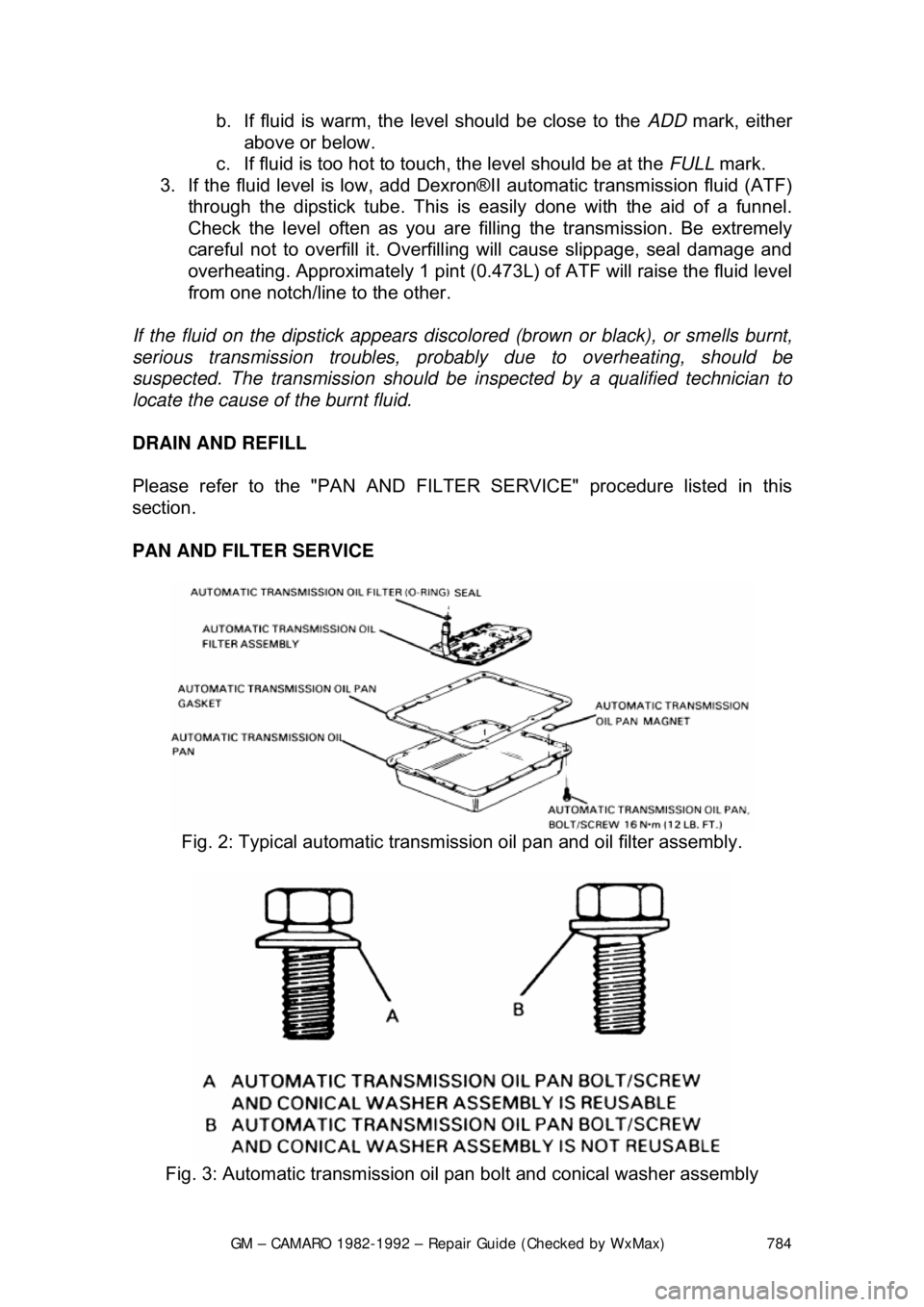

PAN AND FILTER SERVICE

Fig. 2: Typical automatic transmiss ion oil pan and oil filter assembly.

Fig. 3: Automatic transmission oil pan bolt and conical washer assembly

Page 785 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 785

The automatic transmission fluid and fi

lter should be changed every 15,000

miles (24,000km) if your Camaro is driven in heavy city traffic in hot weather, in

hilly or mountainous terrain, frequent trailer pulling, or uses such as found in

taxi, police car or delivery service. If your Camaro is driven under other than

listed above conditions, change the fl uid and filter every 30,000 miles

(48,300km).

1. Raise and support the car on jackst ands. Place an oil catch pan under

the transmission.

2. Remove the oil pan bolts fr om the front and sides only.

3. Loosen rear oil pan bolts approximately 4 turns.

WARNING - Do not damage the transmission case or oil pan sealing surfaces.

4. Lightly tap the oil pan with a rubber mallet or gently pry it downward to

allow fluid to drain.

5. Remove the remaining oil pan bolt s, then remove the oil pan and pan

gasket.

6. Remove the filter and seal.

7. Clean the transmission case and oi l pan gasket surfaces with suitable

solvent and air dry. Make sure to re move all traces of the old gasket.

To install: 8. Coat the seal with a sm all amount of Transjel®.

9. Install the new s eal onto the filter.

10. Install the new filter into the case.

11. Install the oil pan and new gasket.

On 1991 and later vehicles, inspect t he oil pan screws and washer assemblies.

The screws must not be used if the coni cal washer is reversed. Failure to

replace the screw and washer assembly may result in improper fastening of

system components.

12. Install the oil pan bolts and tighten them to 12 ft. lbs. (16 Nm).

13. Lower the car.

14. Fill the transmission to proper level with Dexron®II fluid.

15. Check cold fluid level reading fo r initial fill. Do not overfill the

transmission.

16. Follow the fluid level che ck procedure described before.

17. Check the oil pan gasket for leaks.