check engine light CHEVROLET CAMARO 1982 Repair Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1982, Model line: CAMARO, Model: CHEVROLET CAMARO 1982Pages: 875, PDF Size: 88.64 MB

Page 352 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 352

To prevent serious damage to the alte

rnator and the rest of the charging

system, the following precauti ons must be observed:

• Never reverse the battery connections.

• Booster batteries for starting must be connected properly: positive-to-

positive and negative-to-ground.

• Disconnect the battery cables before using a fast charger; the charger

has a tendency to force current through the diodes in the opposite

direction for which they were designed. This burns out the diodes.

• Never use a fast charger as a booster for starting the vehicle.

• Never disconnect the voltage regulator while the engine is running.

• Avoid long soldering times when replacing diodes or transistors.

Prolonged heat is damaging to AC alternators.

• Do not use test lamps of more t han 12 volts (V) for checking diode

continuity.

• Do not short across or ground any of the terminals on the AC alternator.

• The polarity of the battery, alter nator, and regulator must be matched

and considered before making any elec trical connections within the

system.

• Never operate the alternator on an open circuit. make sure that all

connections within the circ uit are clean and tight.

• Disconnect the battery terminals when performing any service on the

electrical system. This wil l eliminate the possibility of accidental reversal

of polarity.

• Disconnect the battery ground cable if arc welding is to be done on any

part of the car.

CHARGING SYSTEM TROUBLESHOOTING

There are many possible ways in whic h the charging system can malfunction.

Often the source of a problem is diffi cult to diagnose, requiring special

equipment and a good deal of experience. However, when the charging system

fails completely and causes the dash boar d warning light to come on or the

battery to become dead the following items may be checked:

1. The battery is known to be good and fully charged.

2. The alternator belt is in good condition and adjusted to the proper

tension.

3. All connections in t he system are clean and tight.

REMOVAL & INSTALLATION

Page 431 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 431

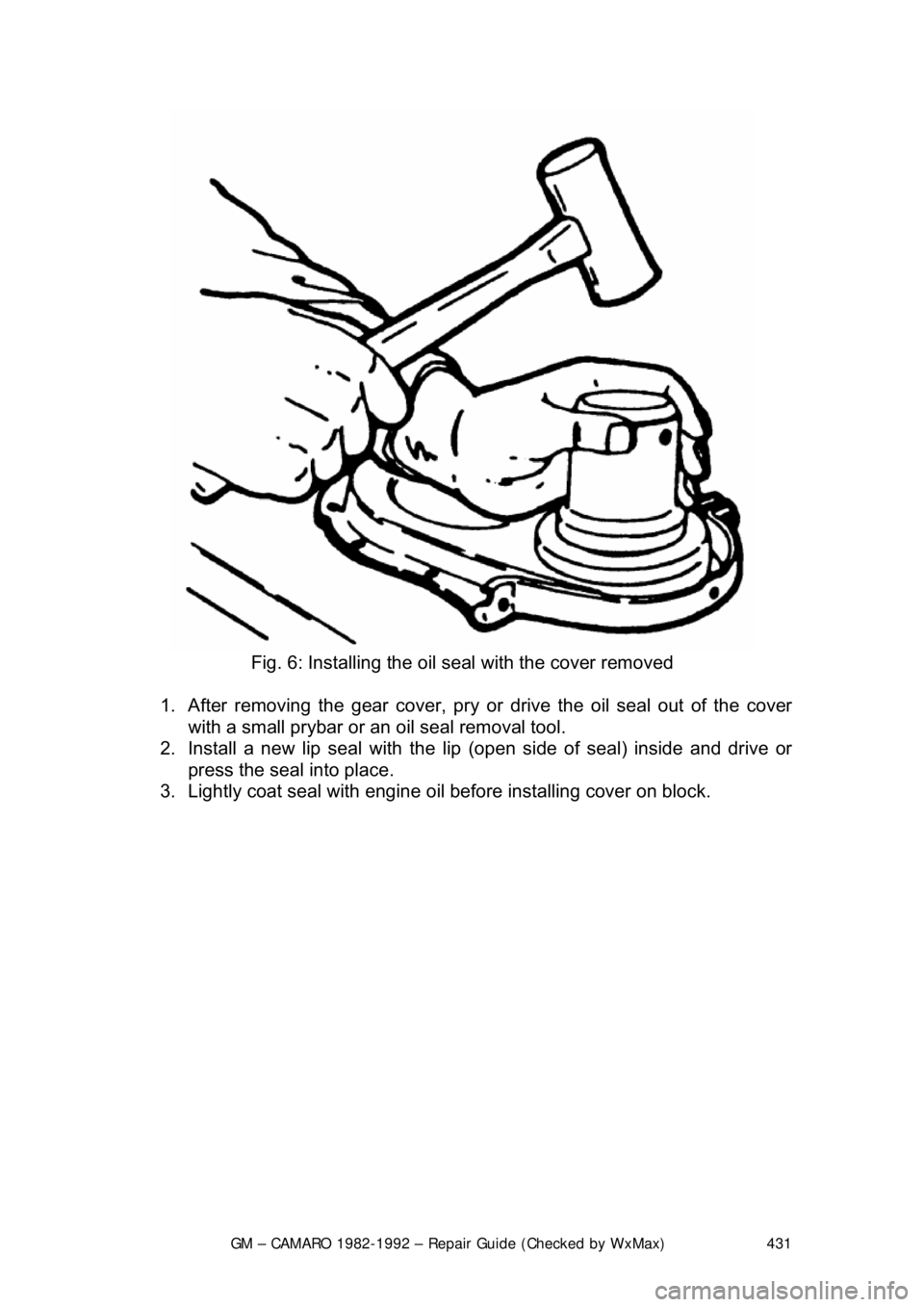

Fig. 6: Installing the oil seal with the cover removed

1. After removing the gear cover, pry or drive the oil seal out of the cover

with a small prybar or an oil seal removal tool.

2. Install a new lip seal with the lip (open side of seal) inside and drive or

press the seal into place.

3. Lightly coat seal with engine oil before installing cover on block.

Page 433 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 433

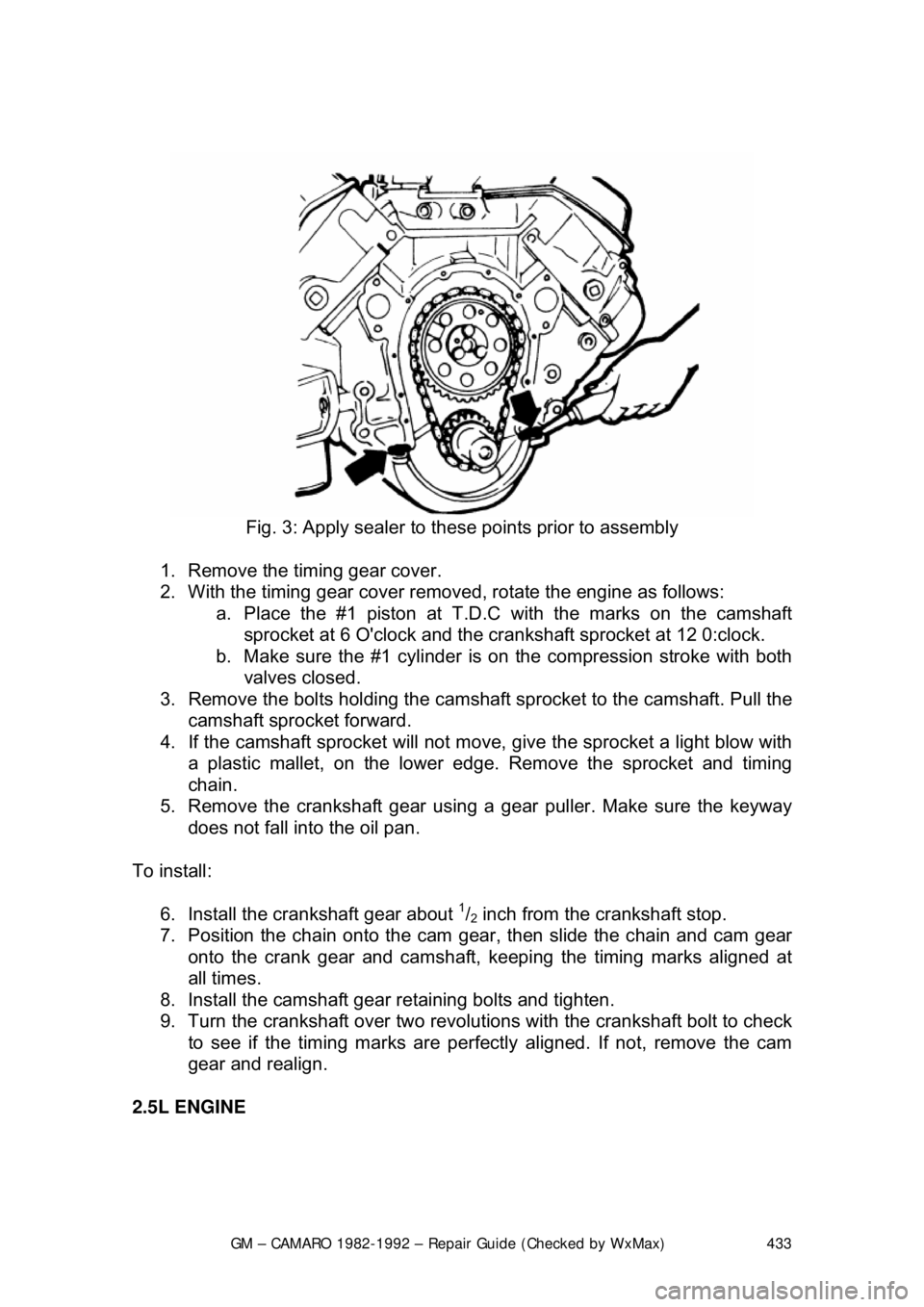

Fig. 3: Apply sealer to t hese points prior to assembly

1. Remove the timing gear cover.

2. With the timing gear cover remov ed, rotate the engine as follows:

a. Place the #1 piston at T.D. C with the marks on the camshaft

sprocket at 6 O'clock and the cranks haft sprocket at 12 0:clock.

b. Make sure the #1 cylinder is on the compression stroke with both

valves closed.

3. Remove the bolts holding the cams haft sprocket to the camshaft. Pull the

camshaft sprocket forward.

4. If the camshaft sprocket will not move, give the sprocket a light blow with

a plastic mallet, on the lower edge. Remove the sprocket and timing

chain.

5. Remove the crankshaft gear using a gear puller. Make sure the keyway

does not fall into the oil pan.

To install: 6. Install the crankshaft gear about

1/2 inch from the crankshaft stop.

7. Position the chain onto the cam gear, then slide the chain and cam gear

onto the crank gear and camshaft, keepi ng the timing marks aligned at

all times.

8. Install the camshaft gear retaining bolts and tighten.

9. Turn the crankshaft over two revolutions with the crankshaft bolt to check to see if the timing marks are perfectly aligned. If not, remove the cam

gear and realign.

2.5L ENGINE

Page 453 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 453

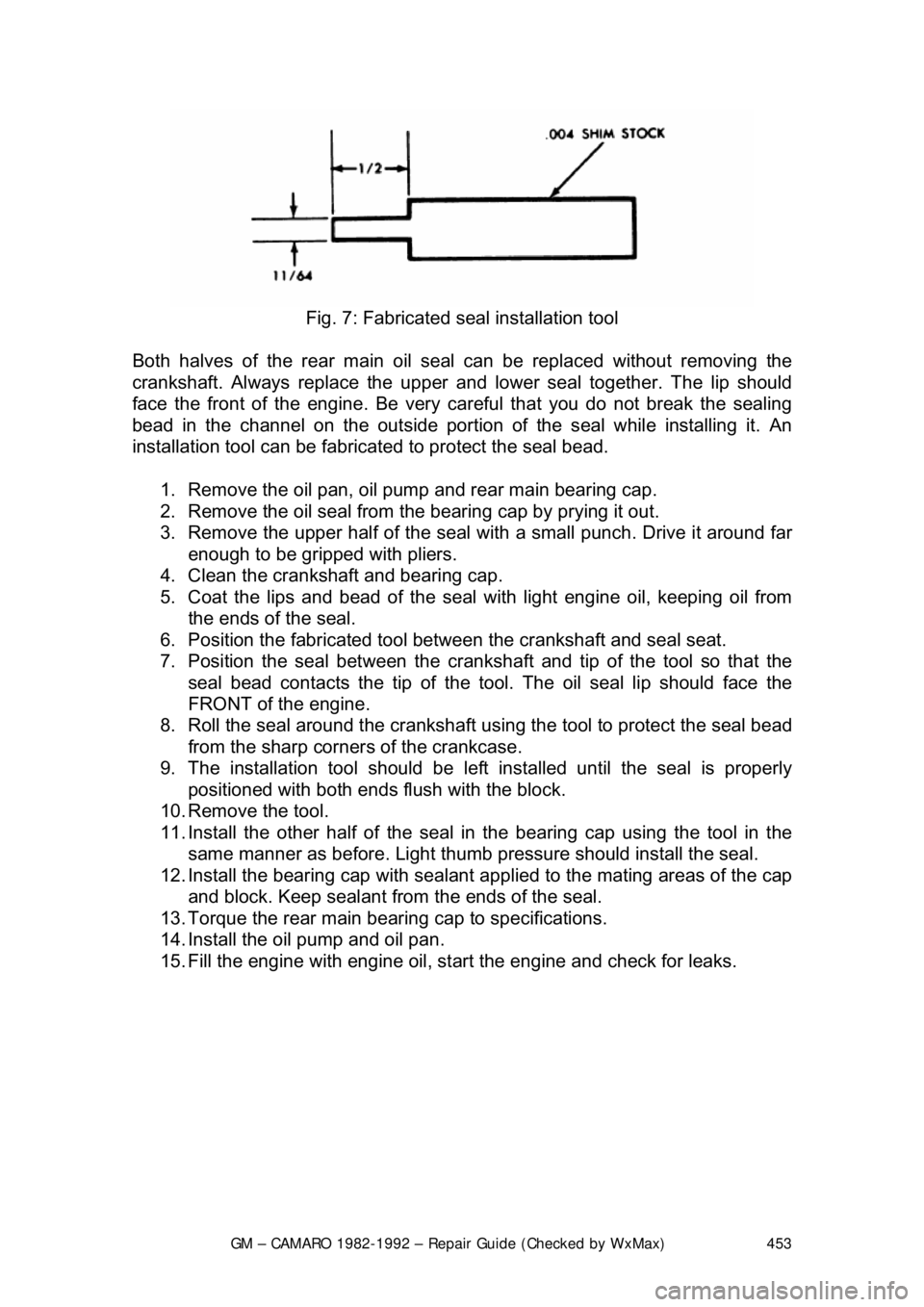

Fig. 7: Fabricated s eal installation tool

Both halves of the rear main oil s eal can be replaced without removing the

crankshaft. Always replace the upper and lower seal together. The lip should

face the front of the engine. Be very ca reful that you do not break the sealing

bead in the channel on the out side portion of the seal while installing it. An

installation tool can be fabricat ed to protect the seal bead.

1. Remove the oil pan, oil pump and rear main bearing cap.

2. Remove the oil seal from the bearing cap by prying it out.

3. Remove the upper half of the seal wit h a small punch. Drive it around far

enough to be gripped with pliers.

4. Clean the crankshaft and bearing cap.

5. Coat the lips and bead of the seal with light engine oil, keeping oil from

the ends of the seal.

6. Position the fabricated tool bet ween the crankshaft and seal seat.

7. Position the seal between the cranks haft and tip of the tool so that the

seal bead contacts the ti p of the tool. The oil seal lip should face the

FRONT of the engine.

8. Roll the seal around the crankshaft us ing the tool to protect the seal bead

from the sharp corner s of the crankcase.

9. The installation tool should be le ft installed until the seal is properly

positioned with both ends fl ush with the block.

10. Remove the tool.

11. Install the other half of the seal in the bearing cap using the tool in the

same manner as before. Light thumb pressure should install the seal.

12. Install the bearing cap with sealant applied to the mating areas of the cap

and block. Keep sealant from the ends of the seal.

13. Torque the rear main bear ing cap to specifications.

14. Install the oil pump and oil pan.

15. Fill the engine with engine oil, st art the engine and check for leaks.

Page 465 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 465

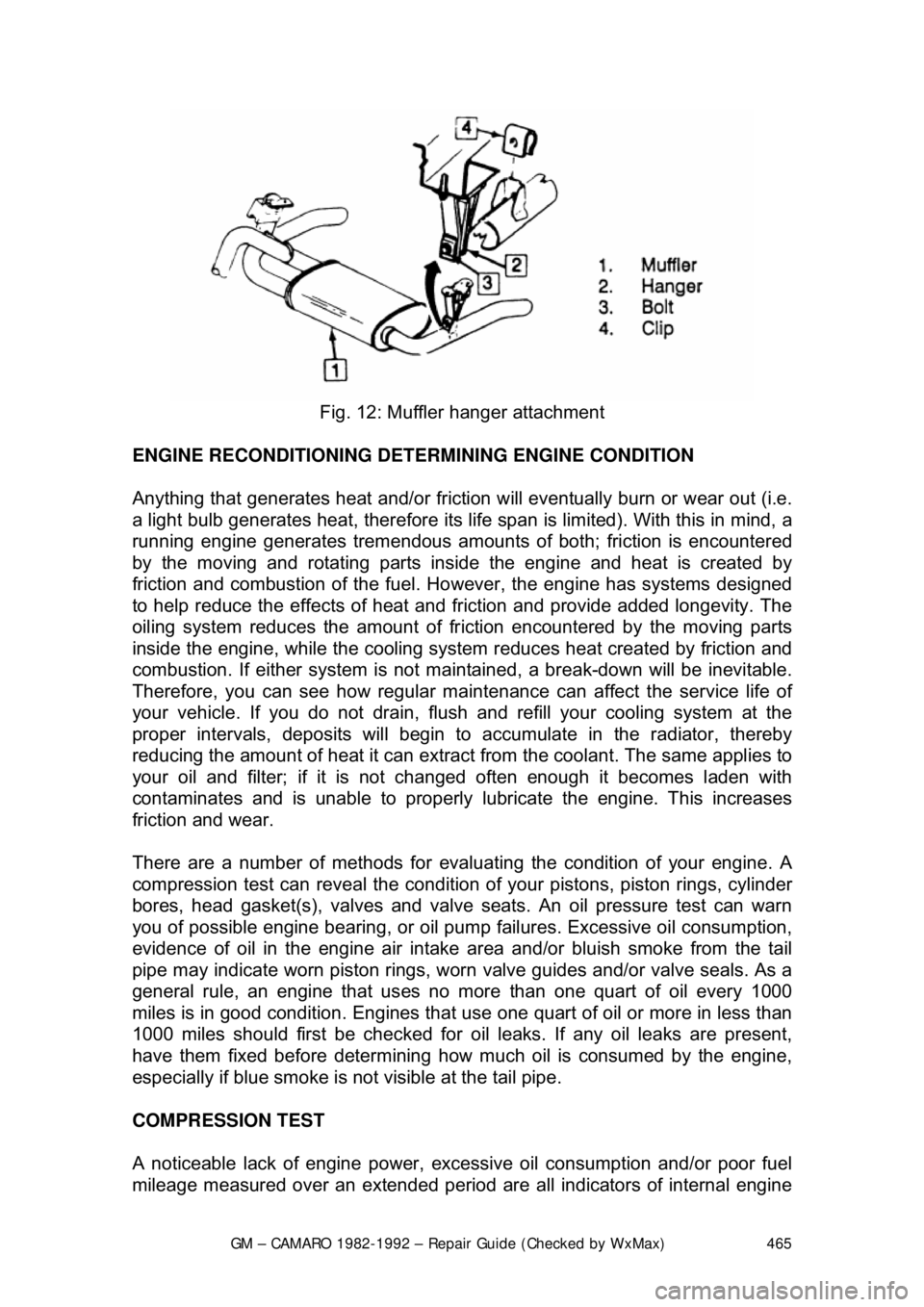

Fig. 12: Muffler hanger attachment

ENGINE RECONDITIONING DETE RMINING ENGINE CONDITION

Anything that generates heat and/or friction will eventually burn or wear out (i.e.

a light bulb generates heat, therefore its life span is limited). With this in mind, a

running engine generates trem endous amounts of both; friction is encountered

by the moving and rotating parts inside the engine and heat is created b\

y

friction and combustion of the fuel. Ho wever, the engine has systems designed

to help reduce the effects of heat and fr iction and provide added longevity. The

oiling system reduces the amount of fr iction encountered by the moving parts

inside the engine, while the cooling system reduces heat created by friction and

combustion. If either system is not main tained, a break-down will be inevitable.

Therefore, you can see how regular main tenance can affect the service life of

your vehicle. If you do not drain, flush and refill your cooling system at the

proper intervals, deposits will begin to accumulate in the radiator, thereby

reducing the amount of heat it can extrac t from the coolant. The same applies to

your oil and filter; if it is not changed often enoug h it becomes laden with

contaminates and is unable to properly lubricate the engine. This increases

friction and wear.

There are a number of methods for evaluat ing the condition of your engine. A

compression test can reveal the condition of your pistons, piston rings, cylinder

bores, head gasket(s), valves and valve seat s. An oil pressure test can warn

you of possible engine bearing, or oil pump failures. Excessive oil consumption,

evidence of oil in the engine air intake area and/or bluish smoke from the tail

pipe may indicate worn piston rings, worn valve guides and/or valve seals. As a

general rule, an engine that uses no more than one quart of oil every 1000

miles is in good condi tion. Engines that use one quart of oil or more in less than

1000 miles should first be checked for oil leaks. If any oil leaks are present,

have them fixed before dete rmining how much oil is consumed by the engine,

especially if blue smoke is not visible at the tail pipe.

COMPRESSION TEST

A noticeable lack of engine power, excessive oil consumption and/or poor fuel

mileage measured over an extended period are all indicators of internal engine

Page 466 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 466

wear. Worn piston rings, scored or wo

rn cylinder bores, blown head gaskets,

sticking or burnt valves, and worn valve seats are all possible culprits. A check

of each cylinder's compression will help locate the problem.

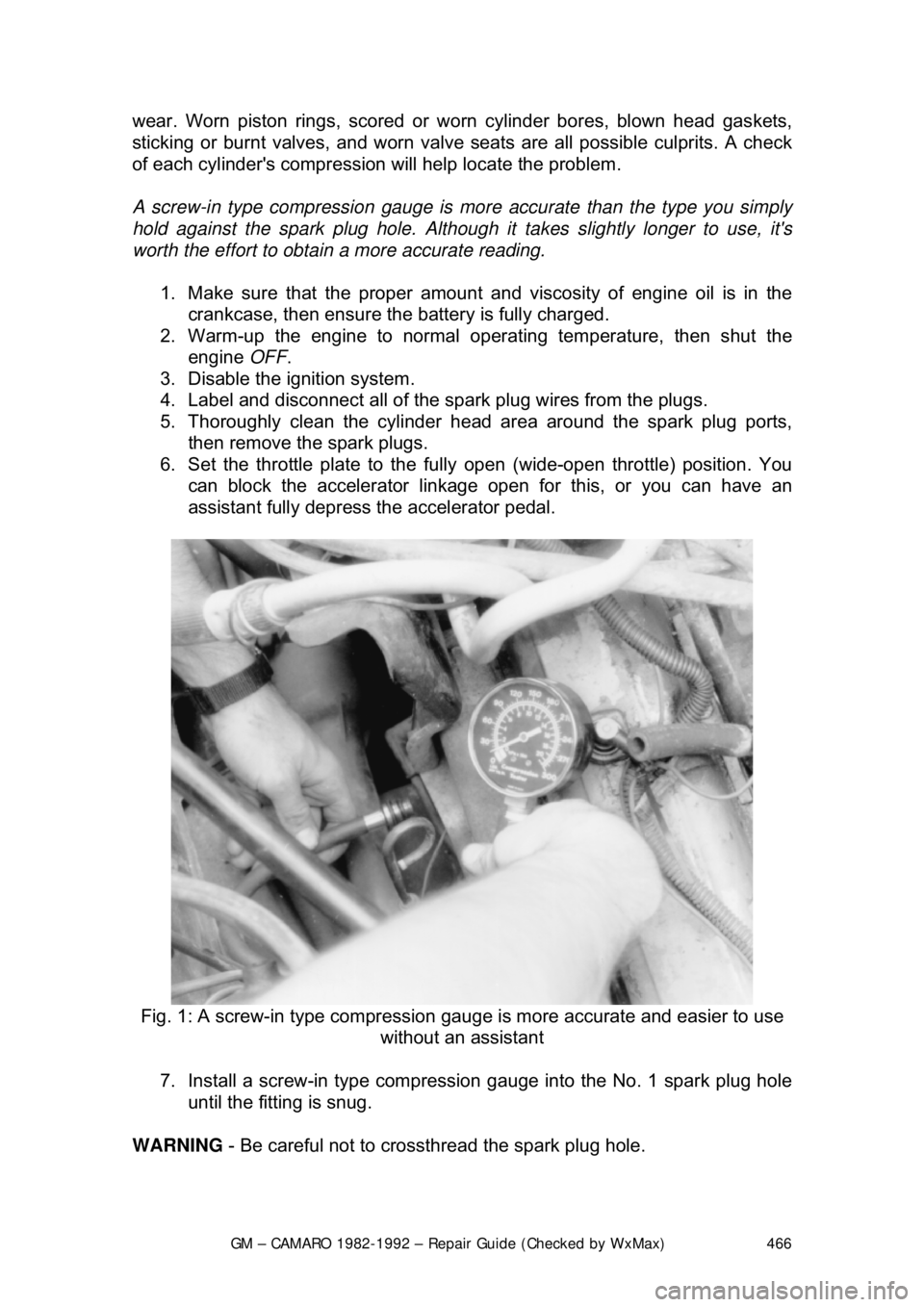

A screw-in type compression gauge is more accurate than the type you simply

hold against the spark plug hole. Although it takes slightly longer to use, it's

worth the effort to obtain a more accurate reading.

1. Make sure that the proper amount and viscosity of engine oil is in the

crankcase, then ensure the battery is fully charged.

2. Warm-up the engine to normal operat ing temperature, then shut the

engine OFF.

3. Disable the ignition system.

4. Label and disconnect all of the spark plug wires from the plugs.

5. Thoroughly clean the cylinder h ead area around the spark plug ports,

then remove the spark plugs.

6. Set the throttle plate to the fully open (wide-open throttle) position. You

can block the accelerator linkage open for this, or you can have an

assistant fully depress the accelerator pedal.

Fig. 1: A screw-in type compression gauge is more accurate and easier to use

without an assistant

7. Install a screw-in type compression gauge into the No. 1 spark plug hole

until the fitting is snug.

WARNING - Be careful not to crossthread the spark plug hole.

Page 470 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 470

•

Never hot tank aluminum parts (the c austic hot tank solution will eat the

aluminum.

• Remove all aluminum parts (identif ication tag, etc.) from engine parts

prior to the tanking.

• Always coat threads lightly with engine oil or anti-seize compounds

before installation, to prevent seizure.

• Never overtighten bolts or spark plugs especially in aluminum threads.

When assembling the engine, any parts that will be exposed to frictional contact

must be prelubed to provide lubricatio n at initial start-up. Any product

specifically formulated for this purpos e can be used, but engine oil is not

recommended as a prelube in most cases.

When semi-permanent (locked, but removabl e) installation of bolts or nuts is

desired, threads should be cleaned and coat ed with Loctite® or another similar,

commercial non-hardening sealant.

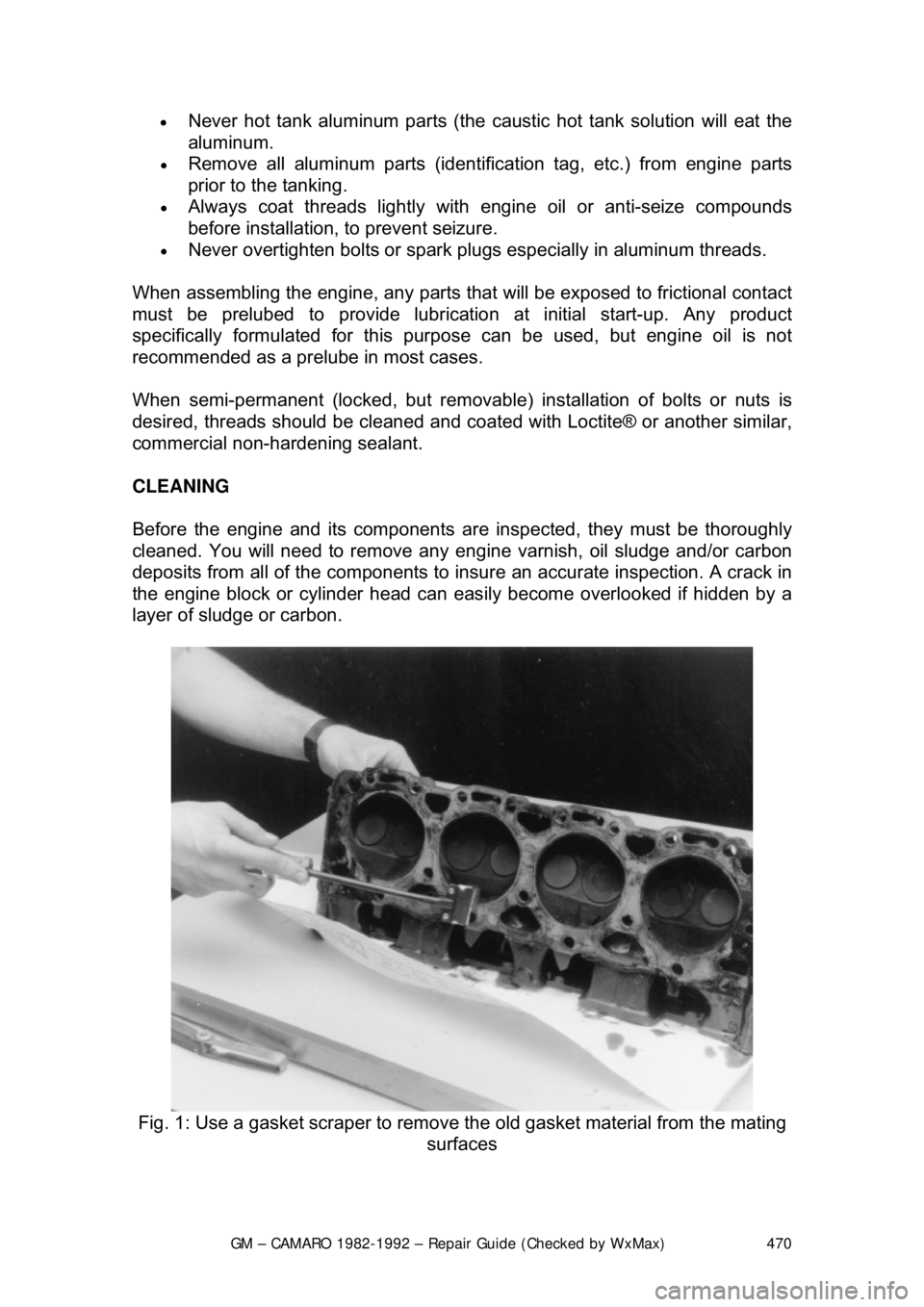

CLEANING

Before the engine and its components ar e inspected, they must be thoroughly

cleaned. You will need to remove any eng ine varnish, oil sludge and/or carbon

deposits from all of the com ponents to insure an accurate inspection. A crack in

the engine block or cylinder head can eas ily become overlooked if hidden by a

layer of sludge or carbon.

Fig. 1: Use a gasket scraper to remove t he old gasket material from the mating

surfaces

Page 477 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 477

Most cylinder heads these days are made of

an aluminum alloy due to its light

weight, durability and heat transfer qualit ies. However, cast iron was the

material of choice in the past, and is st ill used on many vehicles today. Whether

made from aluminum or iron, all cylinder heads hav e valves and seats. Some

use two valves per cylinder, while the more hi-tech engines will utilize a multi-

valve configuration using 3, 4 and

even 5 valves per cylinder. When the va lve contacts the seat, it does so on

precision machined surfaces, which seal s the combustion chamber. All cylinder

heads have a valve guide for each valve. The guide centers the valve to the

seat and allows it to move up and down within it. The clearance between the

valve and guide can be critical. Too much clearance and the engine may

consume oil, lose vacuum and/or damage the seat. Too little, and the valve can

stick in the guide causing t he engine to run poorly if at all, and possibly causing

severe damage. The last component all cylinder heads have are valve springs.

The spring holds the valve against its s eat. It also returns the valve to this

position when the valve has been opened by the valve train or camshaft. The

spring is fastened to the valve by a retainer and valve locks (sometime\

s called

keepers). Aluminum heads will also have a valve spring shim to keep the spring

from wearing away the aluminum.

An ideal method of rebuilding the cylin der head would involve replacing all of

the valves, guides, seats, springs, et c. with new ones. However, depending on

how the engine was maintained, often this is not necessary. A major cause of

valve, guide and seat wear is an improperly tuned engine. An engine that is

running too rich, will often wash the lubric ating oil out of the guide with gasoline,

causing it to wear rapidly. Conversely, an engine which is running too lean will

place higher combustion temperatures on the valves and seats allowing them to

wear or even burn. Springs fall victim to the driving habits of the individual. A

driver who often runs the engine rpm to the redline will wear out or break the

springs faster then one that stays well below it. Unfortunately, mileage takes it

toll on all of the parts. G enerally, the valves, guides, springs and seats in a

cylinder head can be machined and re-used, saving you money. However, if a

valve is burnt, it may be wise to replace all of the valves, since they were all

operating in the same environment. The same goes for any other component\

on

the cylinder head. Think of it as an insurance policy against future problems

related to that component.

Unfortunately, the only way to find out wh ich components need replacing, is to

disassemble and carefully check each piece. After the cylinder head(s) are

disassembled, thoroughly clean all of the components.

DISASSEMBLY

Before disassembling the cylinder head, you may want to fabricate some

containers to hold the various parts, as some of them can be quite small (such

as keepers) and easily lost. Also keeping yourself and the components

organized will aid in assembly and reduce confusion. Where possible, try to

maintain a components original location; th is is especially important if there is

not going to be any machine work performed on the components.

Page 482 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 482

If you do not have access to the proper

tools, you may want to bring the

components to a shop that does.

VALVES

The first thing to inspect are the valve heads. Look closely at the head, margin

and face for any cracks, excessive wear or burning. The margin is the best

place to look for burning. It should have a squared edge with an even width all

around the diameter. When a valve burns, the margin will look melted and the

edges rounded. Also inspect the valve head for any signs of tulipping. This will

show as a lifting of the edges or dishi ng in the center of the head and will

usually not occur to all of the valves. All of the heads should look the same, any

that seem dished more t han others are probably bad. Next, inspect the valve

lock grooves and valve tips. Check fo r any burrs around the lock grooves,

especially if you had to file them to remove the valve. Valve tips should appear

flat, although slight rounding with high mile age engines is normal. Slightly worn

valve tips will need to be machined flat. Last, measure the valve stem diameter

with the micrometer. Measure the area that rides within the guide, especially

towards the tip where most of the wear occurs. Take several measurements

along its length and compare them to each other. Wear should be even along

the length with little to no taper. If no minimum diameter is given in the

specifications, then the stem should not read more than 0.001 in. (0.025mm)

below the specification. Any valves that fail these inspections should be

replaced.

Fig. 7: Valve stems may be rolled on a flat surface to check for bends

Page 487 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 487

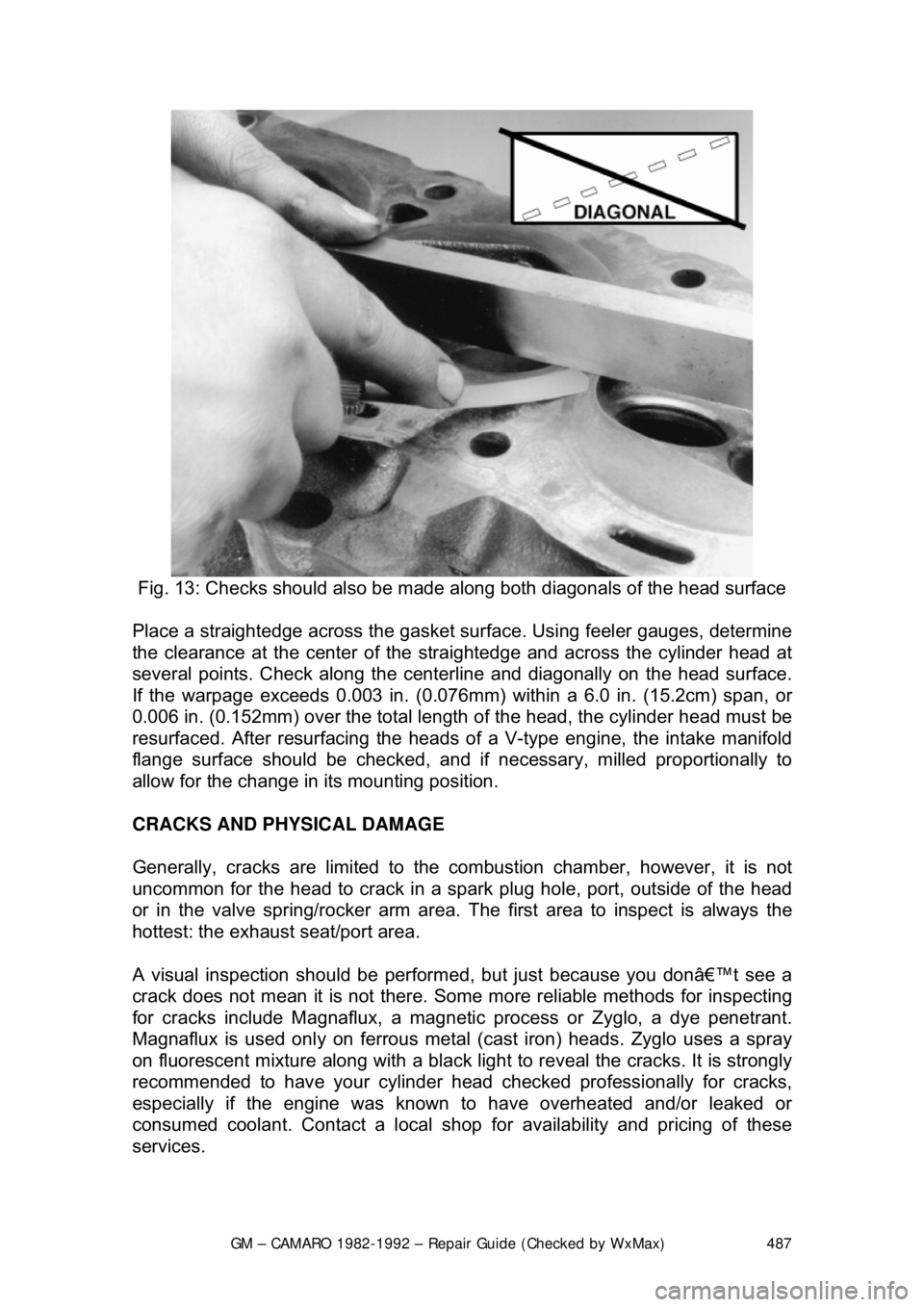

Fig. 13: Checks should also be made al ong both diagonals of the head surface

Place a straightedge across the gasket surf ace. Using feeler gauges, determine

the clearance at the cent er of the straightedge and across the cylinder head at

several points. Check along the centerli ne and diagonally on the head surface.

If the warpage exceeds 0.003 in. (0.076mm) within a 6.0 in. (15.2cm) span, or

0.006 in. (0.152mm) over the total length of the head, the cylinder head must be

resurfaced. After resurfacing the heads of a V-type engine, the intake manifold

flange surface should be checked, and if necessary, milled proportionally to

allow for the change in its mounting position.

CRACKS AND PHYSICAL DAMAGE

Generally, cracks are limited to the comb ustion chamber, however, it is not

uncommon for the head to crack in a s park plug hole, port, outside of the head

or in the valve spring/rocker arm area. The first area to inspect is always the

hottest: the exhaust seat/port area.

A visual inspection should be perform ed, but just because you don’t see a

crack does not mean it is not there. Some more reliable methods for inspecting

for cracks include Magnaflux, a magnetic process or Zyglo, a dye penetrant.

Magnaflux is used onl y on ferrous metal (cast iron) heads. Zyglo uses a spray

on fluorescent mixture along with a black light to reveal the cracks. It is strongly

recommended to have your cylinder head c hecked professionally for cracks,

especially if the engine was known to have overheated and/or leaked or

consumed coolant. Contact a local shop fo r availability and pricing of these

services.