check engine light CHEVROLET CAMARO 1982 Repair Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1982, Model line: CAMARO, Model: CHEVROLET CAMARO 1982Pages: 875, PDF Size: 88.64 MB

Page 660 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 660

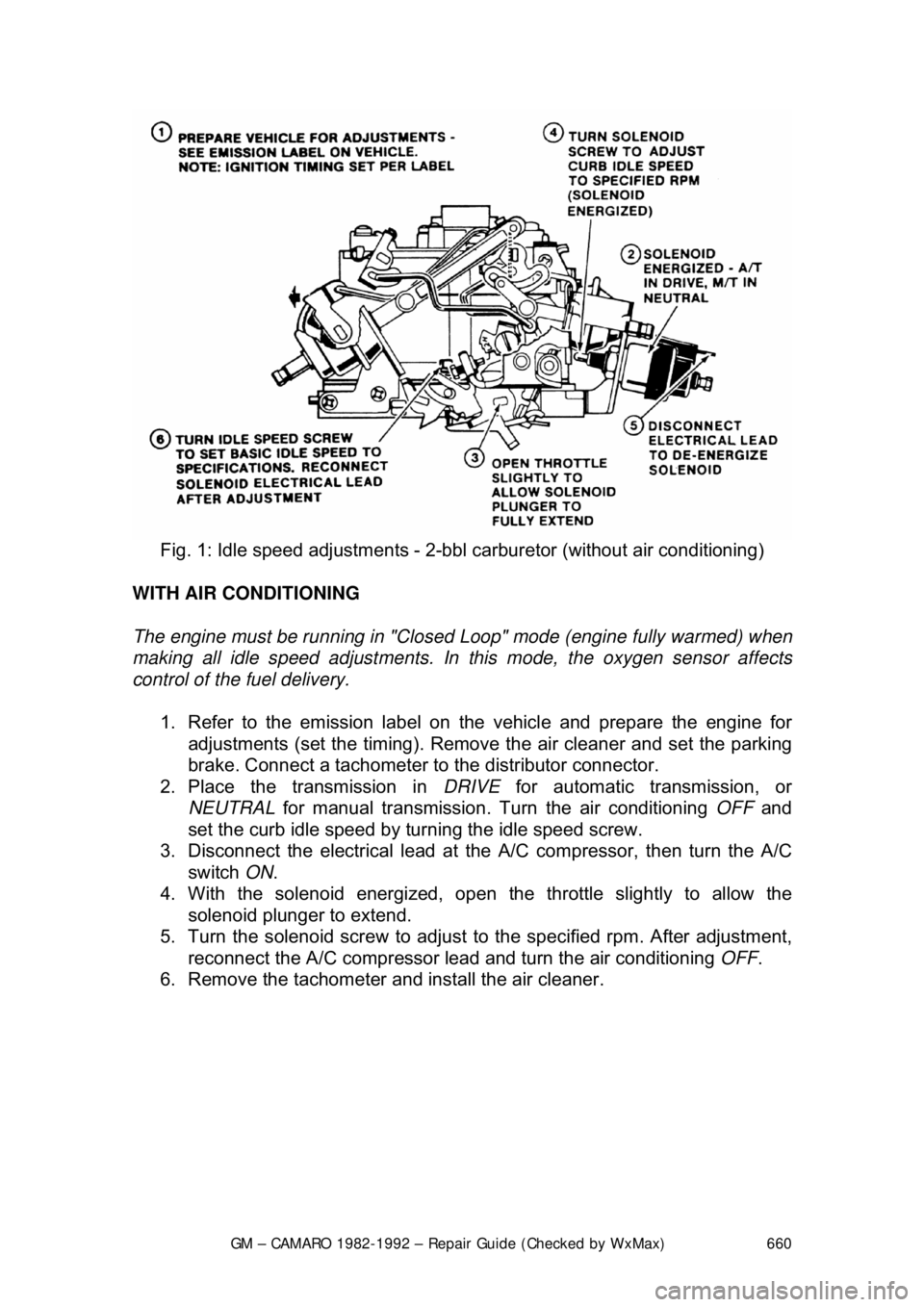

Fig. 1: Idle speed adjustm ents - 2-bbl carburetor (without air conditioning)

WITH AIR CONDITIONING

The engine must be running in "Closed Loop" mode (engine fully warmed) when

making all idle speed adjustments. In this mode, the oxygen sensor affects

control of the fuel delivery.

1. Refer to the emission label on the vehicle and prepare the engine for

adjustments (set the timing). Remove the air cleaner and set the parking

brake. Connect a tachometer to the distributor connector.

2. Place the transmission in DRIVE for automatic transmission, or

NEUTRAL for manual transmission. Tu rn the air conditioning OFF and

set the curb idle speed by turning the idle speed screw.

3. Disconnect the electrical lead at the A/C compressor, then turn the A/C

switch ON.

4. With the solenoid e nergized, open the throttle slightly to allow the

solenoid plunger to extend.

5. Turn the solenoid screw to adjust to the specified rpm. After adjustment,

reconnect the A/C compressor lead and turn the air conditioning OFF.

6. Remove the tachometer and install the air cleaner.

Page 670 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 670

the idle speed or mixture,

adjust the idle and mixture again when you are

finished.

Before you make any carburetor adjustment s make sure that the engine is in

tune. Many problems which are thought to be carburetor related can be traced

to an engine which is simply out-of-tune. Any trouble in these areas will have

symptoms like those of carburetor problems.

ADJUSTMENTS

FAST IDLE

ROCHESTER E2SE 1. Refer to the emission label and pr epare the vehicle for adjustment.

2. Place the fast idle screw on the highest step of the fast idle cam.

3. Turn the fast idle screw to obtain the fast idle speed.

ROCHESTER E4ME AND E4MC

The fast idle adjustment must be perform ed according to the directions of the

emissions label.

FLOAT AND FUEL LEVEL

ROCHESTER E2SE

1. Remove the air horn and gasket.

2. While holding the retainer in place, push the float down lightly against the

needle.

3. Place a measuring gauge on the float at the farthest point from the float

hinge.

4. To adjust, remove the float and bend the arm up or down. Also check the

float alignment.

5. Install the air horn and gasket.

Page 688 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 688

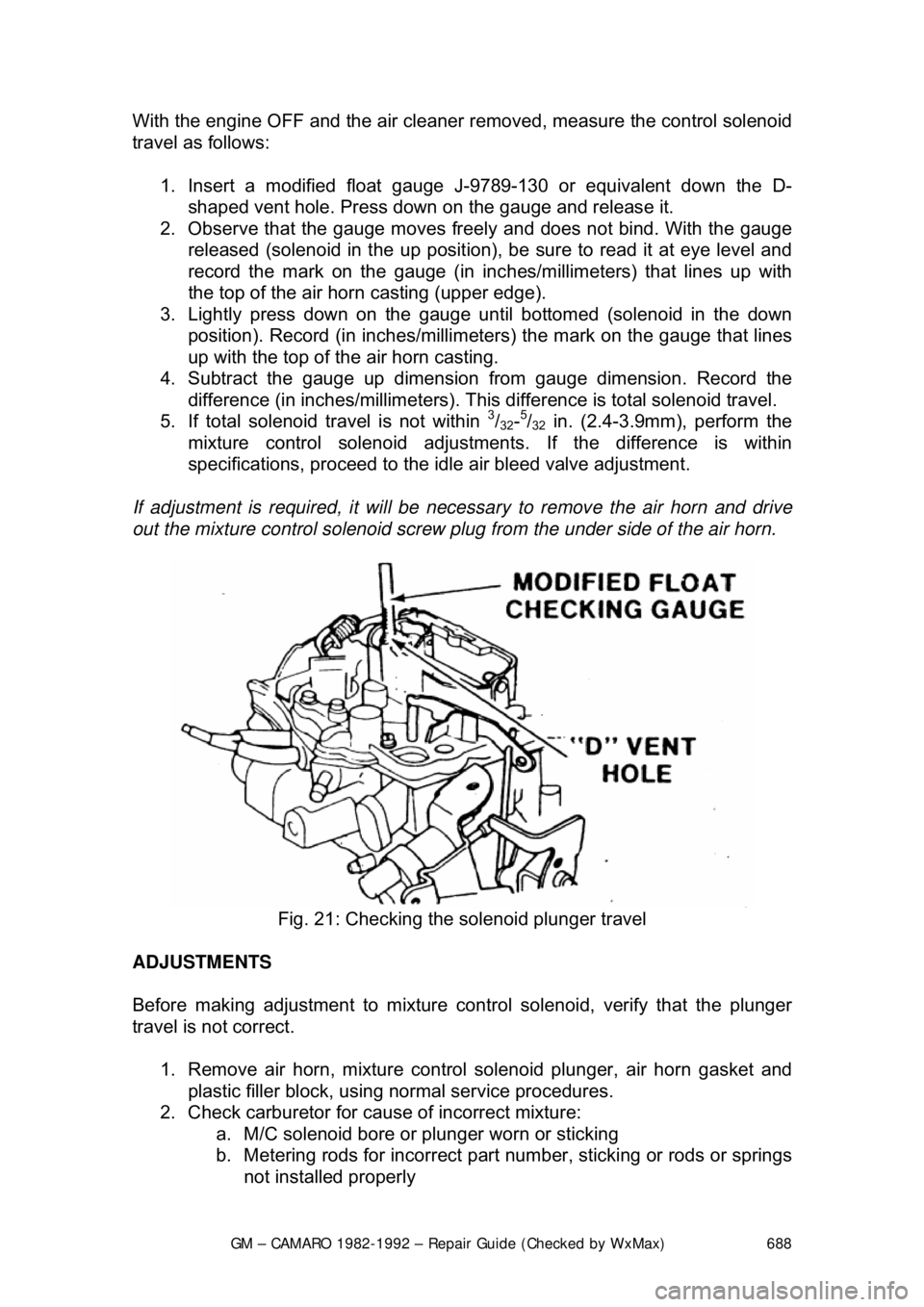

With the engine OFF and the air cleaner re

moved, measure the control solenoid

travel as follows:

1. Insert a modified float gauge J- 9789-130 or equivalent down the D-

shaped vent hole. Press down on the gauge and release it.

2. Observe that the gauge moves freel y and does not bind. With the gauge

released (solenoid in the up position), be sure to read it at eye level and

record the mark on the gauge (in inc hes/millimeters) that lines up with

the top of the air hor n casting (upper edge).

3. Lightly press down on the gauge until bottomed (solenoid in the down

position). Record (in inches/millimeters) the mark on the gauge that lines

up with the top of the air horn casting.

4. Subtract the gauge up dimension from gauge dimension. Record the

difference (in inches/millimet ers). This difference is total solenoid travel.

5. If total solenoid travel is not within

3/32-5/32 in. (2.4-3.9mm), perform the

mixture control solenoid adjustment s. If the difference is within

specifications, proceed to the id le air bleed valve adjustment.

If adjustment is required, it will be necessary to remove the air horn and drive

out the mixture control solenoid screw pl ug from the under side of the air horn.

Fig. 21: Checking the solenoid plunger travel

ADJUSTMENTS

Before making adjustment to mixture cont rol solenoid, verify that the plunger

travel is not correct.

1. Remove air horn, mixture control solenoid plunger, air horn gasket and

plastic filler block, using normal service procedures.

2. Check carburetor for caus e of incorrect mixture:

a. M/C solenoid bore or plunger worn or sticking

b. Metering rods for incorrect part number, sticking or rods or springs

not installed properly

Page 694 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 694

IDLE MIXTURE

E2SE CARBURETORS

1. Remove the carburet or from the engine.

2. Remove the plugs coveri ng the idle mixture needles.

3. Turn the mixture needle in until slight ly seated, then back it out 4 turns.

4. If the plug in the air horn coveri ng the idle air bleed has been removed,

replace the air horn. If the plug is still in place, do not remove it.

5. Remove the vent stack screen a ssembly to gain access to the lean

mixture screw.

6. Using tool J-28696-10 or equivalent, turn the lean mixture screw in until

lightly seated, then back out 2

1/2 turns.

7. Install the carburetor on the engine.

8. Disconnect the bowl vent line at the carburetor.

9. Disconnect the EGR hos e and canister purge hose at the carburetor.

Cap the ports on t he carburetor.

10. Find the hose from port D of the carburetor to the temperature sensor

and secondary vacuum break thermal vacuum switch. Disconnect and

plug the vacuum hose going to the air cleaner.

11. Connect the positive lead of a dwell me ter to the mixture control solenoid

test lead (green connector). Connect the other lead to ground. Set the

meter to the 6 cylinder position.

12. Run the engine on the high step of the fast idle cam until the cooling fan

starts to cycle.

13. Run the engine at 3,0 00 rpm and adjust the lean mixture screw slowly.

Allow the reading to stabilize, obtain an average dwell of 35 degrees. It is

normal for the dwell to vary in a narrow range.

14. Return to idle.

15. Adjust the idle mixt ure screw to obtain an av erage dwell of 25 degrees.

Allow time for the reading to stabilize.

16. Run the engine at 3,000 rpm and not e the dwell reading. It should be

varying with an average reading of 35 degrees. If it does not, repeat the

earlier steps.

Page 695 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 695

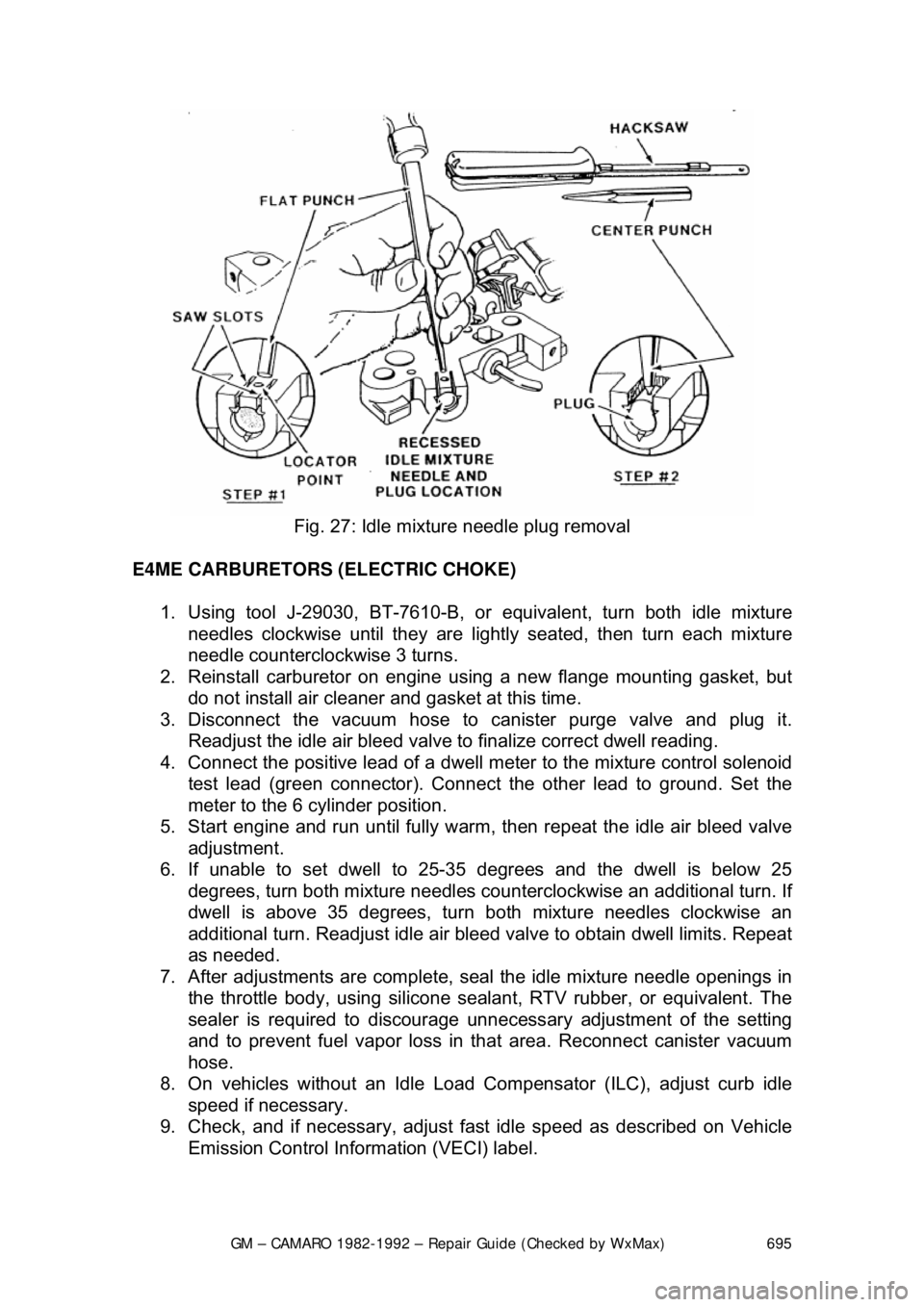

Fig. 27: Idle mixture needle plug removal

E4ME CARBURETORS (ELECTRIC CHOKE) 1. Using tool J-29030, BT-7610-B, or equivalent, turn both idle mixture

needles clockwise until they are lightly seated, then turn each mixture

needle counterclockwise 3 turns.

2. Reinstall carburetor on engine using a new flange mounting gasket, but

do not install air cleaner and gasket at this time.

3. Disconnect the vacuum hose to canister purge valve and plug it.

Readjust the idle air bleed valve to finalize correct dwell reading.

4. Connect the positive lead of a dwell me ter to the mixture control solenoid

test lead (green connector). Connect the other lead to ground. Set the

meter to the 6 cylinder position.

5. Start engine and run unt il fully warm, then repeat the idle air bleed valve

adjustment.

6. If unable to set dwell to 25-35 degrees and the dwell is below 25

degrees, turn both mixture needles counter clockwise an additional turn. If

dwell is above 35 degrees, turn both mixture needles clockwise an

additional turn. Readjust idle air bleed valve to obtain dwell limits. Repeat

as needed.

7. After adjustments are complete, seal the idle mixture needle openings in

the throttle body, using silicone sealant, RTV rubber, or equivalent. The

sealer is required to discourage unnecessary adjus tment of the setting

and to prevent fuel vapor loss in that area. Reconnect canister vacuum

hose.

8. On vehicles without an Idle Load Co mpensator (ILC), adjust curb idle

speed if necessary.

9. Check, and if necessary, adjust fa st idle speed as described on Vehicle

Emission Control Information (VECI) label.

Page 696 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 696

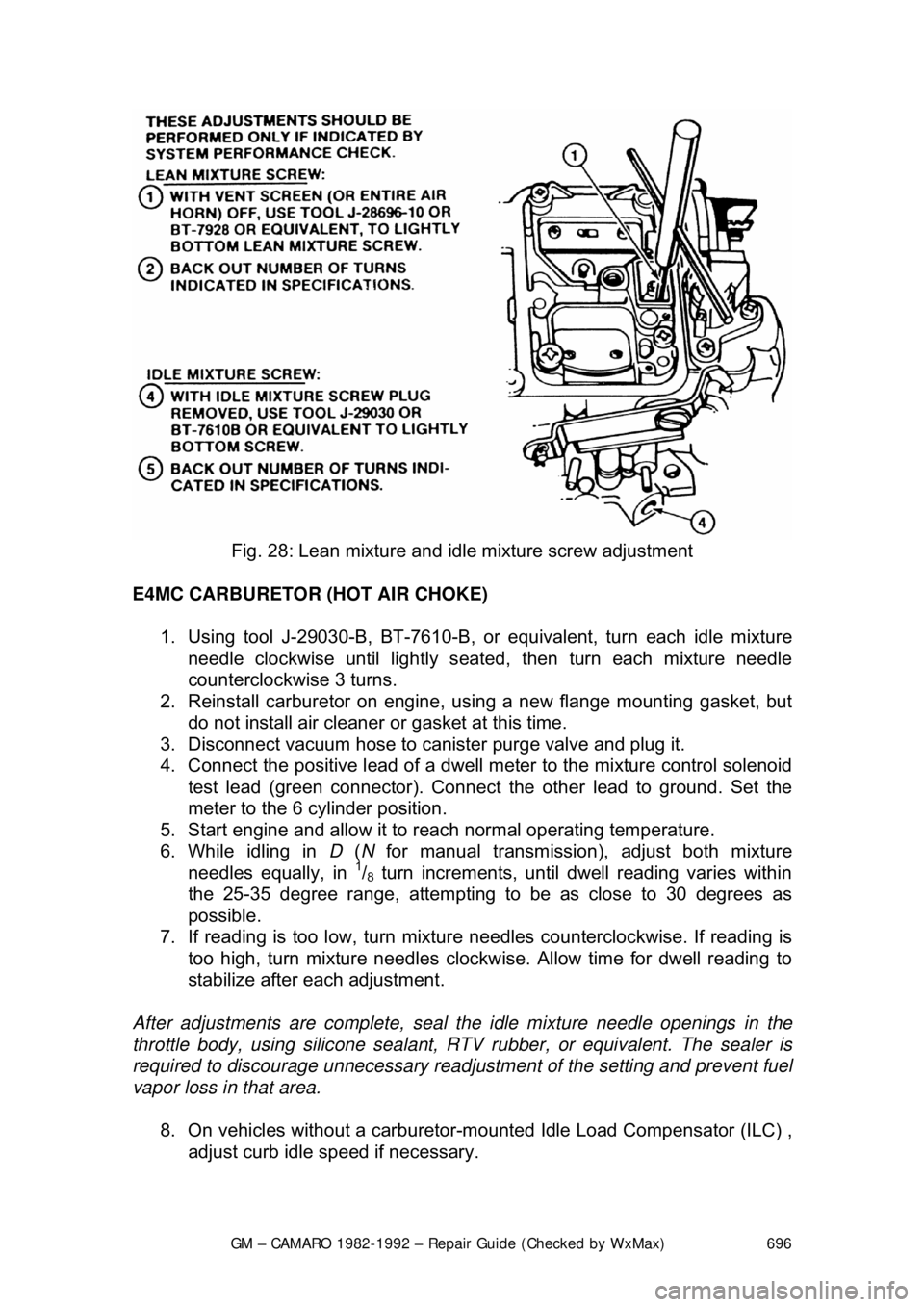

Fig. 28: Lean mixture and idle mixture screw adjustment

E4MC CARBURETOR (HOT AIR CHOKE) 1. Using tool J-29030-B, BT-7610-B, or equivalent, turn each idle mixture

needle clockwise until lightly seated, then turn each mixture needle

counterclockwise 3 turns.

2. Reinstall carburetor on engine, using a new flange mounting gasket, but

do not install air cleaner or gasket at this time.

3. Disconnect vacuum hose to c anister purge valve and plug it.

4. Connect the positive lead of a dwell me ter to the mixture control solenoid

test lead (green connector). Connect the other lead to ground. Set the

meter to the 6 cylinder position.

5. Start engine and allow it to reac h normal operating temperature.

6. While idling in D ( N for manual transmission), adjust both mixture

needles equally, in

1/8 turn increments, until dwell reading varies within

the 25-35 degree range, attempting to be as close to 30 degrees as

possible.

7. If reading is too low, turn mixtur e needles counterclockwise. If reading is

too high, turn mixture needl es clockwise. Allow time for dwell reading to

stabilize after each adjustment.

After adjustments are complete, seal t he idle mixture needle openings in the

throttle body, using silicone sealant, RTV rubber, or equivalent. The sealer is

required to discourage unnece ssary readjustment of the setting and prevent fuel

vapor loss in that area.

8. On vehicles without a carburetor -mounted Idle Load Compensator (ILC) ,

adjust curb idle speed if necessary.

Page 739 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 739

3. Make sure the ignition switch has

been in the OFF position for at least 10

seconds and that all accessories are OFF.

4. Turn the ignition switch ON and the pump will run for about 2 seconds.

Note the system pressure with t he pump running, it should be between

40-47 psi.

The ignition switch may have to be cycled to the ON position more than once to

obtain maximum pressure. It is also norma l for the pressure to drop slightly

when the pump first stops, but it should then hold steady.

5. If the pressure is not as specified, verify that fuel pump operation is

heard in the tank.

6. If fuel pump operation is not heard, inspect the fuel pump relay and

wiring.

7. If fuel pump operation is heard, inspect the filter and lines for restriction.

8. Start the engine and make sure the pr essure decreases about 3-10 psi at

idle.

9. If fuel pressure does not decrease, inspect the fuel pressure regulator

and hose.

10. Disconnect the fuel pressure gauge.

THROTTLE BODY

REMOVAL & INSTALLATION 1. Disconnect the negative (-) battery c able and partially drain the radiator.

2. Remove the air inlet duct and unplug the IAC and TPS electrical connectors.

3. Label and disconnect the vacuum and coolant lines.

4. Disconnect the accelerator, thro ttle valve (transmission control) and

cruise control cables, as applicable.

5. Remove the throttle body attaching bolts, then separate the throttle body from the plenum.

6. Discard the gasket.

To install: 7. Install the throttle body to the plenum using a new gasket. Tighten the \

bolts to specification.

8. Engage the accelerator, throttle valve and cruise control cables, as

necessary. Make sure that the link ages do not hold the throttle open.

9. Connect the vacuum and coolant lines.

10. Install the air inlet duct and plug the IAC and TPS electrical connectors

into their sockets.

11. Connect the negative (-) battery cable and refill the radiator.

12. With the engine OFF, check to s ee that the accelerator pedal is free.

Depress the pedal to the floor and release.

Page 743 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 743

MINIMUM IDLE SPEED

The minimum idle speed should onl

y be adjusted under two conditions:

If the throttle body has been replaced.

After every other possible cause for the in correct idle speed has been explored.

There are many possible causes for incorre ct idle speed, most of which require

a high level of diagnostic skill as well as expensive testing equipment. Check

the vehicle for vacuum leaks, incorrect valve or ignition timing, deposit

accumulation in the throttle bore or valve, sticking throttle linkage or bent throttle

valves. If the vehicle will still not idle pr operly after checking these areas, it

should be diagnosed by a professional.

1. Pierce the idle stop screw with an awl. Apply leverage to remove it.

2. Make sure the IAC valve is connect ed. Short the A and B terminals of the

ALDL connector together with a length of wire.

3. Turn the ignition to the ON positi on, but do not start the engine. Wait at

least 30 seconds before proceeding.

4. With the ignition ON, disconnect the IAC valve connector.

5. Separate the set-timing connector. Th is eliminates the possibility of

changes in engine speed due to variations of engine timing.

6. Start the engine and remove t he wire shorting the A and B terminals

together. It may be necessary to hold the throttle open slightly to prevent

the engine from stalling.

7. Allow the engine to reach no rmal operating temperature.

8. Adjust the idle speed to the following: a. 2.8L Engines - 450-550 rp m A/T or 550-650 rpm M/T

b. 3.1L Engines - Refer to the underhood emissions sticker

c. 5.0L and 5.7L TPI engines - 400-450 rpm.

If these figures differ from t hose on the underhood emissions

sticker, always follow the specifications on the emissions sticker.

9. Turn the ignition OFF and connect the IAC valve harness. On models up

to 1989, adjust the Throttle Position Sensor.

THROTTLE POSITION SENSOR (TPS) 1. Install three jumper wires betw een the TPS and the harness connector.

2. Use a digital voltmeter connected to terminals A and B of the TPS.

3. Turn the ignition switch ON , but do not start the engine.

4. Loosen the TPS attaching screws and adj ust the sensor to the following:

a. 2.8L Engines - 0.50-0.60 volts

b. 5.0L and 5.7L TPI Engines - 0.47-0.61 volts

5. Tighten the attaching screws, then check that the reading has not been

disturbed.

6. With the ignition OFF, remove the jumper wires. Reconnect the TPS

harness.

Page 761 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 761

MAINTENANCE OR REPAIR?

Maintenance includes routine inspecti

ons, adjustments, and replacement of

parts which show signs of normal wear . Maintenance compensates for wear or

deterioration. Repair implies that someth ing has broken or is not working. A

need for a repair is often caused by lack of maintenance. for example: draining

and refilling automatic transmission fl uid is maintenance recommended at

specific intervals. Failure to do this can shorten the life of the

transmission/transaxle, requiring very expen sive repairs. While no maintenance

program can prevent items from eventually breaking or wearing out, a general

rule is true: MAINTENANCE IS CHEAPER THAN REPAIR.

Two basic mechanic's rules should be mentioned here. First, whenever the left

side of the vehicle or engine is refe rred to, it means the driver's side.

Conversely, the right side of the vehi cle means the passenger's side. Second,

screws and bolts are removed by turn ing counterclockwise, and tightened by

turning clockwise unless specifically noted.

Safety is always the most important rule. Constantly be aware of the dangers

involved in working on an automobile and take the proper precautions. Please

refer to the information in this se ction regarding SERVICING YOUR VEHICLE

SAFELY and the SAFETY NOTICE on the acknowledgment page.

AVOIDING THE MOST COMMON MISTAKES

Pay attention to the instructions prov ided. There are 3 common mistakes in

mechanical work:

1. Incorrect order of assembly, di sassembly or adjustment. When taking

something apart or putting it toget her, performing steps in the wrong

order usually just costs you ex tra time; however, it CAN break

something. Read the entire proc edure before beginning. Perform

everything in the order in which the instructions say you should, even if

you can't see a reason for it. When you' re taking apart something that is

very intricate, you might want to draw a picture of how it looks when

assembled in order to make sure you get everything back in its proper

position. When making adjustments, per form them in the proper order.

One adjustment possibly will affect another.

2. Overtorquing (or undertorquing). While it is more common for overtorquing to cause damage, undertorquing may allow a fastener to

vibrate loose causing serious dam age. Especially when dealing with

aluminum parts, pay attention to tor que specifications and utilize a torque

wrench in assembly. If a torque figure is not available, remember that if

you are using the right tool to perfo rm the job, you will probably not have

to strain yourself to get a fast ener tight enough. The pitch of most

threads is so slight that the te nsion you put on the wrench will be

multiplied many times in actual fo rce on what you are tightening.

There are many commercial products avai lable for ensuring that fasteners won't

come loose, even if they are not torqued just right (a very common brand is

Page 771 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 771

A more advanced set of tools, suit

able for tune-up work, can be drawn up

easily. While the tools are slightly more sophisticated, they need not be

outrageously expensive. There are severa l inexpensive tach/dwell meters on

the market that are every bit as good for the average mechanic as a

professional model. Just be sure that it goes to a least 1200-1500 rpm on the

tach scale and that it works on 4, 6 and 8-cylinder engines. The key to these

purchases is to make them with an eye towards adaptability and wide range. A

basic list of tune-up tools could include:

• Tach/dwell meter.

• Spark plug wrench and gapping tool.

• Feeler gauges for valve adjustment.

• Timing light.

The choice of a timing light should be made carefully. A light which works on the

DC current supplied by the vehicle's battery is the best choice; it should have a

xenon tube for brightness. On any vehi cle with an electronic ignition system, a

timing light with an inductive pickup that clamps around the No. 1 spark plug

cable is preferred.

In addition to these basic tools, ther e are several other tools and gauges you

may find useful. These include:

• Compression gauge. The screw-in type is slower to use, but eliminates

the possibility of a faulty r eading due to escaping pressure.

• Manifold vacuum gauge.

• 12V test light.

• A combination volt/ohmmeter

• Induction Ammeter. This is used for determining whether or not there is

current in a wire. These are handy fo r use if a wire is broken somewhere

in a wiring harness.

As a final note, you will probably find a torque wrench necessary for all but the

most basic work. The beam type models are perfectly adequate, although the

newer click types (breakaway) are eas ier to use. The click type torque

wrenches tend to be more expensive. Also keep in mind that all types of torque

wrenches should be periodically checked a nd/or recalibrated. You will have to

decide for yourself which better fits your pocketbook, and purpose.

SPECIAL TOOLS

Normally, the use of special factory tool s is avoided for repair procedures, since

these are not readily available for the do-it-yourself mechanic. When it is

possible to perform the job with more co mmonly available tools, it will be

pointed out, but occasionally, a special t ool was designed to perform a specific

function and should be used. Before s ubstituting another tool, you should be

convinced that neither your safety nor the performance of the vehicle will be

compromised.