hose CHEVROLET CAMARO 1982 Repair Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1982, Model line: CAMARO, Model: CHEVROLET CAMARO 1982Pages: 875, PDF Size: 88.64 MB

Page 82 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 82

Avoid inhaling any dust from

any brake surface! When cleaning brake surfaces,

use a commercially available brake cleaning fluid.

1. Remove

2/3 of the brake fluid from the mast er cylinder. Raise the vehicle and

remove the wheel.

2. Place a C-clamp across the caliper, positioned on the brake pads. Tighten it

until the piston is forced into its bore.

3. Remove the C-clamp. Remove the bolt holding the brake hose to the caliper.

4. Remove the Allen head caliper mounting bolts. Inspect them for corrosion

and replace them if necessary. Remove the caliper.

To install:

5. Position the caliper with the brake pad installed and install Allen head caliper

mounting bolts. Mounting bo lt torque is 21-35 ft. lbs. (28-47 Nm.) for the

caliper.

6. Install the bolt holding the brake hos e to the caliper and tighten to 18-30 ft.

lbs. (24-40 Nm.).

7. Fill the master cylinder with brake fluid.

8. Install the wheels and lower the vehicle.

CAUTION - Before moving the vehicle, pump the brakes several times to seat

the brake pad against the rotor

OVERHAUL

Some vehicles may be equipped dual piston calipers. The procedure to

overhaul the caliper is e ssentially the same with t he exception of multiple

pistons, O-rings and dust boots.

1. Remove the caliper from the ve hicle and place on a clean workbench.

CAUTION - NEVER place your finger s in front of the pistons in an attempt to

catch or protect the pistons when applying compressed air. This could result in

personal injury!

Depending upon the vehicle, there are two different ways to remove the piston

from the caliper. Refer to the brake pad replacement procedure to make sure

you have the correct procedure for your vehicle.

2. The first method is as follows: a. Stuff a shop towel or a block of wood into the caliper to catch the piston.

b. Remove the caliper piston using co mpressed air applied into the caliper

inlet hole. Inspect the piston for scor ing, nicks, corrosion and/or worn or

damaged chrome plating. The piston mu st be replaced if any of these

conditions are found.

Page 112 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 112

4. Position a C-clamp a

nd tighten until the piston bottoms in the base of the

caliper housing. Make sure 1 end of the C-clamp rests on the inlet fitting bolt

and the other against the outboard disc brake pad.

It is not necessary to remove the parki ng brake caliper lever return spring to

replace the disc brake pads.

5. Remove the upper caliper guide pin bolt and discard.

6. Rotate the caliper housing. Be careful not to strain the hose or cable conduit.

7. Remove the disc brake pads.

To install:

8. Clean all residue from the pad guide surfaces on the mounting bracket and

caliper housing. Inspect the guide pins for free movement in the mounting

bracket. Replace the guide pins or boot s, if they are corroded or damaged.

9. Install the disc brake pads. The out board pad with insulator is installed

toward the caliper housing. The inboard pad with the w ear sensor is installed

nearest the caliper piston. The wear sens or must be in the trailing position

with forward wheel rotation.

10. Rotate the caliper housing into it 's operating position. The springs on the

outboard brake pad must not stick through the inspection hole in the caliper

housing. If the springs are sticking thr ough the inspection hole in the caliper

housing, lift the caliper housing and make the necessary corrections to the

outboard brake pad positions.

11. Install a new upper cali per guide pin bolt and tight en to 26 ft. lbs. (35 Nm).

Tighten the lower caliper guide pin bolt to 16 ft. lbs. (22 Nm).

12. With the engine runni ng, pump the brake pedal slo wly and firmly to seat the

brake pads.

13. Check the caliper parking brake levers to make sure they are against the

stops on the caliper housing. If the leve rs are not on their stops, check the

parking brake adjustment.

14. Remove the 2 wheel nuts from t he rotor and install the wheel and tire

assembly.

15. Lower the vehicle, che ck the master cylinder fluid level and road test the

vehicle.

BRAKE CALIPER

REMOVAL & INSTALLATION

CAUTION - Brake pads contain asbestos, which has been determined to be a

cancer causing agent. Never clean the brake surfaces with compressed air!

Avoid inhaling any dust from any brake surface! When cleaning brake surfaces,

use a commercially available brake cleaning fluid.

1982-88 MODELS

Page 117 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 117

5. Remove the shaft seal and washer.

6. Remove the dust boot. Be careful not to scratch the housing bore.

7. Remove the locator retainer if so

equipped. Remove the piston locator if so

equipped.

8. Remove the piston seal usi ng a wooden or plastic tool.

9. Remove the bleeder screw, bolt, fi tting, and copper washer. Remove the

bracket only if it is damaged.

10. Inspect caliper bore for scoring, nicks, corrosion, and wear. Use crocus cloth

for light corrosion. Replace caliper if bore will not clean up.

To install:

11. Replace the bleeder screw, bolt, fitting, and copper washer.

12. Install the piston. Lubricate seal s and piston with brake fluid prior to

reinstallation.

13. Install the locator retainer if so equi pped. Install the piston locator if so

equipped.

14. Install the dust boot.

15. Install the shaft seal and washer.

16. Install actuator scr ew to the housing.

17. Install the nut, lever, lever seal, and anti-friction washer. It may be necessary

to rotate the parking brake lever away from the stop to install the nut. Torque

the nut 30-40 ft. lbs. (41-54 Nm) and ro tate the lever back to the stop.

18. Install the shoe dampening spri ng to the end of the piston.

It may be necessary to move the parking brake lever off the stop, extending the

piston slightly, making the dampening spring groove acce ssible. If the piston is

extended, push it back into the caliper before installing the caliper on the car.

1989-92 MODELS

1. Remove the caliper assembly. Remove the 2 collar return springs from the

actuating collar. Remove the actuator collar assembly with parts attached

out of the housing.

2. Remove the clamp rod and compliance bushing.

3. Remove the boot retainers, 2 boots and pushrod from the compliance

bushing. Discard the retainers and boots.

4. Remove the preload spring from the retainer.

5. Using compressed air directed into the brake hose port, carefully extract

piston.

CAUTION - Do not place fingers between piston and brake shoe flange, or

personal injury may occur when piston breaks free from bore. Cover caliper

assembly with a rag to prevent brake fluid from spraying when piston is

extracted

6. Inspect and clean piston and bore a ssembly for cracks or scoring.

7. Remove the piston seal.

8. Remove the bleeder valve.

Page 127 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 127

The normal automotive circuit differs from

this simple example in two ways.

First, instead of having a return wire from the bulb to the battery, the current

travels through the frame of the vehicle. Since the negative (—) battery cable is

attached to the frame (made of electrically conductive metal), the frame of the

vehicle can serve as a ground wire to complete the circuit. Secondly, mo\

st

automotive circuits contain multiple components which receive power from a

single circuit. This lessens the amount of wire needed to power components on

the vehicle.

HOW DOES ELECTRICITY WORK: THE WATER ANALOGY

Electricity is the flow of electrons - t he subatomic particles that constitute the

outer shell of an atom. Elec trons spin in an orbit around the center core of an

atom. The center core is comprised of protons (positive charge) and neutrons

(neutral charge). Electrons have a negativ e charge and balance out the positive

charge of the protons. When an outside forc e causes the number of electrons to

unbalance the charge of the protons, the electrons will split off the atom and

look for another atom to balance out. If th is imbalance is kept up, electrons will

continue to move and an elec trical flow will exist.

Many people have been taught electrical th eory using an analogy with water. In

a comparison with water flowing through a pipe, the electrons would be the

water and the wire is the pipe.

The flow of electricity can be measur ed much like the flow of water through a

pipe. The unit of measur ement used is amperes, frequently abbreviated as

amps (a). You can compare amperage to th e volume of water flowing through a

pipe. When connected to a circuit, an ammeter will measure the actual amount

of current flowing through the circuit. W hen relatively few electrons flow through

a circuit, the amperage is low. When many electrons flow, the amperage is high.

Water pressure is measured in units su ch as pounds per square inch (psi); The

electrical pressure is m easured in units called volts (v). When a voltmeter is

connected to a circuit, it is meas uring the electrical pressure.

The actual flow of electricity depends not only on voltage and amperage, but

also on the resistance of the circuit. T he higher the resistance, the higher the

force necessary to push the current through the circuit. The standard unit for

measuring resistance is an ohm. Resistance in a circuit varies depending on the

amount and type of components used in t he circuit. The main factors which

determine resistance are:

• Material - some materials have more resistance than others. Those with

high resistance are said to be insulato rs. Rubber materials (or rubber-like

plastics) are some of the most common insulators used in vehicles as

they have a very high resistance to electricity. Very low resistance

materials are said to be conductors. Copper wire is among the best

conductors. Silver is actually a super ior conductor to copper and is used

in some relay contacts, but its hi gh cost prohibits its use as common

wiring. Most automotive wir ing is made of copper.

Page 154 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 154

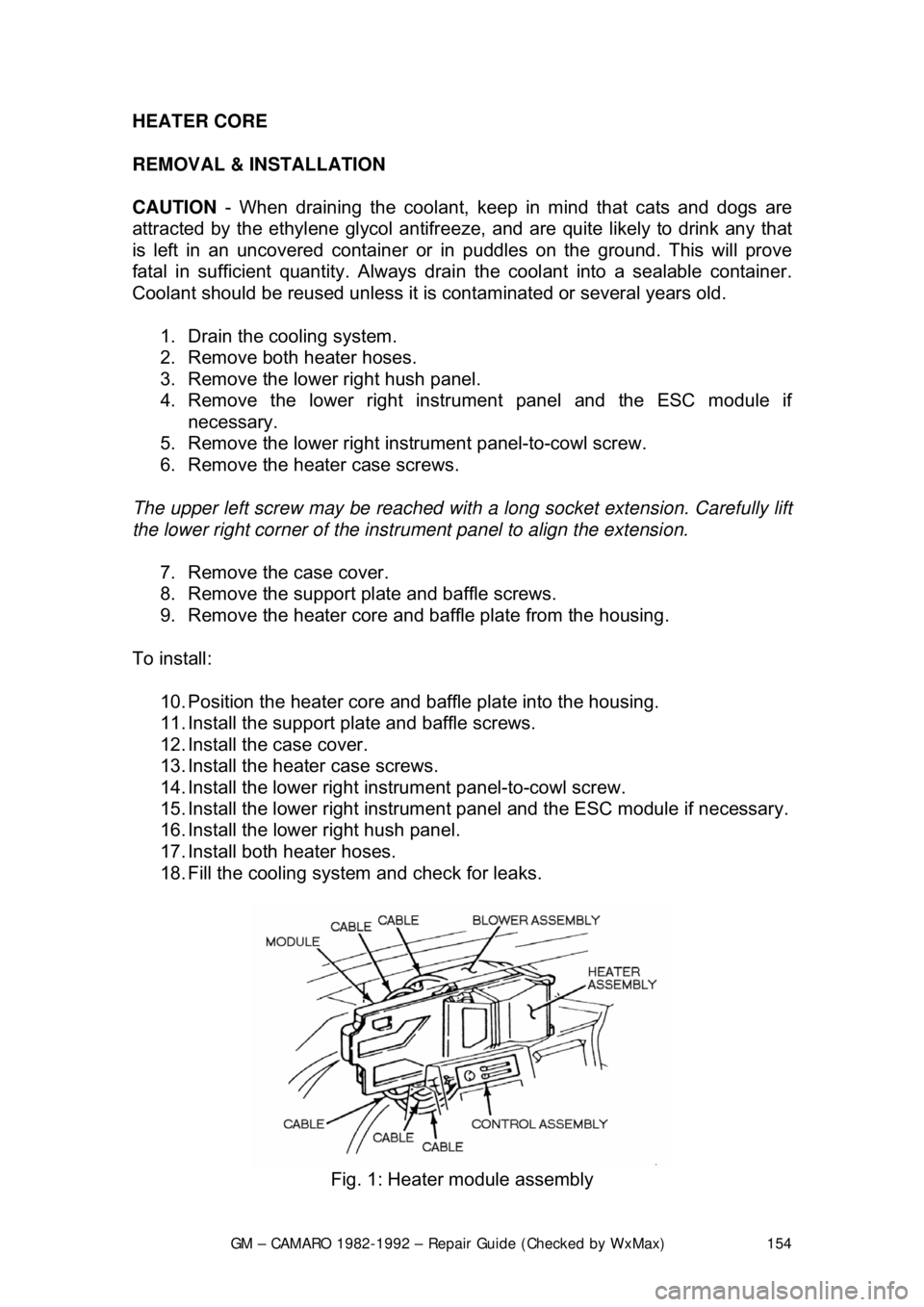

HEATER CORE

REMOVAL & INSTALLATION

CAUTION - When draining the coolant, keep in mind that cats and dogs are

attracted by the ethylene gl ycol antifreeze, and are quite likely to drink any that

is left in an uncovered container or in puddles on the ground. This will prove

fatal in sufficient quantity. Always drai n the coolant into a sealable container.

Coolant should be reused unless it is contaminated or several years old.

1. Drain the cooling system.

2. Remove both heater hoses.

3. Remove the lower right hush panel.

4. Remove the lower right instru ment panel and the ESC module if

necessary.

5. Remove the lower right in strument panel-to-cowl screw.

6. Remove the heater case screws.

The upper left screw may be reached with a long socket extension. Carefully lift

the lower right corner of the instrument panel to align the extension.

7. Remove the case cover.

8. Remove the support plate and baffle screws.

9. Remove the heater core and ba ffle plate from the housing.

To install: 10. Position the heater core and baffle plate into the housing.

11. Install the support plate and baffle screws.

12. Install the case cover.

13. Install the heater case screws.

14. Install the lower right in strument panel-to-cowl screw.

15. Install the lower right instrument panel and the ESC module if necessary.

16. Install the lower right hush panel.

17. Install both heater hoses.

18. Fill the cooling system and check for leaks.

Fig. 1: Heater module assembly

Page 155 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 155

Fig. 2: Removing the heater core inlet hoses

Fig. 3: Removing the sound insulator attaching screws

Page 158 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 158

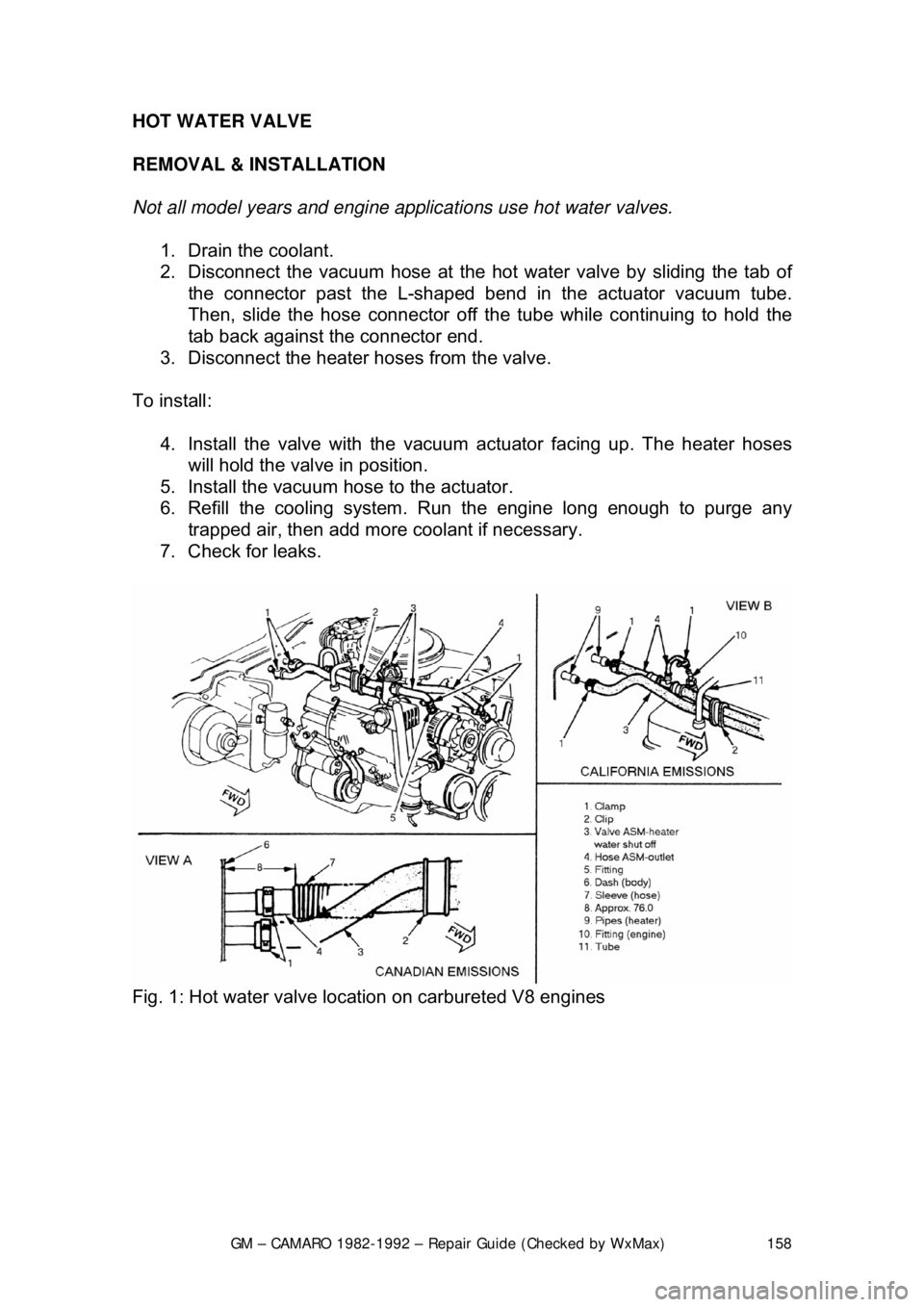

HOT WATER VALVE

REMOVAL & INSTALLATION

Not all model years and engine applic

ations use hot water valves.

1. Drain the coolant.

2. Disconnect the vacuum hose at the hot water valve by sliding the tab of

the connector past the L-shaped bend in the ac tuator vacuum tube.

Then, slide the hose connector off the tube while continuing to hold the

tab back against the connector end.

3. Disconnect the heater hos es from the valve.

To install: 4. Install the valve with the vacuum actuator faci ng up. The heater hoses

will hold the valve in position.

5. Install the vacuum hose to the actuator.

6. Refill the cooling system. R un the engine long enough to purge any

trapped air, then add more coolant if necessary.

7. Check for leaks.

Fig. 1: Hot water valve loca tion on carbureted V8 engines

Page 168 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 168

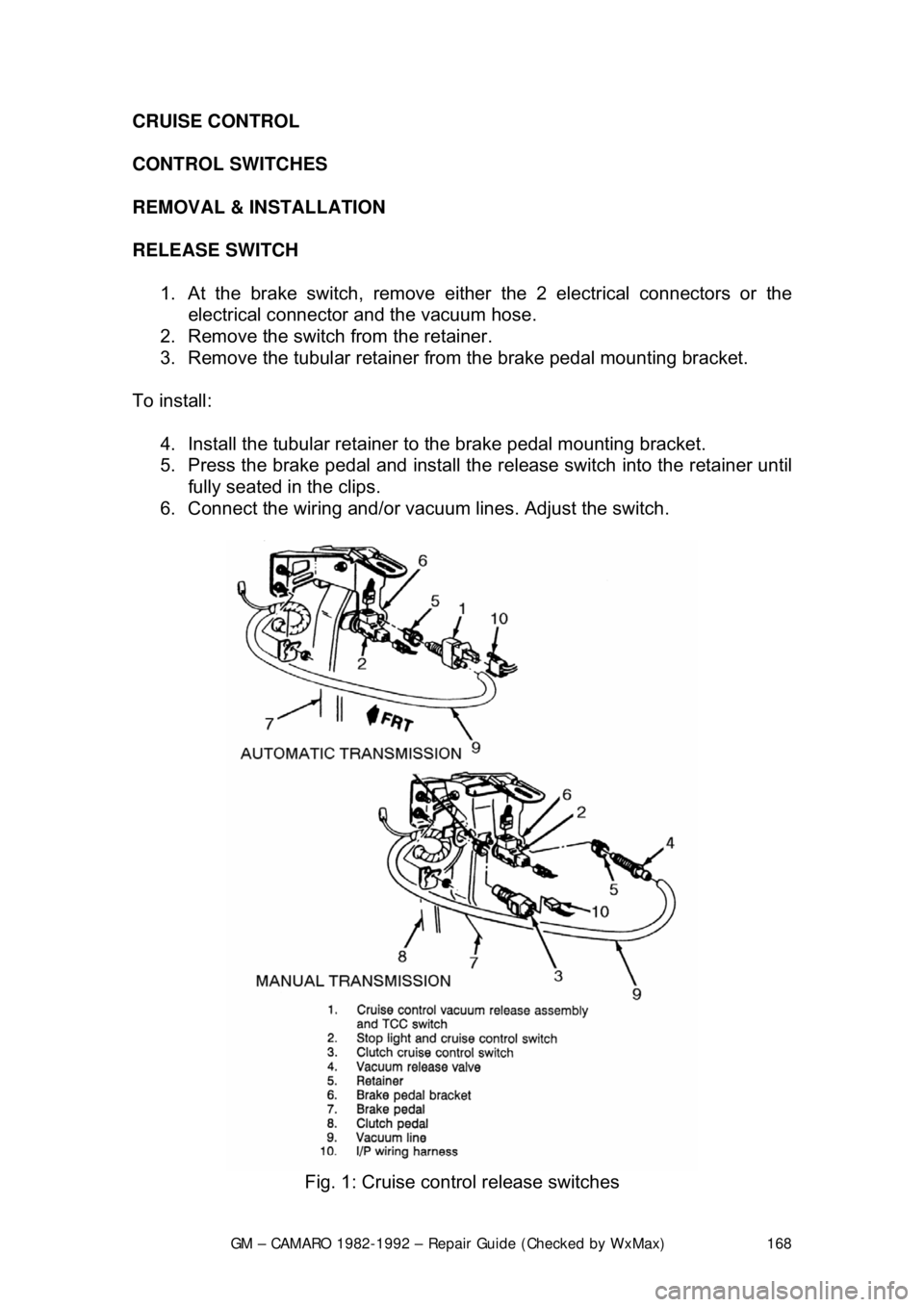

CRUISE CONTROL

CONTROL SWITCHES

REMOVAL & INSTALLATION

RELEASE

SWITCH

1. At the brake switch, remove either the 2 electrical connectors or the

electrical connector and the vacuum hose.

2. Remove the switch from the retainer.

3. Remove the tubular retainer fr om the brake pedal mounting bracket.

To install: 4. Install the tubular retainer to the brake pedal mounting bracket.

5. Press the brake pedal and install the release switch into the retainer until

fully seated in the clips.

6. Connect the wiring and/or vac uum lines. Adjust the switch.

Fig. 1: Cruise control release switches

Page 169 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 169

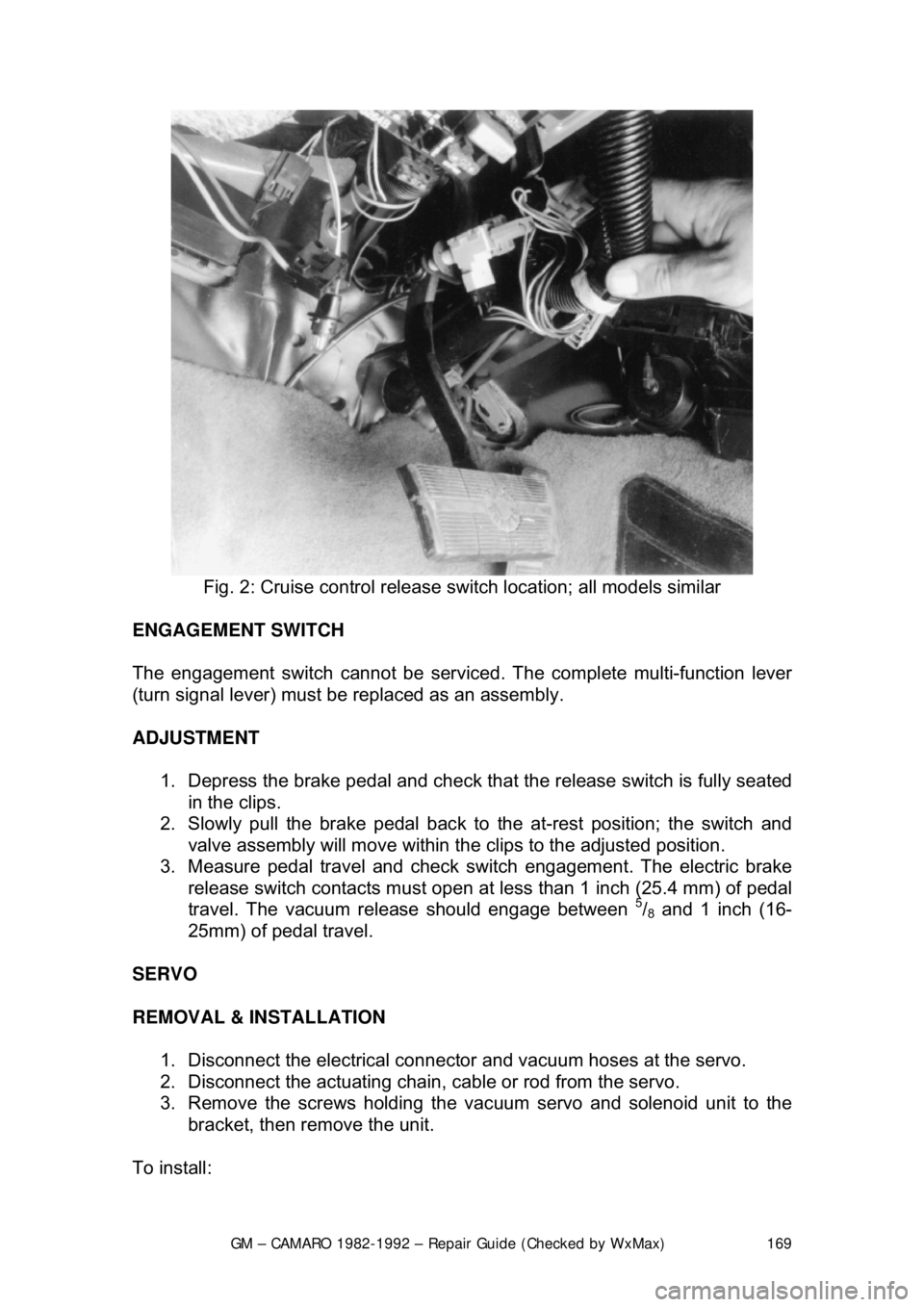

Fig. 2: Cruise control release sw itch location; all models similar

ENGAGEMENT SWITCH

The engagement switch cannot be serviced . The complete multi-function lever

(turn signal lever) must be replaced as an assembly.

ADJUSTMENT

1. Depress the brake pedal and check that the release switch is fully seated

in the clips.

2. Slowly pull the brake pedal back to the at-rest position; the switch and

valve assembly will move within the clips to the adjusted position.

3. Measure pedal travel and check s witch engagement. The electric brake

release switch contacts must open at less than 1 inch (25.4 mm) of pedal

travel. The vacuum release should engage between

5/8 and 1 inch (16-

25mm) of pedal travel.

SERVO

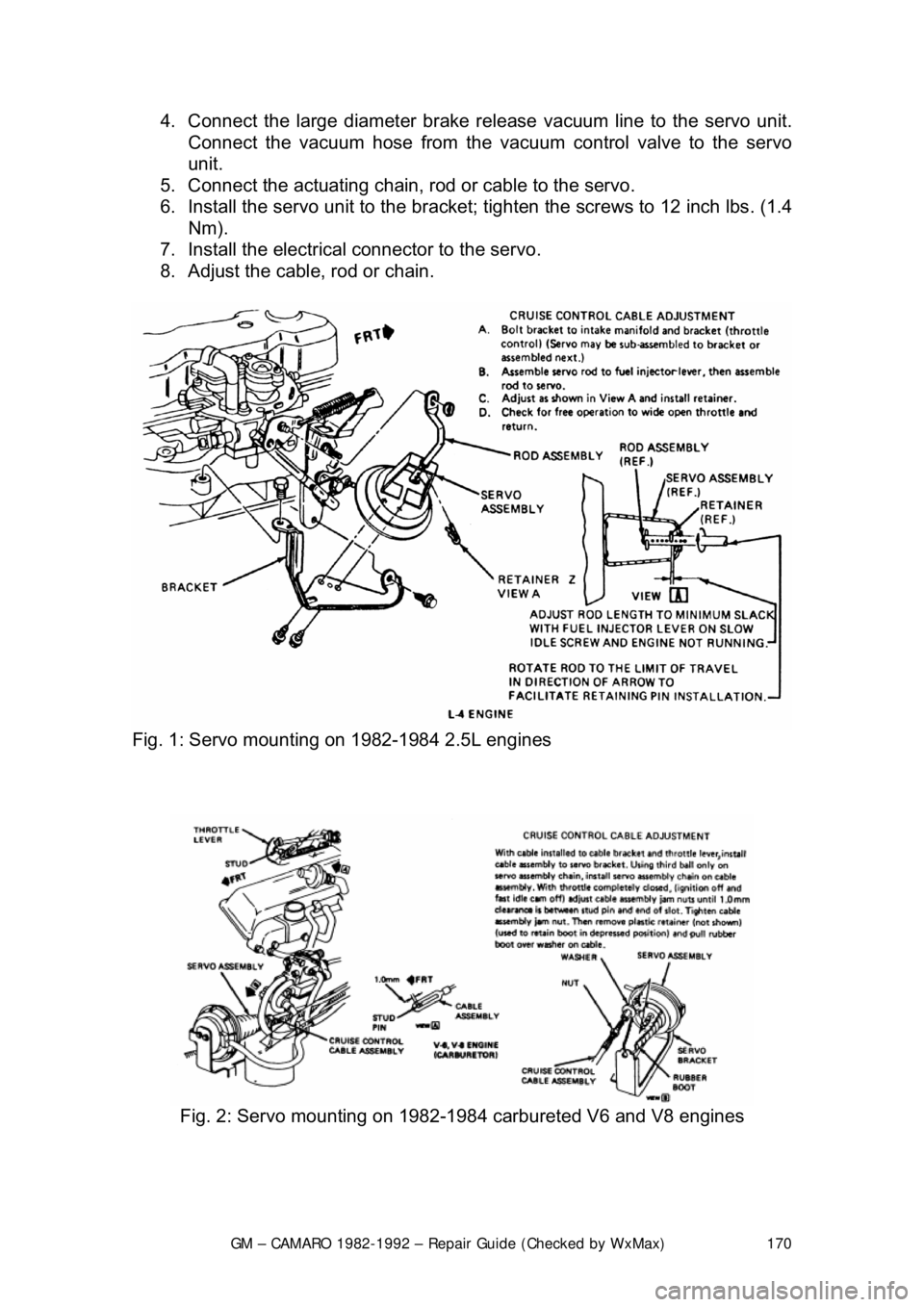

REMOVAL & INSTALLATION 1. Disconnect the electrical connecto r and vacuum hoses at the servo.

2. Disconnect the actuating chain, cable or rod from the servo.

3. Remove the screws holding the vac uum servo and solenoid unit to the

bracket, then remove the unit.

To install:

Page 170 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 170

4. Connect the large diamet

er brake release vacuum line to the servo unit.

Connect the vacuum hose from the va cuum control valve to the servo

unit.

5. Connect the actuating chain, rod or cable to the servo.

6. Install the servo unit to the bracket; tighten the screws to 12 inch lbs. (1.4

Nm).

7. Install the electrical connector to the servo.

8. Adjust the cable, rod or chain.

Fig. 1: Servo mounting on 1982-1984 2.5L engines

Fig. 2: Servo mounting on 1982-1984 carbureted V6 and V8 engines