torque CHEVROLET CAMARO 1982 Repair Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1982, Model line: CAMARO, Model: CHEVROLET CAMARO 1982Pages: 875, PDF Size: 88.64 MB

Page 117 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 117

5. Remove the shaft seal and washer.

6. Remove the dust boot. Be careful not to scratch the housing bore.

7. Remove the locator retainer if so

equipped. Remove the piston locator if so

equipped.

8. Remove the piston seal usi ng a wooden or plastic tool.

9. Remove the bleeder screw, bolt, fi tting, and copper washer. Remove the

bracket only if it is damaged.

10. Inspect caliper bore for scoring, nicks, corrosion, and wear. Use crocus cloth

for light corrosion. Replace caliper if bore will not clean up.

To install:

11. Replace the bleeder screw, bolt, fitting, and copper washer.

12. Install the piston. Lubricate seal s and piston with brake fluid prior to

reinstallation.

13. Install the locator retainer if so equi pped. Install the piston locator if so

equipped.

14. Install the dust boot.

15. Install the shaft seal and washer.

16. Install actuator scr ew to the housing.

17. Install the nut, lever, lever seal, and anti-friction washer. It may be necessary

to rotate the parking brake lever away from the stop to install the nut. Torque

the nut 30-40 ft. lbs. (41-54 Nm) and ro tate the lever back to the stop.

18. Install the shoe dampening spri ng to the end of the piston.

It may be necessary to move the parking brake lever off the stop, extending the

piston slightly, making the dampening spring groove acce ssible. If the piston is

extended, push it back into the caliper before installing the caliper on the car.

1989-92 MODELS

1. Remove the caliper assembly. Remove the 2 collar return springs from the

actuating collar. Remove the actuator collar assembly with parts attached

out of the housing.

2. Remove the clamp rod and compliance bushing.

3. Remove the boot retainers, 2 boots and pushrod from the compliance

bushing. Discard the retainers and boots.

4. Remove the preload spring from the retainer.

5. Using compressed air directed into the brake hose port, carefully extract

piston.

CAUTION - Do not place fingers between piston and brake shoe flange, or

personal injury may occur when piston breaks free from bore. Cover caliper

assembly with a rag to prevent brake fluid from spraying when piston is

extracted

6. Inspect and clean piston and bore a ssembly for cracks or scoring.

7. Remove the piston seal.

8. Remove the bleeder valve.

Page 287 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 287

DRIVE TRAIN

MANUAL TRANSMISSION

UNDERSTANDING THE MANUAL TRANSMISSION

Because of the way an internal combus tion engine breathes, it can produce

torque (or twisting force) only withi n a narrow speed range. Most overhead

valve pushrod engines must turn at about 2500 rpm to produce their peak

torque. Often by 4500 rpm, they are prod ucing so little torque that continued

increases in engine speed produce no power increases.

The torque peak on overhead camshaft engines is, generally, much higher, but

much narrower.

The manual transmission and clutch are employed to vary the relationship

between engine RPM and the speed of the w heels so that adequate power can

be produced under all circumst ances. The clutch allows engine torque to be

applied to the transmission input shaft gradually, due to mechanical slippage.

The vehicle can, consequently, be star ted smoothly from a full stop.

The transmission changes the ratio between the rotating speeds of the engine

and the wheels by the use of gears. 4-speed or 5-speed transmissions are most

common. The lower gears al low full engine power to be applied to the rear

wheels during acceleration at low speeds.

The clutch driveplate is a thin disc, the center of which is splined to the

transmission input shaft. Both sides of the disc are covered with a layer of

material which is similar to brake li ning and which is capable of allowing

slippage without roughness or excessive noise.

The clutch cover is bolted to the engine flywheel and incorporates a diaphragm

spring which provides the pressure to engage the clutch. The cover also houses

the pressure plate. When the clutch pe dal is released, the driven disc is

sandwiched between the pressu re plate and the smooth surface of the flywheel,

thus forcing the disc to turn at th e same speed as the engine crankshaft.

The transmission contains a mainshaft which passes all the way through the

transmission, from the clutch to the dr iveshaft. This shaft is separated at one

point, so that front and rear portions can turn at different speeds.

Power is transmitted by a countershaft in the lower gears and reverse. The

gears of the countershaft mesh with gear s on the mainshaft, allowing power to

be carried from one to the other. Countershaft gears are often integral with that

shaft, while several of the mainshaft gea rs can either rotate independently of

the shaft or be locked to it. Shifting from one gear to the next causes one of the

gears to be freed from rotating with the shaft and locks another to it. Gears are

locked and unlocked by internal dog clutc hes which slide between the center of

the gear and the shaft. The forward gears us ually employ synchronizers; friction

Page 290 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 290

4. Remove the switch attaching bo

lt and remove the clutch switch.

5. Installation is the reverse of t he removal procedure. The switch will

automatically adjust when depres sed for the first time.

SPEED SENSOR

REMOVAL & INSTALLATION

5-SPEED TRANSMISSION 1. Disconnect the negative battery cable.

2. Disconnect the electrical connector.

3. Remove the attaching bolt and remove the sensor.

4. Installation is the reverse of the removal procedure. The bolt torque is 89

inch lbs. (10 Nm).

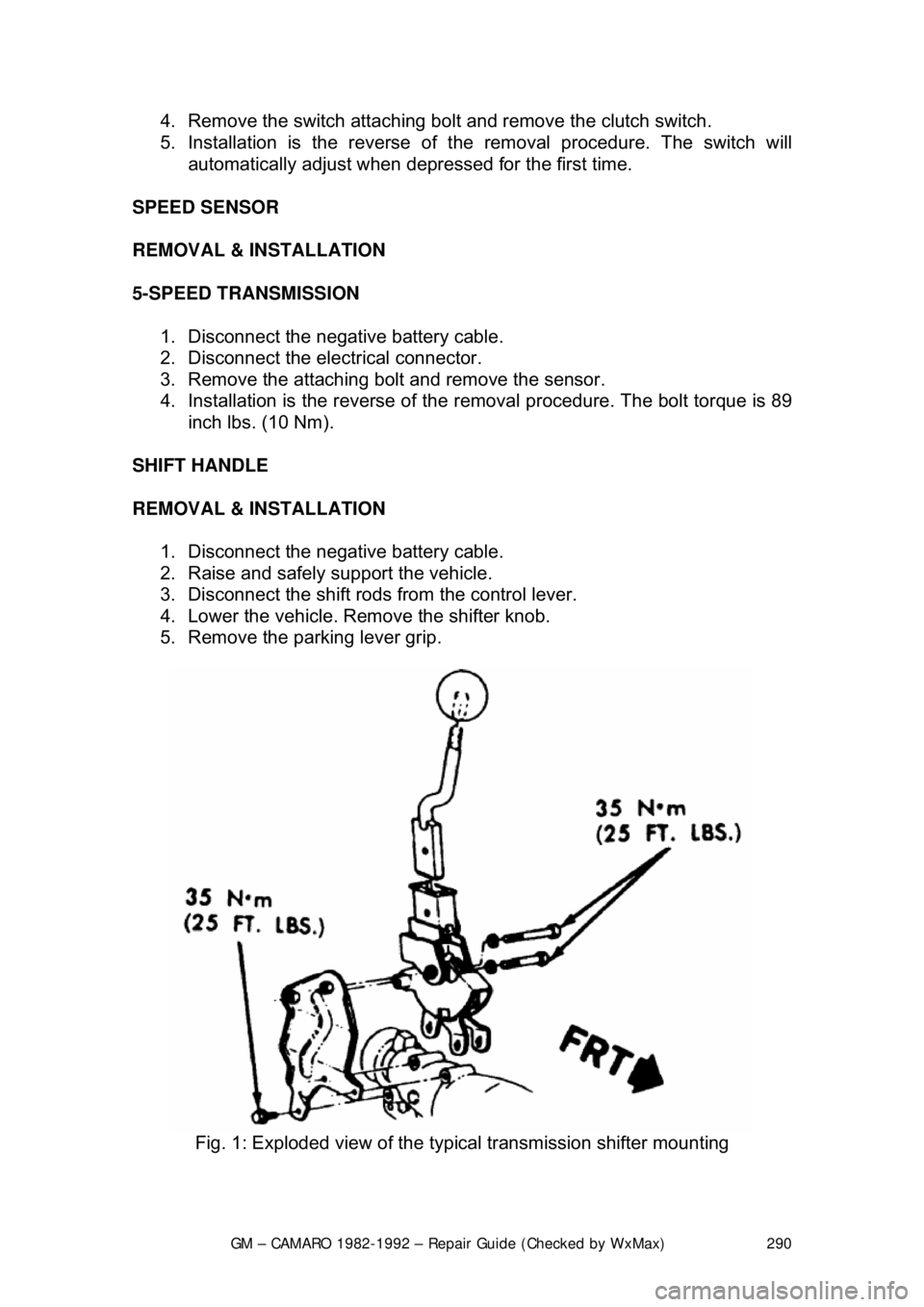

SHIFT HANDLE

REMOVAL & INSTALLATION 1. Disconnect the negative battery cable.

2. Raise and safely support the vehicle.

3. Disconnect the shift rods from the control lever.

4. Lower the vehicle. Remove the shifter knob.

5. Remove the parking lever grip.

Fig. 1: Exploded view of the typi cal transmission shifter mounting

Page 292 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 292

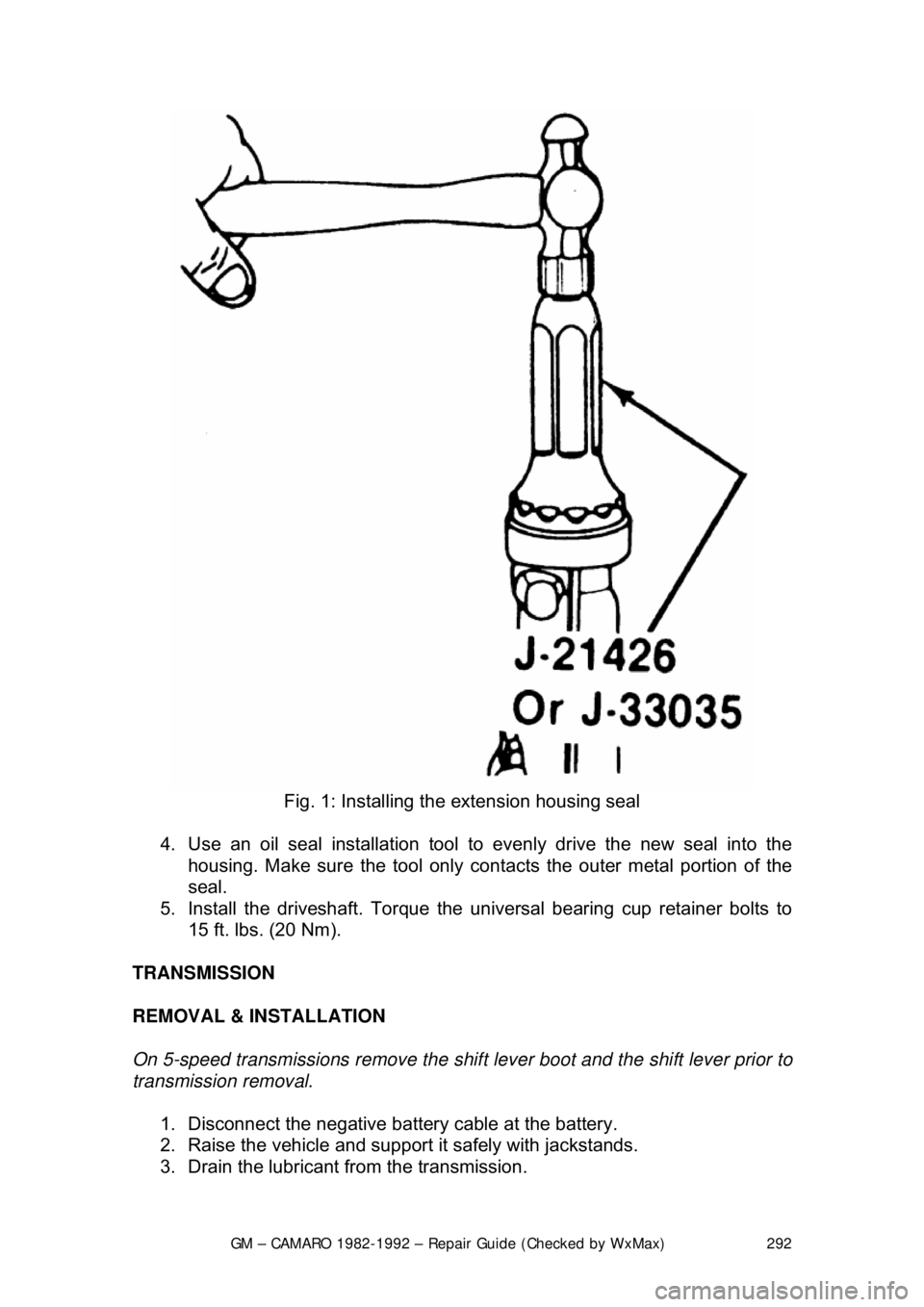

Fig. 1: Installing the extension housing seal

4. Use an oil seal installation tool to evenly drive the new seal into the

housing. Make sure the tool only cont acts the outer metal portion of the

seal.

5. Install the driveshaft. Torque the uni versal bearing cup retainer bolts to

15 ft. lbs. (20 Nm).

TRANSMISSION

REMOVAL & INSTALLATION

On 5-speed transmissions remove the shif t lever boot and the shift lever prior to

transmission removal.

1. Disconnect the negative batte ry cable at the battery.

2. Raise the vehicle and support it safely with jackstands.

3. Drain the lubricant from the transmission.

Page 293 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 293

4. Remove the torque arm from t

he vehicle as outlined under Rear

Suspension in

Suspension & Steering of this repair guide.

5. Mark the driveshaft and the rear ax le pinion flange to indicate their

relationship. Unbolt the rear universal joint straps. Lower the rear of the

driveshaft, being careful to keep the universal joint caps in place.

Withdraw the driveshaft from the transmission and remove it from the

vehicle.

6. Disconnect the speedometer cable a nd the electrical connectors from the

transmission.

7. Remove the exhaust pipe brace.

8. Remove the transmission shifter support attaching bolts from the

transmission.

9. On 4-speed transmissions only, disconnec t the shift linkage at the shifter.

10. Raise the transmission slight ly with a jack, then remove the

crossmember attaching bolts.

11. Remove the transmission mount atta ching bolts, then remove the mount

and crossmember from the vehicle.

12. Remove the transmission attachi ng bolts, then with the aid of an

assistant, move the transmission r earward and downward out of the

vehicle.

To install: 13. Apply a light coating of high temperature grease to the main drive gear

bearing retainer and to the splined por tion of the main drive gear. This

will assure free movement of the clutch and transmission components

during assembly.

14. Install the transmission and secu re with transmission mounting bolts

Torque transmission-to-clutch housing bo lts to 55 ft. lbs. (74 Nm).

15. Install the mount and cr ossmember into the vehicle, then install the

transmission mount attaching bolts. Torque both the mount-to-

crossmember bolts and t he mount-to-transmission bolts to 35 ft. lbs. (47

Nm).

16. Install the crossmember attach ing bolts. Torque the crossmember-to-

body bolts to 35 ft. lbs.

17. On 4-speed transmissions only, connect the shift linkage at the shifter and adjust the shift linkage.

18. Install the transmission shifte r support attaching bolts to the

transmission. Torque shifter bracket-to -extension housing to 25 ft. lbs.

(35 Nm).

19. Install the exhaust pipe brace.

20. Connect the speedometer cable and the electrical connectors to the

transmission.

21. Install the driveshaft into the tr ansmission. Then, align the marks on the

driveshaft and the rear axle pinion fl ange. Bolt the rear universal joint

straps.

22. Install the torque arm into the vehicle.

23. Fill the transmission wi th lubricant. Then install the filler plug and torque

to 15 ft. lbs. (20 Nm).

24. Lower the vehicle.

Page 294 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 294

25. Connect the negative battery cable at the battery.

CLUTCH

UNDERSTANDING THE CLUTCH

The purpose of the clutch is to disconnect and connect engine power at the

transmission. A vehicle at rest requires a lot of engine torque to get all that

weight moving. An internal combustion engine does not develop a high starting

torque (unlike steam engines) so it must be allowed to operate without any load

until it builds up enough torque to move the vehicle. To a point, torque

increases with engine rpm. The clutch a llows the engine to build up torque by

physically disconnecting t he engine from the transmission, relieving the engine

of any load or resistance.

The transfer of engine power to the tr ansmission (the load) must be smooth and

gradual; if it weren't, driv e line components would wear out or break quickly.

This gradual power transfer is made possi ble by gradually releasing the clutch

pedal. The clutch disc and pressure plat e are the connecting link between the

engine and transmission. When the clutch pedal is released, the disc and plate

contact each other (the clutch is engag ed) physically joining the engine and

transmission. When the pedal is pushed in, the disc and plate separate (the

clutch is disengaged) disconnecting the engine from the transmission.

Most clutch assemblies consists of t he flywheel, the clutch disc, the clutch

pressure plate, the throw out bearing and fork, the actuating linkage and the

pedal. The flywheel and clutch pressure plate (driving members) are connected

to the engine crankshaft and rotate with it. The clutch disc is located between

the flywheel and pressure plate, and is splined to the transmission shaft. A

driving member is one that is attached to the engine and transfers engine power

to a driven member (clutch disc) on t he transmission shaft. A driving member

(pressure plate) rotates (drives) a driv en member (clutch disc) on contact and,

in so doing, turns the transmission shaft.

There is a circular di aphragm spring within th e pressure plate cover

(transmission side). In a relaxed state (w hen the clutch pedal is fully released)

this spring is convex; that is, it is dished outward toward the transmission.

Pushing in the clutch peda l actuates the attached linkage. Connected to the

other end of this is the throw out fork, which hold the throw out bearing. When

the clutch pedal is depre ssed, the clutch linkage pushes the fork and bearing

forward to contact the diaphragm spring of the pressure plate. The outer edges

of the spring are secured to the pressure plate and are pivoted on rings so that

when the center of the spring is compre ssed by the throw out bearing, the outer

edges bow outward and, by so doing, pu ll the pressure plate in the same

direction - away from the clutch disc. This action se parates the disc from the

plate, disengaging the clutch and allowing the transmission to be shifted into

another gear. A coil type clutch return sp ring attached to the clutch pedal arm

permits full release of the pedal. Releasing the pedal pulls the throw out bearing

away from the diaphragm spring resulting in a reversal of spring position. As

bearing pressure is gradually released from the spring center, the outer edges

Page 302 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 302

7. To install, reverse the removal

procedures. Torque the master cylinder-

to-cowl brace nuts to 10-15 ft. lbs. (14-20 Nm). Fill master cylinder with

new hydraulic fluid conforming to DO T 3 specifications. Bleed and check

the hydraulic clutch system for leaks.

OVERHAUL 1. Remove the filler cap and drain fl uid from the master cylinder.

2. Remove the reservoir and seal from the master cylinder. Pull back the

dust cover and remove the snapring.

3. Remove the push rod assembly. Usi ng a block of wood, tap the master

cylinder on it to eject the plunger a ssembly from the cylinder bore.

4. Remove the seal (carefully) from the front of the plunger assembly,

ensuring no damage occurs to the plunger surfaces.

5. From the rear of t he plunger assembly, remove the spring, the support,

the seal and the shim.

6. Using clean brake fluid, clean all of the parts.

7. Inspect the cylinder bore and t he plunger for ridges, pitting and/or

scratches, the dust cover for wear and cracking; replace the parts if any

of the conditions exist.

To assemble: 8. Use new seals, lubric ate all of the parts in clean brake fluid, fit the

plunger seal to the plunger and reve rse the disassembly procedures.

9. Insert the plunger assembly, va lve end leading into the cylinder bore

(easing the entrance of the plunger seal).

10. Position the push rod assembly into the cylinder bore, then install a new

snapring to retain the push rod. Install dust cover onto the master

cylinder. Lubricate the inside of t he dust cover with Girling® Rubber

Grease or equivalent.

Be careful not to use any lubricant that will deteriorate rubber dust covers or

seals.

SLAVE CYLINDER

On vehicles equipped with a hydraulic clutch release mechanism, the slave

cylinder is located on the left side of the bellhousing and controls the clutch

release fork operation.

REMOVAL & INSTALLATION

1. Disconnect the negative battery cable.

2. Raise and safely support the front of the vehicle on jackstands.

3. Disconnect the hydraulic line from clutch master cylinder. Remove the

line-to-chassis screw and the c lip from the chassis.

Be sure to plug the line opening to k eep dirt and moisture out of the system.

Page 303 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 303

4. Remove the slave cyli

nder-to-bellhousing nuts.

5. Remove the push rod and the slav e cylinder from the vehicle, then

overhaul it (if necessary).

6. To install, reverse the removal pr ocedures. Lubricate leading end of the

slave cylinder with Girli ng® Rubber Lube or equiva lent. Torque the slave

cylinder-to-bellhousing nuts to 10-15 ft. lbs. (14-20 Nm). Fill the master

cylinder with new brake fluid conformi ng to DOT 3 specifications. Bleed

the hydraulic system.

OVERHAUL 1. Remove the shield, the pushrod and the dust cover from the slave cylinder, then inspect the cover for damage or deterioration.

2. Remove the snapring form t he end of the cylinder bore.

3. Using a block of wood, tap the slave cylinder on it to eject the plunger,

then remove the seal and the spring.

4. Using clean brake fluid, clean all of the parts.

5. Inspect the cylinder bore and the plunger for ridges, pitting and/or

scratches, the dust cover for wear and cracking; replace the parts if any

of the conditions exist.

To assemble: 6. Use new seals and lubricat e all of the parts in clean brake fluid. Install

the spring, the plunger seal and the plunger into the cylinder bore, then

install anew snapring.

7. Lubricate the inside of the dust co ver with Girling® Rubber Grease or

equivalent, then install it into the slave cylinder.

Be careful not to use any lubricant that will deteriorate rubber dust covers or

seals.

BLEEDING THE HYDRAULIC CLUTCH

Bleeding air from the hydrau lic clutch system is necessary whenever any part of

the system has been disconnect ed or the fluid level (in the reservoir) has been

allowed to fall so low that air has been drawn into the master cylinder.

1. Fill master cylinder reservoir wit h new brake fluid conforming to DOT 3

specifications.

2. Raise and safely support the front of the vehicle on jackstands.

3. Remove the slave cylinder attaching bolts.

4. Hold slave cylinder at approximatel y 45 degrees with the bleeder at

highest point. Fully depress clutch pedal and open the bleeder screw.

5. Close the bleeder screw and release clutch pedal.

6. Repeat the procedure until all of t he air is evacuated from the system.

Check and refill master cylinder reserv oir as required to prevent air from

being drawn through the master cylinder.

Page 304 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 304

Never release a depressed clutch pedal

with the bleeder screw open or air will

be drawn into the system.

AUTOMATIC TRANSMISSION

UNDERSTANDING AUTOMATIC TRANSMISSIONS

The automatic transmission allows eng ine torque and power to be transmitted

to the rear wheels within a narrow range of engine operating speeds. It will

allow the engine to turn fast enough to produce plenty of power and torque at

very low speeds, while keeping it at a s ensible rpm at high vehicle speeds (and

it does this job without driv er assistance). The transmission uses a light fluid as

the medium for the transmission of power. This fluid also works in the operation

of various hydraulic control circui ts and as a lubricant. Because the

transmission fluid performs all of thes e functions, trouble within the unit can

easily travel from one part to another. For this reason, and because of the

complexity and unusual oper ating principles of the transmission, a very sound

understanding of the basic principles of operation will simplify troubleshooting.

TORQUE CONVERTER

The torque converter replaces the convent ional clutch. It has three functions:

1. It allows the engine to idle with t he vehicle at a standstill, even with the

transmission in gear.

2. It allows the transmission to shi ft from range-to-range smoothly, without

requiring that the driver close the throttle during the shift.

3. It multiplies engine torque to an incr easing extent as vehicle speed drops

and throttle opening is increased. This has the effect of making the

transmission more responsive and redu ces the amount of shifting

required.

The torque converter is a metal case which is shaped like a sphere that

has been flattened on opposite sides. It is bolted to the rear end of the

engine's crankshaft. Generally, the ent ire metal case rotates at engine

speed and serves as the engine's flywheel.

The case contains three sets of bl ades. One set is attached directly to

the case. This set forms the torus or pump. Another set is directly

connected to the output shaft, and forms the turbine. The third set is

mounted on a hub which, in turn, is mounted on a stationary shaft

through a one-way clutch. This third set is known as the stator.

A pump, which is driven by the conv erter hub at engine speed, keeps the

torque converter full of transmission fluid at all times. Fluid flows

continuously through the unit to provide cooling.

Under low speed acceleration, the tor que converter functions as follows:

Page 305 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 305

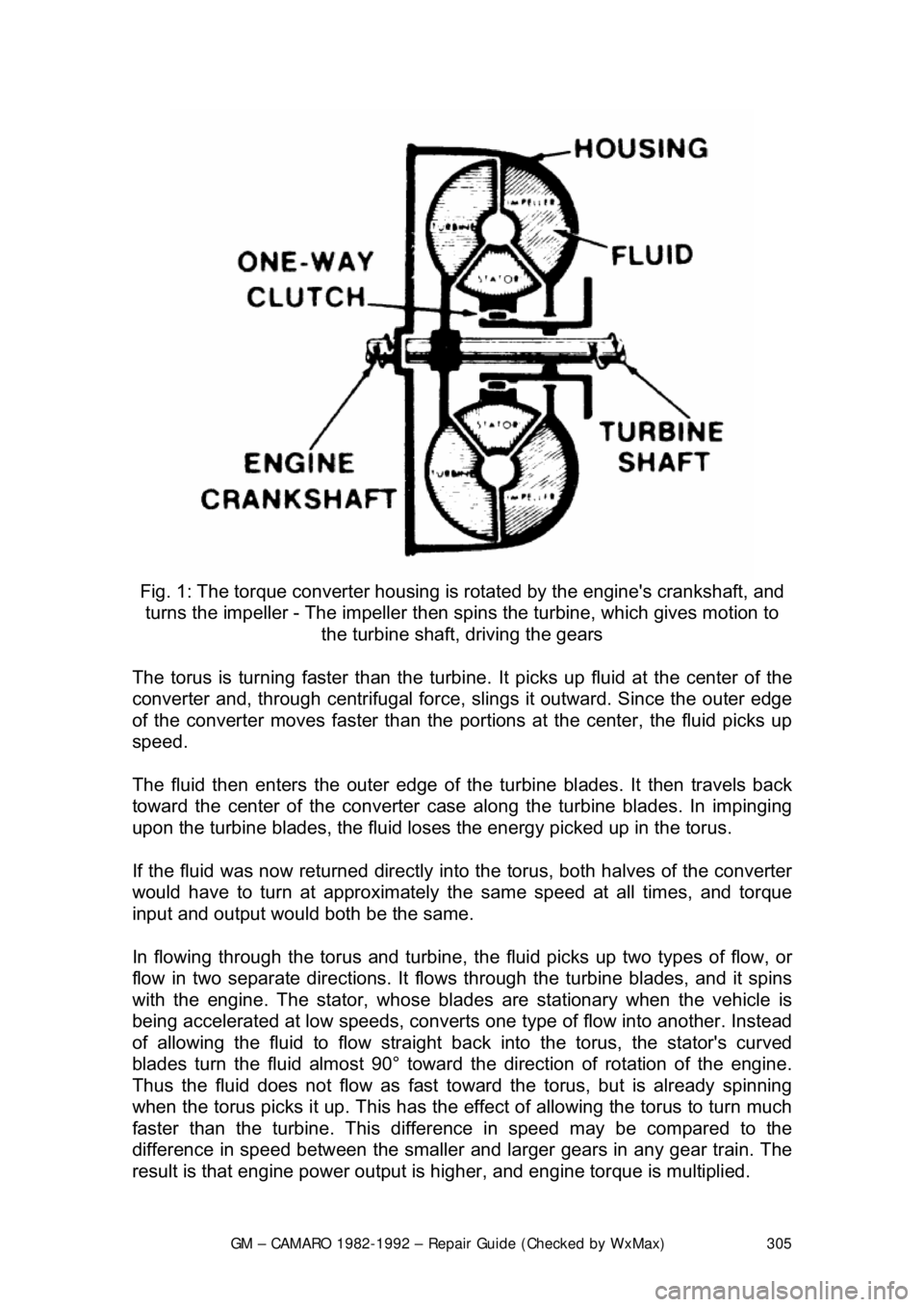

Fig. 1: The torque converter housing is rotated by the engine's crankshaft, and

turns the impeller - The impeller then spin s the turbine, which gives motion to

the turbine shaft, driving the gears

The torus is turning faster than the turbi ne. It picks up fluid at the center of the

converter and, through centrifugal force, slings it outward. Since the outer edge

of the converter moves faster than the portions at the center, the fluid picks up

speed.

The fluid then enters the outer edge of th e turbine blades. It then travels back

toward the center of the converter case along the turbine blades. In impinging

upon the turbine blades, the fluid loses the energy picked up in the torus.

If the fluid was now returned directly into the torus, both halves of the converter

would have to turn at approximately t he same speed at all times, and torque

input and output would both be the same.

In flowing through the torus and turbine, the fluid picks up two types of flow, or

flow in two separate directions. It flow s through the turbine blades, and it spins

with the engine. The stator, whose blades are stationary when the vehicle is

being accelerated at low speeds, converts one type of flow into another. Instead

of allowing the fluid to flow straight back into the torus, the stator's curved

blades turn the fluid almost 90° toward the direction of rotation of the engine.

Thus the fluid does not flow as fast to ward the torus, but is already spinning

when the torus picks it up. This has the effe ct of allowing the torus to turn much

faster than the turbine. This differ ence in speed may be compared to the

difference in speed between the smaller and larger gears in any gear train. The

result is that engine powe r output is higher, and engine torque is multiplied.