steering CHEVROLET CAMARO 1982 Repair Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1982, Model line: CAMARO, Model: CHEVROLET CAMARO 1982Pages: 875, PDF Size: 88.64 MB

Page 366 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 366

8. Remove the air conditioning co

mpressor and lay aside. Remove the

power steering pump and lay aside.

Do not disconnect the air conditioning or power steering lines.

9. Remove the vacuum brake booster line.

10. Remove the distributor cap and spark plug wires.

11. Disconnect the necessary elec trical connections and hoses.

12. Raise and safely support the vehicle.

13. Disconnect the exhaust pipes at the exhaust manifolds.

14. Remove the flywheel cover and remove the converter bolts.

15. Disconnect the star ter wire connections.

16. Remove the bellhousing and t he motor mount through-bolts.

17. Lower the vehicle.

18. Relieve the fuel system pressu re. Disconnect the fuel lines.

19. Support the transmission with a suit able jack. Attach an engine lifting

device.

20. Remove the engine assembly.

To install: 21. Position the engine assembly in the vehicle.

22. Attach the motor mount to engine br ackets and lower the engine in place.

Remove the engine lifting device and the transmission jack.

23. Raise and support the vehicle safely.

24. Install the motor mount through-bolts and tighten the nuts to 50 ft. lbs. (68 Nm). Install the bellhousing bolts and tighten to 35 ft. lbs. (47 Nm).

25. On vehicles with automatic transmissi on, install the converter to flywheel

attaching bolts to 46 ft. lbs. (63 Nm).

26. Install the flywheel splash shield and tighten to 89 inch lbs. (10 Nm).

27. Connect the starter wires and the fuel lines.

28. Install the exhaust pipe on the exhaust manifold.

29. Lower the vehicle.

30. Install the power steering pump and the air conditioning compressor.

31. Connect the necessary wires and hoses.

32. Install the radiator, fan and fan sh roud. Connect the radiator and heater

hoses and the transmission cooler lines.

33. Connect the vacuum brake booster li ne, the throttle linkage and cruise

control cable. Install the distributor cap.

34. Fill the cooling system with the proper type and amount of coolant and

the crankcase with the proper type of oil to the correct level.

35. Install the water pump drive bel t, the air cleaner duct and the hood.

36. Connect the negative battery cable, st art the engine and check for leaks.

Page 367 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 367

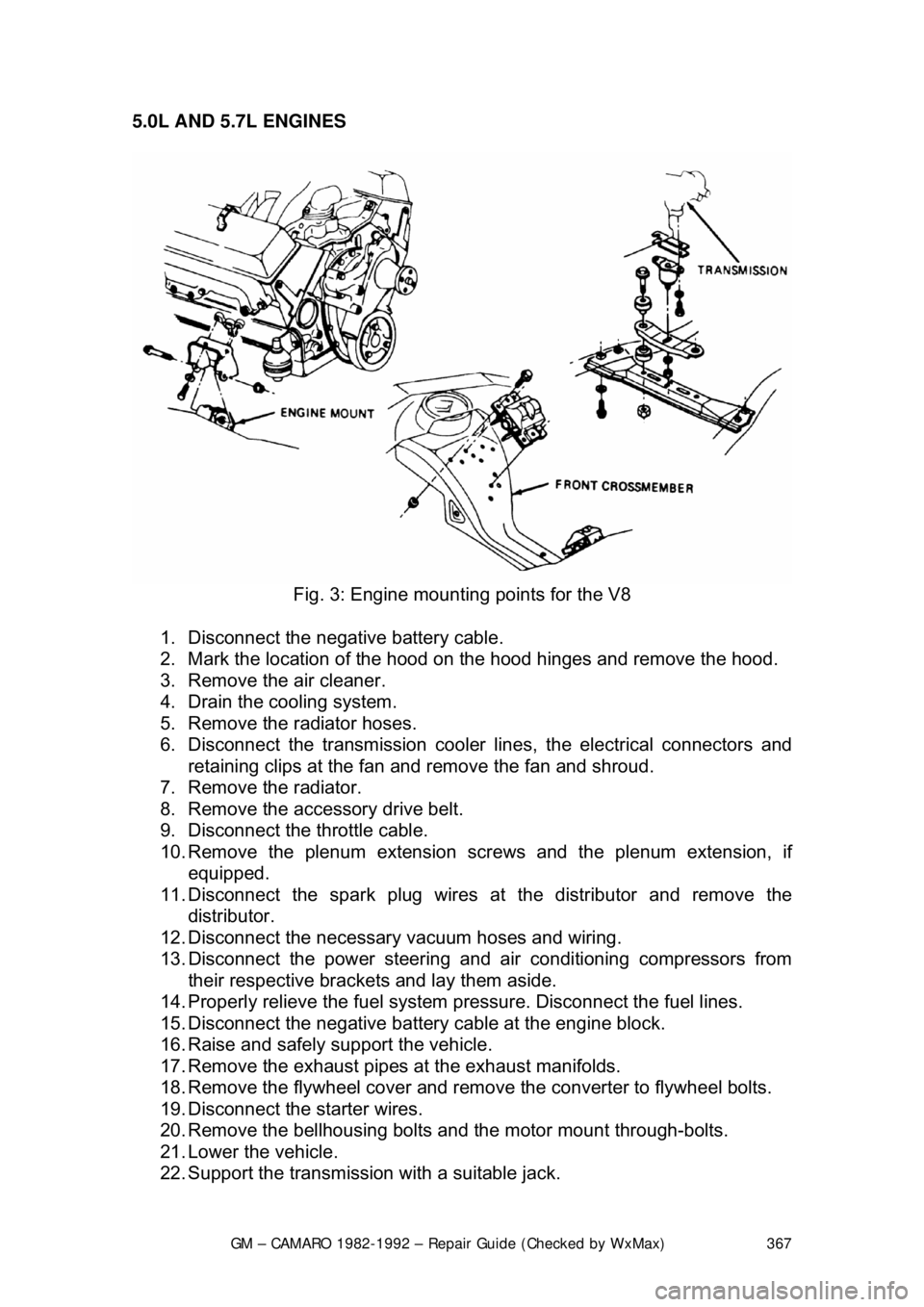

5.0L AND 5.7L ENGINES

Fig. 3: Engine mountin g points for the V8

1. Disconnect the negative battery cable.

2. Mark the location of the hood on the hood hinges and remove the hood.

3. Remove the air cleaner.

4. Drain the cooling system.

5. Remove the radiator hoses.

6. Disconnect the transmission cooler li nes, the electrical connectors and

retaining clips at the fan and remove the fan and shroud.

7. Remove the radiator.

8. Remove the accessory drive belt.

9. Disconnect the throttle cable.

10. Remove the plenum extension scr ews and the plenum extension, if

equipped.

11. Disconnect the spark plug wires at the distributor and remove the

distributor.

12. Disconnect the necessary vacuum hoses and wiring.

13. Disconnect the power steering and air conditioning compressors from

their respective brackets and lay them aside.

14. Properly relieve the fuel system pressure. Disconnect the fuel lines.

15. Disconnect the negative battery cable at the engine block.

16. Raise and safely support the vehicle.

17. Remove the exhaust pipes at the exhaust manifolds.

18. Remove the flywheel cover and remove the converter to flywheel bolts.

19. Disconnect the starter wires.

20. Remove the bellhousing bolts and the motor mount through-bolts.

21. Lower the vehicle.

22. Support the transmission with a suitable jack.

Page 368 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 368

23. Remove the AIR/converter bracket

and ground wires from the rear of the

cylinder head.

24. Attach a suitable lifting devic e and remove the engine assembly.

To install: 25. Position the engine assembly in the vehicle.

26. Attach the motor mount to engine brackets and lower the engine into

place.

27. Remove the engine lifting device and the transmission jack.

28. Raise and safely support the vehicle.

29. Install the motor mount through-bolts and tighten to 50 ft. lbs. (68 (Nm).

30. Install the bellhousing bolts and tighten to 35 ft. lbs. (47 Nm).

31. On vehicles with automatic transmissi on, install the converter to flywheel

bolts. Tighten the bolts to 46 ft. lbs. ( 63 Nm). Install the flywheel cover.

32. Connect the starter wires and the fuel lines.

33. Connect the exhaust pipe at the exhaust manifold.

34. Lower the vehicle.

35. Connect the necessary wires and hoses.

36. Install the power steering pump and air conditioning compressor in their

respective brackets.

37. Install the radiator, fan and fan sh roud, radiator hoses and heater hoses.

38. Connect the transmission cooler lines and cooling fan electrical

connectors.

39. Install the distributor.

40. Install the plenum ex tension, if equipped.

41. Fill the cooling system with the proper type and quantity of coolant and

the crankcase with the proper type of oil to the correct level.

42. Install the air cleaner and the hood.

43. Connect the negative battery cable, start the engine, check for leaks and

check timing.

Page 406 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 406

10. Fill the cooling syst

em, start the engine and check for leaks.

V6 ENGINES 1. Disconnect the negative battery cable.

2. Drain the cooling system.

3. Remove the air intake duct and air cleaner, if necessary.

4. Remove the drive belt.

5. Disconnect the heater and radiator hoses from the water pump.

6. Remove the power steering pump bracket and swing aside.

7. Remove the water pump bolts. Mark the bolts to their corresponding

locations for proper installation.

To install: 8. Clean the gasket surface.

9. Install the water pump with a new gasket. Apply sealer to the bolt

threads.

10. Tighten the large bolts to 25 ft lbs. ( 34 Nm), medium bolts to 15 ft lbs. (21

Nm) and the small bolts to 88 inch lbs. (10 Nm).

11. Install the power steering pump bracket.

12. Connect the heater and radiator hoses.

13. Install the drive belt.

14. Install the air cleaner and duct.

15. Fill the cooling syst em. Start the engine and check for leaks.

V8 ENGINES

Fig. 2: Removing the heater hoses

Page 411 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 411

1. Disconnect the negative battery cable.

2. Relieve the fuel system pressure

and drain the engine coolant from the

radiator into a suitable container.

3. Remove the intake manifold and the spark plugs.

4. Remove the dipstick tube and bra cket. Raise and support the vehicle

safely. Drain the oil and remove the oil filter. Lower the vehicle.

5. Remove the exhaust manifolds.

6. Remove the drive belt(s).

7. Remove the air conditioning compresso r and bracket, reposition it aside.

Do not disconnect the lines.

8. Remove the power steering pump and bracket, reposition it aside.

9. Remove the alternator and br acket, reposition it aside.

10. Remove the ground cable from the rear of the cylinder head and remove

the engine lift bracket.

11. Remove the rocker arm covers.

12. Loosen the rocker arms until the pushrods can be removed.

13. Remove the cylinder head bolts and remove the cylinder heads.

To install: 14. Clean the gasket mating surfaces of all components. Be careful not to

nick or scratch any surfaces as this will allow leak paths. Clean the bolt

threads in the cylinder bl ock and on the head bolts. Dirt will affect bolt

torque.

15. Place the head gaskets in pos ition over the dowel pins.

16. Install the cylinder heads.

17. Coat the cylinder head bolts th reads with GM sealer 1052080 or

equivalent, and install the bolts. Tight en the bolts in the proper sequence

to:

• 1982-1987 engines: 70 ft lbs. (90 Nm)

• 1988-1992 engines: 1st step: 40 ft lbs. (55 Nm); 2nd step: tighten

an additional 1/4 (90 degree) turn

18. Install the pushrods a nd loosely retain them wit h the rocker arms. Make

sure the lower ends of the pushrods ar e in the lifter seats. Refer to the

rocker arm procedures outlined ea rlier in this section.

19. Install the power steering pump br acket and pump. Do the same for the

air conditioning compressor bracket and compressor.

20. Install the ground cable to t he rear of the cylinder head.

21. Install the exhaust manifolds.

22. Install the dipstick tube and bracket.

23. Install the intake manifold.

24. Install the alternator bracket and alternator.

25. Install the drive belt(s).

26. Install the spark plugs.

27. Fill the cooling system with the proper type and quantity of coolant. Install

a new oil filter and fill the crankca se with the proper type and quantity of

oil.

28. Connect the negative battery cable, star t the vehicle and check for leaks.

Page 416 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 416

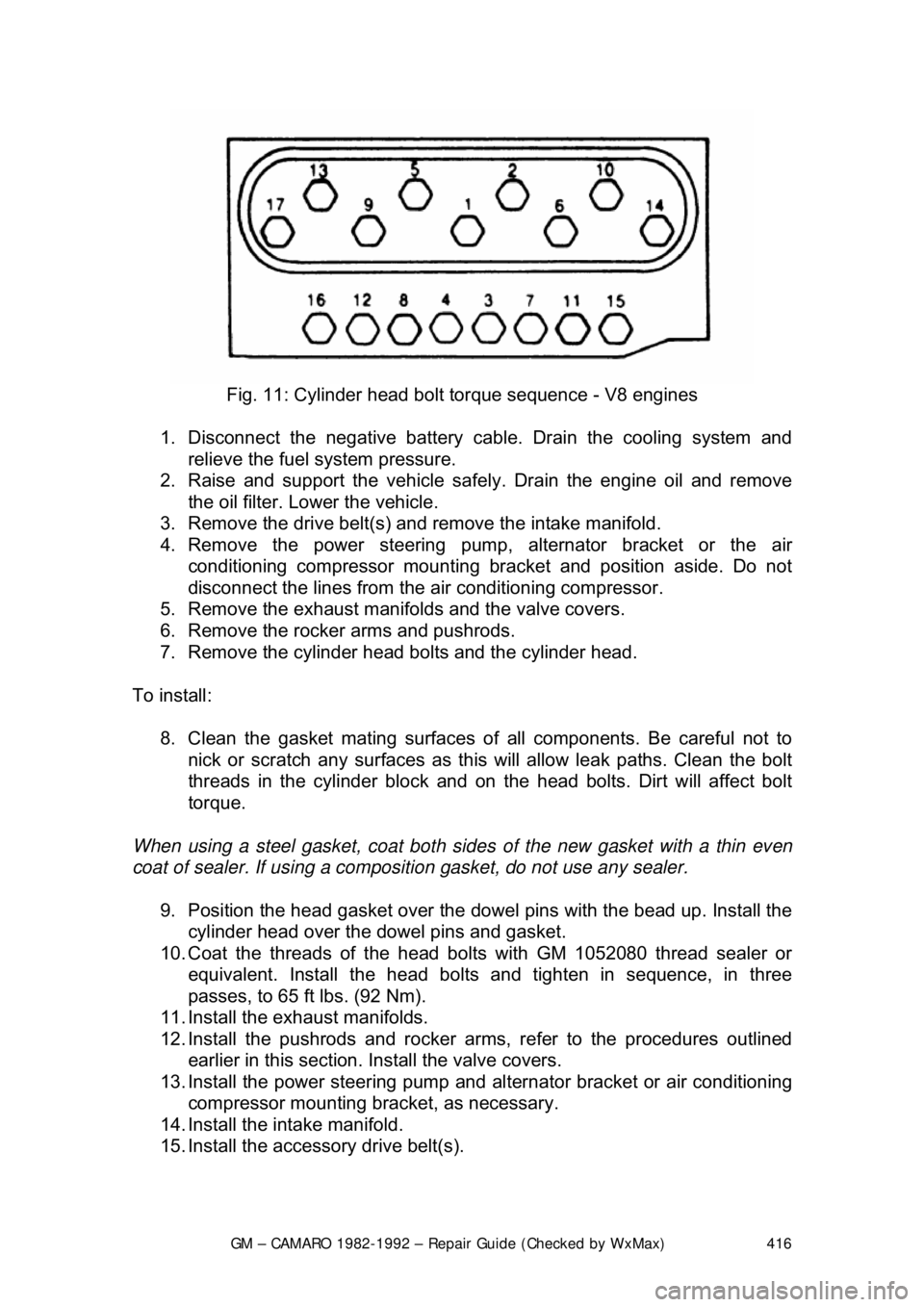

Fig. 11: Cylinder head bolt torque sequence - V8 engines

1. Disconnect the negative battery c able. Drain the cooling system and

relieve the fuel system pressure.

2. Raise and support the vehicle safe ly. Drain the engine oil and remove

the oil filter. Lower the vehicle.

3. Remove the drive belt(s) and remove the intake manifold.

4. Remove the power steering pump, alternator bracket or the air

conditioning compressor mounting br acket and position aside. Do not

disconnect the lines from the air conditioning compressor.

5. Remove the exhaust manifolds and the valve covers.

6. Remove the rocker arms and pushrods.

7. Remove the cylinder head bolts and the cylinder head.

To install: 8. Clean the gasket mating surfaces of all components. Be careful not to

nick or scratch any surfaces as this will allow leak paths. Clean the bolt

threads in the cylinder bl ock and on the head bolts. Dirt will affect bolt

torque.

When using a steel gasket, coat both sides of the new gasket with a thin even

coat of sealer. If using a compos ition gasket, do not use any sealer.

9. Position the head gasket over the dow el pins with the bead up. Install the

cylinder head over the dowel pins and gasket.

10. Coat the threads of the head bo lts with GM 1052080 thread sealer or

equivalent. Install the head bolts and tighten in sequence, in three

passes, to 65 ft lbs. (92 Nm).

11. Install the exhaust manifolds.

12. Install the pushrods and rocker arms, refer to the procedures outlined earlier in this section. Install the valve covers.

13. Install the power steering pump and al ternator bracket or air conditioning

compressor mounting bra cket, as necessary.

14. Install the intake manifold.

15. Install the accessory drive belt(s).

Page 428 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 428

1. Disconnect the battery ground c

able. Drain the cooling system.

2. Remove the fan shroud or the upper radiator support and drive belts.

Remove the fan and pulley from the water pump.

3. Remove the alternator upper and lower brackets, air brace with brackets,

and power steering lower bra cket (move it aside).

4. Remove the radiator lower hose and the heater hose from the water

pump. Remove the water pump bolts and the water pump.

5. If A/C equipped, remove the comp ressor and move aside. Remove the

compressor mounting bracket.

6. Remove the damper pulley retain ing bolt and the damper pulley.

7. Remove the timing gear cover bolts and the timing gear cover.

With the timing gear cover removed, use a large screwdriver to pry the oil seal

from the cover. To install the new oil se al, lubricate it with engine oil and drive it

into place.

To install: 8. Prepare the mating surfaces for reinst allation of the timing gear cover.

Coat the new gasket with RTV sealer.

9. Install the timing gear cover and timing gear cover bolts. Torque the

cover bolts to specifications:

• V6 engines (M8 x 1.25 bolts): 13-22 ft. lbs. (18-30 Nm)

• V6 engines (M10 x 1.5 bolts): 20-35 ft. lbs. (27-48 Nm)

• V8 engines (all bolts): 69-130 inch lbs. (8-14 Nm)

10. Install the damper pulley by pulli ng the damper onto the crankshaft. Use

tool J-23523 or equivalent. Install t he damper pulley retaining bolt and

torque bolts to 67-85 ft lbs. (90-110 Nm).

11. If A/C equipped, install the compressor mounting bracket and

compressor.

12. Install the water pump and the water pump bolts.

13. Install the radiator lower hose and the heater hose to the water pump.

14. Install the alternator upper and lower brackets, air brace with brackets

and the power steering lower bracket.

15. Install the fan and pull ey to the water pump. Inst all the fan shroud or the

upper radiator support and drive belts and adjust.

16. Connect the battery ground cable.

17. Fill the cooling syst em, start the engine and check for leaks.

Page 476 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 476

Before attempting to repair a threaded

hole, remove any snapped, broken or

damaged bolts or studs. Penetrating oil ca n be used to free frozen threads. The

offending item can usually be removed with locking pliers or using a screw/stud

extractor. After the hole is clear, the thread can be repaired, as shown in the

series of accompanying illustrations and in the kit manufacturer's instructions.

ENGINE PREPARATION

To properly rebuild an engine, you must fi rst remove it from the vehicle, then

disassemble and diagnose it. Ideally you should place your engine on an engine

stand. This affords you the best access to the engine components. Follow the

manufacturer's directions for using the stand with your particular engine.

Remove the flywheel or fl explate before installing the engine to the stand.

Now that you have the engine on a stand, and assuming that you have drained

the oil and coolant from the engine, it's ti me to strip it of all but the necessary

components. Before you start disassembli ng the engine, you may want to take

a moment to draw some pictures, or fabr icate some labels or containers to mark

the locations of various components and the bolts and/or studs which fasten

them. Modern day engines use a lot of littl e brackets and clips which hold wiring

harnesses and such, and these holders are often mounted on studs and/or bolts

that can be easily mixed up. The manufacturer spent a lot of time and money

designing your vehicle, and they wouldn't have wasted any of it by haphazardly

placing brackets, clips or fasteners on t he vehicle. If it's present when you

disassemble it, put it back when you asse mble, you will regret not remembering

that little bracket which holds a wire har ness out of the path of a rotating part.

You should begin by unbolting any accessories still attached to the engine, such

as the water pump, power steering pump, alternator, etc. Then, unfasten any

manifolds (intake or exhaust) which were not removed during the engine

removal procedure. Finally, remove any covers remaining on the engine such

as the rocker arm, front or timing cove r and oil pan. Some front covers may

require the vibration dam per and/or crank pulley to be removed beforehand.

The idea is to reduce the engine to the bar e necessities (cylinder head(s), valve

train, engine block, crankshaft, pistons and connecting rods), plus any other 'in

block' components such as oil pumps, balance shafts and auxiliary shafts.

Finally, remove the cylinder head(s) from the engine block and carefully place

on a bench. Disassembly instructions fo r each component follow later in this

section.

CYLINDER HEAD

There are two basic types of cylinder heads used on today’s automobiles:

the Overhead Valve (OHV) and the Over head Camshaft (OHC). The latter can

also be broken down into two subgr oups: the Single Overhead Camshaft

(SOHC) and the Dual Overhead Camshaft (DO HC). Generally, if there is only a

single camshaft on a head, it is just referred to as an OHC head. Also, an

engine with a OHV cylinder head is also known as a pushrod engine.

Page 573 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 573

7. Install the retaining bracket.

8. Connect the negative battery cable.

ELECTRONIC ENGINE CONTROLS

COMPUTER COMMAND CO NTROL (CCC) SYSTEM

The Computer Command Control (CCC) Sy stem is an electronically controlled

exhaust emission system that can m onitor and control a large number of

interrelated emission cont rol systems. It can monitor various engine/vehicle

operating conditions and then use this in formation to control multiple engine

related systems. The CCC syst em is thereby making constant adjustments to

maintain optimum vehicle performance und er all normal driving conditions while

at the same time allowing the catalyti c converter to effectively control the

emissions of HC, CO and NO

x.

OPERATION

The Electronic Control Module (ECM) is required to maintain the exhaust

emissions at acceptable le vels. The module is a sma ll, solid state computer

which receives signals from many source s and sensors; it uses these data to

make judgements about operating conditions and then control output signals to

the fuel and emission systems to ma tch the current requirements.

Inputs are received from m any sources to form a complete picture of engine

operating conditions. Some inputs are simp ly Yes or No messages, such as that

from the Park/Neutral switch; the vehicle is either in gear or in Park/Neutral;

there are no other choices. Other data is sent in quantitative input, such as

engine rpm or coolant temperature. T he ECM is pre-programmed to recognize

acceptable ranges or combinations of si gnals and control the outputs to control

emissions while providing good driv eability and economy. The ECM also

monitors some output circuits, making sure that the components function as

commanded. For proper engine oper ation, it is essential that all input and output

components function properly and comm unicate properly with the ECM.

Since the control module is programmed to recognize the presence and value

of electrical inputs, it will also note the lack of a signal or a radical change in

values. It will, for example, react to the loss of signal from the vehicle speed

sensor or note that engine coolant temperature has risen beyond acceptable

(programmed) limits. Once a fault is recognized, a numeric code is assigned

and held in memory. The SERVICE ENGIN E SOON Malfunction Indicator Lamp

(MIL), will illuminate to advise the operator that the system has detected a fault.

More than one code may be stored. Although not every engine uses every

code, possible codes range from 12-999. Additionally, the same code may carry

different meanings relative to each engine or engine family. For example, on the

3.3L (VIN N) engine, code 46 indicates a fault found in the power steering

pressure switch circuit. The same code on the 5.7L (VIN F) engine indicates a

fault in the VATS anti-theft system.

Page 799 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 799

The master cylinder is located in

the left rear section of the engine

compartment. The brake master cylinder consists of an aluminum body and a

translucent nylon reservoir with minimum fill indicators.

1. Check the master cylinder body for cracks. Inspect the area around the

master cylinder for brake fluid. Leaks are indicated if there is at least a

drop of fluid. A damp condition is not normal.

2. Inspect the level of the brake fluid to assure it is at the correct height.

Clean the top of the reservoir cap so t hat all dirt is removed. Remove the

cap(s) or reservoir cover and the reservoir diaphragm.

3. Inspect the brake fluid level. Add clean DOT-3 brake fluid as required to

bring the fluid level to the line located inside the neck of the reservoir fill

opening.

4. Install the reservoir cap.

WARNING - Any sudden decrease in the fluid level indicates a possible leak in

the system and should be check ed out immediately. Do not allow brake fluid to

spill on the vehicle's finish; it will remove the paint. In case of a spill, flush the

area with water and mild soap.

HYDRAULIC CLUTCH SYSTEM

FLUID RECOMMENDATIONS

• 1982-1991 - Delco Supreme II Brake fl uid or an equivalent fluid that

meets DOT-3 specifications

• 1992 - Hydraulic clutch fluid, GM part number 12345347 or equivalent

LEVEL CHECK

The clutch master cylinder is normally lo cated below the brake master cylinder.

The reservoir for it is located right bes ide the brake master cylinder and is made

of translucent nylon. The fl uid level of the reservoir sh ould be kept near the top

of the observation window. Before removing the cap to the reservoir, clean all

dirt from the area. This will prevent syst em contamination due to particles falling

into the reservoir when the caps are removed.

POWER STEERING PUMP

FLUID RECOMMENDATIONS

• GM power steering fluid, or equivalent.