CHEVROLET CAMARO 1982 Repair Guide

Manufacturer: CHEVROLET, Model Year: 1982, Model line: CAMARO, Model: CHEVROLET CAMARO 1982Pages: 875, PDF Size: 88.64 MB

Page 491 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 491

The first step for any assembly job is

to have a clean area in which to work.

Next, thoroughly clean all of the parts and components that are to be

assembled. Finally, place all of the co mponents onto a suitable work space and,

if necessary, arrange the parts to their respective positions.

1. Lightly lubricate the valve stems and insert all of the valves into the

cylinder head. If possible, maintain their original locations.

2. If equipped, install any valve spring shims which were removed.

3. If equipped, install the new valve seal s, keeping the following in mind:

• If the valve seal presses over the guide, lightly lubricate the outer

guide surfaces.

• If the seal is an O-ring type, it is installed just after compressing

the spring but before the valve locks.

4. Place the valve spring and retainer over the stem.

5. Position the spring compressor tool and compress the spring.

6. Assemble the valv e locks to the stem.

7. Relieve the spring pressure slowly and insure that neither valve lock

becomes dislodged by the retainer.

8. Remove the spring compressor tool.

9. Repeat Steps 2 through 8 until all of the springs have been installed.

ENGINE BLOCK

GENERAL INFORMATION

A thorough overhaul or rebuild of an engine block would include replacing the

pistons, rings, bearings, timing belt/chai n assembly and oil pump. For OHV

engines also include a new camshaft and lifters. The block would then have the

cylinders bored and honed oversize (or if using removable cylinder sleeves,

new sleeves installed) and the cranksha ft would be cut undersize to provide

new wearing surfaces and per fect clearances. However, your particular engine

may not have everything worn out. What if only the piston rings have worn out

and the clearances on everything else are still within factory specifications?

Well, you could just replace the rings and put it back together, but this would be

a very rare example. Chances are, if one component in your engine is worn,

other components are sure to follow, and soon. At the very least, you should

always replace the rings, bearings and oil pump. This is what is commonly

called a "freshen up".

CYLINDER RIDGE REMOVAL

Because the top piston ring does not travel to the very top of the cylinder, a

ridge is built up between the end of the trav el and the top of the cylinder bore.

Pushing the piston and connecting rod assembly past the ridge can be difficult,

and damage to the piston ring lands could occur. If the ridge is not removed

before installing a new piston or not re moved at all, piston ring breakage and

piston damage may occur.

Page 492 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 492

It is always recommended that you remo

ve any cylinder ridges before removing

the piston and connecting rod assemblies . If you know that new pistons are

going to be installed and the engine bl ock will be bored oversize, you may be

able to forego this step. However, some ridges may actually prevent the

assemblies from being remove d, necessitating its removal.

There are several different types of ridge reamers on the market, none of which

are inexpensive. Unless a great deal of engine rebuild ing is anticipated, borrow

or rent a reamer.

1. Turn the crankshaft until the piston is at the bottom of its travel.

2. Cover the head of the piston with a rag.

3. Follow the tool manufacturers in structions and cut away the ridge,

exercising extreme care to avoid cutting too deeply.

4. Remove the ridge reamer, the r ag and as many of the cuttings as

possible. Continue until all of the cylinder ridges have been removed.

DISASSEMBLY

The engine disassembly instructions fo llowing assume that you have the engine

mounted on an engine stand. If not, it is easiest to disassemble the engine on a

bench or the floor with it resting on t he bellhousing or transmission mounting

surface. You must be able to access the connecting rod fasteners and turn the

crankshaft during disassembly. Also, all en gine covers (timing, front, side, oil

pan, whatever) should have already been removed. Engines which are seized

or locked up may not be able to be co mpletely disassembled, and a core

(salvage yard) engine should be purchased.

If not done during the cylinder head removal, remove the pushrods and li\

fters,

keeping them in order for assembly. Remove the timing gears and/or timing

chain assembly, then remove the oil pu mp drive assembly and withdraw the

camshaft from the engine block. Remove the oil pick-up and pump assembly. If

equipped, remove any balanc e or auxiliary shafts. If necessary, remove the

cylinder ridge from the top of the bore. See the cylinder ridge removal

procedure earlier in this section.

Rotate the engine over so that the cr ankshaft is exposed. Use a number punch

or scribe and mark each connecting rod wit h its respective cylinder number. The

cylinder closest to the front of t he engine is always number 1. However,

depending on the engine placemen t, the front of the engine could either be the

flywheel or damper/pulley end. Generally the front of the engine faces the front

of the vehicle. Use a number punch or scribe and also mark the main bearing

caps from front to rear wit h the front most cap being nu mber 1 (if there are five

caps, mark them 1 through 5, front to rear).

Page 493 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 493

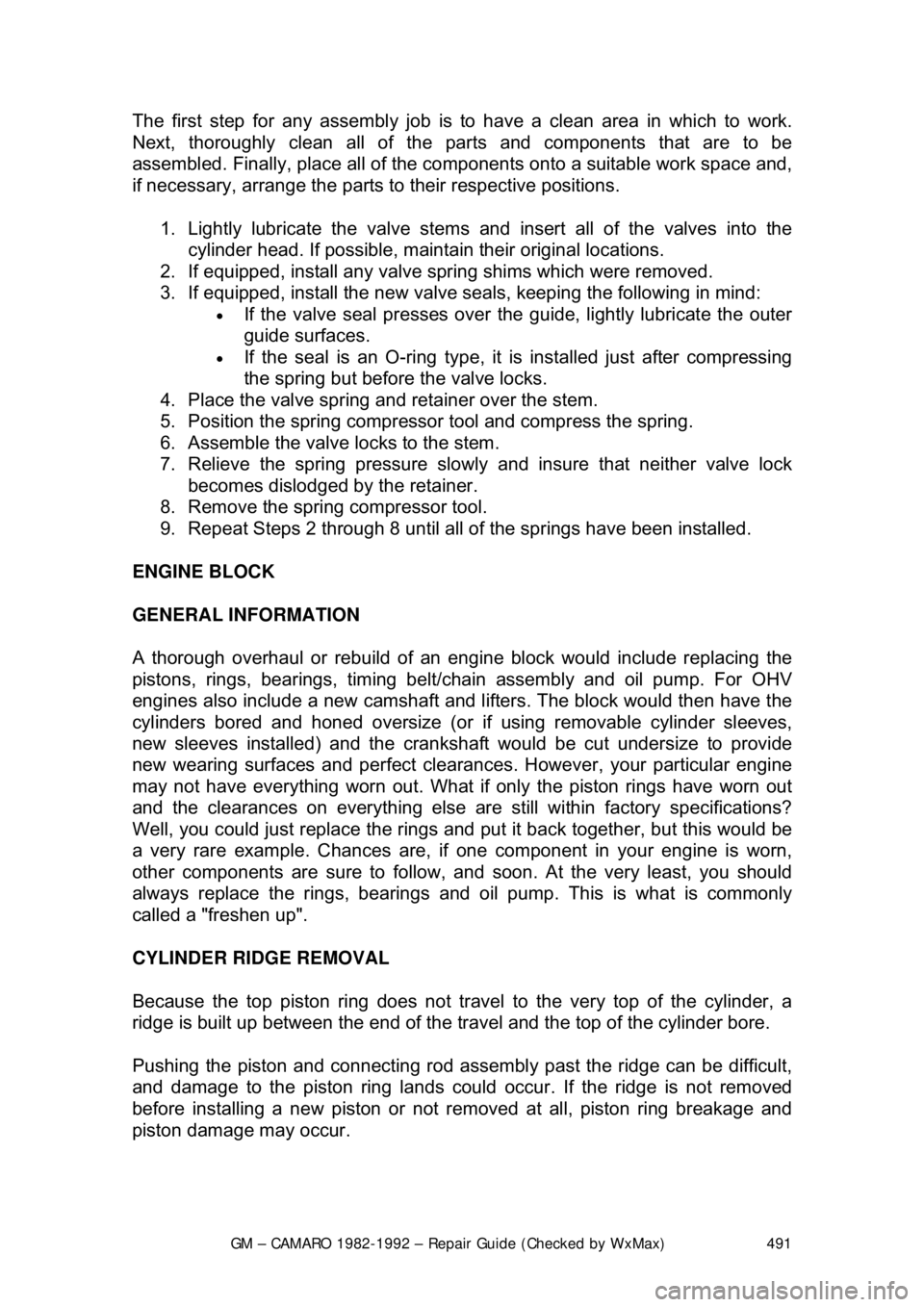

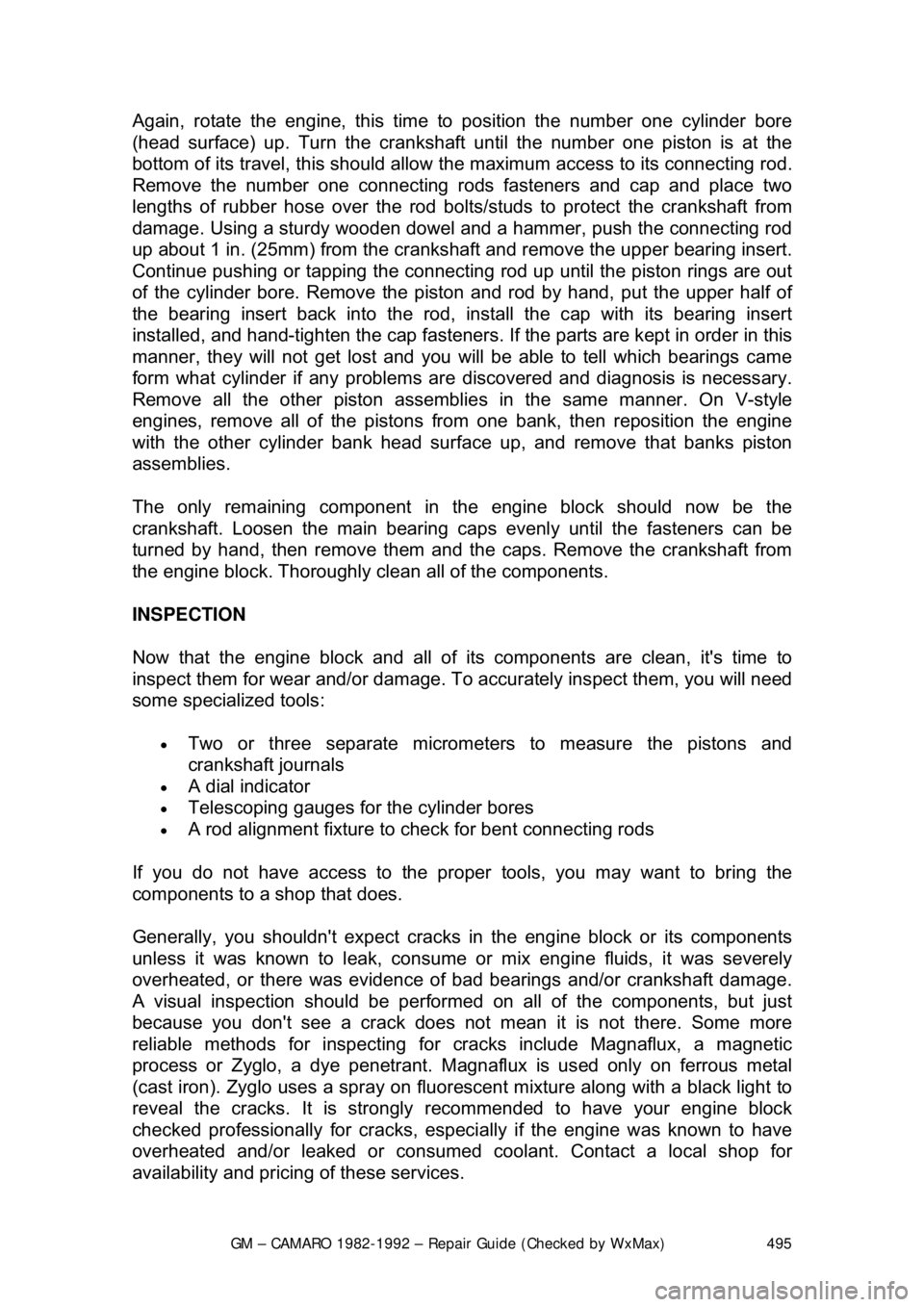

Fig. 1: Place rubber hose over the connecting rod studs to protect the

crankshaft and cylinde r bores from damage

WARNING - Take special care when pushi ng the connecting rod up from the

crankshaft because the sharp threads of the rod bolts/studs will score the

crankshaft journal. Insure that special pl astic caps are installed over them, or

cut two pieces of rubber hose to do the same.

Page 494 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 494

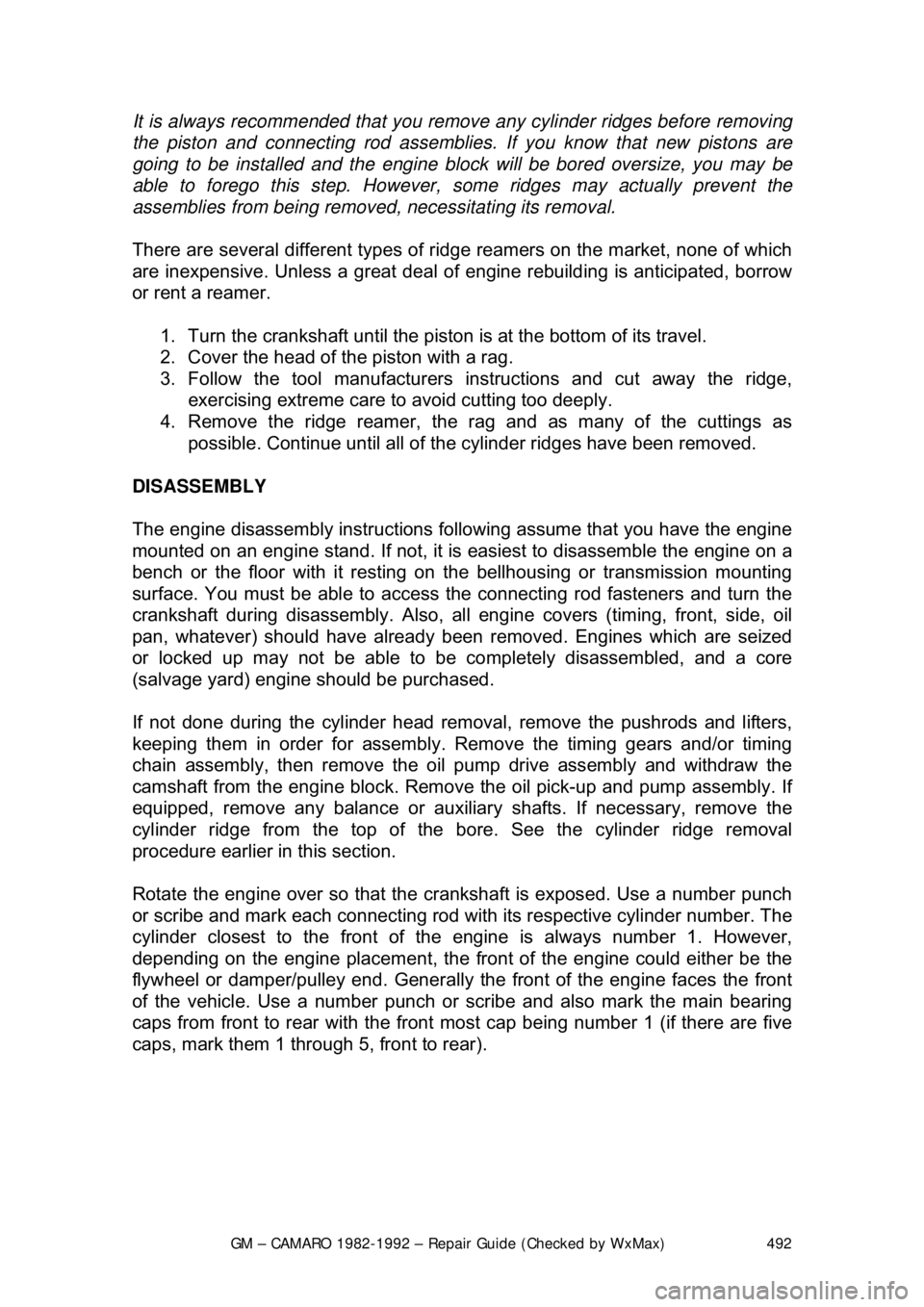

Fig. 2: Carefully tap the piston out of the bore using a wooden dowel

Page 495 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 495

Again, rotate the engine, this time

to position the number one cylinder bore

(head surface) up. Turn the crankshaft until the number one piston is at the

bottom of its travel, this should allow t he maximum access to its connecting rod.

Remove the number one co nnecting rods fasteners and cap and place two

lengths of rubber hose over the rod bolts/studs to protect the crankshaft from

damage. Using a sturdy wooden dowel and a hammer, push the connecting rod

up about 1 in. (25mm) from the cranks haft and remove the upper bearing insert.

Continue pushing or tapping the connecti ng rod up until the piston rings are out

of the cylinder bore. Remove the piston and rod by hand, put the upper half of

the bearing insert back into the rod, in stall the cap with its bearing insert

installed, and hand-tighten the cap fasteners. If the parts are kept in order in this

manner, they will not get lost and you wil l be able to tell which bearings came

form what cylinder if any problems are discovered and diagnosis is necessary.

Remove all the other piston assemblie s in the same manner. On V-style

engines, remove all of the pistons from one bank, then reposition the engine

with the other cylinder bank head surface up, and remo ve that banks piston

assemblies.

The only remaining component in the engine block should now be the

crankshaft. Loosen the main bearing ca ps evenly until the fasteners can be

turned by hand, then remove them and the caps. Remove the crankshaft fro\

m

the engine block. Thoroughly clea n all of the components.

INSPECTION

Now that the engine block and all of its components ar e clean, it's time to

inspect them for wear and/or damage. To accurately inspect them, you will need

some specialized tools:

• Two or three separate micromet ers to measure the pistons and

crankshaft journals

• A dial indicator

• Telescoping gauges for the cylinder bores

• A rod alignment fixture to check for bent connecting rods

If you do not have access to the proper tools, you may want to bring the

components to a shop that does.

Generally, you shouldn't expect cracks in the engine block or its components

unless it was known to leak, consume or mix engine fluids, it was severely

overheated, or there was ev idence of bad bearings and/or crankshaft damage.

A visual inspection should be performed on all of the components, but just

because you don't see a crack does not mean it is not there. Some more

reliable methods for inspecting for cracks include Magnaflux, a magnetic

process or Zyglo, a dye penetrant. M agnaflux is used only on ferrous metal

(cast iron). Zyglo uses a spray on fluoresce nt mixture along with a black light to

reveal the cracks. It is strongly recommended to have your engine block

checked professionally for cracks, especia lly if the engine was known to have

overheated and/or leaked or consumed coolant. Contact a local shop for

availability and pricing of these services.

Page 496 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 496

ENGINE BLOCK

ENGINE BLOCK BEARING ALIGNMENT

Remove the main bearing caps and, if sti

ll installed, the main bearing inserts.

Inspect all of the main bearing saddles and caps for damage, burrs or high

spots. If damage is found, and it is caused from a spun main bearing, the block

will need to be align-bored or, if severe enough, replacement. Any burrs or high

spots should be carefully removed with a metal file.

Place a straightedge on the bearing saddles, in the engine block, along the

centerline of the crankshaft. If any cl earance exists between the straightedge

and the saddles, the block must be align-bored.

Align-boring consists of machining th e main bearing saddles and caps by

means of a flycutter that runs through the bearing saddles.

DECK FLATNESS

The top of the engine blo ck where the cylinder head m ounts is called the deck.

Insure that the deck surface is clean of dirt, carbon deposits and old gasket

material. Place a straightedge across the surface of the deck along its

centerline and, using feeler gauges, check the clearance along several points.

Repeat the checking procedure with th e straightedge placed along both

diagonals of the deck surface. If the reading exceeds 0.003 in. (0.076mm)

within a 6.0 in. (15.2cm) span, or 0.006 in . (0.152mm) over the total length of

the deck, it must be machined.

CYLINDER BORES

The cylinder bores house the pistons and are slightly larger than the pistons

themselves. A common piston-to-bor e clearance is 0.0015-0.0025 in.

(0.0381mm-0.0635mm). Inspect and measur e the cylinder bores. The bore

should be checked for out-of-roundness, t aper and size. The results of this

inspection will determine w hether the cylinder can be us ed in its existing size

and condition, or a rebore to the next oversize is required (or in the case of

removable sleeves, have replacements installed).

Page 497 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 497

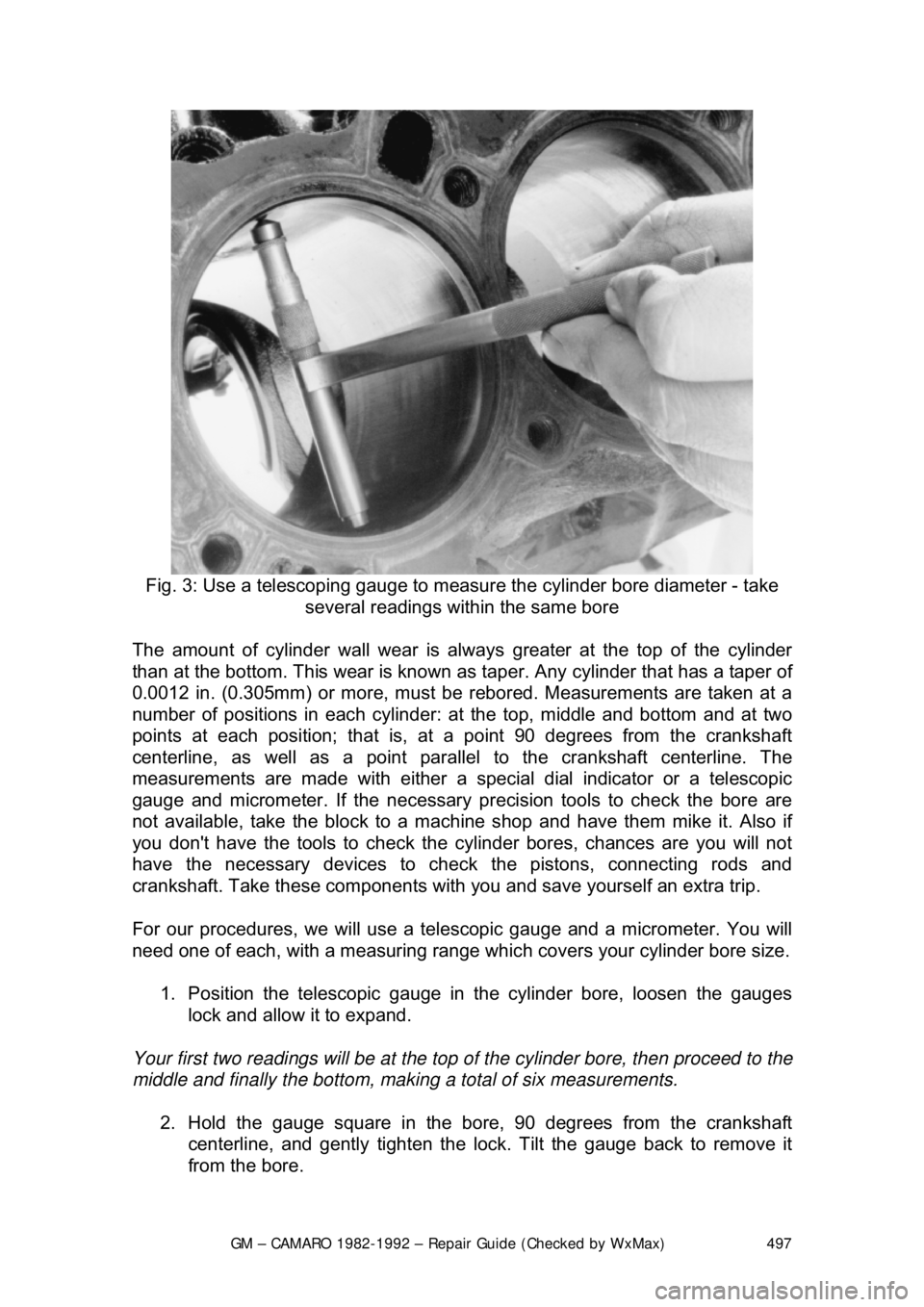

Fig. 3: Use a telescoping gauge to measur e the cylinder bore diameter - take

several readings within the same bore

The amount of cylinder wall wear is a lways greater at the top of the cylinder

than at the bottom. This wear is known as taper. Any cylinder that has a taper of

0.0012 in. (0.305mm) or more, must be rebored. Measurements are taken at a

number of positions in eac h cylinder: at the top, middle and bottom and at two

points at each position; that is, at a point 90 degrees from the crankshaft

centerline, as well as a point para llel to the crankshaft centerline. The

measurements are made with either a special dial indicator or a telescopic

gauge and micrometer. If the necessary pr ecision tools to check the bore are

not available, take the block to a mach ine shop and have them mike it. Also if

you don't have the tools to check the cylinder bores, chances are you will not

have the necessary devices to check the pistons, connecting rods and

crankshaft. Take these components with you and save yourself an extra trip.

For our procedures, we will use a tele scopic gauge and a micrometer. You will

need one of each, with a measuring range whic h covers your cylinder bore size.

1. Position the telescopic gauge in t he cylinder bore, loosen the gauges

lock and allow it to expand.

Your first two readings will be at the top of the cylinder bore, then proceed to the

middle and finally the bottom, ma king a total of six measurements.

2. Hold the gauge square in the bore, 90 degrees from the crankshaft

centerline, and gently ti ghten the lock. Tilt the gauge back to remove it

from the bore.

Page 498 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 498

3. Measure the gauge with the microm

eter and record the reading.

4. Again, hold the gauge square in t he bore, this time parallel to the

crankshaft centerline, and ge ntly tighten the lock. Again, you will tilt the

gauge back to remove it from the bore.

5. Measure the gaug e with the micrometer and record this reading. The

difference between these two readings is the out-of-round measurement

of the cylinder.

6. Repeat steps 1 through 5, each time going to the next lower position,

until you reach the bottom of the cyli nder. Then go to the next cylinder,

and continue until all of the cylinders have been measured.

The difference between these measurements will tell you all about the wear in

your cylinders. The measurements whic h were taken 90 degrees from the

crankshaft centerline will always reflect t he most wear. That is because at this

position is where the engine power presses the piston against the cylinder bore

the hardest. This is known as thrust wear. Take your top, 90 degree

measurement and compare it to your bottom, 90 degree measurement. The

difference between them is the taper. W hen you measure your pistons, you will

compare these readings to your pist on sizes and determine piston-to-wall

clearance.

CRANKSHAFT

Inspect the crankshaft for visible signs of wear or damage. All of the journals

should be perfectly round and smooth. Slight scores are normal for a used

crankshaft, but you should hardly feel them with your fingernail. When

measuring the crankshaft wit h a micrometer, you will take readings at the front

and rear of each journal, then turn t he micrometer 90 degrees and take two

more readings, front and rear. The differ ence between the front-to-rear readings

is the journal taper and the first-to -90 degree reading is the out-of-round

measurement. Generally, there should be no taper or out-of-roundness found,

however, up to 0.0005 in. (0.0127mm) fo r either can be overlooked. Also, the

readings should fall within the factory s pecifications for journal diameters.

If the crankshaft journals fall within specif ications, it is recommended that it be

polished before being returned to service. Polishing the crankshaft insures that

any minor burrs or high spots are smoot hed, thereby reducing the chance of

scoring the new bearings.

PISTONS AND CONNECTING RODS

PISTONS

The piston should be visually inspect ed for any signs of cracking or burning

(caused by hot spots or detonation), and scuffing or excessive wear on the

skirts. The wristpin attaches the piston to the connecting rod. The piston should

move freely on the wrist pin, both sliding and pivoting. Grasp the connecting rod

securely, or mount it in a vise, and tr y to rock the piston back and forth along

the centerline of t he wristpin. There should not be any excessive play evident

between the piston and the pin. If there are C-clips retaining the pin in the piston

Page 499 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 499

then you have wrist pin bushings in the rods. There should not be any

excessive play between the wrist pin

and the rod bushing. Normal clearance for

the wrist pin is approx. 0.001-0.002 in. (0.025mm-0.051mm).

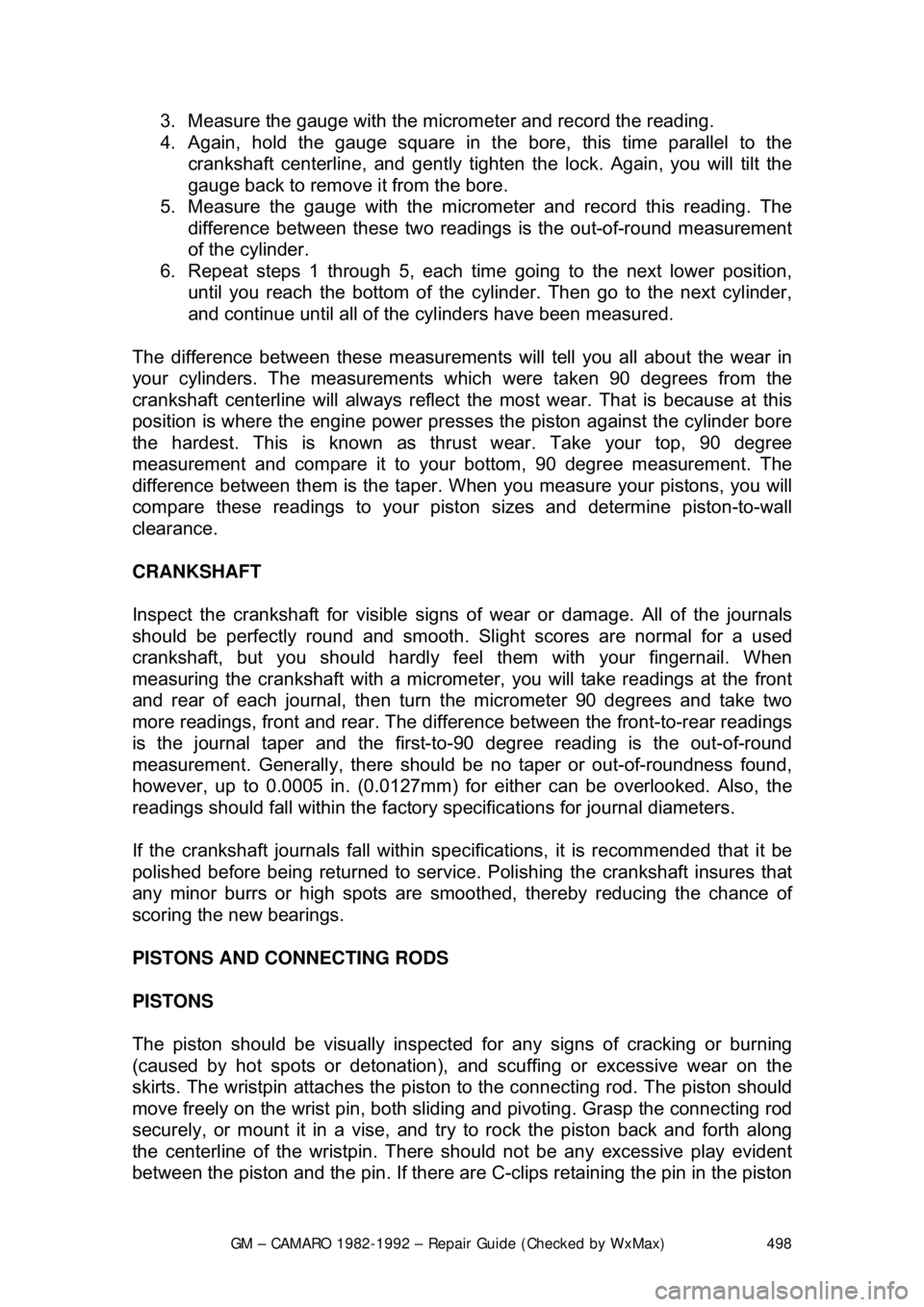

Fig. 4: Measure the piston's outer diam eter, perpendicular to the wrist pin, with

a micrometer

Use a micrometer and measure the diamet er of the piston, perpendicular to the

wrist pin, on the skirt. Com pare the reading to its original cylinder measurement

obtained earlier. The diffe rence between the two readings is the piston-to-wall

clearance. If the clearance is within specif ications, the piston may be used as is.

If the piston is out of specification, but the bore is not, you will need a new

piston. If both are out of specificati on, you will need the cylinder rebored and

oversize pistons installed. Generally if two or more pistons/bores are out of

specification, it is best to rebore the entire block and purchase a complete set of

oversize pistons.

CONNECTING ROD

You should have the connecting rod chec ked for straightness at a machine

shop. If the connecting rod is bent, it will unevenly wear the bearing and piston,

as well as place greater stress on these components. Any bent or twisted

connecting rods must be replaced. If the rods are straight and the wrist pin

clearance is within specifications, t hen only the bearing end of the rod need be

checked. Place the connecting rod into a vi ce, with the bearing inserts in place,

install the cap to the rod and torque t he fasteners to specifications. Use a

telescoping gauge and carefully measure t he inside diameter of the bearings.

Compare this reading to the rods or iginal crankshaft journal diameter

measurement. The difference is the oil clearance. If the oil clearance is not

Page 500 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 500

within specifications, install new bear

ings in the rod and take another

measurement. If the clearance is still out of specifications, and the crankshaft is

not, the rod will need to be reconditioned by a machine shop.

You can also use Plastigage to check the bearing clearances. The assembling

section has complete instructions on its use.

CAMSHAFT

Inspect the camshaft and lifters/followers as described earlier in this section.

BEARINGS

All of the engine bearings should be visua lly inspected for wear and/or damage.

The bearing should look evenly worn a ll around with no deep scores or pits. If

the bearing is severely worn, scored, pi tted or heat blued, then the bearing, and

the components that use it, should be brought to a machine shop for inspection.

Full-circle bearings (used on most camshafts, auxiliary shafts, balance shafts,

etc.) require specialized tools for re moval and installation, and should be

brought to a machine shop for service.

OIL PUMP

The oil pump is responsible for provid ing constant lubrication to the whole

engine and so it is re commended that a new oil pump be installed when

rebuilding the engine.

Completely disassemble the oil pump and thoroughly clean all of the

components. Inspect the oil pump gears and housing for wear and/or damage.

Insure that the pressure relief valve oper ates properly and there is no binding or

sticking due to varnish or debris. If all of the parts are in proper working

condition, lubricate the gears and relie f valve, and assemble the pump.

REFINISHING

Almost all engine block refinishing must be performed by a machine shop. If the

cylinders are not to be rebored, then t he cylinder glaze can be removed with a

ball hone. When removing cylinder glaz e with a ball hone, use a light or

penetrating type oil to lubricate the hone. Do not allow the hone to run dry as

this may cause excessive scoring of t he cylinder bores and wear on the hone. If

new pistons are required, t hey will need to be installed to the connecting rods.

This should be performed by a machine shop as the pistons must be installed in

the correct relationship to the rod or engine damage can occur.