fuel pressure CHEVROLET CAMARO 1982 Repair Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1982, Model line: CAMARO, Model: CHEVROLET CAMARO 1982Pages: 875, PDF Size: 88.64 MB

Page 367 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 367

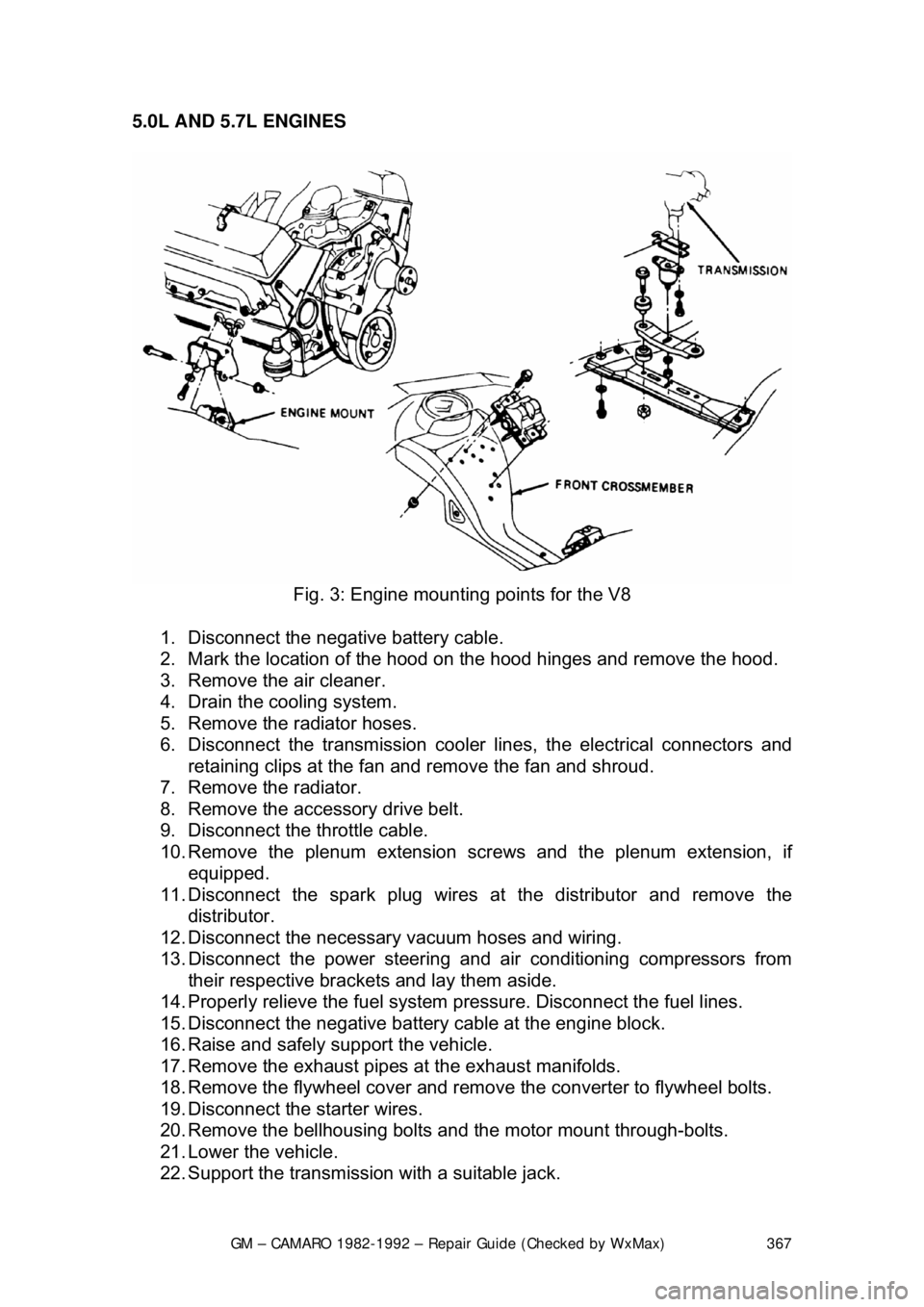

5.0L AND 5.7L ENGINES

Fig. 3: Engine mountin g points for the V8

1. Disconnect the negative battery cable.

2. Mark the location of the hood on the hood hinges and remove the hood.

3. Remove the air cleaner.

4. Drain the cooling system.

5. Remove the radiator hoses.

6. Disconnect the transmission cooler li nes, the electrical connectors and

retaining clips at the fan and remove the fan and shroud.

7. Remove the radiator.

8. Remove the accessory drive belt.

9. Disconnect the throttle cable.

10. Remove the plenum extension scr ews and the plenum extension, if

equipped.

11. Disconnect the spark plug wires at the distributor and remove the

distributor.

12. Disconnect the necessary vacuum hoses and wiring.

13. Disconnect the power steering and air conditioning compressors from

their respective brackets and lay them aside.

14. Properly relieve the fuel system pressure. Disconnect the fuel lines.

15. Disconnect the negative battery cable at the engine block.

16. Raise and safely support the vehicle.

17. Remove the exhaust pipes at the exhaust manifolds.

18. Remove the flywheel cover and remove the converter to flywheel bolts.

19. Disconnect the starter wires.

20. Remove the bellhousing bolts and the motor mount through-bolts.

21. Lower the vehicle.

22. Support the transmission with a suitable jack.

Page 381 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 381

It is not necessary to remove the radi

ator hose from the thermostat housing.

4. Remove the two retaining bolts from the thermostat housing and remove

the thermostat.

To install: 5. Using a new gasket, install the thermostat and housing.

6. Tighten the bolts to 21 ft lbs. (28 Nm).

7. Fill and bleed t he cooling system.

INTAKE MANIFOLD

REMOVAL & INSTALLATION

When servicing all vehicles, be absolutel y sure to mark vacuum hoses and

wiring so that these items may be properly reconnected during installation. Also,

when disconnecting fitting lines (fuel lines, power brake vacuum lines,

transmission and engine cooler lines, etc.), always use two flare nut (or line)

wrenches. Hold the wrench on the large fitti ng with pressure on the wrench as if

you were tightening the fitting (clockw ise), THEN loosen and disconnect the

smaller fitting from the larger fitting. If this is not done, damage to the line will

result. Always relieve fuel system pressure before disconnecting lines.

CAUTION - When draining the coolant, keep in mind that cats and dogs are

attracted by the ethylene gl ycol antifreeze, and are quite likely to drink any that

is left in an uncovered container or in puddles on the ground. This will prove

fatal in sufficient quantity. Always drai n the coolant into a sealable container.

Coolant should be reused unless it is contaminated or several years old.

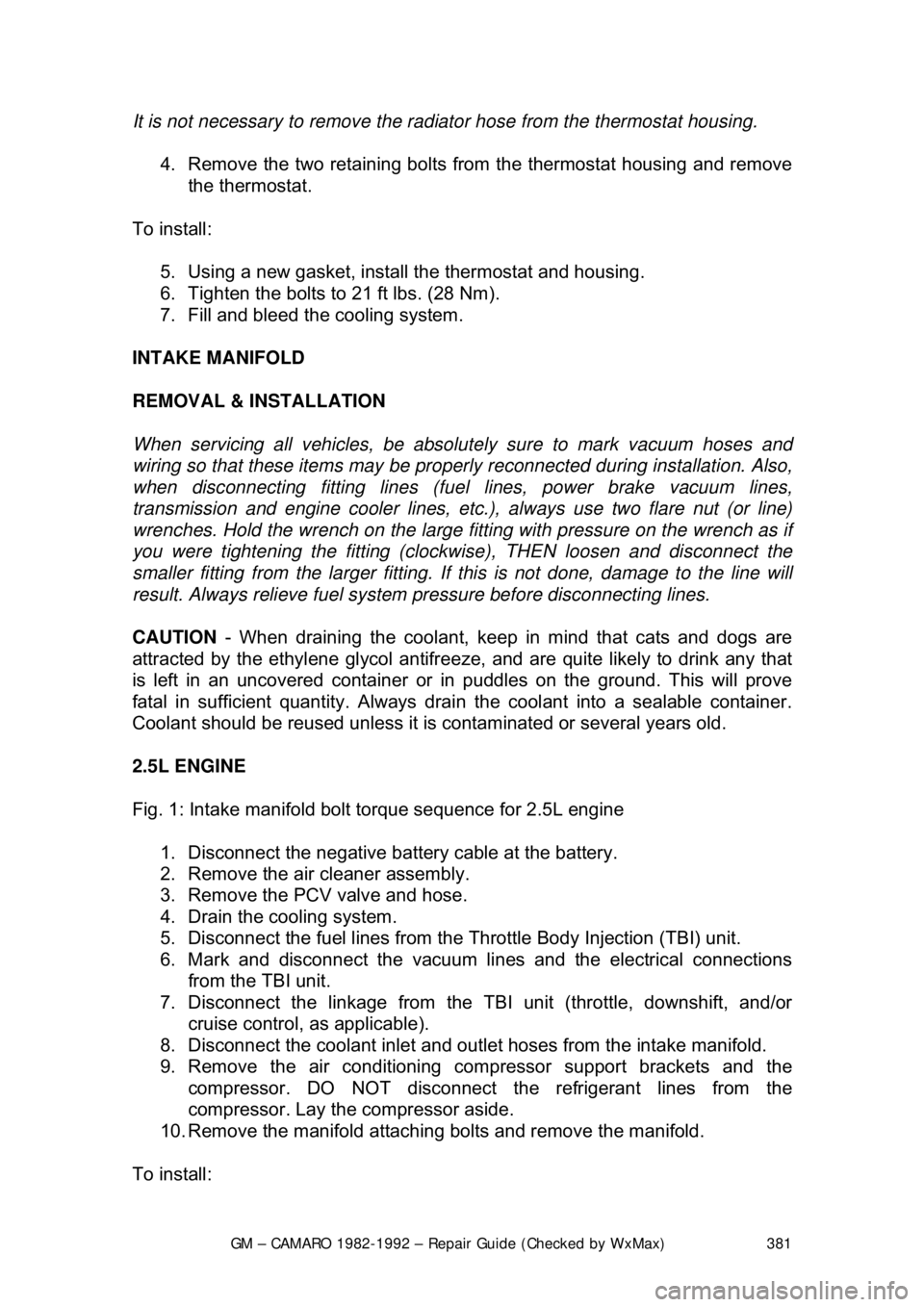

2.5L ENGINE

Fig. 1: Intake manifold bol t torque sequence for 2.5L engine

1. Disconnect the negative batte ry cable at the battery.

2. Remove the air cleaner assembly.

3. Remove the PCV valve and hose.

4. Drain the cooling system.

5. Disconnect the fuel lines from the Throttle Body Injection (TBI) unit.

6. Mark and disconnect the vacuum li nes and the electrical connections

from the TBI unit.

7. Disconnect the linkage from the TBI unit (throttle, downshift, and/or

cruise control, as applicable).

8. Disconnect the coolant inlet and outlet hoses from the intake manifold.

9. Remove the air conditioning co mpressor support brackets and the

compressor. DO NOT disconnect the refrigerant lines from the

compressor. Lay the compressor aside.

10. Remove the manifold attachi ng bolts and remove the manifold.

To install:

Page 408 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 408

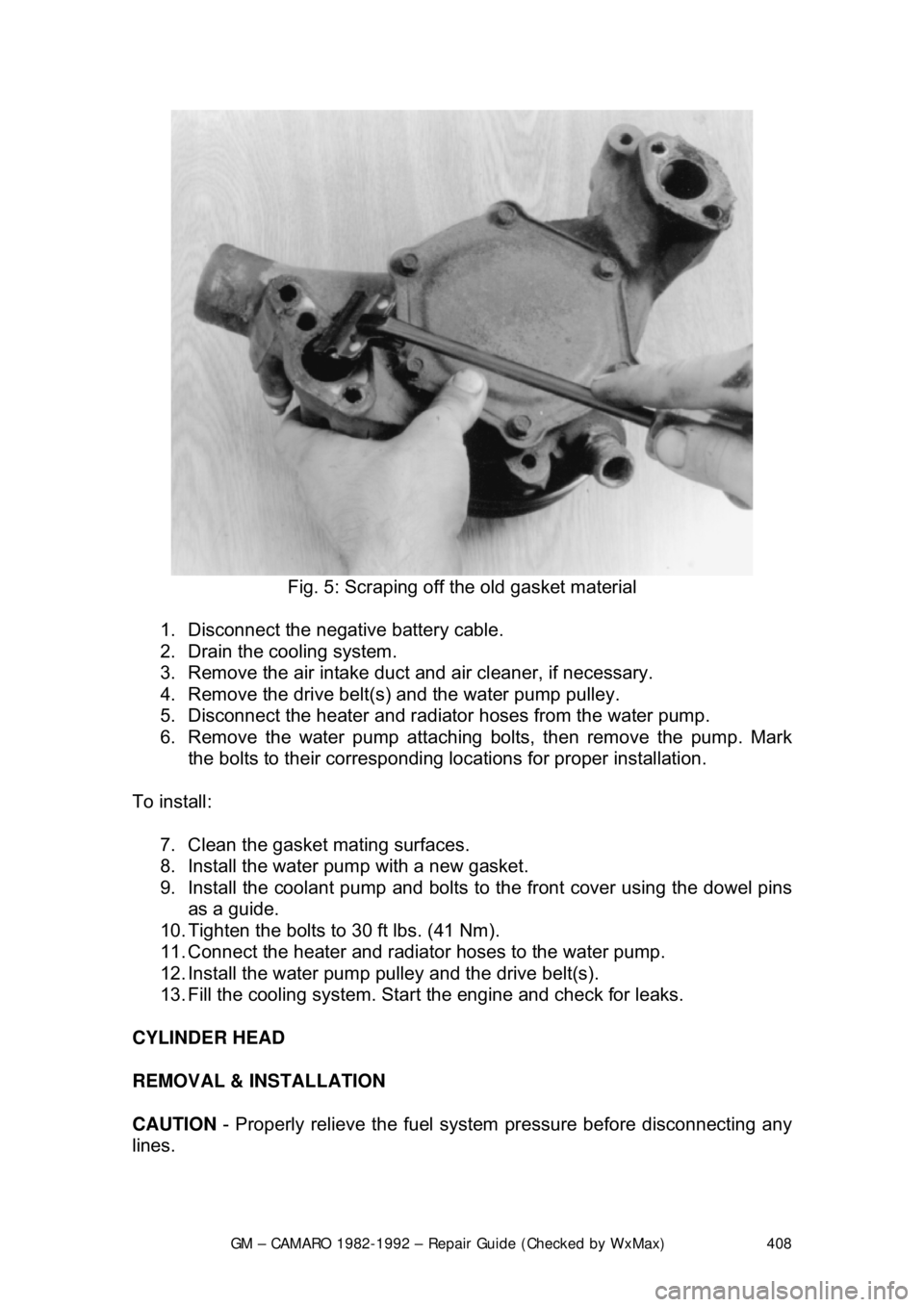

Fig. 5: Scraping off the old gasket material

1. Disconnect the negative battery cable.

2. Drain the cooling system.

3. Remove the air intake duct and air cleaner, if necessary.

4. Remove the drive belt(s) and the water pump pulley.

5. Disconnect the heater and radiator hoses from the water pump.

6. Remove the water pump attaching bolts, then remove the pump. Mark

the bolts to their corresponding loca tions for proper installation.

To install: 7. Clean the gasket mating surfaces.

8. Install the water pump with a new gasket.

9. Install the coolant pump and bolts to the front cover using the dowel pins

as a guide.

10. Tighten the bolts to 30 ft lbs. (41 Nm).

11. Connect the heater and radiator hoses to the water pump.

12. Install the water pump pu lley and the drive belt(s).

13. Fill the cooling syst em. Start the engine and check for leaks.

CYLINDER HEAD

REMOVAL & INSTALLATION

CAUTION - Properly relieve the fuel system pressure before disconnecting any

lines.

Page 409 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 409

When servicing the engine, be absolutely sure to mark vacuum hoses and

wiring so that these items

may be properly reconnected during installation. Also,

when disconnecting fittings of metal lines (fuel, power brake vacuum), always

use two flare nut (or line) wrenches. Ho ld the wrench on the large fitting with

pressure on the wrench as if you were tightening the fitting (clockwise), THEN

loosen and disconnect the smaller fitting fr om the larger fitting. If this is not

done, damage to the line will result.

CAUTION - When draining the coolant, keep in mind that cats and dogs are

attracted by the ethylene gl ycol antifreeze, and are quite likely to drink any that

is left in an uncovered container or in puddles on the ground. This will prove

fatal in sufficient quantity. Always drai n the coolant into a sealable container.

Coolant should be reused unless it is contaminated or several years old.

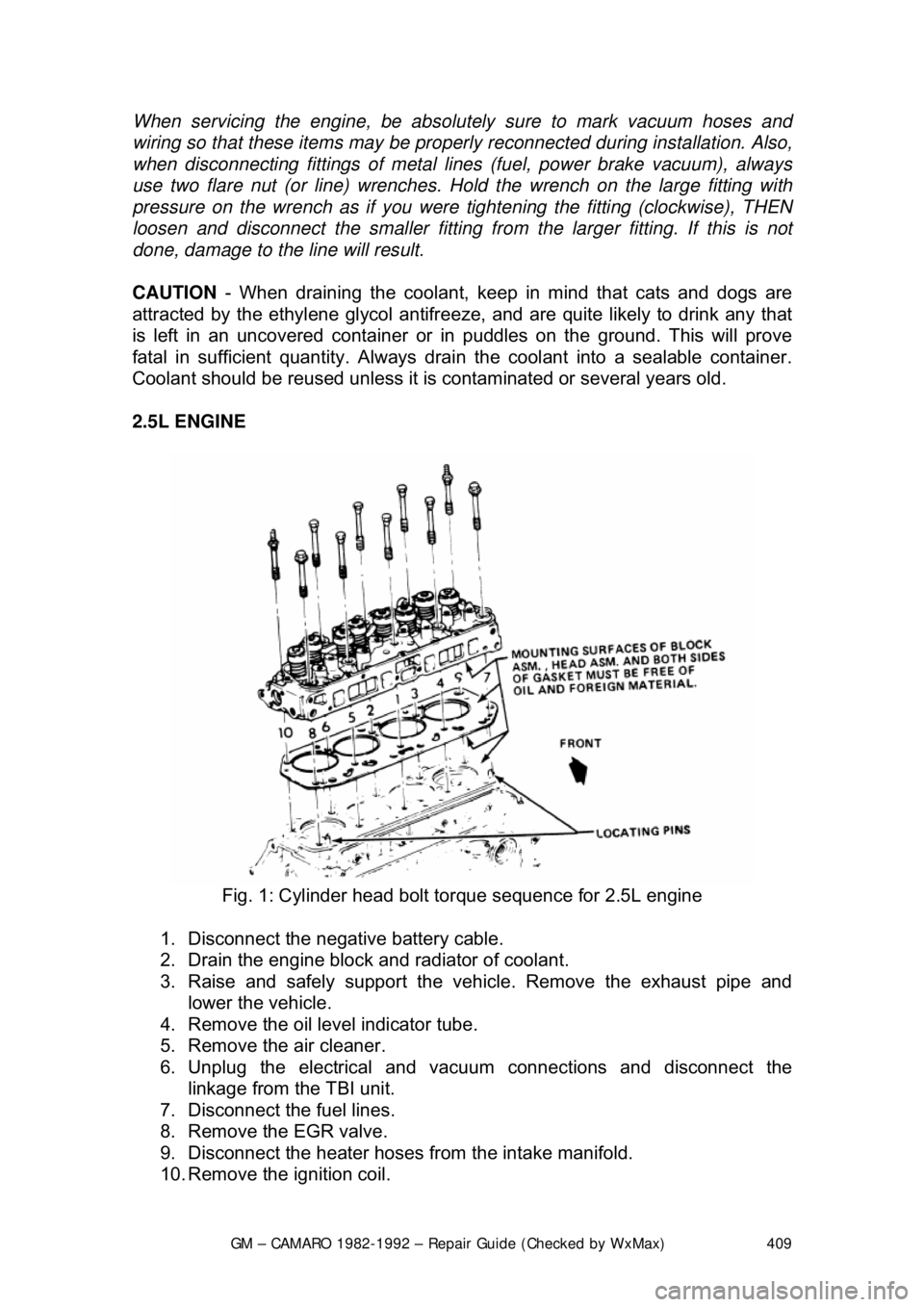

2.5L ENGINE

Fig. 1: Cylinder head bolt torque sequence for 2.5L engine

1. Disconnect the negative battery cable.

2. Drain the engine block and radiator of coolant.

3. Raise and safely support the vehi cle. Remove the exhaust pipe and

lower the vehicle.

4. Remove the oil level indicator tube.

5. Remove the air cleaner.

6. Unplug the electrical and vac uum connections and disconnect the

linkage from the TBI unit.

7. Disconnect the fuel lines.

8. Remove the EGR valve.

9. Disconnect the heater hoses from the intake manifold.

10. Remove the ignition coil.

Page 411 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 411

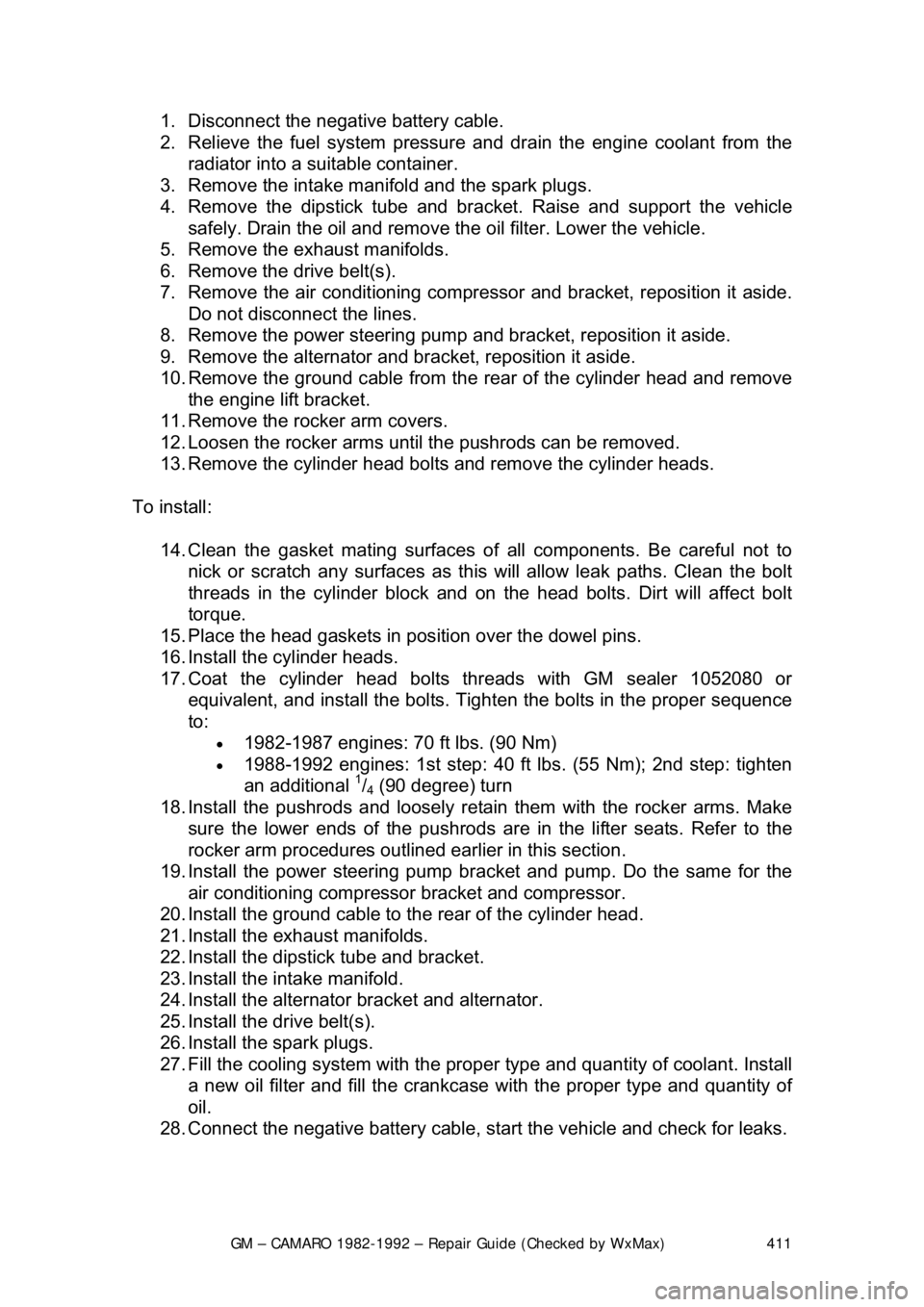

1. Disconnect the negative battery cable.

2. Relieve the fuel system pressure

and drain the engine coolant from the

radiator into a suitable container.

3. Remove the intake manifold and the spark plugs.

4. Remove the dipstick tube and bra cket. Raise and support the vehicle

safely. Drain the oil and remove the oil filter. Lower the vehicle.

5. Remove the exhaust manifolds.

6. Remove the drive belt(s).

7. Remove the air conditioning compresso r and bracket, reposition it aside.

Do not disconnect the lines.

8. Remove the power steering pump and bracket, reposition it aside.

9. Remove the alternator and br acket, reposition it aside.

10. Remove the ground cable from the rear of the cylinder head and remove

the engine lift bracket.

11. Remove the rocker arm covers.

12. Loosen the rocker arms until the pushrods can be removed.

13. Remove the cylinder head bolts and remove the cylinder heads.

To install: 14. Clean the gasket mating surfaces of all components. Be careful not to

nick or scratch any surfaces as this will allow leak paths. Clean the bolt

threads in the cylinder bl ock and on the head bolts. Dirt will affect bolt

torque.

15. Place the head gaskets in pos ition over the dowel pins.

16. Install the cylinder heads.

17. Coat the cylinder head bolts th reads with GM sealer 1052080 or

equivalent, and install the bolts. Tight en the bolts in the proper sequence

to:

• 1982-1987 engines: 70 ft lbs. (90 Nm)

• 1988-1992 engines: 1st step: 40 ft lbs. (55 Nm); 2nd step: tighten

an additional 1/4 (90 degree) turn

18. Install the pushrods a nd loosely retain them wit h the rocker arms. Make

sure the lower ends of the pushrods ar e in the lifter seats. Refer to the

rocker arm procedures outlined ea rlier in this section.

19. Install the power steering pump br acket and pump. Do the same for the

air conditioning compressor bracket and compressor.

20. Install the ground cable to t he rear of the cylinder head.

21. Install the exhaust manifolds.

22. Install the dipstick tube and bracket.

23. Install the intake manifold.

24. Install the alternator bracket and alternator.

25. Install the drive belt(s).

26. Install the spark plugs.

27. Fill the cooling system with the proper type and quantity of coolant. Install

a new oil filter and fill the crankca se with the proper type and quantity of

oil.

28. Connect the negative battery cable, star t the vehicle and check for leaks.

Page 416 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 416

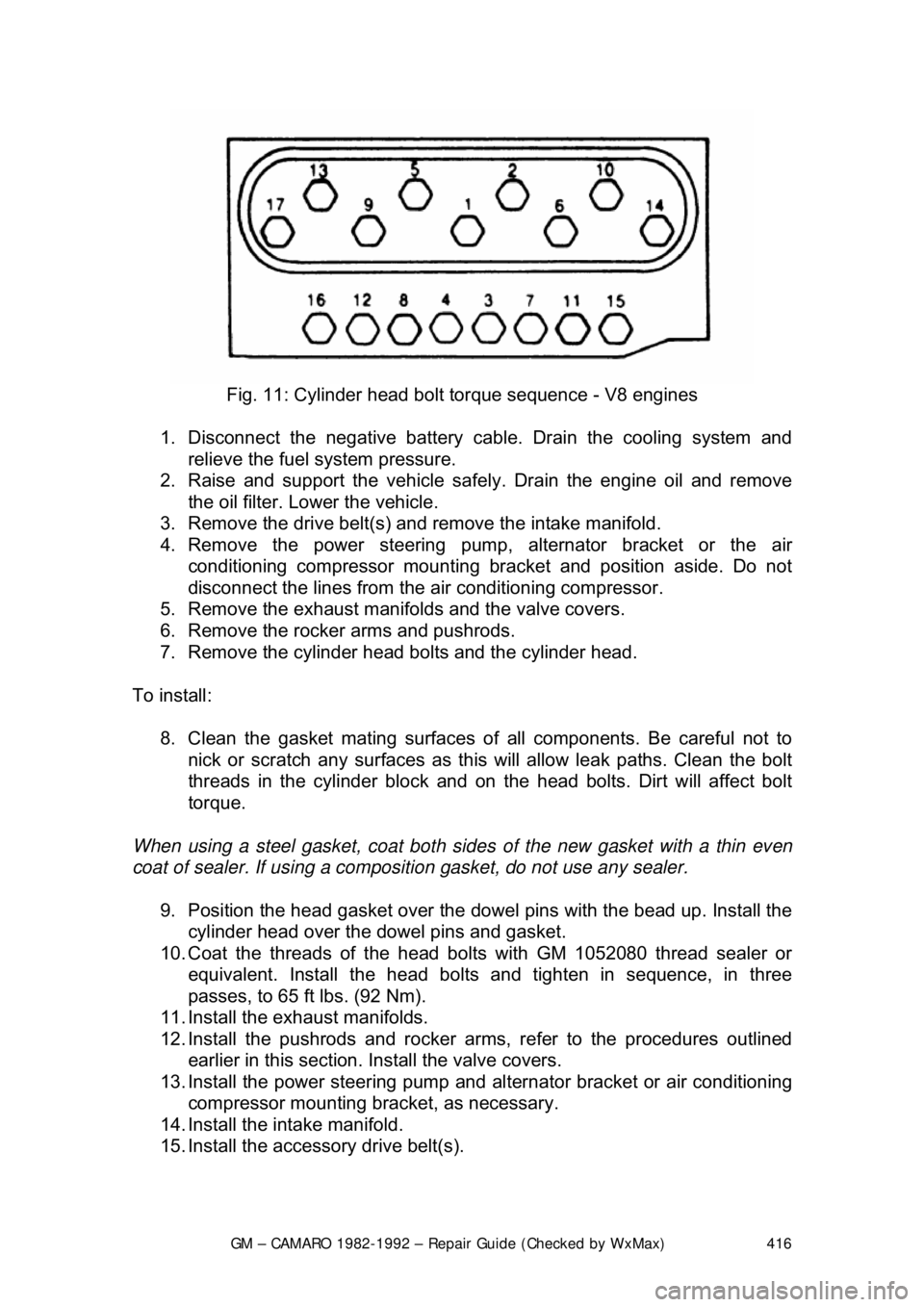

Fig. 11: Cylinder head bolt torque sequence - V8 engines

1. Disconnect the negative battery c able. Drain the cooling system and

relieve the fuel system pressure.

2. Raise and support the vehicle safe ly. Drain the engine oil and remove

the oil filter. Lower the vehicle.

3. Remove the drive belt(s) and remove the intake manifold.

4. Remove the power steering pump, alternator bracket or the air

conditioning compressor mounting br acket and position aside. Do not

disconnect the lines from the air conditioning compressor.

5. Remove the exhaust manifolds and the valve covers.

6. Remove the rocker arms and pushrods.

7. Remove the cylinder head bolts and the cylinder head.

To install: 8. Clean the gasket mating surfaces of all components. Be careful not to

nick or scratch any surfaces as this will allow leak paths. Clean the bolt

threads in the cylinder bl ock and on the head bolts. Dirt will affect bolt

torque.

When using a steel gasket, coat both sides of the new gasket with a thin even

coat of sealer. If using a compos ition gasket, do not use any sealer.

9. Position the head gasket over the dow el pins with the bead up. Install the

cylinder head over the dowel pins and gasket.

10. Coat the threads of the head bo lts with GM 1052080 thread sealer or

equivalent. Install the head bolts and tighten in sequence, in three

passes, to 65 ft lbs. (92 Nm).

11. Install the exhaust manifolds.

12. Install the pushrods and rocker arms, refer to the procedures outlined earlier in this section. Install the valve covers.

13. Install the power steering pump and al ternator bracket or air conditioning

compressor mounting bra cket, as necessary.

14. Install the intake manifold.

15. Install the accessory drive belt(s).

Page 465 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 465

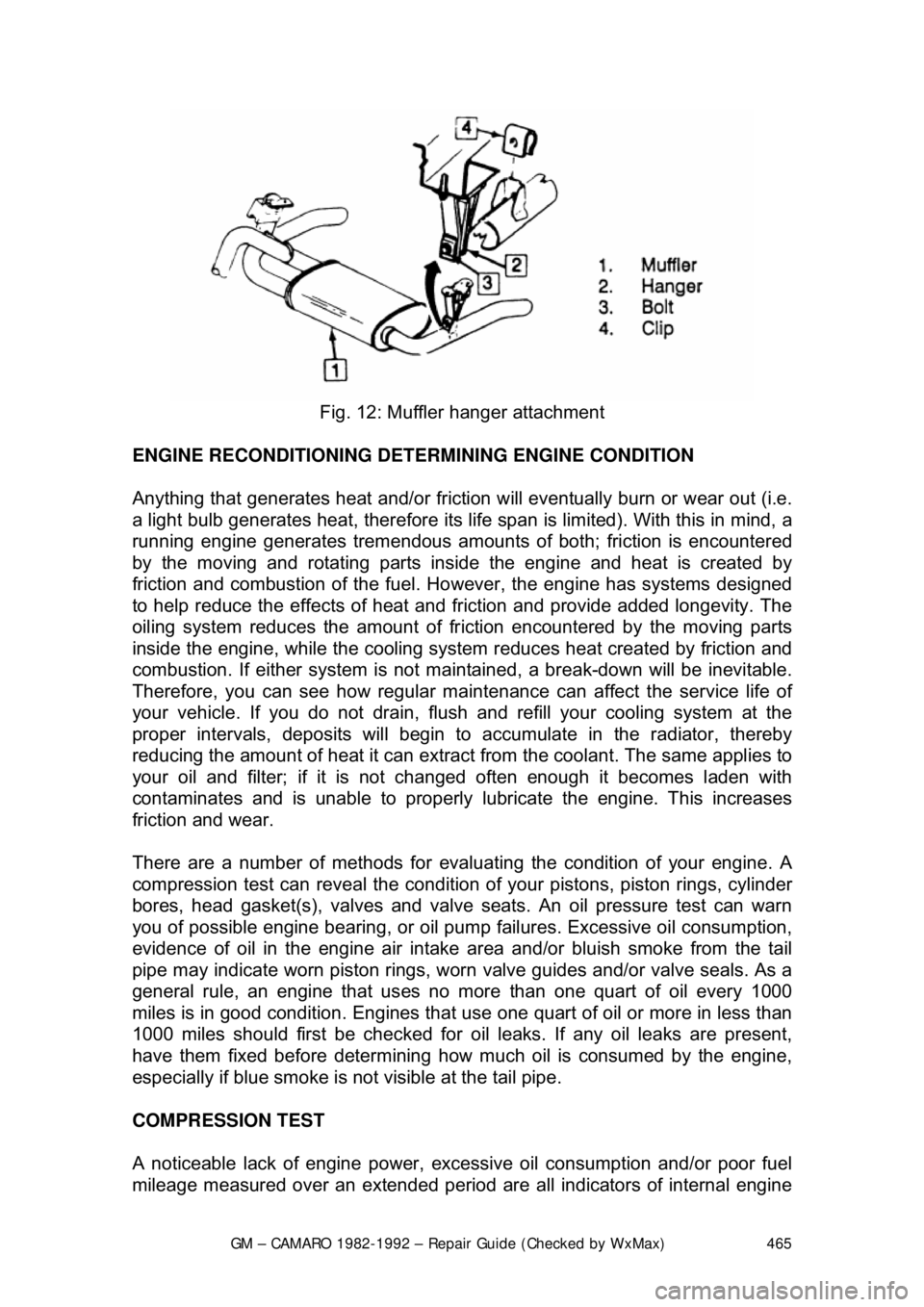

Fig. 12: Muffler hanger attachment

ENGINE RECONDITIONING DETE RMINING ENGINE CONDITION

Anything that generates heat and/or friction will eventually burn or wear out (i.e.

a light bulb generates heat, therefore its life span is limited). With this in mind, a

running engine generates trem endous amounts of both; friction is encountered

by the moving and rotating parts inside the engine and heat is created b\

y

friction and combustion of the fuel. Ho wever, the engine has systems designed

to help reduce the effects of heat and fr iction and provide added longevity. The

oiling system reduces the amount of fr iction encountered by the moving parts

inside the engine, while the cooling system reduces heat created by friction and

combustion. If either system is not main tained, a break-down will be inevitable.

Therefore, you can see how regular main tenance can affect the service life of

your vehicle. If you do not drain, flush and refill your cooling system at the

proper intervals, deposits will begin to accumulate in the radiator, thereby

reducing the amount of heat it can extrac t from the coolant. The same applies to

your oil and filter; if it is not changed often enoug h it becomes laden with

contaminates and is unable to properly lubricate the engine. This increases

friction and wear.

There are a number of methods for evaluat ing the condition of your engine. A

compression test can reveal the condition of your pistons, piston rings, cylinder

bores, head gasket(s), valves and valve seat s. An oil pressure test can warn

you of possible engine bearing, or oil pump failures. Excessive oil consumption,

evidence of oil in the engine air intake area and/or bluish smoke from the tail

pipe may indicate worn piston rings, worn valve guides and/or valve seals. As a

general rule, an engine that uses no more than one quart of oil every 1000

miles is in good condi tion. Engines that use one quart of oil or more in less than

1000 miles should first be checked for oil leaks. If any oil leaks are present,

have them fixed before dete rmining how much oil is consumed by the engine,

especially if blue smoke is not visible at the tail pipe.

COMPRESSION TEST

A noticeable lack of engine power, excessive oil consumption and/or poor fuel

mileage measured over an extended period are all indicators of internal engine

Page 541 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 541

EVAPORATIVE EMISS

ION CONTROLS

OPERATION

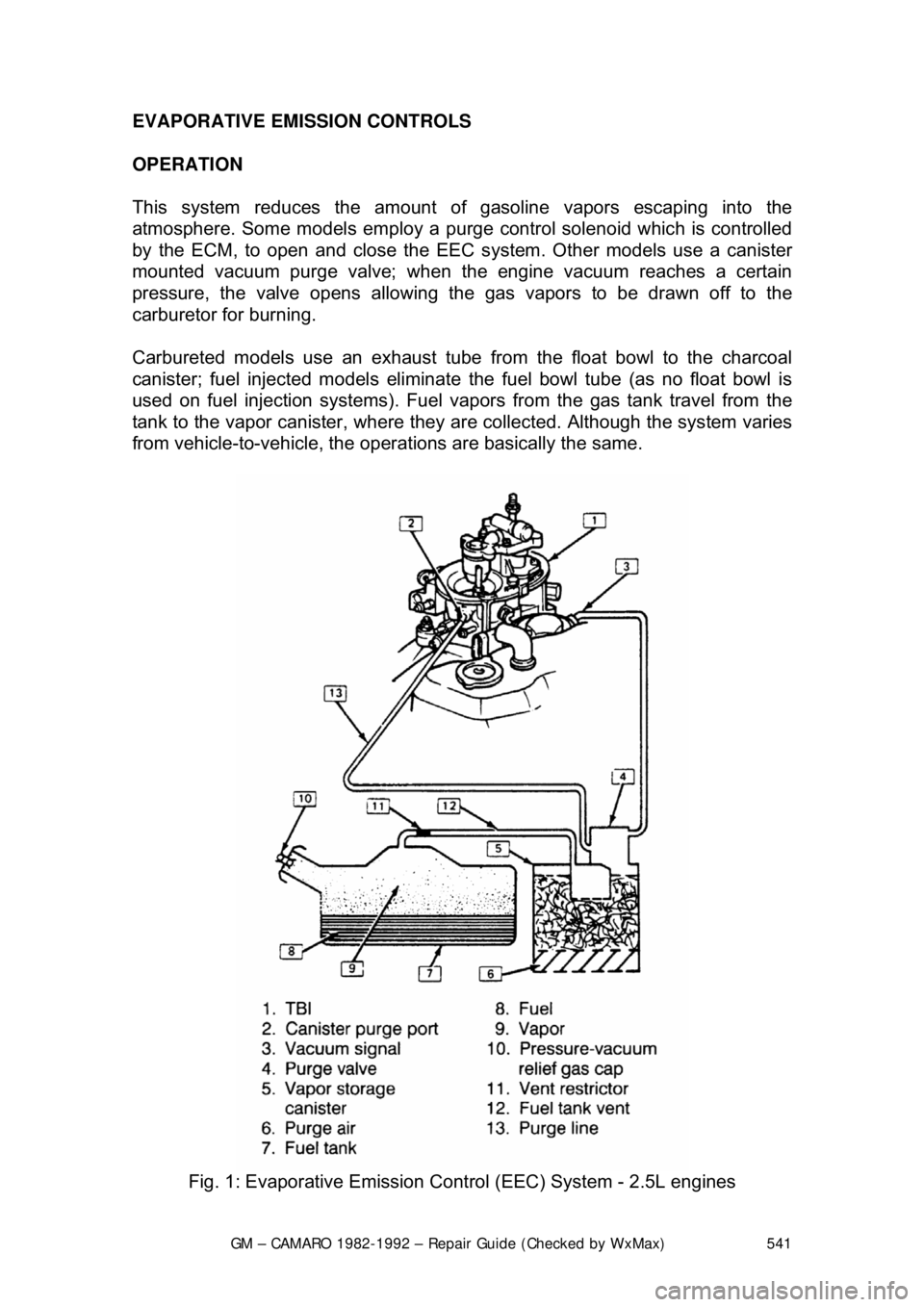

This system reduces the amount of gasoline vapors escaping into the

atmosphere. Some models em ploy a purge control solenoid which is controlled

by the ECM, to open and close the EE C system. Other models use a canister

mounted vacuum purge valve; when the engine vacuum reaches a certain

pressure, the valve opens allowing the gas vapors to be drawn off to the

carburetor for burning.

Carbureted models use an exhaust tube fr om the float bowl to the charcoal

canister; fuel injected models eliminate the fuel bowl tube (as no float bowl is

used on fuel injection systems). Fuel vapor s from the gas tank travel from the

tank to the vapor canister , where they are collected. Although the system varies

from vehicle-to-vehicle, the operat ions are basically the same.

Fig. 1: Evaporative Emission Cont rol (EEC) System - 2.5L engines

Page 547 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 547

EXHAUST GAS RECIRCULATION (EGR) SYSTEM

OPERATION

All models are equipped with

this system, which consists of a metering valve, a

vacuum line to the carburet or or intake manifold, and cast-in exhaust passages

in the intake manifold. The EGR valve is controlled by vacuum, which opens

and closes in response to the vacuum signals to admit exhaust gases into the

air/fuel mixture. The exhaust gases lower peak combustion temperatures,

reducing the formation of NOx. The valve is closed at idle and wide open

throttle, but is open between the two extreme positions.

There are actually four types of EGR systems: Ported, Positive Back-Pressure,

Negative Backpressure and Digital. The pr inciple of all the systems are the

same; the only difference is in the me thod used to control how the EGR valve

opens.

Too much EGR flow at idle, cruise or during cold operation may result in the

engine stalling after cold start, the engine stalling at idle after deceleration,

vehicle surge during cruise and rough idle . If the EGR valve is always open, the

vehicle may not idle. Too little or no EGR flow allows combustion temperatures

to rise, which could result in spar k knock (detonation), engine overheating

and/or emission test failure.

A Thermal Vacuum Switch (TVS) or vacuum control solenoid may sometimes\

be used in combination with the EGR va lve. The TVS will close off vacuum

during cold operation. A va cuum control solenoid uses Pulse Width Modulation

(PWM) to turn the solenoid ON and OFF numerous times a second and varies

the amount of ON time (pulse width) to vary the amount of ported vacuum

supplied the EGR valve.

PORTED VALVE

In the ported system, the amount of ex haust gas admitted into the intake

manifold depends on a ported vacuum signal. A ported vacuum signal is one

taken from the carburetor above the th rottle plates; thus, the vacuum signal

(amount of vacuum) is dependent on how far the throttle plates are opened.

When the throttle is closed (idle or dec eleration) there is no vacuum signal.

Thus, the EGR valve is closed, and no exhaust gas enters the intake mani\

fold.

As the throttle is opened, a vacuum is produced, which opens the EGR valve,

admitting exhaust gas into the intake manifold.

POSITIVE BACKPRE SSURE VALVE

This valve operates the same as the ported, except, it has an internal air bleed

that acts as a vacuum regulator. T he bleed valve controls the amount of

vacuum inside the vacuum chamber duri ng operation. When the valve receives

sufficient exhaust backpressure through the hollow shaft, it closes the bleed; at

this point the EGR valve opens.

Page 573 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 573

7. Install the retaining bracket.

8. Connect the negative battery cable.

ELECTRONIC ENGINE CONTROLS

COMPUTER COMMAND CO NTROL (CCC) SYSTEM

The Computer Command Control (CCC) Sy stem is an electronically controlled

exhaust emission system that can m onitor and control a large number of

interrelated emission cont rol systems. It can monitor various engine/vehicle

operating conditions and then use this in formation to control multiple engine

related systems. The CCC syst em is thereby making constant adjustments to

maintain optimum vehicle performance und er all normal driving conditions while

at the same time allowing the catalyti c converter to effectively control the

emissions of HC, CO and NO

x.

OPERATION

The Electronic Control Module (ECM) is required to maintain the exhaust

emissions at acceptable le vels. The module is a sma ll, solid state computer

which receives signals from many source s and sensors; it uses these data to

make judgements about operating conditions and then control output signals to

the fuel and emission systems to ma tch the current requirements.

Inputs are received from m any sources to form a complete picture of engine

operating conditions. Some inputs are simp ly Yes or No messages, such as that

from the Park/Neutral switch; the vehicle is either in gear or in Park/Neutral;

there are no other choices. Other data is sent in quantitative input, such as

engine rpm or coolant temperature. T he ECM is pre-programmed to recognize

acceptable ranges or combinations of si gnals and control the outputs to control

emissions while providing good driv eability and economy. The ECM also

monitors some output circuits, making sure that the components function as

commanded. For proper engine oper ation, it is essential that all input and output

components function properly and comm unicate properly with the ECM.

Since the control module is programmed to recognize the presence and value

of electrical inputs, it will also note the lack of a signal or a radical change in

values. It will, for example, react to the loss of signal from the vehicle speed

sensor or note that engine coolant temperature has risen beyond acceptable

(programmed) limits. Once a fault is recognized, a numeric code is assigned

and held in memory. The SERVICE ENGIN E SOON Malfunction Indicator Lamp

(MIL), will illuminate to advise the operator that the system has detected a fault.

More than one code may be stored. Although not every engine uses every

code, possible codes range from 12-999. Additionally, the same code may carry

different meanings relative to each engine or engine family. For example, on the

3.3L (VIN N) engine, code 46 indicates a fault found in the power steering

pressure switch circuit. The same code on the 5.7L (VIN F) engine indicates a

fault in the VATS anti-theft system.