seat adjustment CHEVROLET CAMARO 1982 Repair Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1982, Model line: CAMARO, Model: CHEVROLET CAMARO 1982Pages: 875, PDF Size: 88.64 MB

Page 55 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 55

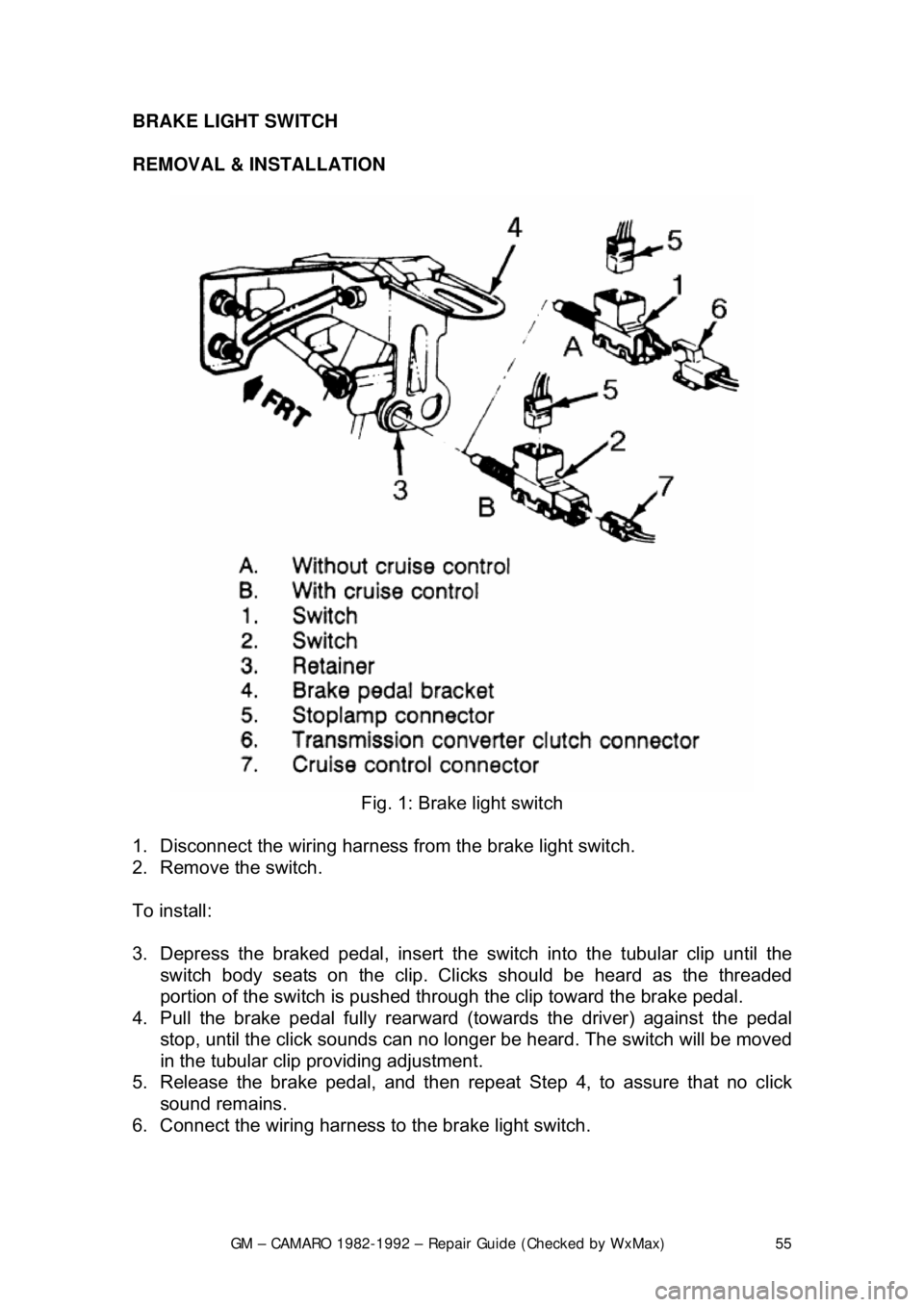

BRAKE LIGHT SWITCH

REMOVAL & INSTALLATION

Fig. 1: Brake light switch

1. Disconnect the wiring harness fr om the brake light switch.

2. Remove the switch.

To install:

3. Depress the braked pedal, insert the switch into the tubular clip until the

switch body seats on the clip. Cli cks should be heard as the threaded

portion of the switch is pushed through the clip toward the brake pedal.\

4. Pull the brake pe dal fully rearward (towards the driver) against the pedal

stop, until the click sounds can no long er be heard. The switch will be moved

in the tubular clip providing adjustment.

5. Release the brak e pedal, and then repeat Step 4, to assure that no click

sound remains.

6. Connect the wiring harness to the brake light switch.

Page 112 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 112

4. Position a C-clamp a

nd tighten until the piston bottoms in the base of the

caliper housing. Make sure 1 end of the C-clamp rests on the inlet fitting bolt

and the other against the outboard disc brake pad.

It is not necessary to remove the parki ng brake caliper lever return spring to

replace the disc brake pads.

5. Remove the upper caliper guide pin bolt and discard.

6. Rotate the caliper housing. Be careful not to strain the hose or cable conduit.

7. Remove the disc brake pads.

To install:

8. Clean all residue from the pad guide surfaces on the mounting bracket and

caliper housing. Inspect the guide pins for free movement in the mounting

bracket. Replace the guide pins or boot s, if they are corroded or damaged.

9. Install the disc brake pads. The out board pad with insulator is installed

toward the caliper housing. The inboard pad with the w ear sensor is installed

nearest the caliper piston. The wear sens or must be in the trailing position

with forward wheel rotation.

10. Rotate the caliper housing into it 's operating position. The springs on the

outboard brake pad must not stick through the inspection hole in the caliper

housing. If the springs are sticking thr ough the inspection hole in the caliper

housing, lift the caliper housing and make the necessary corrections to the

outboard brake pad positions.

11. Install a new upper cali per guide pin bolt and tight en to 26 ft. lbs. (35 Nm).

Tighten the lower caliper guide pin bolt to 16 ft. lbs. (22 Nm).

12. With the engine runni ng, pump the brake pedal slo wly and firmly to seat the

brake pads.

13. Check the caliper parking brake levers to make sure they are against the

stops on the caliper housing. If the leve rs are not on their stops, check the

parking brake adjustment.

14. Remove the 2 wheel nuts from t he rotor and install the wheel and tire

assembly.

15. Lower the vehicle, che ck the master cylinder fluid level and road test the

vehicle.

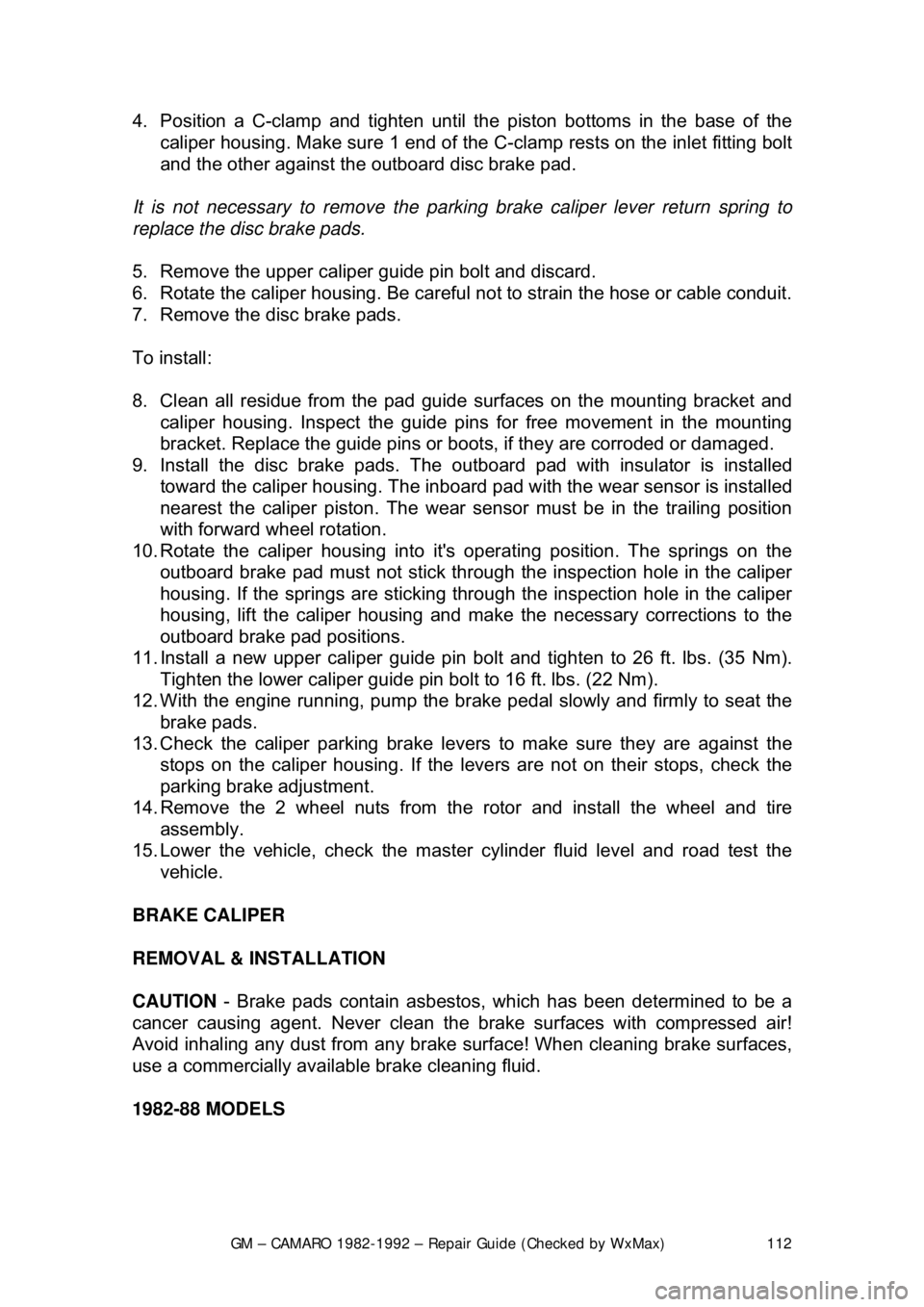

BRAKE CALIPER

REMOVAL & INSTALLATION

CAUTION - Brake pads contain asbestos, which has been determined to be a

cancer causing agent. Never clean the brake surfaces with compressed air!

Avoid inhaling any dust from any brake surface! When cleaning brake surfaces,

use a commercially available brake cleaning fluid.

1982-88 MODELS

Page 114 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 114

9. Inspect the guide pins and boots and re

place if corroded, worn or damaged.

Check the inlet fitting bolt for blockage.

10. Install the caliper housing over t he rotor and into the mounting bracket.

Install the 2 caliper guide pin bolts. Tighten the upper caliper guide pin bolt

to 26 ft. lbs. (35 Nm) and the lower gui de pin bolt to 16 ft. lbs. (22 Nm).

11. Connect the parking brake cable to t he caliper bracket and caliper lever.

Install the caliper lever return spring, if removed.

12. Install the inlet fitting, bolt and 2 new washers to the caliper housing. Tighten

the bolt to 22 ft. lbs. (30 Nm).

13. Bleed the brake system.

14. Adjust the parking brake free trav el if the caliper was overhauled.

15. Lower the vehicle and cycle the parking brake.

16. Raise and safely support the vehicle.

17. Inspect the caliper parking brake levers and ensure they are against the

stops on the caliper housing. If the levers are not on their stop, refer to the

parking brake adjustment.

18. Remove the 2 nuts securing the roto r and then install the wheel and tire

assembly. Lower the vehicle.

19. With the engine running, pump the br ake pedal slowly and firmly 3 times to

seat the disc brake pads. Check the hydraulic system for leaks.

OVERHAUL

1982-88 MODELS

Fig. 1: Rear caliper exploded view

Page 169 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 169

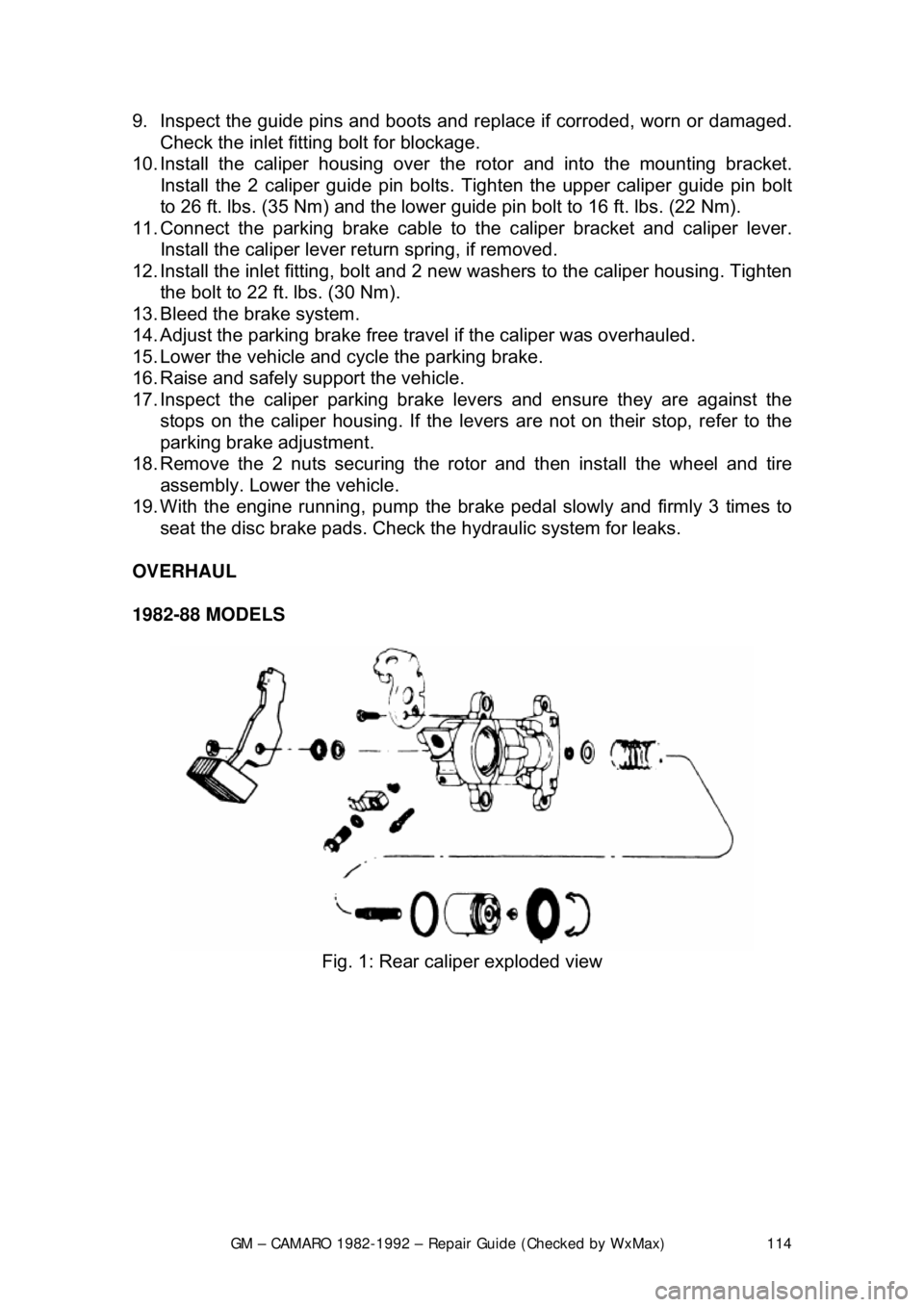

Fig. 2: Cruise control release sw itch location; all models similar

ENGAGEMENT SWITCH

The engagement switch cannot be serviced . The complete multi-function lever

(turn signal lever) must be replaced as an assembly.

ADJUSTMENT

1. Depress the brake pedal and check that the release switch is fully seated

in the clips.

2. Slowly pull the brake pedal back to the at-rest position; the switch and

valve assembly will move within the clips to the adjusted position.

3. Measure pedal travel and check s witch engagement. The electric brake

release switch contacts must open at less than 1 inch (25.4 mm) of pedal

travel. The vacuum release should engage between

5/8 and 1 inch (16-

25mm) of pedal travel.

SERVO

REMOVAL & INSTALLATION 1. Disconnect the electrical connecto r and vacuum hoses at the servo.

2. Disconnect the actuating chain, cable or rod from the servo.

3. Remove the screws holding the vac uum servo and solenoid unit to the

bracket, then remove the unit.

To install:

Page 581 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 581

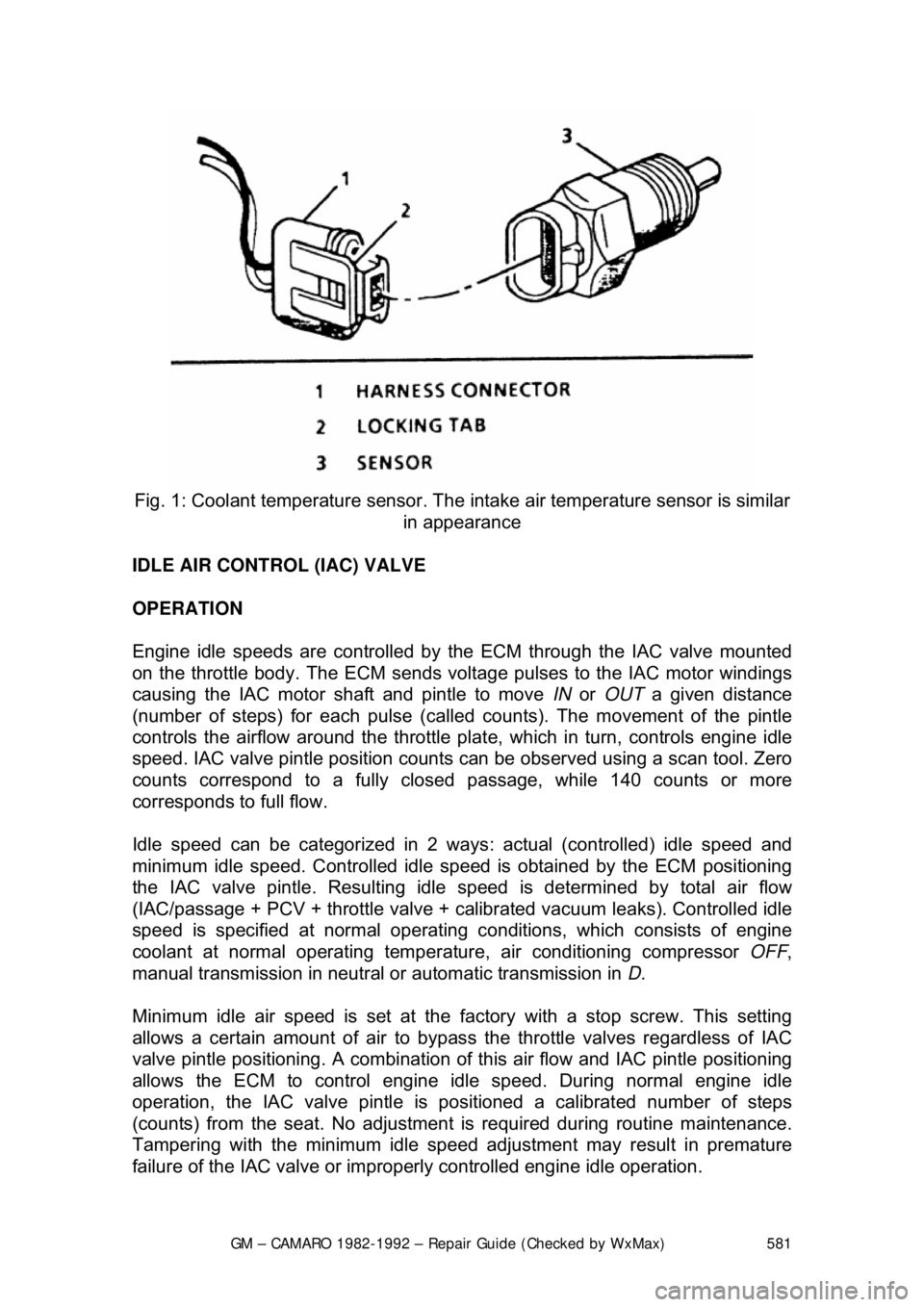

Fig. 1: Coolant temperature sensor. The in take air temperature sensor is similar

in appearance

IDLE AIR CONTROL (IAC) VALVE

OPERATION

Engine idle speeds are controlled by the ECM through the IAC valve mounted

on the throttle body. The ECM sends volt age pulses to the IAC motor windings

causing the IAC motor shaft and pintle to move IN or OUT a given distance

(number of steps) for each pulse (called counts). The movement of the pintle

controls the airflow around the throttle plat e, which in turn, controls engine idle

speed. IAC valve pintle position counts ca n be observed using a scan tool. Zero

counts correspond to a fully closed passage, while 140 counts or more

corresponds to full flow.

Idle speed can be categorized in 2 ways : actual (controlled) idle speed and

minimum idle speed. Contro lled idle speed is obtained by the ECM positioning

the IAC valve pintle. Resulting idle speed is determined by total air fl\

ow

(IAC/passage + PCV + throttle valve + ca librated vacuum leaks). Controlled idle

speed is specified at normal operating c onditions, which consists of engine

coolant at normal operating temper ature, air conditioning compressor OFF,

manual transmission in neutral or automatic transmission in D.

Minimum idle air speed is set at t he factory with a stop screw. This setting

allows a certain amount of air to bypas s the throttle valves regardless of IAC

valve pintle positioning. A co mbination of this air flow and IAC pintle positioning

allows the ECM to control engine idle speed. During normal engine idle

operation, the IAC valve pintle is positioned a calibrated number of steps

(counts) from the seat. No adjustment is required during routine maintenance.

Tampering with the minimum idle speed adjustment may result in premature

failure of the IAC valve or imprope rly controlled engine idle operation.

Page 672 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 672

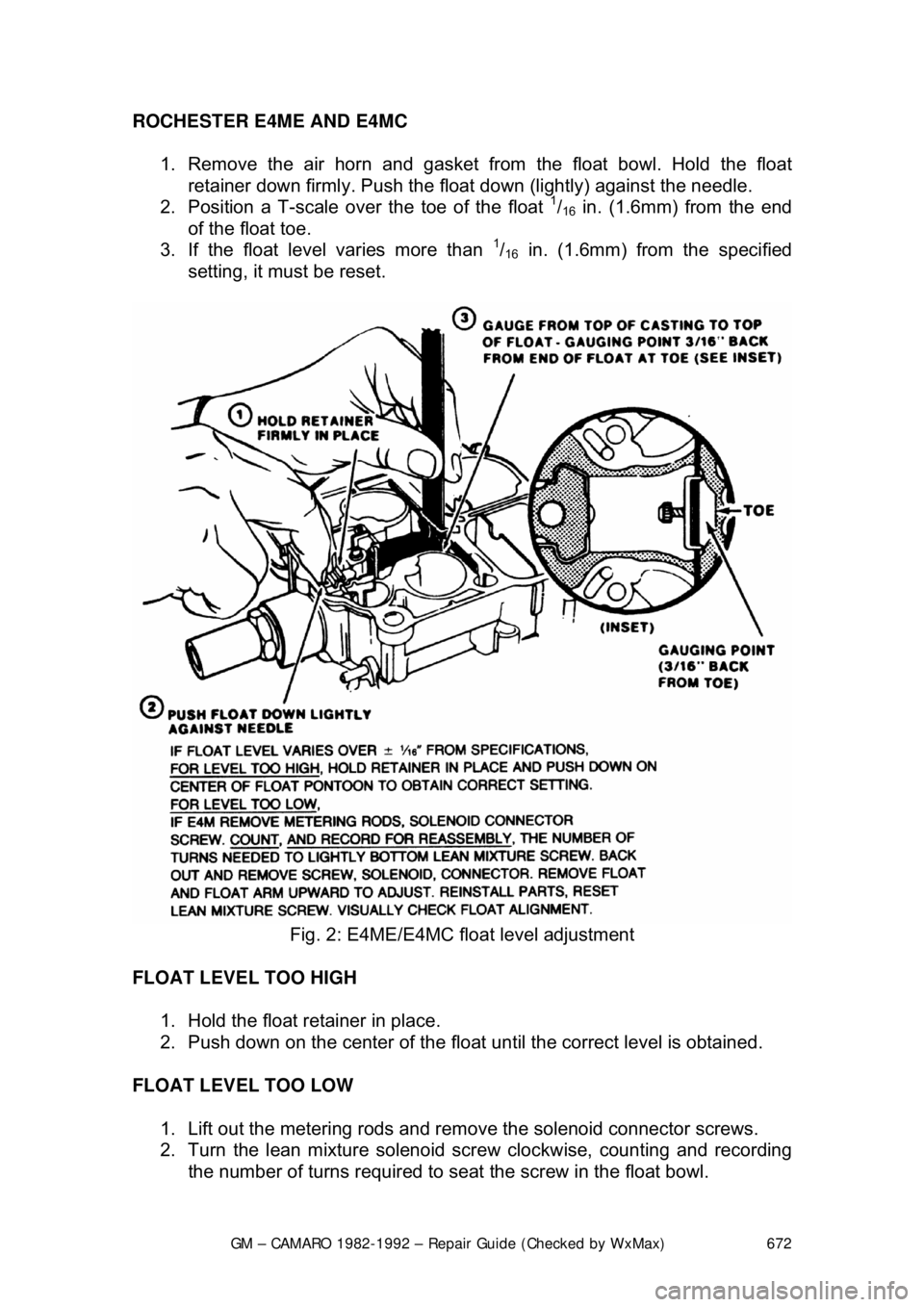

ROCHESTER E4ME AND E4MC

1. Remove the air horn and gasket from the float bowl. Hold the float retainer down firmly. Push the float down (lightly) against the needle.

2. Position a T-scale ov er the toe of the float

1/16 in. (1.6mm) from the end

of the float toe.

3. If the float level varies more than

1/16 in. (1.6mm) from the specified

setting, it must be reset.

Fig. 2: E4ME/E4MC float level adjustment

FLOAT LEVEL TOO HIGH 1. Hold the float retainer in place.

2. Push down on the center of the float until the correct level is obtained.

FLOAT LEVEL TOO LOW 1. Lift out the metering rods and remo ve the solenoid connector screws.

2. Turn the lean mixture solenoid screw clockwise, counting and recording

the number of turns required to seat the screw in the float bowl.

Page 695 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 695

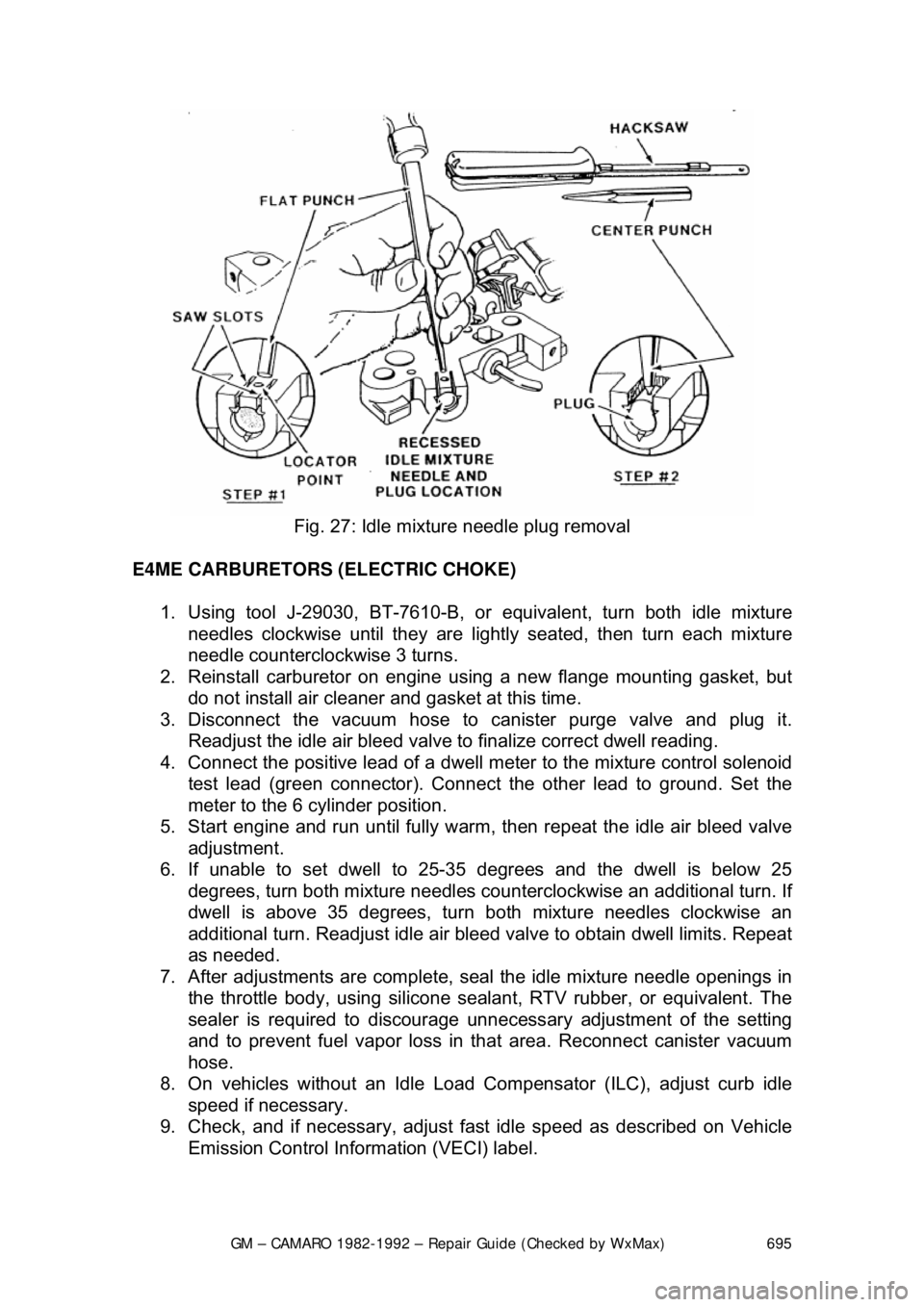

Fig. 27: Idle mixture needle plug removal

E4ME CARBURETORS (ELECTRIC CHOKE) 1. Using tool J-29030, BT-7610-B, or equivalent, turn both idle mixture

needles clockwise until they are lightly seated, then turn each mixture

needle counterclockwise 3 turns.

2. Reinstall carburetor on engine using a new flange mounting gasket, but

do not install air cleaner and gasket at this time.

3. Disconnect the vacuum hose to canister purge valve and plug it.

Readjust the idle air bleed valve to finalize correct dwell reading.

4. Connect the positive lead of a dwell me ter to the mixture control solenoid

test lead (green connector). Connect the other lead to ground. Set the

meter to the 6 cylinder position.

5. Start engine and run unt il fully warm, then repeat the idle air bleed valve

adjustment.

6. If unable to set dwell to 25-35 degrees and the dwell is below 25

degrees, turn both mixture needles counter clockwise an additional turn. If

dwell is above 35 degrees, turn both mixture needles clockwise an

additional turn. Readjust idle air bleed valve to obtain dwell limits. Repeat

as needed.

7. After adjustments are complete, seal the idle mixture needle openings in

the throttle body, using silicone sealant, RTV rubber, or equivalent. The

sealer is required to discourage unnecessary adjus tment of the setting

and to prevent fuel vapor loss in that area. Reconnect canister vacuum

hose.

8. On vehicles without an Idle Load Co mpensator (ILC), adjust curb idle

speed if necessary.

9. Check, and if necessary, adjust fa st idle speed as described on Vehicle

Emission Control Information (VECI) label.

Page 696 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 696

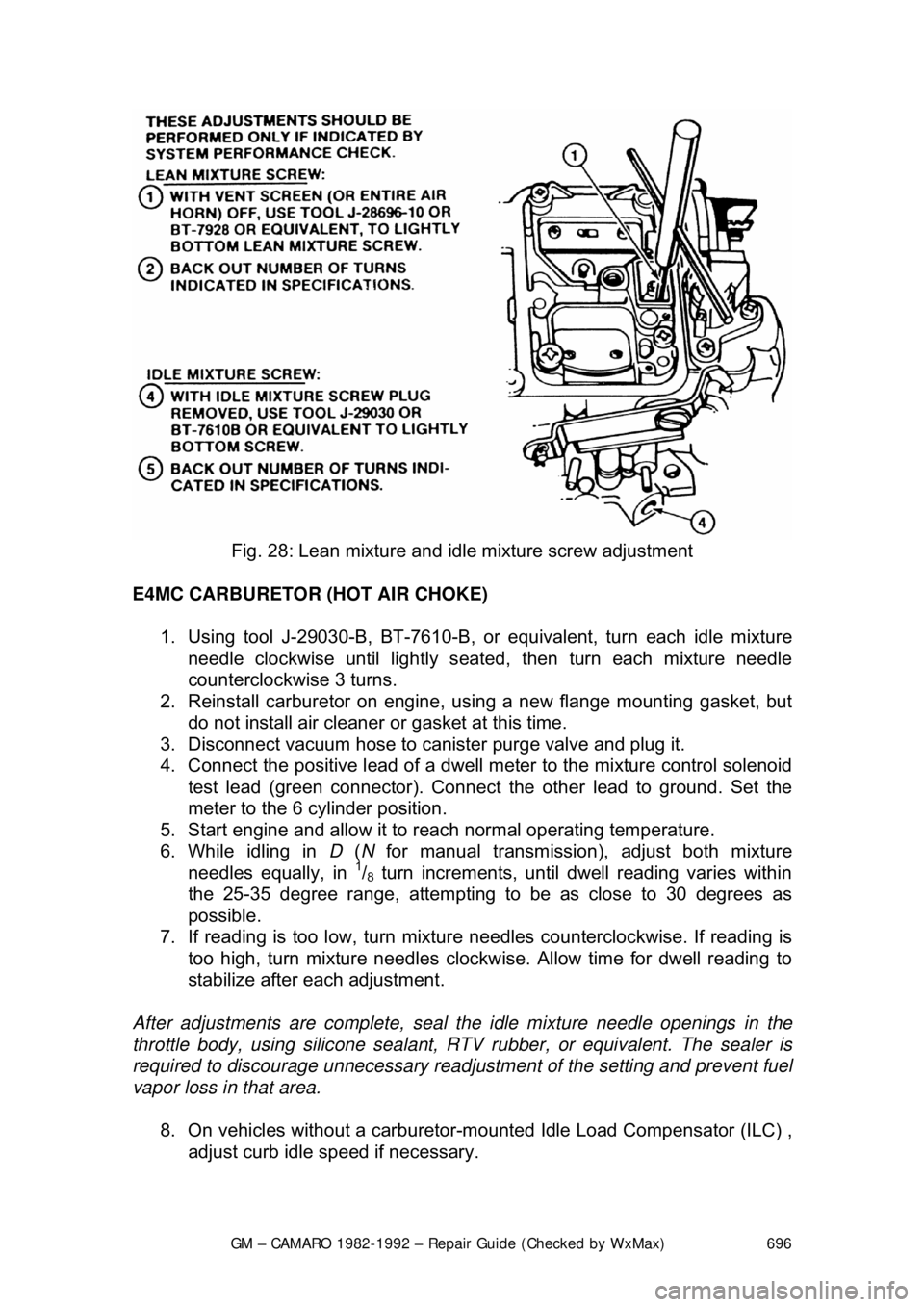

Fig. 28: Lean mixture and idle mixture screw adjustment

E4MC CARBURETOR (HOT AIR CHOKE) 1. Using tool J-29030-B, BT-7610-B, or equivalent, turn each idle mixture

needle clockwise until lightly seated, then turn each mixture needle

counterclockwise 3 turns.

2. Reinstall carburetor on engine, using a new flange mounting gasket, but

do not install air cleaner or gasket at this time.

3. Disconnect vacuum hose to c anister purge valve and plug it.

4. Connect the positive lead of a dwell me ter to the mixture control solenoid

test lead (green connector). Connect the other lead to ground. Set the

meter to the 6 cylinder position.

5. Start engine and allow it to reac h normal operating temperature.

6. While idling in D ( N for manual transmission), adjust both mixture

needles equally, in

1/8 turn increments, until dwell reading varies within

the 25-35 degree range, attempting to be as close to 30 degrees as

possible.

7. If reading is too low, turn mixtur e needles counterclockwise. If reading is

too high, turn mixture needl es clockwise. Allow time for dwell reading to

stabilize after each adjustment.

After adjustments are complete, seal t he idle mixture needle openings in the

throttle body, using silicone sealant, RTV rubber, or equivalent. The sealer is

required to discourage unnece ssary readjustment of the setting and prevent fuel

vapor loss in that area.

8. On vehicles without a carburetor -mounted Idle Load Compensator (ILC) ,

adjust curb idle speed if necessary.

Page 710 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 710

•

Check the pump passages and the jet(s) for dirt, improper seating of the

discharge checkball or t he temperature bypass disc and/or scores in the

pumpwell. Check the condition of t he pump discharge check ball spring,

replace as necessary

• Check the pump linkage for excessiv e wear; repair or replace as

necessary

HARD STARTING-POOR COLD OPERATION

• Check the choke valve and linkage for excessive wear, binds or

distortion

• Test the vacuum break diaphragm(s) for leaks

• Clean or replace the fuel filter

• Inspect the float valve fo r sticking, dirt, etc.

• Also check the items under "Flooding"

POOR PERFORMANCE-POOR GAS MILEAGE

• Clean all fuel and vacuum passages in the castings

• Check the choke valve fo r freedom of movement

• Check the Mixture Control (M/C) soleno id for sticking, binding or leaking

• Check the air valve and secondary me tering rod for binding conditions. If

the air valve or metering rod is da maged or the metering rod adjustment

is changed from the factory setting, the air horn assembly must be

replaced. Also check the air valve le ver spring for proper installation

ROUGH IDLE

• Inspect the gasket and gasket mating su rfaces on the casting for nicks,

burrs or damage to the sealing beads

• Check the operation and sealing of the mixture control solenoid

• Clean all of the idle field passages

• If removed, inspect the idle mixture needle for ridges, burrs or being bent

• Check the throttle lever and valves for binds, nicks. or other damage

• Check all of the diaphragms for possible ruptures or leaks

After cleaning and checking all components, reassemble the carburetor, using

new parts and referring to the exploded view. When reassembling, make sure

that all screws and jets are tight in their seats, but do not overtighten as the tips

will be distorted. Tighten al l screws gradually, in rotation. Do not tighten needle

valves into their seats; uneven jetting will result. Always use new gaskets. Be

sure to follow all assembly and adjustment procedures.

Before performing any service on the carburet or, it is essential that it be placed

on a suitable holding fixtur e, such as tool J-9789-118, BY-30-15 or equivalent.

Without the use of the holding fixture, it is possible to damage throttle valves or

other parts of the carburetor.

Page 719 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 719

11. Lubricate the new large O-ring with cl

ean engine oil and install it directly

over the backup washer. Be sure t he O-ring is seated properly and is

flush with the top of the fuel meter body surface.

12. Lubricate the new small O-ring with clean engine oil and install it on the

nozzle end of the injector. Push t he O-ring on far enough to contact the

filter.

WARNING - Do not attempt to reverse this procedure and install the backup

washer and O-ring after the injector is located in the cavity. To do so will

prevent proper seating of the O-ring in th e cavity recess which could result in a

fuel leak and possible fire.

13. Install the injector by aligning the raised lug on the injector base with the

notch cast into the fuel meter body . Push down on the injector making

sure it is fully seated in the cavity. In jector installation is correct when the

lug is seated in the notch and the electrical terminals are parallel to the

throttle shaft.

14. Using new gaskets on the fuel mete r cover and a new dust seal, install

the cover to the fuel meter body. Use an appropriate thread locking

compound on the cover attaching screws.

15. Connect the injector electrical c onnector by pushing straight down until

seated firmly in place.

16. Connect the negative battery cable.

17. With the engine OFF and the igniti on ON, check for fuel leaks.

18. Install the air cleaner.

ADJUSTMENTS

MINIMUM IDLE SPEED

Minimum idle speed should only be adjus ted when installing a replacement

throttle body. The idle stop screw is used to regulate the minimum idle speed of

the engine. The throttle body is adjusted at the factory, then covered with a cap

or plug to discourage unnecessary readjustment.

2.5L ENGINES 1. Remove the air cleaner and pl ug the THERMAC vacuum port.

2. Disconnect the TV cable from the th rottle control bracket to allow access

to the idle adjustment screw.

3. Remove the throttle stop screw plug or cap.

4. Connect a tachometer to the engine.

5. Disconnect the Idle Air Control (IAC) valve connector.

6. Start the engine with the transmi ssion in PARK (auto transmission) or

NEUTRAL (manual transmission) and allow the engine speed to

stabilize. All accessories (A/C, rear defogger, etc.) should be OFF.

7. Install tool J-33047 in t he idle air passage of the throttle body. Be certain

that the tool seats fully in t he passage and no air leaks exist.