belt CHEVROLET DYNASTY 1993 Owners Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 1702 of 2438

for diagnostic and service procedures on the air control

valve and temperature sensor located in the air

cleaner.

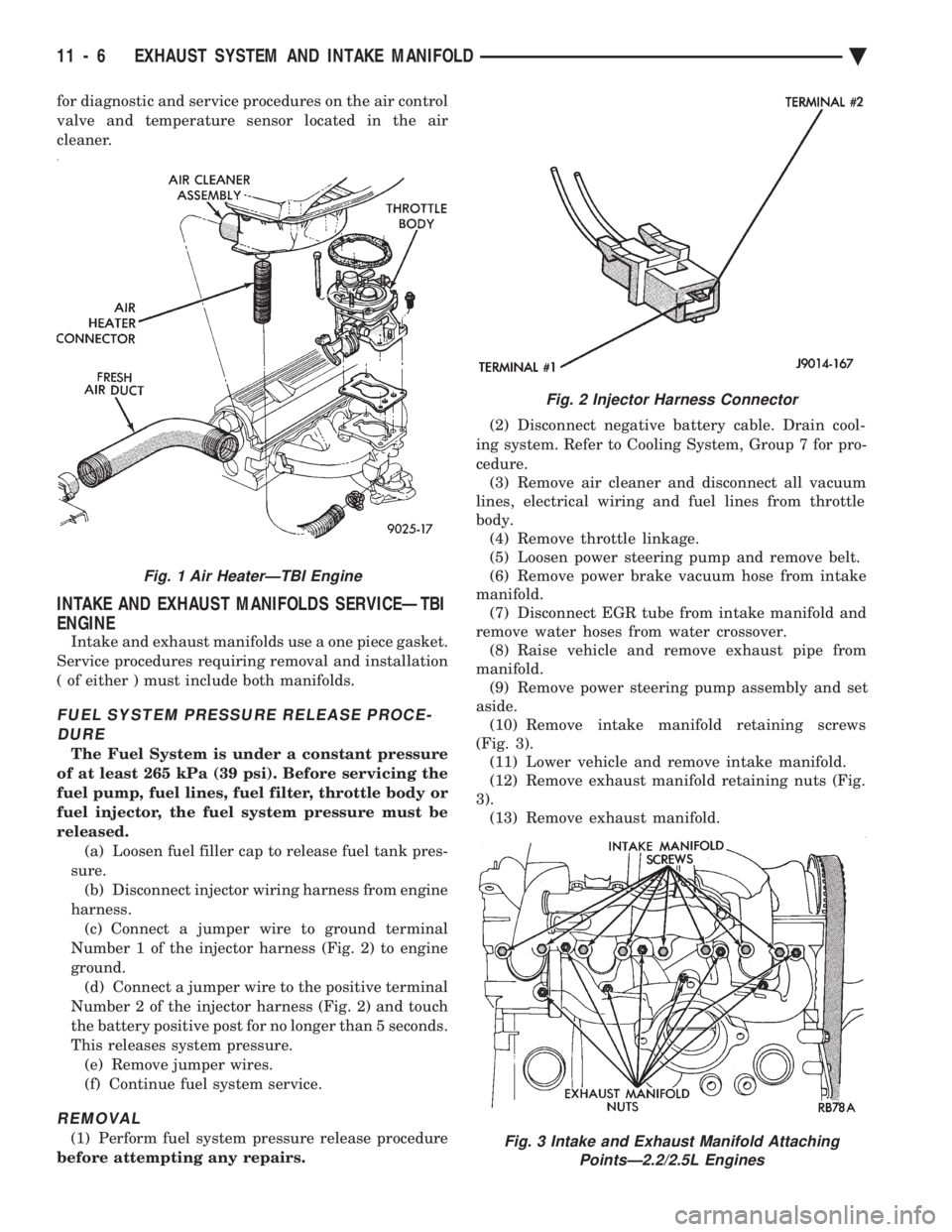

INTAKE AND EXHAUST MANIFOLDS SERVICEÐTBI

ENGINE

Intake and exhaust manifolds use a one piece gasket.

Service procedures requiring removal and installation

( of either ) must include both manifolds.

FUEL SYSTEM PRESSURE RELEASE PROCE- DURE

The Fuel System is under a constant pressure

of at least 265 kPa (39 psi). Before servicing the

fuel pump, fuel lines, fuel filter, throttle body or

fuel injector, the fuel system pressure must be

released. (a) Loosen fuel filler cap to release fuel tank pres-

sure. (b) Disconnect injector wiring harness from engine

harness. (c) Connect a jumper wire to ground terminal

Number 1 of the injector harness (Fig. 2) to engine

ground. (d) Connect a jumper wire to the positive terminal

Number 2 of the injector harness (Fig. 2) and touch

the battery positive post for no longer than 5 seconds.

This releases system pressure. (e) Remove jumper wires.

(f) Continue fuel system service.

REMOVAL

(1) Perform fuel system pressure release procedure

before attempting any repairs. (2) Disconnect negative battery cable. Drain cool-

ing system. Refer to Cooling System, Group 7 for pro-

cedure. (3) Remove air cleaner and disconnect all vacuum

lines, electrical wiring and fuel lines from throttle

body. (4) Remove throttle linkage.

(5) Loosen power steering pump and remove belt.

(6) Remove power brake vacuum hose from intake

manifold. (7) Disconnect EGR tube from intake manifold and

remove water hoses from water crossover. (8) Raise vehicle and remove exhaust pipe from

manifold. (9) Remove power steering pump assembly and set

aside. (10) Remove intake manifold retaining screws

(Fig. 3). (11) Lower vehicle and remove intake manifold.

(12) Remove exhaust manifold retaining nuts (Fig.

3). (13) Remove exhaust manifold.

Fig. 2 Injector Harness Connector

Fig. 3 Intake and Exhaust Manifold Attaching PointsÐ2.2/2.5L Engines

Fig. 1 Air HeaterÐTBI Engine

11 - 6 EXHAUST SYSTEM AND INTAKE MANIFOLD Ä

Page 1729 of 2438

(2) Remove nuts holding bumper fascia to quarter

panels. (3) Remove fasteners holding bumper fascia to

wheel opening flange. (4) Disconnect license plate lamp wire connectors.

(5) Remove bolts holding bumper to rear closure

panel. (6) Remove nuts holding bumper to energy ab-

sorber units. (7) Separate bumper from vehicle.

INSTALLATION

Reverse the preceding operation.

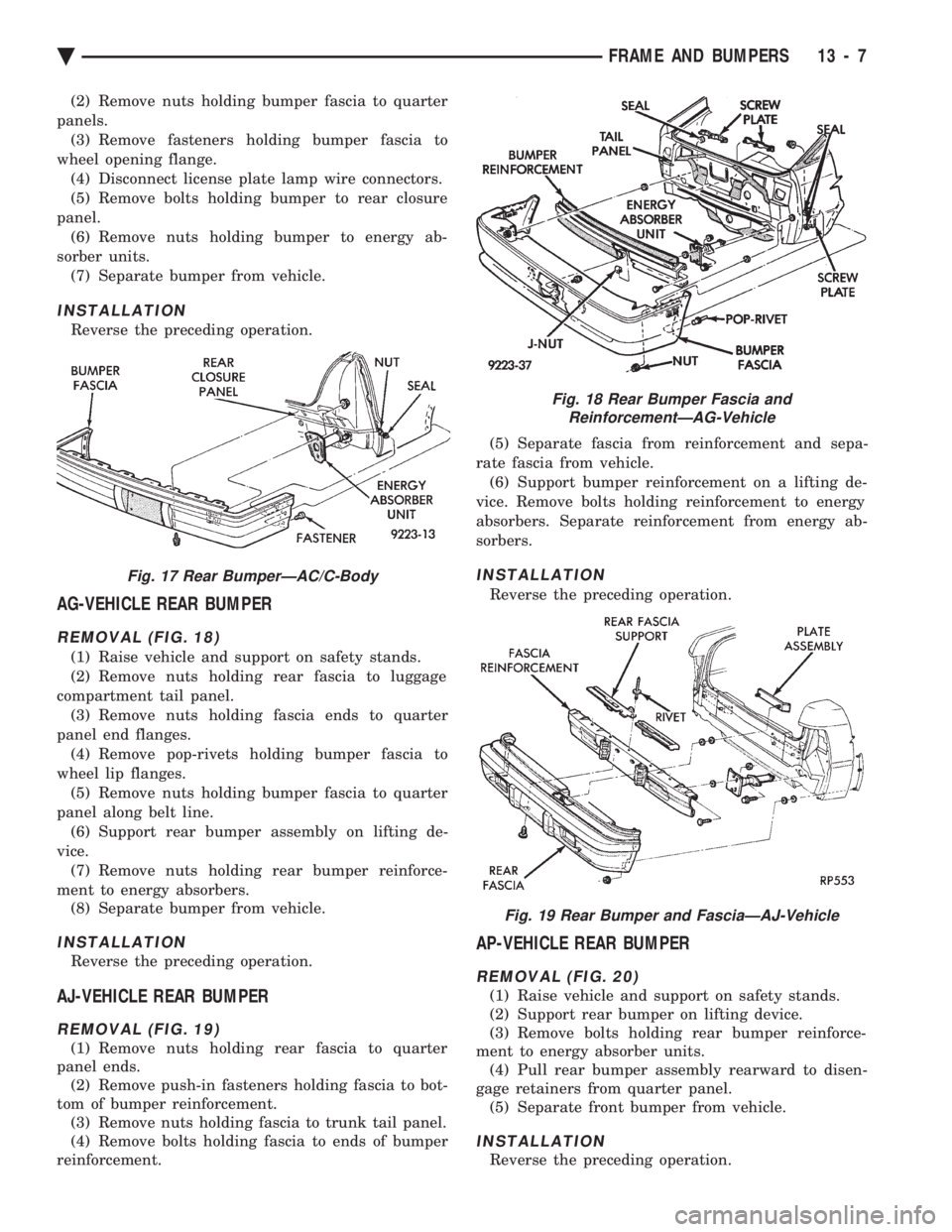

AG-VEHICLE REAR BUMPER

REMOVAL (FIG. 18)

(1) Raise vehicle and support on safety stands.

(2) Remove nuts holding rear fascia to luggage

compartment tail panel. (3) Remove nuts holding fascia ends to quarter

panel end flanges. (4) Remove pop-rivets holding bumper fascia to

wheel lip flanges. (5) Remove nuts holding bumper fascia to quarter

panel along belt line. (6) Support rear bumper assembly on lifting de-

vice. (7) Remove nuts holding rear bumper reinforce-

ment to energy absorbers. (8) Separate bumper from vehicle.

INSTALLATION

Reverse the preceding operation.

AJ-VEHICLE REAR BUMPER

REMOVAL (FIG. 19)

(1) Remove nuts holding rear fascia to quarter

panel ends. (2) Remove push-in fasteners holding fascia to bot-

tom of bumper reinforcement. (3) Remove nuts holding fascia to trunk tail panel.

(4) Remove bolts holding fascia to ends of bumper

reinforcement. (5) Separate fascia from reinforcement and sepa-

rate fascia from vehicle. (6) Support bumper reinforcement on a lifting de-

vice. Remove bolts holding reinforcement to energy

absorbers. Separate reinforcement from energy ab-

sorbers.

INSTALLATION

Reverse the preceding operation.

AP-VEHICLE REAR BUMPER

REMOVAL (FIG. 20)

(1) Raise vehicle and support on safety stands.

(2) Support rear bumper on lifting device.

(3) Remove bolts holding rear bumper reinforce-

ment to energy absorber units. (4) Pull rear bumper assembly rearward to disen-

gage retainers from quarter panel. (5) Separate front bumper from vehicle.

INSTALLATION

Reverse the preceding operation.

Fig. 17 Rear BumperÐAC/C-Body

Fig. 18 Rear Bumper Fascia and ReinforcementÐAG-Vehicle

Fig. 19 Rear Bumper and FasciaÐAJ-Vehicle

Ä FRAME AND BUMPERS 13 - 7

Page 1776 of 2438

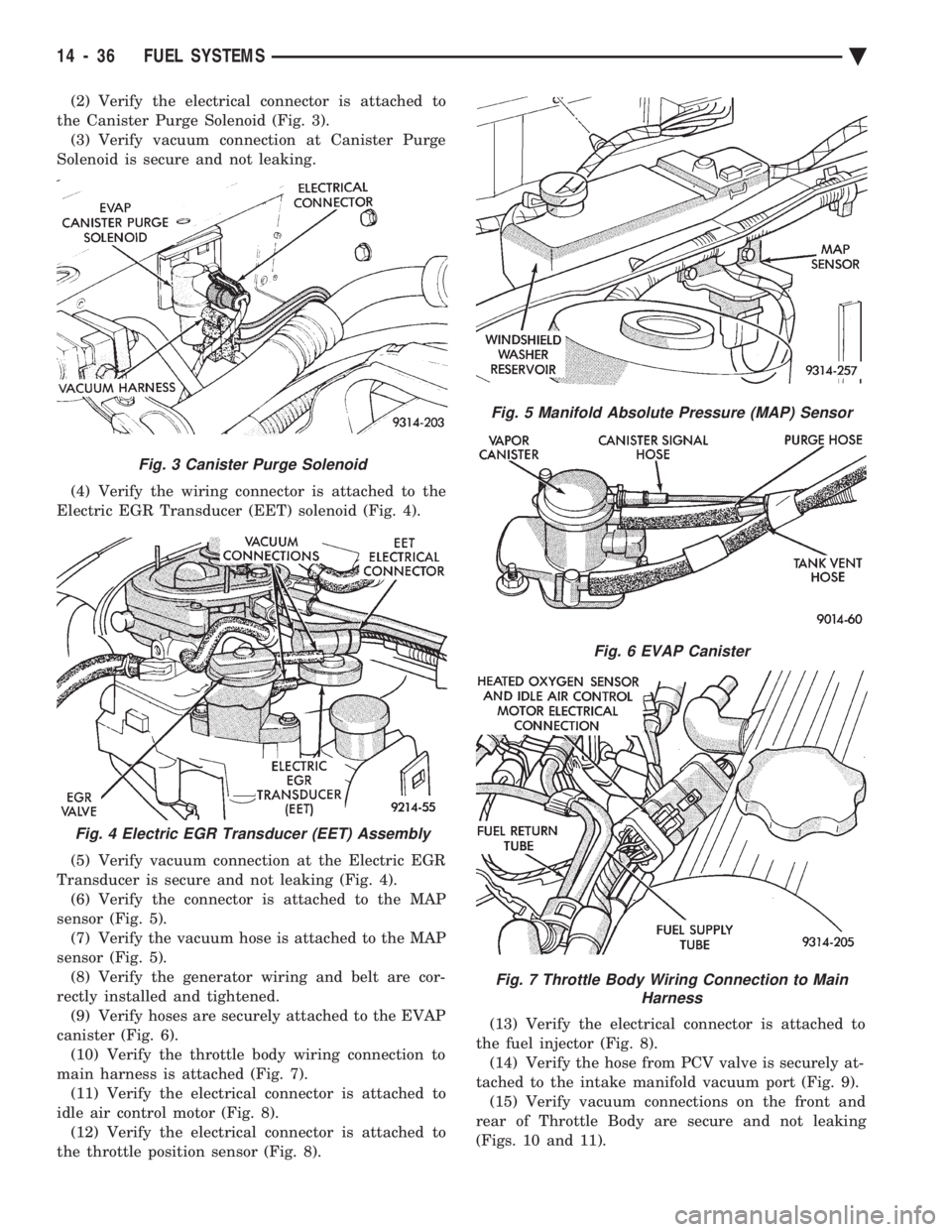

(2) Verify the electrical connector is attached to

the Canister Purge Solenoid (Fig. 3). (3) Verify vacuum connection at Canister Purge

Solenoid is secure and not leaking.

(4) Verify the wiring connector is attached to the

Electric EGR Transducer (EET) solenoid (Fig. 4).

(5) Verify vacuum connection at the Electric EGR

Transducer is secure and not leaking (Fig. 4). (6) Verify the connector is attached to the MAP

sensor (Fig. 5). (7) Verify the vacuum hose is attached to the MAP

sensor (Fig. 5). (8) Verify the generator wiring and belt are cor-

rectly installed and tightened. (9) Verify hoses are securely attached to the EVAP

canister (Fig. 6). (10) Verify the throttle body wiring connection to

main harness is attached (Fig. 7). (11) Verify the electrical connector is attached to

idle air control motor (Fig. 8). (12) Verify the electrical connector is attached to

the throttle position sensor (Fig. 8). (13) Verify the electrical connector is attached to

the fuel injector (Fig. 8). (14) Verify the hose from PCV valve is securely at-

tached to the intake manifold vacuum port (Fig. 9). (15) Verify vacuum connections on the front and

rear of Throttle Body are secure and not leaking

(Figs. 10 and 11).

Fig. 3 Canister Purge Solenoid

Fig. 4 Electric EGR Transducer (EET) Assembly

Fig. 5 Manifold Absolute Pressure (MAP) Sensor

Fig. 6 EVAP Canister

Fig. 7 Throttle Body Wiring Connection to Main Harness

14 - 36 FUEL SYSTEMS Ä

Page 1806 of 2438

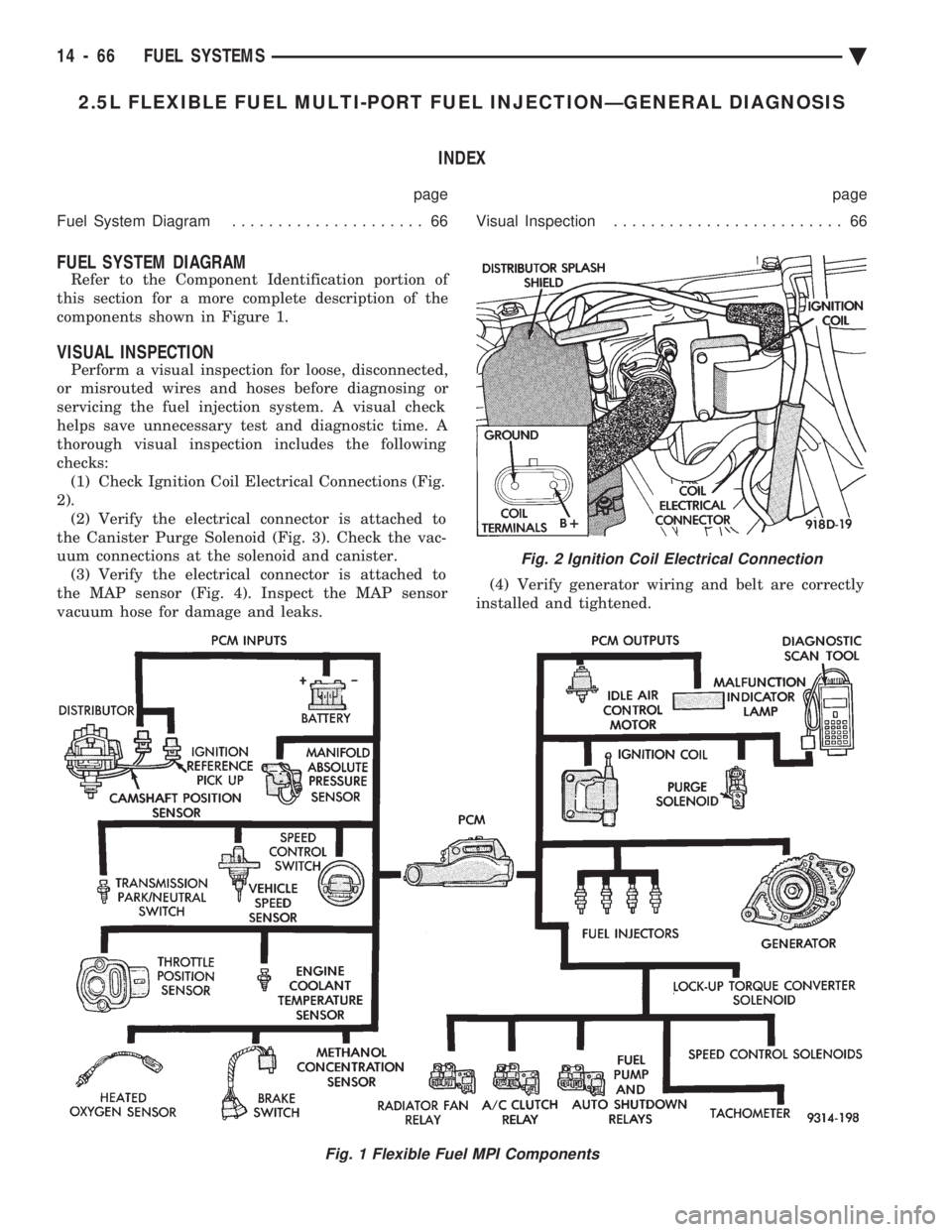

2.5L FLEXIBLE FUEL MULTI-PORT FUEL INJECTIONÐGENERAL DIAGNOSIS INDEX

page page

Fuel System Diagram ..................... 66 Visual Inspection......................... 66

FUEL SYSTEM DIAGRAM

Refer to the Component Identification portion of

this section for a more complete description of the

components shown in Figure 1.

VISUAL INSPECTION

Perform a visual inspection for loose, disconnected,

or misrouted wires and hoses before diagnosing or

servicing the fuel injection system. A visual check

helps save unnecessary test and diagnostic time. A

thorough visual inspection includes the following

checks: (1) Check Ignition Coil Electrical Connections (Fig.

2). (2) Verify the electrical connector is attached to

the Canister Purge Solenoid (Fig. 3). Check the vac-

uum connections at the solenoid and canister. (3) Verify the electrical connector is attached to

the MAP sensor (Fig. 4). Inspect the MAP sensor

vacuum hose for damage and leaks. (4) Verify generator wiring and belt are correctly

installed and tightened.

Fig. 1 Flexible Fuel MPI Components

Fig. 2 Ignition Coil Electrical Connection

14 - 66 FUEL SYSTEMS Ä

Page 1811 of 2438

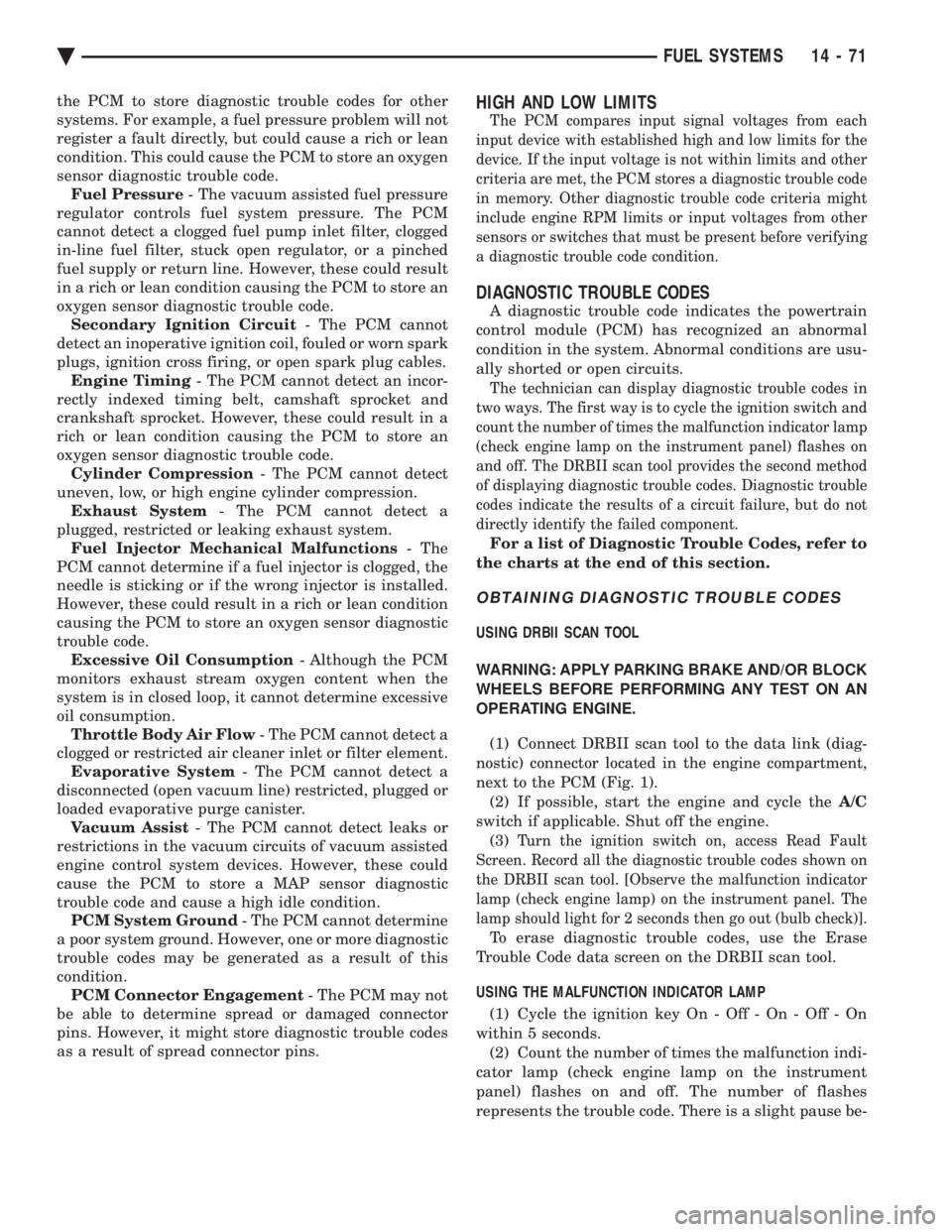

the PCM to store diagnostic trouble codes for other

systems. For example, a fuel pressure problem will not

register a fault directly, but could cause a rich or lean

condition. This could cause the PCM to store an oxygen

sensor diagnostic trouble code. Fuel Pressure - The vacuum assisted fuel pressure

regulator controls fuel system pressure. The PCM

cannot detect a clogged fuel pump inlet filter, clogged

in-line fuel filter, stuck open regulator, or a pinched

fuel supply or return line. However, these could result

in a rich or lean condition causing the PCM to store an

oxygen sensor diagnostic trouble code. Secondary Ignition Circuit - The PCM cannot

detect an inoperative ignition coil, fouled or worn spark

plugs, ignition cross firing, or open spark plug cables. Engine Timing - The PCM cannot detect an incor-

rectly indexed timing belt, camshaft sprocket and

crankshaft sprocket. However, these could result in a

rich or lean condition causing the PCM to store an

oxygen sensor diagnostic trouble code. Cylinder Compression - The PCM cannot detect

uneven, low, or high engine cylinder compression. Exhaust System - The PCM cannot detect a

plugged, restricted or leaking exhaust system. Fuel Injector Mechanical Malfunctions - The

PCM cannot determine if a fuel injector is clogged, the

needle is sticking or if the wrong injector is installed.

However, these could result in a rich or lean condition

causing the PCM to store an oxygen sensor diagnostic

trouble code. Excessive Oil Consumption - Although the PCM

monitors exhaust stream oxygen content when the

system is in closed loop, it cannot determine excessive

oil consumption. Throttle Body Air Flow - The PCM cannot detect a

clogged or restricted air cleaner inlet or filter element. Evaporative System - The PCM cannot detect a

disconnected (open vacuum line) restricted, plugged or

loaded evaporative purge canister. Vacuum Assist - The PCM cannot detect leaks or

restrictions in the vacuum circuits of vacuum assisted

engine control system devices. However, these could

cause the PCM to store a MAP sensor diagnostic

trouble code and cause a high idle condition. PCM System Ground - The PCM cannot determine

a poor system ground. However, one or more diagnostic

trouble codes may be generated as a result of this

condition. PCM Connector Engagement - The PCM may not

be able to determine spread or damaged connector

pins. However, it might store diagnostic trouble codes

as a result of spread connector pins.HIGH AND LOW LIMITS

The PCM compares input signal voltages from each

input device with established high and low limits for the

device. If the input voltage is not within limits and other

criteria are met, the PCM stores a diagnostic trouble code

in memory. Other diagnostic trouble code criteria might

include engine RPM limits or input voltages from other

sensors or switches that must be present before verifying

a diagnostic trouble code condition.

DIAGNOSTIC TROUBLE CODES

A diagnostic trouble code indicates the powertrain

control module (PCM) has recognized an abnormal

condition in the system. Abnormal conditions are usu-

ally shorted or open circuits.

The technician can display diagnostic trouble codes in

two ways. The first way is to cycle the ignition switch and

count the number of times the malfunction indicator lamp

(check engine lamp on the instrument panel) flashes on

and off. The DRBII scan tool provides the second method

of displaying diagnostic trouble codes. Diagnostic trouble

codes indicate the results of a circuit failure, but do not

directly identify the failed component.

For a list of Diagnostic Trouble Codes, refer to

the charts at the end of this section.

OBTAINING DIAGNOSTIC TROUBLE CODES

USING DRBII SCAN TOOL

WARNING: APPLY PARKING BRAKE AND/OR BLOCK

WHEELS BEFORE PERFORMING ANY TEST ON AN

OPERATING ENGINE. (1) Connect DRBII scan tool to the data link (diag-

nostic) connector located in the engine compartment,

next to the PCM (Fig. 1). (2) If possible, start the engine and cycle the A/C

switch if applicable. Shut off the engine. (3)

Turn the ignition switch on, access Read Fault

Screen. Record all the diagnostic trouble codes shown on

the DRBII scan tool. [Observe the malfunction indicator

lamp (check engine lamp) on the instrument panel. The

lamp should light for 2 seconds then go out (bulb check)].

To erase diagnostic trouble codes, use the Erase

Trouble Code data screen on the DRBII scan tool.

USING THE MALFUNCTION INDICATOR LAMP (1) Cycle the ignition key On - Off - On - Off - On

within 5 seconds. (2) Count the number of times the malfunction indi-

cator lamp (check engine lamp on the instrument

panel) flashes on and off. The number of flashes

represents the trouble code. There is a slight pause be-

Ä FUEL SYSTEMS 14 - 71

Page 1836 of 2438

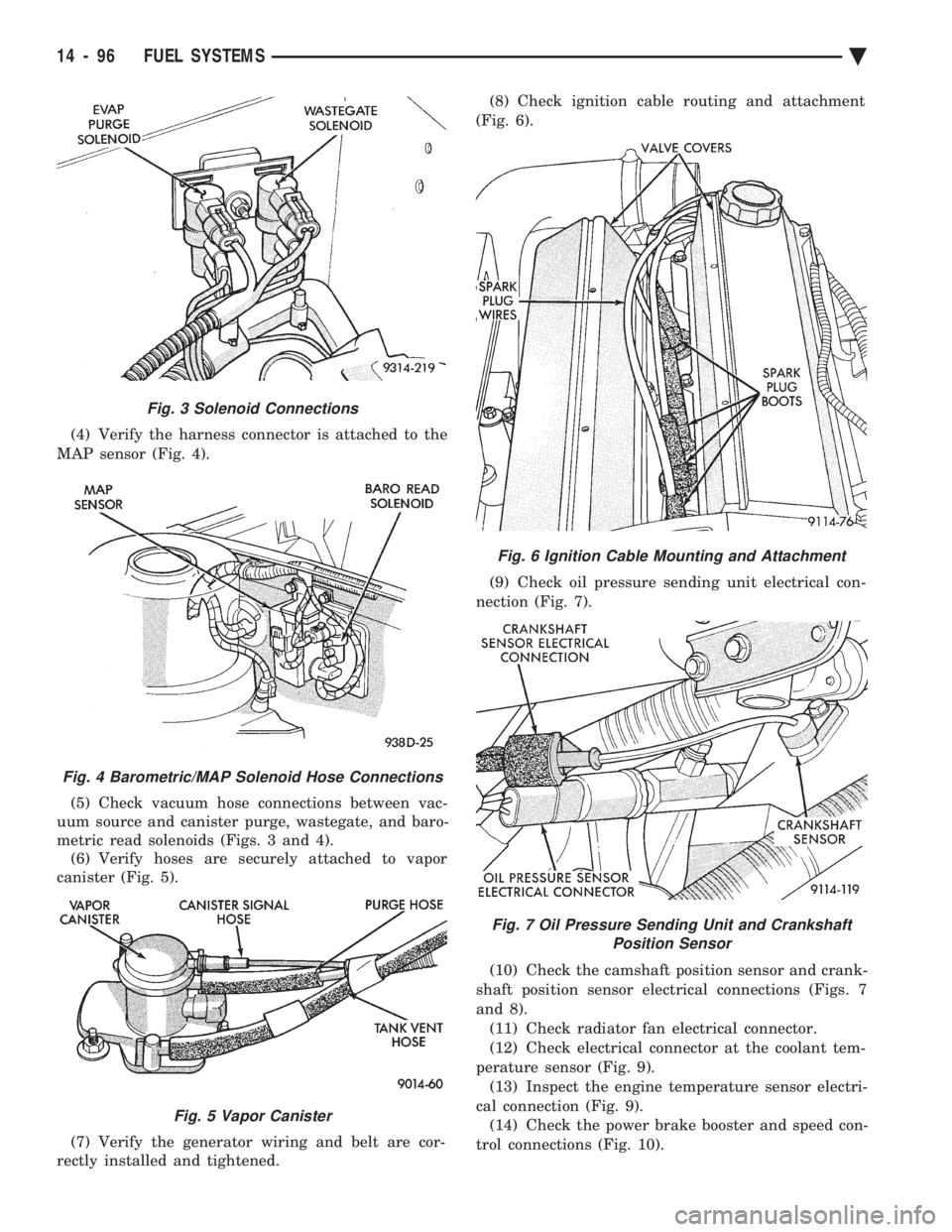

(4) Verify the harness connector is attached to the

MAP sensor (Fig. 4).

(5) Check vacuum hose connections between vac-

uum source and canister purge, wastegate, and baro-

metric read solenoids (Figs. 3 and 4). (6) Verify hoses are securely attached to vapor

canister (Fig. 5).

(7) Verify the generator wiring and belt are cor-

rectly installed and tightened. (8) Check ignition cable routing and attachment

(Fig. 6).

(9) Check oil pressure sending unit electrical con-

nection (Fig. 7).

(10) Check the camshaft position sensor and crank-

shaft position sensor electrical connections (Figs. 7

and 8). (11) Check radiator fan electrical connector.

(12) Check electrical connector at the coolant tem-

perature sensor (Fig. 9). (13) Inspect the engine temperature sensor electri-

cal connection (Fig. 9). (14) Check the power brake booster and speed con-

trol connections (Fig. 10).

Fig. 6 Ignition Cable Mounting and Attachment

Fig. 7 Oil Pressure Sending Unit and Crankshaft Position Sensor

Fig. 3 Solenoid Connections

Fig. 4 Barometric/MAP Solenoid Hose Connections

Fig. 5 Vapor Canister

14 - 96 FUEL SYSTEMS Ä

Page 1866 of 2438

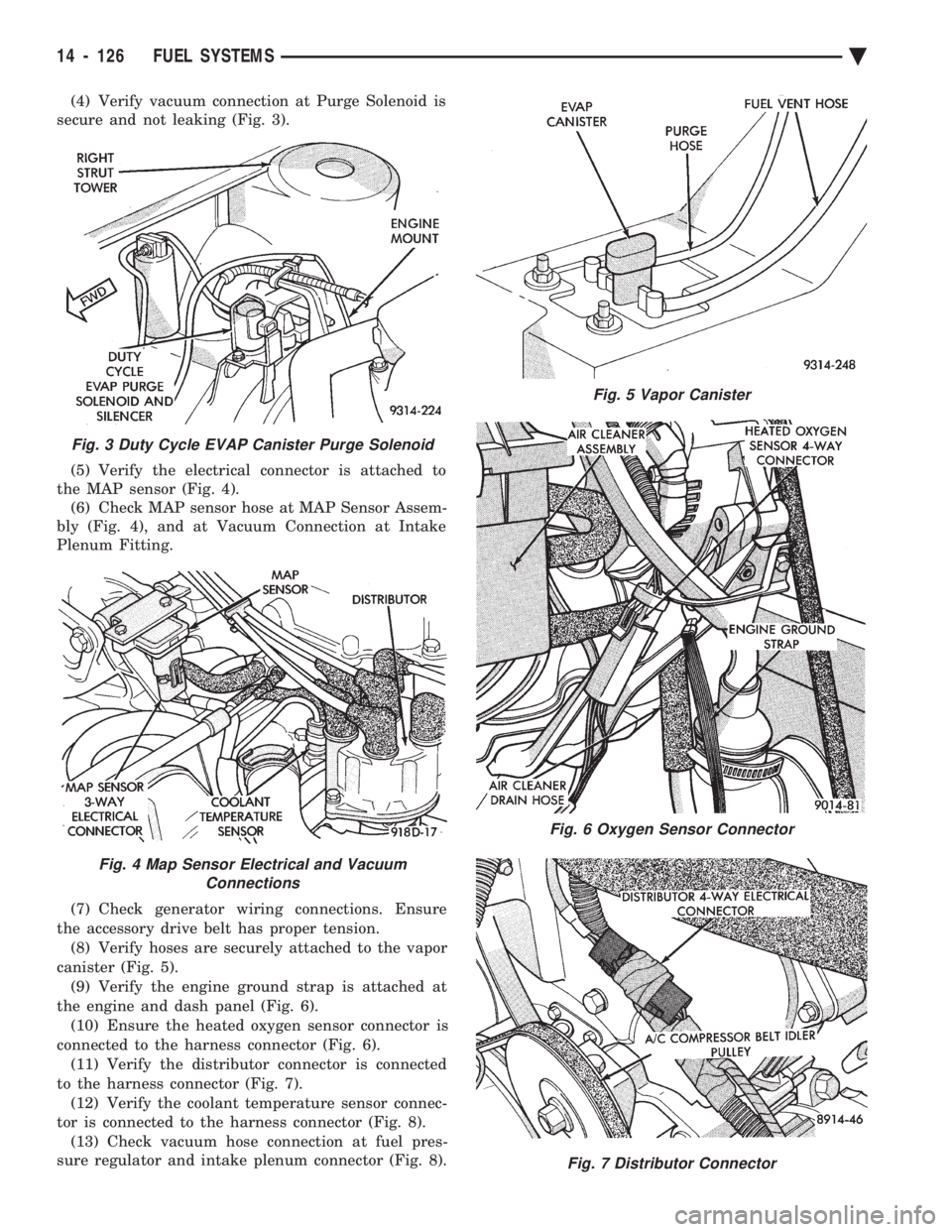

(4) Verify vacuum connection at Purge Solenoid is

secure and not leaking (Fig. 3).

(5) Verify the electrical connector is attached to

the MAP sensor (Fig. 4). (6) Check MAP sensor hose at MAP Sensor Assem-

bly (Fig. 4), and at Vacuum Connection at Intake

Plenum Fitting.

(7) Check generator wiring connections. Ensure

the accessory drive belt has proper tension. (8) Verify hoses are securely attached to the vapor

canister (Fig. 5). (9) Verify the engine ground strap is attached at

the engine and dash panel (Fig. 6). (10) Ensure the heated oxygen sensor connector is

connected to the harness connector (Fig. 6). (11) Verify the distributor connector is connected

to the harness connector (Fig. 7). (12) Verify the coolant temperature sensor connec-

tor is connected to the harness connector (Fig. 8). (13) Check vacuum hose connection at fuel pres-

sure regulator and intake plenum connector (Fig. 8).

Fig. 3 Duty Cycle EVAP Canister Purge Solenoid

Fig. 4 Map Sensor Electrical and Vacuum Connections

Fig. 5 Vapor Canister

Fig. 6 Oxygen Sensor Connector

Fig. 7 Distributor Connector

14 - 126 FUEL SYSTEMS Ä

Page 1900 of 2438

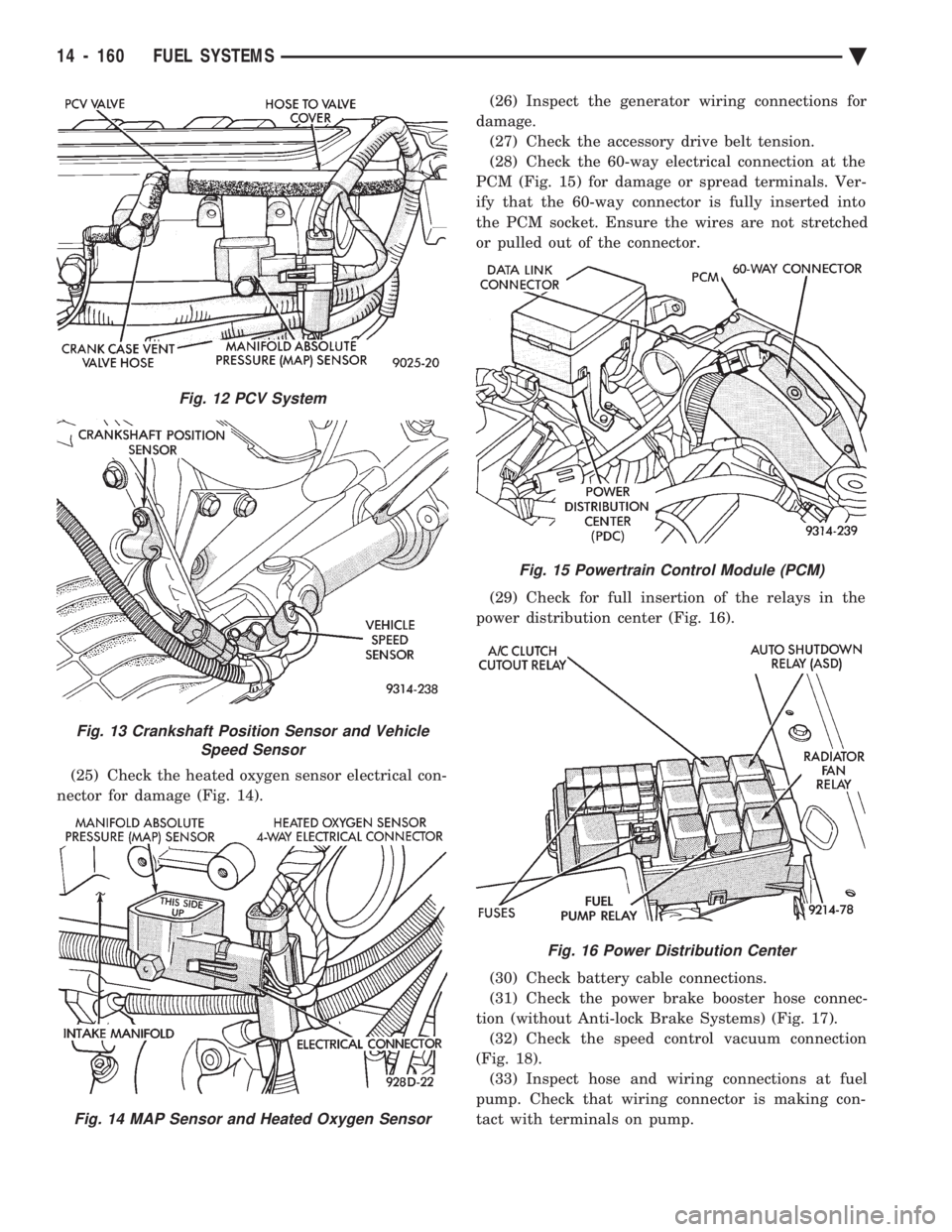

(25) Check the heated oxygen sensor electrical con-

nector for damage (Fig. 14). (26) Inspect the generator wiring connections for

damage. (27) Check the accessory drive belt tension.

(28) Check the 60-way electrical connection at the

PCM (Fig. 15) for damage or spread terminals. Ver-

ify that the 60-way connector is fully inserted into

the PCM socket. Ensure the wires are not stretched

or pulled out of the connector.

(29) Check for full insertion of the relays in the

power distribution center (Fig. 16).

(30) Check battery cable connections.

(31) Check the power brake booster hose connec-

tion (without Anti-lock Brake Systems) (Fig. 17). (32) Check the speed control vacuum connection

(Fig. 18). (33) Inspect hose and wiring connections at fuel

pump. Check that wiring connector is making con-

tact with terminals on pump.

Fig. 12 PCV System

Fig. 13 Crankshaft Position Sensor and Vehicle Speed Sensor

Fig. 14 MAP Sensor and Heated Oxygen Sensor

Fig. 15 Powertrain Control Module (PCM)

Fig. 16 Power Distribution Center

14 - 160 FUEL SYSTEMS Ä

Page 1917 of 2438

is made with the camshaft gear. While holding the

sensor in this position, install and tighten the retain-

ing bolt 12 N Im (105 in. lbs.) torque.

(2) Connect camshaft position sensor electrical con-

nector to harness connector. Position connector away

from the accessory belt.

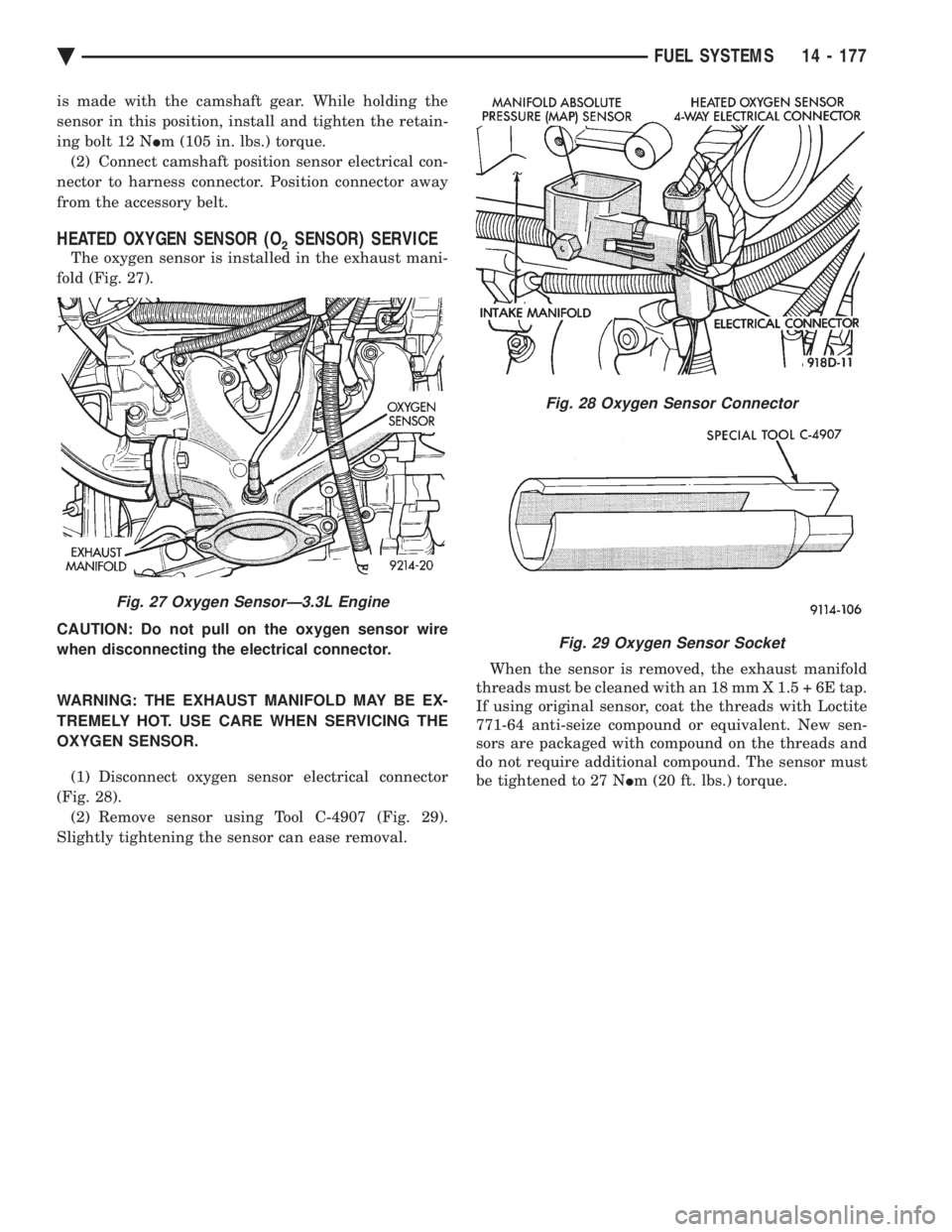

HEATED OXYGEN SENSOR (O2SENSOR) SERVICE

The oxygen sensor is installed in the exhaust mani-

fold (Fig. 27).

CAUTION: Do not pull on the oxygen sensor wire

when disconnecting the electrical connector.

WARNING: THE EXHAUST MANIFOLD MAY BE EX-

TREMELY HOT. USE CARE WHEN SERVICING THE

OXYGEN SENSOR.

(1) Disconnect oxygen sensor electrical connector

(Fig. 28). (2) Remove sensor using Tool C-4907 (Fig. 29).

Slightly tightening the sensor can ease removal. When the sensor is removed, the exhaust manifold

threads must be cleaned with an 18 mm X 1.5 + 6E tap.

If using original sensor, coat the threads with Loctite

771-64 anti-seize compound or equivalent. New sen-

sors are packaged with compound on the threads and

do not require additional compound. The sensor must

be tightened to 27 N Im (20 ft. lbs.) torque.

Fig. 27 Oxygen SensorÐ3.3L Engine

Fig. 28 Oxygen Sensor Connector

Fig. 29 Oxygen Sensor Socket

Ä FUEL SYSTEMS 14 - 177

Page 1919 of 2438

STEERING

CONTENTS

page page

ACUSTAR STANDARD AND TILT STEERING COLUMN ............................ 28

AUTOMATIC TRANSMISSION SHIFTER/IGNITION INTERLOCK .......................... 36

GENERAL INFORMATION .................. 1 POWER STEERING GEAR

................ 25

POWER STEERING PUMPS ................ 1

SPECIFICATIONS AND TIGHTENING REFERENCE .......................... 42

GENERAL INFORMATION

Safety goggles should be worn at all times

when working on any steering gear or pump. Throughout this group, references may be made to

a particular vehicle by letter or number designation.

A chart showing the breakdown of these designations

is included in the Introduction Section at the front of

this service manual. The power steering system consists of these four

major components. Power Steering Pump, Power

Steering Gear, Pressure Hose, and Return Line.

Turning of the steering wheel is converted into lin-

ear travel through the meshing of the helical pinion teeth with the rack teeth. Power assist steering is

provided by an open center, rotary type control valve.

It is used to direct oil from the power steering pump

to either side of the integral steering rack piston. Road feel is controlled by the diameter of a torsion

bar which initially steers the vehicle. As steering ef-

fort increases as in a turn, the torsion bar twists,

causing relative rotary motion between the rotary

valve body and valve spool. This movement directs

oil behind the integral rack piston, which in turn,

builds up hydraulic pressure and assists in the turn-

ing effort.

POWER STEERING PUMPS

INDEX

page page

Checking Power Steering Fluid Level .......... 9

Flow Control Valve Fitting O-Ring Seal ........ 23

General Information ........................ 1

Power Steering Hoses ..................... 11

Power Steering Pressure Switch ............. 10

Power Steering Pump Fluid Reservoirs ........ 22 Power Steering Pump Pressure Test

........... 9

Power Steering Pump Pulley Service .......... 20

Power Steering Pump Removal .............. 12

Power Steering Pump Service ................ 2

Power Steering PumpÐInitial Operation ....... 24

Steering Components Service Diagnosis ........ 2

GENERAL INFORMATION

Hydraulic pressure for operation of the power

steering gear is provided by a belt driven power

steering pump. The power steering pump is a con-

stant flow rate and displacement, vane type pump.

Different styles of Saginaw power steering pumps are

used depending on the engine application of the ve-

hicle. On all four cylinder and 3.0-liter V-6 applications

the Saginaw Ham Can power steering pump is used

(Fig. 1). On the 3.3 & 3.8-liter V-6 and Turbo III applica-

tions, different versions of the Saginaw T/C style

power steering pump is used (Fig. 2). The 3.3 & 3.8 liter V-6 engine application uses the T/C style power

steering pump with a remote mounted reservoir for

the power steering fluid. On the Turbo III application

of the T/C style power steering pump, the power

steering fluid reservoir is integral to the power steer-

ing pump. On the integral reservoir type pump (Fig. 1) the

pump housing and internal components are combined

with the reservoir to form a one-piece mechanism. The Saginaw T/C style power steering pump (Fig.

2), consists of the power steering pump internal com-

ponents and pump housing. The Saginaw T/C style

power steering pump though has no internal reser-

voir for the power steering fluid. Depending on vehi-

Ä STEERING 19 - 1