belt CHEVROLET DYNASTY 1993 Workshop Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 1467 of 2438

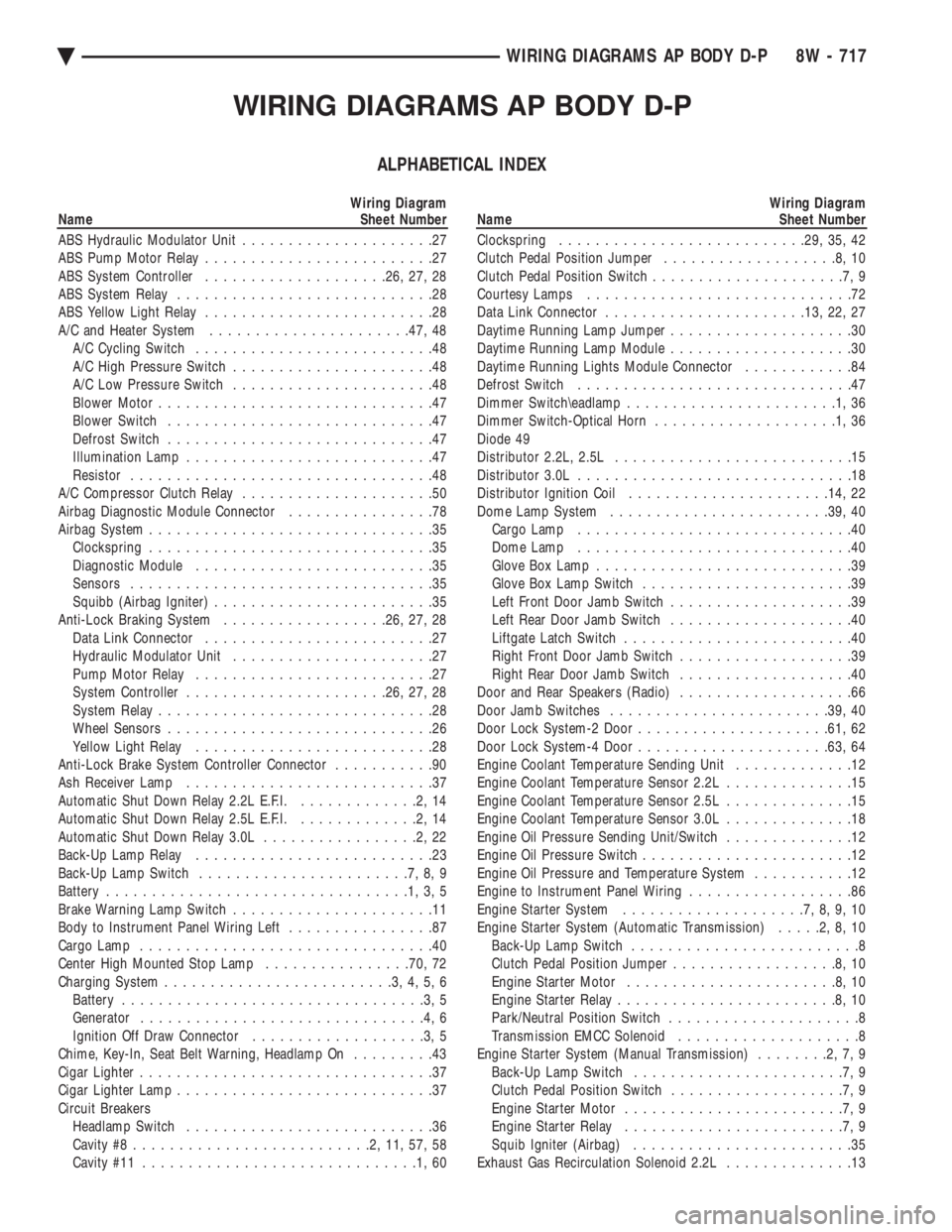

WIRING DIAGRAMS AP BODY D-P

ALPHABETICAL INDEX

Wiring Diagram

Name Sheet Number

ABS Hydraulic Modulator Unit .....................27

ABS Pump Motor Relay .........................27

ABS System Controller ................... .26, 27, 28

ABS System Relay ............................28

ABS Yellow Light Relay .........................28

A/C and Heater System ..................... .47, 48

A/C Cycling Switch ..........................48

A/C High Pressure Switch ......................48

A/C Low Pressure Switch ......................48

Blower Motor ..............................47

Blower Switch .............................47

Defrost Switch .............................47

Illumination Lamp ...........................47

Resistor .................................48

A/C Compressor Clutch Relay .....................50

Airbag Diagnostic Module Connector ................78

Airbag System ...............................35

Clockspring ...............................35

Diagnostic Module ..........................35

Sensors .................................35

Squibb (Airbag Igniter) ........................35

Anti-Lock Braking System ..................26, 27, 28

Data Link Connector .........................27

Hydraulic Modulator Unit ......................27

Pump Motor Relay ..........................27

System Controller ..................... .26, 27, 28

System Relay ..............................28

Wheel Sensors .............................26

Yellow Light Relay ..........................28

Anti-Lock Brake System Controller Connector ...........90

Ash Receiver Lamp ...........................37

Automatic Shut Down Relay 2.2L E.F.I. .............2,14

Automatic Shut Down Relay 2.5L E.F.I. .............2,14

Automatic Shut Down Relay 3.0L .................2,22

Back-Up Lamp Relay ..........................23

Back-Up Lamp Switch .......................7,8,9

Battery .................................1,3,5

Brake Warning Lamp Switch ......................11

Body to Instrument Panel Wiring Left ................87

Cargo Lamp ................................40

Center High Mounted Stop Lamp ................70, 72

Charging System .........................3,4,5,6

Battery .................................3,5

Generator ...............................4,6

Ignition Off Draw Connector ...................3,5

Chime, Key-In, Seat Belt Warning, Headlamp On .........43

Cigar Lighter ................................37

Cigar Lighter Lamp ............................37

Circuit Breakers Headlamp Switch ...........................36

Cavity #8 ..........................2,11,57,58

Cavity #11 ..............................1,60Wiring Diagram

Name Sheet Number

Clockspring .......................... .29, 35, 42

Clutch Pedal Position Jumper ...................8,10

Clutch Pedal Position Switch .....................7,9

Courtesy Lamps .............................72

Data Link Connector ..................... .13, 22, 27

Daytime Running Lamp Jumper ....................30

Daytime Running Lamp Module ....................30

Daytime Running Lights Module Connector ............84

Defrost Switch ..............................47

Dimmer Switch\eadlamp .......................1,36

Dimmer Switch-Optical Horn ....................1,36

Diode 49

Distributor 2.2L, 2.5L ..........................15

Distributor 3.0L ..............................18

Distributor Ignition Coil ..................... .14, 22

Dome Lamp System ....................... .39, 40

Cargo Lamp ..............................40

Dome Lamp ..............................40

Glove Box Lamp ............................39

Glove Box Lamp Switch .......................39

Left Front Door Jamb Switch ....................39

Left Rear Door Jamb Switch ....................40

Liftgate Latch Switch .........................40

Right Front Door Jamb Switch ...................39

Right Rear Door Jamb Switch ...................40

Door and Rear Speakers (Radio) ...................66

Door Jamb Switches ....................... .39, 40

Door Lock System-2 Door .................... .61, 62

Door Lock System-4 Door .................... .63, 64

Engine Coolant Temperature Sending Unit .............12

Engine Coolant Temperature Sensor 2.2L ..............15

Engine Coolant Temperature Sensor 2.5L ..............15

Engine Coolant Temperature Sensor 3.0L ..............18

Engine Oil Pressure Sending Unit/Switch ..............12

Engine Oil Pressure Switch .......................12

Engine Oil Pressure and Temperature System ...........12

Engine to Instrument Panel Wiring ..................86

Engine Starter System ....................7,8,9,10

Engine Starter System (Automatic Transmission) .....2,8,10

Back-Up Lamp Switch .........................8

Clutch Pedal Position Jumper ..................8,10

Engine Starter Motor .......................8,10

Engine Starter Relay ........................8,10

Park/Neutral Position Switch .....................8

Transmission EMCC Solenoid ....................8

Engine Starter System (Manual Transmission) ........2,7,9

Back-Up Lamp Switch .......................7,9

Clutch Pedal Position Switch ...................7,9

Engine Starter Motor ........................7,9

Engine Starter Relay ........................7,9

Squib Igniter (Airbag) ........................35

Exhaust Gas Recirculation Solenoid 2.2L ..............13

Ä WIRING DIAGRAMS AP BODY D-P 8W - 717

Page 1469 of 2438

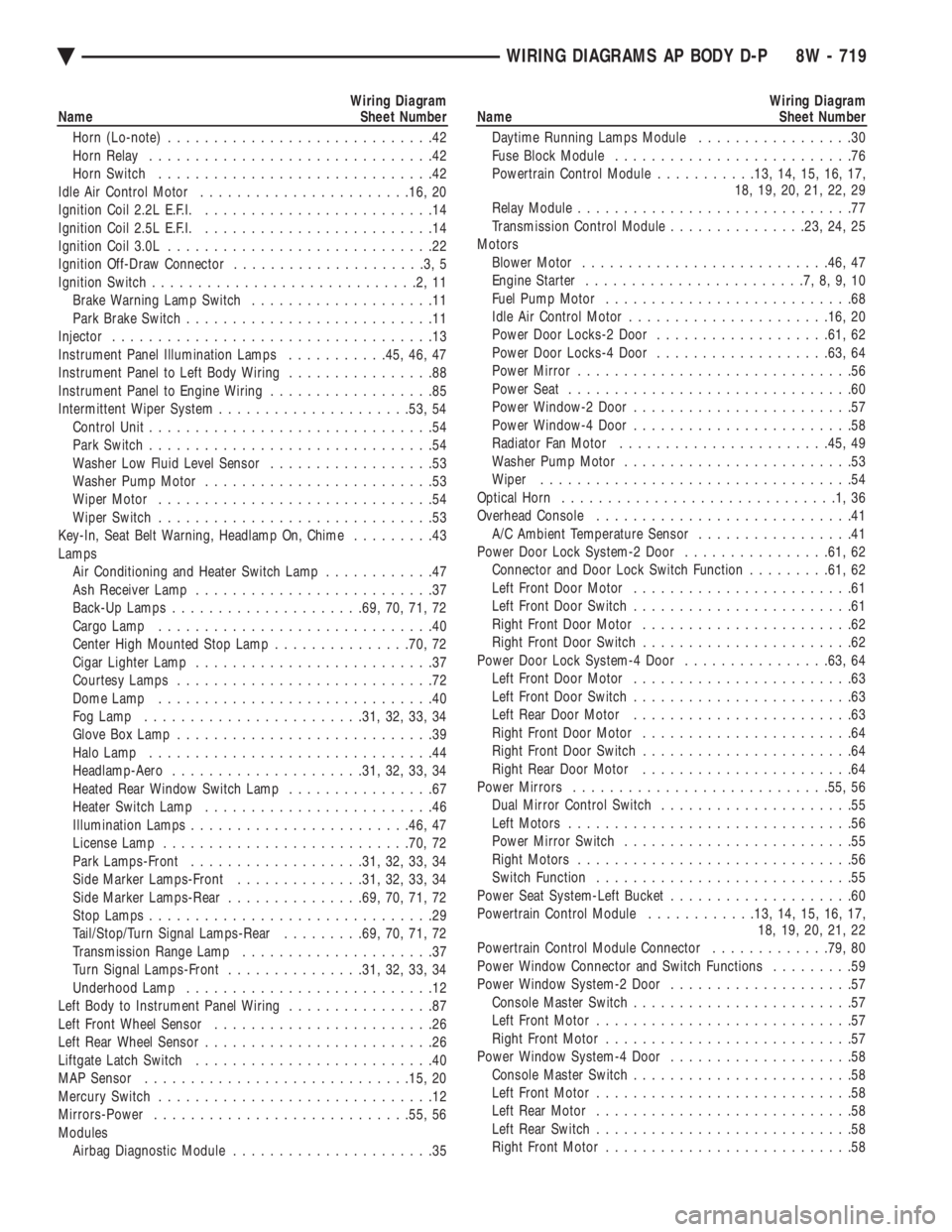

Wiring Diagram

Name Sheet Number

Horn (Lo-note) .............................42

Horn Relay ...............................42

Horn Switch ..............................42

Idle Air Control Motor ...................... .16, 20

Ignition Coil 2.2L E.F.I. .........................14

Ignition Coil 2.5L E.F.I. .........................14

Ignition Coil 3.0L .............................22

Ignition Off-Draw Connector .....................3,5

Ignition Switch .............................2,11

Brake Warning Lamp Switch ....................11

Park Brake Switch ...........................11

Injector ...................................13

Instrument Panel Illumination Lamps ...........45, 46, 47

Instrument Panel to Left Body Wiring ................88

Instrument Panel to Engine Wiring ..................85

Intermittent Wiper System .................... .53, 54

Control Unit ...............................54

Park Switch ...............................54

Washer Low Fluid Level Sensor ..................53

Washer Pump Motor .........................53

Wiper Motor ..............................54

Wiper Switch ..............................53

Key-In, Seat Belt Warning, Headlamp On, Chime .........43

Lamps Air Conditioning and Heater Switch Lamp ............47

Ash Receiver Lamp ..........................37

Back-Up Lamps .................... .69, 70, 71, 72

Cargo Lamp ..............................40

Center High Mounted Stop Lamp ...............70, 72

Cigar Lighter Lamp ..........................37

Courtesy Lamps ............................72

Dome Lamp ..............................40

Fog Lamp ....................... .31, 32, 33, 34

Glove Box Lamp ............................39

Halo Lamp ...............................44

Headlamp-Aero .................... .31, 32, 33, 34

Heated Rear Window Switch Lamp ................67

Heater Switch Lamp .........................46

Illumination Lamps ....................... .46, 47

License Lamp .......................... .70, 72

Park Lamps-Front .................. .31, 32, 33, 34

Side Marker Lamps-Front ..............31, 32, 33, 34

Side Marker Lamps-Rear ...............69, 70, 71, 72

Stop Lamps ...............................29

Tail/Stop/Turn Signal Lamps-Rear .........69, 70, 71, 72

Transmission Range Lamp .....................37

Turn Signal Lamps-Front ...............31, 32, 33, 34

Underhood Lamp ...........................12

Left Body to Instrument Panel Wiring ................87

Left Front Wheel Sensor ........................26

Left Rear Wheel Sensor .........................26

Liftgate Latch Switch ..........................40

MAP Sensor ............................ .15, 20

Mercury Switch ..............................12

Mirrors-Power ........................... .55, 56

Modules Airbag Diagnostic Module ......................35Wiring Diagram

Name Sheet Number

Daytime Running Lamps Module .................30

Fuse Block Module ..........................76

Powertrain Control Module ...........13, 14, 15, 16, 17,

18, 19, 20, 21, 22, 29

Relay Module ..............................77

Transmission Control Module ...............23, 24, 25

Motors Blower Motor .......................... .46, 47

Engine Starter ........................7,8,9,10

Fuel Pump Motor ...........................68

Idle Air Control Motor ..................... .16, 20

Power Door Locks-2 Door .................. .61, 62

Power Door Locks-4 Door .................. .63, 64

Power Mirror ..............................56

Power Seat ...............................60

Power Window-2 Door ........................57

Power Window-4 Door ........................58

Radiator Fan Motor ...................... .45, 49

Washer Pump Motor .........................53

Wiper ..................................54

Optical Horn ..............................1,36

Overhead Console ............................41

A/C Ambient Temperature Sensor .................41

Power Door Lock System-2 Door ................61, 62

Connector and Door Lock Switch Function .........61, 62

Left Front Door Motor ........................61

Left Front Door Switch ........................61

Right Front Door Motor .......................62

Right Front Door Switch .......................62

Power Door Lock System-4 Door ................63, 64

Left Front Door Motor ........................63

Left Front Door Switch ........................63

Left Rear Door Motor ........................63

Right Front Door Motor .......................64

Right Front Door Switch .......................64

Right Rear Door Motor .......................64

Power Mirrors ........................... .55, 56

Dual Mirror Control Switch .....................55

Left Motors ...............................56

Power Mirror Switch .........................55

Right Motors ..............................56

Switch Function ............................55

Power Seat System-Left Bucket ....................60

Powertrain Control Module ............13, 14, 15, 16, 17,

18, 19, 20, 21, 22

Powertrain Control Module Connector .............79, 80

Power Window Connector and Switch Functions .........59

Power Window System-2 Door ....................57

Console Master Switch ........................57

Left Front Motor ............................57

Right Front Motor ...........................57

Power Window System-4 Door ....................58

Console Master Switch ........................58

Left Front Motor ............................58

Left Rear Motor ............................58

Left Rear Switch ............................58

Right Front Motor ...........................58

Ä WIRING DIAGRAMS AP BODY D-P 8W - 719

Page 1470 of 2438

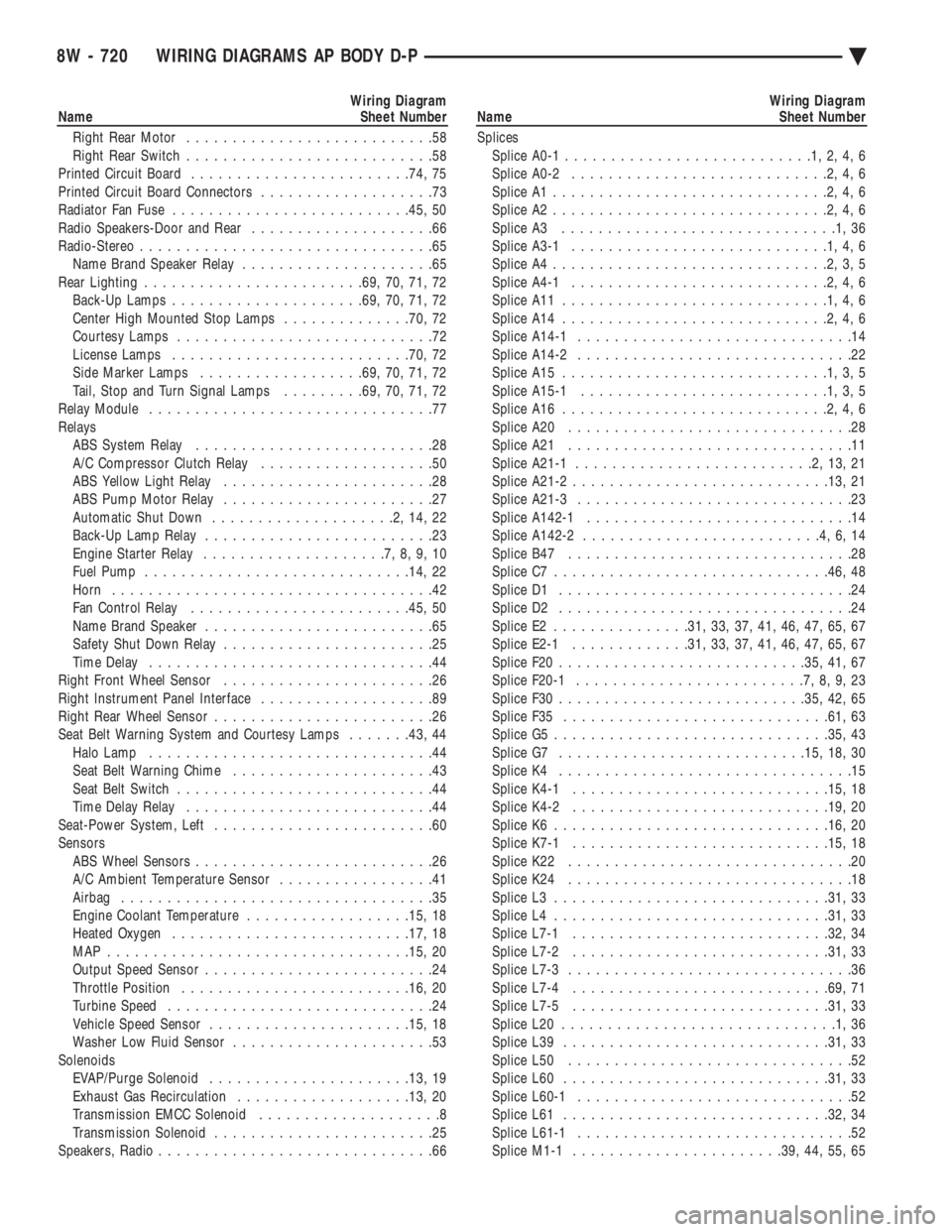

Wiring Diagram

Name Sheet Number

Right Rear Motor ...........................58

Right Rear Switch ...........................58

Printed Circuit Board ....................... .74, 75

Printed Circuit Board Connectors ...................73

Radiator Fan Fuse ......................... .45, 50

Radio Speakers-Door and Rear ....................66

Radio-Stereo ................................65

Name Brand Speaker Relay .....................65

Rear Lighting ....................... .69, 70, 71, 72

Back-Up Lamps .................... .69, 70, 71, 72

Center High Mounted Stop Lamps ..............70, 72

Courtesy Lamps ............................72

License Lamps ......................... .70, 72

Side Marker Lamps ................. .69, 70, 71, 72

Tail, Stop and Turn Signal Lamps .........69, 70, 71, 72

Relay Module ...............................77

Relays ABS System Relay ..........................28

A/C Compressor Clutch Relay ...................50

ABS Yellow Light Relay .......................28

ABS Pump Motor Relay .......................27

Automatic Shut Down ....................2,14,22

Back-Up Lamp Relay .........................23

Engine Starter Relay ....................7,8,9,10

Fuel Pump ............................ .14, 22

Horn ...................................42

Fan Control Relay ....................... .45, 50

Name Brand Speaker .........................65

Safety Shut Down Relay .......................25

Time Delay ...............................44

Right Front Wheel Sensor .......................26

Right Instrument Panel Interface ...................89

Right Rear Wheel Sensor ........................26

Seat Belt Warning System and Courtesy Lamps .......43, 44

Halo Lamp ...............................44

Seat Belt Warning Chime ......................43

Seat Belt Switch ............................44

Time Delay Relay ...........................44

Seat-Power System, Left ........................60

Sensors ABS Wheel Sensors ..........................26

A/C Ambient Temperature Sensor .................41

Airbag ..................................35

Engine Coolant Temperature ..................15, 18

Heated Oxygen ......................... .17, 18

MAP ................................ .15, 20

Output Speed Sensor .........................24

Throttle Position ........................ .16, 20

Turbine Speed .............................24

Vehicle Speed Sensor ..................... .15, 18

Washer Low Fluid Sensor ......................53

Solenoids EVAP/Purge Solenoid ..................... .13, 19

Exhaust Gas Recirculation .................. .13, 20

Transmission EMCC Solenoid ....................8

Transmission Solenoid ........................25

Speakers, Radio ..............................66Wiring Diagram

Name Sheet Number

Splices Splice A0-1 ...........................1,2,4,6

Splice A0-2 ............................2,4,6

Splice A1 ..............................2,4,6

Splice A2 ..............................2,4,6

Splice A3 ..............................1,36

Splice A3-1 ............................1,4,6

Splice A4 ..............................2,3,5

Splice A4-1 ............................2,4,6

Splice A11 .............................1,4,6

Splice A14 .............................2,4,6

Splice A14-1 ..............................14

Splice A14-2 ..............................22

Splice A15 .............................1,3,5

Splice A15-1 ...........................1,3,5

Splice A16 .............................2,4,6

Splice A20 ...............................28

Splice A21 ...............................11

Splice A21-1 ..........................2,13,21

Splice A21-2 ........................... .13, 21

Splice A21-3 ..............................23

Splice A142-1 .............................14

Splice A142-2 ..........................4,6,14

Splice B47 ...............................28

Splice C7 ............................. .46, 48

Splice D1 ................................24

Splice D2 ................................24

Splice E2 .............. .31, 33, 37, 41, 46, 47, 65, 67

Splice E2-1 ............ .31, 33, 37, 41, 46, 47, 65, 67

Splice F20 .......................... .35, 41, 67

Splice F20-1 .........................7,8,9,23

Splice F30 .......................... .35, 42, 65

Splice F35 ............................ .61, 63

Splice G5 ............................. .35, 43

Splice G7 .......................... .15, 18, 30

Splice K4 ................................15

Splice K4-1 ........................... .15, 18

Splice K4-2 ........................... .19, 20

Splice K6 ............................. .16, 20

Splice K7-1 ........................... .15, 18

Splice K22 ...............................20

Splice K24 ...............................18

Splice L3 ............................. .31, 33

Splice L4 ............................. .31, 33

Splice L7-1 ........................... .32, 34

Splice L7-2 ........................... .31, 33

Splice L7-3 ...............................36

Splice L7-4 ........................... .69, 71

Splice L7-5 ........................... .31, 33

Splice L20 ..............................1,36

Splice L39 ............................ .31, 33

Splice L50 ...............................52

Splice L60 ............................ .31, 33

Splice L60-1 ..............................52

Splice L61 ............................ .32, 34

Splice L61-1 ..............................52

Splice M1-1 ...................... .39, 44, 55, 65

8W - 720 WIRING DIAGRAMS AP BODY D-P Ä

Page 1471 of 2438

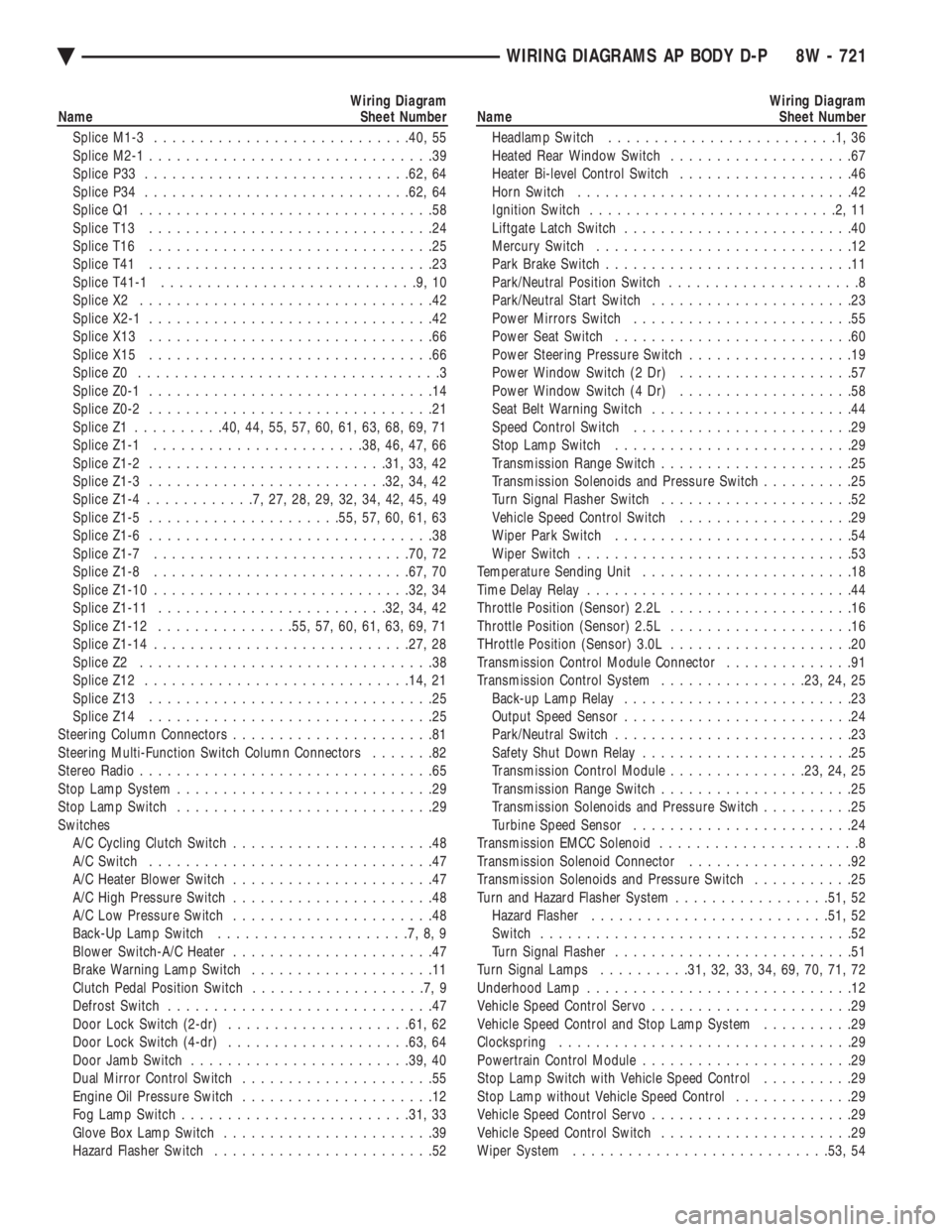

Wiring Diagram

Name Sheet Number

Splice M1-3 ........................... .40, 55

Splice M2-1 ...............................39

Splice P33 ............................ .62, 64

Splice P34 ............................ .62, 64

Splice Q1 ................................58

Splice T13 ...............................24

Splice T16 ...............................25

Splice T41 ...............................23

Splice T41-1 ............................9,10

Splice X2 ................................42

Splice X2-1 ...............................42

Splice X13 ...............................66

Splice X15 ...............................66

Splice Z0 .................................3

Splice Z0-1 ...............................14

Splice Z0-2 ...............................21

Splice Z1 ......... .40, 44, 55, 57, 60, 61, 63, 68, 69, 71

Splice Z1-1 ...................... .38, 46, 47, 66

Splice Z1-2 ......................... .31, 33, 42

Splice Z1-3 ......................... .32, 34, 42

Splice Z1-4 ............7,27,28,29,32,34,42,45,49

Splice Z1-5 .................... .55, 57, 60, 61, 63

Splice Z1-6 ...............................38

Splice Z1-7 ........................... .70, 72

Splice Z1-8 ........................... .67, 70

Splice Z1-10 ........................... .32, 34

Splice Z1-11 ........................ .32, 34, 42

Splice Z1-12 .............. .55, 57, 60, 61, 63, 69, 71

Splice Z1-14 ........................... .27, 28

Splice Z2 ................................38

Splice Z12 ............................ .14, 21

Splice Z13 ...............................25

Splice Z14 ...............................25

Steering Column Connectors ......................81

Steering Multi-Function Switch Column Connectors .......82

Stereo Radio ................................65

Stop Lamp System ............................29

Stop Lamp Switch ............................29

Switches A/C Cycling Clutch Switch ......................48

A/C Switch ...............................47

A/C Heater Blower Switch ......................47

A/C High Pressure Switch ......................48

A/C Low Pressure Switch ......................48

Back-Up Lamp Switch .....................7,8,9

Blower Switch-A/C Heater ......................47

Brake Warning Lamp Switch ....................11

Clutch Pedal Position Switch ...................7,9

Defrost Switch .............................47

Door Lock Switch (2-dr) ................... .61, 62

Door Lock Switch (4-dr) ................... .63, 64

Door Jamb Switch ....................... .39, 40

Dual Mirror Control Switch .....................55

Engine Oil Pressure Switch .....................12

Fog Lamp Switch ........................ .31, 33

Glove Box Lamp Switch .......................39

Hazard Flasher Switch ........................52Wiring Diagram

Name Sheet Number

Headlamp Switch .........................1,36

Heated Rear Window Switch ....................67

Heater Bi-level Control Switch ...................46

Horn Switch ..............................42

Ignition Switch ...........................2,11

Liftgate Latch Switch .........................40

Mercury Switch ............................12

Park Brake Switch ...........................11

Park/Neutral Position Switch .....................8

Park/Neutral Start Switch ......................23

Power Mirrors Switch ........................55

Power Seat Switch ..........................60

Power Steering Pressure Switch ..................19

Power Window Switch (2 Dr) ...................57

Power Window Switch (4 Dr) ...................58

Seat Belt Warning Switch ......................44

Speed Control Switch ........................29

Stop Lamp Switch ..........................29

Transmission Range Switch .....................25

Transmission Solenoids and Pressure Switch ..........25

Turn Signal Flasher Switch .....................52

Vehicle Speed Control Switch ...................29

Wiper Park Switch ..........................54

Wiper Switch ..............................53

Temperature Sending Unit .......................18

Time Delay Relay .............................44

Throttle Position (Sensor) 2.2L ....................16

Throttle Position (Sensor) 2.5L ....................16

THrottle Position (Sensor) 3.0L ....................20

Transmission Control Module Connector ..............91

Transmission Control System ................23, 24, 25

Back-up Lamp Relay .........................23

Output Speed Sensor .........................24

Park/Neutral Switch ..........................23

Safety Shut Down Relay .......................25

Transmission Control Module ...............23, 24, 25

Transmission Range Switch .....................25

Transmission Solenoids and Pressure Switch ..........25

Turbine Speed Sensor ........................24

Transmission EMCC Solenoid ......................8

Transmission Solenoid Connector ..................92

Transmission Solenoids and Pressure Switch ...........25

Turn and Hazard Flasher System .................51, 52

Hazard Flasher ......................... .51, 52

Switch ..................................52

Turn Signal Flasher ..........................51

Turn Signal Lamps ..........31, 32, 33, 34, 69, 70, 71, 72

Underhood Lamp .............................12

Vehicle Speed Control Servo ......................29

Vehicle Speed Control and Stop Lamp System ..........29

Clockspring ................................29

Powertrain Control Module .......................29

Stop Lamp Switch with Vehicle Speed Control ..........29

Stop Lamp without Vehicle Speed Control .............29

Vehicle Speed Control Servo ......................29

Vehicle Speed Control Switch .....................29

Wiper System ........................... .53, 54

Ä WIRING DIAGRAMS AP BODY D-P 8W - 721

Page 1568 of 2438

The MOPAR Silicone Rubber Adhesive Sealant

gasket material or equivalent should be applied in a

continuous bead approximately 3mm (0.120 inch) in

diameter. All mounting holes must be circled. For

corner sealing, a 3.17 or 6.35 mm (1/8 or 1/4 inch.)

drop is placed in the center of the gasket contact

area. Uncured sealant may be removed with a shop

towels. Components should be torqued in place while

the sealant is still wet to the touch (within 10 min-

utes). The usage of a locating dowel is recommended

during assembly to prevent smearing of material off

location.

CRANKSHAFT SPROCKET BOLT ACCESS PLUG

An Access plug is located in the right inner fender

shield. Remove the plug and insert proper size

socket, extension and rachet, when crankshaft rota-

tion is necessary.

ENGINE PERFORMANCE

If a loss of performance is noticed, ignition timing

should be checked. If ignition timing is retarded by

9, 18 or 27É indicating 1, 2 or 3 (timing belt or chain)

teeth may have skipped, then, camshaft and acces-

sory shaft timing with the crankshaft should be

checked. Refer to Engine Timing Sprockets and Oil

Seals of the Engine Section. To provide best vehicle performance and lowest ve-

hicle emissions, it is most important that the tune-up

be done accurately. Use the specifications listed on

the Vehicle Emission Control Information label

found in the engine compartment. (1) Test cranking amperage draw. See Starting

Motor Cranking Amperage Draw Electrical Section

of this manual. (2) Tighten the intake manifold bolts to specifica-

tions. (3) Perform cylinder compression test.(a) Check engine oil level and add oil if neces-

sary. (b) Drive the vehicle until engine reaches normal

operating temperature. (c) Select a route free from traffic and other

forms of congestion, observe all traffic laws, and ac-

celerate through the gears several times briskly.

CAUTION: Do not overspeed the engine. The higher

engine speed may help clean out valve seat deposits

which can prevent accurate compression readings.

(d) Remove all spark plugs from engine. As

spark plugs are being removed, check electrodes for

abnormal firing indicators fouled, hot, oily, etc.

Record cylinder number of spark plug for future

reference. (e) Disconnect coil wire from distributor and se-

cure to good ground to prevent a spark from start- ing a fire (Conventional Ignition System). For Direct

Ignition System DIS disconnect the coil connector. (f) Be sure throttle blade is fully open during the

compression check. (g) Insert compression gage adaptor into the #1

spark plug hole in cylinder head. Crank engine until

maximum pressure is reached on gage. Record this

pressure as #1 cylinder pressure. (h) Repeat Step G for all remaining cylinders.

(i) Compression should not be less than (689kPa)

100 psi and not vary more than 25 percent from

cylinder to cylinder. (j) If one or more cylinders have abnormally low

compression pressures, repeat steps 3b through 3h. (k) If the same cylinder or cylinders repeat an

abnormally low reading on the second compression

test, it could indicate the existence of a problem in

the cylinder in question.

The recommended compression pressures are

to be used only as a guide to diagnosing engine

problems. An engine should not be disassembled

to determine the cause of low compression un-

less some malfunction is present. (4) Clean or replace spark plugs as necessary and

adjust gap as specified in Electrical Group 8. Tighten to

specifications. (5) Test resistance of spark plug cables. Refer to

Ignition System Secondary Circuit Inspection Electri-

cal Section Group 8. (6) Inspect the primary wire. Test coil output volt-

age, primary and secondary resistance. Replace parts

as necessary. Refer to Ignition System and make nec-

essary adjustment. (7) Ignition timing should be set to specifications.

(See Specification Label in engine compartment). (8) Test fuel pump for pressure and vacuum. Refer to

Fuel System Group 14, Specifications. (9) The air filter elements should be replaced as

specified in Lubrication and Maintenance, Group 0. (10) Inspect crankcase ventilation system as out

lined in Lubrication and Maintenance, Group 0. For

emission controls see Emission Controls Group 25 for

service procedures. (11) Inspect and adjust accessory belt drives refer-

ring to Accessory Belt Drive in Cooling System, Group

7 for proper adjustments. (12) Road test vehicle as a final test.

HONING CYLINDER BORES

Before honing, stuff plenty of clean shop towels

under the bores, over the crankshaft to keep abrasive

materials from entering crankcase area. (1) Used carefully, the cylinder bore resizing hone

C-823 equipped with 220 grit stones, is the best tool for

this job. In addition to deglazing, it will reduce taper

and out-of-round as well as removing light

9 - 2 ENGINE Ä

Page 1575 of 2438

Flexible fuel vehicles can operate on a mixture of

up to 85 percent methanol, 15 percent unleaded gas-

oline. These vehicles also operate on mixtures con-

taining a lower percentage of methanol or just pure

unleaded gasoline. Engine components which are required for safe op-

eration using fuel containing methanol alcohol are

identified by a standard green color and/or display

the statement methanol compatible imprinted on the

component. To ensure continued safe operation, these

components must be serviced only with genuine MO-

PAR replacement parts. Methanol compatible parts for the 2.5L FFV (Flex-

ible Fuel Vehicle) engine include, but are not limited

to; the valve stem oil seals, all piston rings, the oil

fill cap, the fuel injectors, fuel rail, fuel pressure reg-

ulator, hoses and the vacuum control harness hose. BLOCK: All four cylinder cast iron blocks have

cast-in recesses in the bottom of each cylinder bore to

provide connecting rod clearance; especially needed

for 2.5L engines. The bores are also siamese to min-

imize engine length. A coolant passage is drilled

cross-ways through the siamese section to enhance

between the bore cooling on some engine types. A

partial open deck is used for cooling and weight re-

duction with oil filter, water pump, and distributor

mounting bosses molded into the front (radiator side)

of the block. Nominal wall thickness is 4.5 mm. Five

main bearing bulkheads and a block skirt extending

3 mm below the crankshaft center line add to the

blocks high rigidity with light weight. CRANKSHAFT: A nodular cast iron crankshaft is

used in TBI engines. A forged steel crankshaft is

used in the Turbo III engine. All engines have 5 main bearings, with number 3 flanged to control

thrust. The 60 mm diameter main and 50 mm diam-

eter crank pin journals (all) have undercut radiuses

fillets that are deep rolled for added strength. To op-

timize bearing loading 4 counterweights are used.

Hydrodynamic seals (installed in diecast aluminum

retainers) provide end sealing, where the crankshaft

exits the block. Anaerobic gasket material is used for

retainer-to-block sealing. No vibration damper is

used. A sintered iron (TBI engine and steel billet

Turbo III engines) timing belt sprocket is mounted

on the crankshaft nose. This sprocket provides mo-

tive power; via timing belt to the camshaft and inter-

mediate shaft sprockets (also sintered iron (TBI

engine and steel billet Turbo III engines) providing

timed valve, distributor, and oil pump actuation. PISTONS: Some Chrysler pistons have cast-in

steel struts at the pin bosses for autothermic control.

All 2.2L and 2.5L piston tops have cuts to provide

valve clearance. Some pistons are dished to provide

various compression ratios. Standard 2.2L and 2.5L

engines are designed for 9.5:1 and 8.9:1 compression

ratios respectively. The 2.5L piston is dished and is a

lightweight design to enhance engine smoothness.

The 2.2L turbo III uses dished pistons providing a

8.3:1 compression ratio. All standard 2.2/2.5L and

2.5L FFV engines use pressed-in piston pins to at-

tach forged steel connecting rods, 2.2L turbo III en-

gine uses a full floating piston pin and connecting

rod assembly. PISTONS RINGS: The 2.2/2.5L engines share

common piston rings throughout, including molybde-

num filled top ring for reliable compression sealing

and a tapered faced intermediate ring for additional

cylinder pressure control. The 2.5L FFV engine fea-

ture all chrome rings for enhanced long term dura-

bility under multi-fueled conditions. CYLINDER HEAD: The cylinder head is cast alu-

minum with in-line valves. The 2.2/2.5L and 2.5L

FFV valves are arranged with alternating exhaust

and intake. The intake and exhaust ports are located

in the rearward, facing side of the head. The Turbo

III valves are arranged in two inline banks, with the

ports of the bank of two intake valves per cylinder

facing toward the radiator side of engine and ports of

the bank of two exhaust valve per cylinder facing to-

ward the dash panel. The intake ports feed fast-burn

design combustion chambers (2.2/2.5L and 2.5L FFV

only) with the spark plug located close to the center

line of the combustion chamber for optimum effi-

ciency. An integral oil gallery within the cylinder

head supplies oil to the hydraulic lash adjusters,

camshaft, and valve mechanisms. CAMSHAFT: The nodular iron camshaft has five

bearing journals (2.2/2.5L and 2.5L FFV). The Turbo

III employs dual camshafts that have nine bearing

journals. Flanges at the rear journal control cam-

Fig. 1 Engine Identification

Ä 2.2/2.5L ENGINE 9 - 9

Page 1576 of 2438

shaft end play. A sintered iron (TBI engine and steel

billet Turbo III engines) timing belt sprocket is

mounted on the cam nose, and a hydrodynamic oil

seal is used for oil control at the front of the cam-

shaft. ACCESSORY SHAFT: The iron accessory shaft

has two bearing journals and is housed in the for-

ward facing side of the block. A hydrodynamic seal,

installed in an aluminum housing attached to the

block, provides retention, shaft thrust, and oil con-

trol. The accessory shaft is driven by the timing belt

through a sintered iron (TBI engine and steel billet

Turbo III engines) sprocket mounted on the nose of

the accessory shaft. The accessory shaft in turn

drives the oil pump and distributor on 2.2/2.5L and

2.5L FFV and the oil pump only on Turbo III. VALVES: The valves are actuated by roller cam

followers which pivot on stationary hydraulic lash

adjusters. The valve train with 40.6 mm (1.60 inch)

diameter intake valves and 35.4 mm (1.39 inch) di-

ameter exhaust valves employ viton rubber valve

stem seals except 2.5L FFv . the 2.5L FFV valve

stem seals are made of special rubber compound

which resist the deteriorating effects of methanol

fuel by-products that enter the oil during combus-

tion. Valve springs, spring retainers, and locks are

conventional. For Turbo III engines the valves are

actuated by roller tipped rocker arms with hydraulic

lash adjusters which pivot on a shaft. The valve train

with 33.88 mm (1.33 in.) diameter intake valves are

arranged in line opposite of the 29.26 mm (1.15 in.)

diameter exhaust valves employ locking valve stem

seals. Valve springs, spring retainers, and locks are

not interchangeable with other engines. BALANCE SHAFTS: 2.2 Turbo III and 2.5L en-

gines are equipped with two counter rotating balance

shafts installed in a carrier attached to the lower

crankcase. The shafts are interconnect through

gears. These gears are driven by a short chain from

the crankshaft, to rotate at two times crankshaft

speed. This counterbalances certain engine recipro-

cating forces. INTAKE MANIFOLDS:

All intake manifolds are

aluminum castings, attached to the cylinder head

with eight bolts. N.A. engines use a four branch de-

sign. This long branch fan design enhances low and

midspeed torque. It also features an integrally cast

water crossover passage to warm incoming fuel/air

mixture, plus an EGR mounting boss and PCV inlet. The Turbo III engine intake manifold is a log type

with tuned runners. The manifold is machined to ac-

cept fuel injectors near the ports of each cylinder. EXHAUST MANIFOLDS: The exhaust manifolds

are made of nodular cast iron for strength and high

temperatures. All naturally aspirated (N.A.) and tur-

bocharged engines exit exhaust gasses through a ma-

chined, articulated joint connection to the exhaust

pipe. 2.2/2.5L and 2.5L FFV manifolds intermesh

with the intake manifold at the cylinder head. N.A. engines use a four branch design with cylin-

ders one and four joined and cylinder two and three

joined to exit at the outlet. The Turbo III engine exhaust manifold also carries

the turbocharger. This manifold has a modified log

type collector with exhaust gasses directed to and

through the turbocharger to exit the conical (articu-

lated joint) outlet machined into the turbocharger ex-

haust elbow. ENGINE LUBRICATION: Refer to Group 0 Lu-

brication and Maintenance for recommended oil to be

used in various engine application. System is full

flow filtration, pressure feed type. The oil pump is

mounted within the crankcase and driven by the ac-

cessory shaft. Pressurized oil is then routed through

the main oil gallery, running the length of the cylin-

der block, supplying main and rod bearings with fur-

ther routing (for 2.2L turbo III and 2.5L engines) to

the lower balance shaft assemblies. Pistons are lubri-

cated from directed holes in the connecting rod as-

semblies. Camshaft and valve mechanisms are

lubricated from a full-length cylinder head oil gallery

supplied from the crankcase main oil gallery.

9 - 10 2.2/2.5L ENGINE Ä

Page 1580 of 2438

CAUTION: Make sure clutch cable has been discon-

nected. (20) Remove front engine mount screw and nut.

(21) Remove manual transmission damper.

(22) Remove left insulator through bolt from inside

wheelhouse or insulator bracket to transmission

screws. (23) Remove engine from vehicle.

INSTALLATION

(1) Install hoist to the engine and lower engine

into the engine compartment. SEE: ENGINE MOUNT RUBBER INSULATORS,

THIS GROUP. (2) Align engine mounts and install but do not

tighten until all mounting bolts have been installed.

(3) Install transmission case to cylinder block

mounting screws. Tighten to 95 N Im (70 ft. lbs.)

torque. (4) Remove engine hoist and transmission holding

fixture. (5) Install ground strap.

(6) Install right inner splash shield.

(7) Connect starter. See Electrical Group 8 for in-

stallation. (8) Connect exhaust system. See Exhaust Systems

Group 11 for installation. (9) Manual Transmission: Install transmission

case lower cover. Automatic Transmission: Remove C clamp from

torque converter housing. Align flexplate to torque

converter and install mounting screws. Tighten to 75

N Im (55 ft. lbs.) torque.

(10) Manual Transmission: Connect clutch cable.

See Clutch Group 6. (11) Install power steering pump. Refer to Cooling

System Group 7, Accessory Drive Section for belt

tension adjustment. (12) Connect fuel line, heater hose, and accelerator

cable. (13) Connect all electrical connections and har-

nesses at throttle body and engine. (14) Install oil filter. Fill engine crankcase with

proper oil to correct level. (15) Install air conditioning compressor (if

equipped). See Heater and Air Conditioning, Group

24 for installation. (16) Install air cleaner and hoses.

(17) Install radiator and shroud assembly . Install

radiator hoses. Fill cooling system. See Cooling Sys-

tem Group 7 for filling procedure. (18) Install hood.

(19) Connect battery.

(20) Start engine and run until operating temper-

ature is reached. (21) Adjust transmission linkage, if necessary.

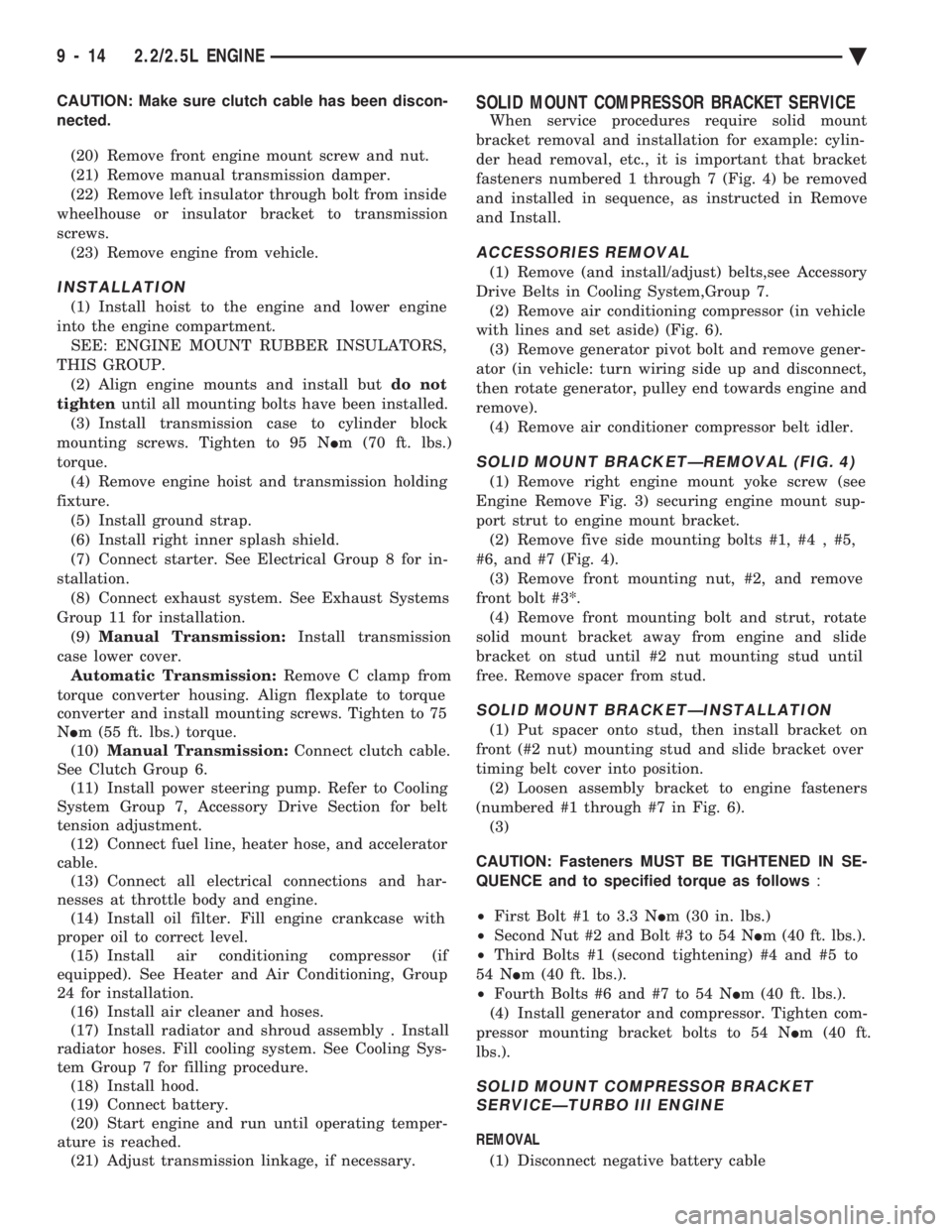

SOLID MOUNT COMPRESSOR BRACKET SERVICE

When service procedures require solid mount

bracket removal and installation for example: cylin-

der head removal, etc., it is important that bracket

fasteners numbered 1 through 7 (Fig. 4) be removed

and installed in sequence, as instructed in Remove

and Install.

ACCESSORIES REMOVAL

(1) Remove (and install/adjust) belts,see Accessory

Drive Belts in Cooling System,Group 7. (2) Remove air conditioning compressor (in vehicle

with lines and set aside) (Fig. 6). (3) Remove generator pivot bolt and remove gener-

ator (in vehicle: turn wiring side up and disconnect,

then rotate generator, pulley end towards engine and

remove). (4) Remove air conditioner compressor belt idler.

SOLID MOUNT BRACKETÐREMOVAL (FIG. 4)

(1) Remove right engine mount yoke screw (see

Engine Remove Fig. 3) securing engine mount sup-

port strut to engine mount bracket. (2) Remove five side mounting bolts #1, #4 , #5,

#6, and #7 (Fig. 4). (3) Remove front mounting nut, #2, and remove

front bolt #3*. (4) Remove front mounting bolt and strut, rotate

solid mount bracket away from engine and slide

bracket on stud until #2 nut mounting stud until

free. Remove spacer from stud.

SOLID MOUNT BRACKETÐINSTALLATION

(1) Put spacer onto stud, then install bracket on

front (#2 nut) mounting stud and slide bracket over

timing belt cover into position. (2) Loosen assembly bracket to engine fasteners

(numbered #1 through #7 in Fig. 6). (3)

CAUTION: Fasteners MUST BE TIGHTENED IN SE-

QUENCE and to specified torque as follows :

² First Bolt #1 to 3.3 N Im (30 in. lbs.)

² Second Nut #2 and Bolt #3 to 54 N Im (40 ft. lbs.).

² Third Bolts #1 (second tightening) #4 and #5 to

54 N Im (40 ft. lbs.).

² Fourth Bolts #6 and #7 to 54 N Im (40 ft. lbs.).

(4) Install generator and compressor. Tighten com-

pressor mounting bracket bolts to 54 N Im (40 ft.

lbs.).

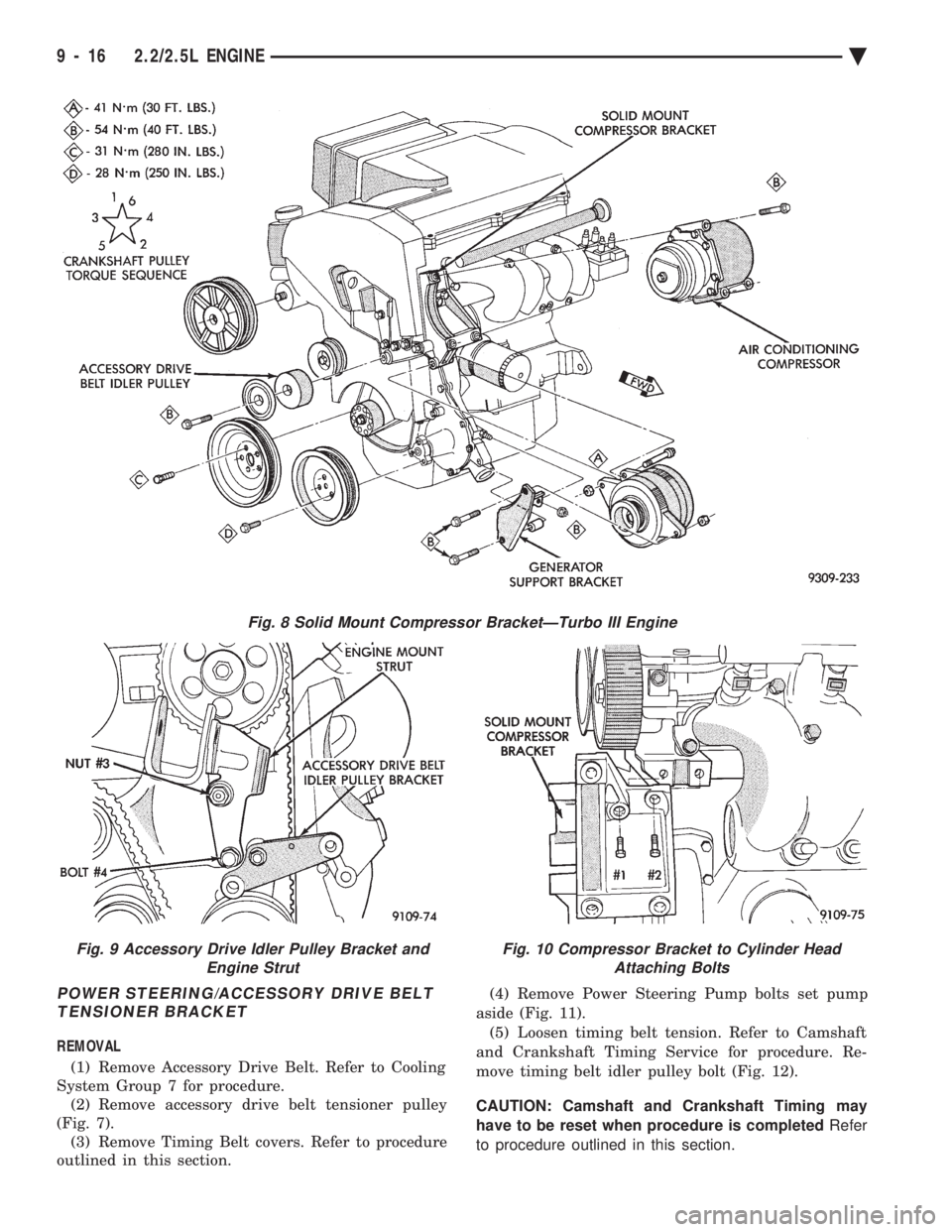

SOLID MOUNT COMPRESSOR BRACKET SERVICEÐTURBO III ENGINE

REMOVAL

(1) Disconnect negative battery cable

9 - 14 2.2/2.5L ENGINE Ä

Page 1581 of 2438

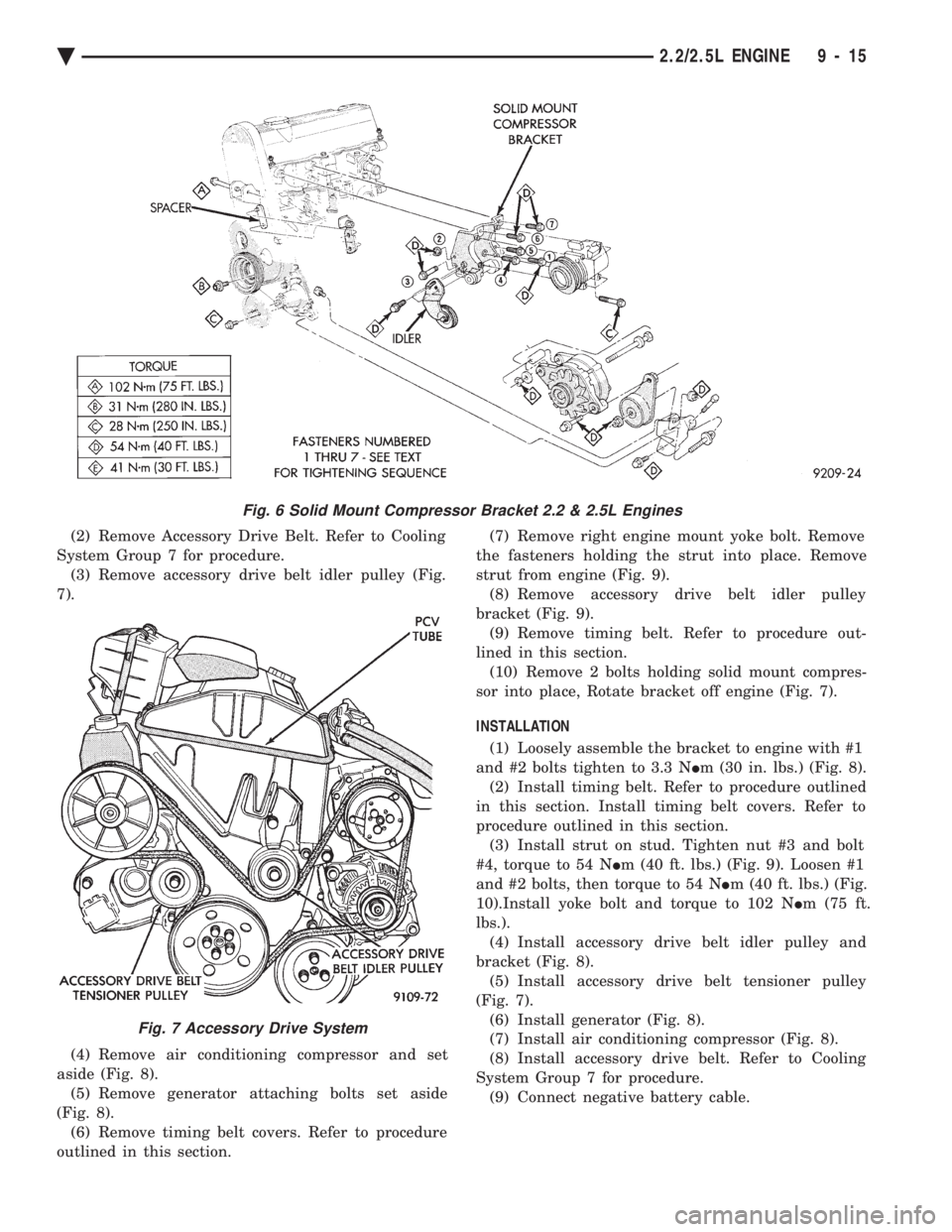

(2) Remove Accessory Drive Belt. Refer to Cooling

System Group 7 for procedure. (3) Remove accessory drive belt idler pulley (Fig.

7).

(4) Remove air conditioning compressor and set

aside (Fig. 8). (5) Remove generator attaching bolts set aside

(Fig. 8). (6) Remove timing belt covers. Refer to procedure

outlined in this section. (7) Remove right engine mount yoke bolt. Remove

the fasteners holding the strut into place. Remove

strut from engine (Fig. 9). (8) Remove accessory drive belt idler pulley

bracket (Fig. 9). (9) Remove timing belt. Refer to procedure out-

lined in this section. (10) Remove 2 bolts holding solid mount compres-

sor into place, Rotate bracket off engine (Fig. 7).

INSTALLATION

(1) Loosely assemble the bracket to engine with #1

and #2 bolts tighten to 3.3 N Im (30 in. lbs.) (Fig. 8).

(2) Install timing belt. Refer to procedure outlined

in this section. Install timing belt covers. Refer to

procedure outlined in this section. (3) Install strut on stud. Tighten nut #3 and bolt

#4, torque to 54 N Im (40 ft. lbs.) (Fig. 9). Loosen #1

and #2 bolts, then torque to 54 N Im (40 ft. lbs.) (Fig.

10).Install yoke bolt and torque to 102 N Im (75 ft.

lbs.). (4) Install accessory drive belt idler pulley and

bracket (Fig. 8). (5) Install accessory drive belt tensioner pulley

(Fig. 7). (6) Install generator (Fig. 8).

(7) Install air conditioning compressor (Fig. 8).

(8) Install accessory drive belt. Refer to Cooling

System Group 7 for procedure. (9) Connect negative battery cable.

Fig. 6 Solid Mount Compressor Bracket 2.2 & 2.5L Engines

Fig. 7 Accessory Drive System

Ä 2.2/2.5L ENGINE 9 - 15

Page 1582 of 2438

POWER STEERING/ACCESSORY DRIVE BELT TENSIONER BRACKET

REMOVAL

(1) Remove Accessory Drive Belt. Refer to Cooling

System Group 7 for procedure. (2) Remove accessory drive belt tensioner pulley

(Fig. 7). (3) Remove Timing Belt covers. Refer to procedure

outlined in this section. (4) Remove Power Steering Pump bolts set pump

aside (Fig. 11). (5) Loosen timing belt tension. Refer to Camshaft

and Crankshaft Timing Service for procedure. Re-

move timing belt idler pulley bolt (Fig. 12).

CAUTION: Camshaft and Crankshaft Timing may

have to be reset when procedure is completed Refer

to procedure outlined in this section.

Fig. 8 Solid Mount Compressor BracketÐTurbo III Engine

Fig. 9 Accessory Drive Idler Pulley Bracket and Engine StrutFig. 10 Compressor Bracket to Cylinder HeadAttaching Bolts

9 - 16 2.2/2.5L ENGINE Ä