CHEVROLET DYNASTY 1993 Service Manual

DYNASTY 1993

CHEVROLET

CHEVROLET

https://www.carmanualsonline.info/img/24/56856/w960_56856-0.png

CHEVROLET DYNASTY 1993 Service Manual

Page 2078 of 2438

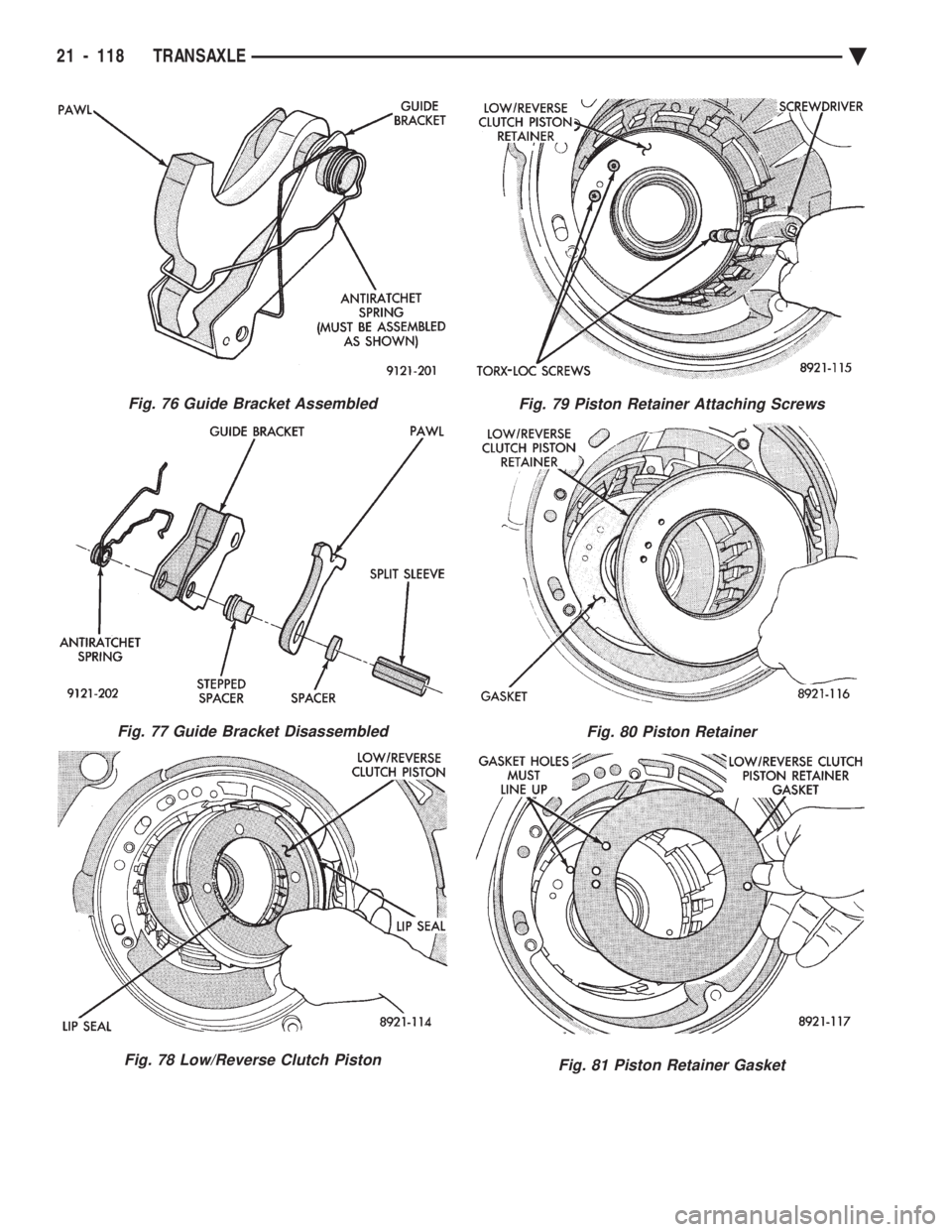

Fig. 76 Guide Bracket Assembled

Fig. 77 Guide Bracket Disassembled

Fig. 78 Low/Reverse Clutch Piston

Fig. 79 Piston Retainer Attaching Screws

Fig. 80 Piston Retainer

Fig. 81 Piston Retainer Gasket

21 - 118 TRANSAXLE Ä

Page 2079 of 2438

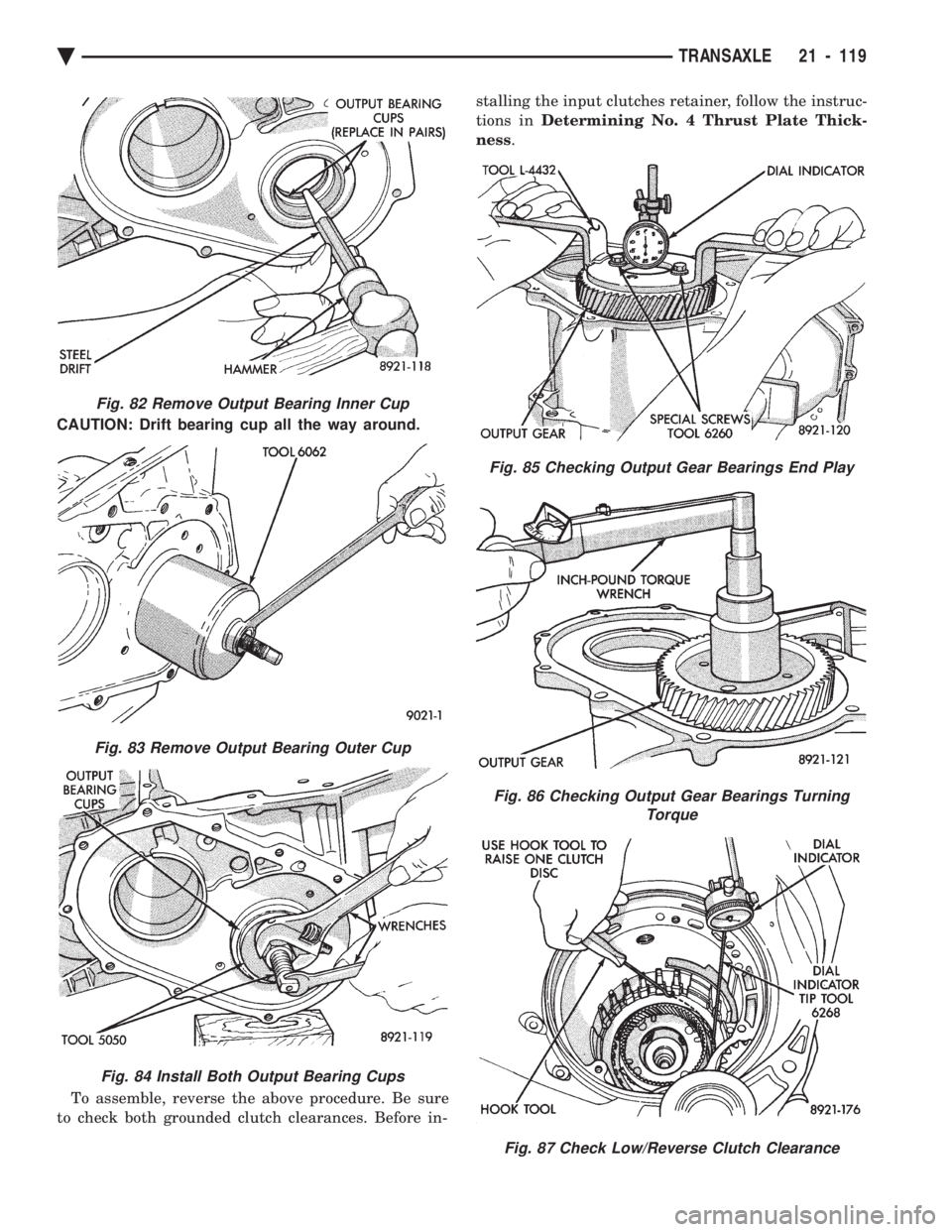

CAUTION: Drift bearing cup all the way around. To assemble, reverse the above procedure. Be sure

to check both grounded clutch clearances. Before in- stalling the input clutches retainer, follow the instruc-

tions in Determining No. 4 Thrust Plate Thick-

ness .

Fig. 82 Remove Output Bearing Inner Cup

Fig. 83 Remove Output Bearing Outer Cup

Fig. 84 Install Both Output Bearing Cups

Fig. 85 Checking Output Gear Bearings End Play

Fig. 86 Checking Output Gear Bearings Turning

Torque

Fig. 87 Check Low/Reverse Clutch Clearance

Ä TRANSAXLE 21 - 119

Page 2080 of 2438

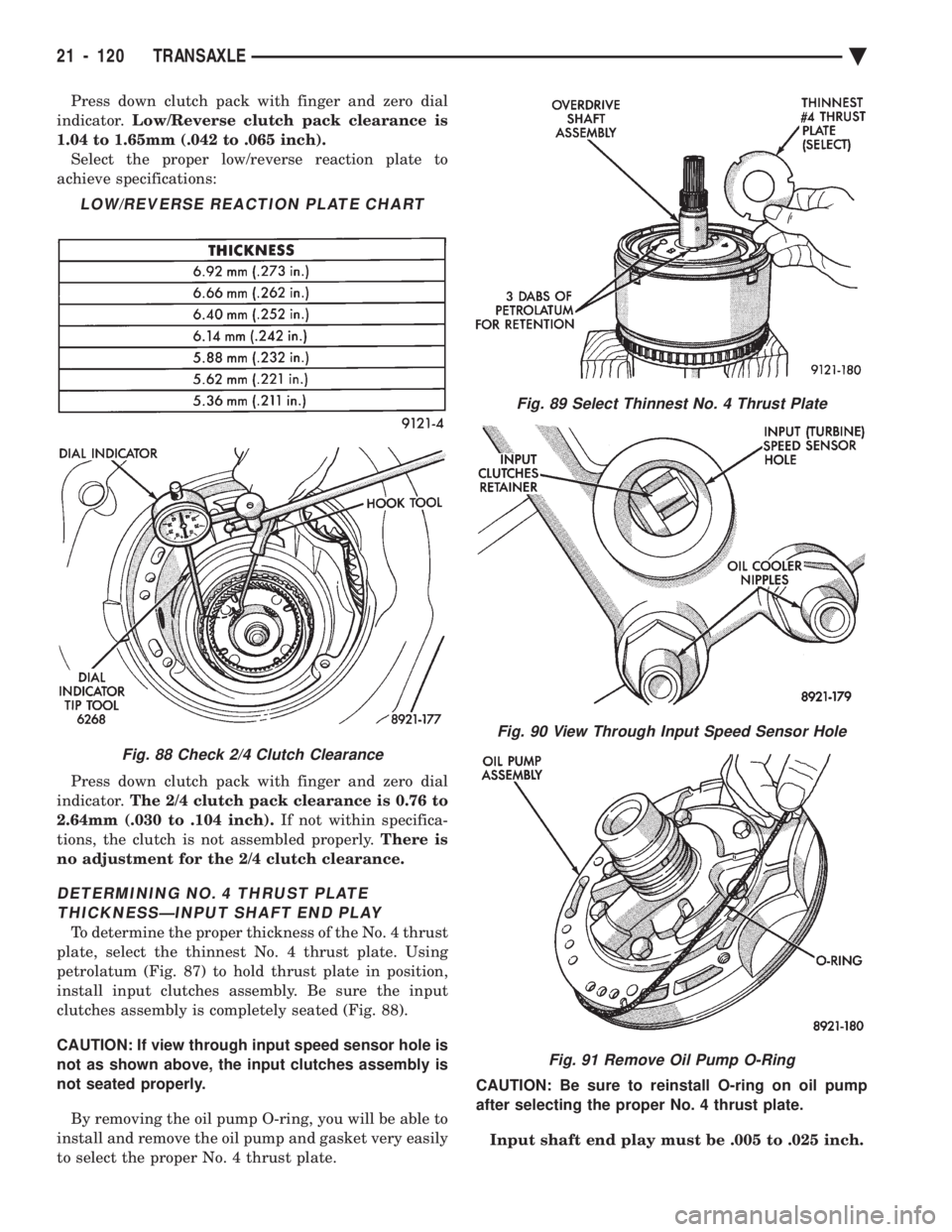

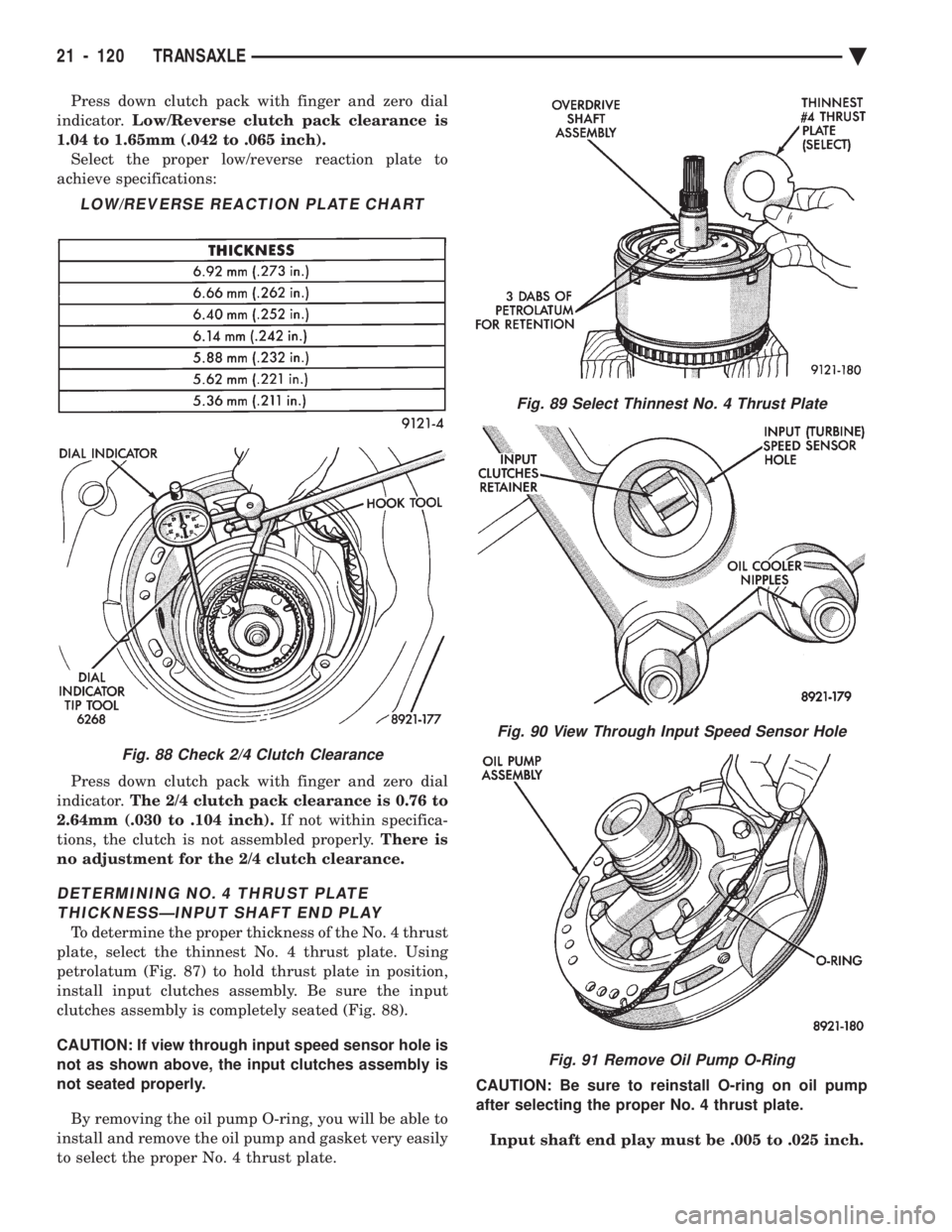

Press down clutch pack with finger and zero dial

indicator. Low/Reverse clutch pack clearance is

1.04 to 1.65mm (.042 to .065 inch). Select the proper low/reverse reaction plate to

achieve specifications:

Press down clutch pack with finger and zero dial

indicator. The 2/4 clutch pack clearance is 0.76 to

2.64mm (.030 to .104 inch). If not within specifica-

tions, the clutch is not assembled properly. There is

no adjustment for the 2/4 clutch clearance.

DETERMINING NO. 4 THRUST PLATE THICKNESSÐINPUT SHAFT END PLAY

To determine the proper thickness of the No. 4 thrust

plate, select the thinnest No. 4 thrust plate. Using

petrolatum (Fig. 87) to hold thrust plate in position,

install input clutches assembly. Be sure the input

clutches assembly is completely seated (Fig. 88).

CAUTION: If view through input speed sensor hole is

not as shown above, the input clutches assembly is

not seated properly.

By removing the oil pump O-ring, you will be able to

install and remove the oil pump and gasket very easily

to select the proper No. 4 thrust plate. CAUTION: Be sure to reinstall O-ring on oil pump

after selecting the proper No. 4 thrust plate.

Input shaft end play must be .005 to .025 inch.

LOW/REVERSE REACTION PLATE CHART

Fig. 88 Check 2/4 Clutch Clearance

Fig. 89 Select Thinnest No. 4 Thrust Plate

Fig. 90 View Through Input Speed Sensor Hole

Fig. 91 Remove Oil Pump O-Ring

21 - 120 TRANSAXLE Ä

Page 2081 of 2438

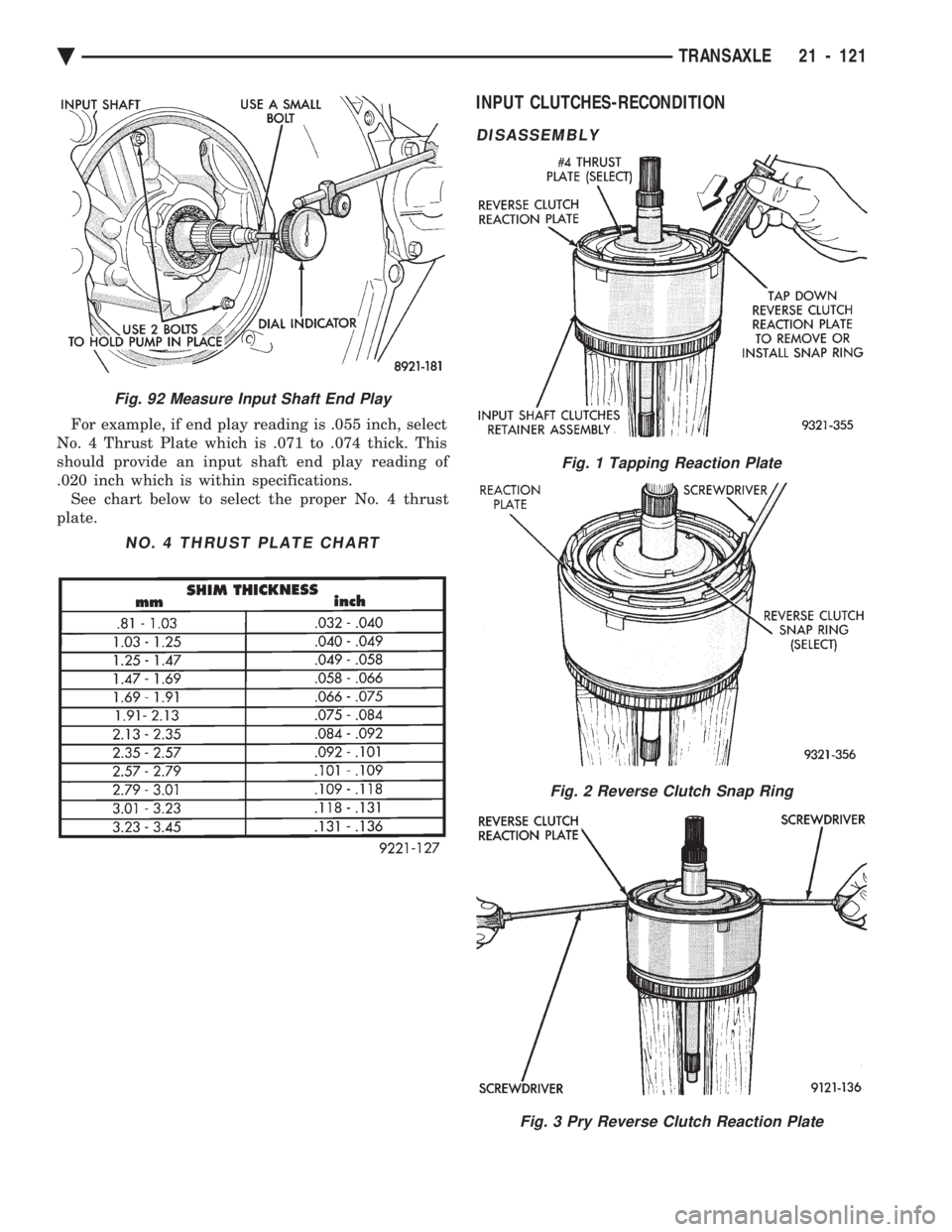

For example, if end play reading is .055 inch, select

No. 4 Thrust Plate which is .071 to .074 thick. This

should provide an input shaft end play reading of

.020 inch which is within specifications. See chart below to select the proper No. 4 thrust

plate.

INPUT CLUTCHES-RECONDITION

DISASSEMBLY

Fig. 92 Measure Input Shaft End Play

NO. 4 THRUST PLATE CHART

Fig. 1 Tapping Reaction Plate

Fig. 2 Reverse Clutch Snap Ring

Fig. 3 Pry Reverse Clutch Reaction Plate

Ä TRANSAXLE 21 - 121

Page 2082 of 2438

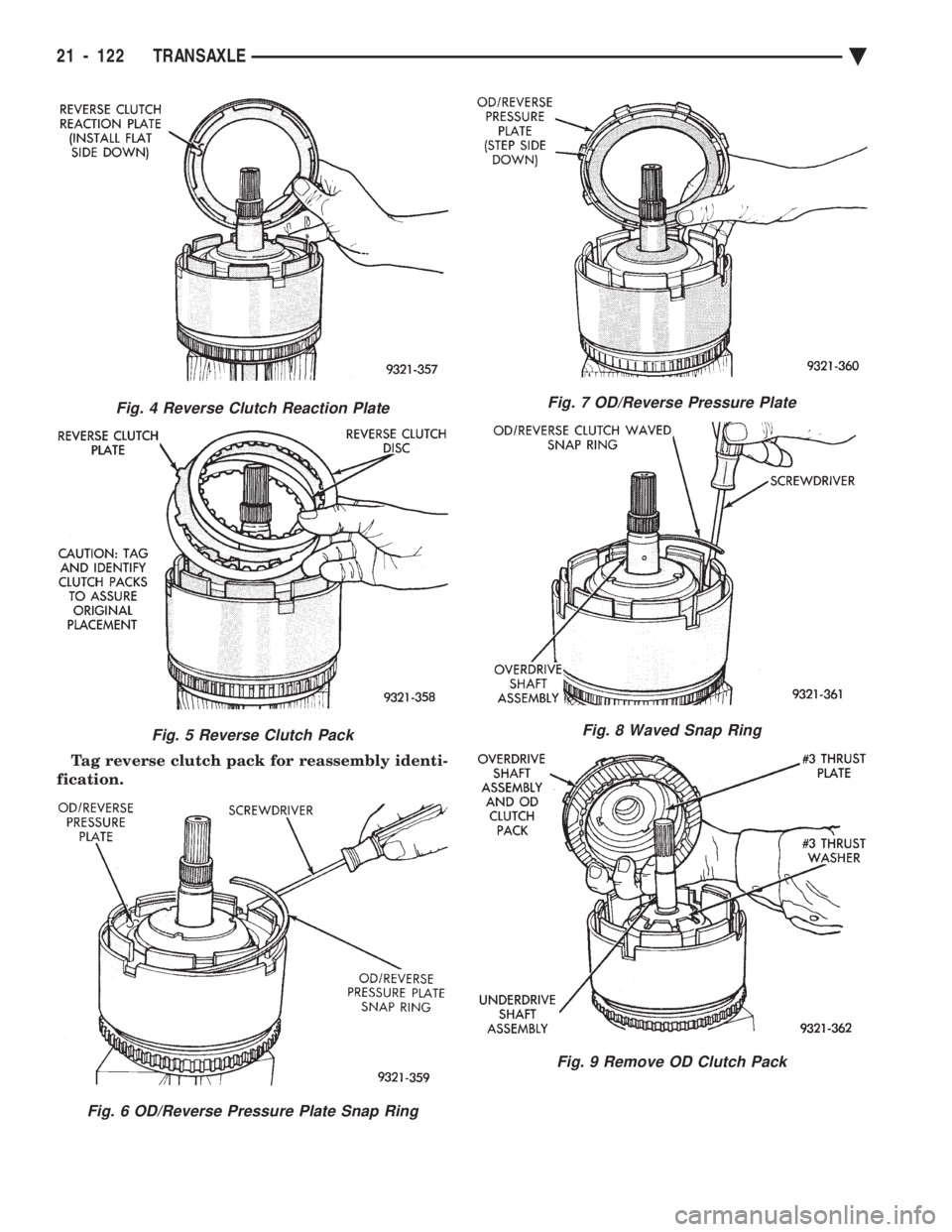

Tag reverse clutch pack for reassembly identi-

fication.

Fig. 7 OD/Reverse Pressure Plate

Fig. 8 Waved Snap Ring

Fig. 9 Remove OD Clutch Pack

Fig. 4 Reverse Clutch Reaction Plate

Fig. 5 Reverse Clutch Pack

Fig. 6 OD/Reverse Pressure Plate Snap Ring

21 - 122 TRANSAXLE Ä

Page 2083 of 2438

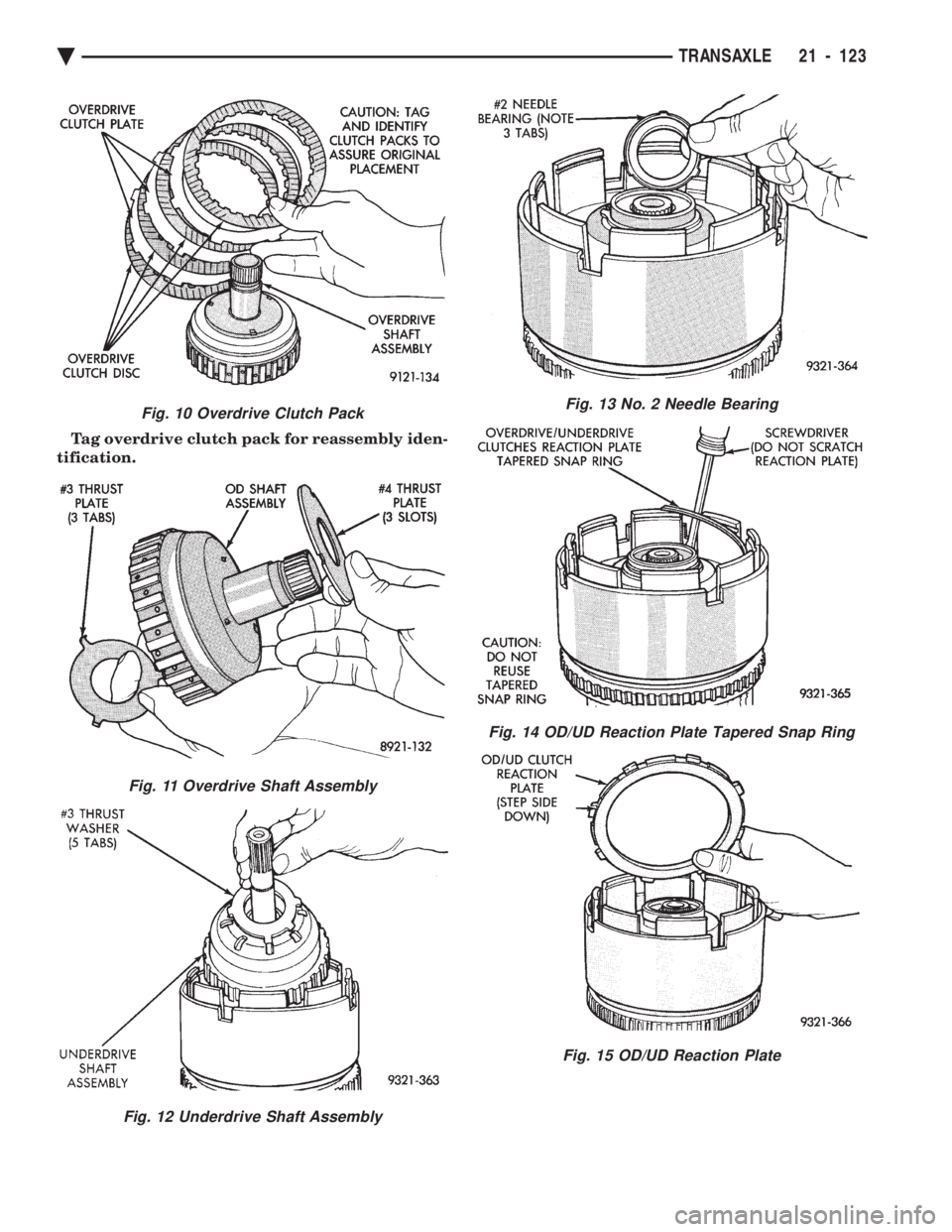

Tag overdrive clutch pack for reassembly iden-

tification.

Fig. 13 No. 2 Needle Bearing

Fig. 14 OD/UD Reaction Plate Tapered Snap Ring

Fig. 15 OD/UD Reaction Plate

Fig. 10 Overdrive Clutch Pack

Fig. 11 Overdrive Shaft Assembly

Fig. 12 Underdrive Shaft Assembly

Ä TRANSAXLE 21 - 123

Page 2084 of 2438

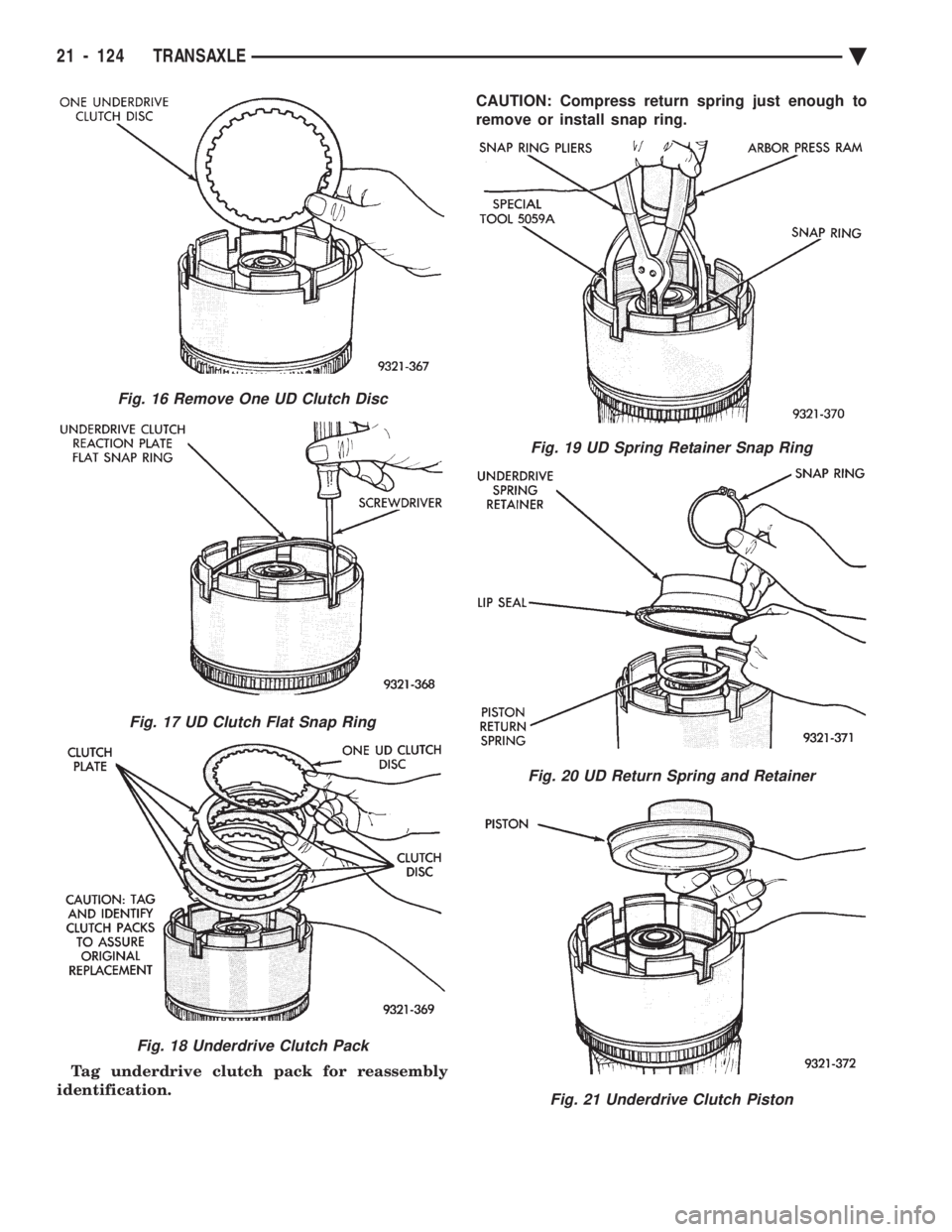

Tag underdrive clutch pack for reassembly

identification. CAUTION: Compress return spring just enough to

remove or install snap ring.

Fig. 19 UD Spring Retainer Snap Ring

Fig. 20 UD Return Spring and Retainer

Fig. 21 Underdrive Clutch Piston

Fig. 16 Remove One UD Clutch Disc

Fig. 17 UD Clutch Flat Snap Ring

Fig. 18 Underdrive Clutch Pack

21 - 124 TRANSAXLE Ä

Page 2087 of 2438

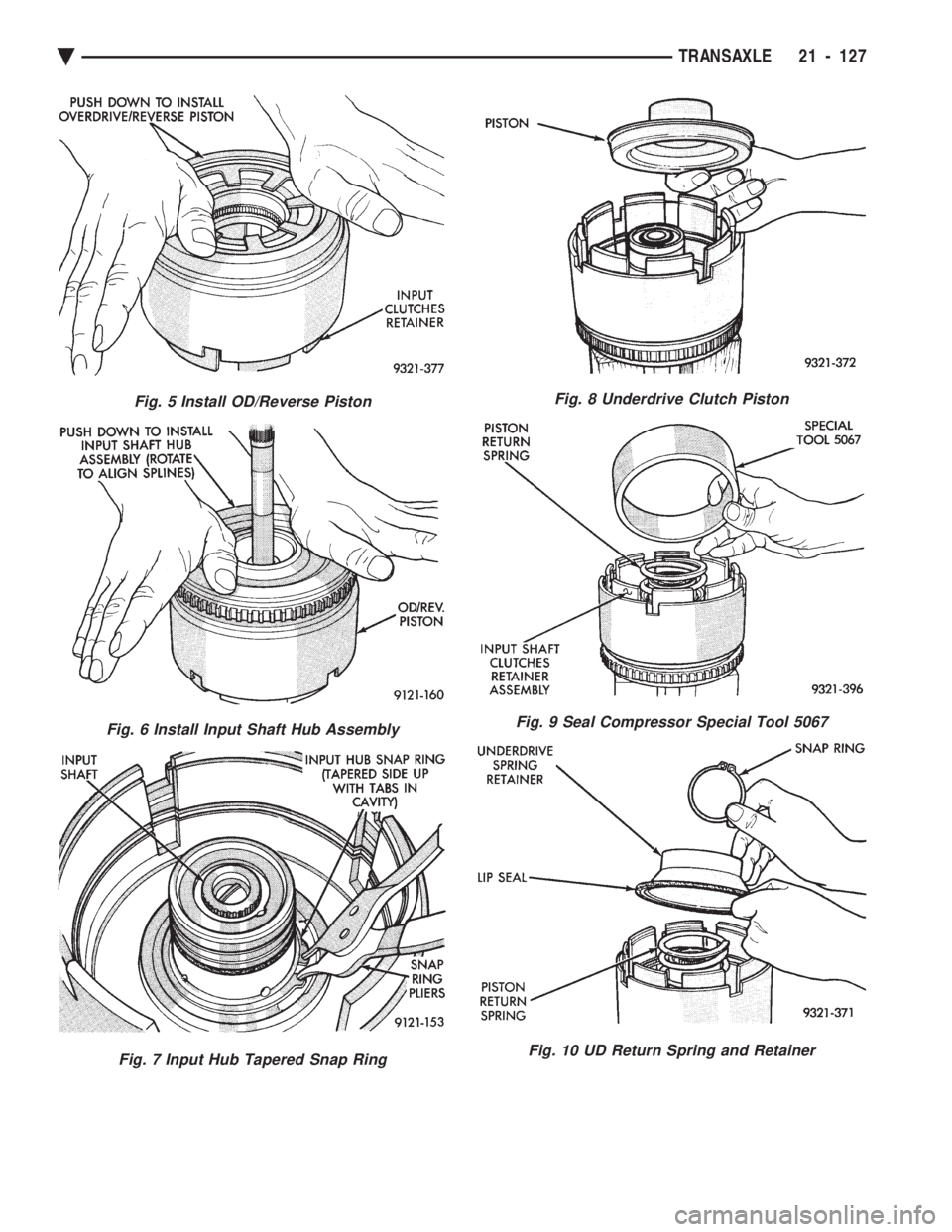

Fig. 5 Install OD/Reverse Piston

Fig. 6 Install Input Shaft Hub Assembly

Fig. 7 Input Hub Tapered Snap Ring

Fig. 8 Underdrive Clutch Piston

Fig. 9 Seal Compressor Special Tool 5067

Fig. 10 UD Return Spring and Retainer

Ä TRANSAXLE 21 - 127

Page 2088 of 2438

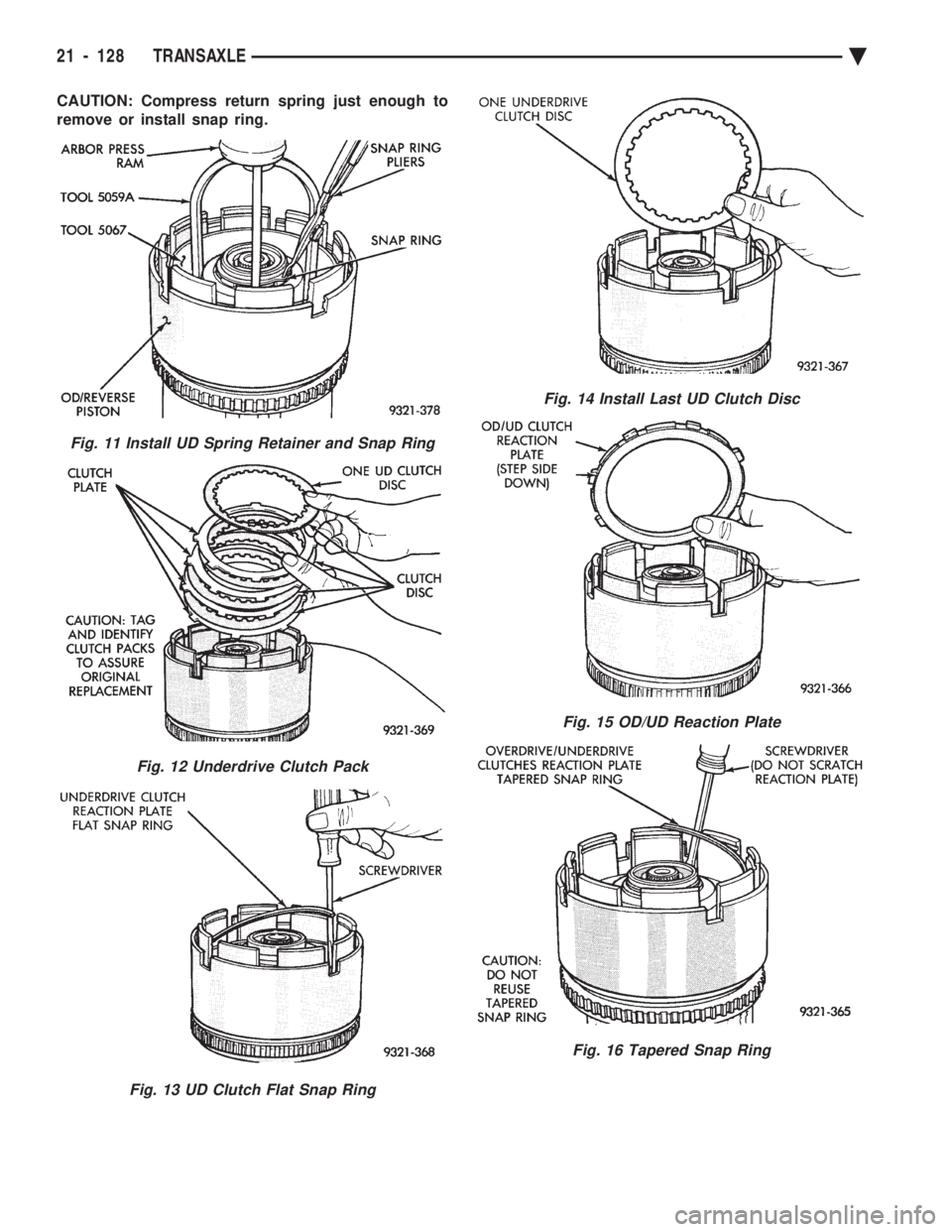

CAUTION: Compress return spring just enough to

remove or install snap ring.

Fig. 11 Install UD Spring Retainer and Snap Ring

Fig. 12 Underdrive Clutch Pack

Fig. 13 UD Clutch Flat Snap Ring

Fig. 14 Install Last UD Clutch Disc

Fig. 15 OD/UD Reaction Plate

Fig. 16 Tapered Snap Ring

21 - 128 TRANSAXLE Ä

Page 2089 of 2438

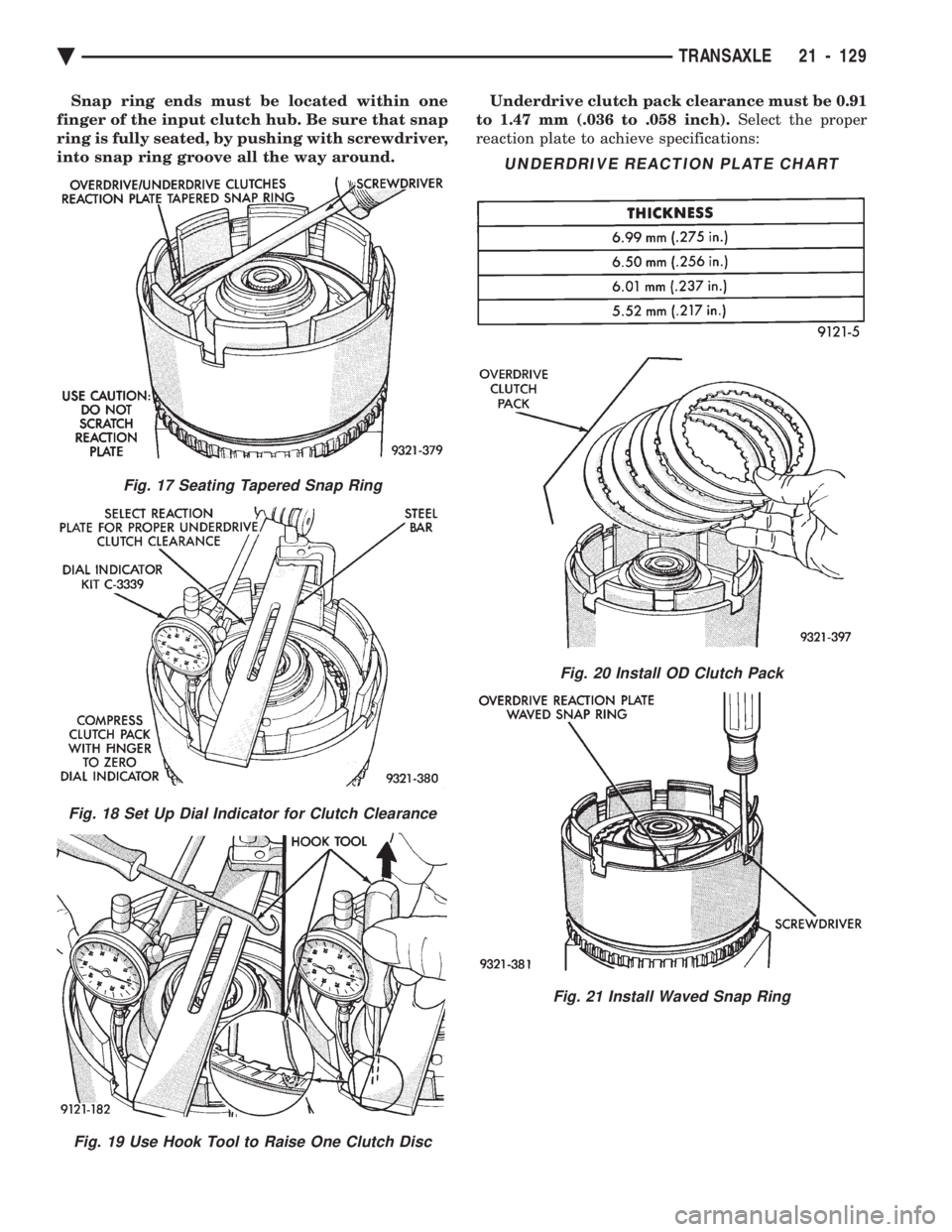

Snap ring ends must be located within one

finger of the input clutch hub. Be sure that snap

ring is fully seated, by pushing with screwdriver,

into snap ring groove all the way around. Underdrive clutch pack clearance must be 0.91

to 1.47 mm (.036 to .058 inch). Select the proper

reaction plate to achieve specifications:

Fig. 17 Seating Tapered Snap Ring

Fig. 18 Set Up Dial Indicator for Clutch Clearance

Fig. 19 Use Hook Tool to Raise One Clutch Disc

UNDERDRIVE REACTION PLATE CHART

Fig. 20 Install OD Clutch Pack

Fig. 21 Install Waved Snap Ring

Ä TRANSAXLE 21 - 129