clutch CHEVROLET DYNASTY 1993 Manual Online

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 2002 of 2438

Unless the condition is obvious, like no drive in D

range first gear only. The transaxle should never be

disassembled until hydraulic pressure tests have

been performed.

HYDRAULIC PRESSURE TESTS

Pressure testing is a very important step in the di-

agnostic procedure. These tests usually reveal the

cause of most transaxle problems. Before performing pressure tests, be certain that

fluid level and condition, and control cable adjust-

ments have been checked and approved. Fluid must be at operating temperature (150 to 200

degrees F.). Install an engine tachometer, raise vehicle on hoist

which allows front wheels to turn, and position ta-

chometer so it can be read. Disconnect throttle cable and shift cable from tran-

saxle levers so they can be controlled from outside

the vehicle. Attach 150 psi gauges to ports required for test be-

ing conducted. A 300 psi gauge (C-3293) is required

for reverse pressure test at rear servo.

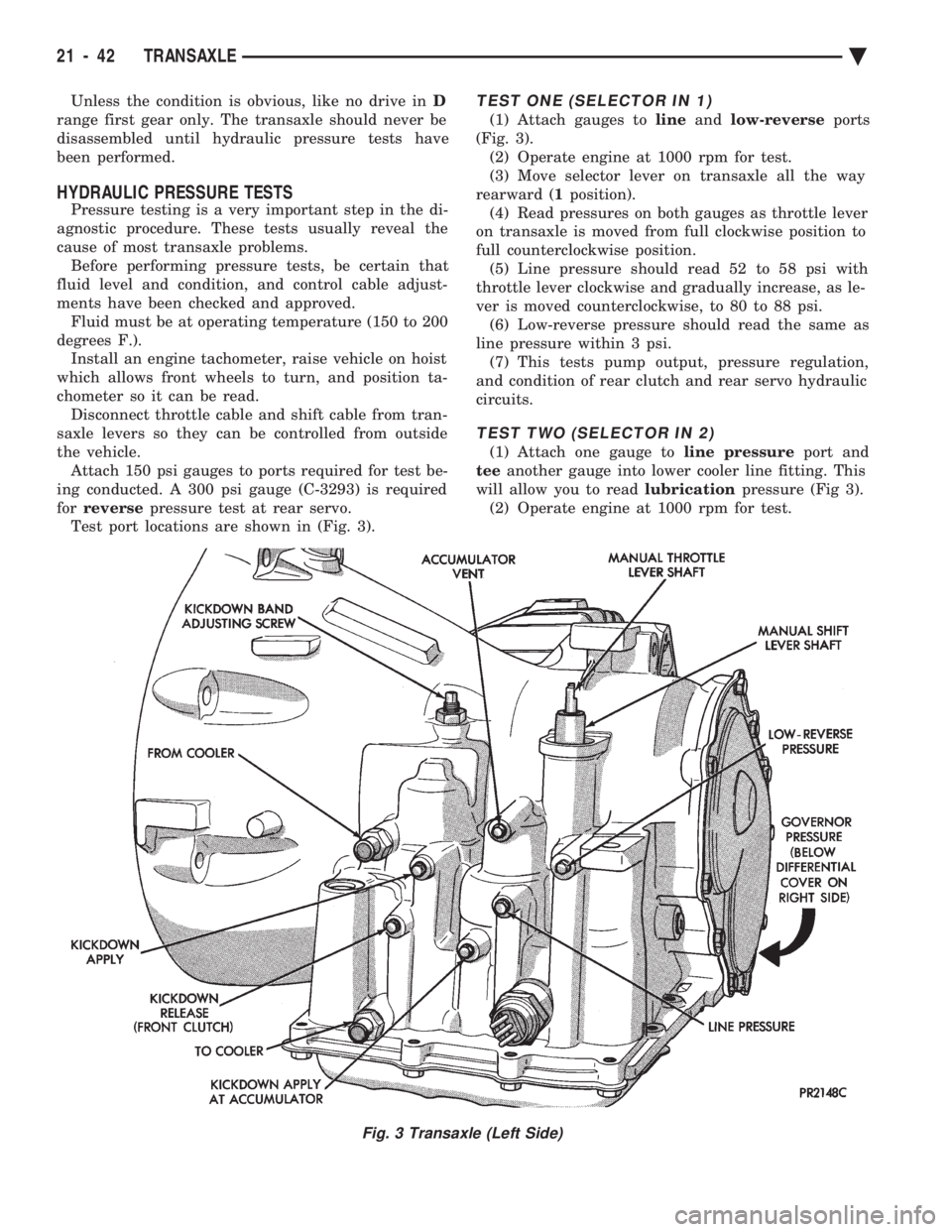

Test port locations are shown in (Fig. 3).

TEST ONE (SELECTOR IN 1)

(1) Attach gauges to lineandlow-reverse ports

(Fig. 3). (2) Operate engine at 1000 rpm for test.

(3) Move selector lever on transaxle all the way

rearward ( 1position).

(4) Read pressures on both gauges as throttle lever

on transaxle is moved from full clockwise position to

full counterclockwise position. (5) Line pressure should read 52 to 58 psi with

throttle lever clockwise and gradually increase, as le-

ver is moved counterclockwise, to 80 to 88 psi. (6) Low-reverse pressure should read the same as

line pressure within 3 psi. (7) This tests pump output, pressure regulation,

and condition of rear clutch and rear servo hydraulic

circuits.

TEST TWO (SELECTOR IN 2)

(1) Attach one gauge to line pressureport and

tee another gauge into lower cooler line fitting. This

will allow you to read lubricationpressure (Fig 3).

(2) Operate engine at 1000 rpm for test.

Fig. 3 Transaxle (Left Side)

21 - 42 TRANSAXLE Ä

Page 2003 of 2438

(3) Move selector lever on transaxle one detent

forward from full rearward position. This is selector

2 position.

(4) Read pressures on both gauges as throttle lever

on transaxle is moved from full clockwise position to

full counterclockwise position. (5) Line pressure should read 52 to 58 psi with

throttle lever clockwise and gradually increase, as le-

ver is moved counterclockwise, to 80 to 88 psi. (6) Lubrication pressure should be 10 to 25 psi

with lever clockwise and 10 to 35 psi with lever full

counterclockwise. (7) This tests pump output, pressure regulation,

and condition of rear clutch and lubrication hydrau-

lic circuits.

TEST THREE (SELECTOR IN D)

(1) Attach gauges to lineandkickdown release

ports (Fig. 3). (2) Operate engine at 1600 rpm for test.

(3) Move selector lever on transaxle two detents

forward from full rearward position. This is selector

D position.

(4) Read pressures on both gauges as throttle lever

on transaxle is moved from full clockwise position to

full counterclockwise position. (5) Line pressure should read 52 to 58 psi with

throttle lever clockwise and gradually increase, as le-

ver is moved counterclockwise to 80 to 88 psi. (6) Kickdown release is pressurized only in direct

drive and should be same as line pressure within 3

psi, up to kickdown point. (7) This tests pump output, pressure regulation,

and condition of rear clutch, front clutch, and hy-

draulic circuits.

TEST FOUR (SELECTOR IN REVERSE)

(1) Attach 300 psi gauge to low-reverseport (Fig.

3). (2) Operate engine at 1600 rpm for test.

(3) Move selector lever on transaxle four detents

forward from full rearward position. This is selector

R position.

(4) Low-reverse pressure should read 180 to 220

psi with throttle lever clockwise and gradually in-

crease, as lever is moved counterclockwise to 260 to

300 psi. (5) This tests pump output, pressure regulation,

and condition of front clutch and rear servo hydraulic

circuits. (6) Move selector lever on transaxle to Dposition

to check that low-reverse pressure drops to zero. (7) This tests for leakage into rear servo, due to

case porosity, which can cause reverse band burn

out.

TEST RESULT INDICATIONS

(1) If proper line pressure, minimum to maximum, is

found in any one test, the pump and pressure regulator

are working properly. (2) Low pressure in D, 1, and 2but correct pressure

in Rindicates rear clutch circuit leakage.

(3) Low pressure in D and Rbut correct pressure in

1 indicates front clutch circuit leakage.

(4) Low pressure in R and 1but correct pressure in

2 indicates rear servo circuit leakage.

(5) Low line pressure in all positions indicates a

defective pump, a clogged filter, or a stuck pressure

regulator valve.

GOVERNOR PRESSURE

Test only if transaxle shifts at wrong vehicle speeds

when throttle cable is correctly adjusted. (1) Connect a 0-150 psi pressure gauge to governor

pressure take-off point, located at lower right side of

case, below differential cover (Fig. 3). (2) Operate transaxle in third gear to read pres-

sures. The governor pressure should respond smoothly

to changes in mph and should return to 0 to 3 psi when vehicle is stopped. High pressure at

standstill (above 3 psi) will prevent the transaxle from

downshifting.

THROTTLE PRESSURE

No gauge port is provided for throttle pressure.

Incorrect throttle pressure should only be suspected if

part throttle upshift speeds are either delayed or occur

too early, with a correctly adjusted throttle cable.

Engine runaway on either upshifts or downshifts can

also be an indicator of incorrect (low) throttle pressure

setting, or misadjusted throttle cable. In no case should throttle pressure be adjusted until

the transaxle throttle cable adjustment has been veri-

fied to be correct.

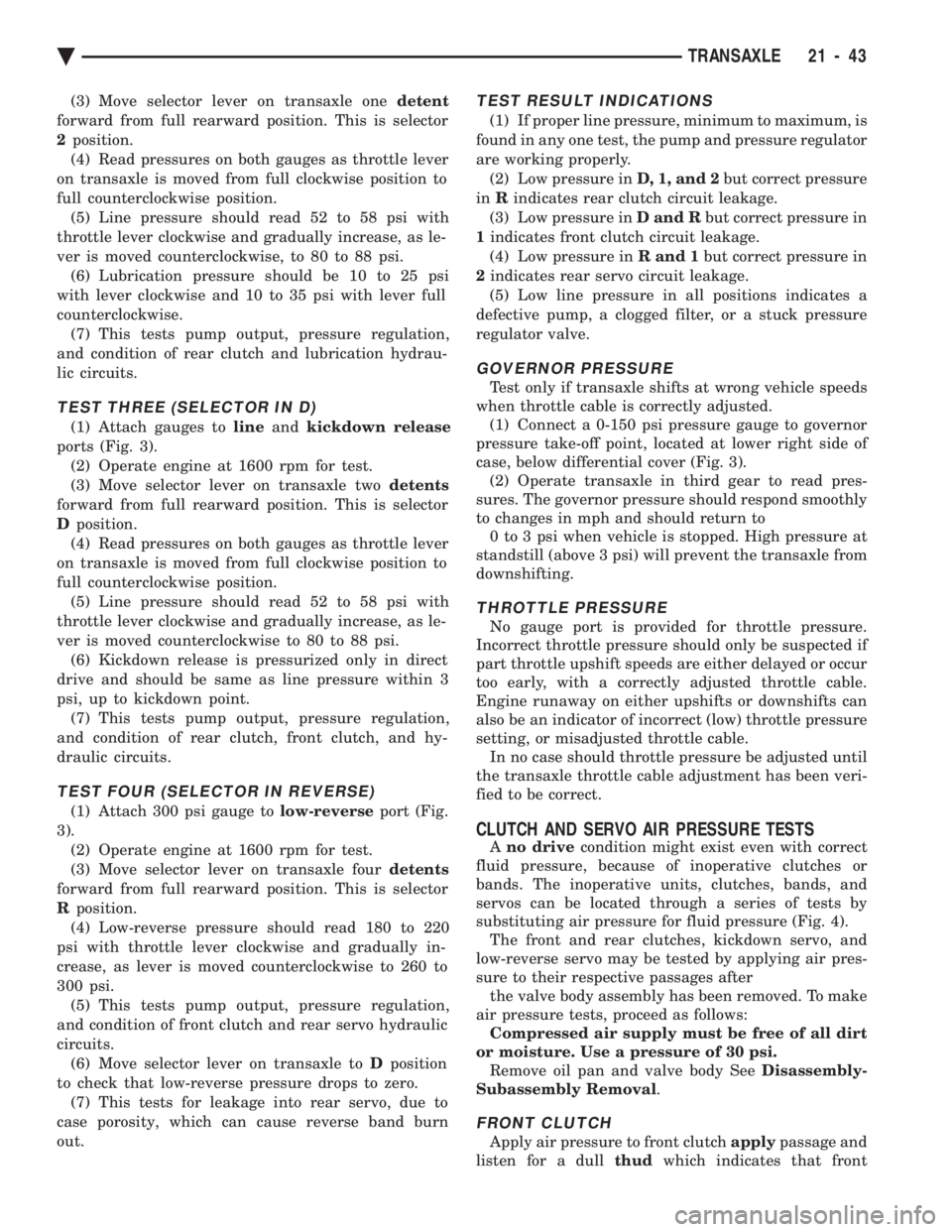

CLUTCH AND SERVO AIR PRESSURE TESTS

A no drive condition might exist even with correct

fluid pressure, because of inoperative clutches or

bands. The inoperative units, clutches, bands, and

servos can be located through a series of tests by

substituting air pressure for fluid pressure (Fig. 4). The front and rear clutches, kickdown servo, and

low-reverse servo may be tested by applying air pres-

sure to their respective passages after the valve body assembly has been removed. To make

air pressure tests, proceed as follows: Compressed air supply must be free of all dirt

or moisture. Use a pressure of 30 psi. Remove oil pan and valve body See Disassembly-

Subassembly Removal .

FRONT CLUTCH

Apply air pressure to front clutch applypassage and

listen for a dull thudwhich indicates that front

Ä TRANSAXLE 21 - 43

Page 2004 of 2438

clutch is operating. Hold air pressure on for a few

seconds and inspect system for excessive oil leaks.

REAR CLUTCH

Apply air pressure to rear clutch applypassage

and listen for a dull thudwhich indicates that rear

clutch is operating. Also inspect for excessive oil

leaks. If a dull thudcannot be heard in the clutches,

place finger tips on clutch housing and again apply

air pressure. Movement of piston can be felt as the

clutch is applied.

KICKDOWN SERVO (FRONT)

Direct air pressure into kickdown servo ONpas-

sage. Operation of servo is indicated by a tightening

of front band. Spring tension on servo piston should

release the band.

LOW AND REVERSE SERVO (REAR)

Direct air pressure into LOW-REVERSE SERVO

APPLY passage. Operation of servo is indicated by a

tightening of rear band. Spring tension on servo pis-

ton should release the band. If clutches and servos operate properly, no upshift

or erratic shift conditions indicate that malfunctions

exist in the valve body.

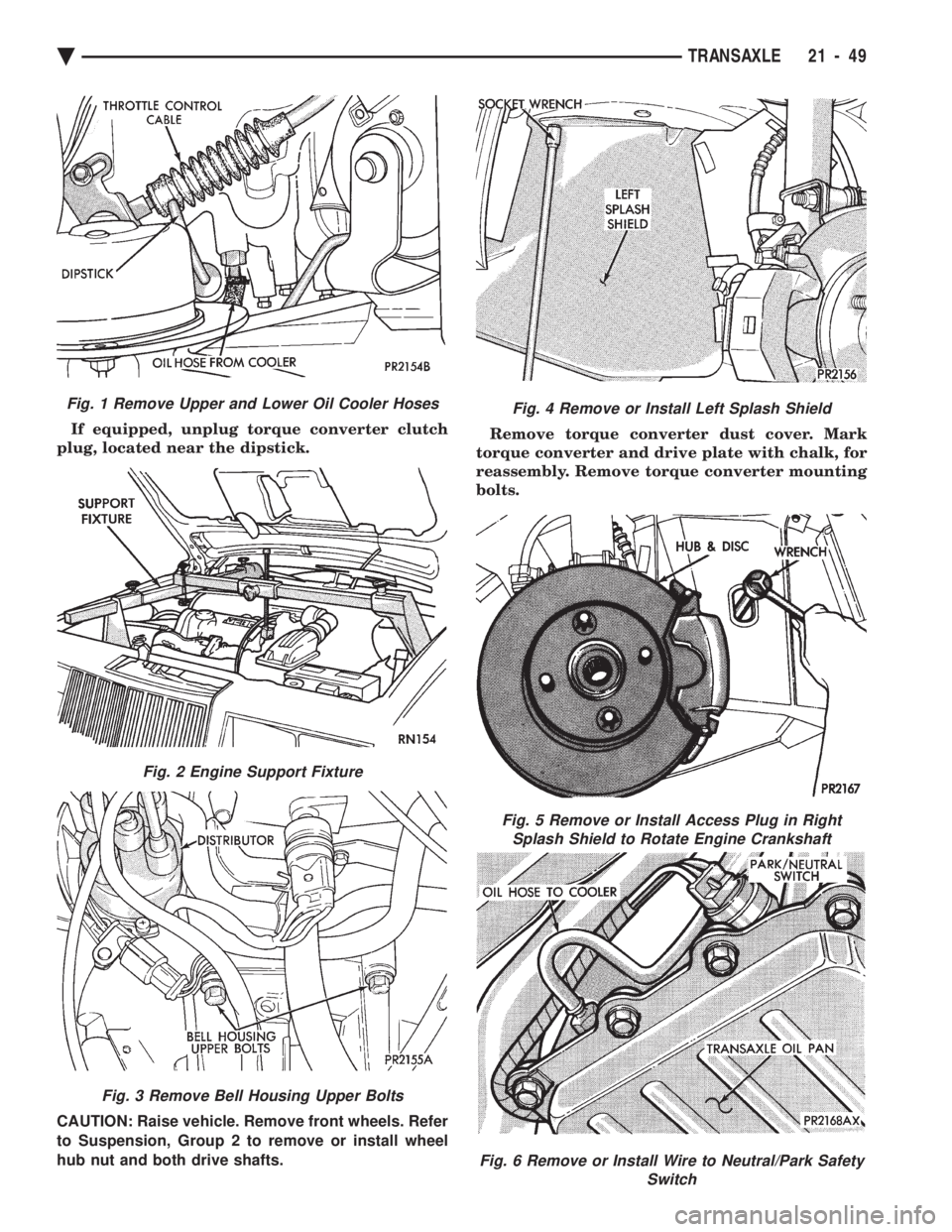

FLUID LEAKAGE-TRANSAXLE TORQUE

CONVERTER HOUSING AREA

(1) Check for Source of Leakage.

Since fluid leakage at or around the torque con-

verter area may originate from an engine oil leak,

the area should be examined closely. Factory fill

fluid is dyed red and, therefore, can be distinguished

from engine oil. (2) Prior to removing the transaxle, perform the

following checks:

² When leakage is determined to originate from the

transaxle, check fluid level prior to removal of the

transaxle and torque converter.

² High oil level can result in oil leakage out the

vent in the dipstick. If the fluid level is high, adjust

to proper level. After performing this operation, inspect for leak-

age. If a leak persists, perform the following opera-

tion on the vehicle to determine if it is the torque

converter or transaxle that is leaking.

LEAKAGE TEST PROBE

(1) Remove torque converter housing dust shield.

(2) Clean the inside of torque converter housing

(lower area) as dry as possible. A solvent spray fol-

lowed by compressed air drying is preferable.

Fig. 4 Air Pressure Tests

21 - 44 TRANSAXLE Ä

Page 2009 of 2438

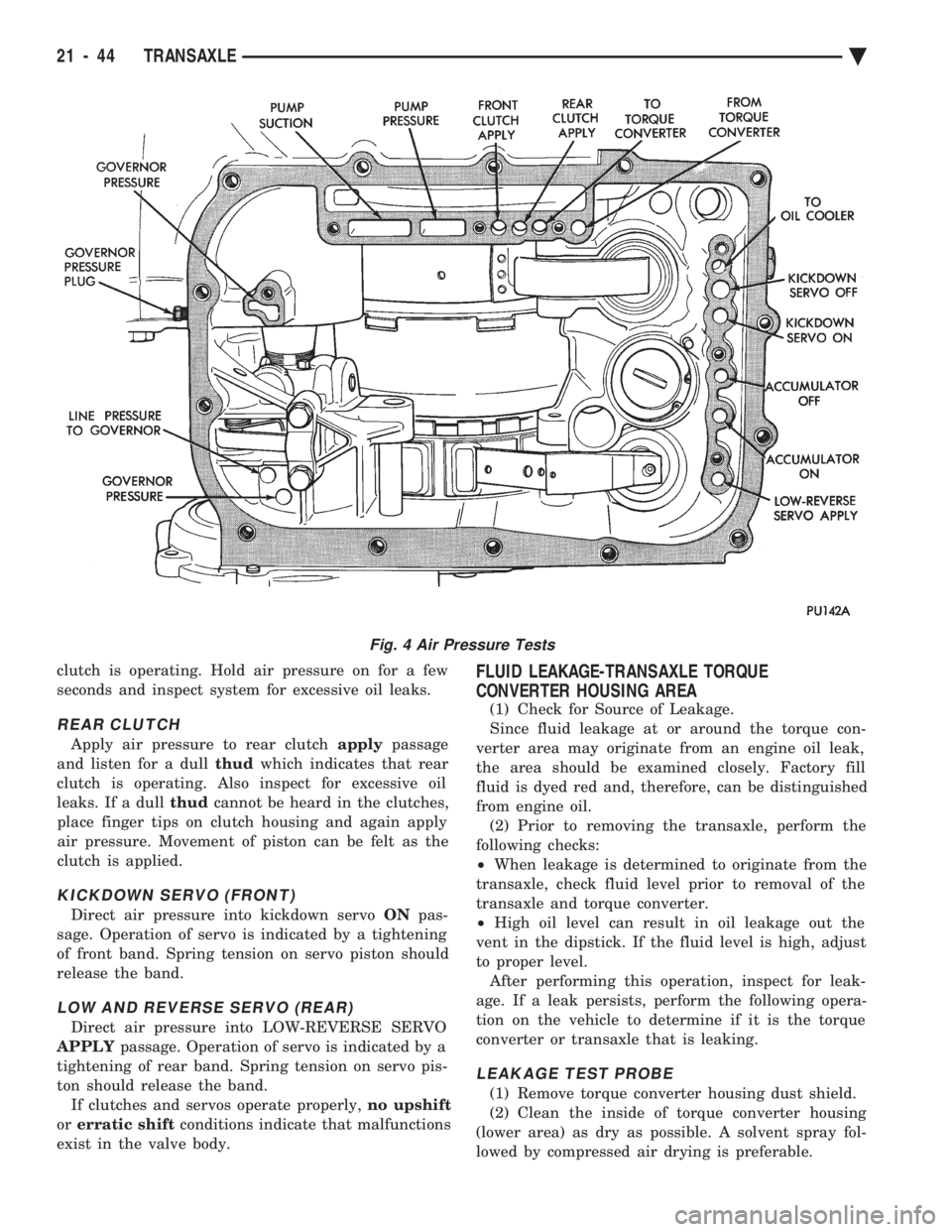

If equipped, unplug torque converter clutch

plug, located near the dipstick.

CAUTION: Raise vehicle. Remove front wheels. Refer

to Suspension, Group 2 to remove or install wheel

hub nut and both drive shafts. Remove torque converter dust cover. Mark

torque converter and drive plate with chalk, for

reassembly. Remove torque converter mounting

bolts.

Fig. 1 Remove Upper and Lower Oil Cooler Hoses

Fig. 2 Engine Support Fixture

Fig. 3 Remove Bell Housing Upper Bolts

Fig. 4 Remove or Install Left Splash Shield

Fig. 5 Remove or Install Access Plug in Right Splash Shield to Rotate Engine Crankshaft

Fig. 6 Remove or Install Wire to Neutral/Park Safety Switch

Ä TRANSAXLE 21 - 49

Page 2014 of 2438

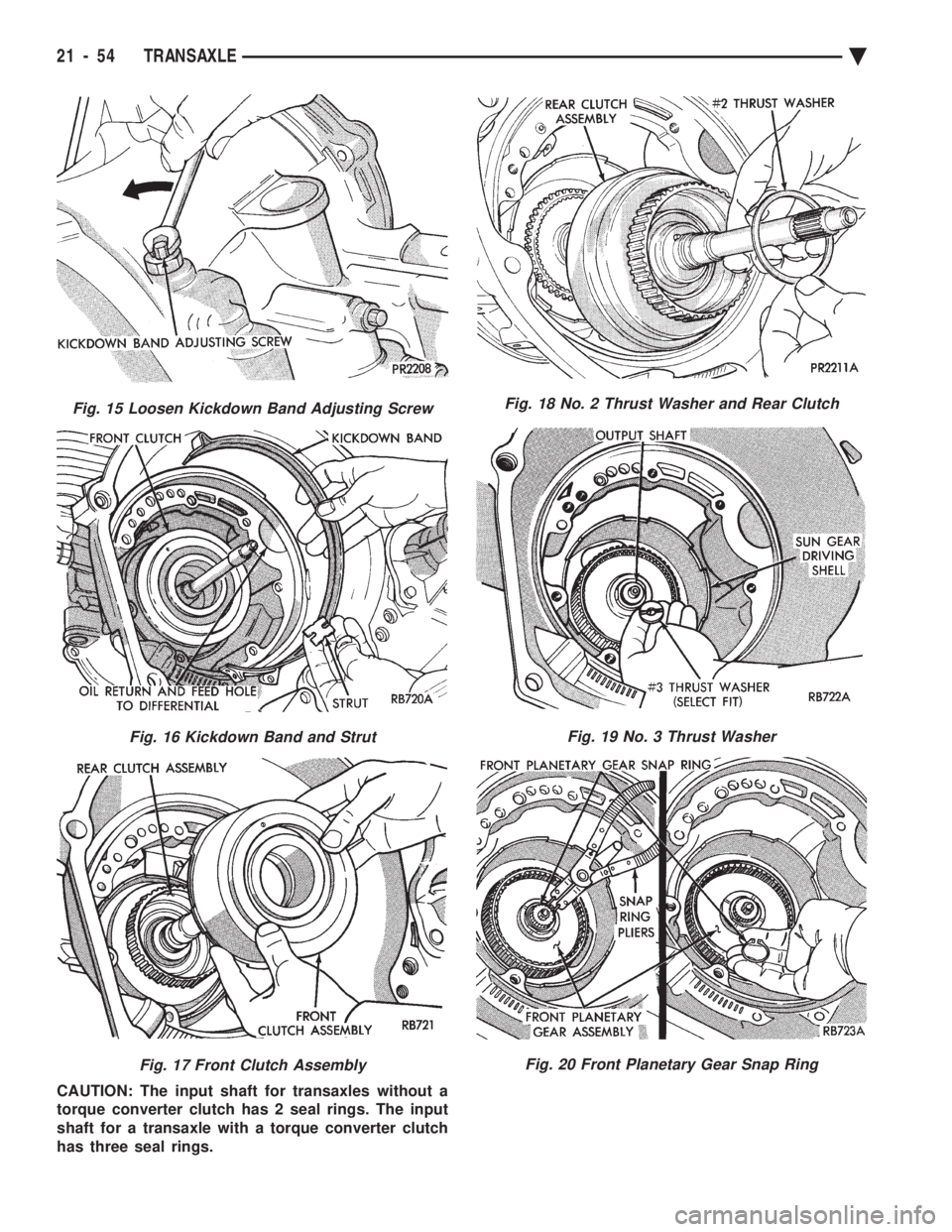

CAUTION: The input shaft for transaxles without a

torque converter clutch has 2 seal rings. The input

shaft for a transaxle with a torque converter clutch

has three seal rings.

Fig. 15 Loosen Kickdown Band Adjusting Screw

Fig. 16 Kickdown Band and Strut

Fig. 17 Front Clutch Assembly

Fig. 18 No. 2 Thrust Washer and Rear Clutch

Fig. 19 No. 3 Thrust Washer

Fig. 20 Front Planetary Gear Snap Ring

21 - 54 TRANSAXLE Ä

Page 2016 of 2438

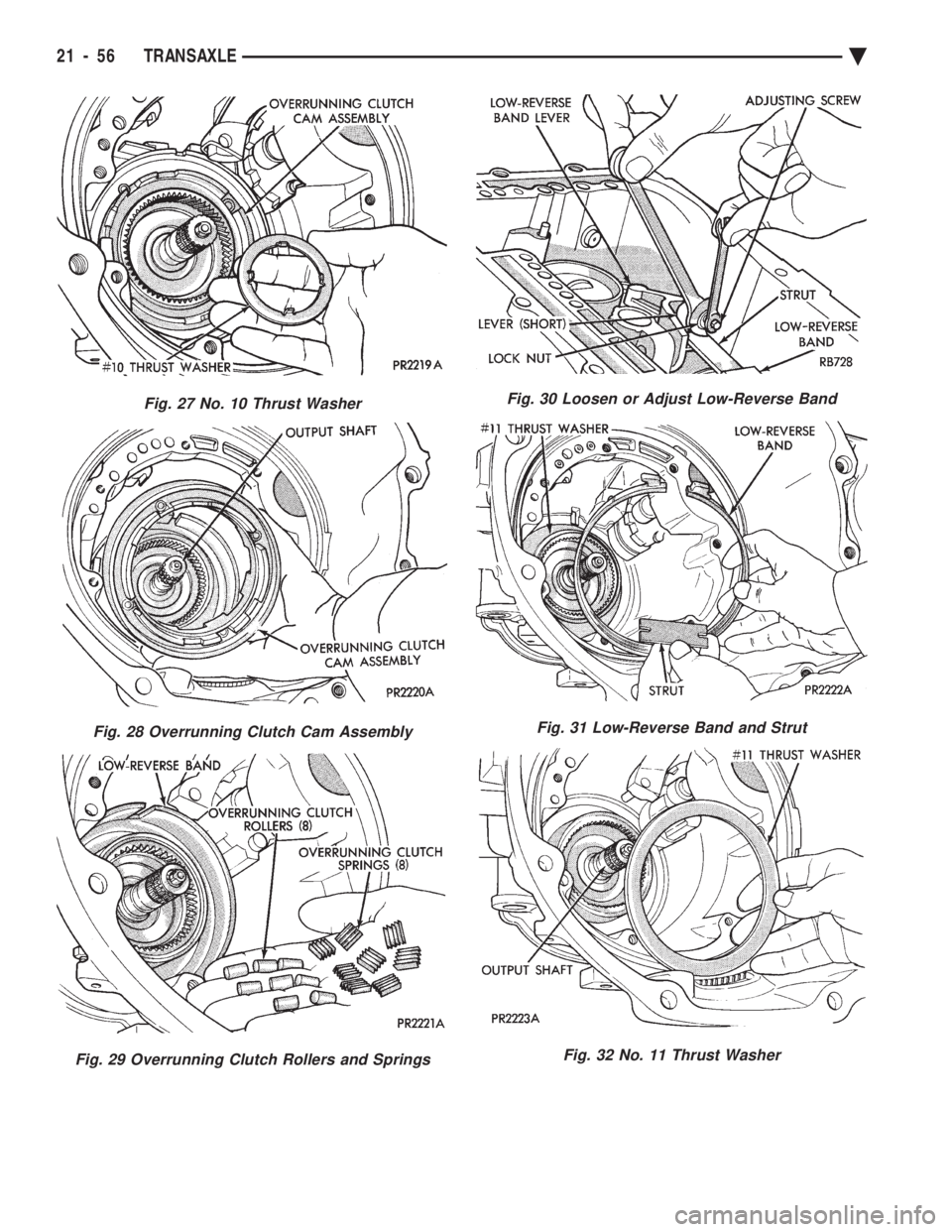

Fig. 27 No. 10 Thrust Washer

Fig. 28 Overrunning Clutch Cam Assembly

Fig. 29 Overrunning Clutch Rollers and Springs

Fig. 30 Loosen or Adjust Low-Reverse Band

Fig. 31 Low-Reverse Band and Strut

Fig. 32 No. 11 Thrust Washer

21 - 56 TRANSAXLE Ä

Page 2017 of 2438

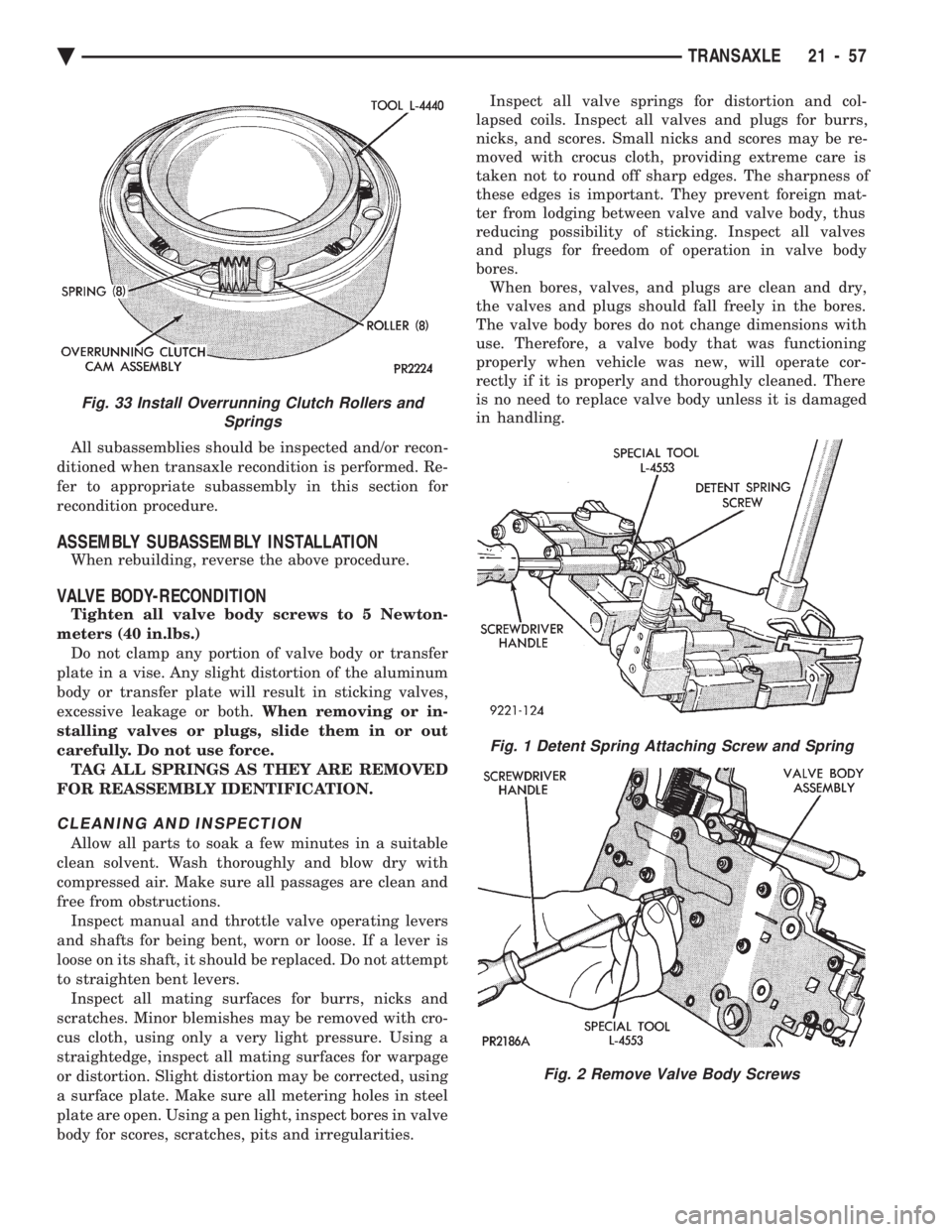

All subassemblies should be inspected and/or recon-

ditioned when transaxle recondition is performed. Re-

fer to appropriate subassembly in this section for

recondition procedure.

ASSEMBLY SUBASSEMBLY INSTALLATION

When rebuilding, reverse the above procedure.

VALVE BODY-RECONDITION

Tighten all valve body screws to 5 Newton-

meters (40 in.lbs.) Do not clamp any portion of valve body or transfer

plate in a vise. Any slight distortion of the aluminum

body or transfer plate will result in sticking valves,

excessive leakage or both. When removing or in-

stalling valves or plugs, slide them in or out

carefully. Do not use force. TAG ALL SPRINGS AS THEY ARE REMOVED

FOR REASSEMBLY IDENTIFICATION.

CLEANING AND INSPECTION

Allow all parts to soak a few minutes in a suitable

clean solvent. Wash thoroughly and blow dry with

compressed air. Make sure all passages are clean and

free from obstructions. Inspect manual and throttle valve operating levers

and shafts for being bent, worn or loose. If a lever is

loose on its shaft, it should be replaced. Do not attempt

to straighten bent levers. Inspect all mating surfaces for burrs, nicks and

scratches. Minor blemishes may be removed with cro-

cus cloth, using only a very light pressure. Using a

straightedge, inspect all mating surfaces for warpage

or distortion. Slight distortion may be corrected, using

a surface plate. Make sure all metering holes in steel

plate are open. Using a pen light, inspect bores in valve

body for scores, scratches, pits and irregularities. Inspect all valve springs for distortion and col-

lapsed coils. Inspect all valves and plugs for burrs,

nicks, and scores. Small nicks and scores may be re-

moved with crocus cloth, providing extreme care is

taken not to round off sharp edges. The sharpness of

these edges is important. They prevent foreign mat-

ter from lodging between valve and valve body, thus

reducing possibility of sticking. Inspect all valves

and plugs for freedom of operation in valve body

bores. When bores, valves, and plugs are clean and dry,

the valves and plugs should fall freely in the bores.

The valve body bores do not change dimensions with

use. Therefore, a valve body that was functioning

properly when vehicle was new, will operate cor-

rectly if it is properly and thoroughly cleaned. There

is no need to replace valve body unless it is damaged

in handling.

Fig. 1 Detent Spring Attaching Screw and Spring

Fig. 2 Remove Valve Body Screws

Fig. 33 Install Overrunning Clutch Rollers and Springs

Ä TRANSAXLE 21 - 57

Page 2022 of 2438

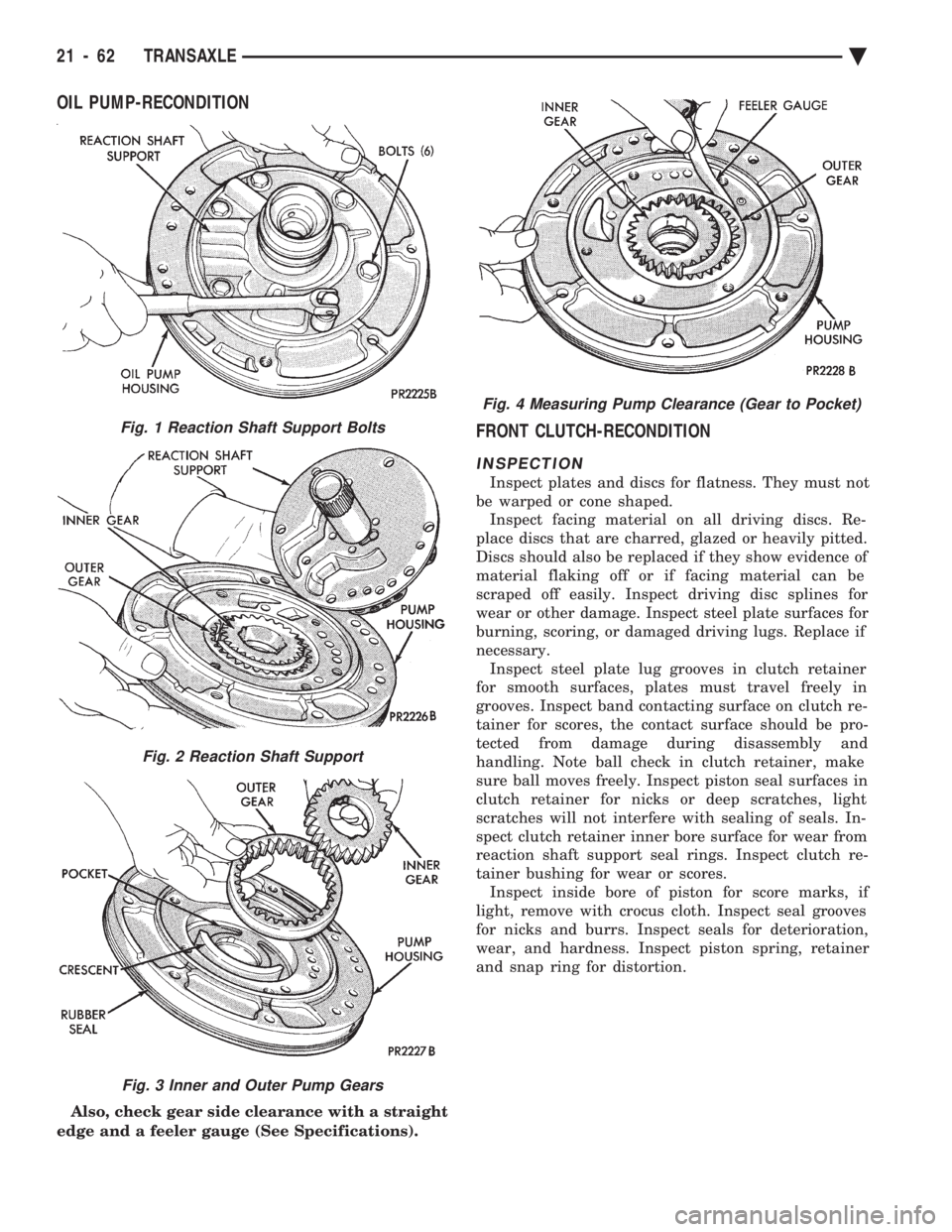

OIL PUMP-RECONDITION

Also, check gear side clearance with a straight

edge and a feeler gauge (See Specifications).

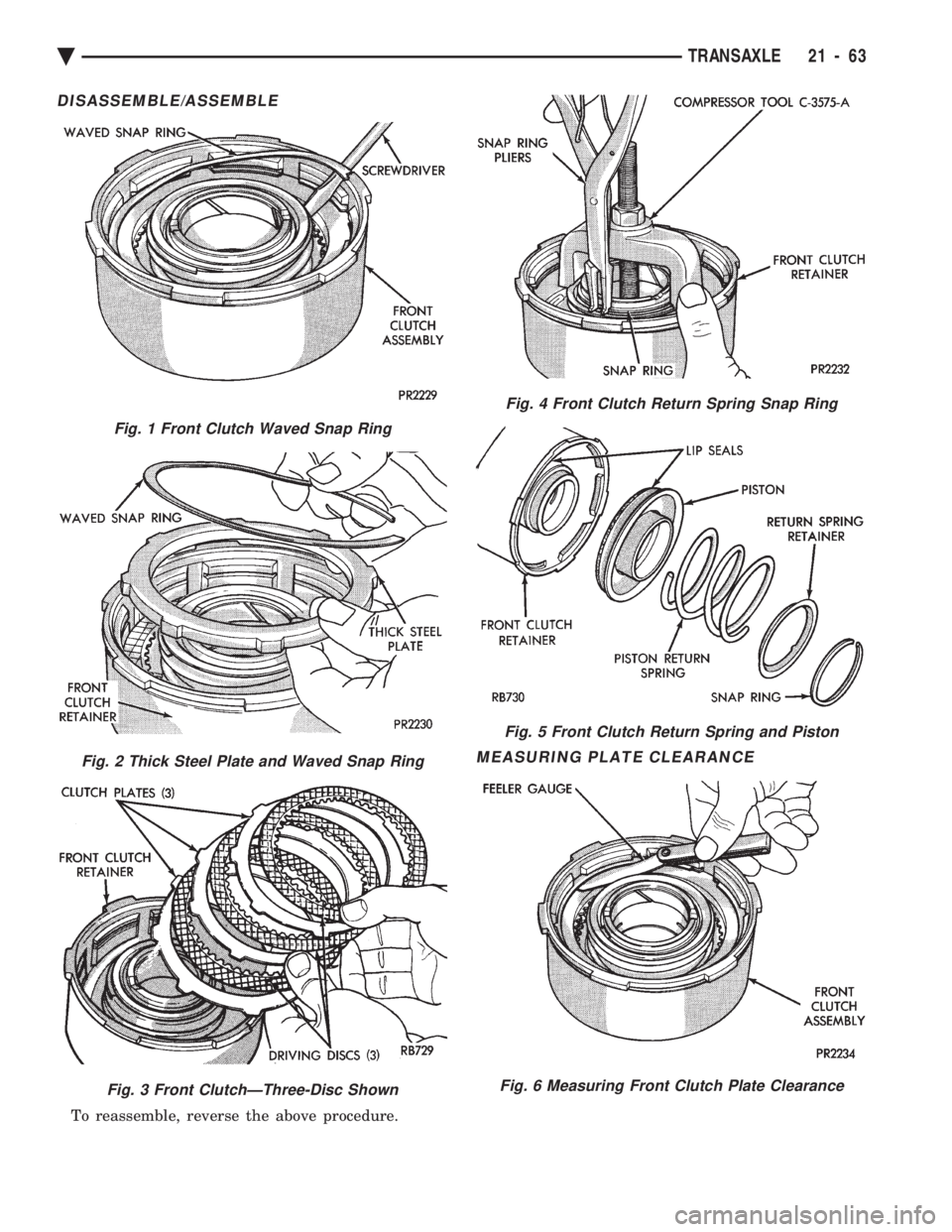

FRONT CLUTCH-RECONDITION

INSPECTION

Inspect plates and discs for flatness. They must not

be warped or cone shaped. Inspect facing material on all driving discs. Re-

place discs that are charred, glazed or heavily pitted.

Discs should also be replaced if they show evidence of

material flaking off or if facing material can be

scraped off easily. Inspect driving disc splines for

wear or other damage. Inspect steel plate surfaces for

burning, scoring, or damaged driving lugs. Replace if

necessary. Inspect steel plate lug grooves in clutch retainer

for smooth surfaces, plates must travel freely in

grooves. Inspect band contacting surface on clutch re-

tainer for scores, the contact surface should be pro-

tected from damage during disassembly and

handling. Note ball check in clutch retainer, make

sure ball moves freely. Inspect piston seal surfaces in

clutch retainer for nicks or deep scratches, light

scratches will not interfere with sealing of seals. In-

spect clutch retainer inner bore surface for wear from

reaction shaft support seal rings. Inspect clutch re-

tainer bushing for wear or scores. Inspect inside bore of piston for score marks, if

light, remove with crocus cloth. Inspect seal grooves

for nicks and burrs. Inspect seals for deterioration,

wear, and hardness. Inspect piston spring, retainer

and snap ring for distortion.

Fig. 4 Measuring Pump Clearance (Gear to Pocket)

Fig. 1 Reaction Shaft Support Bolts

Fig. 2 Reaction Shaft Support

Fig. 3 Inner and Outer Pump Gears

21 - 62 TRANSAXLE Ä

Page 2023 of 2438

DISASSEMBLE/ASSEMBLE

To reassemble, reverse the above procedure.

MEASURING PLATE CLEARANCE

Fig. 1 Front Clutch Waved Snap Ring

Fig. 2 Thick Steel Plate and Waved Snap Ring

Fig. 3 Front ClutchÐThree-Disc Shown

Fig. 4 Front Clutch Return Spring Snap Ring

Fig. 5 Front Clutch Return Spring and Piston

Fig. 6 Measuring Front Clutch Plate Clearance

Ä TRANSAXLE 21 - 63

Page 2024 of 2438

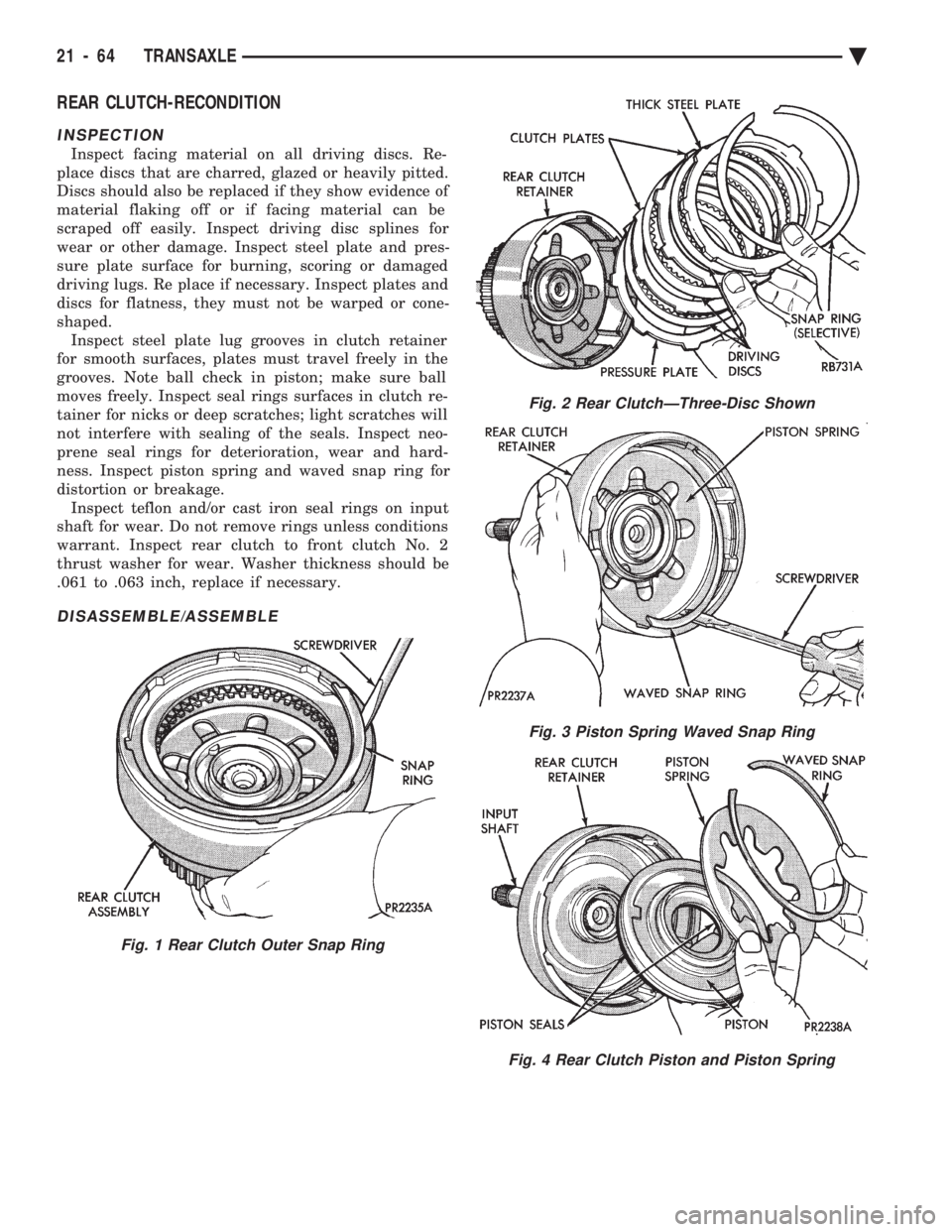

REAR CLUTCH-RECONDITION

INSPECTION

Inspect facing material on all driving discs. Re-

place discs that are charred, glazed or heavily pitted.

Discs should also be replaced if they show evidence of

material flaking off or if facing material can be

scraped off easily. Inspect driving disc splines for

wear or other damage. Inspect steel plate and pres-

sure plate surface for burning, scoring or damaged

driving lugs. Re place if necessary. Inspect plates and

discs for flatness, they must not be warped or cone-

shaped. Inspect steel plate lug grooves in clutch retainer

for smooth surfaces, plates must travel freely in the

grooves. Note ball check in piston; make sure ball

moves freely. Inspect seal rings surfaces in clutch re-

tainer for nicks or deep scratches; light scratches will

not interfere with sealing of the seals. Inspect neo-

prene seal rings for deterioration, wear and hard-

ness. Inspect piston spring and waved snap ring for

distortion or breakage. Inspect teflon and/or cast iron seal rings on input

shaft for wear. Do not remove rings unless conditions

warrant. Inspect rear clutch to front clutch No. 2

thrust washer for wear. Washer thickness should be

.061 to .063 inch, replace if necessary.

DISASSEMBLE/ASSEMBLE

Fig. 1 Rear Clutch Outer Snap Ring

Fig. 2 Rear ClutchÐThree-Disc Shown

Fig. 3 Piston Spring Waved Snap Ring

Fig. 4 Rear Clutch Piston and Piston Spring

21 - 64 TRANSAXLE Ä