clutch CHEVROLET DYNASTY 1993 Service Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 2336 of 2438

FIXED DISPLACEMENT COMPRESSORÐMODEL TR105 INDEX

page page

Compressor ............................. 32

Compressor Clutch/Coil Assembly ............ 32

Compressor Shaft Bearing/Seal .............. 35 Refrigerant System Diagnosis

............... 36

Thermal Limiter Switch .................... 34

COMPRESSOR

Cleanliness is extremely important when disassem-

bly of the compressor is necessary. The surfaces

around the suction and discharge ports of the com-

pressor should be cleaned thoroughly before opening

the system at these points. If compressor is removed

from vehicle, apply tape to the opened ports to pre-

vent any contamination.

REMOVAL

(1) Disconnect battery negative cable.

(2) Loosen and remove drive belts (refer to Group

7, Cooling System). (3) Disconnect compressor clutch wire lead.

(4) Using a refrigerant recovery machine, remove

refrigerant from the A/C system. (5) Remove refrigerant lines from compressor.

(6) Remove compressor attaching bolts.

(7) Remove compressor.

INSTALLATION

(1) Position the compressor on the mount and fit

drive belt. (2) Tighten the compressor attaching bolts to 41

N Im (30 ft. lbs.) torque.

(3) Adjust drive belt (see Group 7, Cooling Sys-

tem). (4) Install refrigerant hoses.

(5) Connect the clutch wire.

(6) Evacuate and charge the system.

(7) Connect the battery negative cable.

COMPRESSOR CLUTCH/COIL ASSEMBLY

CLUTCH INOPERATIVE

The air conditioning compressor clutch electrical

circuit is controlled by the engine controller. The

controller is located in the engine compartment out-

board of the battery. If the compressor clutch does not engage:

Verify refrigerant charge.

If the compressor clutch still does not engage check

for battery voltage at the low pressure or differential

pressure cut-off switch located on the expansion

valve. If voltage is not detected, refer to:

² Group 8W, Wiring Diagrams.

² The appropriate Powertrain Diagnostic Procedures

Manual for diagnostic information. If voltage is detected at the cut-off switch, recon-

nect switch. Then check for battery voltage between

the compressor clutch connector terminals. If voltage is detected, perform A/C Clutch Coil

Tests.

CLUTCH COIL TESTS

(1) Verify battery state of charge. (Test indicator

in battery should be green). (2) Connect an ammeter (0-10 ampere scale) in se-

ries with the clutch coil terminal. Use a volt meter

(0-20 volt scale) with clip leads measuring voltage

across the battery and A/C clutch. (3) With A/C control in A/C mode and blower at

low speed, start the engine and run at normal idle. (4) The A/C clutch should engage immediately and

the clutch voltage should be within two volts of the

battery voltage. If the A/C clutch does not engage,

test the fusible link. (5) The A/C clutch coil is acceptable if the current

draw is 2.0 to 3.7 amperes at 11.5-12.5 volts at clutch

coil. This is with the work area temperature at 21ÉC

(70ÉF). If voltage is more than 12.5 volts, add electri-

cal loads by turning on electrical accessories until

voltage reads below 12.5 volts. If coil current reads zero, the coil is open and

should be replaced. If the ammeter reading is 4 am-

peres or more, the coil is shorted and should be re-

placed. If the coil voltage is not within two volts of

the battery voltage, test clutch coil feed circuit for

excessive voltage drop.

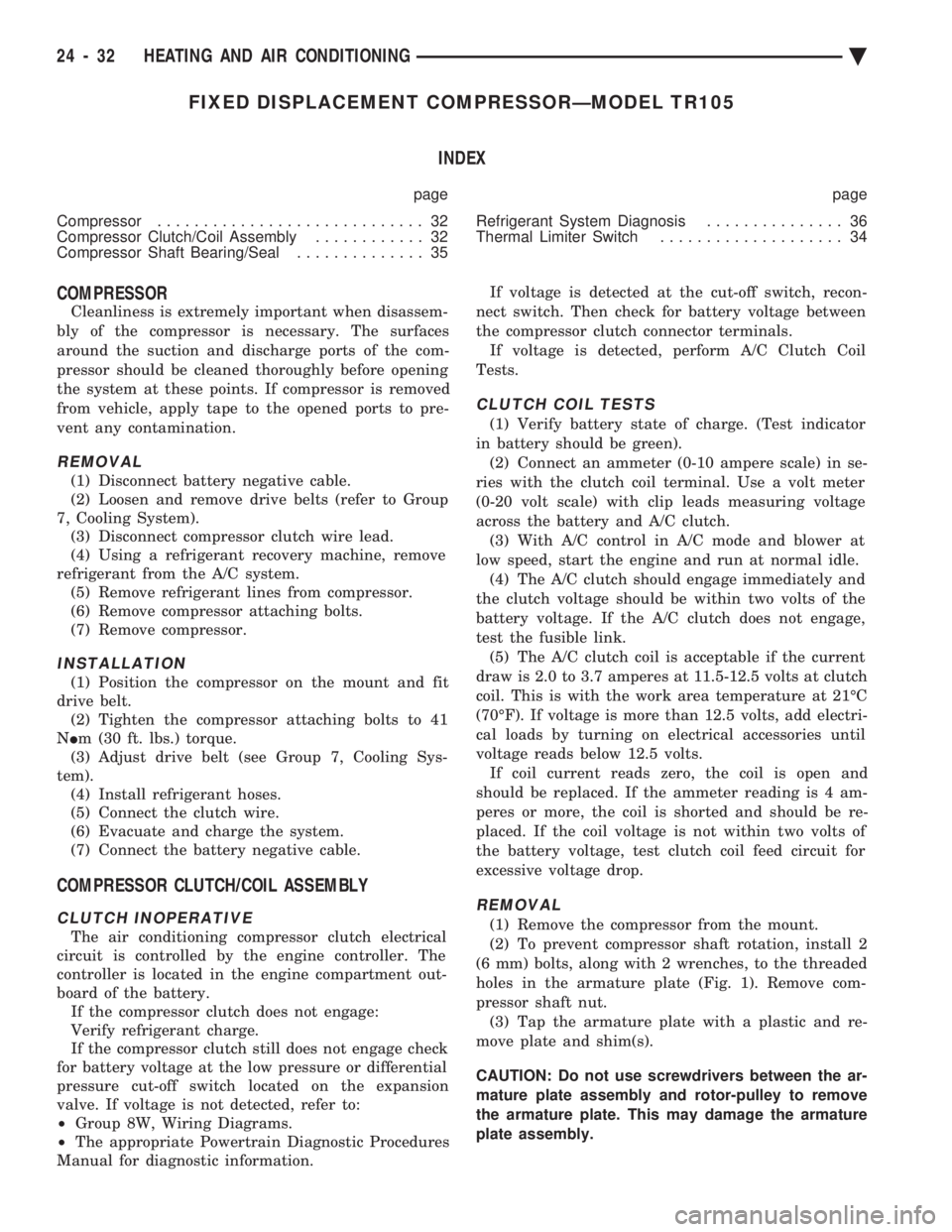

REMOVAL

(1) Remove the compressor from the mount.

(2) To prevent compressor shaft rotation, install 2

(6 mm) bolts, along with 2 wrenches, to the threaded

holes in the armature plate (Fig. 1). Remove com-

pressor shaft nut. (3) Tap the armature plate with a plastic and re-

move plate and shim(s).

CAUTION: Do not use screwdrivers between the ar-

mature plate assembly and rotor-pulley to remove

the armature plate. This may damage the armature

plate assembly.

24 - 32 HEATING AND AIR CONDITIONING Ä

Page 2337 of 2438

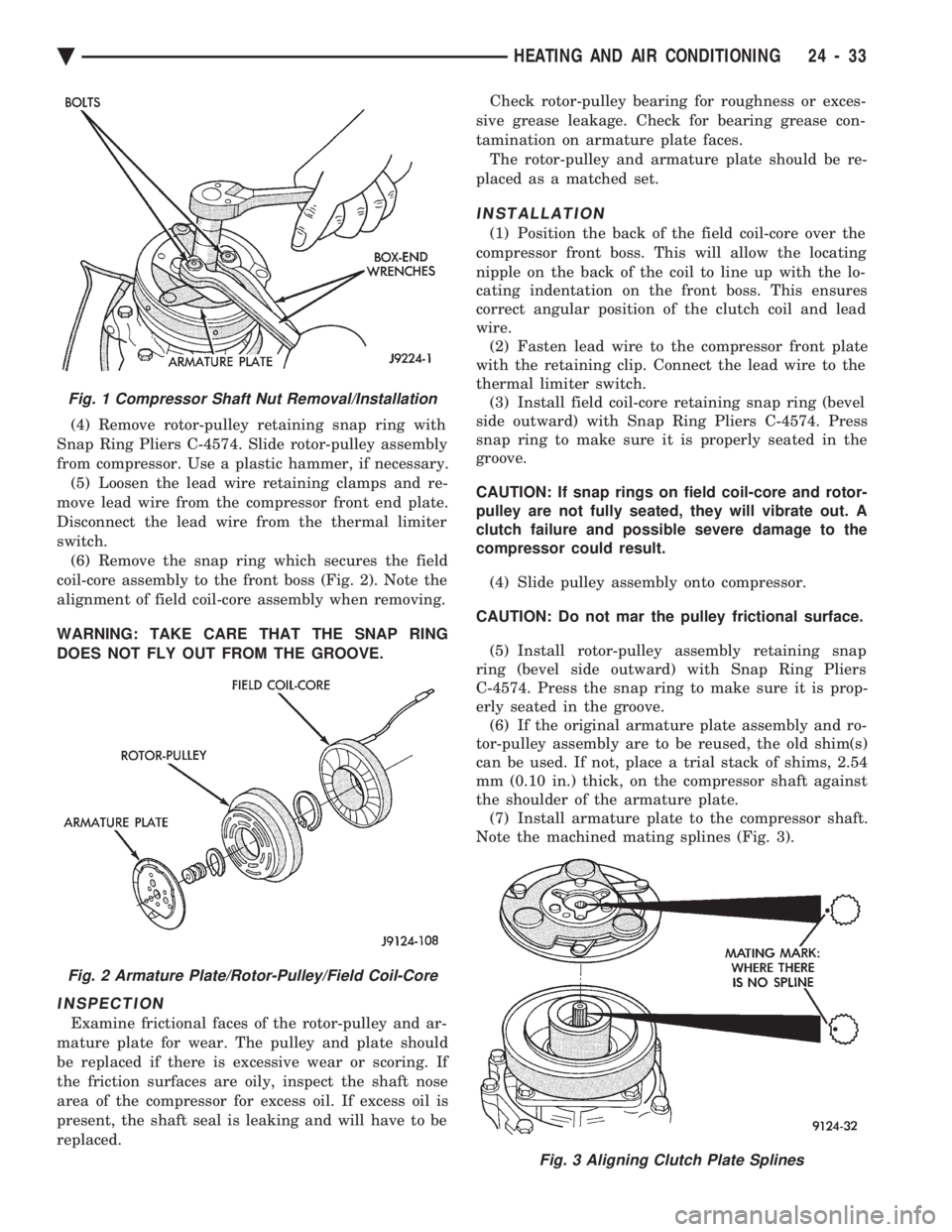

(4) Remove rotor-pulley retaining snap ring with

Snap Ring Pliers C-4574. Slide rotor-pulley assembly

from compressor. Use a plastic hammer, if necessary. (5) Loosen the lead wire retaining clamps and re-

move lead wire from the compressor front end plate.

Disconnect the lead wire from the thermal limiter

switch. (6) Remove the snap ring which secures the field

coil-core assembly to the front boss (Fig. 2). Note the

alignment of field coil-core assembly when removing.

WARNING: TAKE CARE THAT THE SNAP RING

DOES NOT FLY OUT FROM THE GROOVE.

INSPECTION

Examine frictional faces of the rotor-pulley and ar-

mature plate for wear. The pulley and plate should

be replaced if there is excessive wear or scoring. If

the friction surfaces are oily, inspect the shaft nose

area of the compressor for excess oil. If excess oil is

present, the shaft seal is leaking and will have to be

replaced. Check rotor-pulley bearing for roughness or exces-

sive grease leakage. Check for bearing grease con-

tamination on armature plate faces. The rotor-pulley and armature plate should be re-

placed as a matched set.

INSTALLATION

(1) Position the back of the field coil-core over the

compressor front boss. This will allow the locating

nipple on the back of the coil to line up with the lo-

cating indentation on the front boss. This ensures

correct angular position of the clutch coil and lead

wire. (2) Fasten lead wire to the compressor front plate

with the retaining clip. Connect the lead wire to the

thermal limiter switch. (3) Install field coil-core retaining snap ring (bevel

side outward) with Snap Ring Pliers C-4574. Press

snap ring to make sure it is properly seated in the

groove.

CAUTION: If snap rings on field coil-core and rotor-

pulley are not fully seated, they will vibrate out. A

clutch failure and possible severe damage to the

compressor could result.

(4) Slide pulley assembly onto compressor.

CAUTION: Do not mar the pulley frictional surface. (5) Install rotor-pulley assembly retaining snap

ring (bevel side outward) with Snap Ring Pliers

C-4574. Press the snap ring to make sure it is prop-

erly seated in the groove. (6) If the original armature plate assembly and ro-

tor-pulley assembly are to be reused, the old shim(s)

can be used. If not, place a trial stack of shims, 2.54

mm (0.10 in.) thick, on the compressor shaft against

the shoulder of the armature plate. (7) Install armature plate to the compressor shaft.

Note the machined mating splines (Fig. 3).

Fig. 1 Compressor Shaft Nut Removal/Installation

Fig. 2 Armature Plate/Rotor-Pulley/Field Coil-Core

Fig. 3 Aligning Clutch Plate Splines

Ä HEATING AND AIR CONDITIONING 24 - 33

Page 2338 of 2438

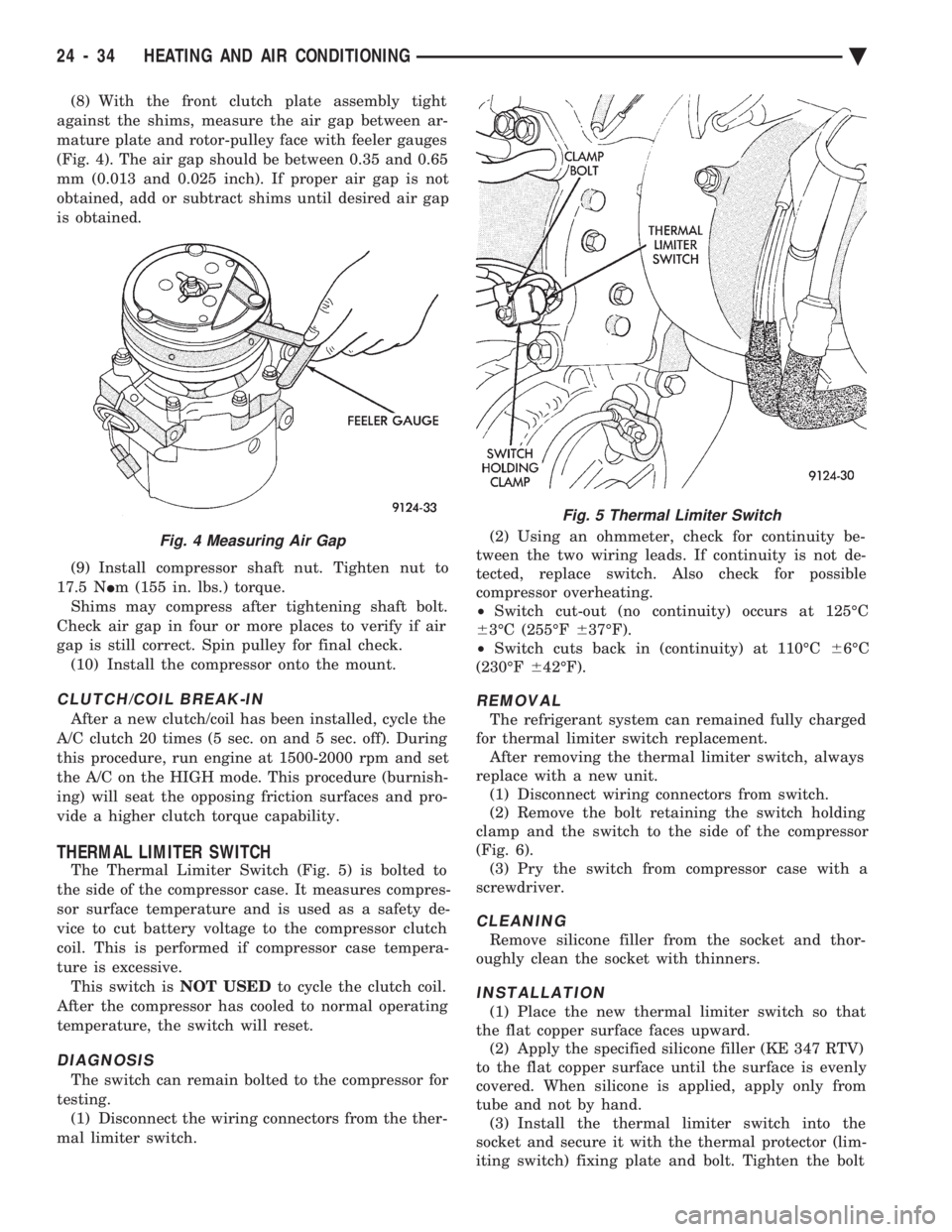

(8) With the front clutch plate assembly tight

against the shims, measure the air gap between ar-

mature plate and rotor-pulley face with feeler gauges

(Fig. 4). The air gap should be between 0.35 and 0.65

mm (0.013 and 0.025 inch). If proper air gap is not

obtained, add or subtract shims until desired air gap

is obtained.

(9) Install compressor shaft nut. Tighten nut to

17.5 N Im (155 in. lbs.) torque.

Shims may compress after tightening shaft bolt.

Check air gap in four or more places to verify if air

gap is still correct. Spin pulley for final check. (10) Install the compressor onto the mount.

CLUTCH/COIL BREAK-IN

After a new clutch/coil has been installed, cycle the

A/C clutch 20 times (5 sec. on and 5 sec. off). During

this procedure, run engine at 1500-2000 rpm and set

the A/C on the HIGH mode. This procedure (burnish-

ing) will seat the opposing friction surfaces and pro-

vide a higher clutch torque capability.

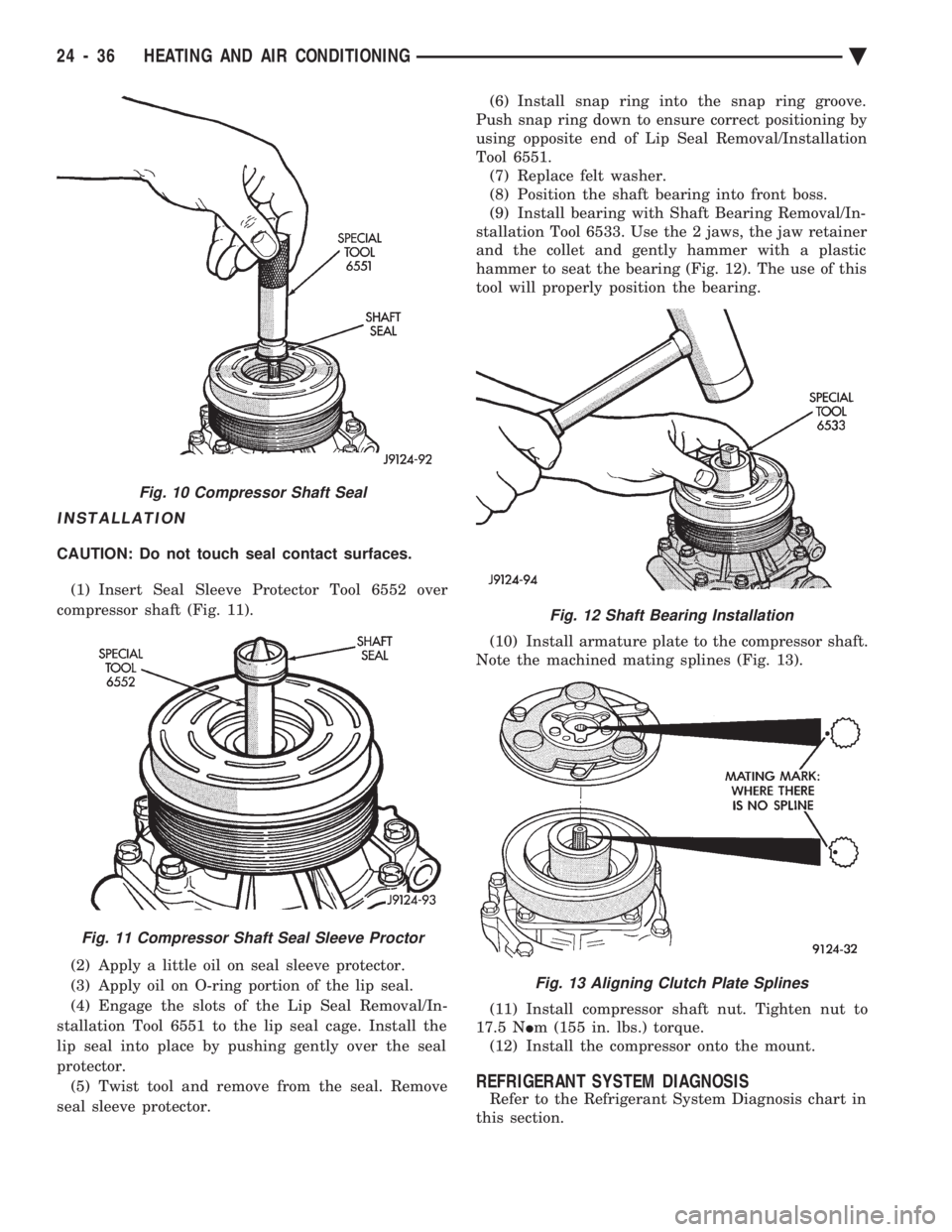

THERMAL LIMITER SWITCH

The Thermal Limiter Switch (Fig. 5) is bolted to

the side of the compressor case. It measures compres-

sor surface temperature and is used as a safety de-

vice to cut battery voltage to the compressor clutch

coil. This is performed if compressor case tempera-

ture is excessive. This switch is NOT USEDto cycle the clutch coil.

After the compressor has cooled to normal operating

temperature, the switch will reset.

DIAGNOSIS

The switch can remain bolted to the compressor for

testing. (1) Disconnect the wiring connectors from the ther-

mal limiter switch. (2) Using an ohmmeter, check for continuity be-

tween the two wiring leads. If continuity is not de-

tected, replace switch. Also check for possible

compressor overheating.

² Switch cut-out (no continuity) occurs at 125ÉC

6 3ÉC (255ÉF 637ÉF).

² Switch cuts back in (continuity) at 110ÉC 66ÉC

(230ÉF 642ÉF).

REMOVAL

The refrigerant system can remained fully charged

for thermal limiter switch replacement. After removing the thermal limiter switch, always

replace with a new unit. (1) Disconnect wiring connectors from switch.

(2) Remove the bolt retaining the switch holding

clamp and the switch to the side of the compressor

(Fig. 6). (3) Pry the switch from compressor case with a

screwdriver.

CLEANING

Remove silicone filler from the socket and thor-

oughly clean the socket with thinners.

INSTALLATION

(1) Place the new thermal limiter switch so that

the flat copper surface faces upward. (2) Apply the specified silicone filler (KE 347 RTV)

to the flat copper surface until the surface is evenly

covered. When silicone is applied, apply only from

tube and not by hand. (3) Install the thermal limiter switch into the

socket and secure it with the thermal protector (lim-

iting switch) fixing plate and bolt. Tighten the bolt

Fig. 4 Measuring Air Gap

Fig. 5 Thermal Limiter Switch

24 - 34 HEATING AND AIR CONDITIONING Ä

Page 2340 of 2438

INSTALLATION

CAUTION: Do not touch seal contact surfaces. (1) Insert Seal Sleeve Protector Tool 6552 over

compressor shaft (Fig. 11).

(2) Apply a little oil on seal sleeve protector.

(3) Apply oil on O-ring portion of the lip seal.

(4) Engage the slots of the Lip Seal Removal/In-

stallation Tool 6551 to the lip seal cage. Install the

lip seal into place by pushing gently over the seal

protector. (5) Twist tool and remove from the seal. Remove

seal sleeve protector. (6) Install snap ring into the snap ring groove.

Push snap ring down to ensure correct positioning by

using opposite end of Lip Seal Removal/Installation

Tool 6551. (7) Replace felt washer.

(8) Position the shaft bearing into front boss.

(9) Install bearing with Shaft Bearing Removal/In-

stallation Tool 6533. Use the 2 jaws, the jaw retainer

and the collet and gently hammer with a plastic

hammer to seat the bearing (Fig. 12). The use of this

tool will properly position the bearing.

(10) Install armature plate to the compressor shaft.

Note the machined mating splines (Fig. 13).

(11) Install compressor shaft nut. Tighten nut to

17.5 N Im (155 in. lbs.) torque.

(12) Install the compressor onto the mount.

REFRIGERANT SYSTEM DIAGNOSIS

Refer to the Refrigerant System Diagnosis chart in

this section.

Fig. 10 Compressor Shaft Seal

Fig. 11 Compressor Shaft Seal Sleeve Proctor

Fig. 12 Shaft Bearing Installation

Fig. 13 Aligning Clutch Plate Splines

24 - 36 HEATING AND AIR CONDITIONING Ä

Page 2342 of 2438

FIXED DISPLACEMENT COMPRESSORÐMODEL SD709P INDEX

page page

Compressor ............................. 38

Compressor Clutch/Coil Assembly ............ 38

Compressor Shaft Seal .................... 41 Cylinder Head/Valve Plate

.................. 44

Description ............................. 38

Refrigerant System Diagnosis ............... 45

DESCRIPTION

The Sanden compressor is a 7 piston design. Sys-

tem lubrication is provided by 135 ml 615 ml (4.6 oz.

6 0.5 oz.) of 500 viscosity refrigerant oil.

The clutch used on the compressor consists of 3 ba-

sic components:

² The pulley

² Front plate

² Field coil

The pulley and field coil are attached to the front

head of the compressor with tapered snap rings. The

hub is keyed to the compressor shaft and is retained

on the shaft with a self-locking nut. Special service

tools are required to remove and install the clutch

plate on the compressor shaft.

COMPRESSOR

The A/C compressor may be removed and posi-

tioned without discharging the refrigerant system.

Discharging is not necessary if removing the A/C

compressor clutch/coil assembly, engine, cylinder

head, or generator.

WARNING: REFRIGERANT PRESSURES REMAIN

HIGH EVEN THOUGH THE ENGINE MAY BE

TURNED OFF. BEFORE REMOVING A FULLY

CHARGED COMPRESSOR, REVIEW THE SAFETY

PRECAUTIONS AND WARNINGS SECTION IN THIS

GROUP. DO NOT TWIST OR KINK THE REFRIGER-

ANT LINES WHEN REMOVING A FULLY CHARGED

COMPRESSOR. SAFETY GLASSES MUST BE

WORN.

REMOVAL

(1) Disconnect negative cable from battery.

(2) Loosen and remove drive belts (refer to group

7, Cooling System) and disconnect compressor clutch

wire lead. (3) Remove refrigerant lines from compressor (if

necessary). (4) Remove compressor attaching nuts and bolts.

(5) Remove compressor. If refrigerant lines were

not removed, lift compressor/clutch assembly and tie

it to a suitable component. To install, reverse the removal procedure.

COMPRESSOR CLUTCH/COIL ASSEMBLY

The magnetic clutch consists of a stationary elec-

tro-magnetic coil and a rotating pulley and plate as-

sembly. The electromagnetic coil is retained on the com-

pressor with a snap ring and is dimpled to maintain

its position. The pulley and plate assembly are mounted on the

compressor shaft. When the compressor is not in operation, the pul-

ley free wheels on the clutch hub bearing. When the

coil is energized the plate is magnetically engaged

with the pulley and turns the compressor shaft.

REMOVAL

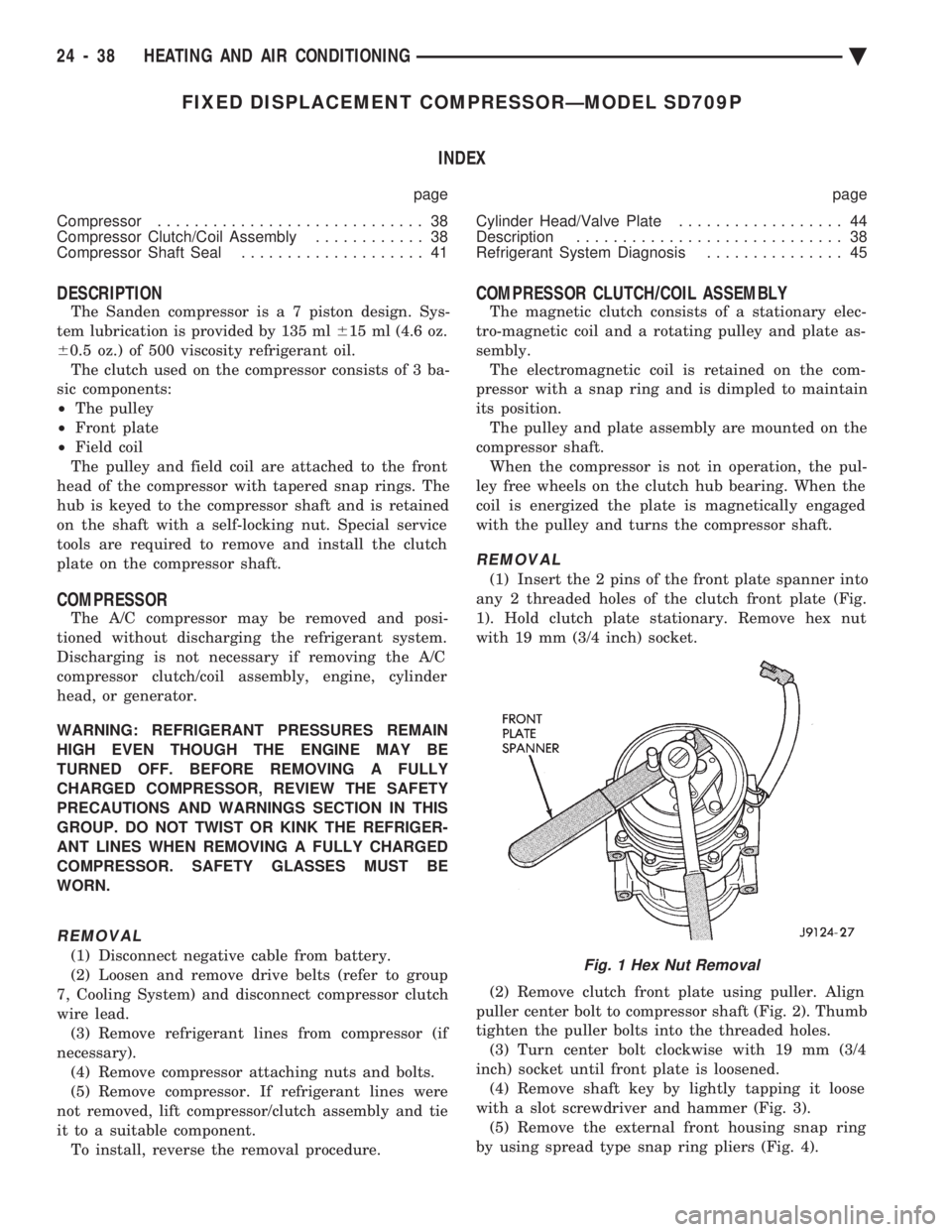

(1) Insert the 2 pins of the front plate spanner into

any 2 threaded holes of the clutch front plate (Fig.

1). Hold clutch plate stationary. Remove hex nut

with 19 mm (3/4 inch) socket.

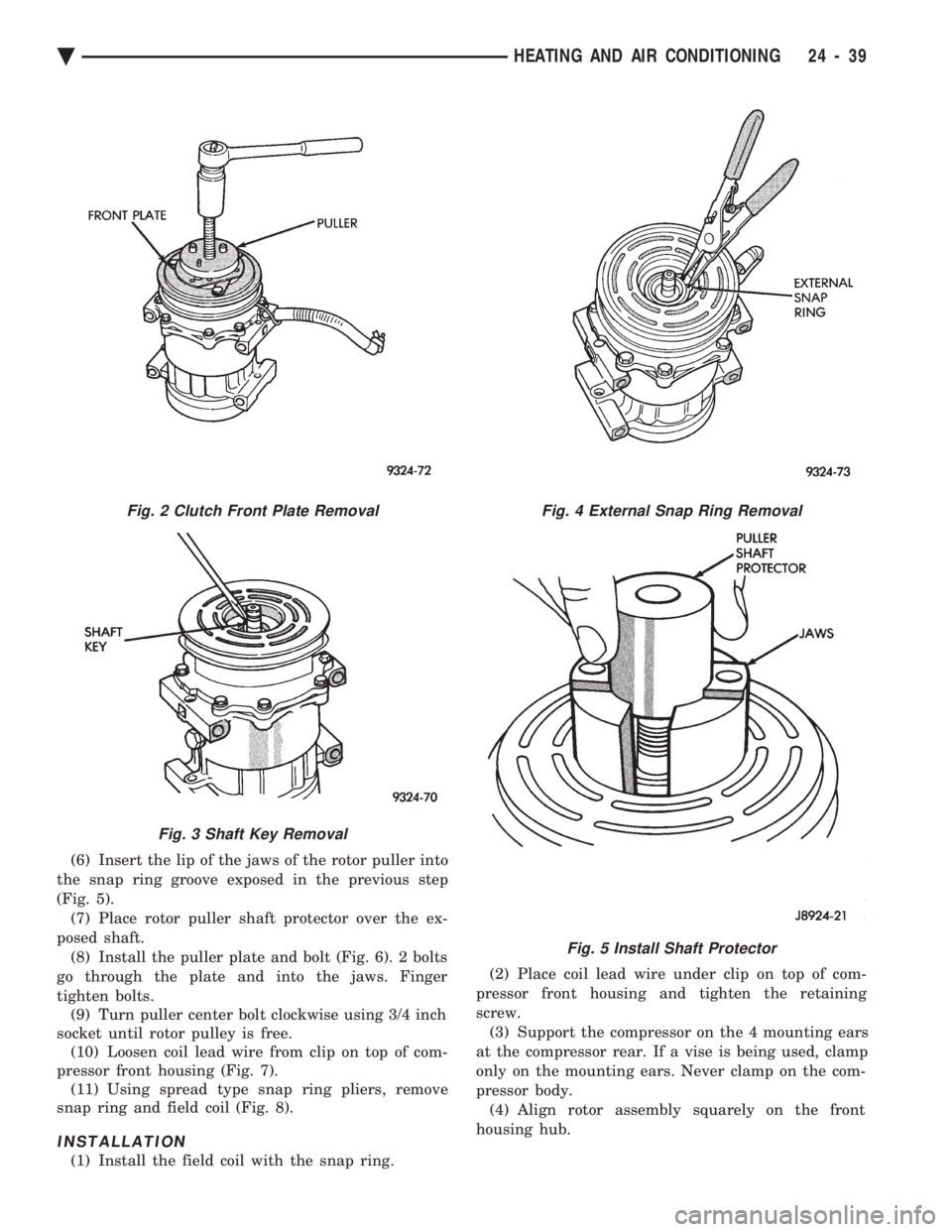

(2) Remove clutch front plate using puller. Align

puller center bolt to compressor shaft (Fig. 2). Thumb

tighten the puller bolts into the threaded holes. (3) Turn center bolt clockwise with 19 mm (3/4

inch) socket until front plate is loosened. (4) Remove shaft key by lightly tapping it loose

with a slot screwdriver and hammer (Fig. 3). (5) Remove the external front housing snap ring

by using spread type snap ring pliers (Fig. 4).

Fig. 1 Hex Nut Removal

24 - 38 HEATING AND AIR CONDITIONING Ä

Page 2343 of 2438

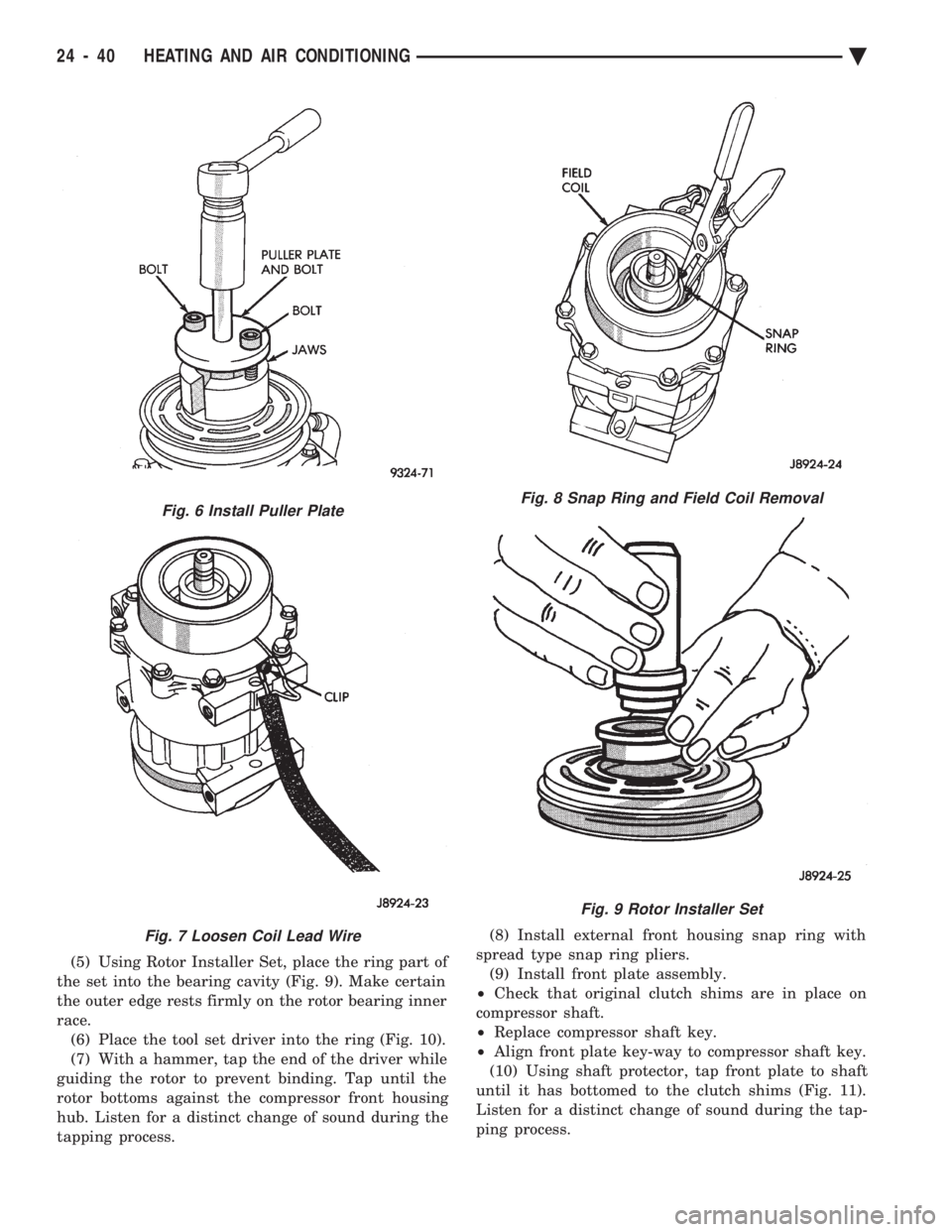

(6) Insert the lip of the jaws of the rotor puller into

the snap ring groove exposed in the previous step

(Fig. 5). (7) Place rotor puller shaft protector over the ex-

posed shaft. (8) Install the puller plate and bolt (Fig. 6). 2 bolts

go through the plate and into the jaws. Finger

tighten bolts. (9) Turn puller center bolt clockwise using 3/4 inch

socket until rotor pulley is free. (10) Loosen coil lead wire from clip on top of com-

pressor front housing (Fig. 7). (11) Using spread type snap ring pliers, remove

snap ring and field coil (Fig. 8).

INSTALLATION

(1) Install the field coil with the snap ring. (2) Place coil lead wire under clip on top of com-

pressor front housing and tighten the retaining

screw. (3) Support the compressor on the 4 mounting ears

at the compressor rear. If a vise is being used, clamp

only on the mounting ears. Never clamp on the com-

pressor body. (4) Align rotor assembly squarely on the front

housing hub.

Fig. 2 Clutch Front Plate Removal

Fig. 3 Shaft Key Removal

Fig. 4 External Snap Ring Removal

Fig. 5 Install Shaft Protector

Ä HEATING AND AIR CONDITIONING 24 - 39

Page 2344 of 2438

(5) Using Rotor Installer Set, place the ring part of

the set into the bearing cavity (Fig. 9). Make certain

the outer edge rests firmly on the rotor bearing inner

race. (6) Place the tool set driver into the ring (Fig. 10).

(7) With a hammer, tap the end of the driver while

guiding the rotor to prevent binding. Tap until the

rotor bottoms against the compressor front housing

hub. Listen for a distinct change of sound during the

tapping process. (8) Install external front housing snap ring with

spread type snap ring pliers. (9) Install front plate assembly.

² Check that original clutch shims are in place on

compressor shaft.

² Replace compressor shaft key.

² Align front plate key-way to compressor shaft key.

(10) Using shaft protector, tap front plate to shaft

until it has bottomed to the clutch shims (Fig. 11).

Listen for a distinct change of sound during the tap-

ping process.

Fig. 6 Install Puller Plate

Fig. 7 Loosen Coil Lead Wire

Fig. 8 Snap Ring and Field Coil Removal

Fig. 9 Rotor Installer Set

24 - 40 HEATING AND AIR CONDITIONING Ä

Page 2345 of 2438

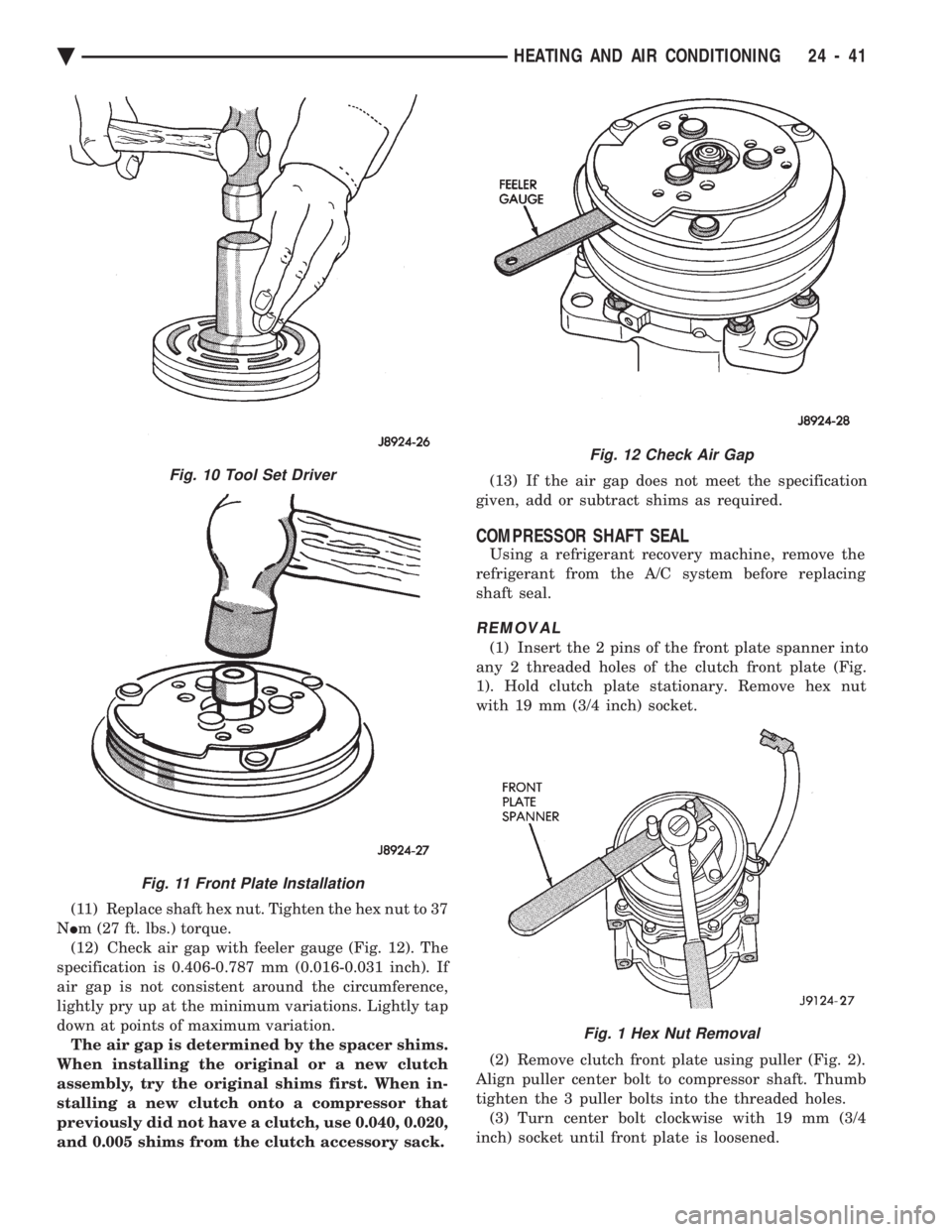

(11) Replace shaft hex nut. Tighten the hex nut to 37

N Im (27 ft. lbs.) torque.

(12) Check air gap with feeler gauge (Fig. 12). The

specification is 0.406-0.787 mm (0.016-0.031 inch). If

air gap is not consistent around the circumference,

lightly pry up at the minimum variations. Lightly tap

down at points of maximum variation. The air gap is determined by the spacer shims.

When installing the original or a new clutch

assembly, try the original shims first. When in-

stalling a new clutch onto a compressor that

previously did not have a clutch, use 0.040, 0.020,

and 0.005 shims from the clutch accessory sack. (13) If the air gap does not meet the specification

given, add or subtract shims as required.

COMPRESSOR SHAFT SEAL

Using a refrigerant recovery machine, remove the

refrigerant from the A/C system before replacing

shaft seal.

REMOVAL

(1) Insert the 2 pins of the front plate spanner into

any 2 threaded holes of the clutch front plate (Fig.

1). Hold clutch plate stationary. Remove hex nut

with 19 mm (3/4 inch) socket.

(2) Remove clutch front plate using puller (Fig. 2).

Align puller center bolt to compressor shaft. Thumb

tighten the 3 puller bolts into the threaded holes. (3) Turn center bolt clockwise with 19 mm (3/4

inch) socket until front plate is loosened.

Fig. 12 Check Air Gap

Fig. 1 Hex Nut Removal

Fig. 10 Tool Set Driver

Fig. 11 Front Plate Installation

Ä HEATING AND AIR CONDITIONING 24 - 41

Page 2346 of 2438

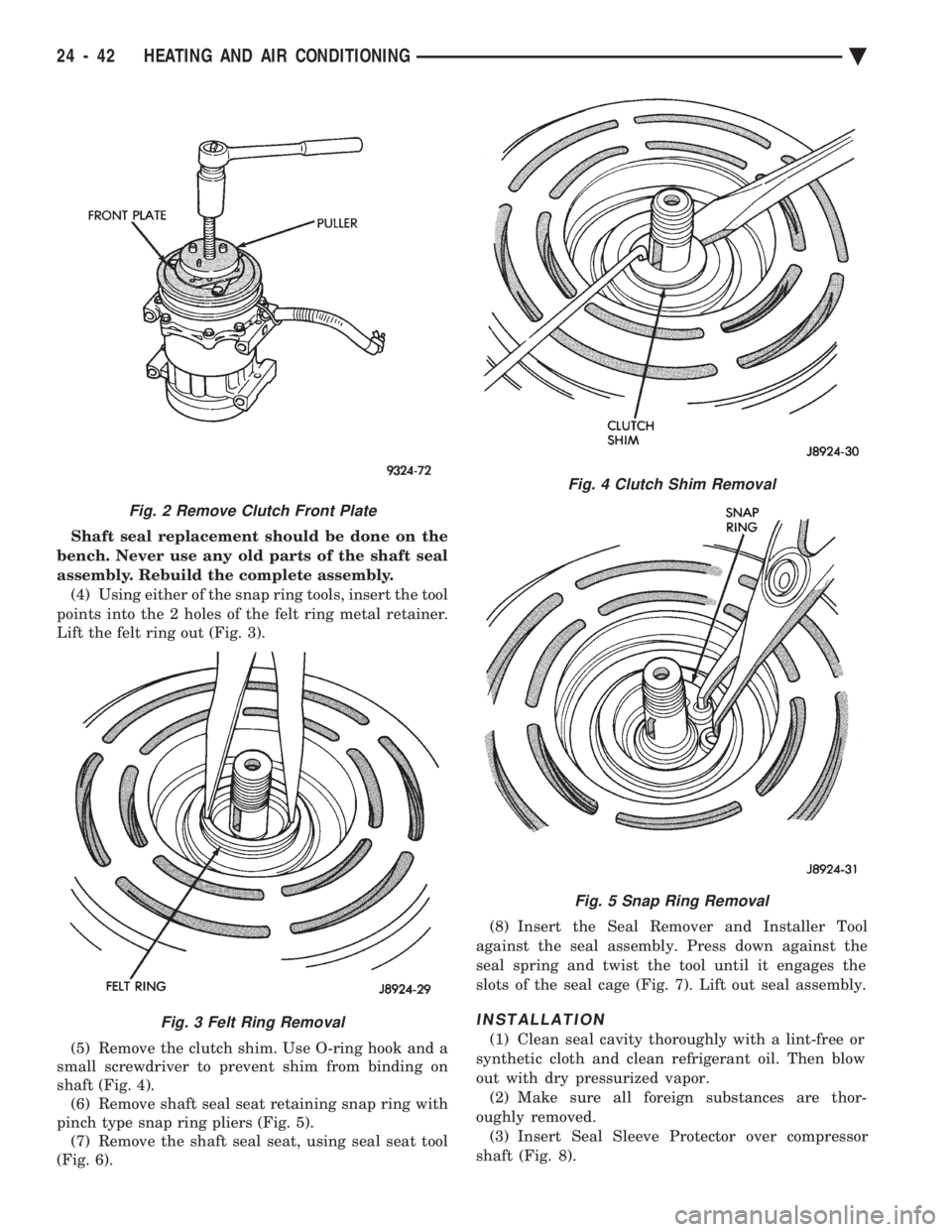

Shaft seal replacement should be done on the

bench. Never use any old parts of the shaft seal

assembly. Rebuild the complete assembly. (4) Using either of the snap ring tools, insert the tool

points into the 2 holes of the felt ring metal retainer.

Lift the felt ring out (Fig. 3).

(5) Remove the clutch shim. Use O-ring hook and a

small screwdriver to prevent shim from binding on

shaft (Fig. 4). (6) Remove shaft seal seat retaining snap ring with

pinch type snap ring pliers (Fig. 5). (7) Remove the shaft seal seat, using seal seat tool

(Fig. 6). (8) Insert the Seal Remover and Installer Tool

against the seal assembly. Press down against the

seal spring and twist the tool until it engages the

slots of the seal cage (Fig. 7). Lift out seal assembly.

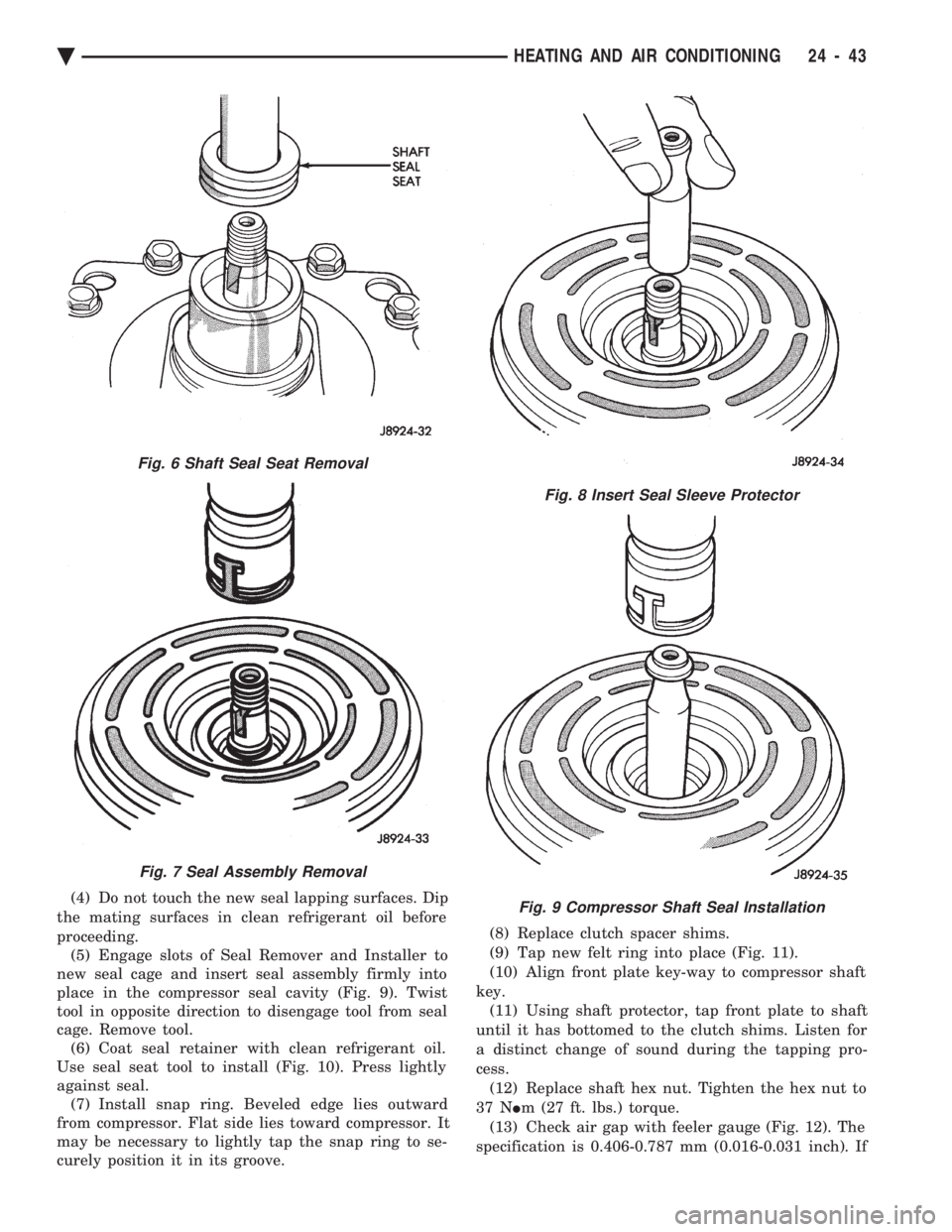

INSTALLATION

(1) Clean seal cavity thoroughly with a lint-free or

synthetic cloth and clean refrigerant oil. Then blow

out with dry pressurized vapor. (2) Make sure all foreign substances are thor-

oughly removed. (3) Insert Seal Sleeve Protector over compressor

shaft (Fig. 8).

Fig. 4 Clutch Shim Removal

Fig. 5 Snap Ring Removal

Fig. 2 Remove Clutch Front Plate

Fig. 3 Felt Ring Removal

24 - 42 HEATING AND AIR CONDITIONING Ä

Page 2347 of 2438

(4) Do not touch the new seal lapping surfaces. Dip

the mating surfaces in clean refrigerant oil before

proceeding. (5) Engage slots of Seal Remover and Installer to

new seal cage and insert seal assembly firmly into

place in the compressor seal cavity (Fig. 9). Twist

tool in opposite direction to disengage tool from seal

cage. Remove tool. (6) Coat seal retainer with clean refrigerant oil.

Use seal seat tool to install (Fig. 10). Press lightly

against seal. (7) Install snap ring. Beveled edge lies outward

from compressor. Flat side lies toward compressor. It

may be necessary to lightly tap the snap ring to se-

curely position it in its groove. (8) Replace clutch spacer shims.

(9) Tap new felt ring into place (Fig. 11).

(10) Align front plate key-way to compressor shaft

key. (11) Using shaft protector, tap front plate to shaft

until it has bottomed to the clutch shims. Listen for

a distinct change of sound during the tapping pro-

cess. (12) Replace shaft hex nut. Tighten the hex nut to

37 N Im (27 ft. lbs.) torque.

(13) Check air gap with feeler gauge (Fig. 12). The

specification is 0.406-0.787 mm (0.016-0.031 inch). If

Fig. 6 Shaft Seal Seat Removal

Fig. 7 Seal Assembly Removal

Fig. 8 Insert Seal Sleeve Protector

Fig. 9 Compressor Shaft Seal Installation

Ä HEATING AND AIR CONDITIONING 24 - 43