light CHEVROLET DYNASTY 1993 Service Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 737 of 2438

POWER MIRRORS

CONTENTS

page page

AUTOMATIC DAY/NIGHT INSIDE MIRROR .... 7

AUTOMATIC DAY/NIGHT INSIDE MIRROR WITH ULTRALIGHT HEADLAMP CONTROL ....... 7

GENERAL INFORMATION .................. 1

HEATED MIRROR ........................ 2

INSIDE MIRROR/READING LAMPS BULB/LENS REPLACEMENT ........................ 6

INSIDE MIRROR/READING LAMPS REPLACEMENT ........................ 6

MIRROR ASSEMBLY REPLACEMENTÐAA BODY.5

MIRROR ASSEMBLY REPLACEMENTÐ AC AND AY BODIES .................... 5

MIRROR ASSEMBLY REPLACEMENTÐAG BODY.5

MIRROR ASSEMBLY REPLACEMENTÐAJ BODY.5

MIRROR ASSEMBLY REPLACEMENTÐAP BODY.5

MIRROR MOTOR TEST PROCEDURE ........ 2

MIRROR SWITCH REPLACEMENTÐAA BODY . 3

MIRROR SWITCH REPLACEMENTÐAC AND AY BODIES .............................. 4

MIRROR SWITCH REPLACEMENTÐAG AND AJ BODIES .............................. 3

MIRROR SWITCH REPLACEMENTÐAP BODY . 4

MIRROR SWITCH TEST PROCEDURE ....... 2

TEST PROCEDURES ...................... 2

GENERAL INFORMATION

Electrically operated power mirrors are available

on all car lines. The mirrors are controlled by a sin-

gle switch assembly located either on the driver's

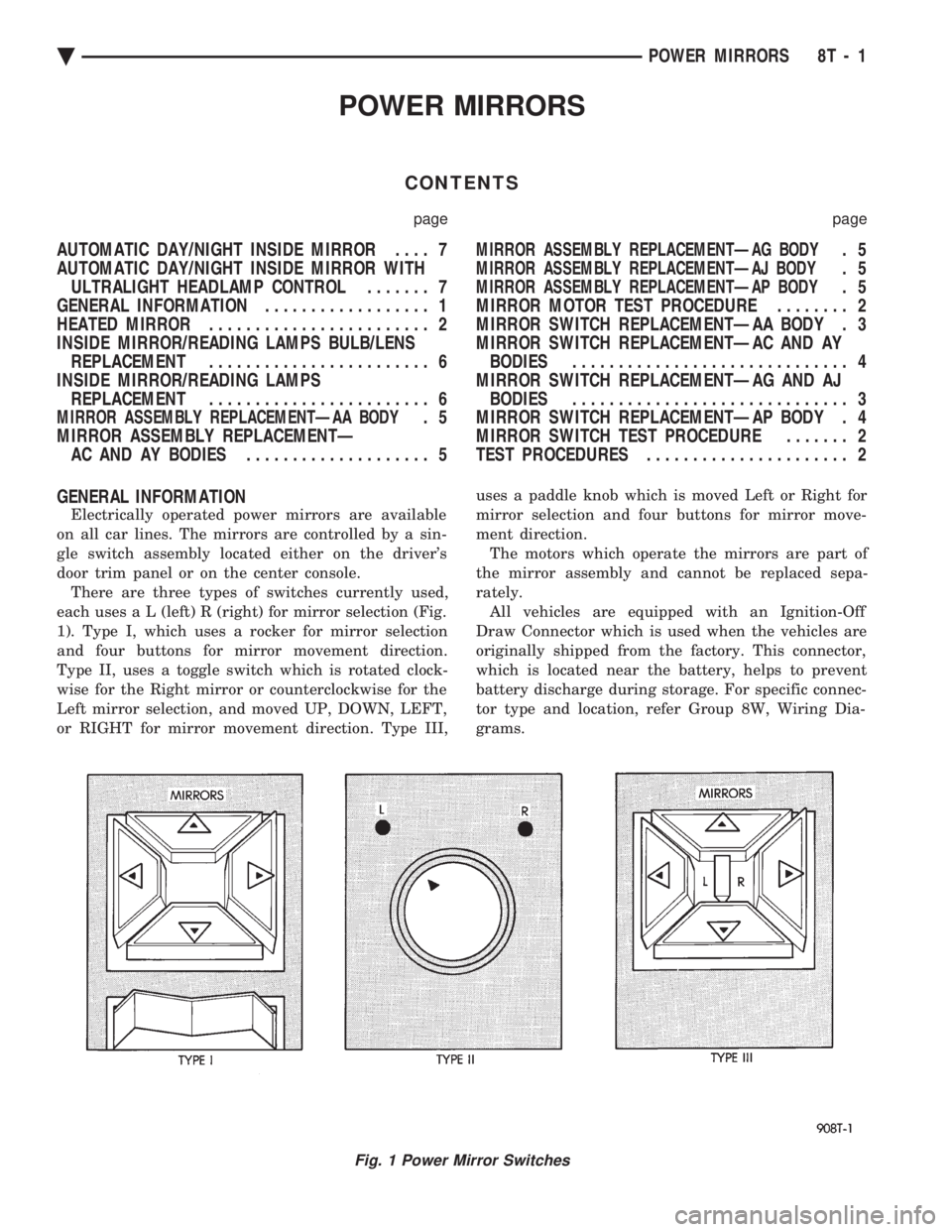

door trim panel or on the center console. There are three types of switches currently used,

each use s a L (left) R (right) for mirror selection (Fig.

1). Type I, which uses a rocker for mirror selection

and four buttons for mirror movement direction.

Type II, uses a toggle switch which is rotated clock-

wise for the Right mirror or counterclockwise for the

Left mirror selection, and moved UP, DOWN, LEFT,

or RIGHT for mirror movement direction. Type III, uses a paddle knob which is moved Left or Right for

mirror selection and four buttons for mirror move-

ment direction.

The motors which operate the mirrors are part of

the mirror assembly and cannot be replaced sepa-

rately. All vehicles are equipped with an Ignition-Off

Draw Connector which is used when the vehicles are

originally shipped from the factory. This connector,

which is located near the battery, helps to prevent

battery discharge during storage. For specific connec-

tor type and location, refer Group 8W, Wiring Dia-

grams.

Fig. 1 Power Mirror Switches

Ä POWER MIRRORS 8T - 1

Page 743 of 2438

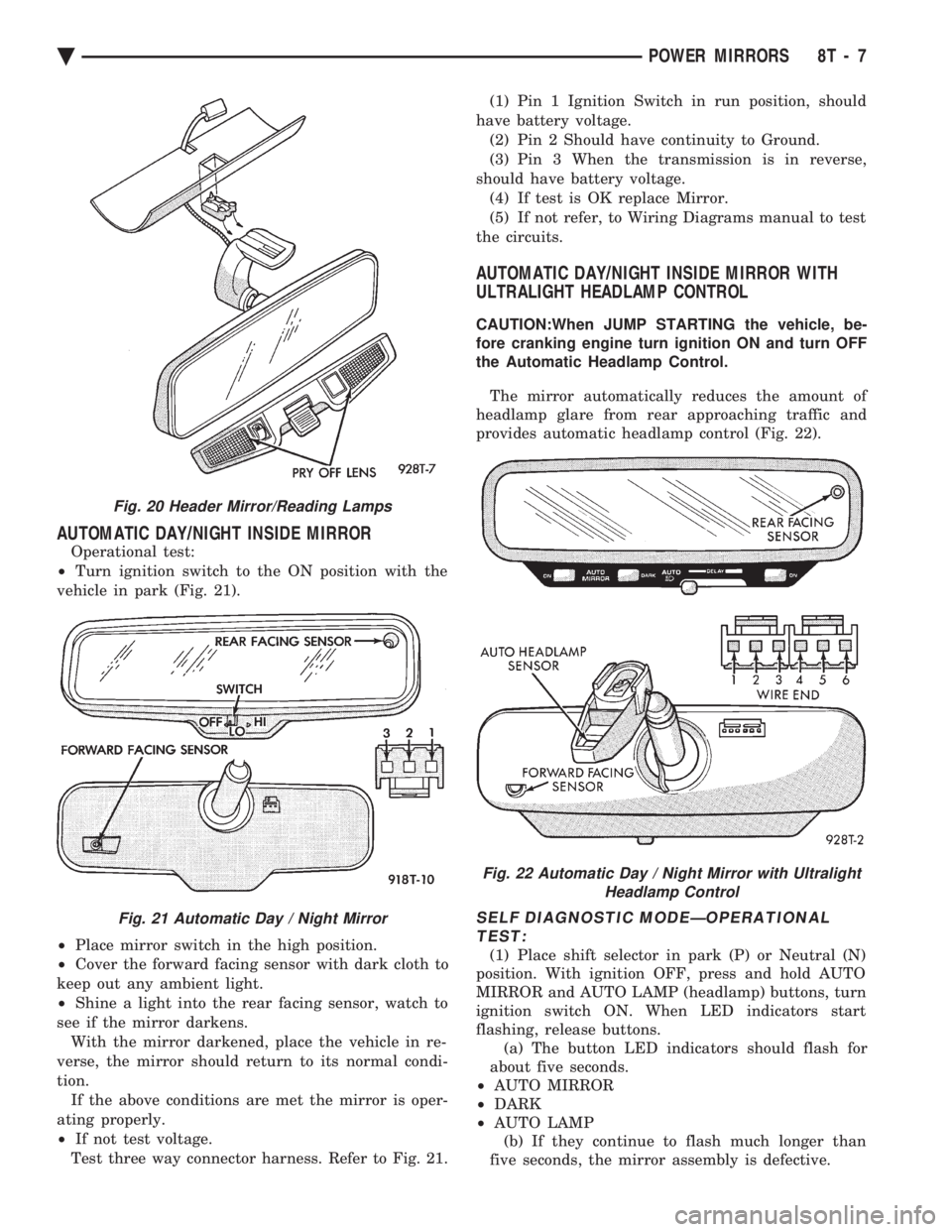

AUTOMATIC DAY/NIGHT INSIDE MIRROR

Operational test:

² Turn ignition switch to the ON position with the

vehicle in park (Fig. 21).

² Place mirror switch in the high position.

² Cover the forward facing sensor with dark cloth to

keep out any ambient light.

² Shine a light into the rear facing sensor, watch to

see if the mirror darkens. With the mirror darkened, place the vehicle in re-

verse, the mirror should return to its normal condi-

tion. If the above conditions are met the mirror is oper-

ating properly.

² If not test voltage.

Test three way connector harness. Refer to Fig. 21. (1) Pin 1 Ignition Switch in run position, should

have battery voltage. (2) Pin 2 Should have continuity to Ground.

(3) Pin 3 When the transmission is in reverse,

should have battery voltage. (4) If test is OK replace Mirror.

(5) If not refer, to Wiring Diagrams manual to test

the circuits.

AUTOMATIC DAY/NIGHT INSIDE MIRROR WITH

ULTRALIGHT HEADLAMP CONTROL

CAUTION:When JUMP STARTING the vehicle, be-

fore cranking engine turn ignition ON and turn OFF

the Automatic Headlamp Control.

The mirror automatically reduces the amount of

headlamp glare from rear approaching traffic and

provides automatic headlamp control (Fig. 22).

SELF DIAGNOSTIC MODEÐOPERATIONAL TEST:

(1) Place shift selector in park (P) or Neutral (N)

position. With ignition OFF, press and hold AUTO

MIRROR and AUTO LAMP (headlamp) buttons, turn

ignition switch ON. When LED indicators start

flashing, release buttons. (a) The button LED indicators should flash for

about five seconds.

² AUTO MIRROR

² DARK

² AUTO LAMP

(b) If they continue to flash much longer than

five seconds, the mirror assembly is defective.

Fig. 20 Header Mirror/Reading Lamps

Fig. 21 Automatic Day / Night Mirror

Fig. 22 Automatic Day / Night Mirror with Ultralight Headlamp Control

Ä POWER MIRRORS 8T - 7

Page 745 of 2438

CHIME WARNING/REMINDER SYSTEM

CONTENTS

page page

BODY CONTROLLER REPLACEMENT ........ 5

CHIME MODULE REPLACEMENT AA and AP BODIES .............................. 5

CHIME SYSTEM DIAGNOSISÐAA AND AP BODIES .............................. 2

CHIME SYSTEM DIAGNOSISÐAC, AG, AJ AND AY BODIES ....................... 3

CHIME WARNING/REMINDER SYSTEM TEST . 1 GENERAL INFORMATION

.................. 1

HEADLAMP SWITCH REPLACEMENT ........ 5

KEY-IN SWITCH REPLACEMENT ............ 5

SEAT BELT BUCKLE REPLACEMENT ........ 5

SEAT BELT BUCKLE SWITCH TEST BUZZER SYSTEM .............................. 1

SERVICE PROCEDURES ................... 5

TIMED BUZZER-RELAY TESTÐAP BODY ..... 1

GENERAL INFORMATION

WARNING: ON VEHICLES EQUIPPED WITH AN AIR

BAG REFER TO THE AIR BAG PORTION OF THIS

SECTION FOR STEERING WHEEL OR SWITCH RE-

MOVAL AND INSTALLATION PROCEDURES.

BUZZER SYSTEM

The seat belt warning system uses both visual and

audible signals. A combined seat belt and key warn-

ing buzzer with a red light on the instrument panel. The system will always illuminate the seat belt

warning lamp for four to eight seconds when the ig-

nition switch is turned to the ON position. Also, only

if the driver does not fasten his seat belt, the buzzer

will sound during the same time interval. Passenger

belts are not connected to the system. A timed buzzer-relay is used to operate the system

for the time period. It consists of a time delay mech-

anism and buzzer assembly. Only the driver's seat

belt buckle has a switch that is connected to the sys-

tem.

CHIME WARNING/REMINDER SYSTEM

The chime warning/reminder system is similar in

operation to the buzzer system except for a more

pleasant sounding tone. This chime type tone sounds

for all three warning/reminder conditions; namely

headlamps left on, keys left in ignition and fasten

seat belt.

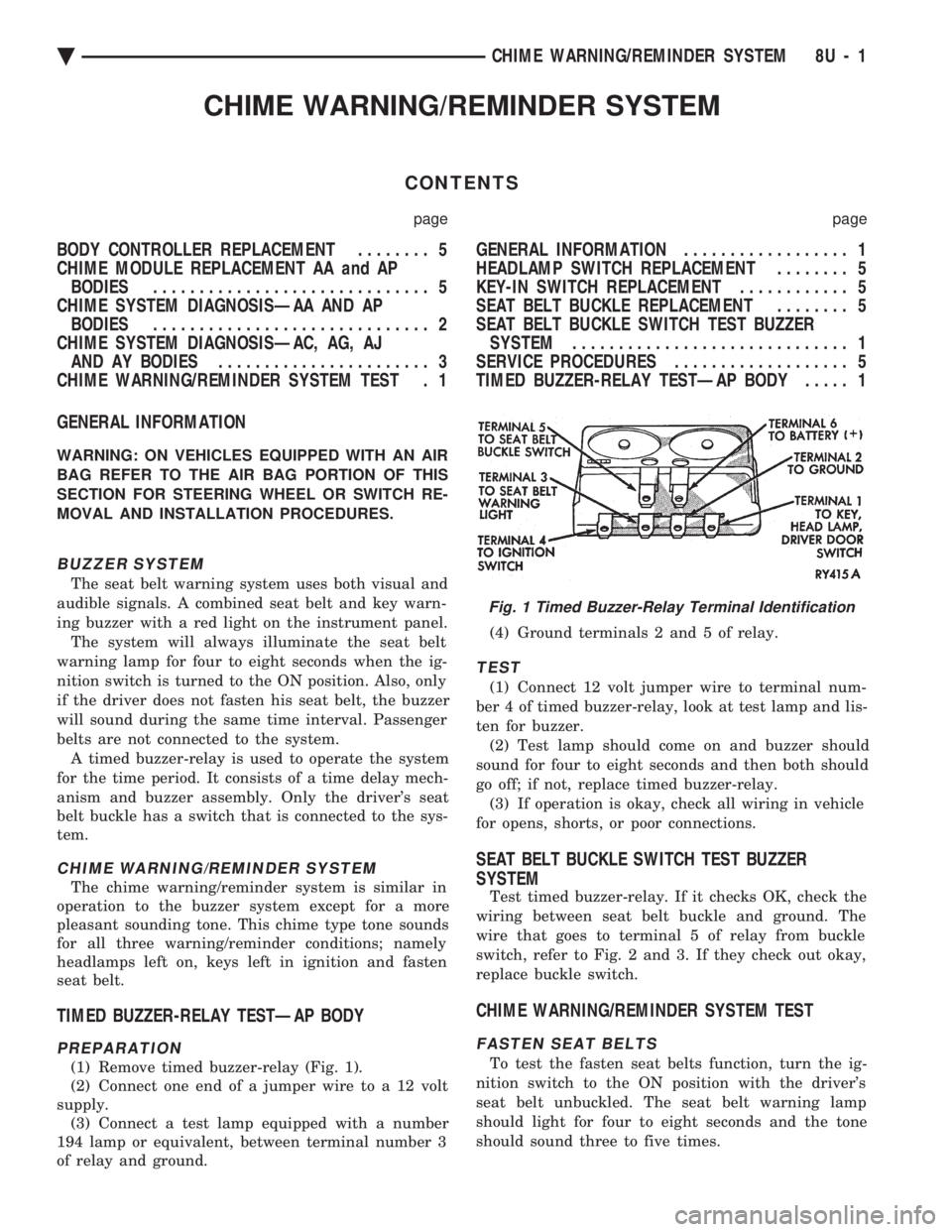

TIMED BUZZER-RELAY TESTÐAP BODY

PREPARATION

(1) Remove timed buzzer-relay (Fig. 1).

(2) Connect one end of a jumper wire to a 12 volt

supply. (3) Connect a test lamp equipped with a number

194 lamp or equivalent, between terminal number 3

of relay and ground. (4) Ground terminals 2 and 5 of relay.

TEST

(1) Connect 12 volt jumper wire to terminal num-

ber 4 of timed buzzer-relay, look at test lamp and lis-

ten for buzzer. (2) Test lamp should come on and buzzer should

sound for four to eight seconds and then both should

go off; if not, replace timed buzzer-relay. (3) If operation is okay, check all wiring in vehicle

for opens, shorts, or poor connections.

SEAT BELT BUCKLE SWITCH TEST BUZZER

SYSTEM

Test timed buzzer-relay. If it checks OK, check the

wiring between seat belt buckle and ground. The

wire that goes to terminal 5 of relay from buckle

switch, refer to Fig. 2 and 3. If they check out okay,

replace buckle switch.

CHIME WARNING/REMINDER SYSTEM TEST

FASTEN SEAT BELTS

To test the fasten seat belts function, turn the ig-

nition switch to the ON position with the driver's

seat belt unbuckled. The seat belt warning lamp

should light for four to eight seconds and the tone

should sound three to five times.

Fig. 1 Timed Buzzer-Relay Terminal Identification

Ä CHIME WARNING/REMINDER SYSTEM 8U - 1

Page 749 of 2438

CONDITION: NO TONE WHEN HEADLAMPS ARE ON AND DRIVER'S DOOR IS OPEN, ANDIGNITION IS OFF

PROCEDURE

(1) Check left door jamb switch for good ground

when driver's door is open. This may be checked at

terminal 1 of 25-way body controller connector. (2) Check for battery feed at terminal 16 of 25-way

body controller connector. (3) Check headlamp switch.

CONDITION: NO TONE WHEN KEY IS LEFT INIGNITION AND DRIVER'S DOOR IS OPEN

PROCEDURE

(1) Check left door jamb switch for good ground

when driver's door is open. This may be checked at

terminal 1 of 25-way body controller connector. (2) Check for battery feed at terminal 16 of 25-way

body controller connector. (3) Check key-in switch.

CONDITION: CHIMES CONTINUE WHENHEADLAMPS ARE TURNED OFF AND/OR KEYIS REMOVED FROM IGNITION

PROCEDURE

Check wiring for a grounded condition between

headlamp switch, key-in switch, and body controller.

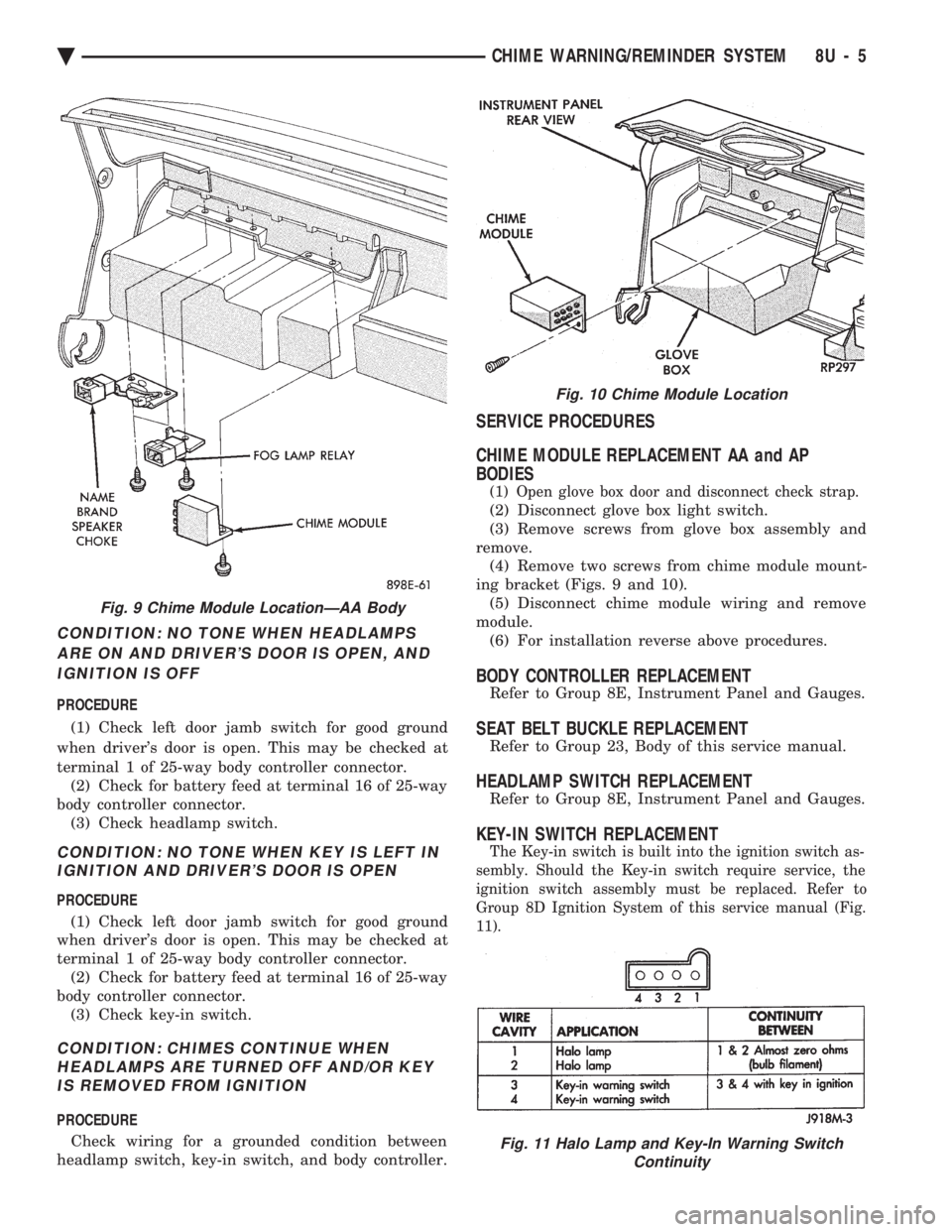

SERVICE PROCEDURES

CHIME MODULE REPLACEMENT AA and AP

BODIES

(1) Open glove box door and disconnect check strap.

(2) Disconnect glove box light switch.

(3) Remove screws from glove box assembly and

remove. (4) Remove two screws from chime module mount-

ing bracket (Figs. 9 and 10). (5) Disconnect chime module wiring and remove

module. (6) For installation reverse above procedures.

BODY CONTROLLER REPLACEMENT

Refer to Group 8E, Instrument Panel and Gauges.

SEAT BELT BUCKLE REPLACEMENT

Refer to Group 23, Body of this service manual.

HEADLAMP SWITCH REPLACEMENT

Refer to Group 8E, Instrument Panel and Gauges.

KEY-IN SWITCH REPLACEMENT

The Key-in switch is built into the ignition switch as-

sembly. Should the Key-in switch require service, the

ignition switch assembly must be replaced. Refer to

Group 8D Ignition System of this service manual (Fig.

11).

Fig. 9 Chime Module LocationÐAA Body

Fig. 10 Chime Module Location

Fig. 11 Halo Lamp and Key-In Warning Switch Continuity

Ä CHIME WARNING/REMINDER SYSTEM 8U - 5

Page 769 of 2438

WIRING AND COMPONENT IDENTIFICATION

CONTENTS

page page

AA BODY C, D, P ...................... 19

AC BODY C,D ......................... 37

AG BODY ............................. 61 AJ BODY

.............................. 77

AP BODY D, P ......................... 94

AY BODY-C ........................... 111

The wiring and components shown in this section

are divided into groups by vehicle line. When locat-

ing a specific harness routing or component, first

turn to the appropriate index, then look up the fig-

ure number that applies.Page numbers at the top of each page do not refer to figure numbers.

Throughout this section references may be made to

a particular vehicle by letter or number designation.

A chart showing the breakdown of these is shown in

the general information section.

AA BODY C, D, P

Caption Fig.

Anti Lock Brake System Wiring .....................4

Body Left Side Wiring ...........................6

Body Right Side Wiring ..........................5

Deck Lid Wiring ..............................1

Door Wiring (Body Side) .........................7

Door Wiring (Front) ............................8

Door Wiring (Rear) ............................9

Engine Compartment Wiring ......................16

Engine Wiring 2.5L ............................19

Engine Wiring 2.5L Flex Fuel ......................20Caption Fig.

Engine Wiring 3.0L ............................21

Front End Lighting ............................22

Ground Strap Locations .........................15

Instrument Panel Wiring .................. .11, 12, 13

Rear End Wiring ..............................2

Steering Column Wiring .........................10

Transmission Wiring ...........................17

Transmission Wiring ETAX .......................18

Trunk Wiring ................................3

Underhood Lamp Wiring ........................14

Ä WIRING AND COMPONENT IDENTIFICATION 8W - 19

Page 787 of 2438

AC BODY C,D

Caption Fig.

Air Suspension Wiring ..........................4

Body Left Side Wiring ...........................8

Body Right Side Wiring ..........................9

Cellular Phone Wiring ...........................7

Deck Lid Wiring ..............................5

Door Wiring (Body) ...........................10

Door Wiring (Front) ...........................11

Door Wiring (Rear) ............................12

Engine Wiring 2.5L ............................27

Engine Wiring 3.0L ............................28

Engine Wiring 3.3L, 3.8L ........................29

Engine Compartment Wiring 2.5L ................18, 19

Engine Compartment Wiring 3.0L .............20, 22, 23

Engine Compartment Wiring 3.3L, 3.8L ..........21, 22, 23Caption Fig.

Front End Lighting (Aero Headlamps) ................32

Front End Lighting (Concealed Headlamps) ............33

Ground Strap Locations .........................30

Heated Rear Window Wiring .......................6

Instrument Panel Wiring .................. .13, 14, 15

Load Leveling Wiring ...........................3

Radiator Fan Assembly .........................31

Rear End Wiring (Chrysler) .......................1

Rear End Wiring (Dodge) ........................2

Steering Column Wiring .........................16

Transmission Wiring 2.5L .......................24

Transmission WIring 3.0L .......................25

Transmission Wiring 3.3L, 3.8L ....................26

Underhood Lamp Wiring ........................17

Ä WIRING AND COMPONENT IDENTIFICATION 8W - 37

Page 809 of 2438

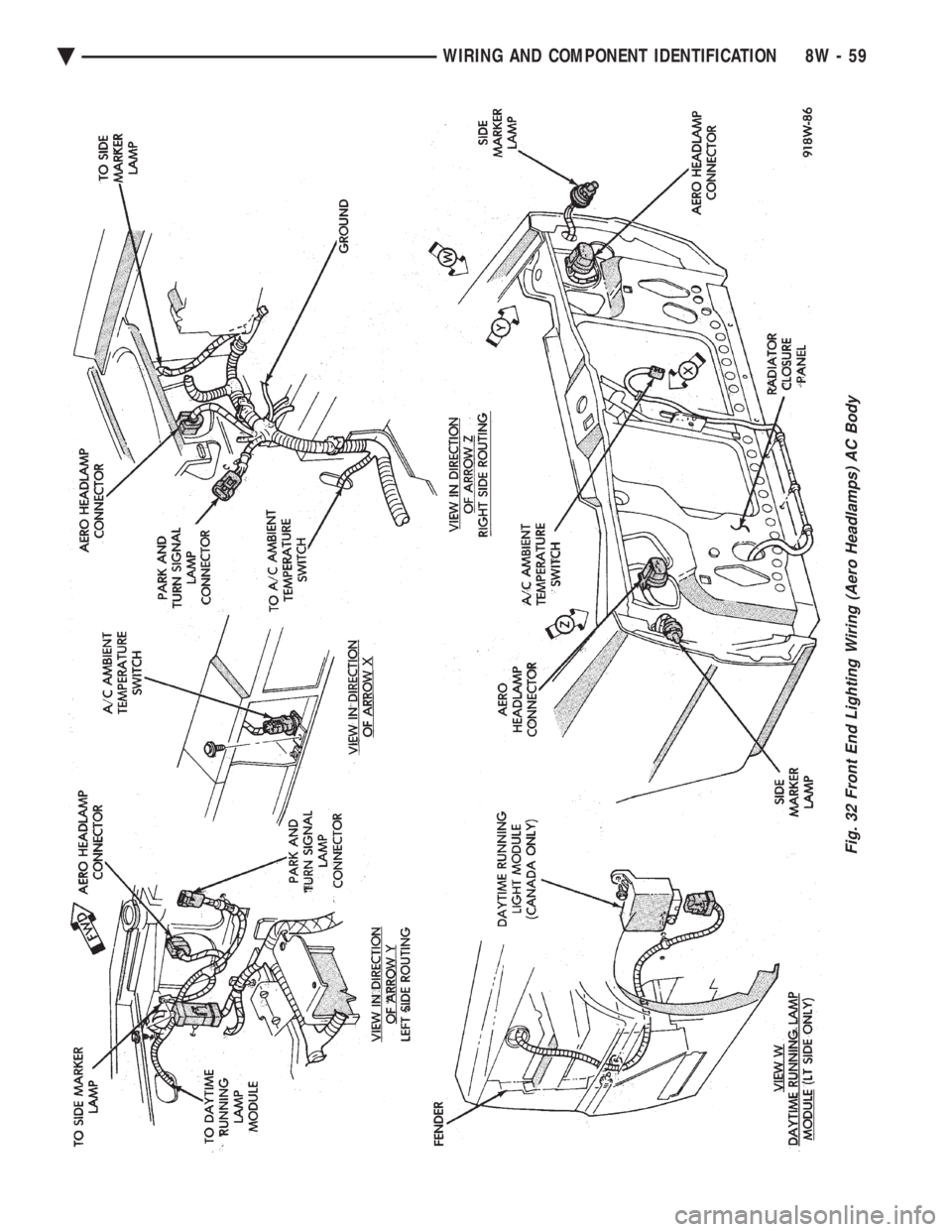

Fig. 32 Front End Lighting Wiring (Aero Headlamps) AC Body

Ä WIRING AND COMPONENT IDENTIFICATION 8W - 59

Page 810 of 2438

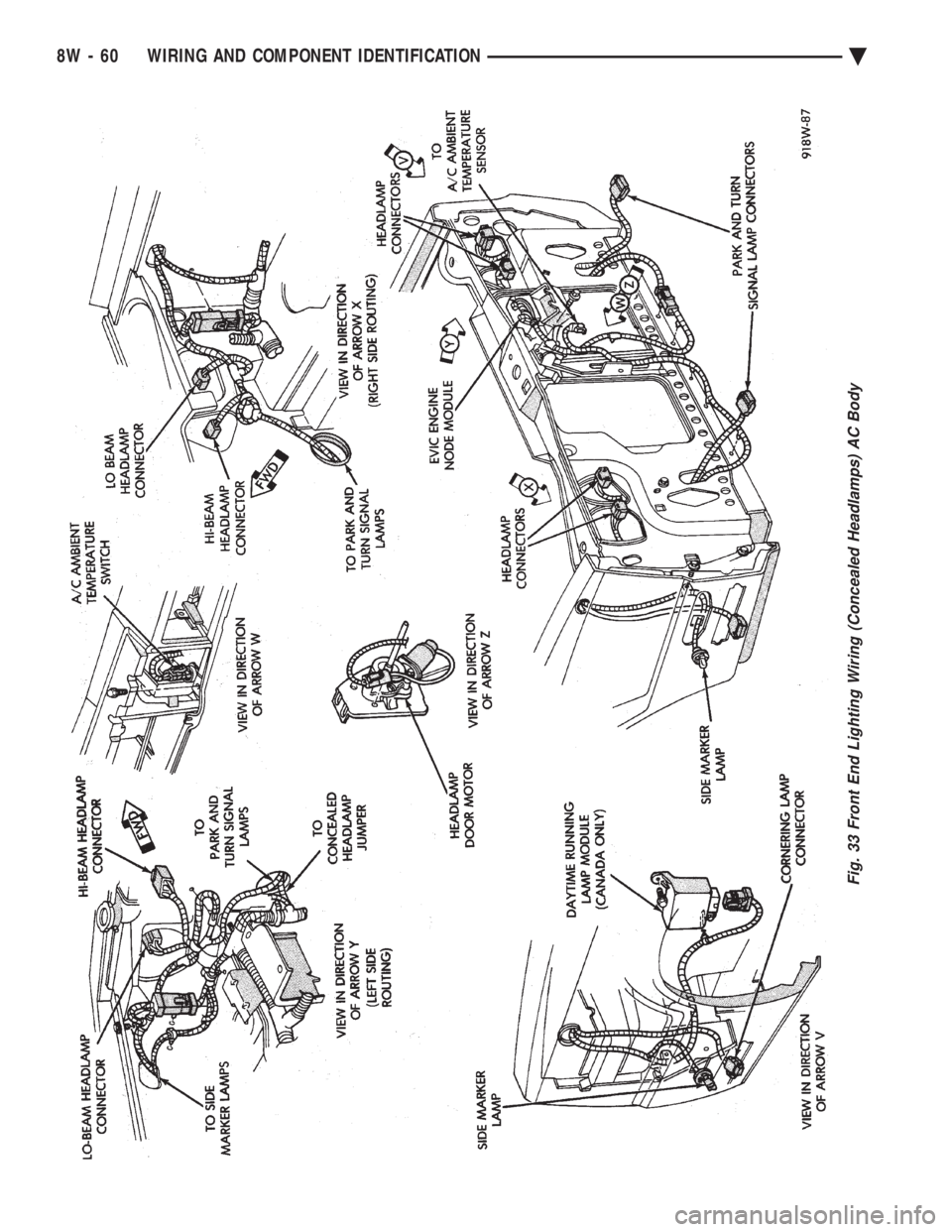

Fig. 33 Front End Lighting Wiring (Concealed Headlamps) AC Body

8W - 60 WIRING AND COMPONENT IDENTIFICATION Ä

Page 861 of 2438

AY BODY-C

Caption Fig.

Air Suspension Wiring ..........................3

Body Left Side Wiring ...........................8

Body Right Side Wiring ..........................9

Cellular Phone Wiring ...........................7

Deck Lid Wiring ..............................5

Door Wiring (Body) ...........................10

Door Wiring (Front) ...........................11

Door Wiring (Rear) ............................12

Engine Wiring 3.3L and 3.8L .....................23

Engine Compartment Wiring 3.3L and 3.8L .......18, 19, 20Caption Fig.

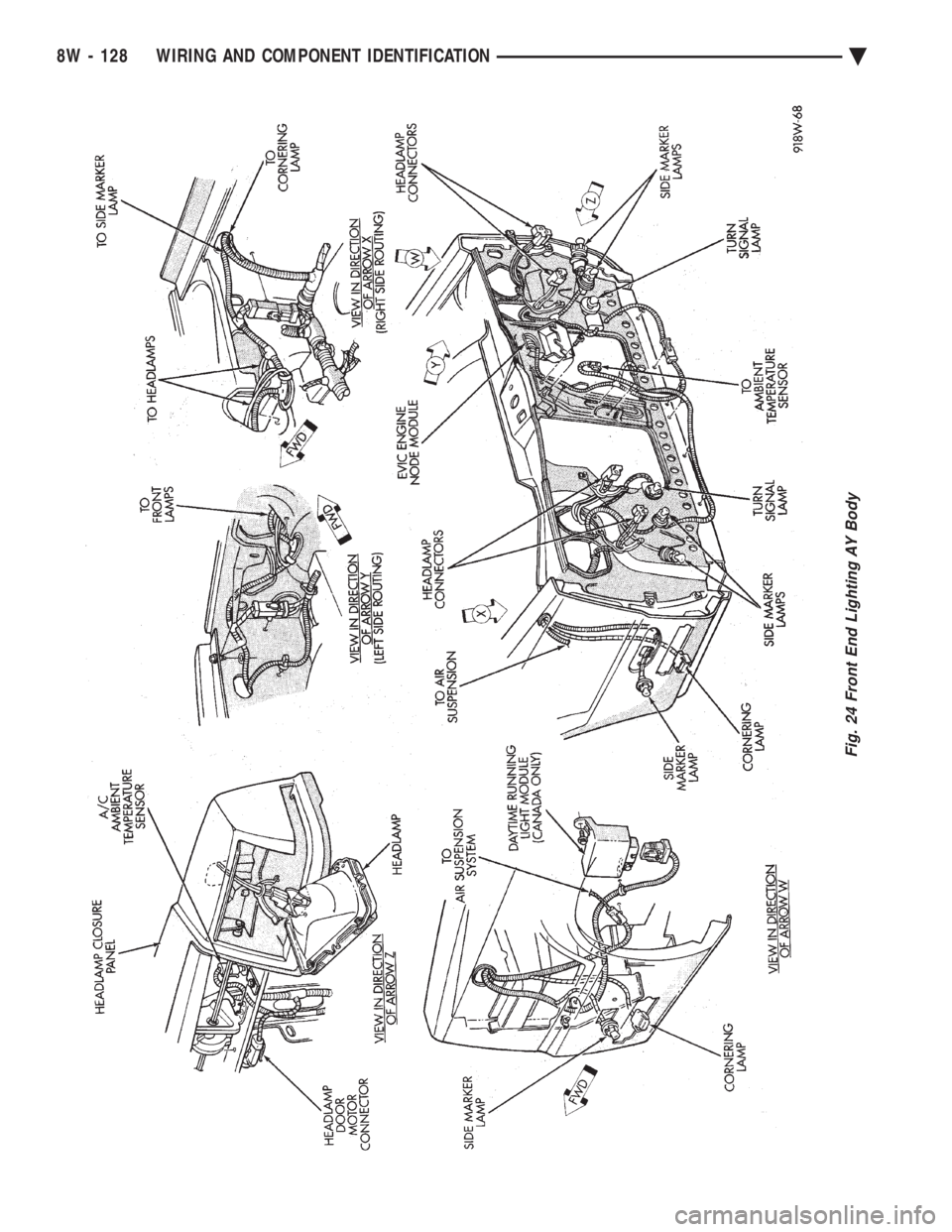

Front End Lighting ............................24

Ground Strap Locations .........................6

Heated Rear Window Wiring .......................4

Instrument Panel Wiring .................. .13, 14, 15

Load Leveling Wiring ...........................2

Radiator Fan Assembly .........................21

Rear End Wiring ..............................1

Steering Column Wiring .........................16

Transmission Wiring 3.3L and 3.8L .................22

Underhood Lamp Wiring ........................17

Ä WIRING AND COMPONENT IDENTIFICATION 8W - 111

Page 878 of 2438

Fig. 24 Front End Lighting AY Body

8W - 128 WIRING AND COMPONENT IDENTIFICATION Ä