relay CHEVROLET DYNASTY 1993 Service Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 1750 of 2438

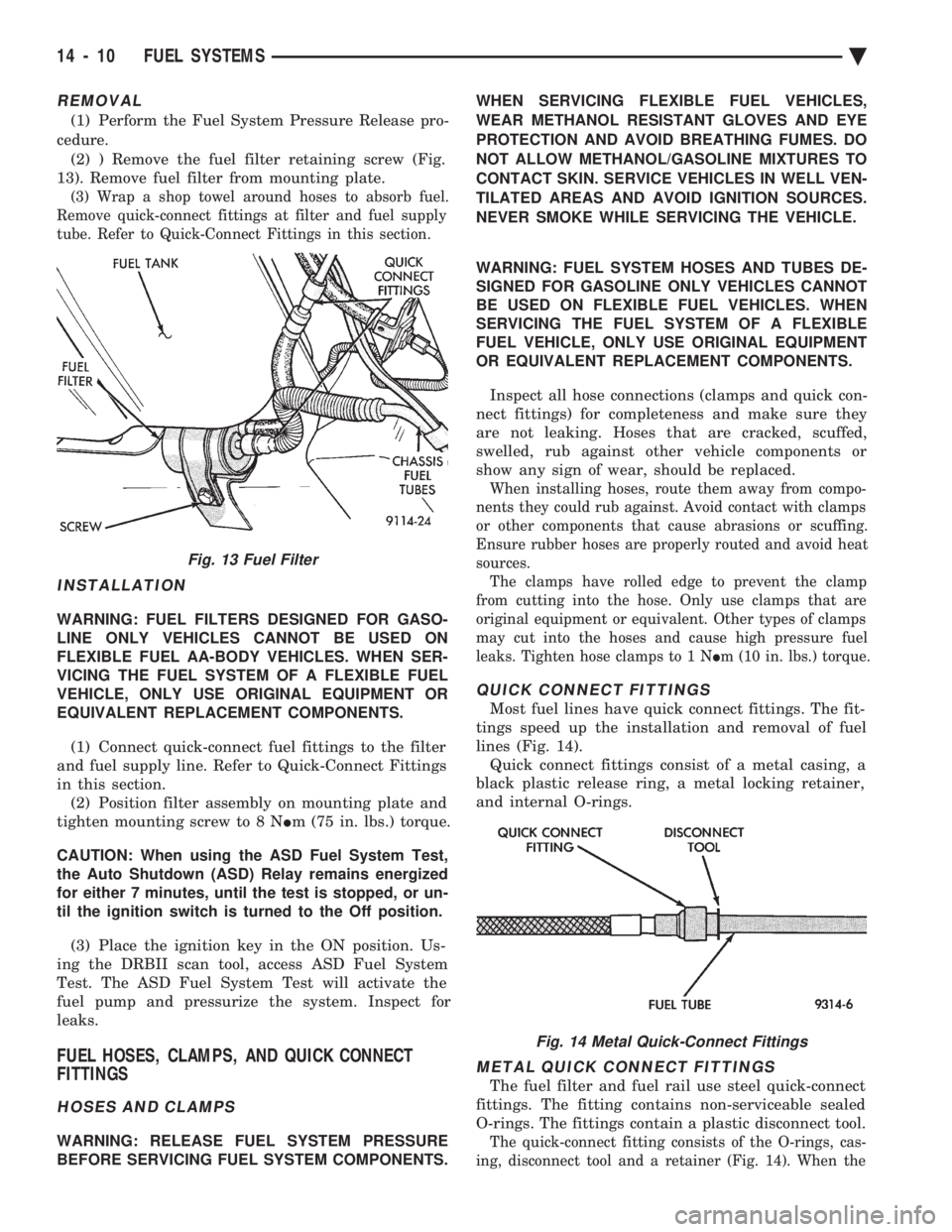

REMOVAL

(1) Perform the Fuel System Pressure Release pro-

cedure. (2) ) Remove the fuel filter retaining screw (Fig.

13). Remove fuel filter from mounting plate.

(3) Wrap a shop towel around hoses to absorb fuel.

Remove quick-connect fittings at filter and fuel supply

tube. Refer to Quick-Connect Fittings in this section.

INSTALLATION

WARNING: FUEL FILTERS DESIGNED FOR GASO-

LINE ONLY VEHICLES CANNOT BE USED ON

FLEXIBLE FUEL AA-BODY VEHICLES. WHEN SER-

VICING THE FUEL SYSTEM OF A FLEXIBLE FUEL

VEHICLE, ONLY USE ORIGINAL EQUIPMENT OR

EQUIVALENT REPLACEMENT COMPONENTS.

(1) Connect quick-connect fuel fittings to the filter

and fuel supply line. Refer to Quick-Connect Fittings

in this section. (2) Position filter assembly on mounting plate and

tighten mounting screw to 8 N Im (75 in. lbs.) torque.

CAUTION: When using the ASD Fuel System Test,

the Auto Shutdown (ASD) Relay remains energized

for either 7 minutes, until the test is stopped, or un-

til the ignition switch is turned to the Off position.

(3) Place the ignition key in the ON position. Us-

ing the DRBII scan tool, access ASD Fuel System

Test. The ASD Fuel System Test will activate the

fuel pump and pressurize the system. Inspect for

leaks.

FUEL HOSES, CLAMPS, AND QUICK CONNECT

FITTINGS

HOSES AND CLAMPS

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE SERVICING FUEL SYSTEM COMPONENTS. WHEN SERVICING FLEXIBLE FUEL VEHICLES,

WEAR METHANOL RESISTANT GLOVES AND EYE

PROTECTION AND AVOID BREATHING FUMES. DO

NOT ALLOW METHANOL/GASOLINE MIXTURES TO

CONTACT SKIN. SERVICE VEHICLES IN WELL VEN-

TILATED AREAS AND AVOID IGNITION SOURCES.

NEVER SMOKE WHILE SERVICING THE VEHICLE.

WARNING: FUEL SYSTEM HOSES AND TUBES DE-

SIGNED FOR GASOLINE ONLY VEHICLES CANNOT

BE USED ON FLEXIBLE FUEL VEHICLES. WHEN

SERVICING THE FUEL SYSTEM OF A FLEXIBLE

FUEL VEHICLE, ONLY USE ORIGINAL EQUIPMENT

OR EQUIVALENT REPLACEMENT COMPONENTS.

Inspect all hose connections (clamps and quick con-

nect fittings) for completeness and make sure they

are not leaking. Hoses that are cracked, scuffed,

swelled, rub against other vehicle components or

show any sign of wear, should be replaced.

When installing hoses, route them away from compo-

nents they could rub against. Avoid contact with clamps

or other components that cause abrasions or scuffing.

Ensure rubber hoses are properly routed and avoid heat

sources. The clamps have rolled edge to prevent the clamp

from cutting into the hose. Only use clamps that are

original equipment or equivalent. Other types of clamps

may cut into the hoses and cause high pressure fuel

leaks. Tighten hose clamps to 1 N Im (10 in. lbs.) torque.

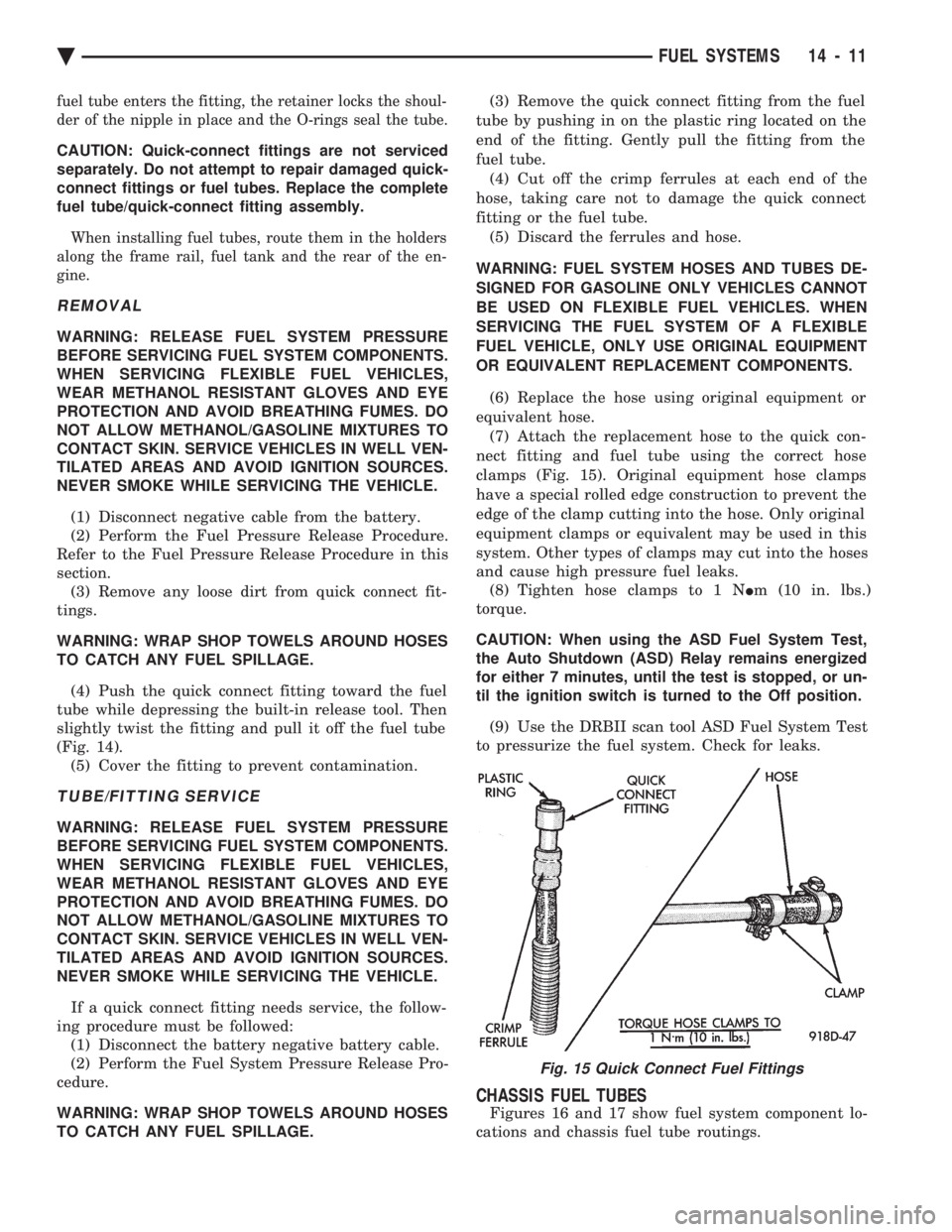

QUICK CONNECT FITTINGS

Most fuel lines have quick connect fittings. The fit-

tings speed up the installation and removal of fuel

lines (Fig. 14). Quick connect fittings consist of a metal casing, a

black plastic release ring, a metal locking retainer,

and internal O-rings.

METAL QUICK CONNECT FITTINGS

The fuel filter and fuel rail use steel quick-connect

fittings. The fitting contains non-serviceable sealed

O-rings. The fittings contain a plastic disconnect tool.

The quick-connect fitting consists of the O-rings, cas-

ing, disconnect tool and a retainer (Fig. 14). When the

Fig. 13 Fuel Filter

Fig. 14 Metal Quick-Connect Fittings

14 - 10 FUEL SYSTEMS Ä

Page 1751 of 2438

fuel tube enters the fitting, the retainer locks the shoul-

der of the nipple in place and the O-rings seal the tube.

CAUTION: Quick-connect fittings are not serviced

separately. Do not attempt to repair damaged quick-

connect fittings or fuel tubes. Replace the complete

fuel tube/quick-connect fitting assembly.

When installing fuel tubes, route them in the holders

along the frame rail, fuel tank and the rear of the en-

gine.

REMOVAL

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE SERVICING FUEL SYSTEM COMPONENTS.

WHEN SERVICING FLEXIBLE FUEL VEHICLES,

WEAR METHANOL RESISTANT GLOVES AND EYE

PROTECTION AND AVOID BREATHING FUMES. DO

NOT ALLOW METHANOL/GASOLINE MIXTURES TO

CONTACT SKIN. SERVICE VEHICLES IN WELL VEN-

TILATED AREAS AND AVOID IGNITION SOURCES.

NEVER SMOKE WHILE SERVICING THE VEHICLE.

(1) Disconnect negative cable from the battery.

(2) Perform the Fuel Pressure Release Procedure.

Refer to the Fuel Pressure Release Procedure in this

section. (3) Remove any loose dirt from quick connect fit-

tings.

WARNING: WRAP SHOP TOWELS AROUND HOSES

TO CATCH ANY FUEL SPILLAGE.

(4) Push the quick connect fitting toward the fuel

tube while depressing the built-in release tool. Then

slightly twist the fitting and pull it off the fuel tube

(Fig. 14). (5) Cover the fitting to prevent contamination.

TUBE/FITTING SERVICE

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE SERVICING FUEL SYSTEM COMPONENTS.

WHEN SERVICING FLEXIBLE FUEL VEHICLES,

WEAR METHANOL RESISTANT GLOVES AND EYE

PROTECTION AND AVOID BREATHING FUMES. DO

NOT ALLOW METHANOL/GASOLINE MIXTURES TO

CONTACT SKIN. SERVICE VEHICLES IN WELL VEN-

TILATED AREAS AND AVOID IGNITION SOURCES.

NEVER SMOKE WHILE SERVICING THE VEHICLE.

If a quick connect fitting needs service, the follow-

ing procedure must be followed: (1) Disconnect the battery negative battery cable.

(2) Perform the Fuel System Pressure Release Pro-

cedure.

WARNING: WRAP SHOP TOWELS AROUND HOSES

TO CATCH ANY FUEL SPILLAGE. (3) Remove the quick connect fitting from the fuel

tube by pushing in on the plastic ring located on the

end of the fitting. Gently pull the fitting from the

fuel tube. (4) Cut off the crimp ferrules at each end of the

hose, taking care not to damage the quick connect

fitting or the fuel tube. (5) Discard the ferrules and hose.

WARNING: FUEL SYSTEM HOSES AND TUBES DE-

SIGNED FOR GASOLINE ONLY VEHICLES CANNOT

BE USED ON FLEXIBLE FUEL VEHICLES. WHEN

SERVICING THE FUEL SYSTEM OF A FLEXIBLE

FUEL VEHICLE, ONLY USE ORIGINAL EQUIPMENT

OR EQUIVALENT REPLACEMENT COMPONENTS.

(6) Replace the hose using original equipment or

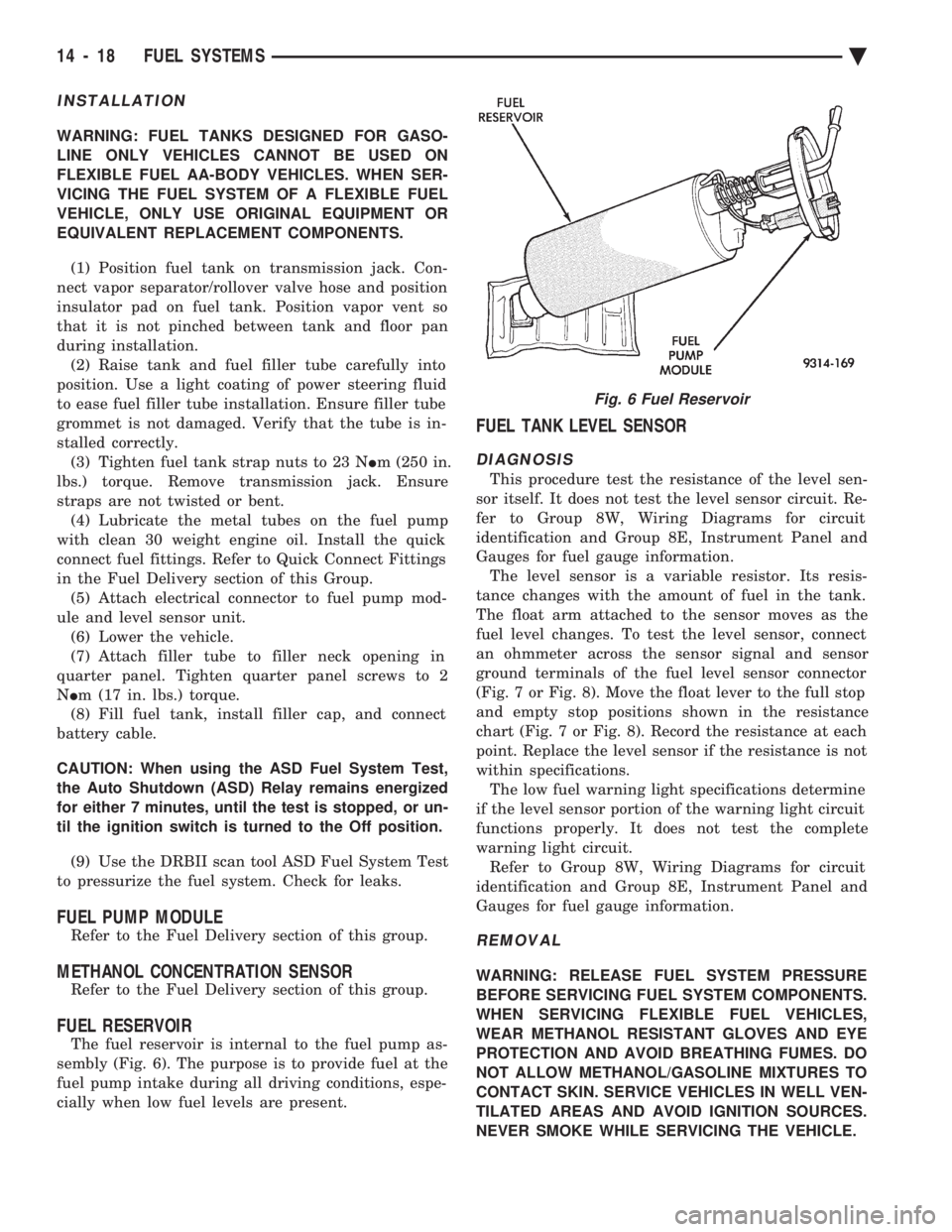

equivalent hose. (7) Attach the replacement hose to the quick con-

nect fitting and fuel tube using the correct hose

clamps (Fig. 15). Original equipment hose clamps

have a special rolled edge construction to prevent the

edge of the clamp cutting into the hose. Only original

equipment clamps or equivalent may be used in this

system. Other types of clamps may cut into the hoses

and cause high pressure fuel leaks. (8) Tighten hose clamps to 1 N Im (10 in. lbs.)

torque.

CAUTION: When using the ASD Fuel System Test,

the Auto Shutdown (ASD) Relay remains energized

for either 7 minutes, until the test is stopped, or un-

til the ignition switch is turned to the Off position.

(9) Use the DRBII scan tool ASD Fuel System Test

to pressurize the fuel system. Check for leaks.

CHASSIS FUEL TUBES

Figures 16 and 17 show fuel system component lo-

cations and chassis fuel tube routings.

Fig. 15 Quick Connect Fuel Fittings

Ä FUEL SYSTEMS 14 - 11

Page 1758 of 2438

INSTALLATION

WARNING: FUEL TANKS DESIGNED FOR GASO-

LINE ONLY VEHICLES CANNOT BE USED ON

FLEXIBLE FUEL AA-BODY VEHICLES. WHEN SER-

VICING THE FUEL SYSTEM OF A FLEXIBLE FUEL

VEHICLE, ONLY USE ORIGINAL EQUIPMENT OR

EQUIVALENT REPLACEMENT COMPONENTS. (1) Position fuel tank on transmission jack. Con-

nect vapor separator/rollover valve hose and position

insulator pad on fuel tank. Position vapor vent so

that it is not pinched between tank and floor pan

during installation. (2) Raise tank and fuel filler tube carefully into

position. Use a light coating of power steering fluid

to ease fuel filler tube installation. Ensure filler tube

grommet is not damaged. Verify that the tube is in-

stalled correctly. (3) Tighten fuel tank strap nuts to 23 N Im (250 in.

lbs.) torque. Remove transmission jack. Ensure

straps are not twisted or bent. (4) Lubricate the metal tubes on the fuel pump

with clean 30 weight engine oil. Install the quick

connect fuel fittings. Refer to Quick Connect Fittings

in the Fuel Delivery section of this Group. (5) Attach electrical connector to fuel pump mod-

ule and level sensor unit. (6) Lower the vehicle.

(7) Attach filler tube to filler neck opening in

quarter panel. Tighten quarter panel screws to 2

N Im (17 in. lbs.) torque.

(8) Fill fuel tank, install filler cap, and connect

battery cable.

CAUTION: When using the ASD Fuel System Test,

the Auto Shutdown (ASD) Relay remains energized

for either 7 minutes, until the test is stopped, or un-

til the ignition switch is turned to the Off position.

(9) Use the DRBII scan tool ASD Fuel System Test

to pressurize the fuel system. Check for leaks.

FUEL PUMP MODULE

Refer to the Fuel Delivery section of this group.

METHANOL CONCENTRATION SENSOR

Refer to the Fuel Delivery section of this group.

FUEL RESERVOIR

The fuel reservoir is internal to the fuel pump as-

sembly (Fig. 6). The purpose is to provide fuel at the

fuel pump intake during all driving conditions, espe-

cially when low fuel levels are present.

FUEL TANK LEVEL SENSOR

DIAGNOSIS

This procedure test the resistance of the level sen-

sor itself. It does not test the level sensor circuit. Re-

fer to Group 8W, Wiring Diagrams for circuit

identification and Group 8E, Instrument Panel and

Gauges for fuel gauge information. The level sensor is a variable resistor. Its resis-

tance changes with the amount of fuel in the tank.

The float arm attached to the sensor moves as the

fuel level changes. To test the level sensor, connect

an ohmmeter across the sensor signal and sensor

ground terminals of the fuel level sensor connector

(Fig. 7 or Fig. 8). Move the float lever to the full stop

and empty stop positions shown in the resistance

chart (Fig. 7 or Fig. 8). Record the resistance at each

point. Replace the level sensor if the resistance is not

within specifications. The low fuel warning light specifications determine

if the level sensor portion of the warning light circuit

functions properly. It does not test the complete

warning light circuit. Refer to Group 8W, Wiring Diagrams for circuit

identification and Group 8E, Instrument Panel and

Gauges for fuel gauge information.

REMOVAL

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE SERVICING FUEL SYSTEM COMPONENTS.

WHEN SERVICING FLEXIBLE FUEL VEHICLES,

WEAR METHANOL RESISTANT GLOVES AND EYE

PROTECTION AND AVOID BREATHING FUMES. DO

NOT ALLOW METHANOL/GASOLINE MIXTURES TO

CONTACT SKIN. SERVICE VEHICLES IN WELL VEN-

TILATED AREAS AND AVOID IGNITION SOURCES.

NEVER SMOKE WHILE SERVICING THE VEHICLE.

Fig. 6 Fuel Reservoir

14 - 18 FUEL SYSTEMS Ä

Page 1764 of 2438

2.2L/2.5L SINGLE POINT FUEL INJECTIONÐSYSTEM OPERATION INDEX

page page

Air Conditioning (A/C) Clutch RelayÐPCM Output.28

Air Conditioning Switch SenseÐPCM Input ..... 26

Auto Shutdown (ASD) Relay and Fuel Pump RelayÐPCM Output ..................... 29

Battery VoltageÐPCM Input ................ 26

Brake SwitchÐPCM Input .................. 26

EVAP Canister Purge SolenoidÐPCM Output . . . 29

CCD Bus .............................. 25

Coolant Temperature SensorÐPCM Input ...... 26

Data Link ConnectorÐPCM Output ........... 30

Distributor (Hall Effect) Pick-UpÐPCM Input .... 26

Electric Electronic Gas RecirculationÐPCM Output.30

Fuel InjectorÐPCM Output ................. 31

Fuel Pressure Regulator ................... 33

General Information ....................... 24

Generator FieldÐPCM Output ............... 31

Heated Oxygen Sensor (O

2Sensor)ÐPCM Input . 27

Idle Air Control MotorÐPCM Output .......... 29 Ignition CoilÐPCM Output

.................. 31

Malfunction Indicator Lamp (Check Engine)ÐPCM Output ............................... 30

Manifold Absolute Pressure (MAP) SensorÐPCM Input ................................ 27

Modes of Operation ....................... 32

Part Throttle Unlock SolenoidÐPCM Output .... 31

Powertrain Control Module ................. 25

Radiator Fan RelayÐPCM Output ............ 31

Speed Control SolenoidsÐPCM Output ........ 31

Speed ControlÐPCM Input ................. 27

System Diagnosis ........................ 25

TachometerÐPCM Output .................. 32

Throttle Body ............................ 33

Throttle Position Sensor (TPS)ÐPCM Input ..... 28

Transaxle Park/Neutral SwitchÐPCM Input ..... 28

Vehicle Speed SensorÐPCM Input ........... 28

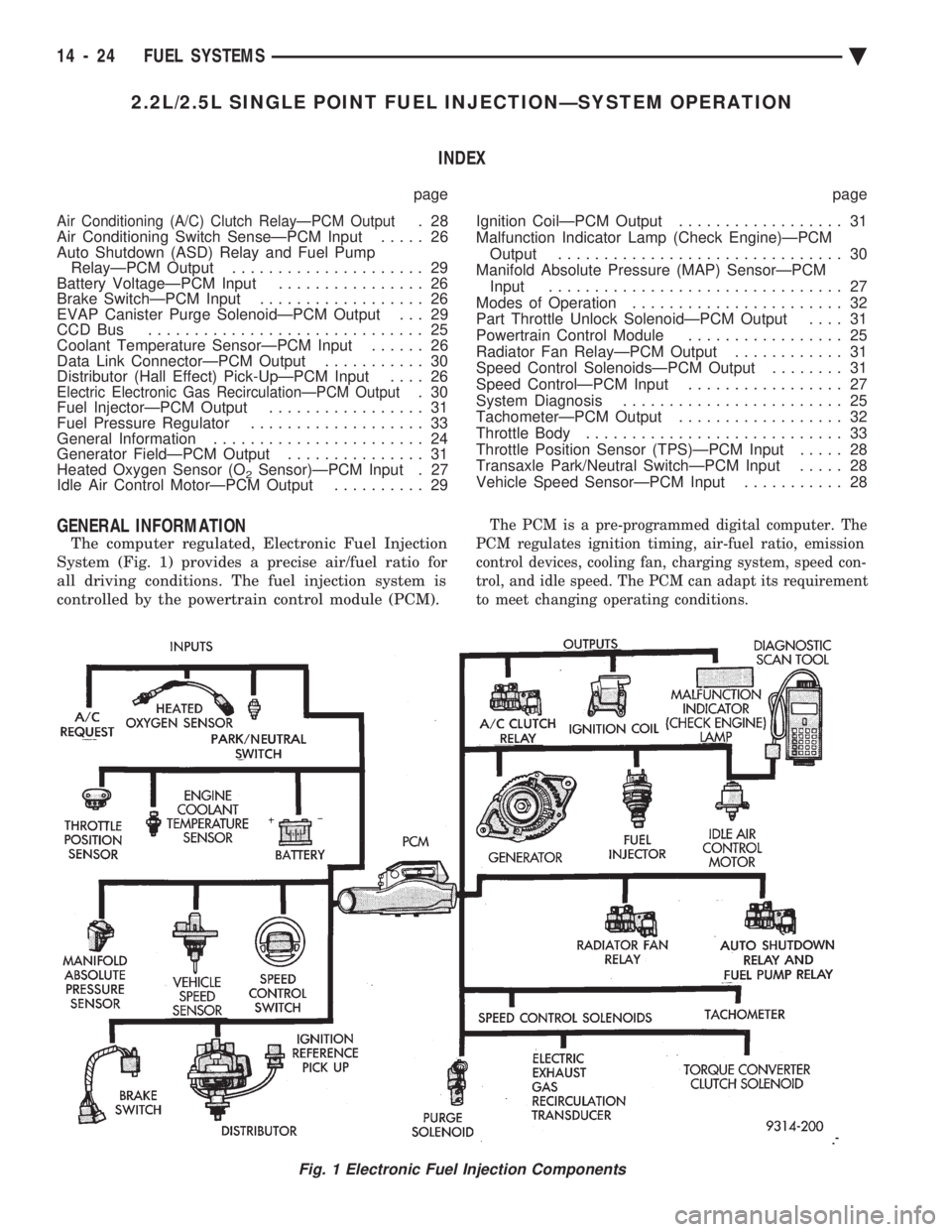

GENERAL INFORMATION

The computer regulated, Electronic Fuel Injection

System (Fig. 1) provides a precise air/fuel ratio for

all driving conditions. The fuel injection system is

controlled by the powertrain control module (PCM).

The PCM is a pre-programmed digital computer. The

PCM regulates ignition timing, air-fuel ratio, emission

control devices, cooling fan, charging system, speed con-

trol, and idle speed. The PCM can adapt its requirement

to meet changing operating conditions.

Fig. 1 Electronic Fuel Injection Components

14 - 24 FUEL SYSTEMS Ä

Page 1765 of 2438

Various sensors provide the inputs necessary for

the PCM to correctly regulate fuel flow at the fuel

injector. These include the manifold absolute pres-

sure, throttle position, oxygen sensor, coolant tem-

perature, and vehicle speed sensors. In addition to

the sensors, various switches and relays provide im-

portant information and system control. The inputs

include the park/neutral switch and air conditioning

clutch switch. The outputs include the auto shutdown

relay and fuel pump relay. All inputs to the PCM are converted into signals.

Based on these inputs the PCM adjusts air-fuel ratio,

ignition timing and other controlled outputs. The

PCM adjusts the air-fuel ratio by changing the injec-

tor pulse width. Injector pulse width is the period of

time the injector is energized.

SYSTEM DIAGNOSIS

The PCM tests many of its own input and output

circuits. If a fault is found in a major system, the in-

formation is stored in memory. Technicians can dis-

play fault information through the instrument panel

Malfunction Indicator lamp (instrument panel Check

Engine lamp) or by connecting the DRBII scan tool.

For diagnostic trouble code information, refer to On

Board Diagnostics in 2.2L/2.5L Single Point Fuel In-

jectionÐGeneral Diagnosis section of this group.

CCD BUS

Various modules exchange information through a

communications port called the CCD Bus. The pow-

ertrain control module (PCM) transmits vehicle load

data on the CCD Bus.

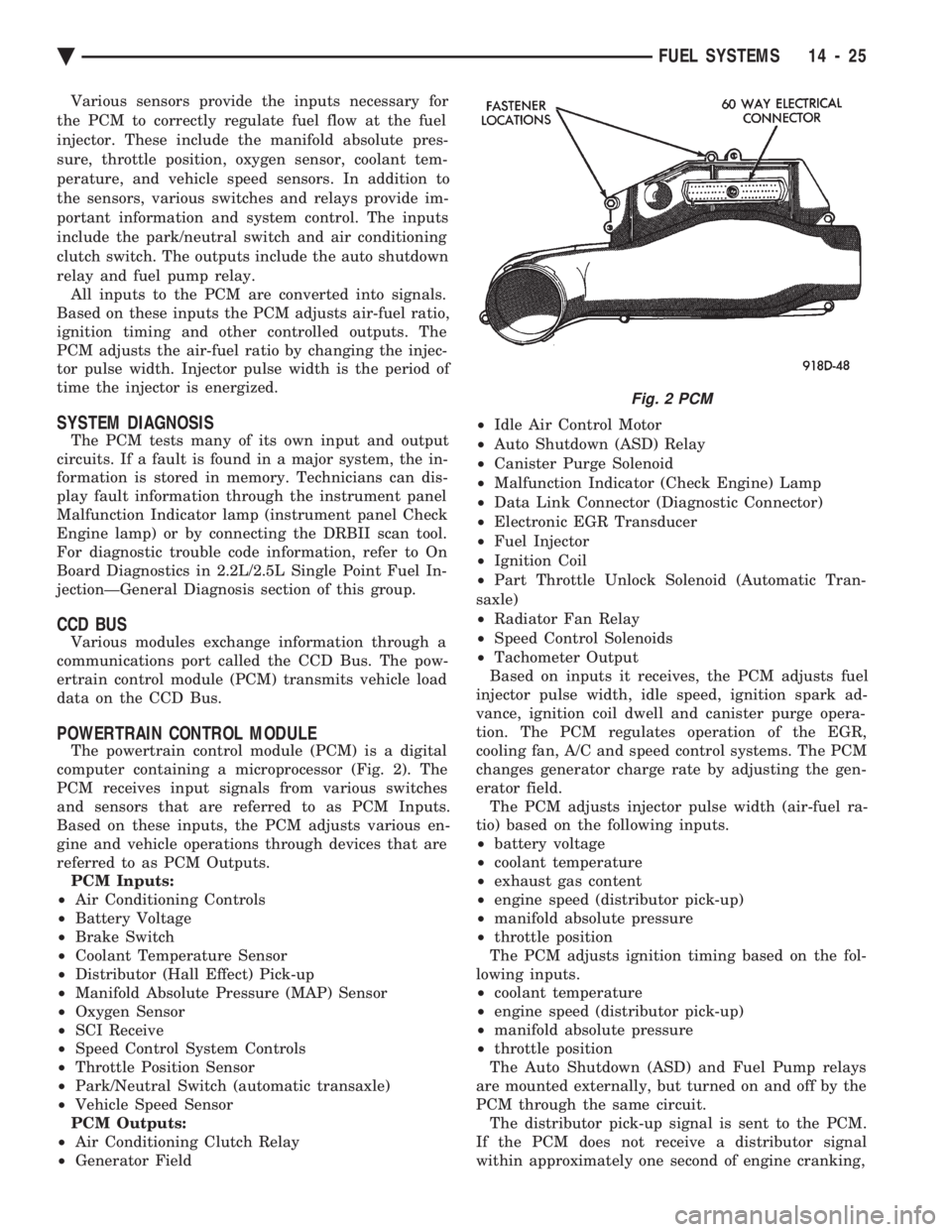

POWERTRAIN CONTROL MODULE

The powertrain control module (PCM) is a digital

computer containing a microprocessor (Fig. 2). The

PCM receives input signals from various switches

and sensors that are referred to as PCM Inputs.

Based on these inputs, the PCM adjusts various en-

gine and vehicle operations through devices that are

referred to as PCM Outputs. PCM Inputs:

² Air Conditioning Controls

² Battery Voltage

² Brake Switch

² Coolant Temperature Sensor

² Distributor (Hall Effect) Pick-up

² Manifold Absolute Pressure (MAP) Sensor

² Oxygen Sensor

² SCI Receive

² Speed Control System Controls

² Throttle Position Sensor

² Park/Neutral Switch (automatic transaxle)

² Vehicle Speed Sensor

PCM Outputs:

² Air Conditioning Clutch Relay

² Generator Field ²

Idle Air Control Motor

² Auto Shutdown (ASD) Relay

² Canister Purge Solenoid

² Malfunction Indicator (Check Engine) Lamp

² Data Link Connector (Diagnostic Connector)

² Electronic EGR Transducer

² Fuel Injector

² Ignition Coil

² Part Throttle Unlock Solenoid (Automatic Tran-

saxle)

² Radiator Fan Relay

² Speed Control Solenoids

² Tachometer Output

Based on inputs it receives, the PCM adjusts fuel

injector pulse width, idle speed, ignition spark ad-

vance, ignition coil dwell and canister purge opera-

tion. The PCM regulates operation of the EGR,

cooling fan, A/C and speed control systems. The PCM

changes generator charge rate by adjusting the gen-

erator field. The PCM adjusts injector pulse width (air-fuel ra-

tio) based on the following inputs.

² battery voltage

² coolant temperature

² exhaust gas content

² engine speed (distributor pick-up)

² manifold absolute pressure

² throttle position

The PCM adjusts ignition timing based on the fol-

lowing inputs.

² coolant temperature

² engine speed (distributor pick-up)

² manifold absolute pressure

² throttle position

The Auto Shutdown (ASD) and Fuel Pump relays

are mounted externally, but turned on and off by the

PCM through the same circuit. The distributor pick-up signal is sent to the PCM.

If the PCM does not receive a distributor signal

within approximately one second of engine cranking,

Fig. 2 PCM

Ä FUEL SYSTEMS 14 - 25

Page 1766 of 2438

it de-activates the ASD relay and fuel pump relay.

When these relays are deactivated, power is shut off

from the fuel injector, fuel pump, ignition coil, and

oxygen sensor heater element. The PCM contains a voltage converter that

changes battery voltage to a regulated 8.0 volts to

power the distributor pick-up and vehicle speed sen-

sor. The PCM also provides a 5.0 volts supply for the

coolant temperature sensor, manifold absolute pres-

sure sensor and throttle position sensor.

AIR CONDITIONING SWITCH SENSEÐPCM INPUT

ALL VEHICLES EXCEPT AC-BODY

When the air conditioning or defrost switch is put

in the ON position and the low pressure and high

pressure switches are closed, the PCM receives an in-

put indicating that the air conditioning has been se-

lected. After receiving this input, the PCM activates

the A/C compressor clutch by grounding the A/C

clutch relay. The PCM also adjusts idle speed to a

scheduled RPM to compensate for increased engine

load.

AC-BODY VEHICLES

When the air conditioning or defrost switch is put

in the ON position and the low pressure switch, high

pressure switch and electronic cycling switch close,

the PCM receives an air conditioning select input.

After receiving this input, the PCM activates the

A/C compressor clutch by grounding the A/C com-

pressor clutch relay. The PCM also adjusts idle speed

to a scheduled RPM to compensate for increased en-

gine load.

BATTERY VOLTAGEÐPCM INPUT

The PCM monitors the battery voltage input to de-

termine fuel injector pulse width and generator field

control. If battery voltage is low, the PCM increases

injector pulse width.

BRAKE SWITCHÐPCM INPUT

When the brake switch is activated, the PCM re-

ceives an input indicating that the brakes are being

applied. After receiving the input, the PCM vents the

speed control servo. Venting the servo turns the

speed control system off.

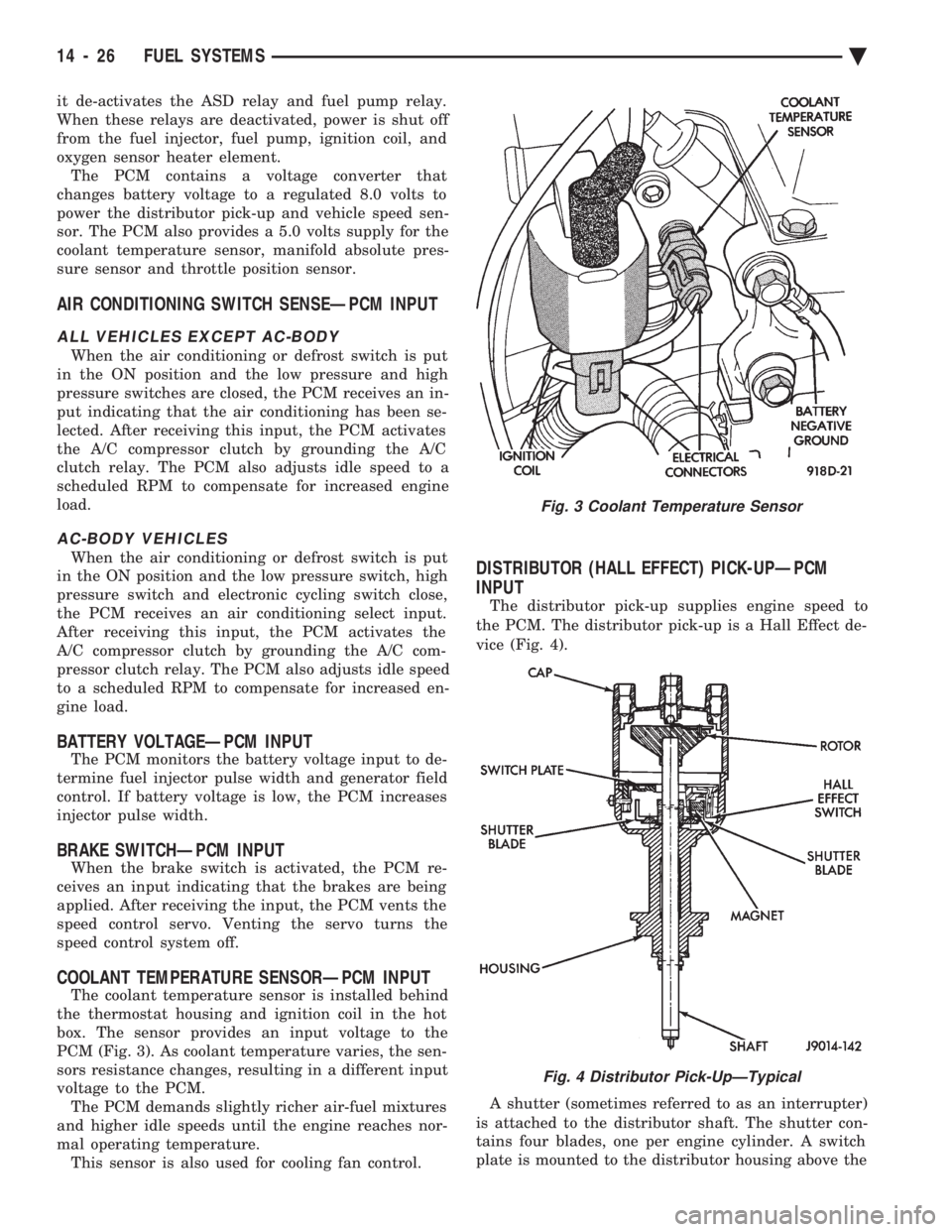

COOLANT TEMPERATURE SENSORÐPCM INPUT

The coolant temperature sensor is installed behind

the thermostat housing and ignition coil in the hot

box. The sensor provides an input voltage to the

PCM (Fig. 3). As coolant temperature varies, the sen-

sors resistance changes, resulting in a different input

voltage to the PCM. The PCM demands slightly richer air-fuel mixtures

and higher idle speeds until the engine reaches nor-

mal operating temperature. This sensor is also used for cooling fan control.

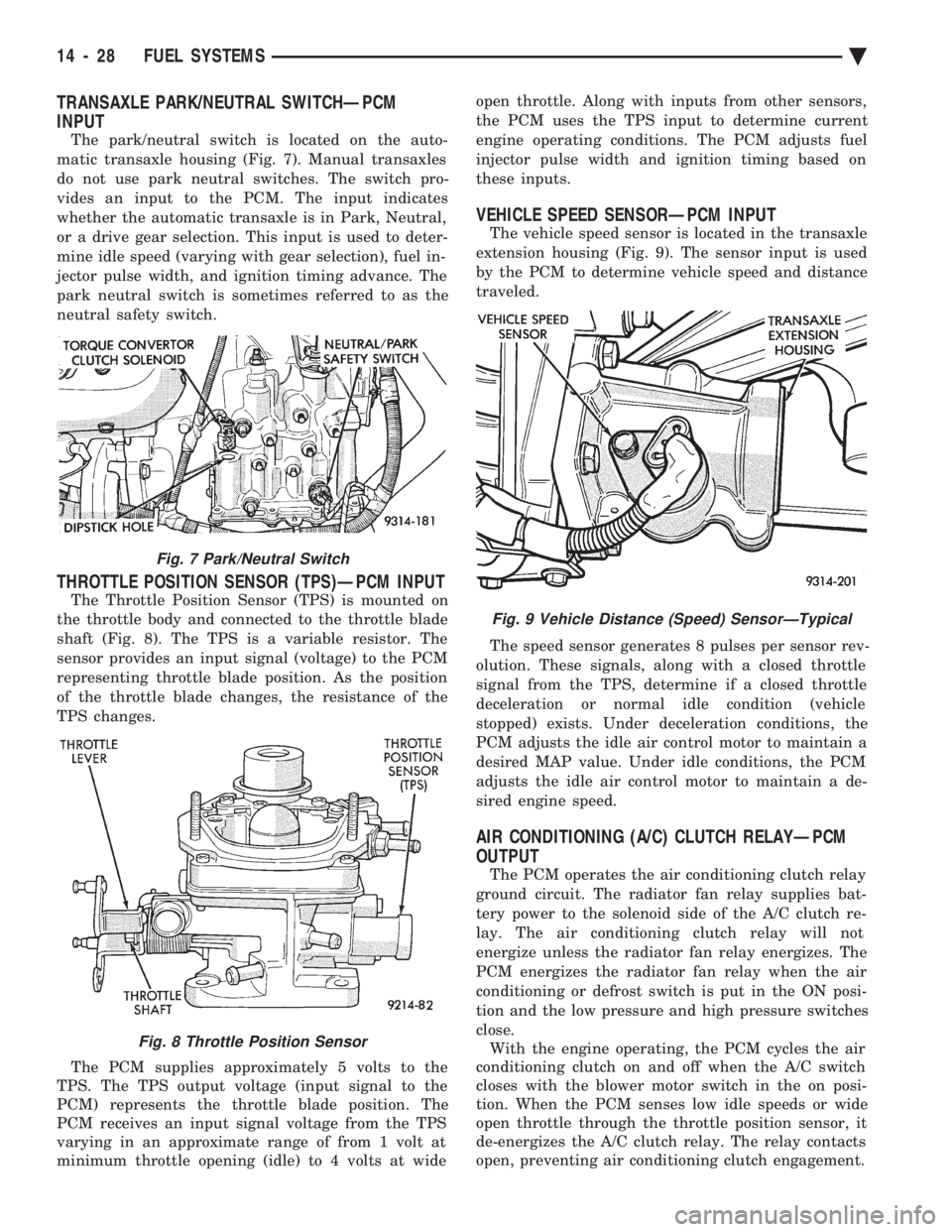

DISTRIBUTOR (HALL EFFECT) PICK-UPÐPCM

INPUT

The distributor pick-up supplies engine speed to

the PCM. The distributor pick-up is a Hall Effect de-

vice (Fig. 4).

A shutter (sometimes referred to as an interrupter)

is attached to the distributor shaft. The shutter con-

tains four blades, one per engine cylinder. A switch

plate is mounted to the distributor housing above the

Fig. 3 Coolant Temperature Sensor

Fig. 4 Distributor Pick-UpÐTypical

14 - 26 FUEL SYSTEMS Ä

Page 1768 of 2438

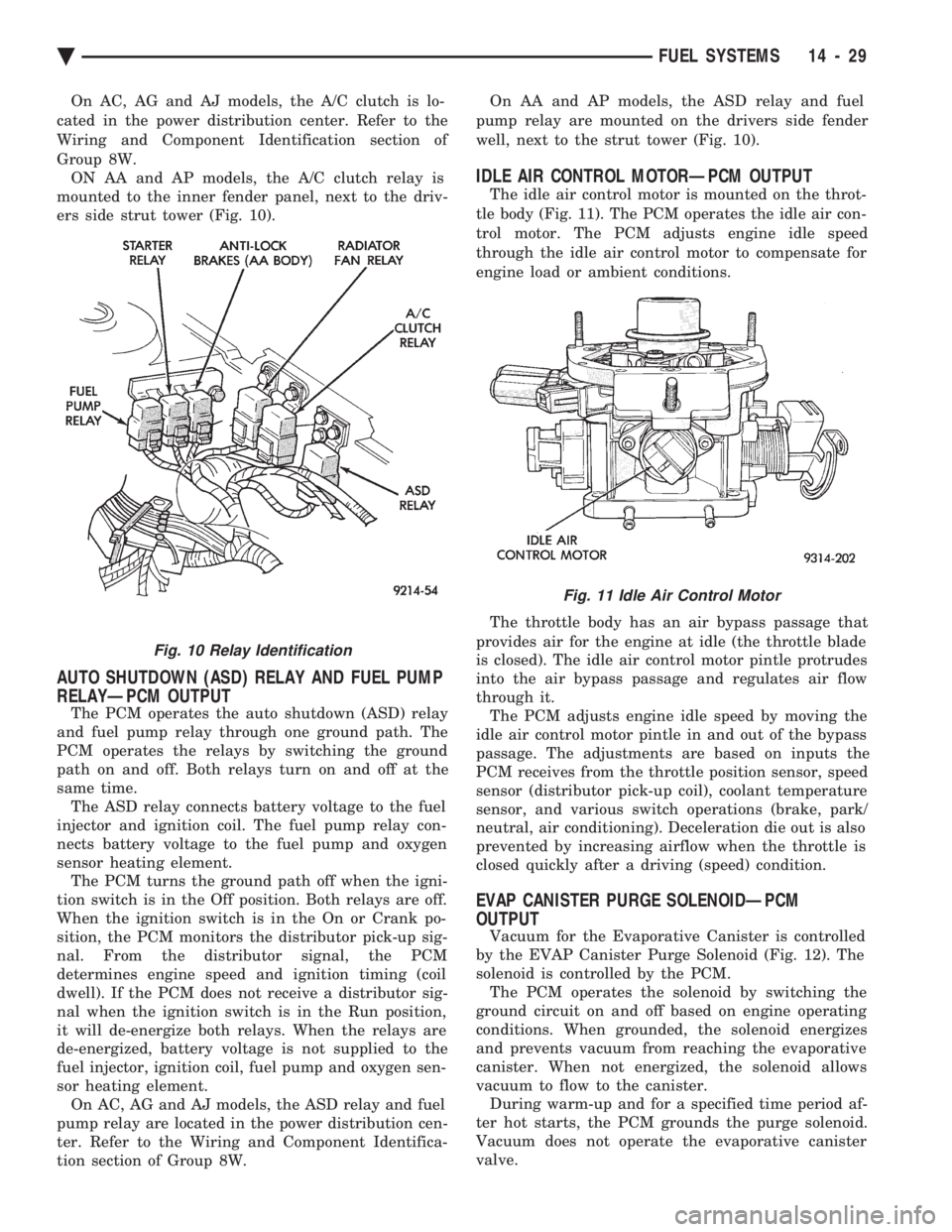

TRANSAXLE PARK/NEUTRAL SWITCHÐPCM

INPUT

The park/neutral switch is located on the auto-

matic transaxle housing (Fig. 7). Manual transaxles

do not use park neutral switches. The switch pro-

vides an input to the PCM. The input indicates

whether the automatic transaxle is in Park, Neutral,

or a drive gear selection. This input is used to deter-

mine idle speed (varying with gear selection), fuel in-

jector pulse width, and ignition timing advance. The

park neutral switch is sometimes referred to as the

neutral safety switch.

THROTTLE POSITION SENSOR (TPS)ÐPCM INPUT

The Throttle Position Sensor (TPS) is mounted on

the throttle body and connected to the throttle blade

shaft (Fig. 8). The TPS is a variable resistor. The

sensor provides an input signal (voltage) to the PCM

representing throttle blade position. As the position

of the throttle blade changes, the resistance of the

TPS changes.

The PCM supplies approximately 5 volts to the

TPS. The TPS output voltage (input signal to the

PCM) represents the throttle blade position. The

PCM receives an input signal voltage from the TPS

varying in an approximate range of from 1 volt at

minimum throttle opening (idle) to 4 volts at wide open throttle. Along with inputs from other sensors,

the PCM uses the TPS input to determine current

engine operating conditions. The PCM adjusts fuel

injector pulse width and ignition timing based on

these inputs.

VEHICLE SPEED SENSORÐPCM INPUT

The vehicle speed sensor is located in the transaxle

extension housing (Fig. 9). The sensor input is used

by the PCM to determine vehicle speed and distance

traveled.

The speed sensor generates 8 pulses per sensor rev-

olution. These signals, along with a closed throttle

signal from the TPS, determine if a closed throttle

deceleration or normal idle condition (vehicle

stopped) exists. Under deceleration conditions, the

PCM adjusts the idle air control motor to maintain a

desired MAP value. Under idle conditions, the PCM

adjusts the idle air control motor to maintain a de-

sired engine speed.

AIR CONDITIONING (A/C) CLUTCH RELAYÐPCM

OUTPUT

The PCM operates the air conditioning clutch relay

ground circuit. The radiator fan relay supplies bat-

tery power to the solenoid side of the A/C clutch re-

lay. The air conditioning clutch relay will not

energize unless the radiator fan relay energizes. The

PCM energizes the radiator fan relay when the air

conditioning or defrost switch is put in the ON posi-

tion and the low pressure and high pressure switches

close. With the engine operating, the PCM cycles the air

conditioning clutch on and off when the A/C switch

closes with the blower motor switch in the on posi-

tion. When the PCM senses low idle speeds or wide

open throttle through the throttle position sensor, it

de-energizes the A/C clutch relay. The relay contacts

open, preventing air conditioning clutch engagement.

Fig. 7 Park/Neutral Switch

Fig. 8 Throttle Position Sensor

Fig. 9 Vehicle Distance (Speed) SensorÐTypical

14 - 28 FUEL SYSTEMS Ä

Page 1769 of 2438

On AC, AG and AJ models, the A/C clutch is lo-

cated in the power distribution center. Refer to the

Wiring and Component Identification section of

Group 8W. ON AA and AP models, the A/C clutch relay is

mounted to the inner fender panel, next to the driv-

ers side strut tower (Fig. 10).

AUTO SHUTDOWN (ASD) RELAY AND FUEL PUMP

RELAYÐPCM OUTPUT

The PCM operates the auto shutdown (ASD) relay

and fuel pump relay through one ground path. The

PCM operates the relays by switching the ground

path on and off. Both relays turn on and off at the

same time. The ASD relay connects battery voltage to the fuel

injector and ignition coil. The fuel pump relay con-

nects battery voltage to the fuel pump and oxygen

sensor heating element. The PCM turns the ground path off when the igni-

tion switch is in the Off position. Both relays are off.

When the ignition switch is in the On or Crank po-

sition, the PCM monitors the distributor pick-up sig-

nal. From the distributor signal, the PCM

determines engine speed and ignition timing (coil

dwell). If the PCM does not receive a distributor sig-

nal when the ignition switch is in the Run position,

it will de-energize both relays. When the relays are

de-energized, battery voltage is not supplied to the

fuel injector, ignition coil, fuel pump and oxygen sen-

sor heating element. On AC, AG and AJ models, the ASD relay and fuel

pump relay are located in the power distribution cen-

ter. Refer to the Wiring and Component Identifica-

tion section of Group 8W. On AA and AP models, the ASD relay and fuel

pump relay are mounted on the drivers side fender

well, next to the strut tower (Fig. 10).

IDLE AIR CONTROL MOTORÐPCM OUTPUT

The idle air control motor is mounted on the throt-

tle body (Fig. 11). The PCM operates the idle air con-

trol motor. The PCM adjusts engine idle speed

through the idle air control motor to compensate for

engine load or ambient conditions.

The throttle body has an air bypass passage that

provides air for the engine at idle (the throttle blade

is closed). The idle air control motor pintle protrudes

into the air bypass passage and regulates air flow

through it. The PCM adjusts engine idle speed by moving the

idle air control motor pintle in and out of the bypass

passage. The adjustments are based on inputs the

PCM receives from the throttle position sensor, speed

sensor (distributor pick-up coil), coolant temperature

sensor, and various switch operations (brake, park/

neutral, air conditioning). Deceleration die out is also

prevented by increasing airflow when the throttle is

closed quickly after a driving (speed) condition.

EVAP CANISTER PURGE SOLENOIDÐPCM

OUTPUT

Vacuum for the Evaporative Canister is controlled

by the EVAP Canister Purge Solenoid (Fig. 12). The

solenoid is controlled by the PCM. The PCM operates the solenoid by switching the

ground circuit on and off based on engine operating

conditions. When grounded, the solenoid energizes

and prevents vacuum from reaching the evaporative

canister. When not energized, the solenoid allows

vacuum to flow to the canister. During warm-up and for a specified time period af-

ter hot starts, the PCM grounds the purge solenoid.

Vacuum does not operate the evaporative canister

valve.

Fig. 10 Relay Identification

Fig. 11 Idle Air Control Motor

Ä FUEL SYSTEMS 14 - 29

Page 1771 of 2438

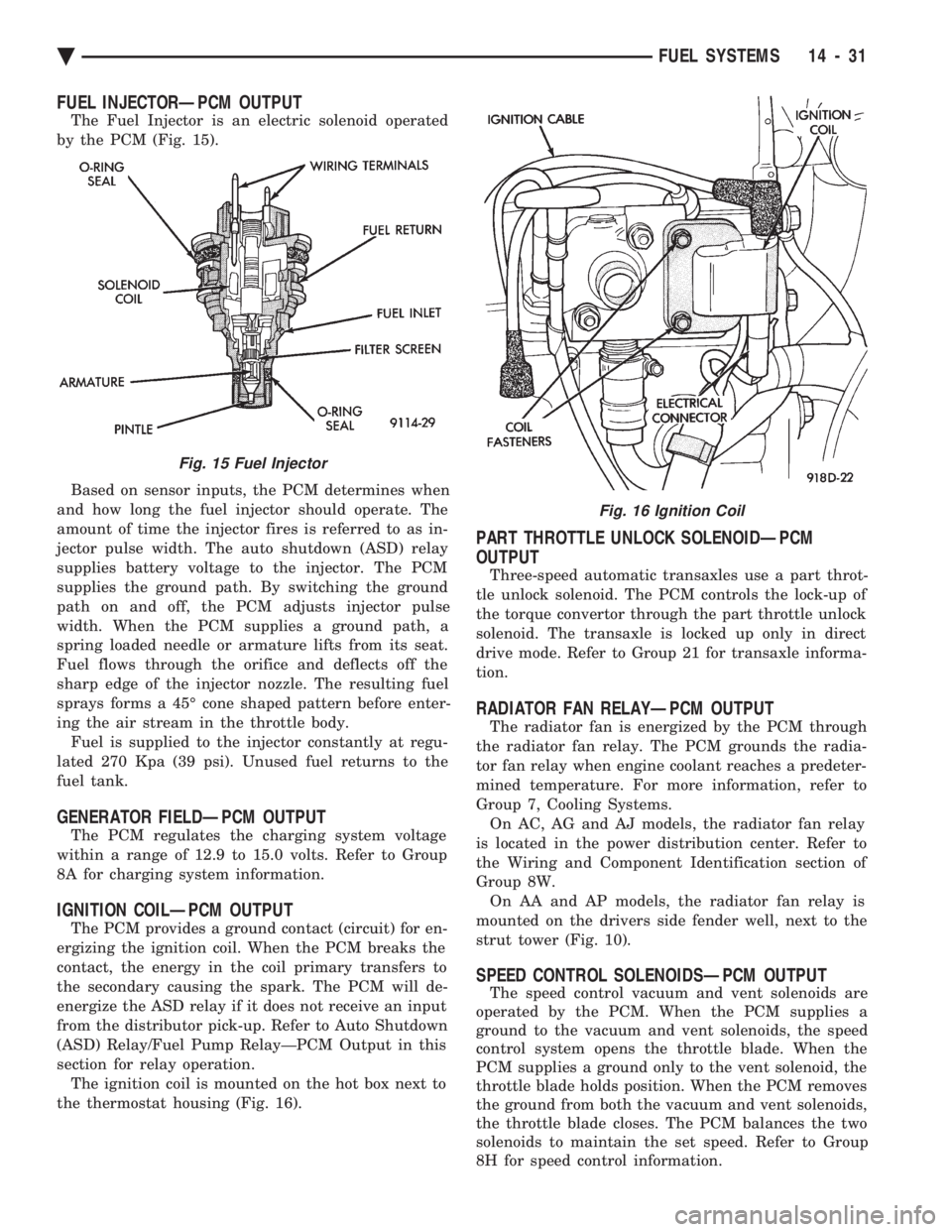

FUEL INJECTORÐPCM OUTPUT

The Fuel Injector is an electric solenoid operated

by the PCM (Fig. 15).

Based on sensor inputs, the PCM determines when

and how long the fuel injector should operate. The

amount of time the injector fires is referred to as in-

jector pulse width. The auto shutdown (ASD) relay

supplies battery voltage to the injector. The PCM

supplies the ground path. By switching the ground

path on and off, the PCM adjusts injector pulse

width. When the PCM supplies a ground path, a

spring loaded needle or armature lifts from its seat.

Fuel flows through the orifice and deflects off the

sharp edge of the injector nozzle. The resulting fuel

sprays forms a 45É cone shaped pattern before enter-

ing the air stream in the throttle body. Fuel is supplied to the injector constantly at regu-

lated 270 Kpa (39 psi). Unused fuel returns to the

fuel tank.

GENERATOR FIELDÐPCM OUTPUT

The PCM regulates the charging system voltage

within a range of 12.9 to 15.0 volts. Refer to Group

8A for charging system information.

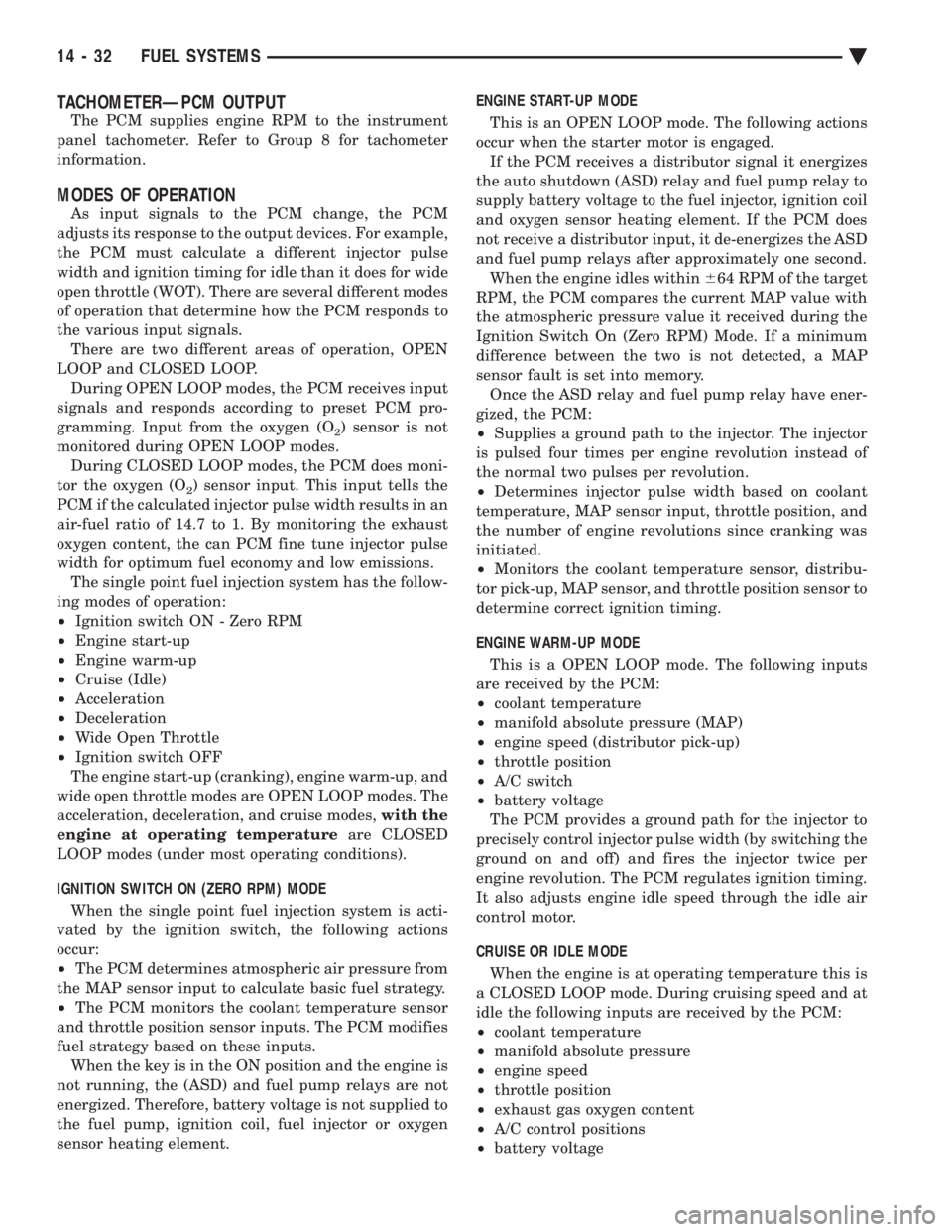

IGNITION COILÐPCM OUTPUT

The PCM provides a ground contact (circuit) for en-

ergizing the ignition coil. When the PCM breaks the

contact, the energy in the coil primary transfers to

the secondary causing the spark. The PCM will de-

energize the ASD relay if it does not receive an input

from the distributor pick-up. Refer to Auto Shutdown

(ASD) Relay/Fuel Pump RelayÐPCM Output in this

section for relay operation. The ignition coil is mounted on the hot box next to

the thermostat housing (Fig. 16).

PART THROTTLE UNLOCK SOLENOIDÐPCM

OUTPUT

Three-speed automatic transaxles use a part throt-

tle unlock solenoid. The PCM controls the lock-up of

the torque convertor through the part throttle unlock

solenoid. The transaxle is locked up only in direct

drive mode. Refer to Group 21 for transaxle informa-

tion.

RADIATOR FAN RELAYÐPCM OUTPUT

The radiator fan is energized by the PCM through

the radiator fan relay. The PCM grounds the radia-

tor fan relay when engine coolant reaches a predeter-

mined temperature. For more information, refer to

Group 7, Cooling Systems. On AC, AG and AJ models, the radiator fan relay

is located in the power distribution center. Refer to

the Wiring and Component Identification section of

Group 8W. On AA and AP models, the radiator fan relay is

mounted on the drivers side fender well, next to the

strut tower (Fig. 10).

SPEED CONTROL SOLENOIDSÐPCM OUTPUT

The speed control vacuum and vent solenoids are

operated by the PCM. When the PCM supplies a

ground to the vacuum and vent solenoids, the speed

control system opens the throttle blade. When the

PCM supplies a ground only to the vent solenoid, the

throttle blade holds position. When the PCM removes

the ground from both the vacuum and vent solenoids,

the throttle blade closes. The PCM balances the two

solenoids to maintain the set speed. Refer to Group

8H for speed control information.

Fig. 15 Fuel Injector

Fig. 16 Ignition Coil

Ä FUEL SYSTEMS 14 - 31

Page 1772 of 2438

TACHOMETERÐPCM OUTPUT

The PCM supplies engine RPM to the instrument

panel tachometer. Refer to Group 8 for tachometer

information.

MODES OF OPERATION

As input signals to the PCM change, the PCM

adjusts its response to the output devices. For example,

the PCM must calculate a different injector pulse

width and ignition timing for idle than it does for wide

open throttle (WOT). There are several different modes

of operation that determine how the PCM responds to

the various input signals. There are two different areas of operation, OPEN

LOOP and CLOSED LOOP. During OPEN LOOP modes, the PCM receives input

signals and responds according to preset PCM pro-

gramming. Input from the oxygen (O

2) sensor is not

monitored during OPEN LOOP modes. During CLOSED LOOP modes, the PCM does moni-

tor the oxygen (O

2) sensor input. This input tells the

PCM if the calculated injector pulse width results in an

air-fuel ratio of 14.7 to 1. By monitoring the exhaust

oxygen content, the can PCM fine tune injector pulse

width for optimum fuel economy and low emissions. The single point fuel injection system has the follow-

ing modes of operation:

² Ignition switch ON - Zero RPM

² Engine start-up

² Engine warm-up

² Cruise (Idle)

² Acceleration

² Deceleration

² Wide Open Throttle

² Ignition switch OFF

The engine start-up (cranking), engine warm-up, and

wide open throttle modes are OPEN LOOP modes. The

acceleration, deceleration, and cruise modes, with the

engine at operating temperature are CLOSED

LOOP modes (under most operating conditions).

IGNITION SWITCH ON (ZERO RPM) MODE

When the single point fuel injection system is acti-

vated by the ignition switch, the following actions

occur:

² The PCM determines atmospheric air pressure from

the MAP sensor input to calculate basic fuel strategy.

² The PCM monitors the coolant temperature sensor

and throttle position sensor inputs. The PCM modifies

fuel strategy based on these inputs. When the key is in the ON position and the engine is

not running, the (ASD) and fuel pump relays are not

energized. Therefore, battery voltage is not supplied to

the fuel pump, ignition coil, fuel injector or oxygen

sensor heating element. ENGINE START-UP MODE

This is an OPEN LOOP mode. The following actions

occur when the starter motor is engaged. If the PCM receives a distributor signal it energizes

the auto shutdown (ASD) relay and fuel pump relay to

supply battery voltage to the fuel injector, ignition coil

and oxygen sensor heating element. If the PCM does

not receive a distributor input, it de-energizes the ASD

and fuel pump relays after approximately one second. When the engine idles within 664 RPM of the target

RPM, the PCM compares the current MAP value with

the atmospheric pressure value it received during the

Ignition Switch On (Zero RPM) Mode. If a minimum

difference between the two is not detected, a MAP

sensor fault is set into memory. Once the ASD relay and fuel pump relay have ener-

gized, the PCM:

² Supplies a ground path to the injector. The injector

is pulsed four times per engine revolution instead of

the normal two pulses per revolution.

² Determines injector pulse width based on coolant

temperature, MAP sensor input, throttle position, and

the number of engine revolutions since cranking was

initiated.

² Monitors the coolant temperature sensor, distribu-

tor pick-up, MAP sensor, and throttle position sensor to

determine correct ignition timing.

ENGINE WARM-UP MODE

This is a OPEN LOOP mode. The following inputs

are received by the PCM:

² coolant temperature

² manifold absolute pressure (MAP)

² engine speed (distributor pick-up)

² throttle position

² A/C switch

² battery voltage

The PCM provides a ground path for the injector to

precisely control injector pulse width (by switching the

ground on and off) and fires the injector twice per

engine revolution. The PCM regulates ignition timing.

It also adjusts engine idle speed through the idle air

control motor.

CRUISE OR IDLE MODE

When the engine is at operating temperature this is

a CLOSED LOOP mode. During cruising speed and at

idle the following inputs are received by the PCM:

² coolant temperature

² manifold absolute pressure

² engine speed

² throttle position

² exhaust gas oxygen content

² A/C control positions

² battery voltage

14 - 32 FUEL SYSTEMS Ä