relay CHEVROLET DYNASTY 1993 Service Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 1823 of 2438

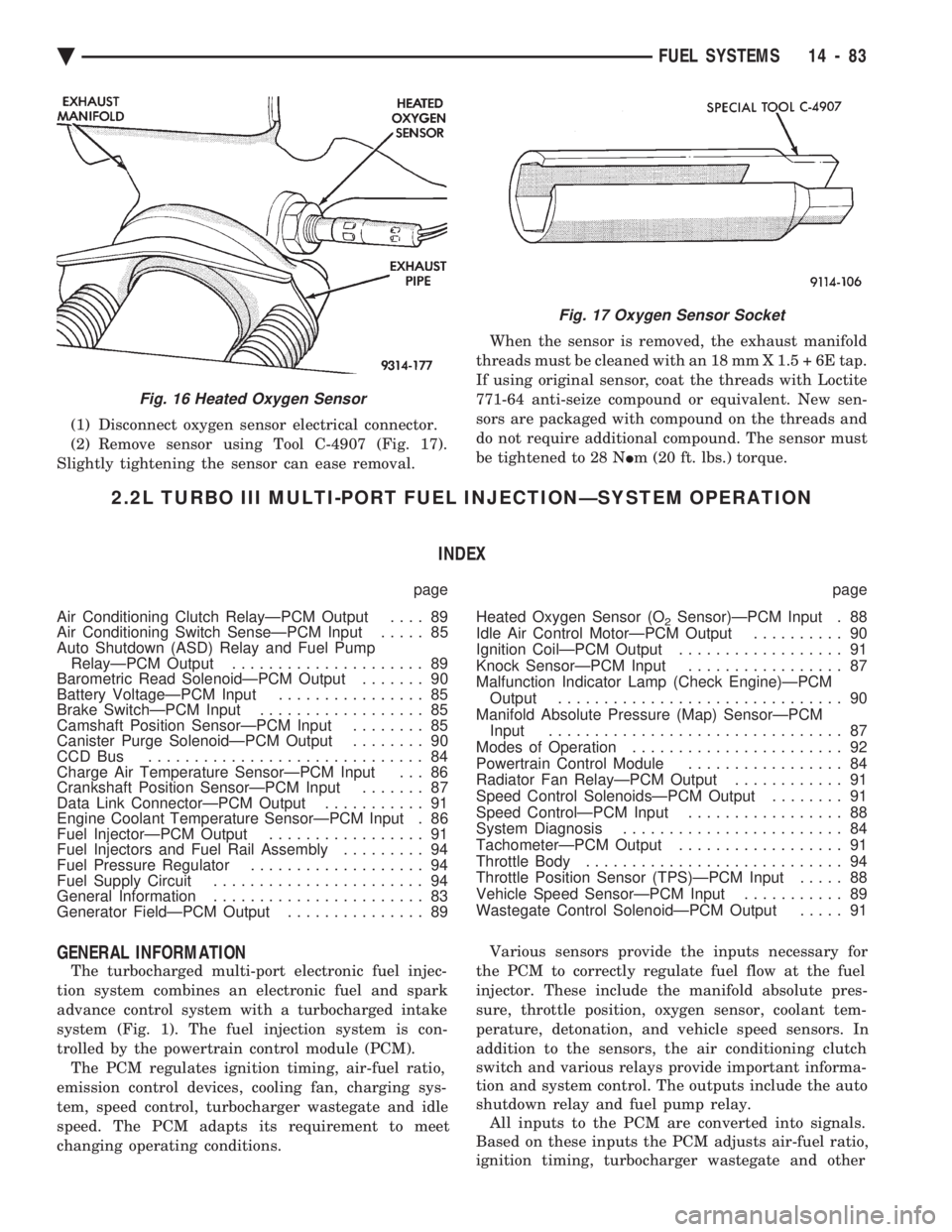

(1) Disconnect oxygen sensor electrical connector.

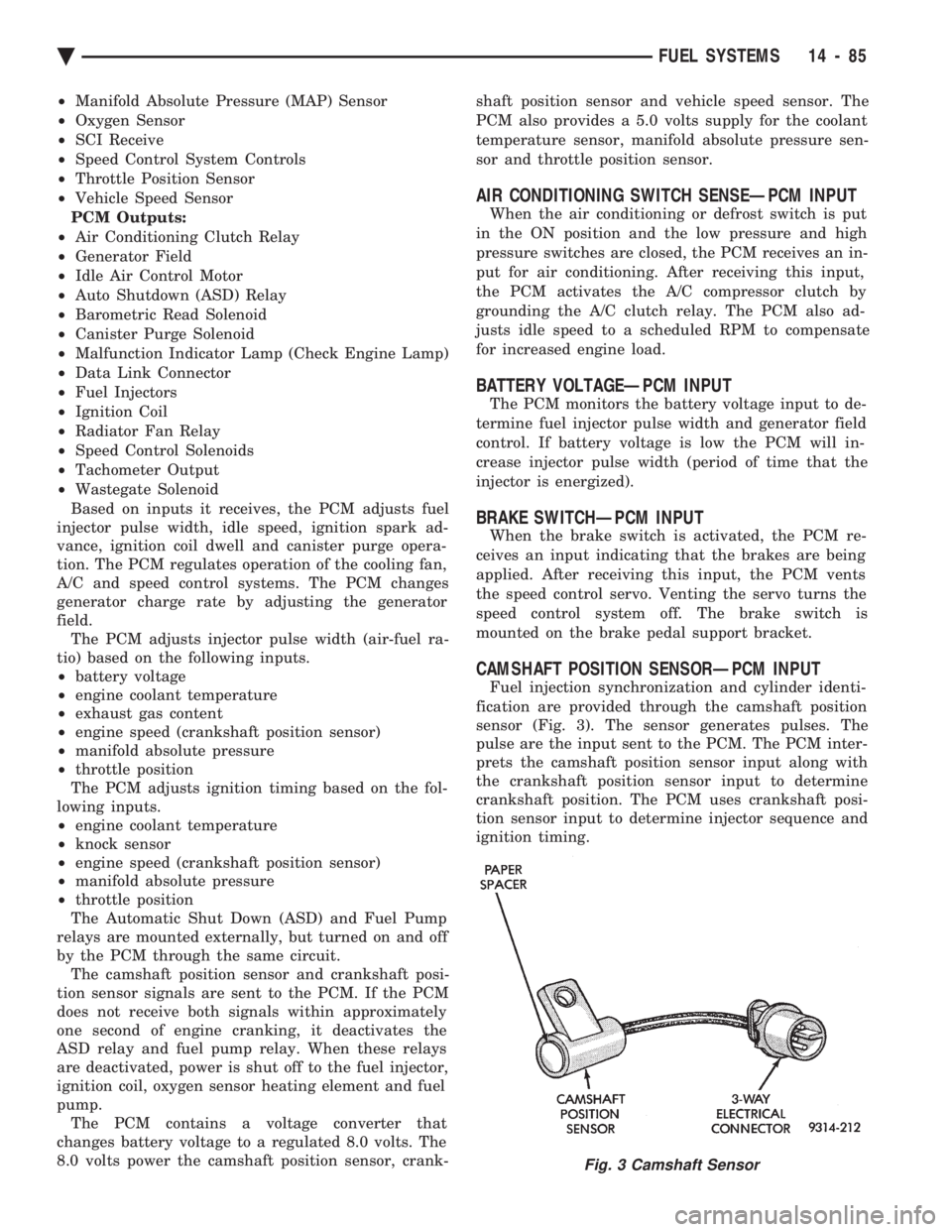

(2) Remove sensor using Tool C-4907 (Fig. 17).

Slightly tightening the sensor can ease removal. When the sensor is removed, the exhaust manifold

threads must be cleaned with an 18 mm X 1.5 + 6E tap.

If using original sensor, coat the threads with Loctite

771-64 anti-seize compound or equivalent. New sen-

sors are packaged with compound on the threads and

do not require additional compound. The sensor must

be tightened to 28 N Im (20 ft. lbs.) torque.

2.2L TURBO III MULTI-PORT FUEL INJECTIONÐSYSTEM OPERATION

INDEX

page page

Air Conditioning Clutch RelayÐPCM Output .... 89

Air Conditioning Switch SenseÐPCM Input ..... 85

Auto Shutdown (ASD) Relay and Fuel Pump RelayÐPCM Output ..................... 89

Barometric Read SolenoidÐPCM Output ....... 90

Battery VoltageÐPCM Input ................ 85

Brake SwitchÐPCM Input .................. 85

Camshaft Position SensorÐPCM Input ........ 85

Canister Purge SolenoidÐPCM Output ........ 90

CCD Bus .............................. 84

Charge Air Temperature SensorÐPCM Input . . . 86

Crankshaft Position SensorÐPCM Input ....... 87

Data Link ConnectorÐPCM Output ........... 91

Engine Coolant Temperature SensorÐPCM Input . 86

Fuel InjectorÐPCM Output ................. 91

Fuel Injectors and Fuel Rail Assembly ......... 94

Fuel Pressure Regulator ................... 94

Fuel Supply Circuit ....................... 94

General Information ....................... 83

Generator FieldÐPCM Output ............... 89 Heated Oxygen Sensor (O

2Sensor)ÐPCM Input . 88

Idle Air Control MotorÐPCM Output .......... 90

Ignition CoilÐPCM Output .................. 91

Knock SensorÐPCM Input ................. 87

Malfunction Indicator Lamp (Check Engine)ÐPCM Output ............................... 90

Manifold Absolute Pressure (Map) SensorÐPCM Input ................................ 87

Modes of Operation ....................... 92

Powertrain Control Module ................. 84

Radiator Fan RelayÐPCM Output ............ 91

Speed Control SolenoidsÐPCM Output ........ 91

Speed ControlÐPCM Input ................. 88

System Diagnosis ........................ 84

TachometerÐPCM Output .................. 91

Throttle Body ............................ 94

Throttle Position Sensor (TPS)ÐPCM Input ..... 88

Vehicle Speed SensorÐPCM Input ........... 89

Wastegate Control SolenoidÐPCM Output ..... 91

GENERAL INFORMATION

The turbocharged multi-port electronic fuel injec-

tion system combines an electronic fuel and spark

advance control system with a turbocharged intake

system (Fig. 1). The fuel injection system is con-

trolled by the powertrain control module (PCM). The PCM regulates ignition timing, air-fuel ratio,

emission control devices, cooling fan, charging sys-

tem, speed control, turbocharger wastegate and idle

speed. The PCM adapts its requirement to meet

changing operating conditions. Various sensors provide the inputs necessary for

the PCM to correctly regulate fuel flow at the fuel

injector. These include the manifold absolute pres-

sure, throttle position, oxygen sensor, coolant tem-

perature, detonation, and vehicle speed sensors. In

addition to the sensors, the air conditioning clutch

switch and various relays provide important informa-

tion and system control. The outputs include the auto

shutdown relay and fuel pump relay. All inputs to the PCM are converted into signals.

Based on these inputs the PCM adjusts air-fuel ratio,

ignition timing, turbocharger wastegate and other

Fig. 16 Heated Oxygen Sensor

Fig. 17 Oxygen Sensor Socket

Ä FUEL SYSTEMS 14 - 83

Page 1825 of 2438

² Manifold Absolute Pressure (MAP) Sensor

² Oxygen Sensor

² SCI Receive

² Speed Control System Controls

² Throttle Position Sensor

² Vehicle Speed Sensor

PCM Outputs:

² Air Conditioning Clutch Relay

² Generator Field

² Idle Air Control Motor

² Auto Shutdown (ASD) Relay

² Barometric Read Solenoid

² Canister Purge Solenoid

² Malfunction Indicator Lamp (Check Engine Lamp)

² Data Link Connector

² Fuel Injectors

² Ignition Coil

² Radiator Fan Relay

² Speed Control Solenoids

² Tachometer Output

² Wastegate Solenoid

Based on inputs it receives, the PCM adjusts fuel

injector pulse width, idle speed, ignition spark ad-

vance, ignition coil dwell and canister purge opera-

tion. The PCM regulates operation of the cooling fan,

A/C and speed control systems. The PCM changes

generator charge rate by adjusting the generator

field. The PCM adjusts injector pulse width (air-fuel ra-

tio) based on the following inputs.

² battery voltage

² engine coolant temperature

² exhaust gas content

² engine speed (crankshaft position sensor)

² manifold absolute pressure

² throttle position

The PCM adjusts ignition timing based on the fol-

lowing inputs.

² engine coolant temperature

² knock sensor

² engine speed (crankshaft position sensor)

² manifold absolute pressure

² throttle position

The Automatic Shut Down (ASD) and Fuel Pump

relays are mounted externally, but turned on and off

by the PCM through the same circuit. The camshaft position sensor and crankshaft posi-

tion sensor signals are sent to the PCM. If the PCM

does not receive both signals within approximately

one second of engine cranking, it deactivates the

ASD relay and fuel pump relay. When these relays

are deactivated, power is shut off to the fuel injector,

ignition coil, oxygen sensor heating element and fuel

pump. The PCM contains a voltage converter that

changes battery voltage to a regulated 8.0 volts. The

8.0 volts power the camshaft position sensor, crank- shaft position sensor and vehicle speed sensor. The

PCM also provides a 5.0 volts supply for the coolant

temperature sensor, manifold absolute pressure sen-

sor and throttle position sensor.

AIR CONDITIONING SWITCH SENSEÐPCM INPUT

When the air conditioning or defrost switch is put

in the ON position and the low pressure and high

pressure switches are closed, the PCM receives an in-

put for air conditioning. After receiving this input,

the PCM activates the A/C compressor clutch by

grounding the A/C clutch relay. The PCM also ad-

justs idle speed to a scheduled RPM to compensate

for increased engine load.

BATTERY VOLTAGEÐPCM INPUT

The PCM monitors the battery voltage input to de-

termine fuel injector pulse width and generator field

control. If battery voltage is low the PCM will in-

crease injector pulse width (period of time that the

injector is energized).

BRAKE SWITCHÐPCM INPUT

When the brake switch is activated, the PCM re-

ceives an input indicating that the brakes are being

applied. After receiving this input, the PCM vents

the speed control servo. Venting the servo turns the

speed control system off. The brake switch is

mounted on the brake pedal support bracket.

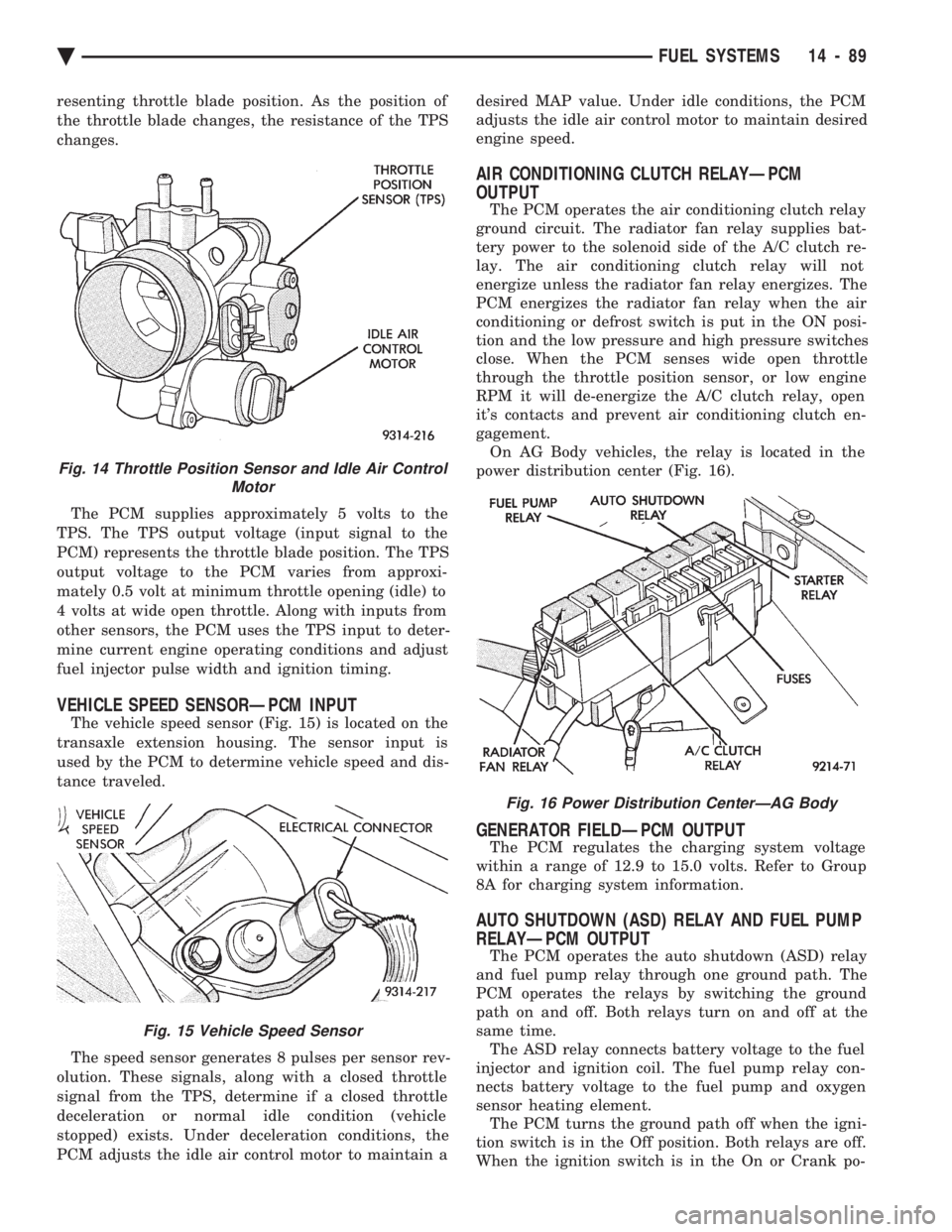

CAMSHAFT POSITION SENSORÐPCM INPUT

Fuel injection synchronization and cylinder identi-

fication are provided through the camshaft position

sensor (Fig. 3). The sensor generates pulses. The

pulse are the input sent to the PCM. The PCM inter-

prets the camshaft position sensor input along with

the crankshaft position sensor input to determine

crankshaft position. The PCM uses crankshaft posi-

tion sensor input to determine injector sequence and

ignition timing.

Fig. 3 Camshaft Sensor

Ä FUEL SYSTEMS 14 - 85

Page 1829 of 2438

resenting throttle blade position. As the position of

the throttle blade changes, the resistance of the TPS

changes. The PCM supplies approximately 5 volts to the

TPS. The TPS output voltage (input signal to the

PCM) represents the throttle blade position. The TPS

output voltage to the PCM varies from approxi-

mately 0.5 volt at minimum throttle opening (idle) to

4 volts at wide open throttle. Along with inputs from

other sensors, the PCM uses the TPS input to deter-

mine current engine operating conditions and adjust

fuel injector pulse width and ignition timing.

VEHICLE SPEED SENSORÐPCM INPUT

The vehicle speed sensor (Fig. 15) is located on the

transaxle extension housing. The sensor input is

used by the PCM to determine vehicle speed and dis-

tance traveled.

The speed sensor generates 8 pulses per sensor rev-

olution. These signals, along with a closed throttle

signal from the TPS, determine if a closed throttle

deceleration or normal idle condition (vehicle

stopped) exists. Under deceleration conditions, the

PCM adjusts the idle air control motor to maintain a desired MAP value. Under idle conditions, the PCM

adjusts the idle air control motor to maintain desired

engine speed.

AIR CONDITIONING CLUTCH RELAYÐPCM

OUTPUT

The PCM operates the air conditioning clutch relay

ground circuit. The radiator fan relay supplies bat-

tery power to the solenoid side of the A/C clutch re-

lay. The air conditioning clutch relay will not

energize unless the radiator fan relay energizes. The

PCM energizes the radiator fan relay when the air

conditioning or defrost switch is put in the ON posi-

tion and the low pressure and high pressure switches

close. When the PCM senses wide open throttle

through the throttle position sensor, or low engine

RPM it will de-energize the A/C clutch relay, open

it's contacts and prevent air conditioning clutch en-

gagement. On AG Body vehicles, the relay is located in the

power distribution center (Fig. 16).

GENERATOR FIELDÐPCM OUTPUT

The PCM regulates the charging system voltage

within a range of 12.9 to 15.0 volts. Refer to Group

8A for charging system information.

AUTO SHUTDOWN (ASD) RELAY AND FUEL PUMP

RELAYÐPCM OUTPUT

The PCM operates the auto shutdown (ASD) relay

and fuel pump relay through one ground path. The

PCM operates the relays by switching the ground

path on and off. Both relays turn on and off at the

same time. The ASD relay connects battery voltage to the fuel

injector and ignition coil. The fuel pump relay con-

nects battery voltage to the fuel pump and oxygen

sensor heating element. The PCM turns the ground path off when the igni-

tion switch is in the Off position. Both relays are off.

When the ignition switch is in the On or Crank po-

Fig. 14 Throttle Position Sensor and Idle Air Control Motor

Fig. 15 Vehicle Speed Sensor

Fig. 16 Power Distribution CenterÐAG Body

Ä FUEL SYSTEMS 14 - 89

Page 1830 of 2438

sition, the PCM monitors the crankshaft position and

camshaft position sensor signals to determine engine

speed and ignition timing (coil dwell). If the PCM

does not receive the crankshaft position sensor and

camshaft position sensor signals when the ignition

switch is in the Run position, it de-energizes both re-

lays. When the relays are de-energized, battery volt-

age is not supplied to the fuel injector, ignition coil,

fuel pump and oxygen sensor heating element. The ASD relay and fuel pump relay are located in

the power distribution center (Fig. 16).

IDLE AIR CONTROL MOTORÐPCM OUTPUT

The idle air control motor is mounted on the throt-

tle body (Fig. 14). The PCM operates the motor. The

PCM adjusts engine idle speed through the idle air

control motor to compensate for engine load or ambi-

ent conditions. The throttle body has an air bypass passage that

provides air for the engine at idle (the throttle blade

is closed). The idle air control motor pintle protrudes

into the air bypass passage and regulates air flow

through it. The PCM adjusts engine idle speed by moving the

idle air control motor pintle in and out of the bypass

passage. The adjustments are based on inputs the

PCM receives. The inputs are from the throttle posi-

tion sensor, camshaft position sensor, crankshaft po-

sition sensor, coolant temperature sensor, and

various switch operations (brake and air condition-

ing). Deceleration die out is also prevented by in-

creasing airflow when the throttle is closed quickly

after a driving (speed) condition.

BAROMETRIC READ SOLENOIDÐPCM OUTPUT

The barometric pressure read solenoid is spliced

into the manifold absolute pressure (MAP) sensor

vacuum hose (Fig. 12). The barometric read solenoid

switches the pressure supply to the MAP sensor from

either barometric pressure (atmospheric) or manifold

vacuum. The PCM operates the solenoid. Atmospheric pressure is periodically supplied to

the MAP sensor to measure barometric pressure.

This occurs at closed throttle, once per throttle clo-

sure but no more often than once every 3 minutes

and within a specified RPM band. Barometric infor-

mation is used primarily for boost control and start

fuel enrichment at various altitudes.

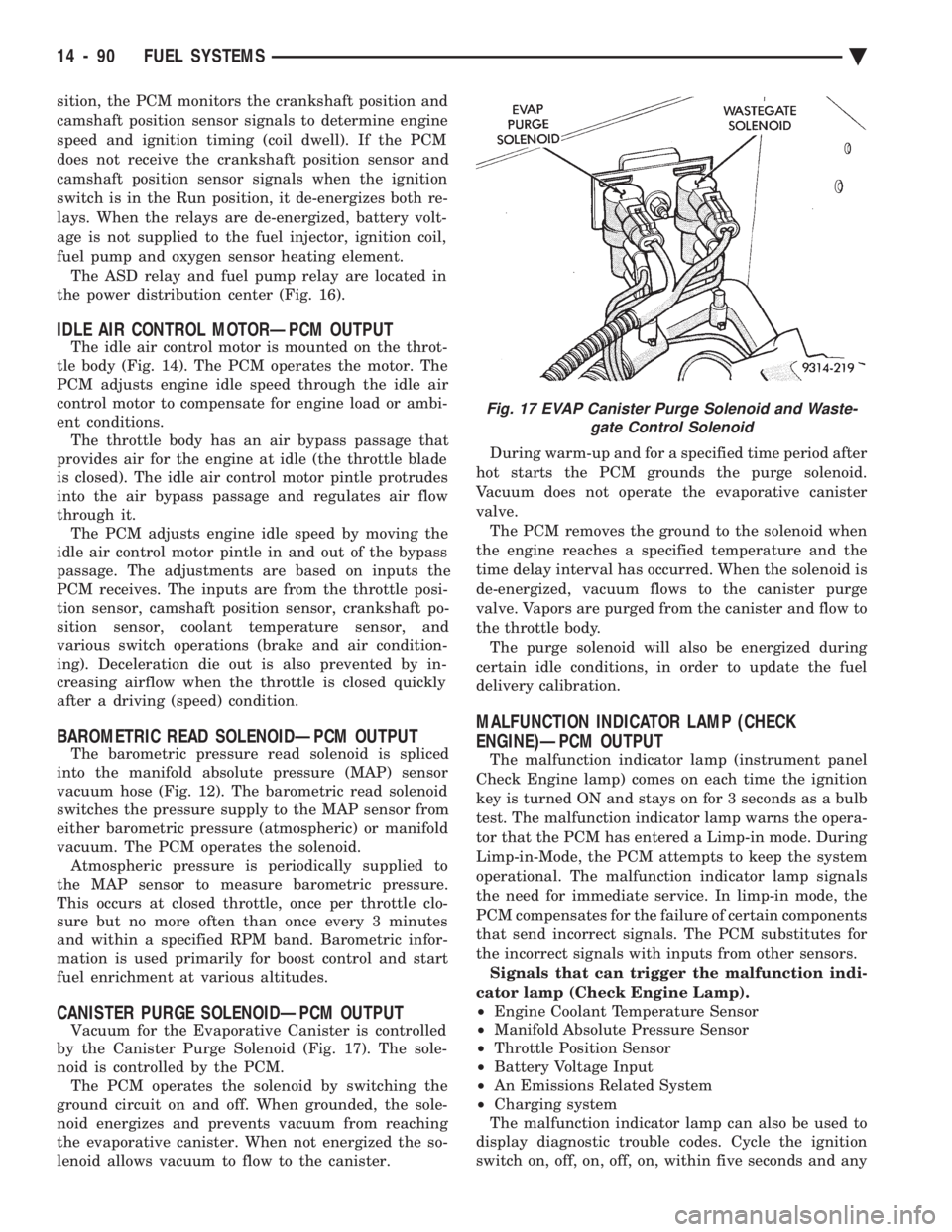

CANISTER PURGE SOLENOIDÐPCM OUTPUT

Vacuum for the Evaporative Canister is controlled

by the Canister Purge Solenoid (Fig. 17). The sole-

noid is controlled by the PCM. The PCM operates the solenoid by switching the

ground circuit on and off. When grounded, the sole-

noid energizes and prevents vacuum from reaching

the evaporative canister. When not energized the so-

lenoid allows vacuum to flow to the canister. During warm-up and for a specified time period after

hot starts the PCM grounds the purge solenoid.

Vacuum does not operate the evaporative canister

valve. The PCM removes the ground to the solenoid when

the engine reaches a specified temperature and the

time delay interval has occurred. When the solenoid is

de-energized, vacuum flows to the canister purge

valve. Vapors are purged from the canister and flow to

the throttle body. The purge solenoid will also be energized during

certain idle conditions, in order to update the fuel

delivery calibration.

MALFUNCTION INDICATOR LAMP (CHECK

ENGINE)ÐPCM OUTPUT

The malfunction indicator lamp (instrument panel

Check Engine lamp) comes on each time the ignition

key is turned ON and stays on for 3 seconds as a bulb

test. The malfunction indicator lamp warns the opera-

tor that the PCM has entered a Limp-in mode. During

Limp-in-Mode, the PCM attempts to keep the system

operational. The malfunction indicator lamp signals

the need for immediate service. In limp-in mode, the

PCM compensates for the failure of certain components

that send incorrect signals. The PCM substitutes for

the incorrect signals with inputs from other sensors. Signals that can trigger the malfunction indi-

cator lamp (Check Engine Lamp).

² Engine Coolant Temperature Sensor

² Manifold Absolute Pressure Sensor

² Throttle Position Sensor

² Battery Voltage Input

² An Emissions Related System

² Charging system

The malfunction indicator lamp can also be used to

display diagnostic trouble codes. Cycle the ignition

switch on, off, on, off, on, within five seconds and any

Fig. 17 EVAP Canister Purge Solenoid and Waste- gate Control Solenoid

14 - 90 FUEL SYSTEMS Ä

Page 1831 of 2438

diagnostic trouble codes stored in the PCM will be

displayed. Refer to the 2.2L Turbo III Multi-port Fuel

InjectionÐOn-Board Diagnostics section of this

Group for Diagnostic trouble code Descriptions.

DATA LINK CONNECTORÐPCM OUTPUT

The data link connector provides the technician

with the means to connect the DRBII scan tool to di-

agnosis the vehicle.

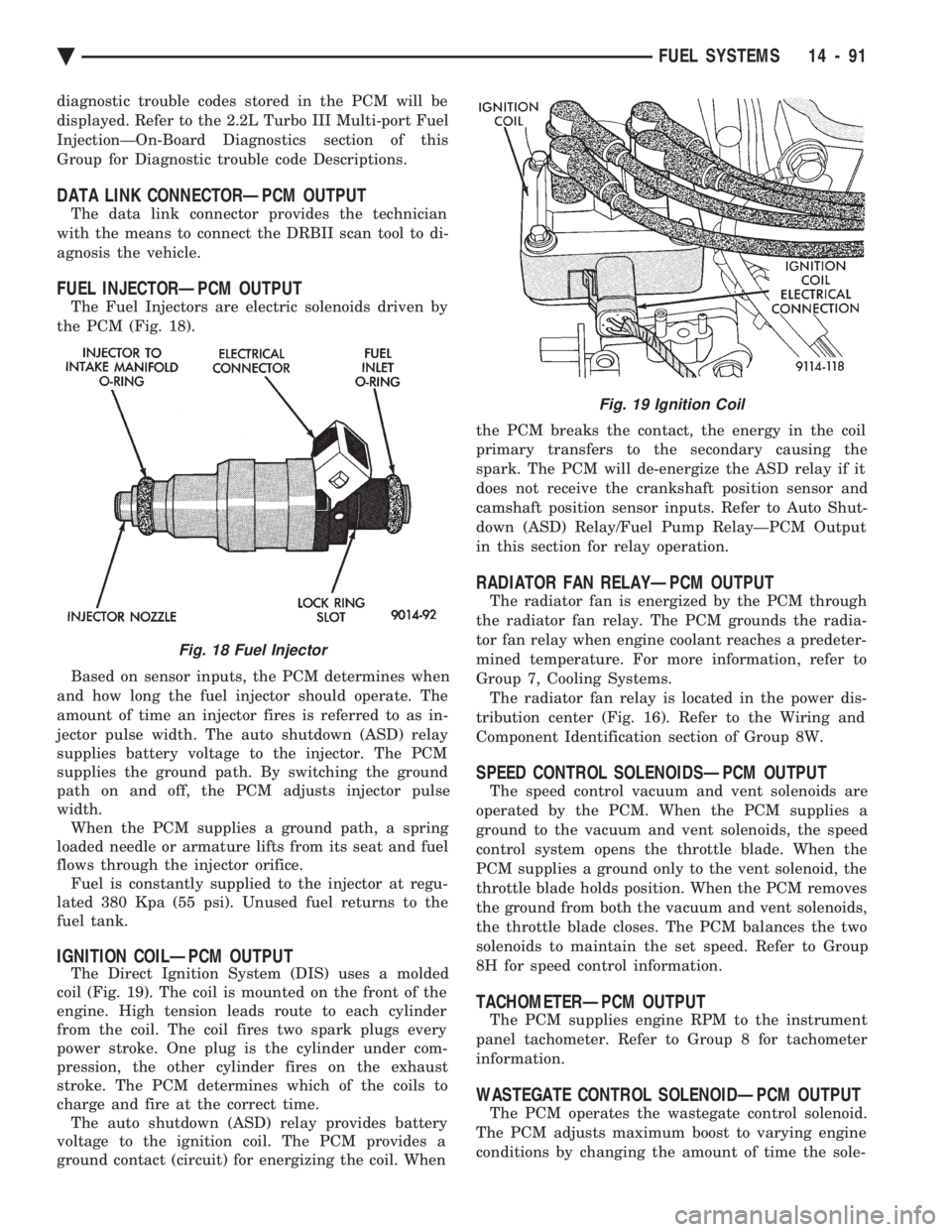

FUEL INJECTORÐPCM OUTPUT

The Fuel Injectors are electric solenoids driven by

the PCM (Fig. 18).

Based on sensor inputs, the PCM determines when

and how long the fuel injector should operate. The

amount of time an injector fires is referred to as in-

jector pulse width. The auto shutdown (ASD) relay

supplies battery voltage to the injector. The PCM

supplies the ground path. By switching the ground

path on and off, the PCM adjusts injector pulse

width. When the PCM supplies a ground path, a spring

loaded needle or armature lifts from its seat and fuel

flows through the injector orifice. Fuel is constantly supplied to the injector at regu-

lated 380 Kpa (55 psi). Unused fuel returns to the

fuel tank.

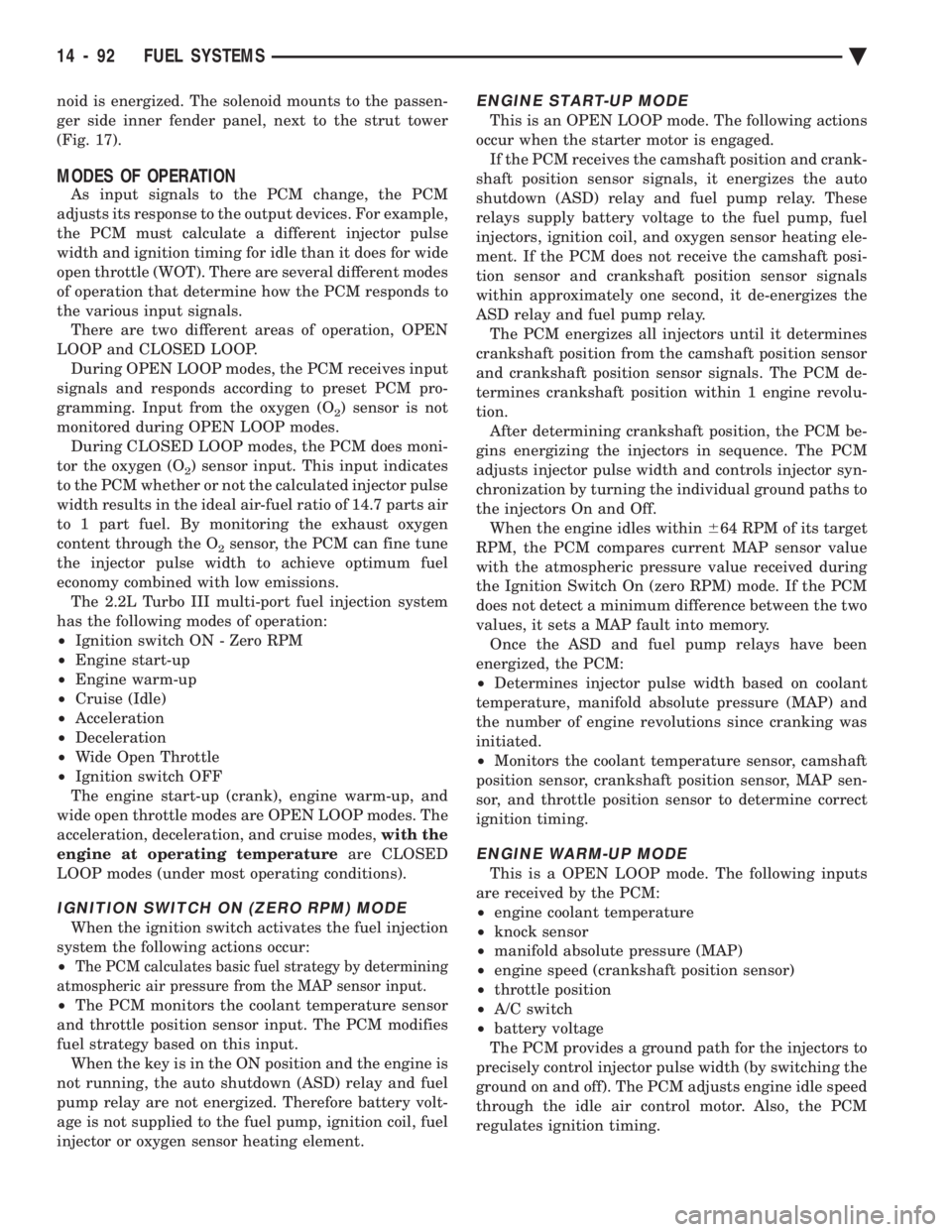

IGNITION COILÐPCM OUTPUT

The Direct Ignition System (DIS) uses a molded

coil (Fig. 19). The coil is mounted on the front of the

engine. High tension leads route to each cylinder

from the coil. The coil fires two spark plugs every

power stroke. One plug is the cylinder under com-

pression, the other cylinder fires on the exhaust

stroke. The PCM determines which of the coils to

charge and fire at the correct time. The auto shutdown (ASD) relay provides battery

voltage to the ignition coil. The PCM provides a

ground contact (circuit) for energizing the coil. When the PCM breaks the contact, the energy in the coil

primary transfers to the secondary causing the

spark. The PCM will de-energize the ASD relay if it

does not receive the crankshaft position sensor and

camshaft position sensor inputs. Refer to Auto Shut-

down (ASD) Relay/Fuel Pump RelayÐPCM Output

in this section for relay operation.

RADIATOR FAN RELAYÐPCM OUTPUT

The radiator fan is energized by the PCM through

the radiator fan relay. The PCM grounds the radia-

tor fan relay when engine coolant reaches a predeter-

mined temperature. For more information, refer to

Group 7, Cooling Systems. The radiator fan relay is located in the power dis-

tribution center (Fig. 16). Refer to the Wiring and

Component Identification section of Group 8W.

SPEED CONTROL SOLENOIDSÐPCM OUTPUT

The speed control vacuum and vent solenoids are

operated by the PCM. When the PCM supplies a

ground to the vacuum and vent solenoids, the speed

control system opens the throttle blade. When the

PCM supplies a ground only to the vent solenoid, the

throttle blade holds position. When the PCM removes

the ground from both the vacuum and vent solenoids,

the throttle blade closes. The PCM balances the two

solenoids to maintain the set speed. Refer to Group

8H for speed control information.

TACHOMETERÐPCM OUTPUT

The PCM supplies engine RPM to the instrument

panel tachometer. Refer to Group 8 for tachometer

information.

WASTEGATE CONTROL SOLENOIDÐPCM OUTPUT

The PCM operates the wastegate control solenoid.

The PCM adjusts maximum boost to varying engine

conditions by changing the amount of time the sole-

Fig. 18 Fuel Injector

Fig. 19 Ignition Coil

Ä FUEL SYSTEMS 14 - 91

Page 1832 of 2438

noid is energized. The solenoid mounts to the passen-

ger side inner fender panel, next to the strut tower

(Fig. 17).

MODES OF OPERATION

As input signals to the PCM change, the PCM

adjusts its response to the output devices. For example,

the PCM must calculate a different injector pulse

width and ignition timing for idle than it does for wide

open throttle (WOT). There are several different modes

of operation that determine how the PCM responds to

the various input signals. There are two different areas of operation, OPEN

LOOP and CLOSED LOOP. During OPEN LOOP modes, the PCM receives input

signals and responds according to preset PCM pro-

gramming. Input from the oxygen (O

2) sensor is not

monitored during OPEN LOOP modes. During CLOSED LOOP modes, the PCM does moni-

tor the oxygen (O

2) sensor input. This input indicates

to the PCM whether or not the calculated injector pulse

width results in the ideal air-fuel ratio of 14.7 parts air

to 1 part fuel. By monitoring the exhaust oxygen

content through the O

2sensor, the PCM can fine tune

the injector pulse width to achieve optimum fuel

economy combined with low emissions. The 2.2L Turbo III multi-port fuel injection system

has the following modes of operation:

² Ignition switch ON - Zero RPM

² Engine start-up

² Engine warm-up

² Cruise (Idle)

² Acceleration

² Deceleration

² Wide Open Throttle

² Ignition switch OFF

The engine start-up (crank), engine warm-up, and

wide open throttle modes are OPEN LOOP modes. The

acceleration, deceleration, and cruise modes, with the

engine at operating temperature are CLOSED

LOOP modes (under most operating conditions).

IGNITION SWITCH ON (ZERO RPM) MODE

When the ignition switch activates the fuel injection

system the following actions occur:

²

The PCM calculates basic fuel strategy by determining

atmospheric air pressure from the MAP sensor input.

² The PCM monitors the coolant temperature sensor

and throttle position sensor input. The PCM modifies

fuel strategy based on this input. When the key is in the ON position and the engine is

not running, the auto shutdown (ASD) relay and fuel

pump relay are not energized. Therefore battery volt-

age is not supplied to the fuel pump, ignition coil, fuel

injector or oxygen sensor heating element.

ENGINE START-UP MODE

This is an OPEN LOOP mode. The following actions

occur when the starter motor is engaged. If the PCM receives the camshaft position and crank-

shaft position sensor signals, it energizes the auto

shutdown (ASD) relay and fuel pump relay. These

relays supply battery voltage to the fuel pump, fuel

injectors, ignition coil, and oxygen sensor heating ele-

ment. If the PCM does not receive the camshaft posi-

tion sensor and crankshaft position sensor signals

within approximately one second, it de-energizes the

ASD relay and fuel pump relay. The PCM energizes all injectors until it determines

crankshaft position from the camshaft position sensor

and crankshaft position sensor signals. The PCM de-

termines crankshaft position within 1 engine revolu-

tion. After determining crankshaft position, the PCM be-

gins energizing the injectors in sequence. The PCM

adjusts injector pulse width and controls injector syn-

chronization by turning the individual ground paths to

the injectors On and Off. When the engine idles within 664 RPM of its target

RPM, the PCM compares current MAP sensor value

with the atmospheric pressure value received during

the Ignition Switch On (zero RPM) mode. If the PCM

does not detect a minimum difference between the two

values, it sets a MAP fault into memory. Once the ASD and fuel pump relays have been

energized, the PCM:

² Determines injector pulse width based on coolant

temperature, manifold absolute pressure (MAP) and

the number of engine revolutions since cranking was

initiated.

² Monitors the coolant temperature sensor, camshaft

position sensor, crankshaft position sensor, MAP sen-

sor, and throttle position sensor to determine correct

ignition timing.

ENGINE WARM-UP MODE

This is a OPEN LOOP mode. The following inputs

are received by the PCM:

² engine coolant temperature

² knock sensor

² manifold absolute pressure (MAP)

² engine speed (crankshaft position sensor)

² throttle position

² A/C switch

² battery voltage

The PCM provides a ground path for the injectors to

precisely control injector pulse width (by switching the

ground on and off). The PCM adjusts engine idle speed

through the idle air control motor. Also, the PCM

regulates ignition timing.

14 - 92 FUEL SYSTEMS Ä

Page 1833 of 2438

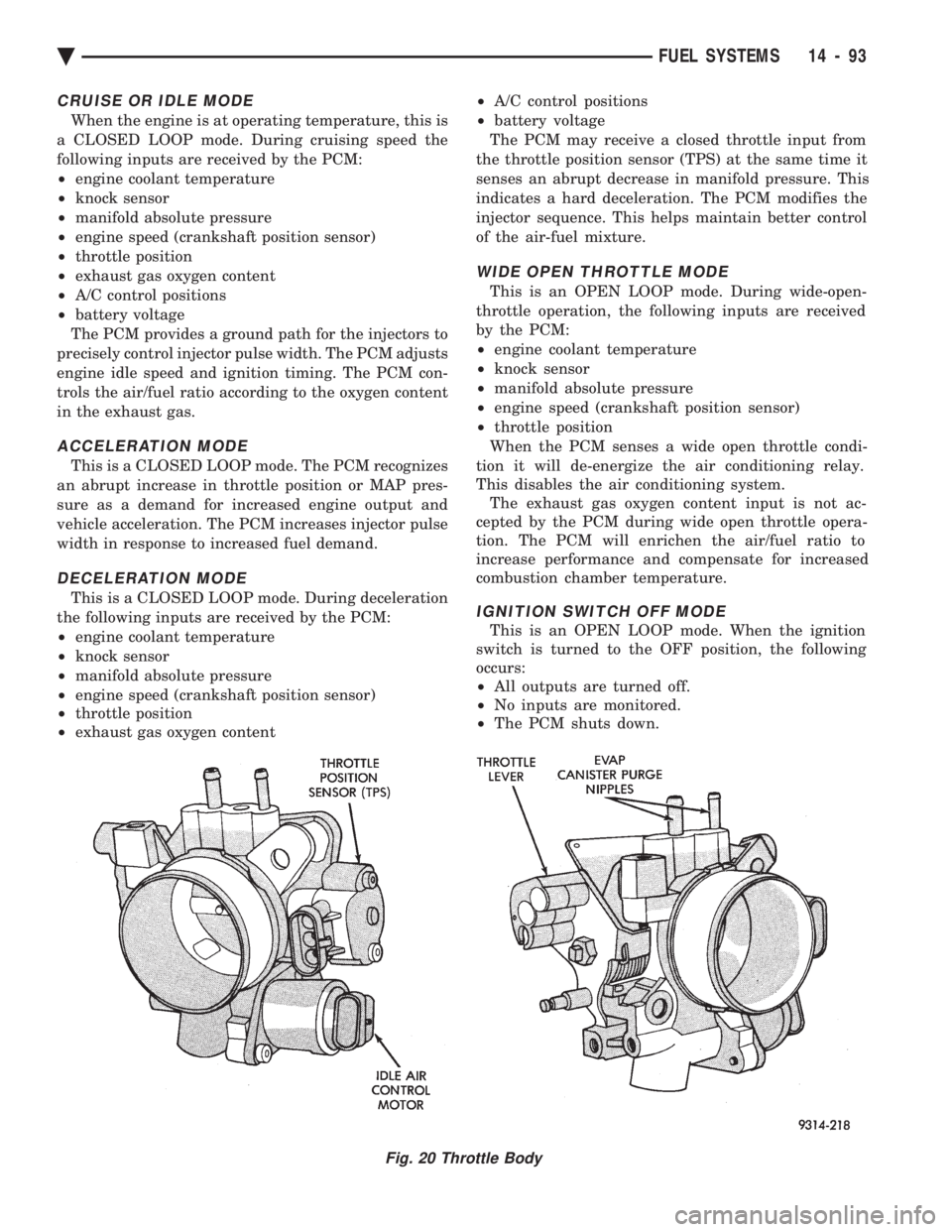

CRUISE OR IDLE MODE

When the engine is at operating temperature, this is

a CLOSED LOOP mode. During cruising speed the

following inputs are received by the PCM:

² engine coolant temperature

² knock sensor

² manifold absolute pressure

² engine speed (crankshaft position sensor)

² throttle position

² exhaust gas oxygen content

² A/C control positions

² battery voltage

The PCM provides a ground path for the injectors to

precisely control injector pulse width. The PCM adjusts

engine idle speed and ignition timing. The PCM con-

trols the air/fuel ratio according to the oxygen content

in the exhaust gas.

ACCELERATION MODE

This is a CLOSED LOOP mode. The PCM recognizes

an abrupt increase in throttle position or MAP pres-

sure as a demand for increased engine output and

vehicle acceleration. The PCM increases injector pulse

width in response to increased fuel demand.

DECELERATION MODE

This is a CLOSED LOOP mode. During deceleration

the following inputs are received by the PCM:

² engine coolant temperature

² knock sensor

² manifold absolute pressure

² engine speed (crankshaft position sensor)

² throttle position

² exhaust gas oxygen content ²

A/C control positions

² battery voltage

The PCM may receive a closed throttle input from

the throttle position sensor (TPS) at the same time it

senses an abrupt decrease in manifold pressure. This

indicates a hard deceleration. The PCM modifies the

injector sequence. This helps maintain better control

of the air-fuel mixture.

WIDE OPEN THROTTLE MODE

This is an OPEN LOOP mode. During wide-open-

throttle operation, the following inputs are received

by the PCM:

² engine coolant temperature

² knock sensor

² manifold absolute pressure

² engine speed (crankshaft position sensor)

² throttle position

When the PCM senses a wide open throttle condi-

tion it will de-energize the air conditioning relay.

This disables the air conditioning system. The exhaust gas oxygen content input is not ac-

cepted by the PCM during wide open throttle opera-

tion. The PCM will enrichen the air/fuel ratio to

increase performance and compensate for increased

combustion chamber temperature.

IGNITION SWITCH OFF MODE

This is an OPEN LOOP mode. When the ignition

switch is turned to the OFF position, the following

occurs:

² All outputs are turned off.

² No inputs are monitored.

² The PCM shuts down.

Fig. 20 Throttle Body

Ä FUEL SYSTEMS 14 - 93

Page 1837 of 2438

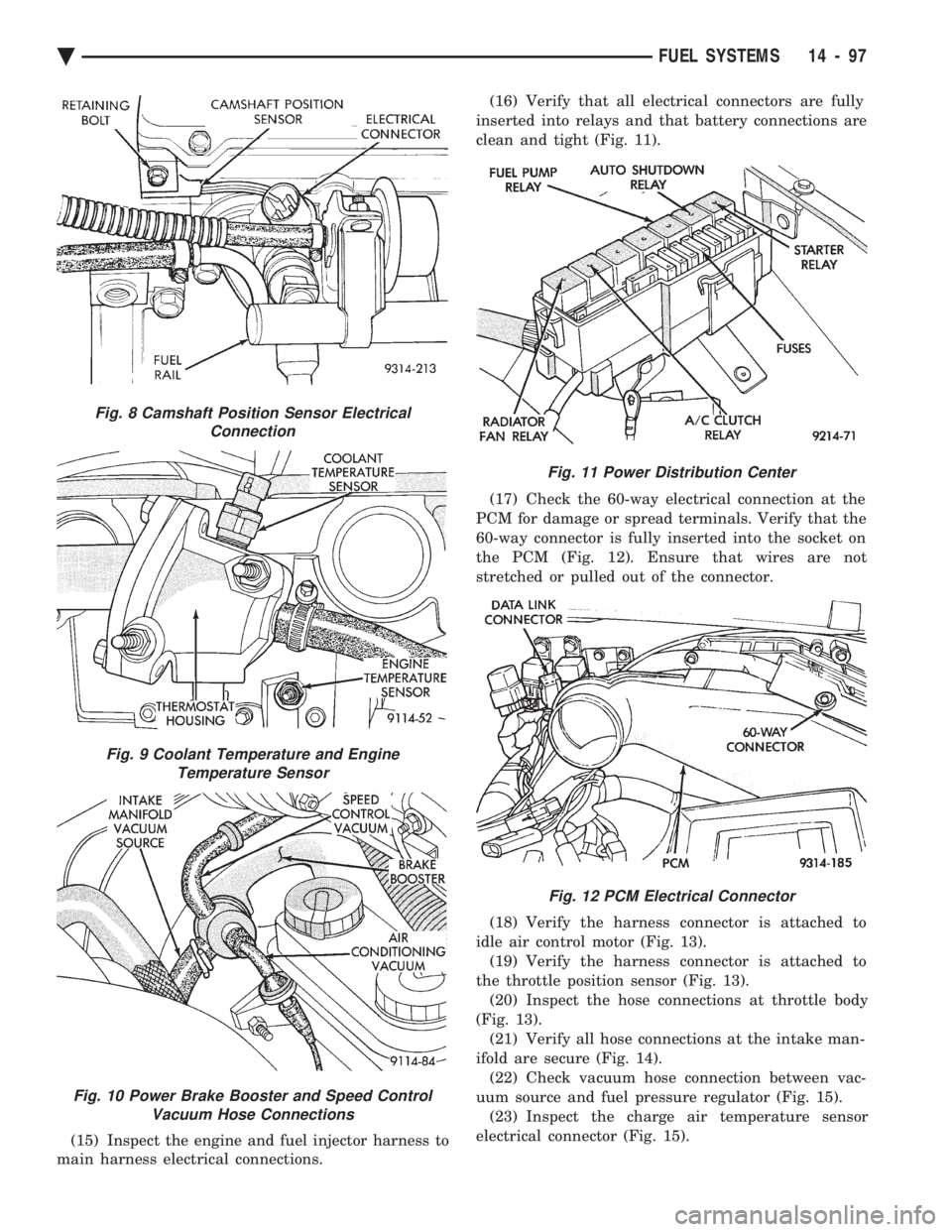

(15) Inspect the engine and fuel injector harness to

main harness electrical connections. (16) Verify that all electrical connectors are fully

inserted into relays and that battery connections are

clean and tight (Fig. 11).

(17) Check the 60-way electrical connection at the

PCM for damage or spread terminals. Verify that the

60-way connector is fully inserted into the socket on

the PCM (Fig. 12). Ensure that wires are not

stretched or pulled out of the connector.

(18) Verify the harness connector is attached to

idle air control motor (Fig. 13). (19) Verify the harness connector is attached to

the throttle position sensor (Fig. 13). (20) Inspect the hose connections at throttle body

(Fig. 13). (21) Verify all hose connections at the intake man-

ifold are secure (Fig. 14). (22) Check vacuum hose connection between vac-

uum source and fuel pressure regulator (Fig. 15). (23) Inspect the charge air temperature sensor

electrical connector (Fig. 15).

Fig. 8 Camshaft Position Sensor Electrical Connection

Fig. 9 Coolant Temperature and EngineTemperature Sensor

Fig. 10 Power Brake Booster and Speed Control Vacuum Hose Connections

Fig. 11 Power Distribution Center

Fig. 12 PCM Electrical Connector

Ä FUEL SYSTEMS 14 - 97

Page 1844 of 2438

SYSTEM TESTS

Apply parking brake and/or block wheels be-

fore performing idle check or adjustment, or any

engine running tests.

OBTAINING DIAGNOSTIC TROUBLE CODES

(1) Connect DRBII scan tool to the data link connec-

tor (Fig. 1). (2) Start the engine if possible, cycle the trans mis-

sion selector and the A/Cswitch if applicable. Shut off

the engine. (3) Turn the ignition switch on, access Read Fault

Screen. Record all the fault messages shown on the

DRBII scan tool. Observe the malfunction indicator

lamp (check engine lamp on the instrument panel). The

lamp should light for 2 seconds then go out (bulb

check). Diagnostic trouble code erasure: access erase

diagnostic trouble code data.

STATE DISPLAY TEST MODE

The switch inputs used by the powertrain control

module (PCM) have only two recognized states, HIGH

and LOW. For this reason, the PCM cannot recognize

the difference between a selected switch position ver-

sus an open circuit, a short circuit, or a defective

switch. If the display changes, assume the entire

switch circuit to the PCM is functional. From the state

display screen access either State Display Inputs and

Outputs or State Display Sensors.

STATE DISPLAY INPUTS AND OUTPUTS

Connect the DRBII scan tool to the vehicle and access

the State Display screen. Then access Inputs and

Outputs. The following is a list of the engine control

system functions accessible through the Inputs and

Outputs screen. Speed Control Resume

Brake Switch

Speed Control On/Off

Speed Control Set

A/C Switch Sense

S/C Vent Solenoid S/C Vacuum Solenoid

A/C Clutch Relay

Baro Read Solenoid

Wastegate Solenoid

Auto Shutdown Relay

Radiator Fan Relay

Purge Solenoid

Malfunction Indicator Lamp (Check Engine Lamp)

STATE DISPLAY SENSORS

Connect the DRBII scan tool to the vehicle and ac-

cess the State Display screen. Then access Sensor

Display. The following is a list of the engine control

system functions accessible through the Sensor Dis-

play screen. Oxygen Sensor Signal

Coolant Temperature

Coolant Temp Sensor

Throttle Position

Minimum Throttle

Knock Sensor Signal

Battery Voltage

MAP Sensor Reading

Idle Air Control Motor Position

Adaptive Fuel Factor

Barometric Pressure

Min Airflow Idle Spd (speed)

Engine Speed

DIS Sensor Status

Fault #1 Key-On Info

Module Spark Advance

Cyl 1 Knock Retard

Cyl 2 Knock Retard

Cyl 3 Knock Retard

Cyl 4 Knock Retard

Boost Pressure Goal

Charge Temperature

Charge Temp Sensor

Speed Control Target

Fault #2 Key-on Info

Fault #3 Key-on Info

Speed Control Status

Charging System Goal

Theft Alarm Status

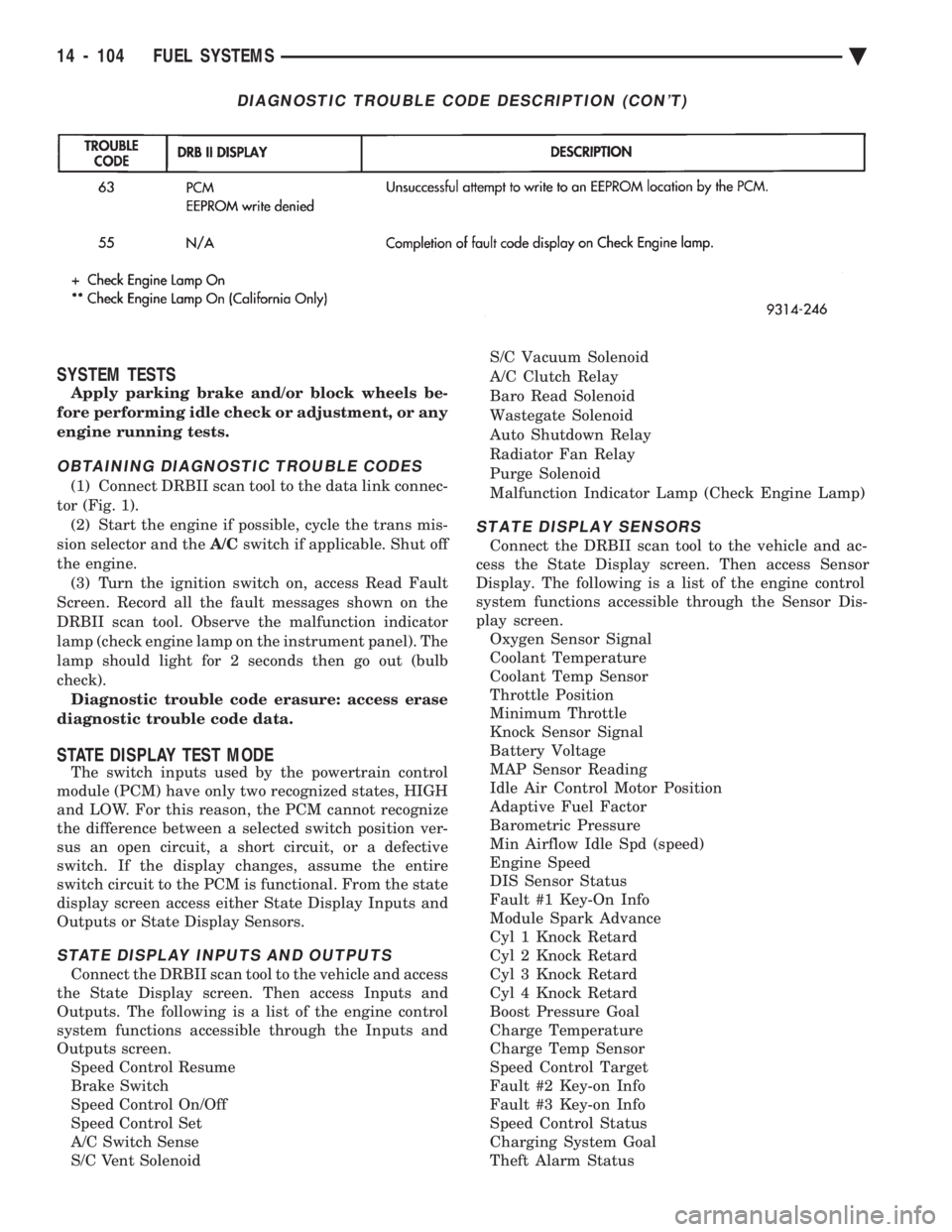

DIAGNOSTIC TROUBLE CODE DESCRIPTION (CON'T)

14 - 104 FUEL SYSTEMS Ä

Page 1845 of 2438

Wastegate Duty Cycle

Battery Temperature

Map Sensor Voltage

Vehicle Speed

Oxygen Sensor State

Baro Read Update

MAP Gauge Reading

Throttle Opening (percentage)

Total Spark Advance

CIRCUIT ACTUATION TEST MODE

The purpose of the circuit actuation test mode is to

check for the proper operation of output circuits or

devices which the powertrain control module (PCM)

cannot internally recognize. The PCM can attempt to

activate these outputs and allow an observer to ver-

ify proper operation. Most of the tests available in

this mode provide an audible or visual indication of

device operation (click of relay contacts, spray fuel,

etc.). With the exception of an intermittent condition,

if a device functions properly during its test, assume

the device, its associated wiring, and its driver cir-

cuit are in working order.

OBTAINING CIRCUIT ACTUATION TEST

Connect the DRBII scan tool to the vehicle and ac-

cess the Actuators screen. The following is a list of

the engine control system functions accessible

through Actuators screens. Stop All Tests

Ignition Coil #1

Ignition Coil #2

Fuel Injector #1

Fuel Injector #2

Fuel Injector #3

Idle Air Control Motor Open/Close

Radiator Fan Relay

A/C Clutch Relay

Auto Shutdown Relay

Purge Solenoid

S/C Serv Solenoids

Generator Field

Tachometer Output

Wastegate Solenoid

Baro Read Solenoid

All Solenoids/Relays

Speed Control Vent Solenoid

Speed Control Vacuum Solenoid

ASD Fuel System Test

Fuel Injector #4

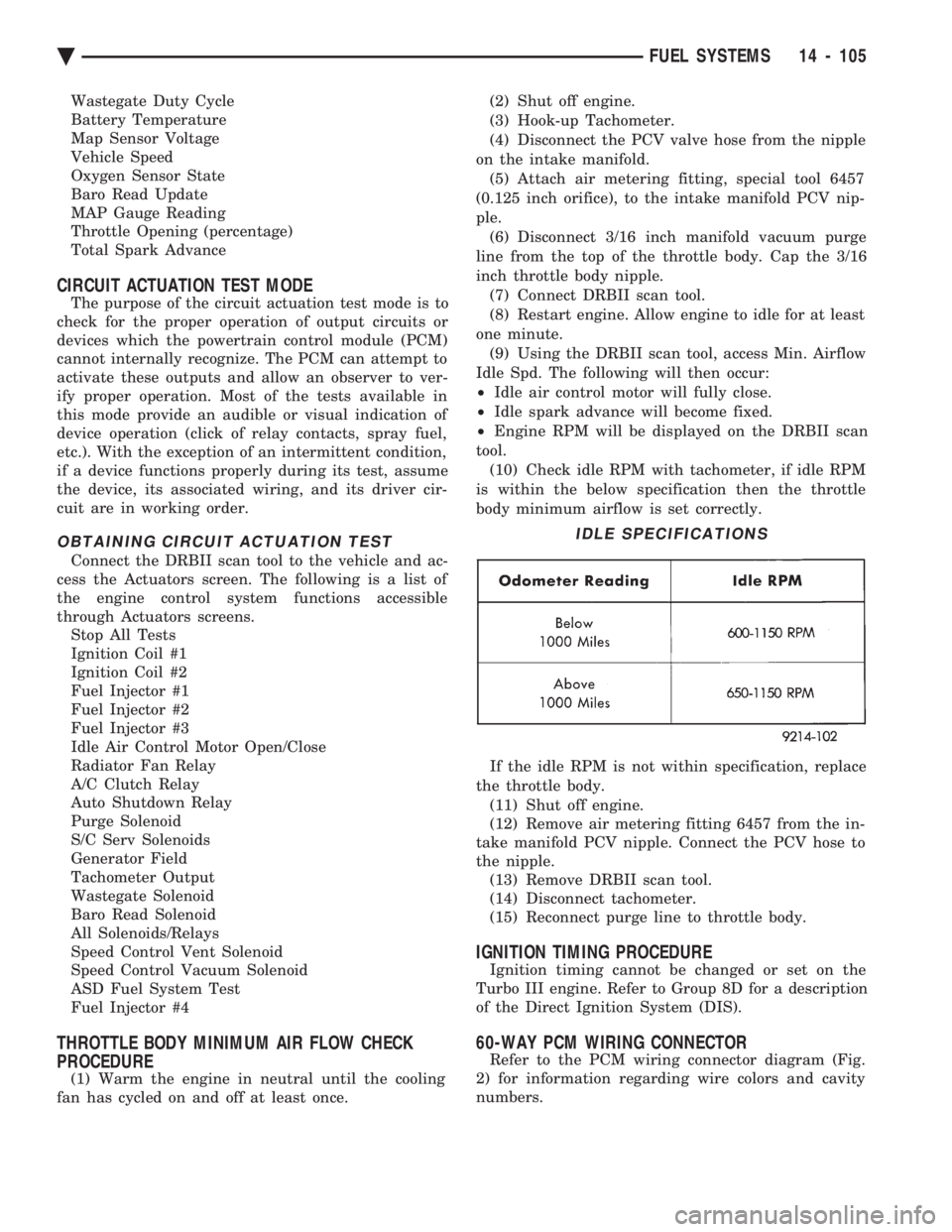

THROTTLE BODY MINIMUM AIR FLOW CHECK

PROCEDURE

(1) Warm the engine in neutral until the cooling

fan has cycled on and off at least once. (2) Shut off engine.

(3) Hook-up Tachometer.

(4) Disconnect the PCV valve hose from the nipple

on the intake manifold. (5) Attach air metering fitting, special tool 6457

(0.125 inch orifice), to the intake manifold PCV nip-

ple. (6) Disconnect 3/16 inch manifold vacuum purge

line from the top of the throttle body. Cap the 3/16

inch throttle body nipple. (7) Connect DRBII scan tool.

(8) Restart engine. Allow engine to idle for at least

one minute. (9) Using the DRBII scan tool, access Min. Airflow

Idle Spd. The following will then occur:

² Idle air control motor will fully close.

² Idle spark advance will become fixed.

² Engine RPM will be displayed on the DRBII scan

tool. (10) Check idle RPM with tachometer, if idle RPM

is within the below specification then the throttle

body minimum airflow is set correctly.

If the idle RPM is not within specification, replace

the throttle body. (11) Shut off engine.

(12) Remove air metering fitting 6457 from the in-

take manifold PCV nipple. Connect the PCV hose to

the nipple. (13) Remove DRBII scan tool.

(14) Disconnect tachometer.

(15) Reconnect purge line to throttle body.

IGNITION TIMING PROCEDURE

Ignition timing cannot be changed or set on the

Turbo III engine. Refer to Group 8D for a description

of the Direct Ignition System (DIS).

60-WAY PCM WIRING CONNECTOR

Refer to the PCM wiring connector diagram (Fig.

2) for information regarding wire colors and cavity

numbers.

IDLE SPECIFICATIONS

Ä FUEL SYSTEMS 14 - 105