ABS CHEVROLET DYNASTY 1993 Service Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 1723 of 2438

FRAME AND BUMPERS

CONTENTS

page page

BUMPER AND FASCIA .................... 1 FRAME................................ 9

BUMPER AND FASCIA INDEX

page page

AA-Vehicle Front Bumper ................... 1

AA-Vehicle Rear Bumper ................... 5

AC-Vehicle Front Bumper ................... 2

AC-Vehicle Rear Bumper ................... 6

AG-Vehicle Front Bumper ................... 3

AG-Vehicle Rear Bumper ................... 7

AJ-Vehicle Front Bumper and Fascia .......... 4 AJ-Vehicle Rear Bumper

.................... 7

AP-Vehicle Front Bumper ................... 4

AP-Vehicle Rear Bumper ................... 7

AY-Vehicle Front Bumper ................... 5

AY-Vehicle Rear Bumper ................... 8

Safety Precautions and Warnings ............. 1

SAFETY PRECAUTIONS AND WARNINGS

WARNING: BUMPER ENERGY ABSORBER UNITS

CONTAIN PRESSURIZE GAS. DO NOT PUNCTURE

OR HEAT ABSORBER UNIT FOR ANY REASON.

PERSONAL INJURY CAN RESULT.

DO NOT VENTURE UNDER A HOISTED VEHICLE

THAT IS NOT SUPPORTED ON SAFETY STANDS.

PERSONAL INJURY CAN RESULT.

CAUTION: To avoid damaging a bright metal or

painted finish bumper or fascia, use a padded work

surface.

AA-VEHICLE FRONT BUMPER

REMOVAL (FIG. 1)

(1) Remove socket and bulb from park and turn

lamp. (2) Disconnect horn and fog lamp connectors (if

equipped). (3) Remove push-in fasteners holding sight shield

to vertical support in front of radiator. (4) Remove nuts holding fascia to fender, from be-

hind forward flange of fender. (5) Support front bumper assembly on suitable lift-

ing device and remove bolts holding bumper rein-

forcement to energy absorber units.

INSTALLATION

Reverse the preceding operation. Align bumper

height to approximately 3 mm (1/8 in.) gap to bottom

of head lamp assemblies and flush to front fenders

below the side marker lamps.

Fig. 1 Standard Front BumperÐAA-Vehicle

Ä FRAME AND BUMPERS 13 - 1

Page 1724 of 2438

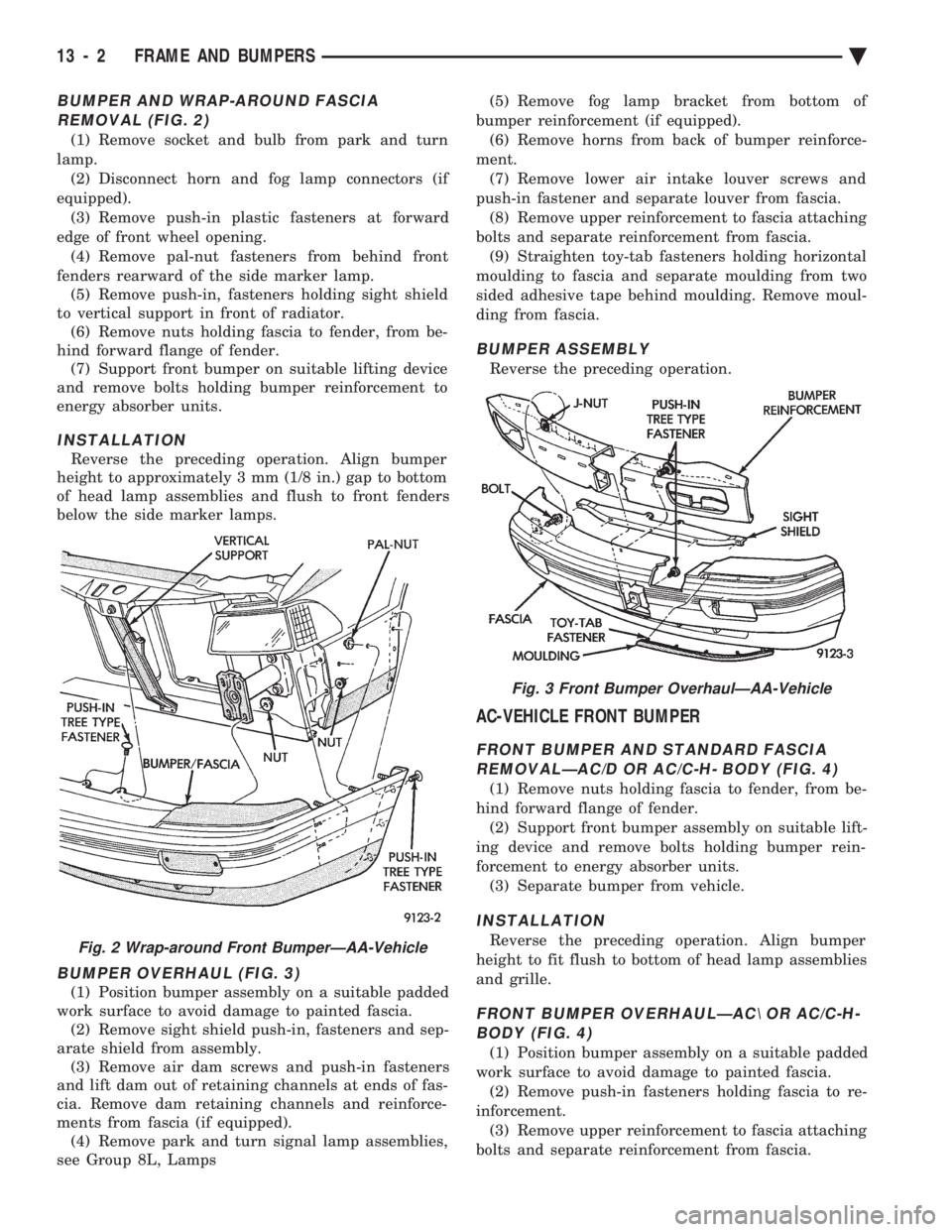

BUMPER AND WRAP-AROUND FASCIA REMOVAL (FIG. 2)

(1) Remove socket and bulb from park and turn

lamp. (2) Disconnect horn and fog lamp connectors (if

equipped). (3) Remove push-in plastic fasteners at forward

edge of front wheel opening. (4) Remove pal-nut fasteners from behind front

fenders rearward of the side marker lamp. (5) Remove push-in, fasteners holding sight shield

to vertical support in front of radiator. (6) Remove nuts holding fascia to fender, from be-

hind forward flange of fender. (7) Support front bumper on suitable lifting device

and remove bolts holding bumper reinforcement to

energy absorber units.

INSTALLATION

Reverse the preceding operation. Align bumper

height to approximately 3 mm (1/8 in.) gap to bottom

of head lamp assemblies and flush to front fenders

below the side marker lamps.

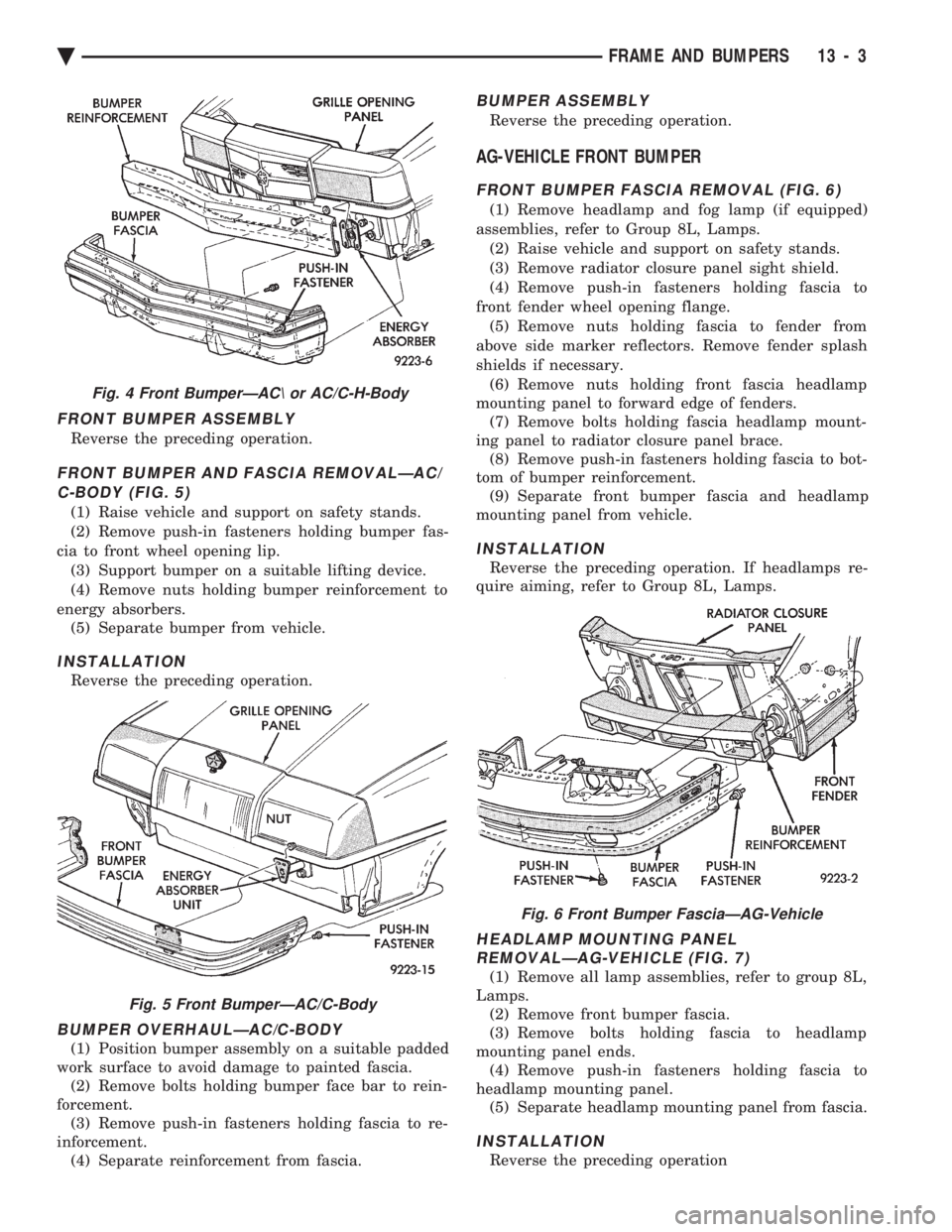

BUMPER OVERHAUL (FIG. 3)

(1) Position bumper assembly on a suitable padded

work surface to avoid damage to painted fascia. (2) Remove sight shield push-in, fasteners and sep-

arate shield from assembly. (3) Remove air dam screws and push-in fasteners

and lift dam out of retaining channels at ends of fas-

cia. Remove dam retaining channels and reinforce-

ments from fascia (if equipped). (4) Remove park and turn signal lamp assemblies,

see Group 8L, Lamps (5) Remove fog lamp bracket from bottom of

bumper reinforcement (if equipped). (6) Remove horns from back of bumper reinforce-

ment. (7) Remove lower air intake louver screws and

push-in fastener and separate louver from fascia. (8) Remove upper reinforcement to fascia attaching

bolts and separate reinforcement from fascia. (9) Straighten toy-tab fasteners holding horizontal

moulding to fascia and separate moulding from two

sided adhesive tape behind moulding. Remove moul-

ding from fascia.

BUMPER ASSEMBLY

Reverse the preceding operation.

AC-VEHICLE FRONT BUMPER

FRONT BUMPER AND STANDARD FASCIA REMOVALÐAC/D OR AC/C-H- BODY (FIG. 4)

(1) Remove nuts holding fascia to fender, from be-

hind forward flange of fender. (2) Support front bumper assembly on suitable lift-

ing device and remove bolts holding bumper rein-

forcement to energy absorber units. (3) Separate bumper from vehicle.

INSTALLATION

Reverse the preceding operation. Align bumper

height to fit flush to bottom of head lamp assemblies

and grille.

FRONT BUMPER OVERHAULÐAC\ OR AC/C-H- BODY (FIG. 4)

(1) Position bumper assembly on a suitable padded

work surface to avoid damage to painted fascia. (2) Remove push-in fasteners holding fascia to re-

inforcement. (3) Remove upper reinforcement to fascia attaching

bolts and separate reinforcement from fascia.

Fig. 2 Wrap-around Front BumperÐAA-Vehicle

Fig. 3 Front Bumper OverhaulÐAA-Vehicle

13 - 2 FRAME AND BUMPERS Ä

Page 1725 of 2438

FRONT BUMPER ASSEMBLY

Reverse the preceding operation.

FRONT BUMPER AND FASCIA REMOVALÐAC/ C-BODY (FIG. 5)

(1) Raise vehicle and support on safety stands.

(2) Remove push-in fasteners holding bumper fas-

cia to front wheel opening lip. (3) Support bumper on a suitable lifting device.

(4) Remove nuts holding bumper reinforcement to

energy absorbers. (5) Separate bumper from vehicle.

INSTALLATION

Reverse the preceding operation.

BUMPER OVERHAULÐAC/C-BODY

(1) Position bumper assembly on a suitable padded

work surface to avoid damage to painted fascia. (2) Remove bolts holding bumper face bar to rein-

forcement. (3) Remove push-in fasteners holding fascia to re-

inforcement. (4) Separate reinforcement from fascia.

BUMPER ASSEMBLY

Reverse the preceding operation.

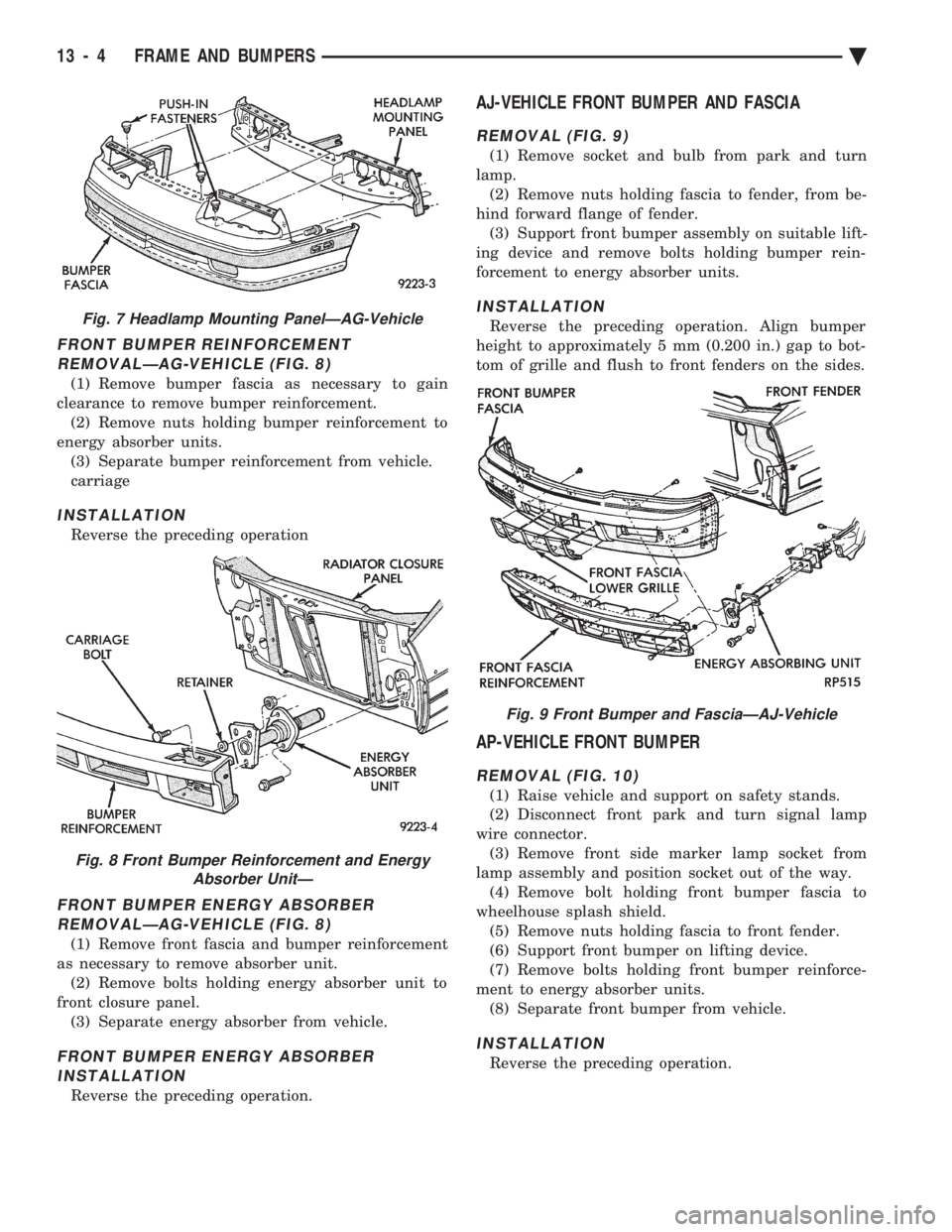

AG-VEHICLE FRONT BUMPER

FRONT BUMPER FASCIA REMOVAL (FIG. 6)

(1) Remove headlamp and fog lamp (if equipped)

assemblies, refer to Group 8L, Lamps. (2) Raise vehicle and support on safety stands.

(3) Remove radiator closure panel sight shield.

(4) Remove push-in fasteners holding fascia to

front fender wheel opening flange. (5) Remove nuts holding fascia to fender from

above side marker reflectors. Remove fender splash

shields if necessary. (6) Remove nuts holding front fascia headlamp

mounting panel to forward edge of fenders. (7) Remove bolts holding fascia headlamp mount-

ing panel to radiator closure panel brace. (8) Remove push-in fasteners holding fascia to bot-

tom of bumper reinforcement. (9) Separate front bumper fascia and headlamp

mounting panel from vehicle.

INSTALLATION

Reverse the preceding operation. If headlamps re-

quire aiming, refer to Group 8L, Lamps.

HEADLAMP MOUNTING PANEL REMOVALÐAG-VEHICLE (FIG. 7)

(1) Remove all lamp assemblies, refer to group 8L,

Lamps. (2) Remove front bumper fascia.

(3) Remove bolts holding fascia to headlamp

mounting panel ends. (4) Remove push-in fasteners holding fascia to

headlamp mounting panel. (5) Separate headlamp mounting panel from fascia.

INSTALLATION

Reverse the preceding operation

Fig. 4 Front BumperÐAC\ or AC/C-H-Body

Fig. 5 Front BumperÐAC/C-Body

Fig. 6 Front Bumper FasciaÐAG-Vehicle

Ä FRAME AND BUMPERS 13 - 3

Page 1726 of 2438

FRONT BUMPER REINFORCEMENT REMOVALÐAG-VEHICLE (FIG. 8)

(1) Remove bumper fascia as necessary to gain

clearance to remove bumper reinforcement. (2) Remove nuts holding bumper reinforcement to

energy absorber units. (3) Separate bumper reinforcement from vehicle.

carriage

INSTALLATION

Reverse the preceding operation

FRONT BUMPER ENERGY ABSORBERREMOVALÐAG-VEHICLE (FIG. 8)

(1) Remove front fascia and bumper reinforcement

as necessary to remove absorber unit. (2) Remove bolts holding energy absorber unit to

front closure panel. (3) Separate energy absorber from vehicle.

FRONT BUMPER ENERGY ABSORBERINSTALLATION

Reverse the preceding operation.

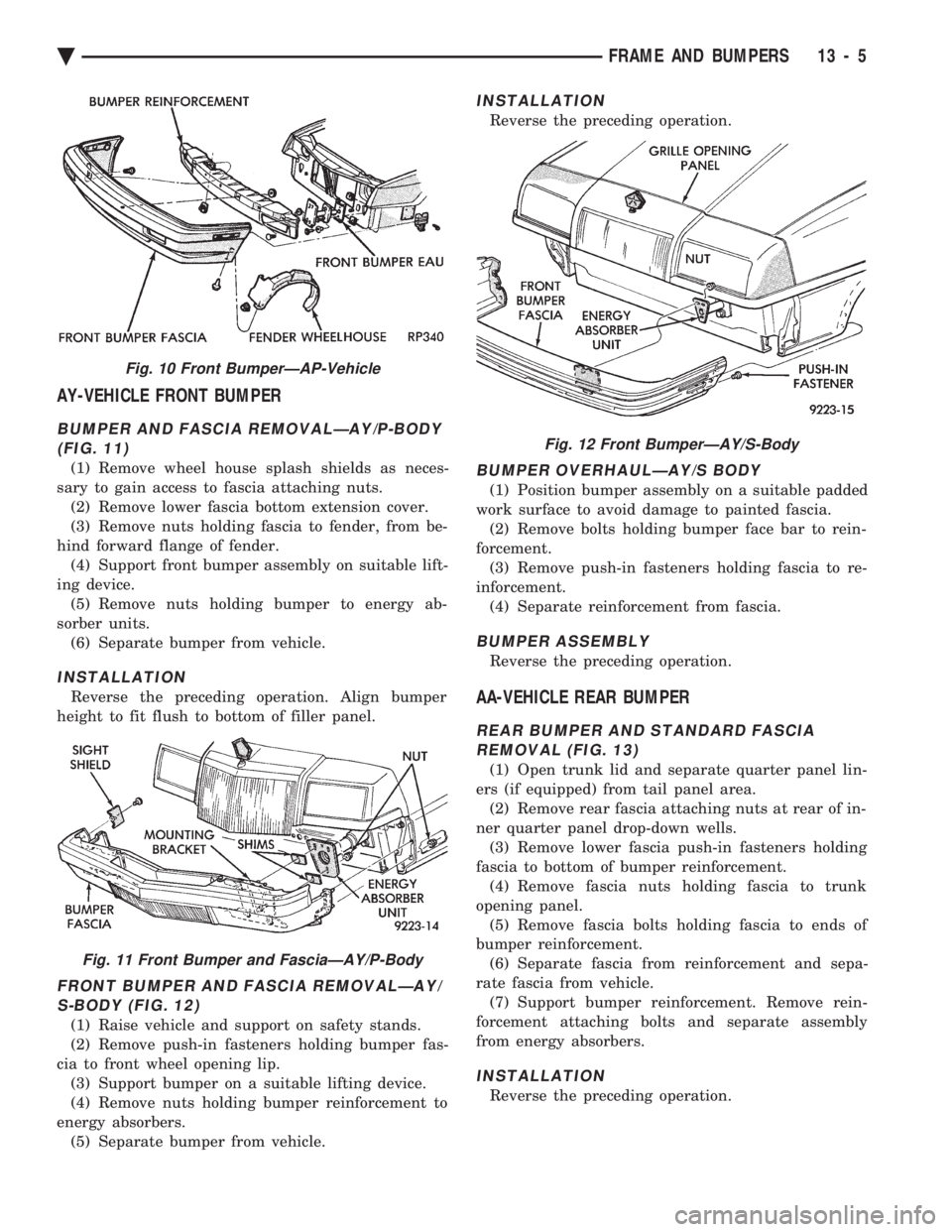

AJ-VEHICLE FRONT BUMPER AND FASCIA

REMOVAL (FIG. 9)

(1) Remove socket and bulb from park and turn

lamp. (2) Remove nuts holding fascia to fender, from be-

hind forward flange of fender. (3) Support front bumper assembly on suitable lift-

ing device and remove bolts holding bumper rein-

forcement to energy absorber units.

INSTALLATION

Reverse the preceding operation. Align bumper

height to approximately 5 mm (0.200 in.) gap to bot-

tom of grille and flush to front fenders on the sides.

AP-VEHICLE FRONT BUMPER

REMOVAL (FIG. 10)

(1) Raise vehicle and support on safety stands.

(2) Disconnect front park and turn signal lamp

wire connector. (3) Remove front side marker lamp socket from

lamp assembly and position socket out of the way. (4) Remove bolt holding front bumper fascia to

wheelhouse splash shield. (5) Remove nuts holding fascia to front fender.

(6) Support front bumper on lifting device.

(7) Remove bolts holding front bumper reinforce-

ment to energy absorber units. (8) Separate front bumper from vehicle.

INSTALLATION

Reverse the preceding operation.

Fig. 7 Headlamp Mounting PanelÐAG-Vehicle

Fig. 8 Front Bumper Reinforcement and Energy Absorber UnitÐ

Fig. 9 Front Bumper and FasciaÐAJ-Vehicle

13 - 4 FRAME AND BUMPERS Ä

Page 1727 of 2438

AY-VEHICLE FRONT BUMPER

BUMPER AND FASCIA REMOVALÐAY/P-BODY (FIG. 11)

(1) Remove wheel house splash shields as neces-

sary to gain access to fascia attaching nuts. (2) Remove lower fascia bottom extension cover.

(3) Remove nuts holding fascia to fender, from be-

hind forward flange of fender. (4) Support front bumper assembly on suitable lift-

ing device. (5) Remove nuts holding bumper to energy ab-

sorber units. (6) Separate bumper from vehicle.

INSTALLATION

Reverse the preceding operation. Align bumper

height to fit flush to bottom of filler panel.

FRONT BUMPER AND FASCIA REMOVALÐAY/ S-BODY (FIG. 12)

(1) Raise vehicle and support on safety stands.

(2) Remove push-in fasteners holding bumper fas-

cia to front wheel opening lip. (3) Support bumper on a suitable lifting device.

(4) Remove nuts holding bumper reinforcement to

energy absorbers. (5) Separate bumper from vehicle.

INSTALLATION

Reverse the preceding operation.

BUMPER OVERHAULÐAY/S BODY

(1) Position bumper assembly on a suitable padded

work surface to avoid damage to painted fascia. (2) Remove bolts holding bumper face bar to rein-

forcement. (3) Remove push-in fasteners holding fascia to re-

inforcement. (4) Separate reinforcement from fascia.

BUMPER ASSEMBLY

Reverse the preceding operation.

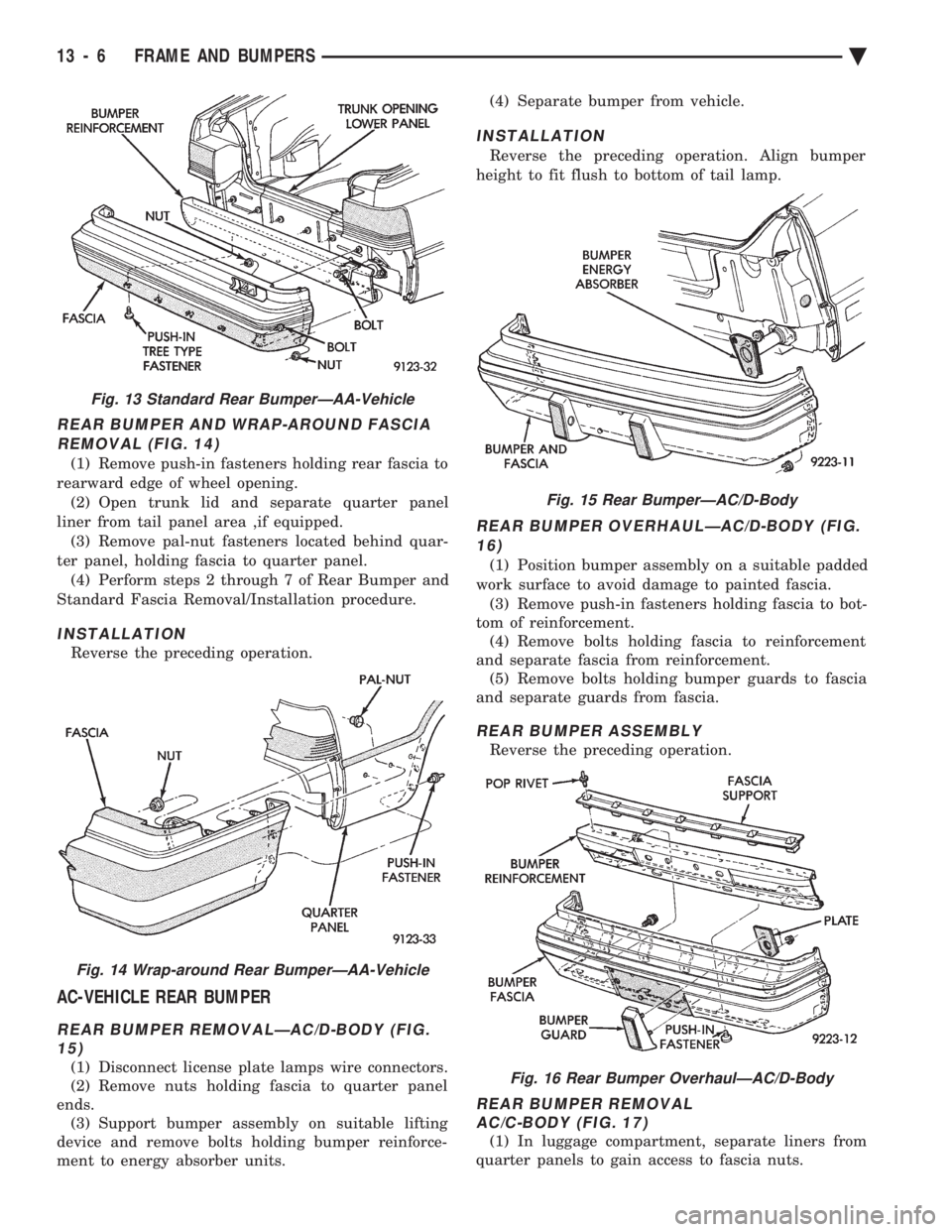

AA-VEHICLE REAR BUMPER

REAR BUMPER AND STANDARD FASCIAREMOVAL (FIG. 13)

(1) Open trunk lid and separate quarter panel lin-

ers (if equipped) from tail panel area. (2) Remove rear fascia attaching nuts at rear of in-

ner quarter panel drop-down wells. (3) Remove lower fascia push-in fasteners holding

fascia to bottom of bumper reinforcement. (4) Remove fascia nuts holding fascia to trunk

opening panel. (5) Remove fascia bolts holding fascia to ends of

bumper reinforcement. (6) Separate fascia from reinforcement and sepa-

rate fascia from vehicle. (7) Support bumper reinforcement. Remove rein-

forcement attaching bolts and separate assembly

from energy absorbers.

INSTALLATION

Reverse the preceding operation.

Fig. 10 Front BumperÐAP-Vehicle

Fig. 11 Front Bumper and FasciaÐAY/P-Body

Fig. 12 Front BumperÐAY/S-Body

Ä FRAME AND BUMPERS 13 - 5

Page 1728 of 2438

REAR BUMPER AND WRAP-AROUND FASCIA REMOVAL (FIG. 14)

(1) Remove push-in fasteners holding rear fascia to

rearward edge of wheel opening. (2) Open trunk lid and separate quarter panel

liner from tail panel area ,if equipped. (3) Remove pal-nut fasteners located behind quar-

ter panel, holding fascia to quarter panel. (4) Perform steps 2 through 7 of Rear Bumper and

Standard Fascia Removal/Installation procedure.

INSTALLATION

Reverse the preceding operation.

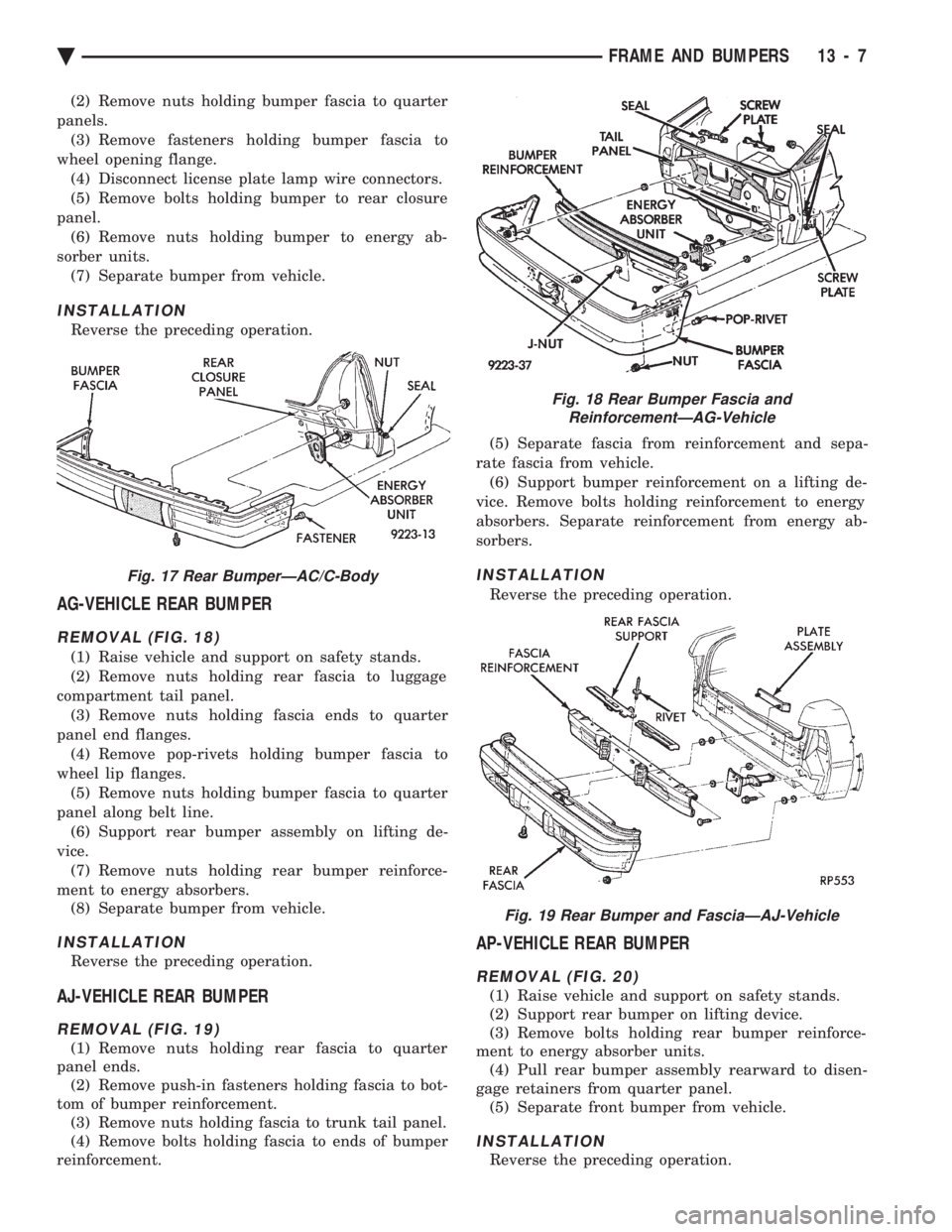

AC-VEHICLE REAR BUMPER

REAR BUMPER REMOVALÐAC/D-BODY (FIG. 15)

(1) Disconnect license plate lamps wire connectors.

(2) Remove nuts holding fascia to quarter panel

ends. (3) Support bumper assembly on suitable lifting

device and remove bolts holding bumper reinforce-

ment to energy absorber units. (4) Separate bumper from vehicle.

INSTALLATION

Reverse the preceding operation. Align bumper

height to fit flush to bottom of tail lamp.

REAR BUMPER OVERHAULÐAC/D-BODY (FIG. 16)

(1) Position bumper assembly on a suitable padded

work surface to avoid damage to painted fascia. (3) Remove push-in fasteners holding fascia to bot-

tom of reinforcement. (4) Remove bolts holding fascia to reinforcement

and separate fascia from reinforcement. (5) Remove bolts holding bumper guards to fascia

and separate guards from fascia.

REAR BUMPER ASSEMBLY

Reverse the preceding operation.

REAR BUMPER REMOVAL AC/C-BODY (FIG. 17)

(1) In luggage compartment, separate liners from

quarter panels to gain access to fascia nuts.

Fig. 13 Standard Rear BumperÐAA-Vehicle

Fig. 14 Wrap-around Rear BumperÐAA-Vehicle

Fig. 15 Rear BumperÐAC/D-Body

Fig. 16 Rear Bumper OverhaulÐAC/D-Body

13 - 6 FRAME AND BUMPERS Ä

Page 1729 of 2438

(2) Remove nuts holding bumper fascia to quarter

panels. (3) Remove fasteners holding bumper fascia to

wheel opening flange. (4) Disconnect license plate lamp wire connectors.

(5) Remove bolts holding bumper to rear closure

panel. (6) Remove nuts holding bumper to energy ab-

sorber units. (7) Separate bumper from vehicle.

INSTALLATION

Reverse the preceding operation.

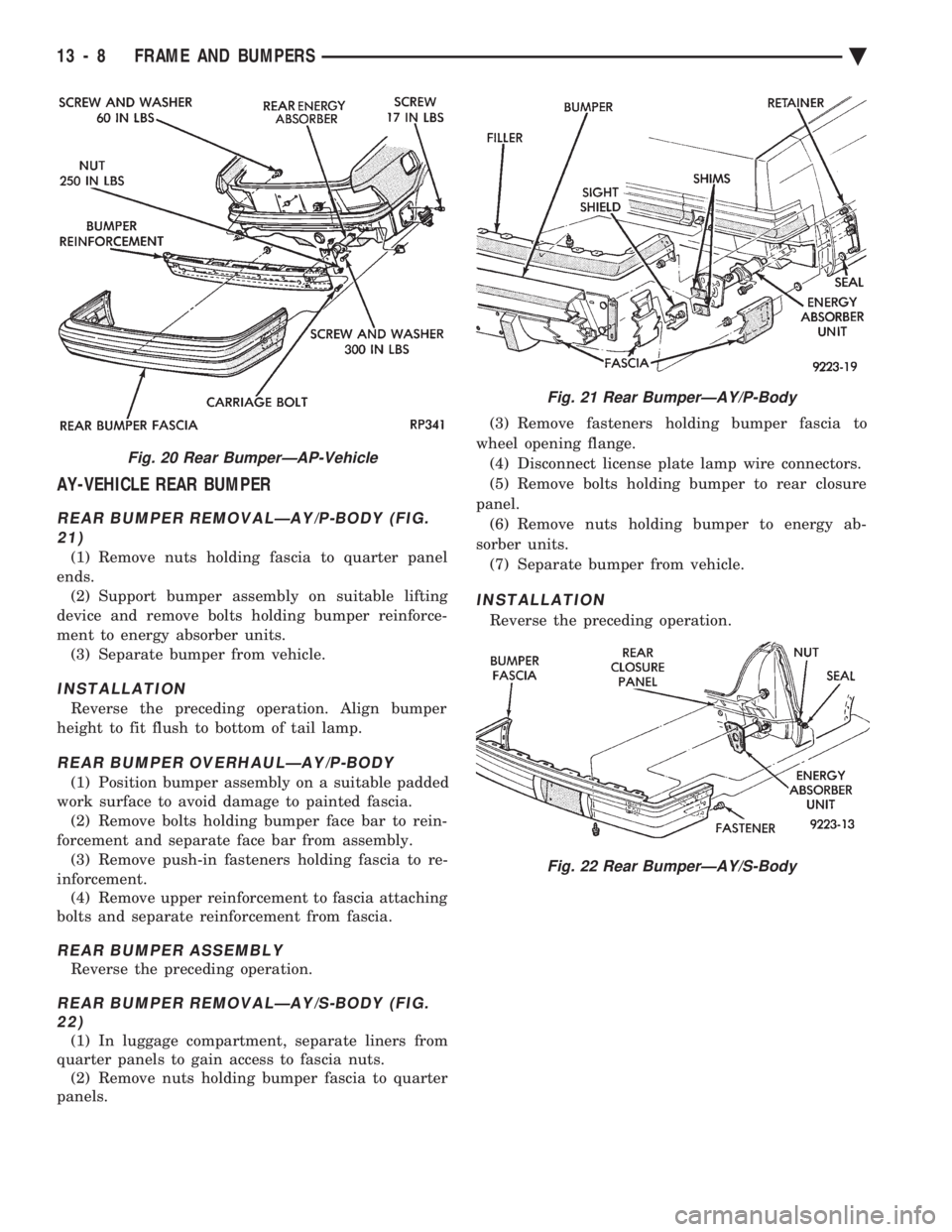

AG-VEHICLE REAR BUMPER

REMOVAL (FIG. 18)

(1) Raise vehicle and support on safety stands.

(2) Remove nuts holding rear fascia to luggage

compartment tail panel. (3) Remove nuts holding fascia ends to quarter

panel end flanges. (4) Remove pop-rivets holding bumper fascia to

wheel lip flanges. (5) Remove nuts holding bumper fascia to quarter

panel along belt line. (6) Support rear bumper assembly on lifting de-

vice. (7) Remove nuts holding rear bumper reinforce-

ment to energy absorbers. (8) Separate bumper from vehicle.

INSTALLATION

Reverse the preceding operation.

AJ-VEHICLE REAR BUMPER

REMOVAL (FIG. 19)

(1) Remove nuts holding rear fascia to quarter

panel ends. (2) Remove push-in fasteners holding fascia to bot-

tom of bumper reinforcement. (3) Remove nuts holding fascia to trunk tail panel.

(4) Remove bolts holding fascia to ends of bumper

reinforcement. (5) Separate fascia from reinforcement and sepa-

rate fascia from vehicle. (6) Support bumper reinforcement on a lifting de-

vice. Remove bolts holding reinforcement to energy

absorbers. Separate reinforcement from energy ab-

sorbers.

INSTALLATION

Reverse the preceding operation.

AP-VEHICLE REAR BUMPER

REMOVAL (FIG. 20)

(1) Raise vehicle and support on safety stands.

(2) Support rear bumper on lifting device.

(3) Remove bolts holding rear bumper reinforce-

ment to energy absorber units. (4) Pull rear bumper assembly rearward to disen-

gage retainers from quarter panel. (5) Separate front bumper from vehicle.

INSTALLATION

Reverse the preceding operation.

Fig. 17 Rear BumperÐAC/C-Body

Fig. 18 Rear Bumper Fascia and ReinforcementÐAG-Vehicle

Fig. 19 Rear Bumper and FasciaÐAJ-Vehicle

Ä FRAME AND BUMPERS 13 - 7

Page 1730 of 2438

AY-VEHICLE REAR BUMPER

REAR BUMPER REMOVALÐAY/P-BODY (FIG. 21)

(1) Remove nuts holding fascia to quarter panel

ends. (2) Support bumper assembly on suitable lifting

device and remove bolts holding bumper reinforce-

ment to energy absorber units. (3) Separate bumper from vehicle.

INSTALLATION

Reverse the preceding operation. Align bumper

height to fit flush to bottom of tail lamp.

REAR BUMPER OVERHAULÐAY/P-BODY

(1) Position bumper assembly on a suitable padded

work surface to avoid damage to painted fascia. (2) Remove bolts holding bumper face bar to rein-

forcement and separate face bar from assembly. (3) Remove push-in fasteners holding fascia to re-

inforcement. (4) Remove upper reinforcement to fascia attaching

bolts and separate reinforcement from fascia.

REAR BUMPER ASSEMBLY

Reverse the preceding operation.

REAR BUMPER REMOVALÐAY/S-BODY (FIG. 22)

(1) In luggage compartment, separate liners from

quarter panels to gain access to fascia nuts. (2) Remove nuts holding bumper fascia to quarter

panels. (3) Remove fasteners holding bumper fascia to

wheel opening flange. (4) Disconnect license plate lamp wire connectors.

(5) Remove bolts holding bumper to rear closure

panel. (6) Remove nuts holding bumper to energy ab-

sorber units. (7) Separate bumper from vehicle.

INSTALLATION

Reverse the preceding operation.

Fig. 20 Rear BumperÐAP-Vehicle

Fig. 21 Rear BumperÐAY/P-Body

Fig. 22 Rear BumperÐAY/S-Body

13 - 8 FRAME AND BUMPERS Ä

Page 1743 of 2438

FUEL DELIVERY SYSTEM INDEX

page page

Chassis Fuel Tubes ...................... 11

Flexible Fuel Components ................... 3

Fuel FilterÐAll Vehicles .................... 9

Fuel Hoses, Clamps, and Quick Connect Fittings . 10

Fuel Pump Assembly ...................... 5

Fuel Pump Module Installation ............... 9

Fuel Pump Module Removal ................. 8

Fuel Pump Pressure TestÐ2.2L/2.5L TBI and 3.0L MPI Engines ........................... 7

Fuel Pump Pressure TestÐAll Except 2.2L/2.5L TBI and 3.0L MPI ....................... 6

Fuel Pump Strainer Service .................. 9 Fuel System Pressure

...................... 6

Fuel System Pressure Release ProcedureÐ 2.2L/2.5L TBI ........................... 4

Fuel System Pressure Release ProcedureÐ3.0L . . 5

Fuel System Pressure Release ProcedureÐExcept 2.2L/2.5L TBI and 3.0L ................... 4

General Information ........................ 3

Identifying Flexible Fuel Components .......... 3

Mechanical Malfunctions .................... 8

Methanol Concentration SensorÐFlexible Fuel AA-Body .............................. 4

Service Precautions for Flexible Fuel Vehicles .... 3

GENERAL INFORMATION

Beginning this model year, Chrysler began produc-

ing AA-Body vehicles designed to operate on a mix-

ture of gasoline and methanol. These automobiles are

referred to as Flexible Fuel vehicles. Flexible fuel vehicles can operate on a mixture of

up to 85 percent methanol, 15 percent unleaded gas-

oline. These vehicles also operate on mixtures con-

taining a lower percentage of methanol or just pure

unleaded gasoline. In many cases, the procedures for servicing flexible

fuel components is identical to gasoline only compo-

nents. Refer to the particular Service Procedure in

this section. If the service procedure for flexible fuel

component differs from a gasoline only component,

the title of each service procedure identifies the ap-

plication.

SERVICE PRECAUTIONS FOR FLEXIBLE FUEL

VEHICLES

Methanol is more toxic than gasoline. Always re-

lease fuel system pressure before servicing fuel sys-

tem components and wear methanol resistant gloves

and eye protection. Avoid breathing methanol vapors or ingesting

methanol. Headaches, dizziness and even uncon-

sciousness could result from breathing these vapors.

Serious injury, blindness and even death could result

from ingesting methanol. Methanol vapors are extremely flammable and can

travel along the ground. Service vehicles in well ven-

tilated areas and avoid ignition sources. Never

smoke while servicing the vehicle. Do not allow methanol to contact skin. Prolonged

contact with methanol can cause dry skin or an al-

lergic skin reaction. Also, prolonged contact could re-

sult in absorption through the skin.

IDENTIFYING FLEXIBLE FUEL COMPONENTS

Flexible Fuel vehicles have unique methanol com-

patible fuel system components. Chrysler identifies

methanol compatible components that could be phys-

ically interchanged with gasoline only parts by color-

ing them green or applying a green label or tag to

them. Even though they may appear physically iden-

tical, components for gasoline only vehicles must not

be used on flexible fuel vehicles.

FLEXIBLE FUEL COMPONENTS

Flexible fuel AA-body vehicles uses many unique

fuel system components. The unique parts are green

in appearance or have a green tag or label attached

to them. While components used on gasoline only ve-

hicles may look similar or identical, they cannot be

used on flexible fuel vehicles. When servicing a com-

ponent, always use an original equipment or equiva-

lent flexible fuel replacement. The fuel system of flexible fuel AA-body vehicles

have the following unique components.

² Fuel pump module

² Fuel level sensor

² Fuel gauge (gauge cluster).

² Fuel tank

² Fuel pressure regulator (including O-rings)

² Fuel rail

² Fuel injectors (including O-rings)

² Fuel tubes

² Fuel filter

² EVAP canister

² Fuel filler cap

² Fuel filler tube

² Pressure relief/Rollover valve

² All fuel system and emission system hoses and

tubes

Ä FUEL SYSTEMS 14 - 3

Page 1749 of 2438

(2) Remove fuel pump and O-ring seal from tank.

Discard old seal.

FUEL PUMP MODULE INSTALLATION

WARNING: FUEL PUMP MODULES DESIGNED FOR

GASOLINE ONLY VEHICLES CANNOT BE USED ON

FLEXIBLE FUEL AA-BODY VEHICLES. WHEN SER-

VICING THE FUEL SYSTEM OF A FLEXIBLE FUEL

VEHICLE, ONLY USE ORIGINAL EQUIPMENT OR

EQUIVALENT REPLACEMENT COMPONENTS.

(1) Wipe seal area of tank clean and place a new

O-ring seal in position on pump. (2) Position fuel pump in tank with locking ring.

(3) Using a hammer and brass drift, drive ring

around in clockwise direction to lock pump in place.

CAUTION: Over tightening the pump lock ring

may result in a leak.

(4) Install tank. Refer to the Fuel Tank Section in

this Group.

FUEL PUMP STRAINER SERVICE

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE SERVICING FUEL SYSTEM COMPONENTS.

WHEN SERVICING FLEXIBLE FUEL VEHICLES,

WEAR METHANOL RESISTANT GLOVES AND EYE

PROTECTION AND AVOID BREATHING FUMES. DO

NOT ALLOW METHANOL/GASOLINE MIXTURES TO

CONTACT SKIN. SERVICE VEHICLES IN WELL VEN-

TILATED AREAS AND AVOID IGNITION SOURCES.

NEVER SMOKE WHILE SERVICING THE VEHICLE.

REMOVAL

(1) Remove fuel pump module. Refer to Fuel Pump

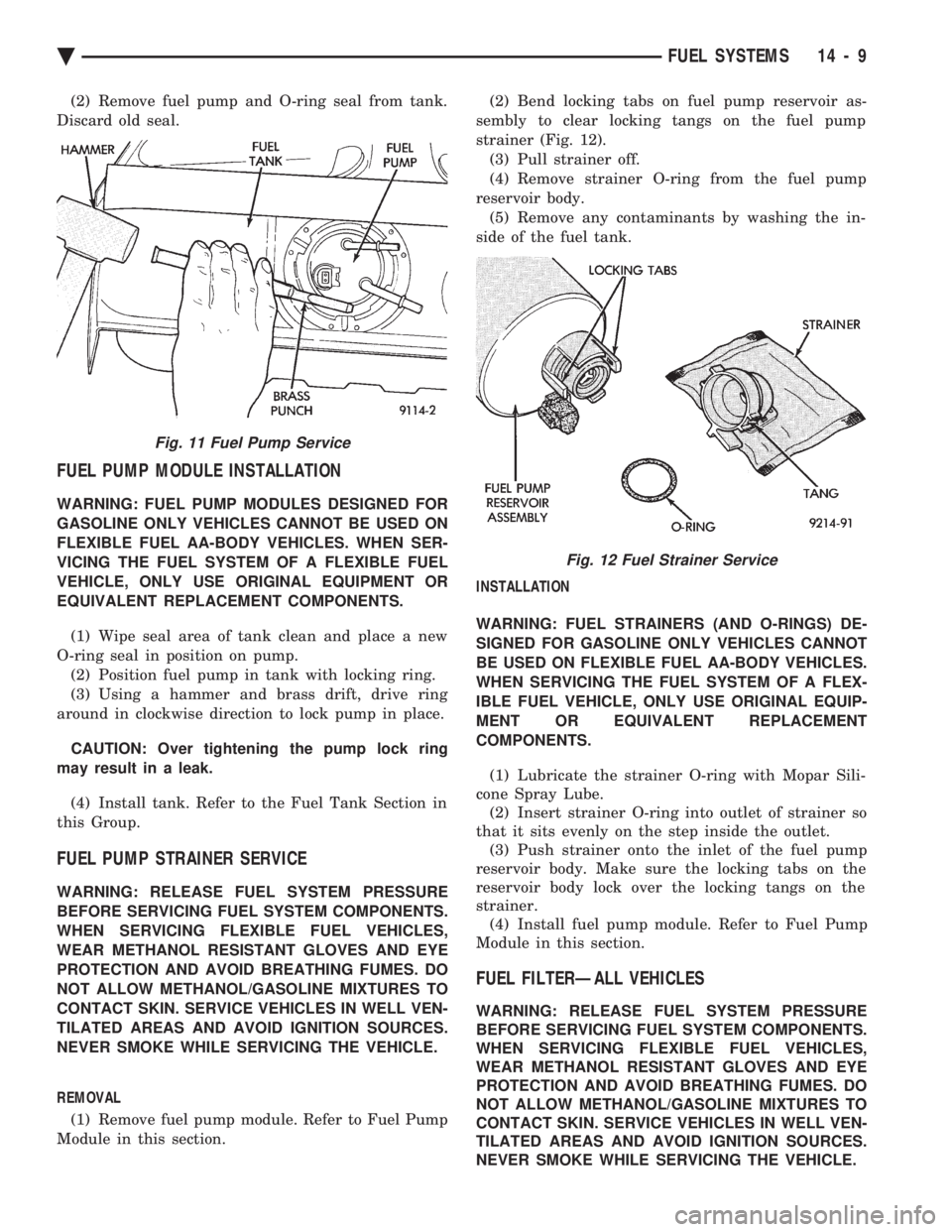

Module in this section. (2) Bend locking tabs on fuel pump reservoir as-

sembly to clear locking tangs on the fuel pump

strainer (Fig. 12). (3) Pull strainer off.

(4) Remove strainer O-ring from the fuel pump

reservoir body. (5) Remove any contaminants by washing the in-

side of the fuel tank.

INSTALLATION

WARNING: FUEL STRAINERS (AND O-RINGS) DE-

SIGNED FOR GASOLINE ONLY VEHICLES CANNOT

BE USED ON FLEXIBLE FUEL AA-BODY VEHICLES.

WHEN SERVICING THE FUEL SYSTEM OF A FLEX-

IBLE FUEL VEHICLE, ONLY USE ORIGINAL EQUIP-

MENT OR EQUIVALENT REPLACEMENT

COMPONENTS.

(1) Lubricate the strainer O-ring with Mopar Sili-

cone Spray Lube. (2) Insert strainer O-ring into outlet of strainer so

that it sits evenly on the step inside the outlet. (3) Push strainer onto the inlet of the fuel pump

reservoir body. Make sure the locking tabs on the

reservoir body lock over the locking tangs on the

strainer. (4) Install fuel pump module. Refer to Fuel Pump

Module in this section.

FUEL FILTERÐALL VEHICLES

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE SERVICING FUEL SYSTEM COMPONENTS.

WHEN SERVICING FLEXIBLE FUEL VEHICLES,

WEAR METHANOL RESISTANT GLOVES AND EYE

PROTECTION AND AVOID BREATHING FUMES. DO

NOT ALLOW METHANOL/GASOLINE MIXTURES TO

CONTACT SKIN. SERVICE VEHICLES IN WELL VEN-

TILATED AREAS AND AVOID IGNITION SOURCES.

NEVER SMOKE WHILE SERVICING THE VEHICLE.

Fig. 11 Fuel Pump Service

Fig. 12 Fuel Strainer Service

Ä FUEL SYSTEMS 14 - 9