fuel pressure CHEVROLET DYNASTY 1993 Service Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 1910 of 2438

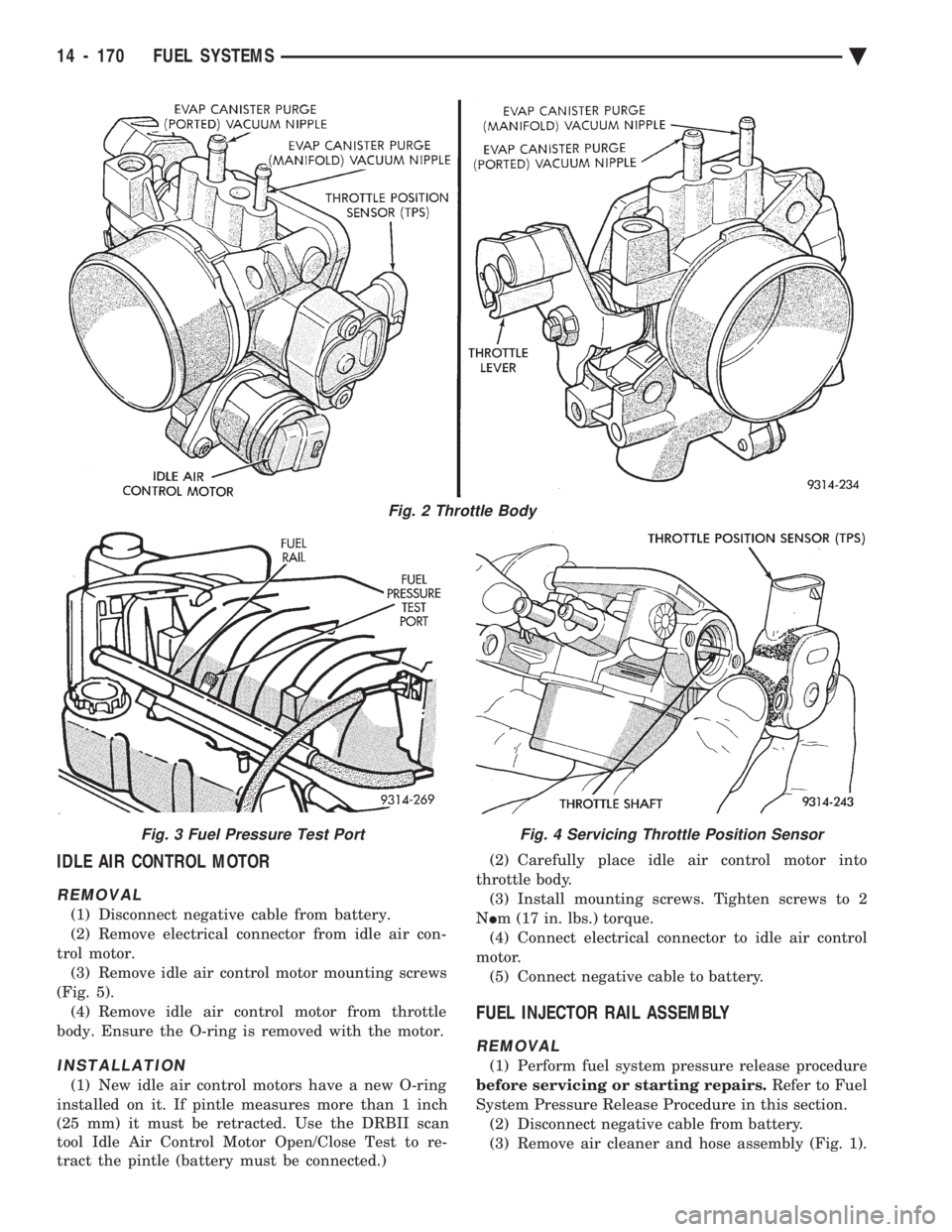

IDLE AIR CONTROL MOTOR

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove electrical connector from idle air con-

trol motor. (3) Remove idle air control motor mounting screws

(Fig. 5). (4) Remove idle air control motor from throttle

body. Ensure the O-ring is removed with the motor.

INSTALLATION

(1) New idle air control motors have a new O-ring

installed on it. If pintle measures more than 1 inch

(25 mm) it must be retracted. Use the DRBII scan

tool Idle Air Control Motor Open/Close Test to re-

tract the pintle (battery must be connected.) (2) Carefully place idle air control motor into

throttle body. (3) Install mounting screws. Tighten screws to 2

N Im (17 in. lbs.) torque.

(4) Connect electrical connector to idle air control

motor. (5) Connect negative cable to battery.

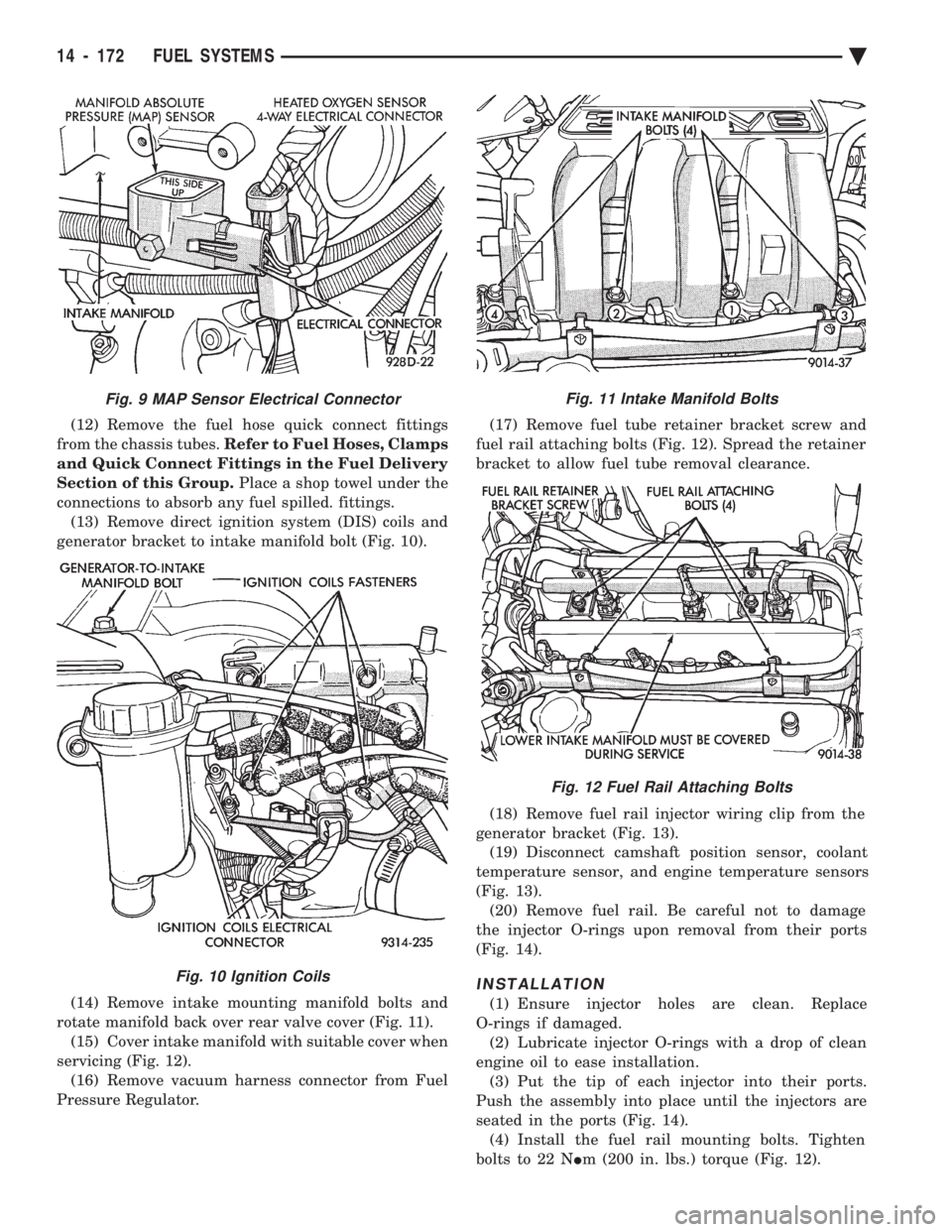

FUEL INJECTOR RAIL ASSEMBLY

REMOVAL

(1) Perform fuel system pressure release procedure

before servicing or starting repairs. Refer to Fuel

System Pressure Release Procedure in this section. (2) Disconnect negative cable from battery.

(3) Remove air cleaner and hose assembly (Fig. 1).

Fig. 2 Throttle Body

Fig. 3 Fuel Pressure Test PortFig. 4 Servicing Throttle Position Sensor

14 - 170 FUEL SYSTEMS Ä

Page 1912 of 2438

(12) Remove the fuel hose quick connect fittings

from the chassis tubes. Refer to Fuel Hoses, Clamps

and Quick Connect Fittings in the Fuel Delivery

Section of this Group. Place a shop towel under the

connections to absorb any fuel spilled. fittings. (13) Remove direct ignition system (DIS) coils and

generator bracket to intake manifold bolt (Fig. 10).

(14) Remove intake mounting manifold bolts and

rotate manifold back over rear valve cover (Fig. 11). (15) Cover intake manifold with suitable cover when

servicing (Fig. 12). (16) Remove vacuum harness connector from Fuel

Pressure Regulator. (17) Remove fuel tube retainer bracket screw and

fuel rail attaching bolts (Fig. 12). Spread the retainer

bracket to allow fuel tube removal clearance.

(18) Remove fuel rail injector wiring clip from the

generator bracket (Fig. 13). (19) Disconnect camshaft position sensor, coolant

temperature sensor, and engine temperature sensors

(Fig. 13). (20) Remove fuel rail. Be careful not to damage

the injector O-rings upon removal from their ports

(Fig. 14).

INSTALLATION

(1) Ensure injector holes are clean. Replace

O-rings if damaged. (2) Lubricate injector O-rings with a drop of clean

engine oil to ease installation. (3) Put the tip of each injector into their ports.

Push the assembly into place until the injectors are

seated in the ports (Fig. 14). (4) Install the fuel rail mounting bolts. Tighten

bolts to 22 N Im (200 in. lbs.) torque (Fig. 12).

Fig. 11 Intake Manifold Bolts

Fig. 12 Fuel Rail Attaching Bolts

Fig. 9 MAP Sensor Electrical Connector

Fig. 10 Ignition Coils

14 - 172 FUEL SYSTEMS Ä

Page 1913 of 2438

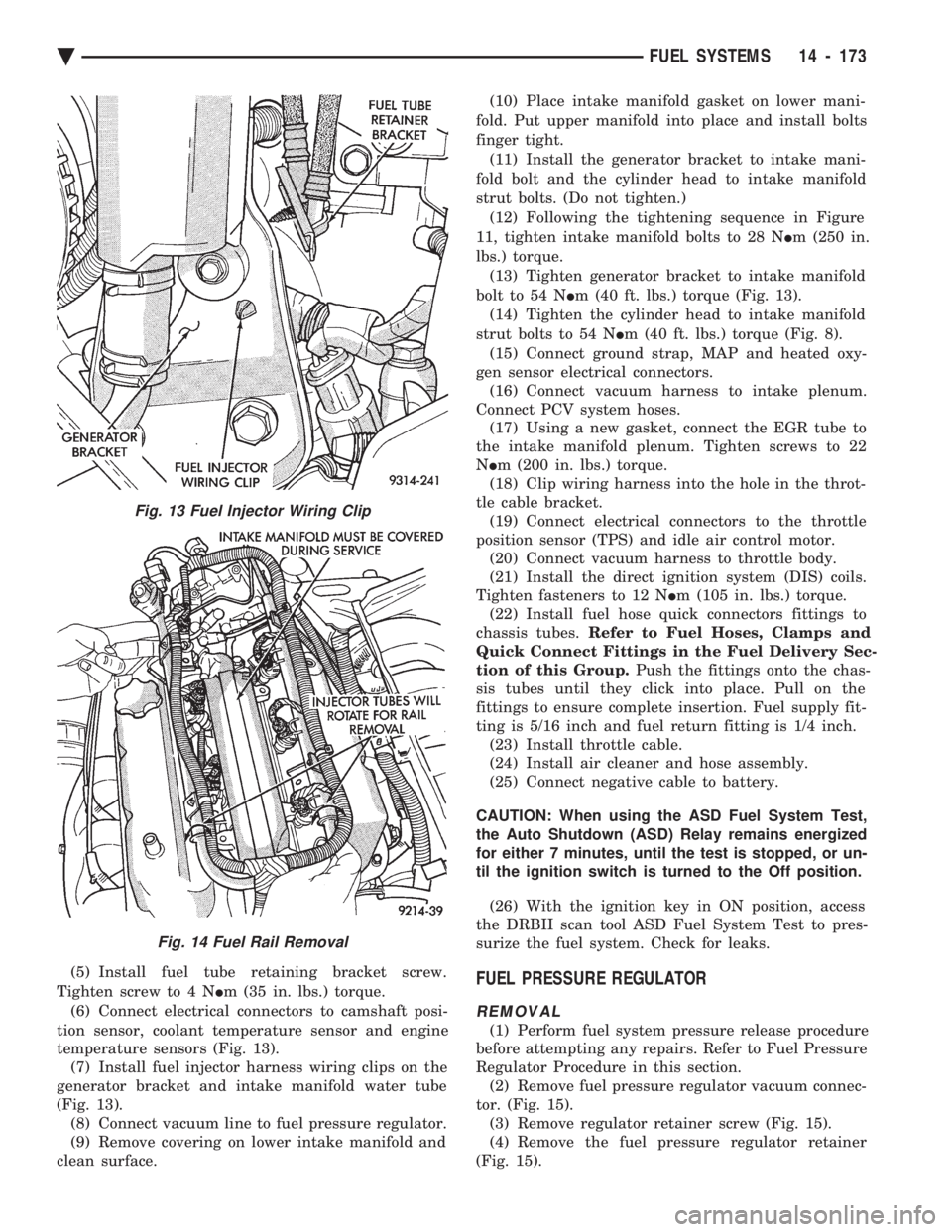

(5) Install fuel tube retaining bracket screw.

Tighten screw to 4 N Im (35 in. lbs.) torque.

(6) Connect electrical connectors to camshaft posi-

tion sensor, coolant temperature sensor and engine

temperature sensors (Fig. 13). (7) Install fuel injector harness wiring clips on the

generator bracket and intake manifold water tube

(Fig. 13). (8) Connect vacuum line to fuel pressure regulator.

(9) Remove covering on lower intake manifold and

clean surface. (10) Place intake manifold gasket on lower mani-

fold. Put upper manifold into place and install bolts

finger tight. (11) Install the generator bracket to intake mani-

fold bolt and the cylinder head to intake manifold

strut bolts. (Do not tighten.) (12) Following the tightening sequence in Figure

11, tighten intake manifold bolts to 28 N Im (250 in.

lbs.) torque. (13) Tighten generator bracket to intake manifold

bolt to 54 N Im (40 ft. lbs.) torque (Fig. 13).

(14) Tighten the cylinder head to intake manifold

strut bolts to 54 N Im (40 ft. lbs.) torque (Fig. 8).

(15) Connect ground strap, MAP and heated oxy-

gen sensor electrical connectors. (16) Connect vacuum harness to intake plenum.

Connect PCV system hoses. (17) Using a new gasket, connect the EGR tube to

the intake manifold plenum. Tighten screws to 22

N Im (200 in. lbs.) torque.

(18) Clip wiring harness into the hole in the throt-

tle cable bracket. (19) Connect electrical connectors to the throttle

position sensor (TPS) and idle air control motor. (20) Connect vacuum harness to throttle body.

(21) Install the direct ignition system (DIS) coils.

Tighten fasteners to 12 N Im (105 in. lbs.) torque.

(22) Install fuel hose quick connectors fittings to

chassis tubes. Refer to Fuel Hoses, Clamps and

Quick Connect Fittings in the Fuel Delivery Sec-

tion of this Group. Push the fittings onto the chas-

sis tubes until they click into place. Pull on the

fittings to ensure complete insertion. Fuel supply fit-

ting is 5/16 inch and fuel return fitting is 1/4 inch. (23) Install throttle cable.

(24) Install air cleaner and hose assembly.

(25) Connect negative cable to battery.

CAUTION: When using the ASD Fuel System Test,

the Auto Shutdown (ASD) Relay remains energized

for either 7 minutes, until the test is stopped, or un-

til the ignition switch is turned to the Off position.

(26) With the ignition key in ON position, access

the DRBII scan tool ASD Fuel System Test to pres-

surize the fuel system. Check for leaks.FUEL PRESSURE REGULATOR

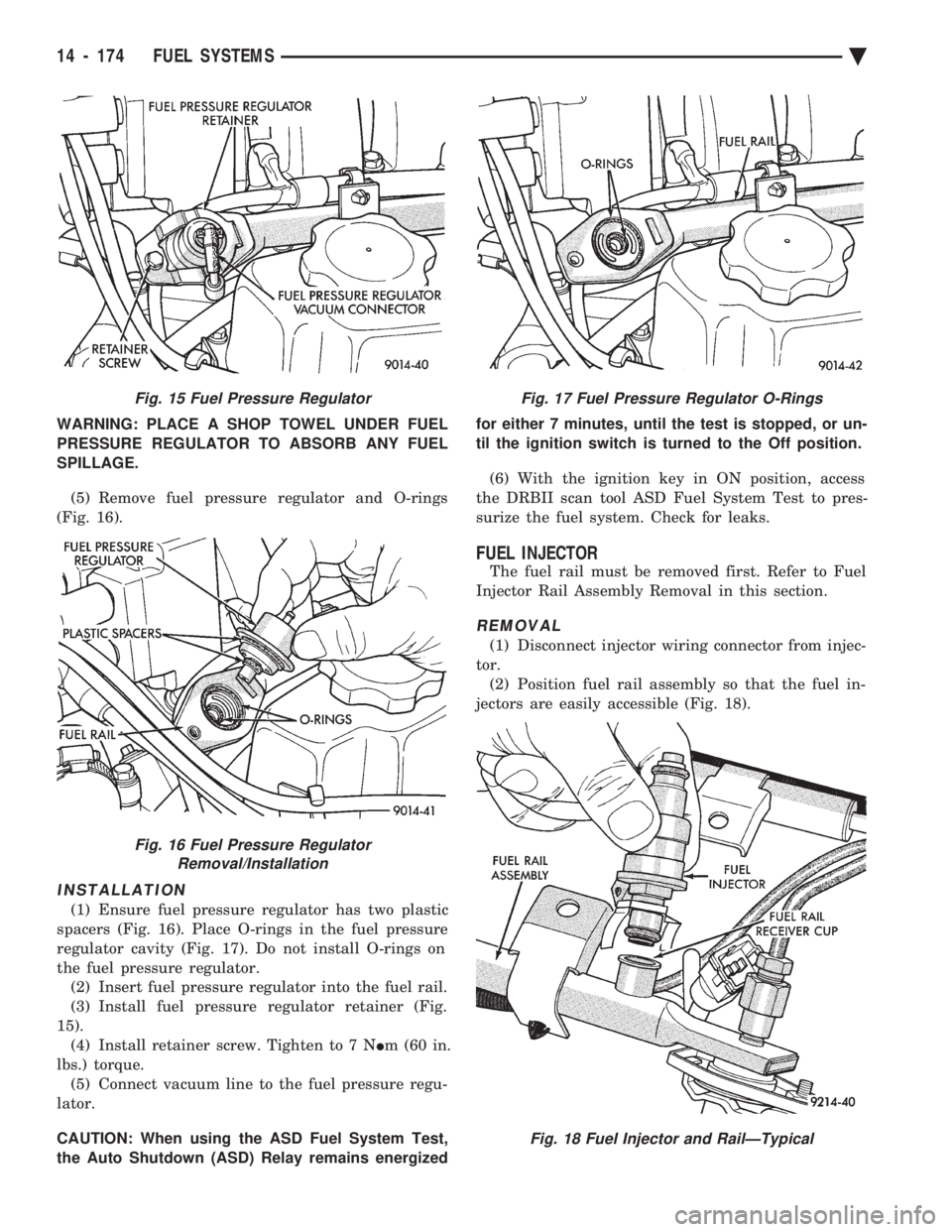

REMOVAL

(1) Perform fuel system pressure release procedure

before attempting any repairs. Refer to Fuel Pressure

Regulator Procedure in this section. (2) Remove fuel pressure regulator vacuum connec-

tor. (Fig. 15). (3) Remove regulator retainer screw (Fig. 15).

(4) Remove the fuel pressure regulator retainer

(Fig. 15).

Fig. 13 Fuel Injector Wiring Clip

Fig. 14 Fuel Rail Removal

Ä FUEL SYSTEMS 14 - 173

Page 1914 of 2438

WARNING: PLACE A SHOP TOWEL UNDER FUEL

PRESSURE REGULATOR TO ABSORB ANY FUEL

SPILLAGE.

(5) Remove fuel pressure regulator and O-rings

(Fig. 16).

INSTALLATION

(1) Ensure fuel pressure regulator has two plastic

spacers (Fig. 16). Place O-rings in the fuel pressure

regulator cavity (Fig. 17). Do not install O-rings on

the fuel pressure regulator. (2) Insert fuel pressure regulator into the fuel rail.

(3) Install fuel pressure regulator retainer (Fig.

15). (4) Install retainer screw. Tighten to 7 N Im (60 in.

lbs.) torque. (5) Connect vacuum line to the fuel pressure regu-

lator.

CAUTION: When using the ASD Fuel System Test,

the Auto Shutdown (ASD) Relay remains energized for either 7 minutes, until the test is stopped, or un-

til the ignition switch is turned to the Off position.

(6) With the ignition key in ON position, access

the DRBII scan tool ASD Fuel System Test to pres-

surize the fuel system. Check for leaks.

FUEL INJECTOR

The fuel rail must be removed first. Refer to Fuel

Injector Rail Assembly Removal in this section.

REMOVAL

(1) Disconnect injector wiring connector from injec-

tor. (2) Position fuel rail assembly so that the fuel in-

jectors are easily accessible (Fig. 18).

Fig. 15 Fuel Pressure Regulator

Fig. 16 Fuel Pressure Regulator Removal/Installation

Fig. 17 Fuel Pressure Regulator O-Rings

Fig. 18 Fuel Injector and RailÐTypical

14 - 174 FUEL SYSTEMS Ä

Page 1915 of 2438

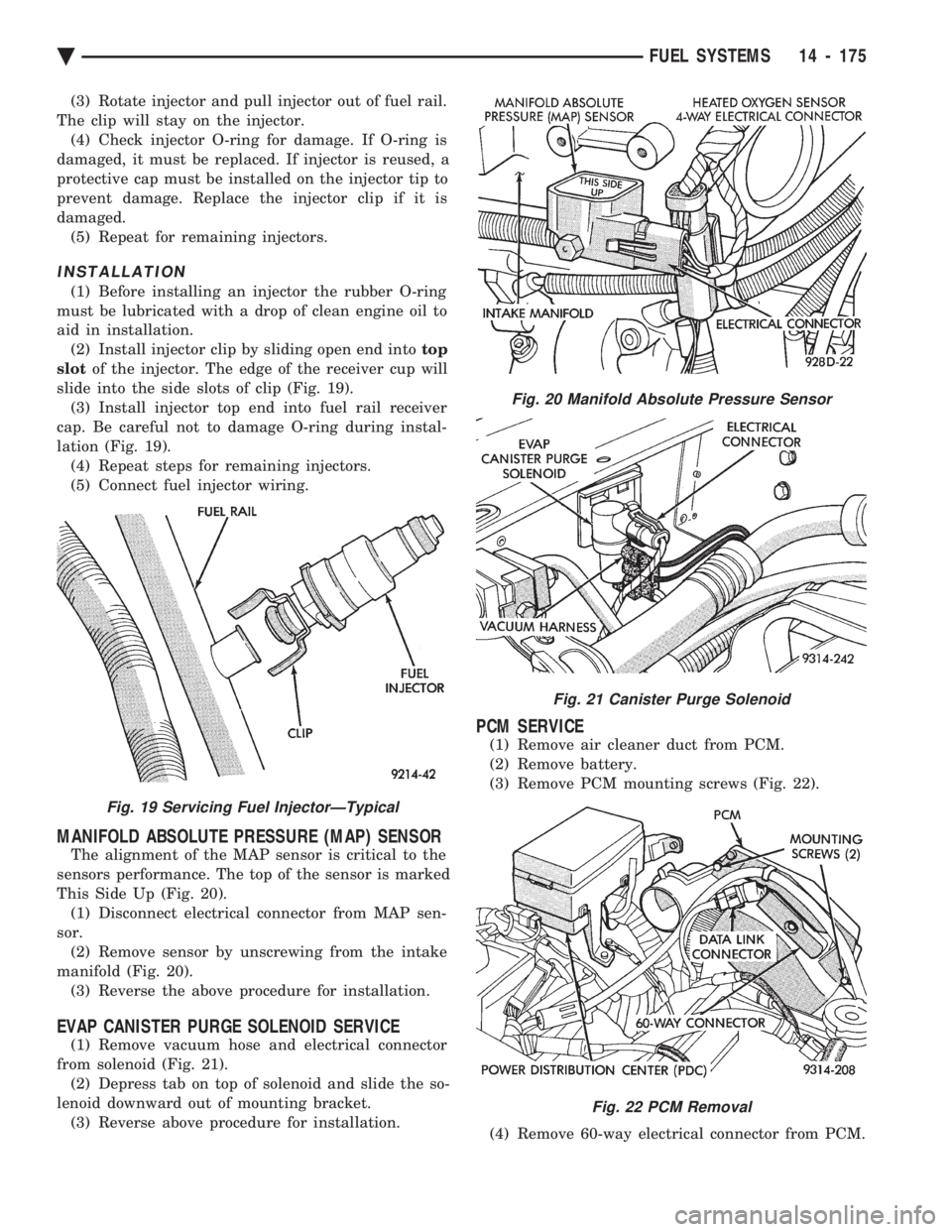

(3) Rotate injector and pull injector out of fuel rail.

The clip will stay on the injector. (4) Check injector O-ring for damage. If O-ring is

damaged, it must be replaced. If injector is reused, a

protective cap must be installed on the injector tip to

prevent damage. Replace the injector clip if it is

damaged. (5) Repeat for remaining injectors.

INSTALLATION

(1) Before installing an injector the rubber O-ring

must be lubricated with a drop of clean engine oil to

aid in installation. (2) Install injector clip by sliding open end into top

slot of the injector. The edge of the receiver cup will

slide into the side slots of clip (Fig. 19). (3) Install injector top end into fuel rail receiver

cap. Be careful not to damage O-ring during instal-

lation (Fig. 19). (4) Repeat steps for remaining injectors.

(5) Connect fuel injector wiring.

MANIFOLD ABSOLUTE PRESSURE (MAP) SENSOR

The alignment of the MAP sensor is critical to the

sensors performance. The top of the sensor is marked

This Side Up (Fig. 20). (1) Disconnect electrical connector from MAP sen-

sor. (2) Remove sensor by unscrewing from the intake

manifold (Fig. 20). (3) Reverse the above procedure for installation.

EVAP CANISTER PURGE SOLENOID SERVICE

(1) Remove vacuum hose and electrical connector

from solenoid (Fig. 21). (2) Depress tab on top of solenoid and slide the so-

lenoid downward out of mounting bracket. (3) Reverse above procedure for installation.

PCM SERVICE

(1) Remove air cleaner duct from PCM.

(2) Remove battery.

(3) Remove PCM mounting screws (Fig. 22).

(4) Remove 60-way electrical connector from PCM.

Fig. 19 Servicing Fuel InjectorÐTypical

Fig. 20 Manifold Absolute Pressure Sensor

Fig. 21 Canister Purge Solenoid

Fig. 22 PCM Removal

Ä FUEL SYSTEMS 14 - 175

Page 2150 of 2438

PRESSURE GAUGES

High quality dial type air pressure gauges are rec-

ommended. After checking pressure with the gauge,

replace valve caps and tighten finger tight.

TIRE INFLATION PRESSURES

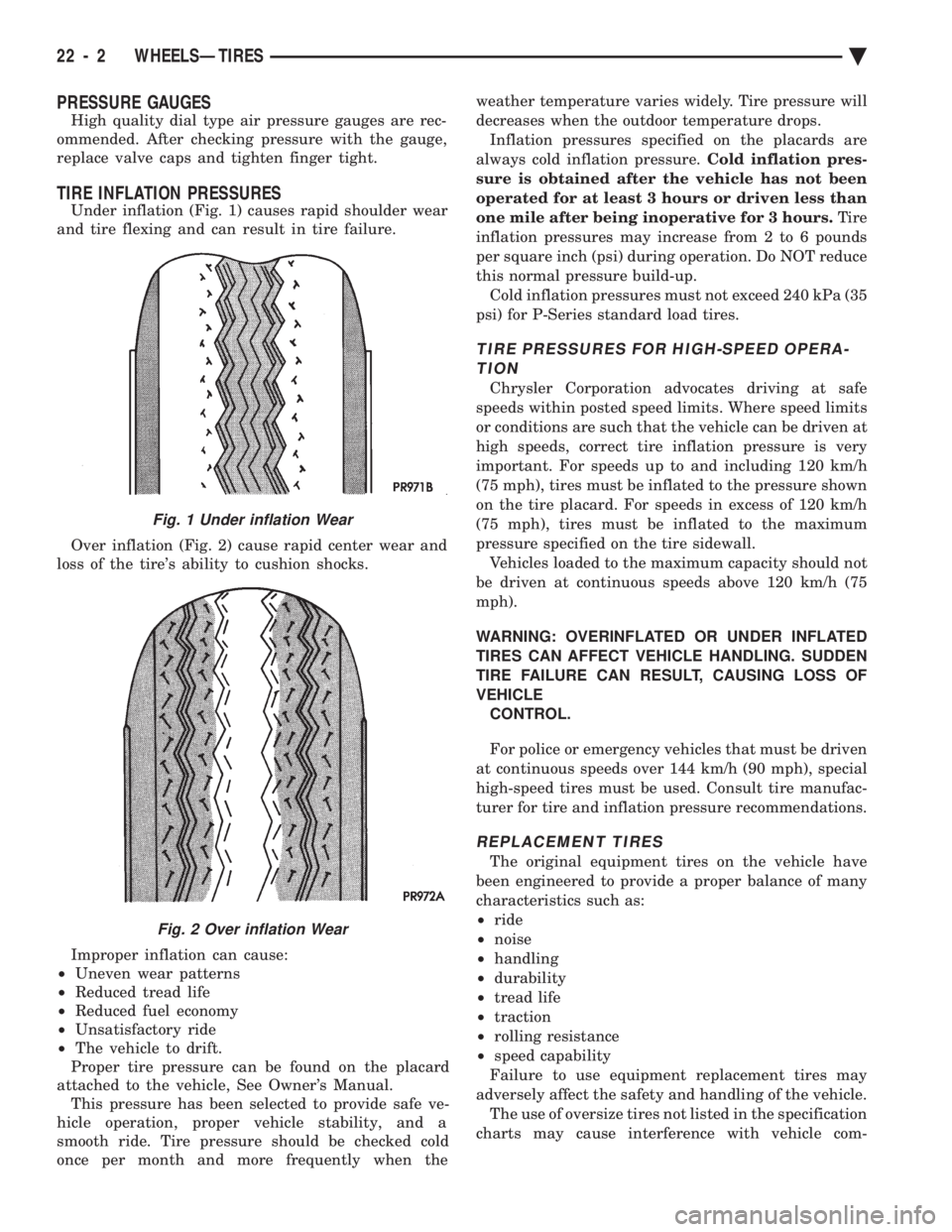

Under inflation (Fig. 1) causes rapid shoulder wear

and tire flexing and can result in tire failure.

Over inflation (Fig. 2) cause rapid center wear and

loss of the tire's ability to cushion shocks.

Improper inflation can cause:

² Uneven wear patterns

² Reduced tread life

² Reduced fuel economy

² Unsatisfactory ride

² The vehicle to drift.

Proper tire pressure can be found on the placard

attached to the vehicle, See Owner's Manual. This pressure has been selected to provide safe ve-

hicle operation, proper vehicle stability, and a

smooth ride. Tire pressure should be checked cold

once per month and more frequently when the weather temperature varies widely. Tire pressure will

decreases when the outdoor temperature drops.

Inflation pressures specified on the placards are

always cold inflation pressure. Cold inflation pres-

sure is obtained after the vehicle has not been

operated for at least 3 hours or driven less than

one mile after being inoperative for 3 hours. Tire

inflation pressures may increase from 2 to 6 pounds

per square inch (psi) during operation. Do NOT reduce

this normal pressure build-up. Cold inflation pressures must not exceed 240 kPa (35

psi) for P-Series standard load tires.

TIRE PRESSURES FOR HIGH-SPEED OPERA- TION

Chrysler Corporation advocates driving at safe

speeds within posted speed limits. Where speed limits

or conditions are such that the vehicle can be driven at

high speeds, correct tire inflation pressure is very

important. For speeds up to and including 120 km/h

(75 mph), tires must be inflated to the pressure shown

on the tire placard. For speeds in excess of 120 km/h

(75 mph), tires must be inflated to the maximum

pressure specified on the tire sidewall. Vehicles loaded to the maximum capacity should not

be driven at continuous speeds above 120 km/h (75

mph).

WARNING: OVERINFLATED OR UNDER INFLATED

TIRES CAN AFFECT VEHICLE HANDLING. SUDDEN

TIRE FAILURE CAN RESULT, CAUSING LOSS OF

VEHICLE CONTROL.

For police or emergency vehicles that must be driven

at continuous speeds over 144 km/h (90 mph), special

high-speed tires must be used. Consult tire manufac-

turer for tire and inflation pressure recommendations.

REPLACEMENT TIRES

The original equipment tires on the vehicle have

been engineered to provide a proper balance of many

characteristics such as:

² ride

² noise

² handling

² durability

² tread life

² traction

² rolling resistance

² speed capability

Failure to use equipment replacement tires may

adversely affect the safety and handling of the vehicle. The use of oversize tires not listed in the specification

charts may cause interference with vehicle com-

Fig. 1 Under inflation Wear

Fig. 2 Over inflation Wear

22 - 2 WHEELSÐTIRES Ä

Page 2401 of 2438

EVAPORATION CONTROL SYSTEM

The evaporation control system prevents the emis-

sion of fuel tank vapors into the atmosphere. When fuel

evaporates in the fuel tank, the vapors pass through

vent hoses or tubes to a charcoal canister. The canister

temporarily holds the vapors. The powertrain control

module (PCM) allows intake manifold vacuum to draw

vapors into the combustion chambers during certain

operating conditions. The PCM uses the canister purge

solenoid to regulate vapor flow. On 2.2L and 2.5L TBI, 3.3L, and 3.8L engines,

manifold vacuum purges the vapors at idle as well as

off idle. These engines use a bi-level purge system. The

system uses 2 sources of vacuum remove fuel vapors

from the canister. Turbo III engines use a tri-level canister purge sys-

tem. In this system, fuel vapors are drawn into the

engine through the throttle body and air cleaner. Fuel

vapors are drawn in at closed throttle, part throttle,

and wide open throttle (in boost). The 2.5L MPI (flexible fuel AA-Body) and 3.0L have

a duty cycle purge system. The powertrain control

module PCM controls vapor flow by operating the duty

cycle EVAP purge solenoid. Refer to Duty Cycle EVAP

Purge Solenoid in this section. The evaporative system uses specially manu-

factured hoses. If they need replacement, only

use fuel resistant hose.

PRESSURE RELIEF/ROLLOVER VALVE

All vehicles have a combination pressure relief and

rollover valve. The dual function valve relieves fuel

tank pressure. The valve also prevents fuel flow

through the fuel tank vent valve hoses if the vehicle

accidentally rolls over. All vehicles pass a 360É rollover. The pressure relief valve opens at a certain pressure.

When fuel tank pressure increases above the cali-

brated pressure, the valve opens to release fuel tank

vapors pressure. The evaporative (charcoal) canister

stores the vapors. For pressure relief/rollover valve

service, refer to the Fuel Tank section of Group 14.

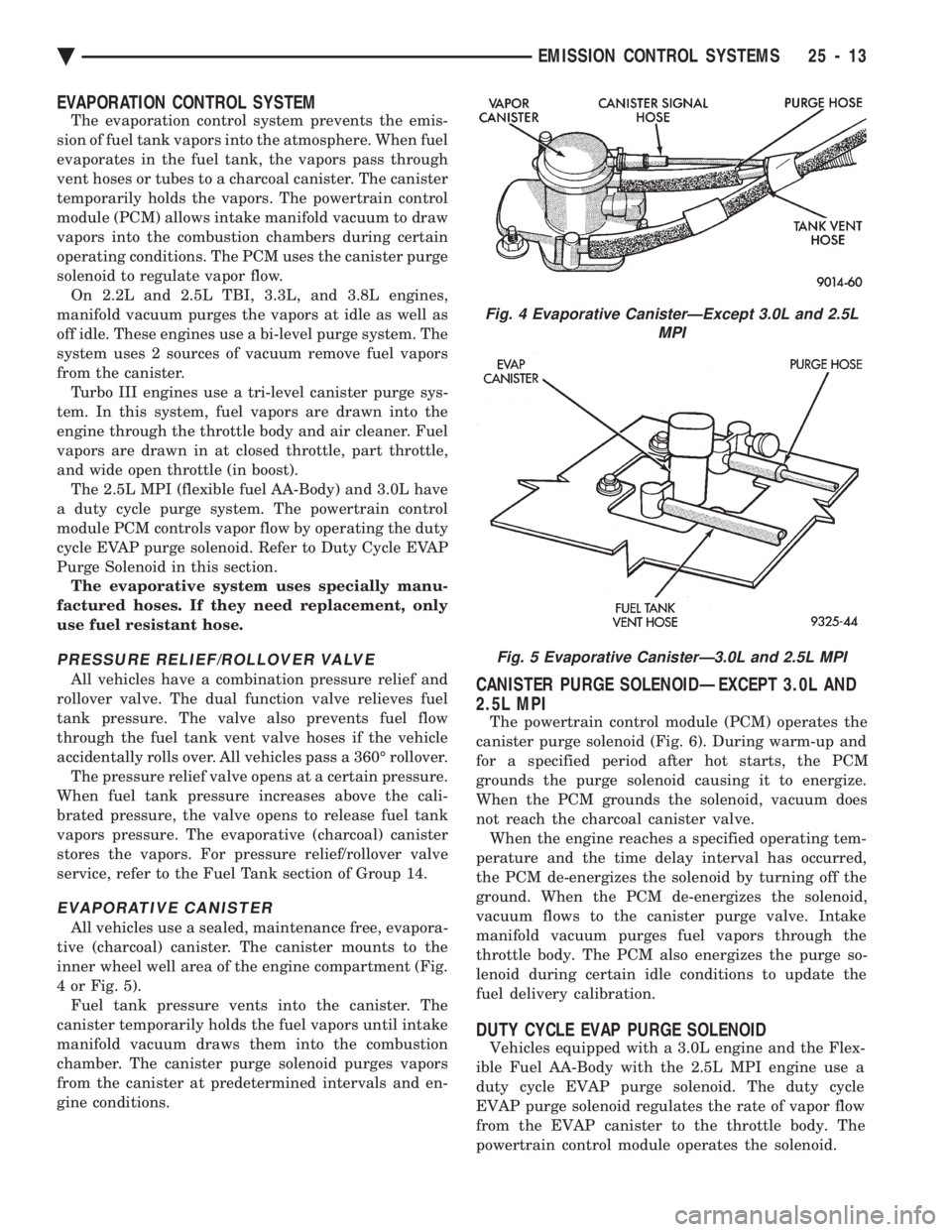

EVAPORATIVE CANISTER

All vehicles use a sealed, maintenance free, evapora-

tive (charcoal) canister. The canister mounts to the

inner wheel well area of the engine compartment (Fig.

4 or Fig. 5). Fuel tank pressure vents into the canister. The

canister temporarily holds the fuel vapors until intake

manifold vacuum draws them into the combustion

chamber. The canister purge solenoid purges vapors

from the canister at predetermined intervals and en-

gine conditions.

CANISTER PURGE SOLENOIDÐEXCEPT 3.0L AND

2.5L MPI

The powertrain control module (PCM) operates the

canister purge solenoid (Fig. 6). During warm-up and

for a specified period after hot starts, the PCM

grounds the purge solenoid causing it to energize.

When the PCM grounds the solenoid, vacuum does

not reach the charcoal canister valve. When the engine reaches a specified operating tem-

perature and the time delay interval has occurred,

the PCM de-energizes the solenoid by turning off the

ground. When the PCM de-energizes the solenoid,

vacuum flows to the canister purge valve. Intake

manifold vacuum purges fuel vapors through the

throttle body. The PCM also energizes the purge so-

lenoid during certain idle conditions to update the

fuel delivery calibration.

DUTY CYCLE EVAP PURGE SOLENOID

Vehicles equipped with a 3.0L engine and the Flex-

ible Fuel AA-Body with the 2.5L MPI engine use a

duty cycle EVAP purge solenoid. The duty cycle

EVAP purge solenoid regulates the rate of vapor flow

from the EVAP canister to the throttle body. The

powertrain control module operates the solenoid.

Fig. 4 Evaporative CanisterÐExcept 3.0L and 2.5L MPI

Fig. 5 Evaporative CanisterÐ3.0L and 2.5L MPI

Ä EMISSION CONTROL SYSTEMS 25 - 13

Page 2402 of 2438

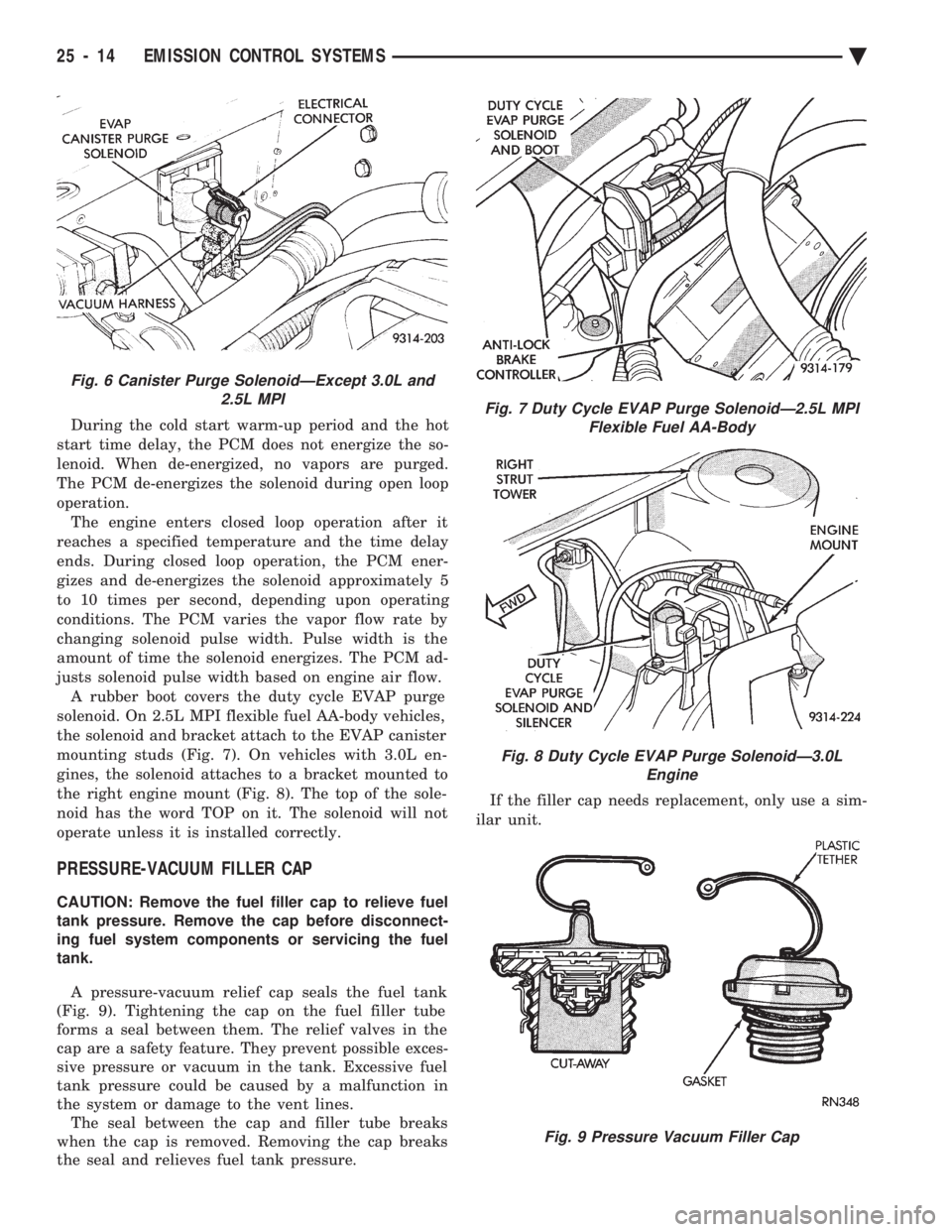

During the cold start warm-up period and the hot

start time delay, the PCM does not energize the so-

lenoid. When de-energized, no vapors are purged.

The PCM de-energizes the solenoid during open loop

operation. The engine enters closed loop operation after it

reaches a specified temperature and the time delay

ends. During closed loop operation, the PCM ener-

gizes and de-energizes the solenoid approximately 5

to 10 times per second, depending upon operating

conditions. The PCM varies the vapor flow rate by

changing solenoid pulse width. Pulse width is the

amount of time the solenoid energizes. The PCM ad-

justs solenoid pulse width based on engine air flow. A rubber boot covers the duty cycle EVAP purge

solenoid. On 2.5L MPI flexible fuel AA-body vehicles,

the solenoid and bracket attach to the EVAP canister

mounting studs (Fig. 7). On vehicles with 3.0L en-

gines, the solenoid attaches to a bracket mounted to

the right engine mount (Fig. 8). The top of the sole-

noid has the word TOP on it. The solenoid will not

operate unless it is installed correctly.

PRESSURE-VACUUM FILLER CAP

CAUTION: Remove the fuel filler cap to relieve fuel

tank pressure. Remove the cap before disconnect-

ing fuel system components or servicing the fuel

tank.

A pressure-vacuum relief cap seals the fuel tank

(Fig. 9). Tightening the cap on the fuel filler tube

forms a seal between them. The relief valves in the

cap are a safety feature. They prevent possible exces-

sive pressure or vacuum in the tank. Excessive fuel

tank pressure could be caused by a malfunction in

the system or damage to the vent lines. The seal between the cap and filler tube breaks

when the cap is removed. Removing the cap breaks

the seal and relieves fuel tank pressure. If the filler cap needs replacement, only use a sim-

ilar unit.

Fig. 6 Canister Purge SolenoidÐExcept 3.0L and 2.5L MPI

Fig. 7 Duty Cycle EVAP Purge SolenoidÐ2.5L MPIFlexible Fuel AA-Body

Fig. 8 Duty Cycle EVAP Purge SolenoidÐ3.0L Engine

Fig. 9 Pressure Vacuum Filler Cap

25 - 14 EMISSION CONTROL SYSTEMS Ä

Page 2408 of 2438

(1) Disconnect oxygen sensor electrical connector.

(2) Remove sensor using Tool C-4907 (Fig. 11).

After removing the sensor, the exhaust manifold

threads must be cleaned with an 18 mm X 1.5 + 6E

tap. If reusing the original sensor, coat the sensor

threads with an anti-seize compound such as Loctite

771-64 or equivalent. New sensors have compound on

the threads and do not require additional compound.

Tighten the sensor to 27 N Im (20 ft. lbs.) torque.

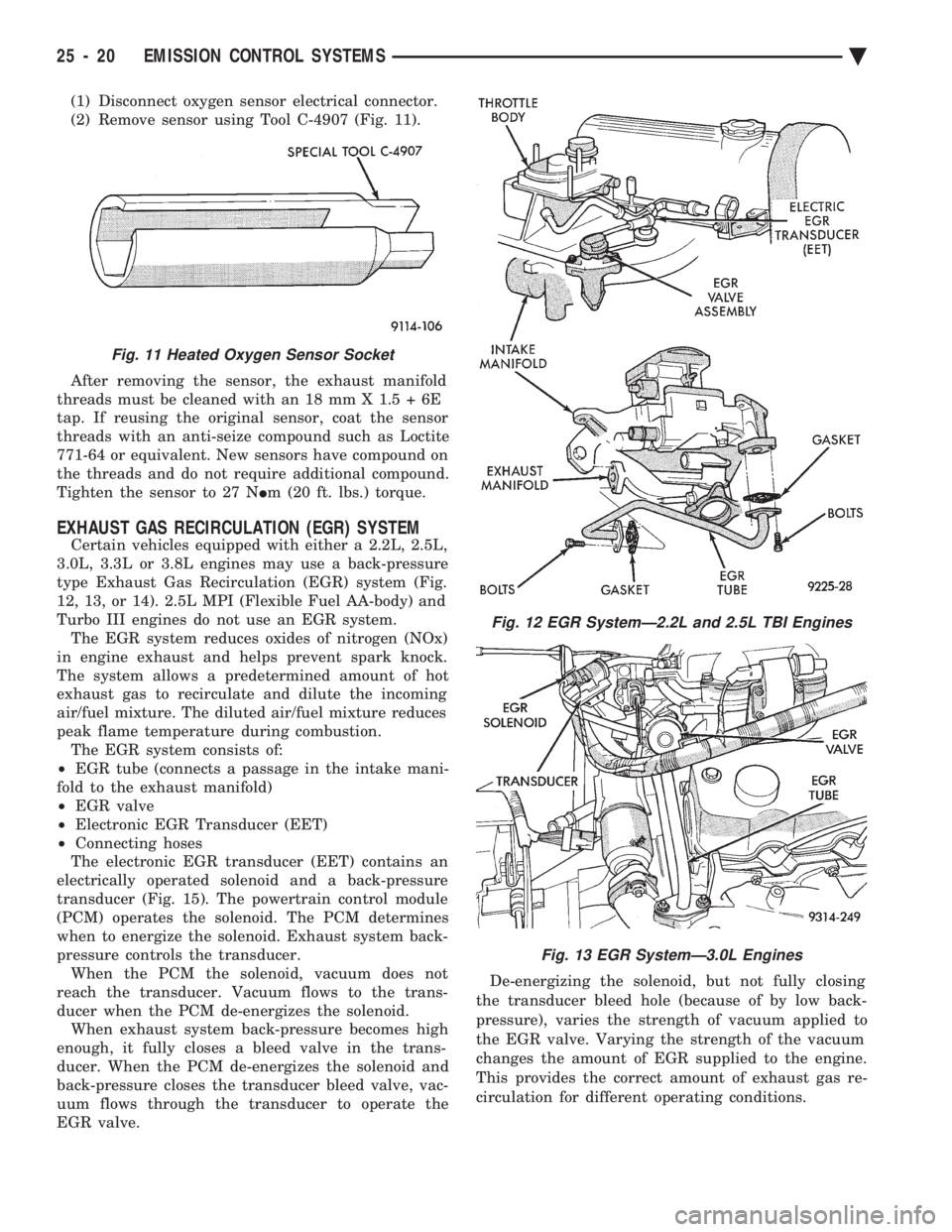

EXHAUST GAS RECIRCULATION (EGR) SYSTEM

Certain vehicles equipped with either a 2.2L, 2.5L,

3.0L, 3.3L or 3.8L engines may use a back-pressure

type Exhaust Gas Recirculation (EGR) system (Fig.

12, 13, or 14). 2.5L MPI (Flexible Fuel AA-body) and

Turbo III engines do not use an EGR system. The EGR system reduces oxides of nitrogen (NOx)

in engine exhaust and helps prevent spark knock.

The system allows a predetermined amount of hot

exhaust gas to recirculate and dilute the incoming

air/fuel mixture. The diluted air/fuel mixture reduces

peak flame temperature during combustion. The EGR system consists of:

² EGR tube (connects a passage in the intake mani-

fold to the exhaust manifold)

² EGR valve

² Electronic EGR Transducer (EET)

² Connecting hoses

The electronic EGR transducer (EET) contains an

electrically operated solenoid and a back-pressure

transducer (Fig. 15). The powertrain control module

(PCM) operates the solenoid. The PCM determines

when to energize the solenoid. Exhaust system back-

pressure controls the transducer. When the PCM the solenoid, vacuum does not

reach the transducer. Vacuum flows to the trans-

ducer when the PCM de-energizes the solenoid. When exhaust system back-pressure becomes high

enough, it fully closes a bleed valve in the trans-

ducer. When the PCM de-energizes the solenoid and

back-pressure closes the transducer bleed valve, vac-

uum flows through the transducer to operate the

EGR valve. De-energizing the solenoid, but not fully closing

the transducer bleed hole (because of by low back-

pressure), varies the strength of vacuum applied to

the EGR valve. Varying the strength of the vacuum

changes the amount of EGR supplied to the engine.

This provides the correct amount of exhaust gas re-

circulation for different operating conditions.

Fig. 11 Heated Oxygen Sensor Socket

Fig. 12 EGR SystemÐ2.2L and 2.5L TBI Engines

Fig. 13 EGR SystemÐ3.0L Engines

25 - 20 EMISSION CONTROL SYSTEMS Ä