automatic transmission fluid CHEVROLET DYNASTY 1993 Service Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 53 of 2438

should be above ADD mark. Add fluid only if level is

below ADD mark on dipstick when transaxle is

warm.The automatic transaxle does not require periodic

maintenance when used for general transportation. If

the vehicle is subjected to severe service conditions,

the automatic transaxle will require fluid/filter

change and band adjustments every 24 000 km

(15,000 miles). For additional information, refer to

Severe Service paragraph and Lubrication and Main-

tenance Schedules in General Information section of

this group. The fluid and filter should be changed

when water contamination is suspected. If fluid has

foamy or milky appearance, it is probably contami-

nated. If the fluid appears brown or dark and a foul

odor is apparent, the fluid is burned, transaxle re-

quires maintenance or service. A circular magnet lo-

cated in the transaxle pan, collects metallic particles

circulating in the oil. For proper diagnostic and ser-

vice procedures, refer to Group 21, Automatic Tran-

saxle.

SELECTING AUTOMATIC TRANSAXLE FLUID

Chrysler Corporation recommends Mopar ATF Plus

(automatic transmission fluid type 7176) be used to

add to or replace automatic transaxle fluid. If ATF

Plus is not available use Mopar Dexron II tAuto-

matic Transmission Fluid or equivalent.

DRIVE SHAFT CV AND TRIPOD JOINT BOOTS

The front drive shaft constant velocity and tripod

joint boots (Fig. 5) should be inspected when other

under vehicle service is performed. Inspect boots for

cracking, tears, leaks or other defects. If service re-

pair is required, refer to Group 2, Suspension.

FRONT WHEEL BEARINGS

The front wheel bearings are permanently sealed,

requiring no lubrication. For proper diagnostic and

service procedures refer to Group 2, Suspension.

TIRES

The tires should be inspected at every engine oil

change for proper inflation and condition. The tires

should be rotated at the distance intervals described

in the Lubrication and Maintenance Schedules of the

General Information section in this group. For tire

inflation specifications refer to the Owner's Manual.

A Tire Inflation sticker is located in the driver door

opening. For proper diagnostic procedures, see Group

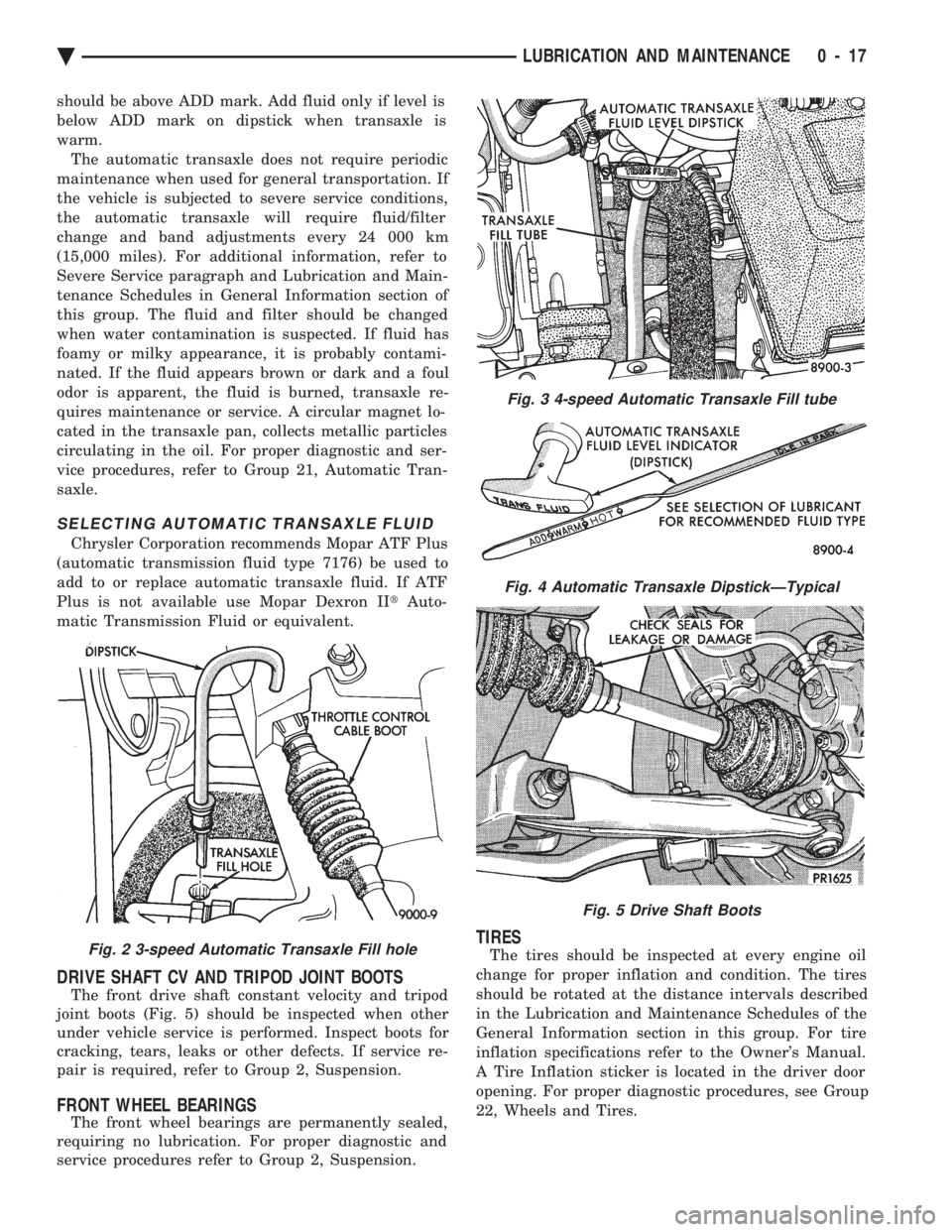

22, Wheels and Tires.Fig. 2 3-speed Automatic Transaxle Fill hole

Fig. 3 4-speed Automatic Transaxle Fill tube

Fig. 4 Automatic Transaxle DipstickÐTypical

Fig. 5 Drive Shaft Boots

Ä LUBRICATION AND MAINTENANCE 0 - 17

Page 362 of 2438

(2) Remove radiator pressure cap when engine is

cold, Idle engine until thermostat opens, you should

observe coolant flow while looking down the filler

neck. Once flow is detected install radiator pressure

cap.

RADIATOR

REMOVAL

(1) Disconnect negative battery cable from battery.

WARNING: DO NOT REMOVE THE CYLINDER

BLOCK PLUG OR THE RADIATOR DRAINCOCK

WITH THE SYSTEM HOT AND UNDER PRESSURE

BECAUSE SERIOUS BURNS FROM COOLANT CAN

OCCUR.

(2) Drain cooling system. Refer to Draining Cool-

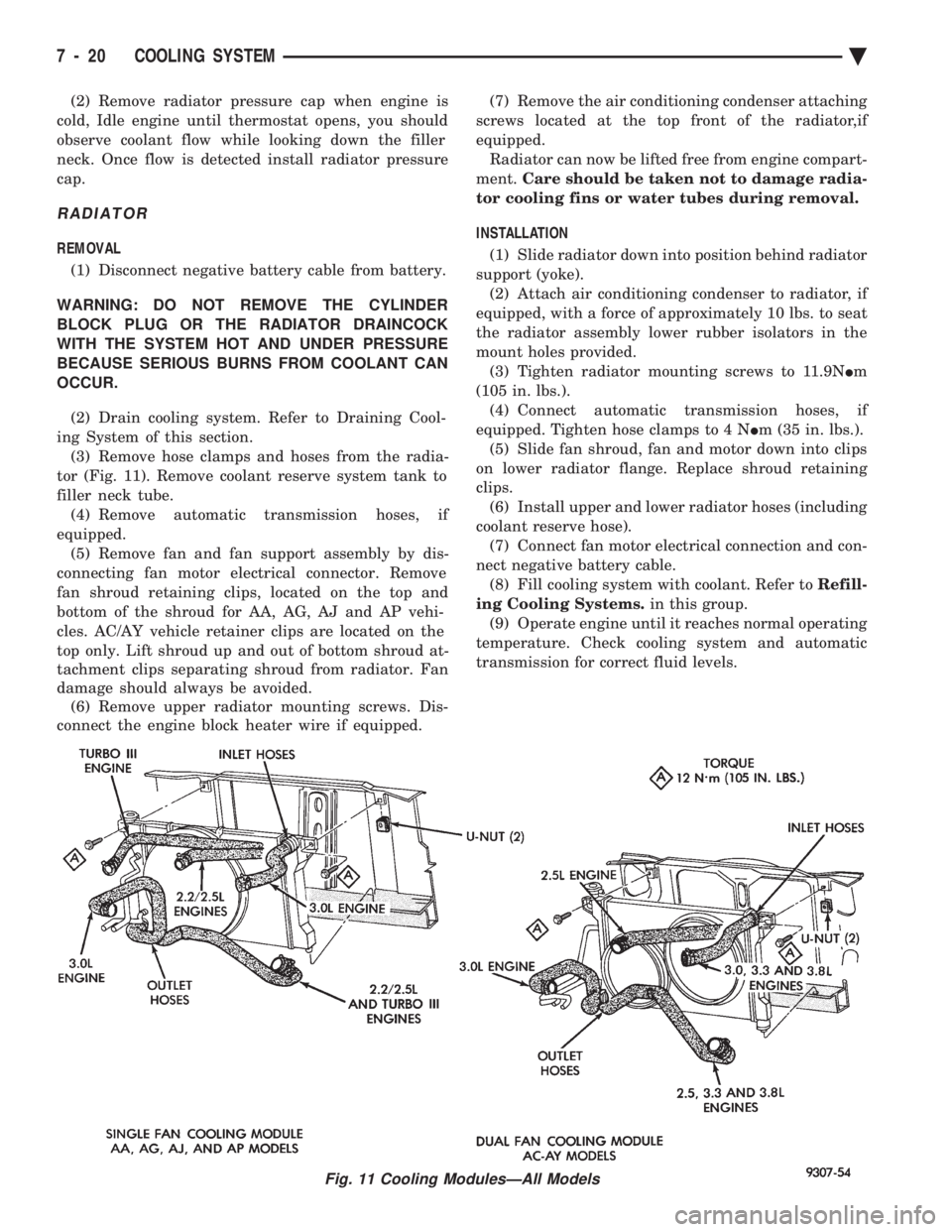

ing System of this section. (3) Remove hose clamps and hoses from the radia-

tor (Fig. 11). Remove coolant reserve system tank to

filler neck tube. (4) Remove automatic transmission hoses, if

equipped. (5) Remove fan and fan support assembly by dis-

connecting fan motor electrical connector. Remove

fan shroud retaining clips, located on the top and

bottom of the shroud for AA, AG, AJ and AP vehi-

cles. AC/AY vehicle retainer clips are located on the

top only. Lift shroud up and out of bottom shroud at-

tachment clips separating shroud from radiator. Fan

damage should always be avoided. (6) Remove upper radiator mounting screws. Dis-

connect the engine block heater wire if equipped. (7) Remove the air conditioning condenser attaching

screws located at the top front of the radiator,if

equipped. Radiator can now be lifted free from engine compart-

ment. Care should be taken not to damage radia-

tor cooling fins or water tubes during removal.

INSTALLATION

(1) Slide radiator down into position behind radiator

support (yoke). (2) Attach air conditioning condenser to radiator, if

equipped, with a force of approximately 10 lbs. to seat

the radiator assembly lower rubber isolators in the

mount holes provided. (3) Tighten radiator mounting screws to 11.9N Im

(105 in. lbs.). (4) Connect automatic transmission hoses, if

equipped. Tighten hose clamps to 4 N Im (35 in. lbs.).

(5) Slide fan shroud, fan and motor down into clips

on lower radiator flange. Replace shroud retaining

clips. (6) Install upper and lower radiator hoses (including

coolant reserve hose). (7) Connect fan motor electrical connection and con-

nect negative battery cable. (8) Fill cooling system with coolant. Refer to Refill-

ing Cooling Systems. in this group.

(9) Operate engine until it reaches normal operating

temperature. Check cooling system and automatic

transmission for correct fluid levels.

Fig. 11 Cooling ModulesÐAll Models

7 - 20 COOLING SYSTEM Ä

Page 1065 of 2438

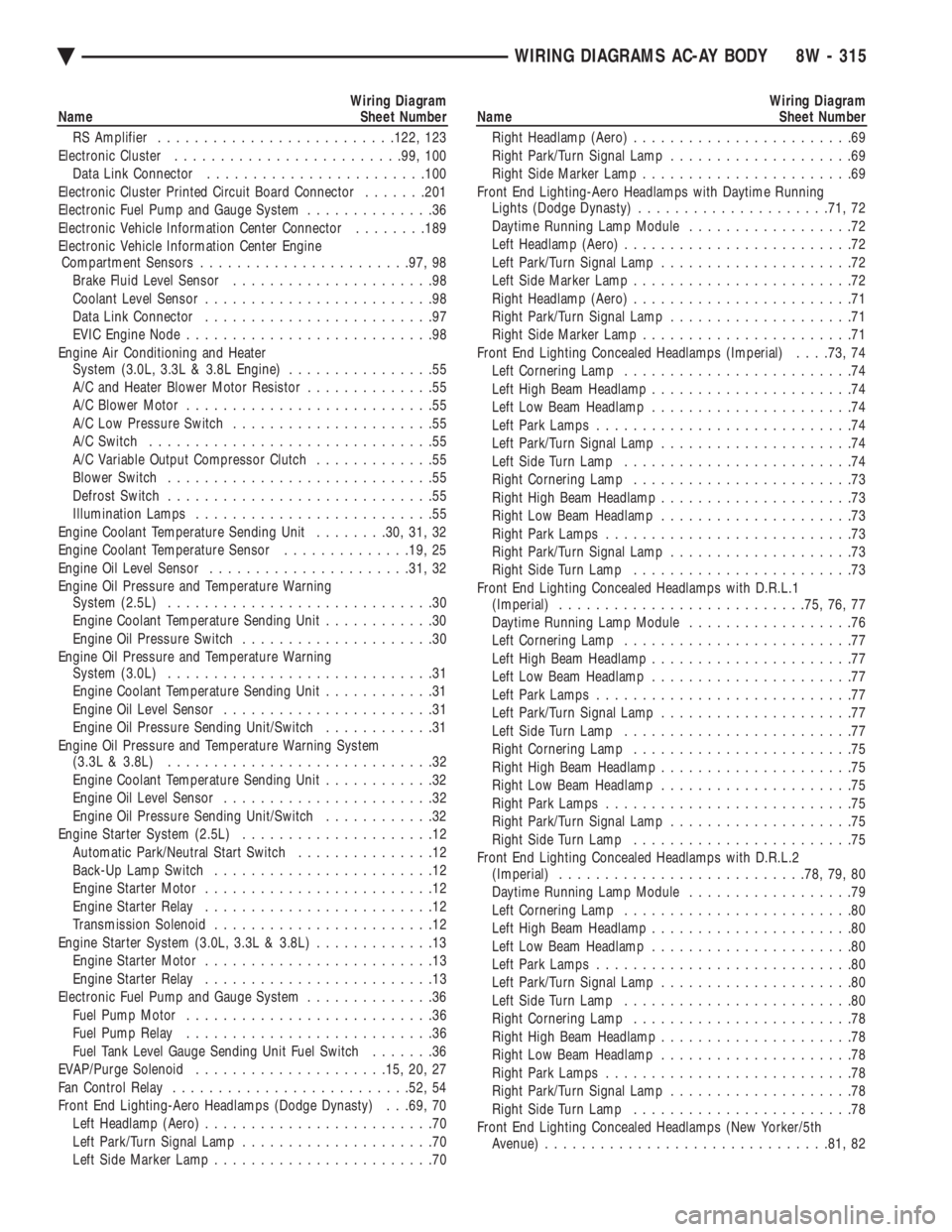

Wiring Diagram

Name Sheet Number

RS Amplifier ......................... .122, 123

Electronic Cluster ........................ .99, 100

Data Link Connector ....................... .100

Electronic Cluster Printed Circuit Board Connector .......201

Electronic Fuel Pump and Gauge System ..............36

Electronic Vehicle Information Center Connector ........189

Electronic Vehicle Information Center Engine Compartment Sensors ...................... .97, 98

Brake Fluid Level Sensor ......................98

Coolant Level Sensor .........................98

Data Link Connector .........................97

EVIC Engine Node ...........................98

Engine Air Conditioning and Heater System (3.0L, 3.3L & 3.8L Engine) ................55

A/C and Heater Blower Motor Resistor ..............55

A/C Blower Motor ...........................55

A/C Low Pressure Switch ......................55

A/C Switch ...............................55

A/C Variable Output Compressor Clutch .............55

Blower Switch .............................55

Defrost Switch .............................55

Illumination Lamps ..........................55

Engine Coolant Temperature Sending Unit ........30, 31, 32

Engine Coolant Temperature Sensor ..............19, 25

Engine Oil Level Sensor ..................... .31, 32

Engine Oil Pressure and Temperature Warning System (2.5L) .............................30

Engine Coolant Temperature Sending Unit ............30

Engine Oil Pressure Switch .....................30

Engine Oil Pressure and Temperature Warning System (3.0L) .............................31

Engine Coolant Temperature Sending Unit ............31

Engine Oil Level Sensor .......................31

Engine Oil Pressure Sending Unit/Switch ............31

Engine Oil Pressure and Temperature Warning System (3.3L & 3.8L) .............................32

Engine Coolant Temperature Sending Unit ............32

Engine Oil Level Sensor .......................32

Engine Oil Pressure Sending Unit/Switch ............32

Engine Starter System (2.5L) .....................12

Automatic Park/Neutral Start Switch ...............12

Back-Up Lamp Switch ........................12

Engine Starter Motor .........................12

Engine Starter Relay .........................12

Transmission Solenoid ........................12

Engine Starter System (3.0L, 3.3L & 3.8L) .............13

Engine Starter Motor .........................13

Engine Starter Relay .........................13

Electronic Fuel Pump and Gauge System ..............36

Fuel Pump Motor ...........................36

Fuel Pump Relay ...........................36

Fuel Tank Level Gauge Sending Unit Fuel Switch .......36

EVAP/Purge Solenoid .................... .15, 20, 27

Fan Control Relay ......................... .52, 54

Front End Lighting-Aero Headlamps (Dodge Dynasty) . . .69, 70 Left Headlamp (Aero) .........................70

Left Park/Turn Signal Lamp .....................70

Left Side Marker Lamp ........................70Wiring Diagram

Name Sheet Number

Right Headlamp (Aero) ........................69

Right Park/Turn Signal Lamp ....................69

Right Side Marker Lamp .......................69

Front End Lighting-Aero Headlamps with Daytime Running Lights (Dodge Dynasty) .................... .71, 72

Daytime Running Lamp Module ..................72

Left Headlamp (Aero) .........................72

Left Park/Turn Signal Lamp .....................72

Left Side Marker Lamp ........................72

Right Headlamp (Aero) ........................71

Right Park/Turn Signal Lamp ....................71

Right Side Marker Lamp .......................71

Front End Lighting Concealed Headlamps (Imperial) . . . .73, 74

Left Cornering Lamp .........................74

Left High Beam Headlamp ......................74

Left Low Beam Headlamp ......................74

Left Park Lamps ............................74

Left Park/Turn Signal Lamp .....................74

Left Side Turn Lamp .........................74

Right Cornering Lamp ........................73

Right High Beam Headlamp .....................73

Right Low Beam Headlamp .....................73

Right Park Lamps ...........................73

Right Park/Turn Signal Lamp ....................73

Right Side Turn Lamp ........................73

Front End Lighting Concealed Headlamps with D.R.L.1 (Imperial) .......................... .75, 76, 77

Daytime Running Lamp Module ..................76

Left Cornering Lamp .........................77

Left High Beam Headlamp ......................77

Left Low Beam Headlamp ......................77

Left Park Lamps ............................77

Left Park/Turn Signal Lamp .....................77

Left Side Turn Lamp .........................77

Right Cornering Lamp ........................75

Right High Beam Headlamp .....................75

Right Low Beam Headlamp .....................75

Right Park Lamps ...........................75

Right Park/Turn Signal Lamp ....................75

Right Side Turn Lamp ........................75

Front End Lighting Concealed Headlamps with D.R.L.2 (Imperial) .......................... .78, 79, 80

Daytime Running Lamp Module ..................79

Left Cornering Lamp .........................80

Left High Beam Headlamp ......................80

Left Low Beam Headlamp ......................80

Left Park Lamps ............................80

Left Park/Turn Signal Lamp .....................80

Left Side Turn Lamp .........................80

Right Cornering Lamp ........................78

Right High Beam Headlamp .....................78

Right Low Beam Headlamp .....................78

Right Park Lamps ...........................78

Right Park/Turn Signal Lamp ....................78

Right Side Turn Lamp ........................78

Front End Lighting Concealed Headlamps (New Yorker/5th Avenue) .............................. .81, 82

Ä WIRING DIAGRAMS AC-AY BODY 8W - 315

Page 1069 of 2438

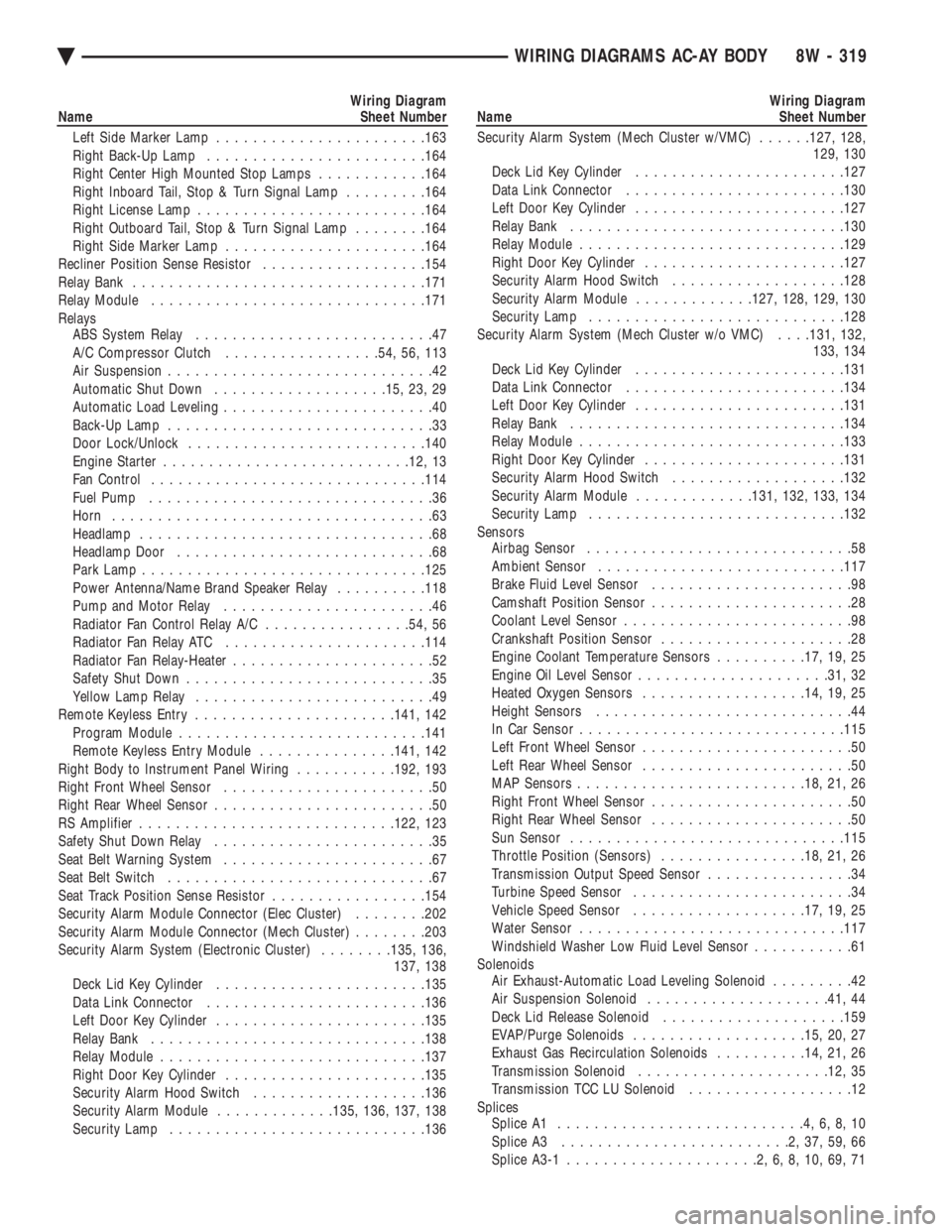

Wiring Diagram

Name Sheet Number

Left Side Marker Lamp ...................... .163

Right Back-Up Lamp ....................... .164

Right Center High Mounted Stop Lamps ............164

Right Inboard Tail, Stop & Turn Signal Lamp .........164

Right License Lamp ........................ .164

Right Outboard Tail, Stop & Turn Signal Lamp ........164

Right Side Marker Lamp ..................... .164

Recliner Position Sense Resistor ..................154

Relay Bank ............................... .171

Relay Module ............................. .171

Relays ABS System Relay ..........................47

A/C Compressor Clutch .................54, 56, 113

Air Suspension .............................42

Automatic Shut Down .................. .15, 23, 29

Automatic Load Leveling .......................40

Back-Up Lamp .............................33

Door Lock/Unlock ......................... .140

Engine Starter .......................... .12, 13

Fan Control ............................. .114

Fuel Pump ...............................36

Horn ...................................63

Headlamp ................................68

Headlamp Door ............................68

Park Lamp .............................. .125

Power Antenna/Name Brand Speaker Relay ..........118

Pump and Motor Relay .......................46

Radiator Fan Control Relay A/C ................54, 56

Radiator Fan Relay ATC ..................... .114

Radiator Fan Relay-Heater ......................52

Safety Shut Down ...........................35

Yellow Lamp Relay ..........................49

Remote Keyless Entry ..................... .141, 142

Program Module .......................... .141

Remote Keyless Entry Module ...............141, 142

Right Body to Instrument Panel Wiring ...........192, 193

Right Front Wheel Sensor .......................50

Right Rear Wheel Sensor ........................50

RS Amplifier ........................... .122, 123

Safety Shut Down Relay ........................35

Seat Belt Warning System .......................67

Seat Belt Switch .............................67

Seat Track Position Sense Resistor .................154

Security Alarm Module Connector (Elec Cluster) ........202

Security Alarm Module Connector (Mech Cluster) ........203

Security Alarm System (Electronic Cluster) ........135, 136,

137, 138

Deck Lid Key Cylinder ...................... .135

Data Link Connector ....................... .136

Left Door Key Cylinder ...................... .135

Relay Bank ............................. .138

Relay Module ............................ .137

Right Door Key Cylinder ..................... .135

Security Alarm Hood Switch ...................136

Security Alarm Module .............135, 136, 137, 138

Security Lamp ........................... .136Wiring Diagram

Name Sheet Number

Security Alarm System (Mech Cluster w/VMC) ......127, 128,

129, 130

Deck Lid Key Cylinder ...................... .127

Data Link Connector ....................... .130

Left Door Key Cylinder ...................... .127

Relay Bank ............................. .130

Relay Module ............................ .129

Right Door Key Cylinder ..................... .127

Security Alarm Hood Switch ...................128

Security Alarm Module .............127, 128, 129, 130

Security Lamp ........................... .128

Security Alarm System (Mech Cluster w/o VMC) . . . .131, 132,

133, 134

Deck Lid Key Cylinder ...................... .131

Data Link Connector ....................... .134

Left Door Key Cylinder ...................... .131

Relay Bank ............................. .134

Relay Module ............................ .133

Right Door Key Cylinder ..................... .131

Security Alarm Hood Switch ...................132

Security Alarm Module .............131, 132, 133, 134

Security Lamp ........................... .132

Sensors Airbag Sensor .............................58

Ambient Sensor .......................... .117

Brake Fluid Level Sensor ......................98

Camshaft Position Sensor ......................28

Coolant Level Sensor .........................98

Crankshaft Position Sensor .....................28

Engine Coolant Temperature Sensors ..........17, 19, 25

Engine Oil Level Sensor .................... .31, 32

Heated Oxygen Sensors ................. .14, 19, 25

Height Sensors ............................44

In Car Senso r............................ .115

Left Front Wheel Sensor .......................50

Left Rear Wheel Sensor .......................50

MAP Sensors ........................ .18, 21, 26

Right Front Wheel Sensor ......................50

Right Rear Wheel Sensor ......................50

Sun Sensor ............................. .115

Throttle Position (Sensors) ................18, 21, 26

Transmission Output Speed Sensor ................34

Turbine Speed Sensor ........................34

Vehicle Speed Sensor .................. .17, 19, 25

Water Sensor ............................ .117

Windshield Washer Low Fluid Level Sensor ...........61

Solenoids Air Exhaust-Automatic Load Leveling Solenoid .........42

Air Suspension Solenoid ................... .41, 44

Deck Lid Release Solenoid ................... .159

EVAP/Purge Solenoids .................. .15, 20, 27

Exhaust Gas Recirculation Solenoids ..........14, 21, 26

Transmission Solenoid .................... .12, 35

Transmission TCC LU Solenoid ..................12

Splices Splice A1 ...........................4,6,8,10

Splice A3 .........................2,37,59,66

Splice A3-1 .....................2,6,8,10,69,71

Ä WIRING DIAGRAMS AC-AY BODY 8W - 319

Page 1288 of 2438

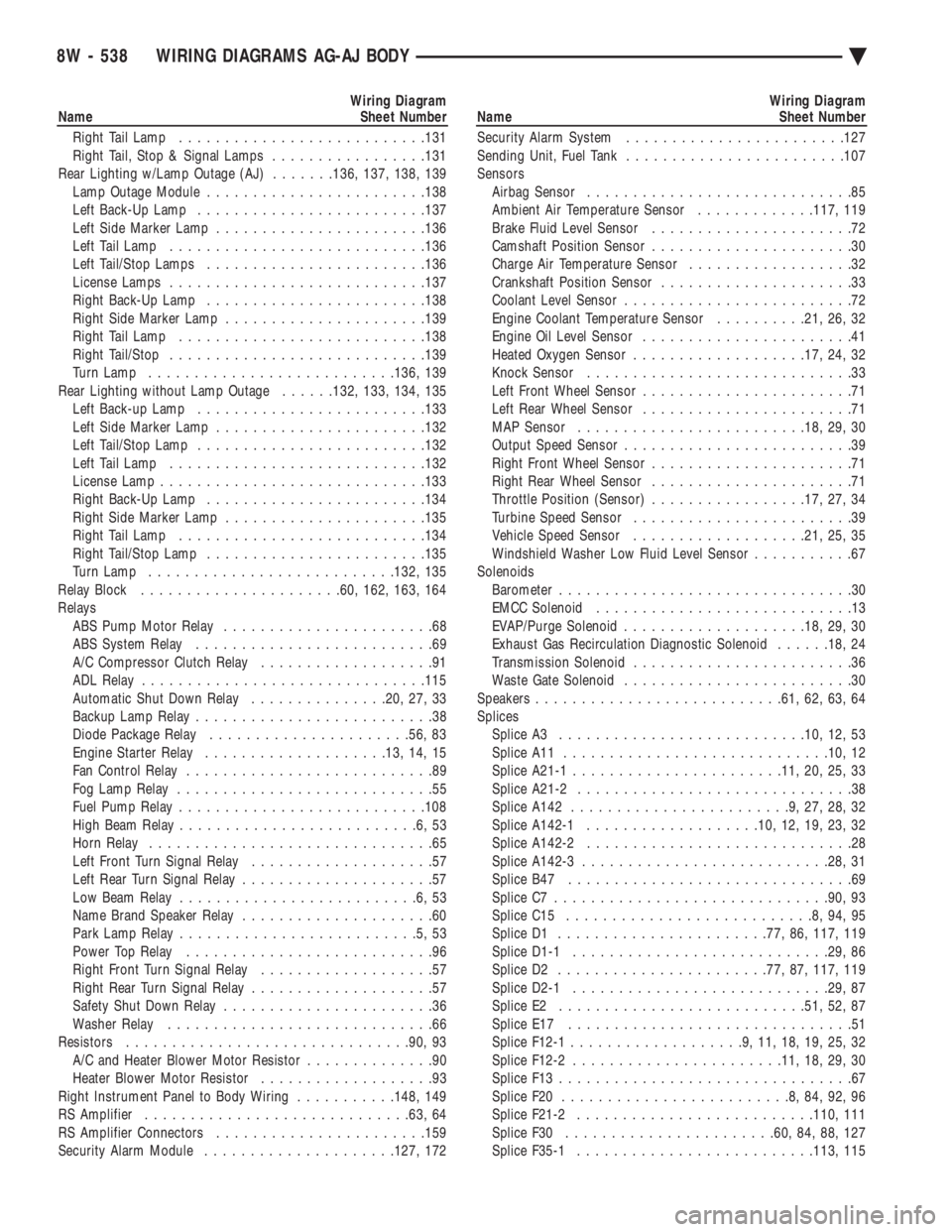

Wiring Diagram

Name Sheet Number

Right Tail Lamp .......................... .131

Right Tail, Stop & Signal Lamps .................131

Rear Lighting w/Lamp Outage (AJ) .......136, 137, 138, 139

Lamp Outage Module ....................... .138

Left Back-Up Lamp ........................ .137

Left Side Marker Lamp ...................... .136

Left Tail Lamp ........................... .136

Left Tail/Stop Lamps ....................... .136

License Lamps ........................... .137

Right Back-Up Lamp ....................... .138

Right Side Marker Lamp ..................... .139

Right Tail Lamp .......................... .138

Right Tail/Stop ........................... .139

Turn Lamp .......................... .136, 139

Rear Lighting without Lamp Outage ......132, 133, 134, 135

Left Back-up Lamp ........................ .133

Left Side Marker Lamp ...................... .132

Left Tail/Stop Lamp ........................ .132

Left Tail Lamp ........................... .132

License Lamp ............................ .133

Right Back-Up Lamp ....................... .134

Right Side Marker Lamp ..................... .135

Right Tail Lamp .......................... .134

Right Tail/Stop Lamp ....................... .135

Turn Lamp .......................... .132, 135

Relay Block ..................... .60, 162, 163, 164

Relays ABS Pump Motor Relay .......................68

ABS System Relay ..........................69

A/C Compressor Clutch Relay ...................91

ADL Relay .............................. .115

Automatic Shut Down Relay ...............20, 27, 33

Backup Lamp Relay ..........................38

Diode Package Relay ..................... .56, 83

Engine Starter Relay ................... .13, 14, 15

Fan Control Relay ...........................89

Fog Lamp Relay ............................55

Fuel Pump Relay .......................... .108

High Beam Relay ..........................6,53

Horn Relay ...............................65

Left Front Turn Signal Relay ....................57

Left Rear Turn Signal Relay .....................57

Low Beam Relay ..........................6,53

Name Brand Speaker Relay .....................60

Park Lamp Relay ..........................5,53

Power Top Relay ...........................96

Right Front Turn Signal Relay ...................57

Right Rear Turn Signal Relay ....................57

Safety Shut Down Relay .......................36

Washer Relay .............................66

Resistors .............................. .90, 93

A/C and Heater Blower Motor Resistor ..............90

Heater Blower Motor Resistor ...................93

Right Instrument Panel to Body Wiring ...........148, 149

RS Amplifier ............................ .63, 64

RS Amplifier Connectors ...................... .159

Security Alarm Module .................... .127, 172Wiring Diagram

Name Sheet Number

Security Alarm System ....................... .127

Sending Unit, Fuel Tank ....................... .107

Sensors Airbag Sensor .............................85

Ambient Air Temperature Sensor .............117, 119

Brake Fluid Level Sensor ......................72

Camshaft Position Sensor ......................30

Charge Air Temperature Sensor ..................32

Crankshaft Position Sensor .....................33

Coolant Level Sensor .........................72

Engine Coolant Temperature Sensor ..........21, 26, 32

Engine Oil Level Sensor .......................41

Heated Oxygen Sensor .................. .17, 24, 32

Knock Sensor .............................33

Left Front Wheel Sensor .......................71

Left Rear Wheel Sensor .......................71

MAP Sensor ........................ .18, 29, 30

Output Speed Sensor .........................39

Right Front Wheel Sensor ......................71

Right Rear Wheel Sensor ......................71

Throttle Position (Sensor) .................17, 27, 34

Turbine Speed Sensor ........................39

Vehicle Speed Sensor .................. .21, 25, 35

Windshield Washer Low Fluid Level Sensor ...........67

Solenoids Barometer ................................30

EMCC Solenoid ............................13

EVAP/Purge Solenoid ................... .18, 29, 30

Exhaust Gas Recirculation Diagnostic Solenoid ......18, 24

Transmission Solenoid ........................36

Waste Gate Solenoid .........................30

Speakers .......................... .61, 62, 63, 64

Splices Splice A3 .......................... .10, 12, 53

Splice A11 ............................ .10, 12

Splice A21-1 ...................... .11, 20, 25, 33

Splice A21-2 ..............................38

Splice A142 ........................9,27,28,32

Splice A142-1 .................. .10, 12, 19, 23, 32

Splice A142-2 .............................28

Splice A142-3 .......................... .28, 31

Splice B47 ...............................69

Splice C7 ............................. .90, 93

Splice C15 ...........................8,94,95

Splice D1 ...................... .77, 86, 117, 119

Splice D1-1 ........................... .29, 86

Splice D2 ...................... .77, 87, 117, 119

Splice D2-1 ........................... .29, 87

Splice E2 .......................... .51, 52, 87

Splice E17 ...............................51

Splice F12-1 ...................9,11,18,19,25,32

Splice F12-2 ...................... .11, 18, 29, 30

Splice F13 ................................67

Splice F20 .........................8,84,92,96

Splice F21-2 ......................... .110, 111

Splice F30 ...................... .60, 84, 88, 127

Splice F35-1 ......................... .113, 115

8W - 538 WIRING DIAGRAMS AG-AJ BODY Ä

Page 1470 of 2438

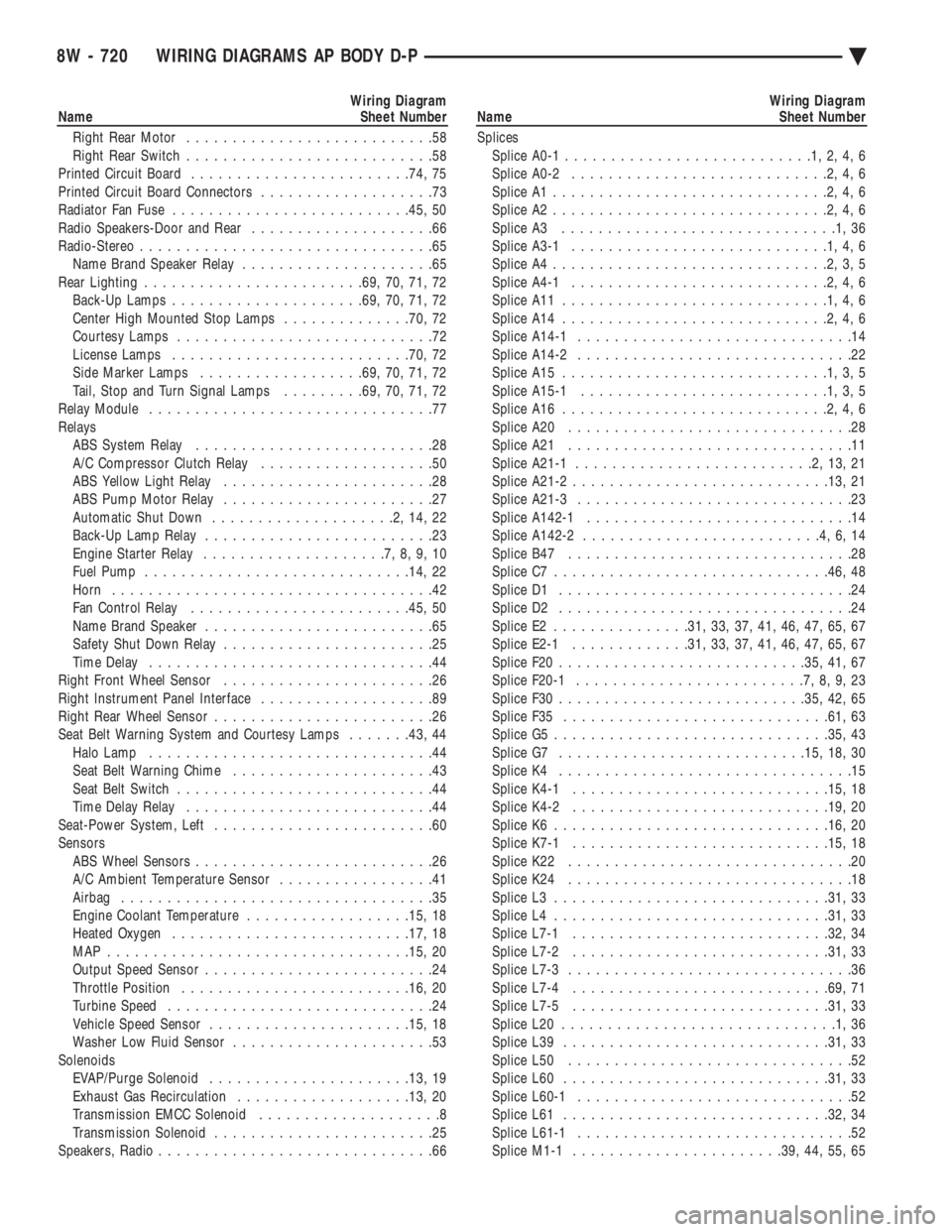

Wiring Diagram

Name Sheet Number

Right Rear Motor ...........................58

Right Rear Switch ...........................58

Printed Circuit Board ....................... .74, 75

Printed Circuit Board Connectors ...................73

Radiator Fan Fuse ......................... .45, 50

Radio Speakers-Door and Rear ....................66

Radio-Stereo ................................65

Name Brand Speaker Relay .....................65

Rear Lighting ....................... .69, 70, 71, 72

Back-Up Lamps .................... .69, 70, 71, 72

Center High Mounted Stop Lamps ..............70, 72

Courtesy Lamps ............................72

License Lamps ......................... .70, 72

Side Marker Lamps ................. .69, 70, 71, 72

Tail, Stop and Turn Signal Lamps .........69, 70, 71, 72

Relay Module ...............................77

Relays ABS System Relay ..........................28

A/C Compressor Clutch Relay ...................50

ABS Yellow Light Relay .......................28

ABS Pump Motor Relay .......................27

Automatic Shut Down ....................2,14,22

Back-Up Lamp Relay .........................23

Engine Starter Relay ....................7,8,9,10

Fuel Pump ............................ .14, 22

Horn ...................................42

Fan Control Relay ....................... .45, 50

Name Brand Speaker .........................65

Safety Shut Down Relay .......................25

Time Delay ...............................44

Right Front Wheel Sensor .......................26

Right Instrument Panel Interface ...................89

Right Rear Wheel Sensor ........................26

Seat Belt Warning System and Courtesy Lamps .......43, 44

Halo Lamp ...............................44

Seat Belt Warning Chime ......................43

Seat Belt Switch ............................44

Time Delay Relay ...........................44

Seat-Power System, Left ........................60

Sensors ABS Wheel Sensors ..........................26

A/C Ambient Temperature Sensor .................41

Airbag ..................................35

Engine Coolant Temperature ..................15, 18

Heated Oxygen ......................... .17, 18

MAP ................................ .15, 20

Output Speed Sensor .........................24

Throttle Position ........................ .16, 20

Turbine Speed .............................24

Vehicle Speed Sensor ..................... .15, 18

Washer Low Fluid Sensor ......................53

Solenoids EVAP/Purge Solenoid ..................... .13, 19

Exhaust Gas Recirculation .................. .13, 20

Transmission EMCC Solenoid ....................8

Transmission Solenoid ........................25

Speakers, Radio ..............................66Wiring Diagram

Name Sheet Number

Splices Splice A0-1 ...........................1,2,4,6

Splice A0-2 ............................2,4,6

Splice A1 ..............................2,4,6

Splice A2 ..............................2,4,6

Splice A3 ..............................1,36

Splice A3-1 ............................1,4,6

Splice A4 ..............................2,3,5

Splice A4-1 ............................2,4,6

Splice A11 .............................1,4,6

Splice A14 .............................2,4,6

Splice A14-1 ..............................14

Splice A14-2 ..............................22

Splice A15 .............................1,3,5

Splice A15-1 ...........................1,3,5

Splice A16 .............................2,4,6

Splice A20 ...............................28

Splice A21 ...............................11

Splice A21-1 ..........................2,13,21

Splice A21-2 ........................... .13, 21

Splice A21-3 ..............................23

Splice A142-1 .............................14

Splice A142-2 ..........................4,6,14

Splice B47 ...............................28

Splice C7 ............................. .46, 48

Splice D1 ................................24

Splice D2 ................................24

Splice E2 .............. .31, 33, 37, 41, 46, 47, 65, 67

Splice E2-1 ............ .31, 33, 37, 41, 46, 47, 65, 67

Splice F20 .......................... .35, 41, 67

Splice F20-1 .........................7,8,9,23

Splice F30 .......................... .35, 42, 65

Splice F35 ............................ .61, 63

Splice G5 ............................. .35, 43

Splice G7 .......................... .15, 18, 30

Splice K4 ................................15

Splice K4-1 ........................... .15, 18

Splice K4-2 ........................... .19, 20

Splice K6 ............................. .16, 20

Splice K7-1 ........................... .15, 18

Splice K22 ...............................20

Splice K24 ...............................18

Splice L3 ............................. .31, 33

Splice L4 ............................. .31, 33

Splice L7-1 ........................... .32, 34

Splice L7-2 ........................... .31, 33

Splice L7-3 ...............................36

Splice L7-4 ........................... .69, 71

Splice L7-5 ........................... .31, 33

Splice L20 ..............................1,36

Splice L39 ............................ .31, 33

Splice L50 ...............................52

Splice L60 ............................ .31, 33

Splice L60-1 ..............................52

Splice L61 ............................ .32, 34

Splice L61-1 ..............................52

Splice M1-1 ...................... .39, 44, 55, 65

8W - 720 WIRING DIAGRAMS AP BODY D-P Ä

Page 1919 of 2438

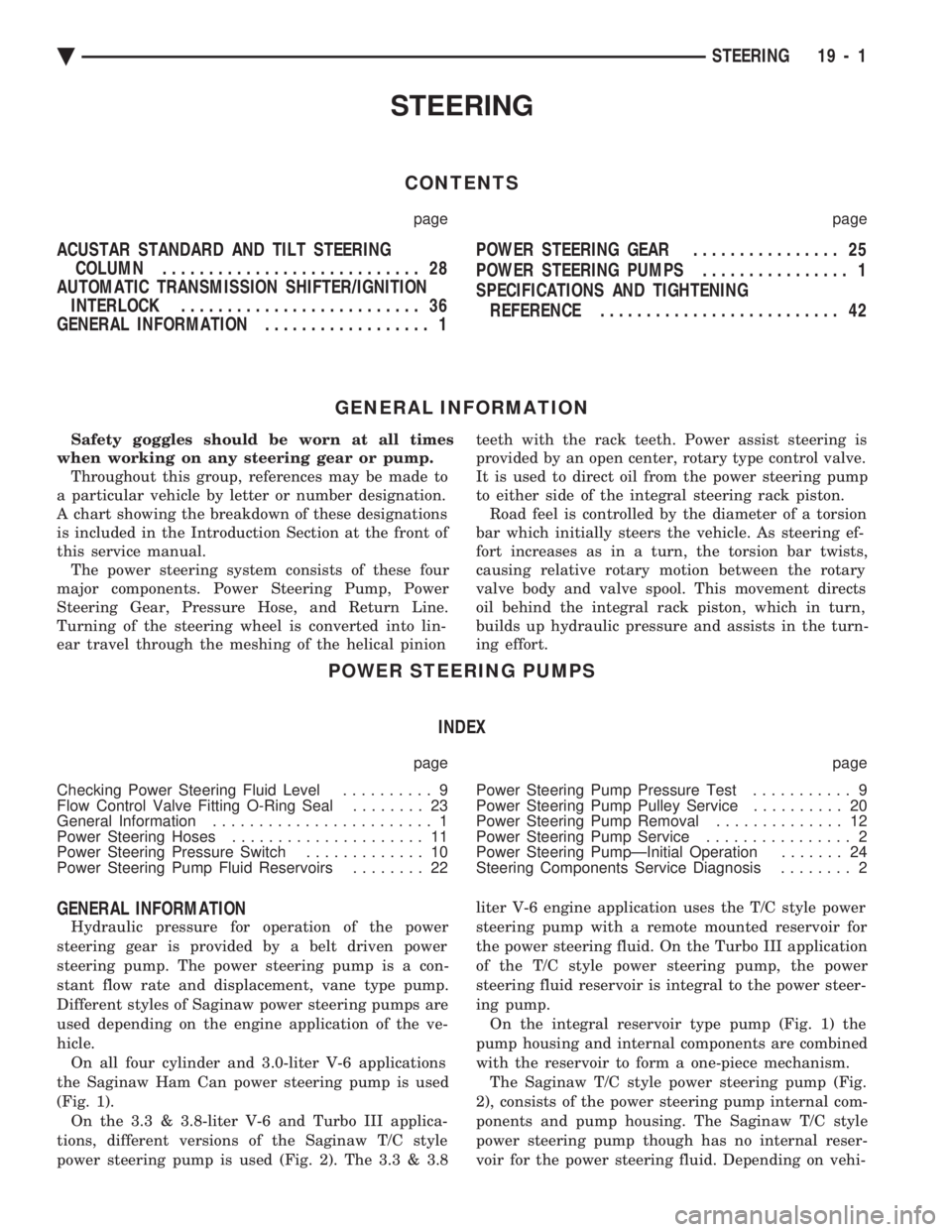

STEERING

CONTENTS

page page

ACUSTAR STANDARD AND TILT STEERING COLUMN ............................ 28

AUTOMATIC TRANSMISSION SHIFTER/IGNITION INTERLOCK .......................... 36

GENERAL INFORMATION .................. 1 POWER STEERING GEAR

................ 25

POWER STEERING PUMPS ................ 1

SPECIFICATIONS AND TIGHTENING REFERENCE .......................... 42

GENERAL INFORMATION

Safety goggles should be worn at all times

when working on any steering gear or pump. Throughout this group, references may be made to

a particular vehicle by letter or number designation.

A chart showing the breakdown of these designations

is included in the Introduction Section at the front of

this service manual. The power steering system consists of these four

major components. Power Steering Pump, Power

Steering Gear, Pressure Hose, and Return Line.

Turning of the steering wheel is converted into lin-

ear travel through the meshing of the helical pinion teeth with the rack teeth. Power assist steering is

provided by an open center, rotary type control valve.

It is used to direct oil from the power steering pump

to either side of the integral steering rack piston. Road feel is controlled by the diameter of a torsion

bar which initially steers the vehicle. As steering ef-

fort increases as in a turn, the torsion bar twists,

causing relative rotary motion between the rotary

valve body and valve spool. This movement directs

oil behind the integral rack piston, which in turn,

builds up hydraulic pressure and assists in the turn-

ing effort.

POWER STEERING PUMPS

INDEX

page page

Checking Power Steering Fluid Level .......... 9

Flow Control Valve Fitting O-Ring Seal ........ 23

General Information ........................ 1

Power Steering Hoses ..................... 11

Power Steering Pressure Switch ............. 10

Power Steering Pump Fluid Reservoirs ........ 22 Power Steering Pump Pressure Test

........... 9

Power Steering Pump Pulley Service .......... 20

Power Steering Pump Removal .............. 12

Power Steering Pump Service ................ 2

Power Steering PumpÐInitial Operation ....... 24

Steering Components Service Diagnosis ........ 2

GENERAL INFORMATION

Hydraulic pressure for operation of the power

steering gear is provided by a belt driven power

steering pump. The power steering pump is a con-

stant flow rate and displacement, vane type pump.

Different styles of Saginaw power steering pumps are

used depending on the engine application of the ve-

hicle. On all four cylinder and 3.0-liter V-6 applications

the Saginaw Ham Can power steering pump is used

(Fig. 1). On the 3.3 & 3.8-liter V-6 and Turbo III applica-

tions, different versions of the Saginaw T/C style

power steering pump is used (Fig. 2). The 3.3 & 3.8 liter V-6 engine application uses the T/C style power

steering pump with a remote mounted reservoir for

the power steering fluid. On the Turbo III application

of the T/C style power steering pump, the power

steering fluid reservoir is integral to the power steer-

ing pump. On the integral reservoir type pump (Fig. 1) the

pump housing and internal components are combined

with the reservoir to form a one-piece mechanism. The Saginaw T/C style power steering pump (Fig.

2), consists of the power steering pump internal com-

ponents and pump housing. The Saginaw T/C style

power steering pump though has no internal reser-

voir for the power steering fluid. Depending on vehi-

Ä STEERING 19 - 1

Page 1927 of 2438

When steering conditions exceed maximum pres-

sure requirements, such as when the wheels are

turned against the stops. The pressure built up in

the steering gear exerts pressure on the spring end of

the flow control valve. The high pressure lifts the re-

lief valve ball from its seat and allows oil to flow

through a trigger orifice located in the outlet fitting.

This reduces pressure on the spring end of the flow

control valve which then opens and allows the oil to

return to the intake side of the pump. This action

limits maximum pressure output of the pump to a

safe level. Under normal power steering pump operating con-

ditions, pressure requirements of the pump are below

maximum, causing the pressure relief valve to re-

main closed.

CHECKING POWER STEERING FLUID LEVEL

WARNING: FLUID LEVEL SHOULD BE CHECKED

WITH ENGINE OFF TO PREVENT INJURY FROM

MOVING PARTS. DO NOT USE AUTOMATIC TRANS-

MISSION FLUID IN THE POWER STEERING SYS-

TEM. DO NOT OVERFILL THE POWER STEERING

SYSTEM.

Wipe reservoir filler cap free of dirt, before check-

ing power steering fluid level. The dipstick should in- dicate FULL COLD when fluid is at normal ambient

temperature, approximately 21ÉC to 27ÉC (70ÉF to

80ÉF). In all pumps add fluid as necessary to obtain

proper level, using only MopartPower Steering

Fluid, or equivalent. DO NOT USE ANY TYPE

OF AUTOMATIC TRANSMISSION FLUID.

POWER STEERING PUMP PRESSURE TEST

The following procedure can be used to test the op-

eration of the power steering system on the vehicle. (1) Check power steering pump drive belt tension

and adjust as necessary. (2) Disconnect power steering fluid pressure hose,

at steering gear or power steering pump. Use a con-

tainer for dripping fluid. (3) Connect Pressure Gauge, Special Tool C-3309-E

(Fig. 1) to both hoses using adapter fittings. Connect

spare pressure hose to gear or pump. (4) Completely open valve on Special Tool

C-3309-E (Fig. 1). (5) Start engine and let idle.

(6) Check power steering fluid level, and add fluid

as necessary. (7) Gauge should read below 862 kPa (125 psi), if

above, inspect the hoses for restrictions and repair as

necessary. The initial pressure should be in the

range of 345-552 kPa (50-80 psi).

PUMP LEAKAGE DIAGNOSIS

Ä STEERING 19 - 9

Page 1929 of 2438

INSTALL

(1) Install power steering pressure switch into fit-

ting on power steering pressure hose by hand until

fully seated. Then torque power steering pressure

switch to 12 N Im (106 in. lbs.).

(2) Install vehicle wiring harness connector onto

power steering pressure switch. Be sure latch on wir-

ing harness connector is fully engaged with locking

tab on power steering pressure switch.

CAUTION: Do not use automatic transmission fluid

in power steering system. Only use Mopar T, Power

Steering Fluid, or equivalent.

(3) Fill power steering pump reservoir to correct

fluid level. (4) Connect negative cable back on negative post of

battery. (5) Start engine and turn steering wheel several

times from stop to stop to bleed air from fluid in sys-

tem. Stop engine, check fluid level, and inspect sys-

tem for leaks. See Checking Fluid Level.

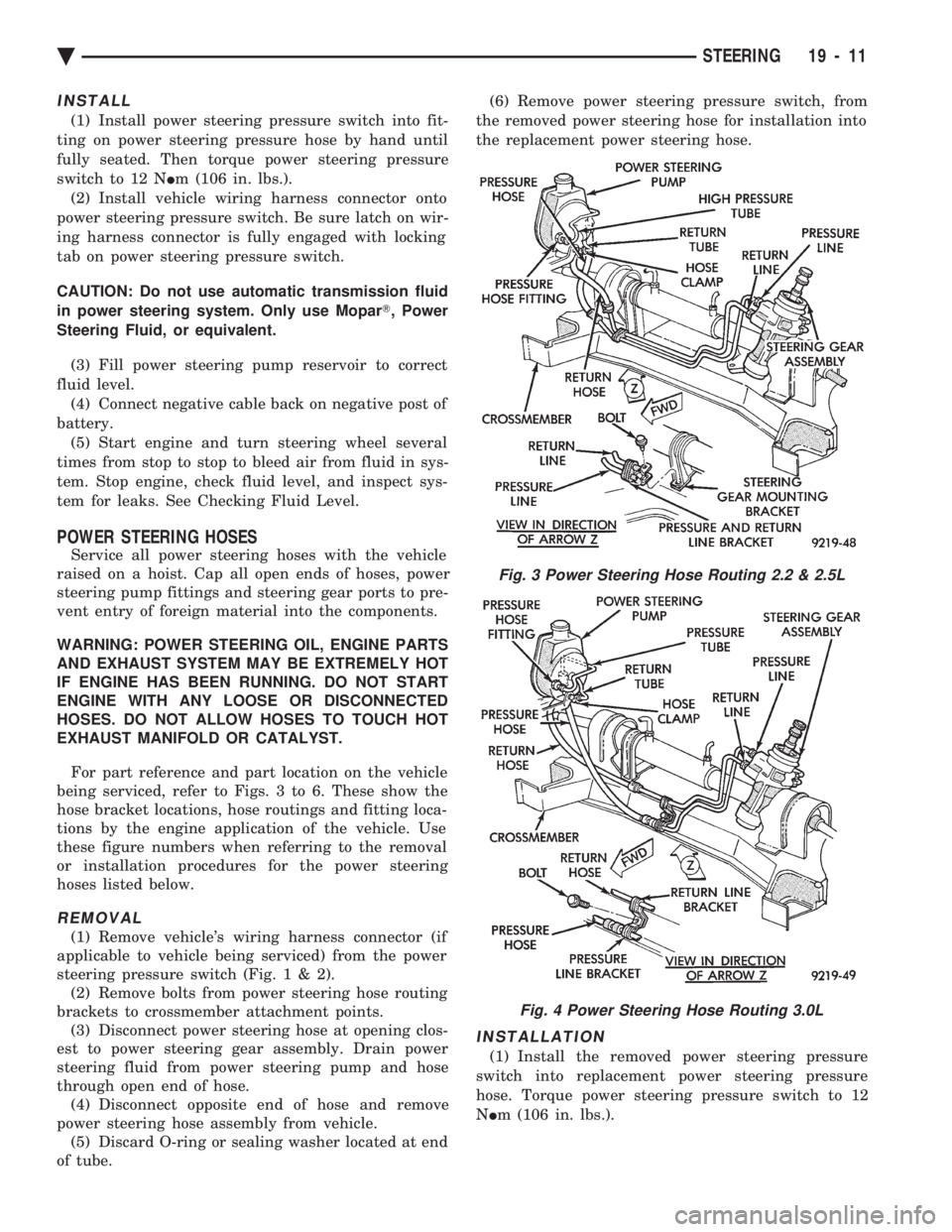

POWER STEERING HOSES

Service all power steering hoses with the vehicle

raised on a hoist. Cap all open ends of hoses, power

steering pump fittings and steering gear ports to pre-

vent entry of foreign material into the components.

WARNING: POWER STEERING OIL, ENGINE PARTS

AND EXHAUST SYSTEM MAY BE EXTREMELY HOT

IF ENGINE HAS BEEN RUNNING. DO NOT START

ENGINE WITH ANY LOOSE OR DISCONNECTED

HOSES. DO NOT ALLOW HOSES TO TOUCH HOT

EXHAUST MANIFOLD OR CATALYST.

For part reference and part location on the vehicle

being serviced, refer to Figs. 3 to 6. These show the

hose bracket locations, hose routings and fitting loca-

tions by the engine application of the vehicle. Use

these figure numbers when referring to the removal

or installation procedures for the power steering

hoses listed below.

REMOVAL

(1) Remove vehicle's wiring harness connector (if

applicable to vehicle being serviced) from the power

steering pressure switch (Fig .1&2).

(2) Remove bolts from power steering hose routing

brackets to crossmember attachment points. (3) Disconnect power steering hose at opening clos-

est to power steering gear assembly. Drain power

steering fluid from power steering pump and hose

through open end of hose. (4) Disconnect opposite end of hose and remove

power steering hose assembly from vehicle. (5) Discard O-ring or sealing washer located at end

of tube. (6) Remove power steering pressure switch, from

the removed power steering hose for installation into

the replacement power steering hose.

INSTALLATION

(1) Install the removed power steering pressure

switch into replacement power steering pressure

hose. Torque power steering pressure switch to 12

N Im (106 in. lbs.).

Fig. 3 Power Steering Hose Routing 2.2 & 2.5L

Fig. 4 Power Steering Hose Routing 3.0L

Ä STEERING 19 - 11

Page 1931 of 2438

bracket, rotating pump 90É and remove it out be-

tween engine and dash panel.(8) Transfer required parts from removed power

steering pump, to replacement power steering pump.

INSTALL

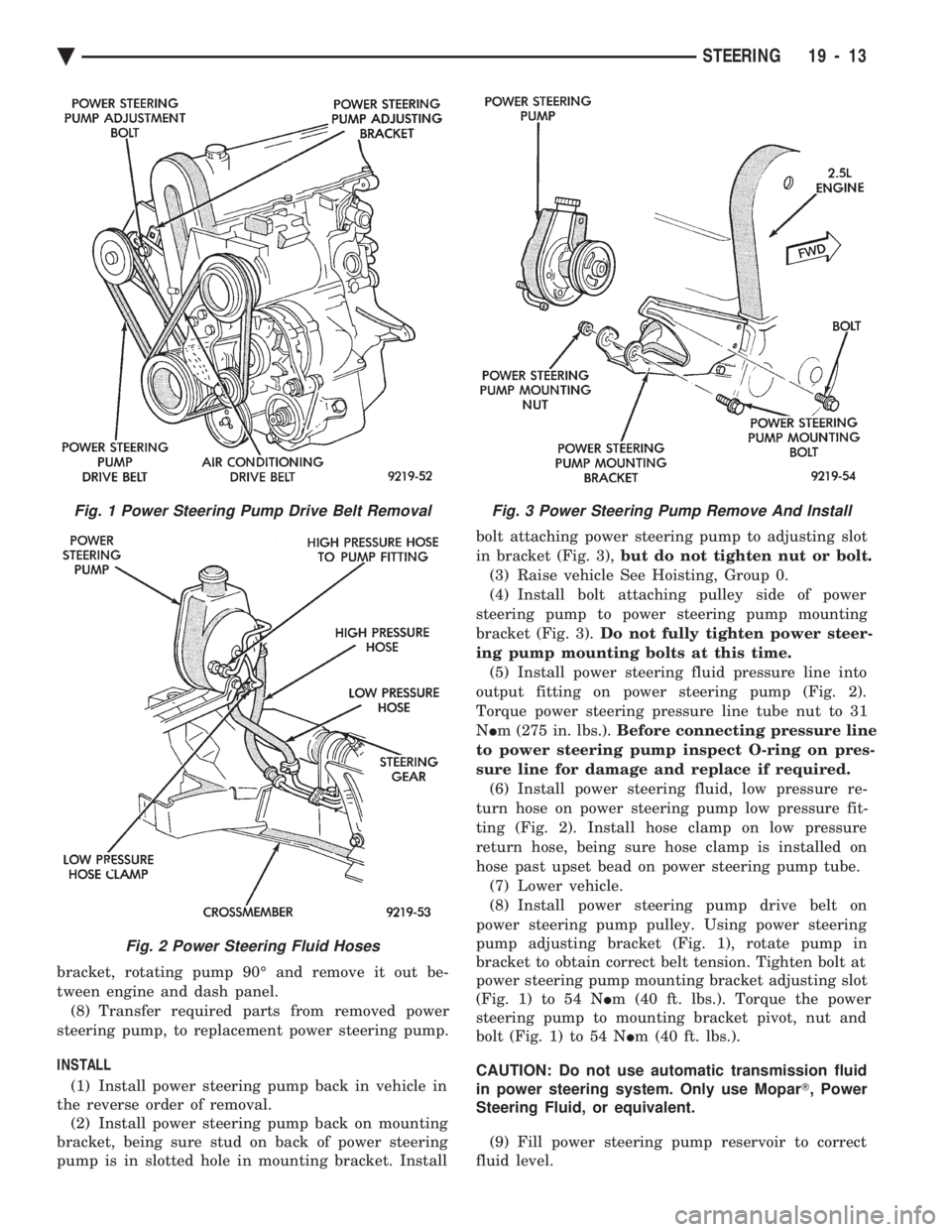

(1) Install power steering pump back in vehicle in

the reverse order of removal. (2) Install power steering pump back on mounting

bracket, being sure stud on back of power steering

pump is in slotted hole in mounting bracket. Install bolt attaching power steering pump to adjusting slot

in bracket (Fig. 3),

but do not tighten nut or bolt.

(3) Raise vehicle See Hoisting, Group 0.

(4) Install bolt attaching pulley side of power

steering pump to power steering pump mounting

bracket (Fig. 3). Do not fully tighten power steer-

ing pump mounting bolts at this time. (5) Install power steering fluid pressure line into

output fitting on power steering pump (Fig. 2).

Torque power steering pressure line tube nut to 31

N Im (275 in. lbs.). Before connecting pressure line

to power steering pump inspect O-ring on pres-

sure line for damage and replace if required. (6) Install power steering fluid, low pressure re-

turn hose on power steering pump low pressure fit-

ting (Fig. 2). Install hose clamp on low pressure

return hose, being sure hose clamp is installed on

hose past upset bead on power steering pump tube. (7) Lower vehicle.

(8) Install power steering pump drive belt on

power steering pump pulley. Using power steering

pump adjusting bracket (Fig. 1), rotate pump in

bracket to obtain correct belt tension. Tighten bolt at

power steering pump mounting bracket adjusting slot

(Fig. 1) to 54 N Im (40 ft. lbs.). Torque the power

steering pump to mounting bracket pivot, nut and

bolt (Fig. 1) to 54 N Im (40 ft. lbs.).

CAUTION: Do not use automatic transmission fluid

in power steering system. Only use Mopar T, Power

Steering Fluid, or equivalent.

(9) Fill power steering pump reservoir to correct

fluid level.

Fig. 1 Power Steering Pump Drive Belt Removal

Fig. 2 Power Steering Fluid Hoses

Fig. 3 Power Steering Pump Remove And Install

Ä STEERING 19 - 13