steering CHEVROLET DYNASTY 1993 Service Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 1939 of 2438

With Serpentine Belts; Run engine until warm (5

min.) and note any belt chirp. If chirp exists, move

pulley outward approximately 0.5 mm (0.020 in.). If

noise increases, press on 1.0mm (0.040 in.). Be careful

that pulley does not contact mounting bolts.

SAGINAW T/C STYLE PUMP

REMOVE

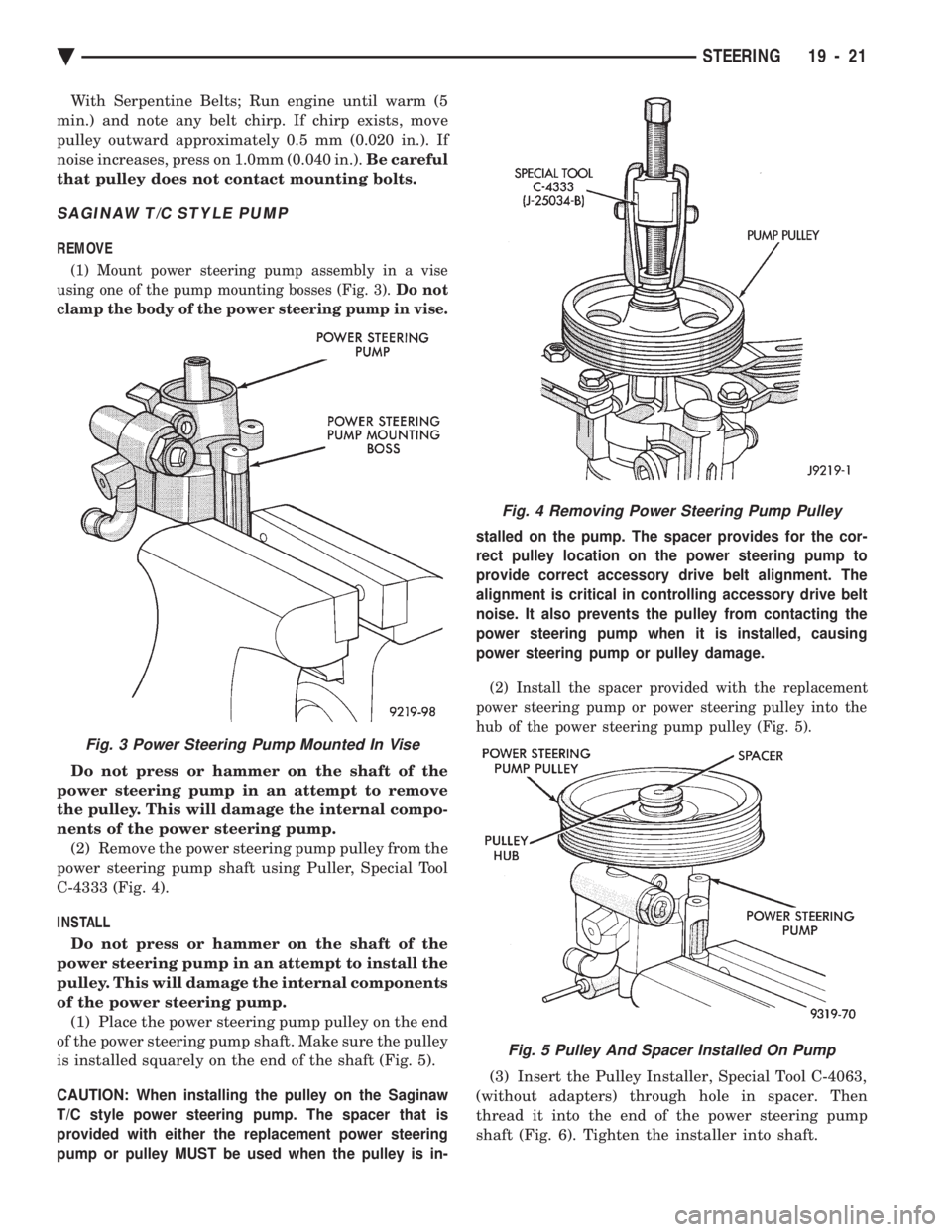

(1) Mount power steering pump assembly in a vise

using one of the pump mounting bosses (Fig. 3). Do not

clamp the body of the power steering pump in vise.

Do not press or hammer on the shaft of the

power steering pump in an attempt to remove

the pulley. This will damage the internal compo-

nents of the power steering pump. (2) Remove the power steering pump pulley from the

power steering pump shaft using Puller, Special Tool

C-4333 (Fig. 4).

INSTALL

Do not press or hammer on the shaft of the

power steering pump in an attempt to install the

pulley. This will damage the internal components

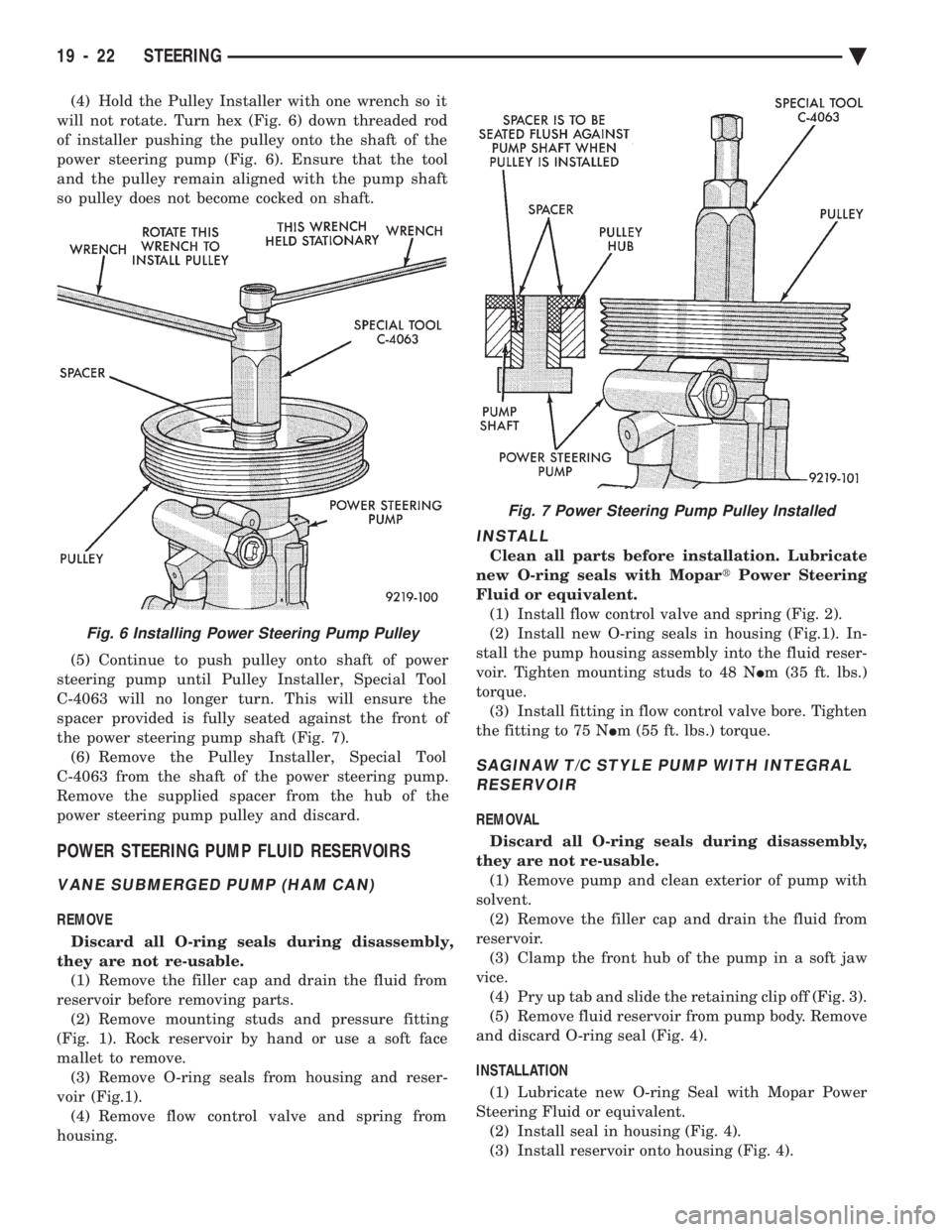

of the power steering pump. (1) Place the power steering pump pulley on the end

of the power steering pump shaft. Make sure the pulley

is installed squarely on the end of the shaft (Fig. 5).

CAUTION: When installing the pulley on the Saginaw

T/C style power steering pump. The spacer that is

provided with either the replacement power steering

pump or pulley MUST be used when the pulley is in- stalled on the pump. The spacer provides for the cor-

rect pulley location on the power steering pump to

provide correct accessory drive belt alignment. The

alignment is critical in controlling accessory drive belt

noise. It also prevents the pulley from contacting the

power steering pump when it is installed, causing

power steering pump or pulley damage.

(2) Install the spacer provided with the replacement

power steering pump or power steering pulley into the

hub of the power steering pump pulley (Fig. 5).

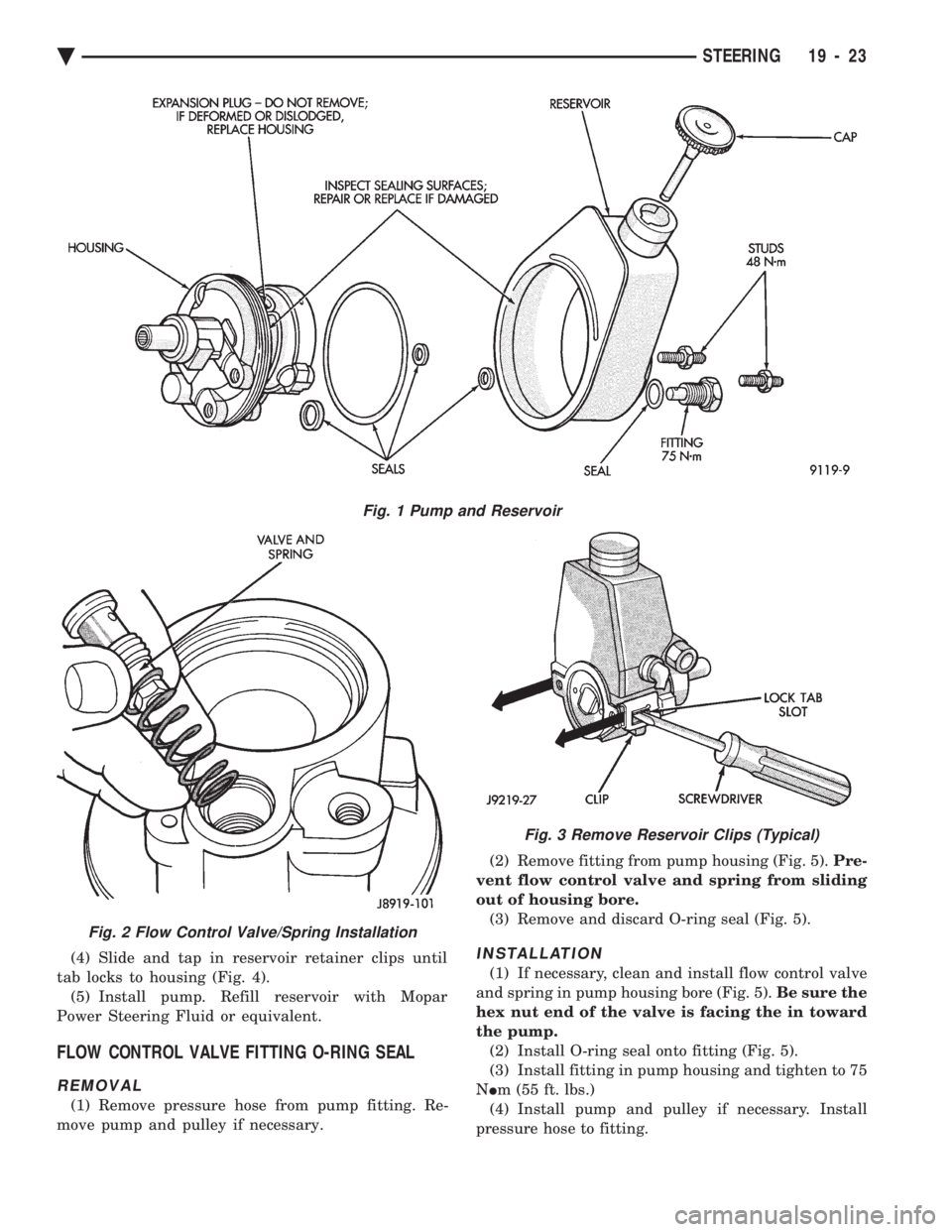

(3) Insert the Pulley Installer, Special Tool C-4063,

(without adapters) through hole in spacer. Then

thread it into the end of the power steering pump

shaft (Fig. 6). Tighten the installer into shaft.

Fig. 4 Removing Power Steering Pump Pulley

Fig. 5 Pulley And Spacer Installed On Pump

Fig. 3 Power Steering Pump Mounted In Vise

Ä STEERING 19 - 21

Page 1940 of 2438

(4) Hold the Pulley Installer with one wrench so it

will not rotate. Turn hex (Fig. 6) down threaded rod

of installer pushing the pulley onto the shaft of the

power steering pump (Fig. 6). Ensure that the tool

and the pulley remain aligned with the pump shaft

so pulley does not become cocked on shaft.

(5) Continue to push pulley onto shaft of power

steering pump until Pulley Installer, Special Tool

C-4063 will no longer turn. This will ensure the

spacer provided is fully seated against the front of

the power steering pump shaft (Fig. 7). (6) Remove the Pulley Installer, Special Tool

C-4063 from the shaft of the power steering pump.

Remove the supplied spacer from the hub of the

power steering pump pulley and discard.

POWER STEERING PUMP FLUID RESERVOIRS

VANE SUBMERGED PUMP (HAM CAN)

REMOVE

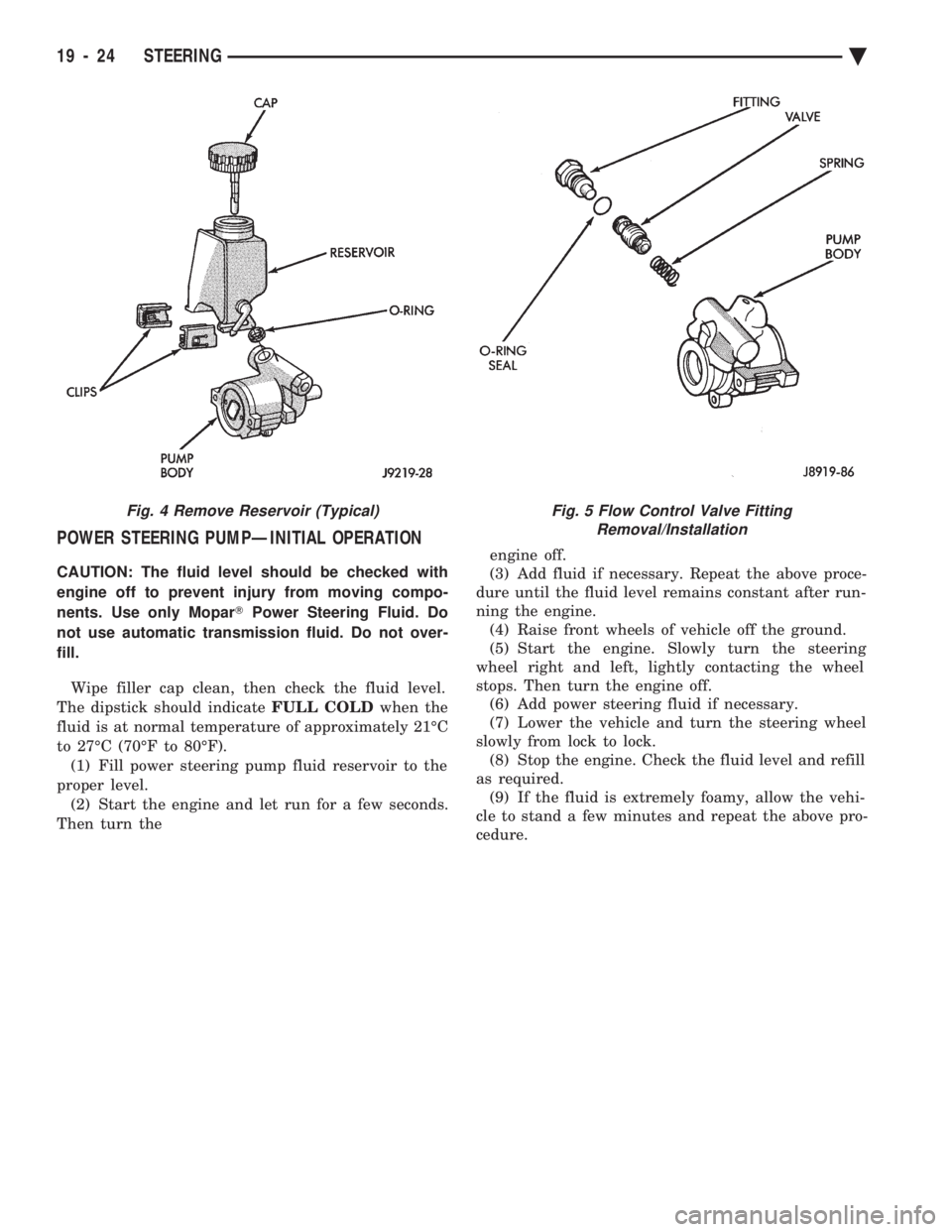

Discard all O-ring seals during disassembly,

they are not re-usable. (1) Remove the filler cap and drain the fluid from

reservoir before removing parts. (2) Remove mounting studs and pressure fitting

(Fig. 1). Rock reservoir by hand or use a soft face

mallet to remove. (3) Remove O-ring seals from housing and reser-

voir (Fig.1). (4) Remove flow control valve and spring from

housing.

INSTALL

Clean all parts before installation. Lubricate

new O-ring seals with Mopar tPower Steering

Fluid or equivalent. (1) Install flow control valve and spring (Fig. 2).

(2) Install new O-ring seals in housing (Fig.1). In-

stall the pump housing assembly into the fluid reser-

voir. Tighten mounting studs to 48 N Im (35 ft. lbs.)

torque. (3) Install fitting in flow control valve bore. Tighten

the fitting to 75 N Im (55 ft. lbs.) torque.

SAGINAW T/C STYLE PUMP WITH INTEGRAL

RESERVOIR

REMOVAL

Discard all O-ring seals during disassembly,

they are not re-usable. (1) Remove pump and clean exterior of pump with

solvent. (2) Remove the filler cap and drain the fluid from

reservoir. (3) Clamp the front hub of the pump in a soft jaw

vice. (4) Pry up tab and slide the retaining clip off (Fig. 3).

(5) Remove fluid reservoir from pump body. Remove

and discard O-ring seal (Fig. 4).

INSTALLATION

(1) Lubricate new O-ring Seal with Mopar Power

Steering Fluid or equivalent. (2) Install seal in housing (Fig. 4).

(3) Install reservoir onto housing (Fig. 4).

Fig. 6 Installing Power Steering Pump Pulley

Fig. 7 Power Steering Pump Pulley Installed

19 - 22 STEERING Ä

Page 1941 of 2438

(4) Slide and tap in reservoir retainer clips until

tab locks to housing (Fig. 4). (5) Install pump. Refill reservoir with Mopar

Power Steering Fluid or equivalent.

FLOW CONTROL VALVE FITTING O-RING SEAL

REMOVAL

(1) Remove pressure hose from pump fitting. Re-

move pump and pulley if necessary. (2) Remove fitting from pump housing (Fig. 5).

Pre-

vent flow control valve and spring from sliding

out of housing bore. (3) Remove and discard O-ring seal (Fig. 5).

INSTALLATION

(1) If necessary, clean and install flow control valve

and spring in pump housing bore (Fig. 5). Be sure the

hex nut end of the valve is facing the in toward

the pump. (2) Install O-ring seal onto fitting (Fig. 5).

(3) Install fitting in pump housing and tighten to 75

N Im (55 ft. lbs.)

(4) Install pump and pulley if necessary. Install

pressure hose to fitting.

Fig. 1 Pump and Reservoir

Fig. 2 Flow Control Valve/Spring Installation

Fig. 3 Remove Reservoir Clips (Typical)

Ä STEERING 19 - 23

Page 1942 of 2438

POWER STEERING PUMPÐINITIAL OPERATION

CAUTION: The fluid level should be checked with

engine off to prevent injury from moving compo-

nents. Use only Mopar TPower Steering Fluid. Do

not use automatic transmission fluid. Do not over-

fill.

Wipe filler cap clean, then check the fluid level.

The dipstick should indicate FULL COLDwhen the

fluid is at normal temperature of approximately 21ÉC

to 27ÉC (70ÉF to 80ÉF). (1) Fill power steering pump fluid reservoir to the

proper level. (2) Start the engine and let run for a few seconds.

Then turn the engine off.

(3) Add fluid if necessary. Repeat the above proce-

dure until the fluid level remains constant after run-

ning the engine. (4) Raise front wheels of vehicle off the ground.

(5) Start the engine. Slowly turn the steering

wheel right and left, lightly contacting the wheel

stops. Then turn the engine off. (6) Add power steering fluid if necessary.

(7) Lower the vehicle and turn the steering wheel

slowly from lock to lock. (8) Stop the engine. Check the fluid level and refill

as required. (9) If the fluid is extremely foamy, allow the vehi-

cle to stand a few minutes and repeat the above pro-

cedure.

Fig. 4 Remove Reservoir (Typical)Fig. 5 Flow Control Valve Fitting Removal/Installation

19 - 24 STEERING Ä

Page 1943 of 2438

POWER STEERING GEAR INDEX

page page

General Information ....................... 25

Outer Tie Rod ........................... 27 Steering Gear Service

..................... 25

GENERAL INFORMATION

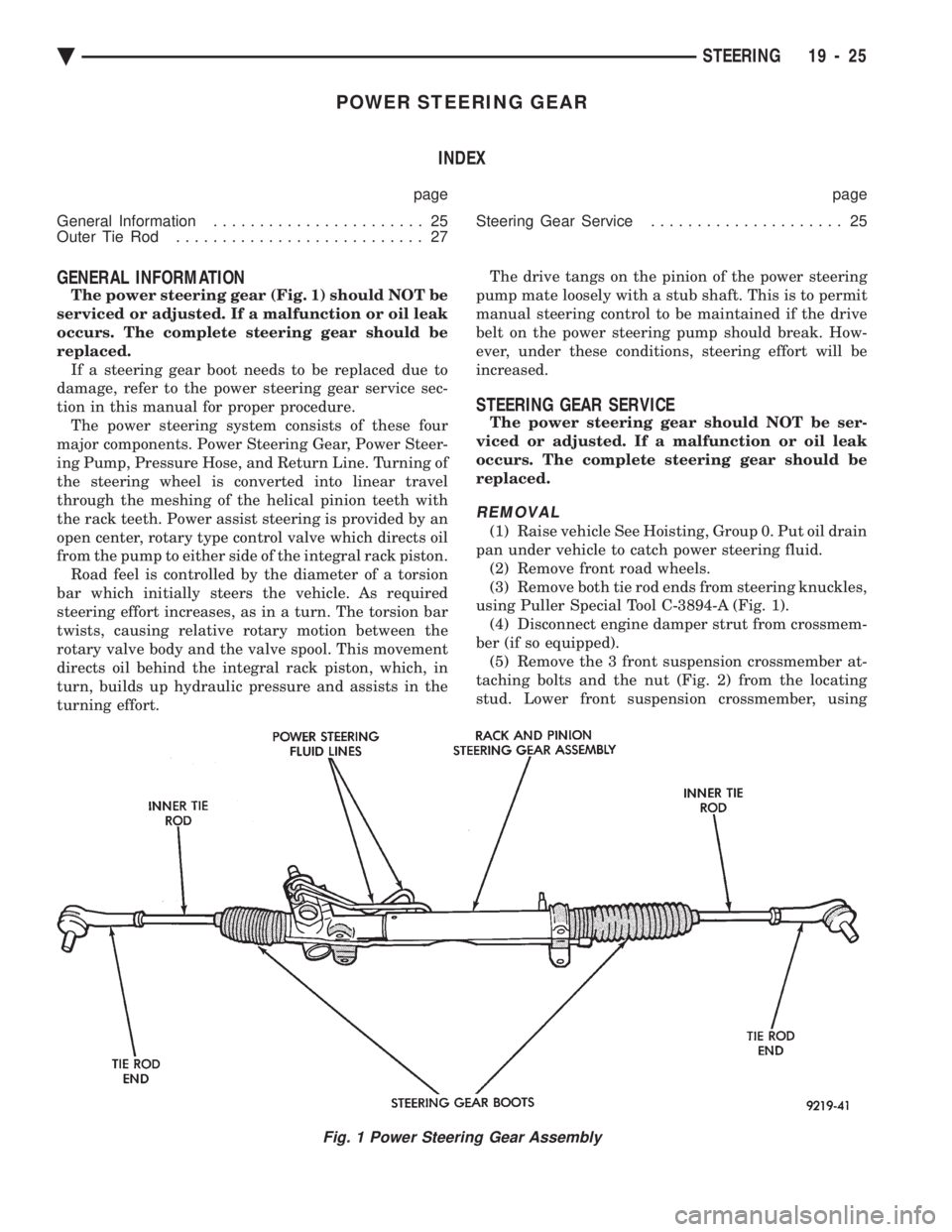

The power steering gear (Fig. 1) should NOT be

serviced or adjusted. If a malfunction or oil leak

occurs. The complete steering gear should be

replaced. If a steering gear boot needs to be replaced due to

damage, refer to the power steering gear service sec-

tion in this manual for proper procedure. The power steering system consists of these four

major components. Power Steering Gear, Power Steer-

ing Pump, Pressure Hose, and Return Line. Turning of

the steering wheel is converted into linear travel

through the meshing of the helical pinion teeth with

the rack teeth. Power assist steering is provided by an

open center, rotary type control valve which directs oil

from the pump to either side of the integral rack piston. Road feel is controlled by the diameter of a torsion

bar which initially steers the vehicle. As required

steering effort increases, as in a turn. The torsion bar

twists, causing relative rotary motion between the

rotary valve body and the valve spool. This movement

directs oil behind the integral rack piston, which, in

turn, builds up hydraulic pressure and assists in the

turning effort. The drive tangs on the pinion of the power steering

pump mate loosely with a stub shaft. This is to permit

manual steering control to be maintained if the drive

belt on the power steering pump should break. How-

ever, under these conditions, steering effort will be

increased.

STEERING GEAR SERVICE

The power steering gear should NOT be ser-

viced or adjusted. If a malfunction or oil leak

occurs. The complete steering gear should be

replaced.

REMOVAL

(1) Raise vehicle See Hoisting, Group 0. Put oil drain

pan under vehicle to catch power steering fluid. (2) Remove front road wheels.

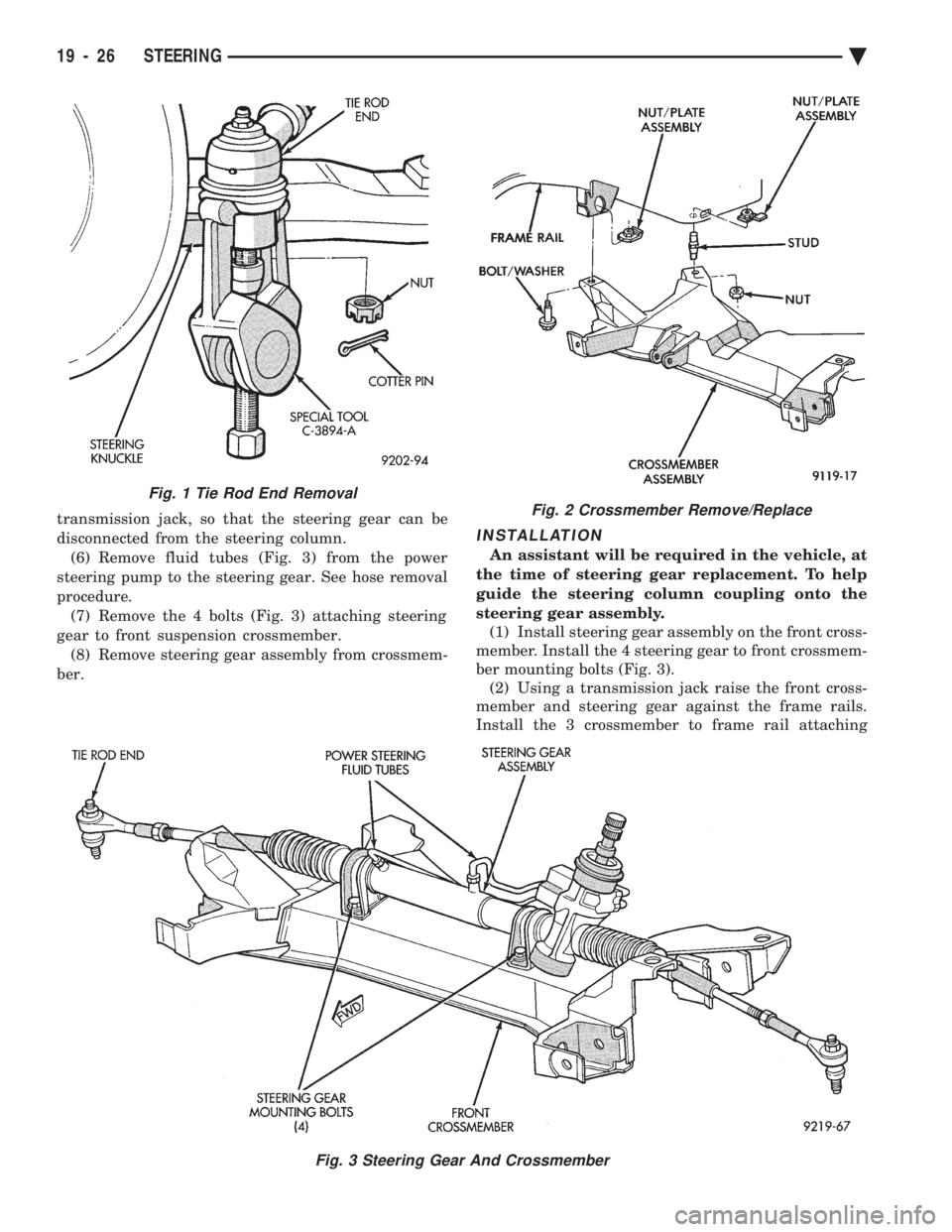

(3) Remove both tie rod ends from steering knuckles,

using Puller Special Tool C-3894-A (Fig. 1). (4) Disconnect engine damper strut from crossmem-

ber (if so equipped). (5) Remove the 3 front suspension crossmember at-

taching bolts and the nut (Fig. 2) from the locating

stud. Lower front suspension crossmember, using

Fig. 1 Power Steering Gear Assembly

Ä STEERING 19 - 25

Page 1944 of 2438

transmission jack, so that the steering gear can be

disconnected from the steering column.(6) Remove fluid tubes (Fig. 3) from the power

steering pump to the steering gear. See hose removal

procedure. (7) Remove the 4 bolts (Fig. 3) attaching steering

gear to front suspension crossmember. (8) Remove steering gear assembly from crossmem-

ber.

INSTALLATION

An assistant will be required in the vehicle, at

the time of steering gear replacement. To help

guide the steering column coupling onto the

steering gear assembly. (1) Install steering gear assembly on the front cross-

member. Install the 4 steering gear to front crossmem-

ber mounting bolts (Fig. 3). (2) Using a transmission jack raise the front cross-

member and steering gear against the frame rails.

Install the 3 crossmember to frame rail attaching

Fig. 2 Crossmember Remove/Replace

Fig. 3 Steering Gear And Crossmember

Fig. 1 Tie Rod End Removal

19 - 26 STEERING Ä

Page 1945 of 2438

bolts and nut on locating stud (Fig. 2). The right rear

crossmember stud is a pilot that correctly locates

the crossmember. Tighten down this bolt first,

then torque all 4 crossmember fasteners to 122

N Im (90 ft. lbs.).

CAUTION: Proper torque on the crossmember to

frame rail mounting bolts is very important.

(3) Torque the 4 bolts (Fig. 3) attaching the steering

gear assembly to front crossmember, to 68 N Im (50 ft.

lbs.). To ensure proper alignment of the steering

gear tighten left front bolt first. (4) Attach the engine damper strut from the engine

to the crossmember (if so equipped). (5) Attach the fluid tubes (Fig. 3) from the power

steering pump to the fittings on the steering gear.

Torque the fluid pressure line to steering gear tube nut

to 31 N Im (275 in. lbs.).

(6) Mount the outer tie rod ends to the steering

knuckles. Install the tie rod end to steering knuckle

attaching nuts. Torque the tie rod end to steering

knuckle nuts to 52 N Im (38 ft. lbs.). Install cotter pin

in tie rod end. (7) Install the front tire and wheel assemblies on

vehicle. Install the wheel lug nuts and torque to 129

N Im (95 ft. lbs.).

(8) Lower vehicle.

CAUTION: Do not use automatic transmission fluid. (9) Fill power steering pump fluid reservoir to the

(Full-Cold) proper level. (10) Start the engine and let run for a few seconds.

Then turn the engine off.

(11) Add fluid if necessary.

(12) Raise front wheels of vehicle off the ground.

(13) Start engine and turn steering wheel several

times from stop to stop to bleed air from fluid in

system. Stop engine, check fluid level, and inspect

system for leaks. Fill pump reservoir to correct

level with Mopar t, Power Steering Fluid, or

equivalent. See Checking Fluid Level.

(14) Lower front wheels of vehicle back on the

ground. (15) Adjust toe (Refer to Group 2 Suspension).

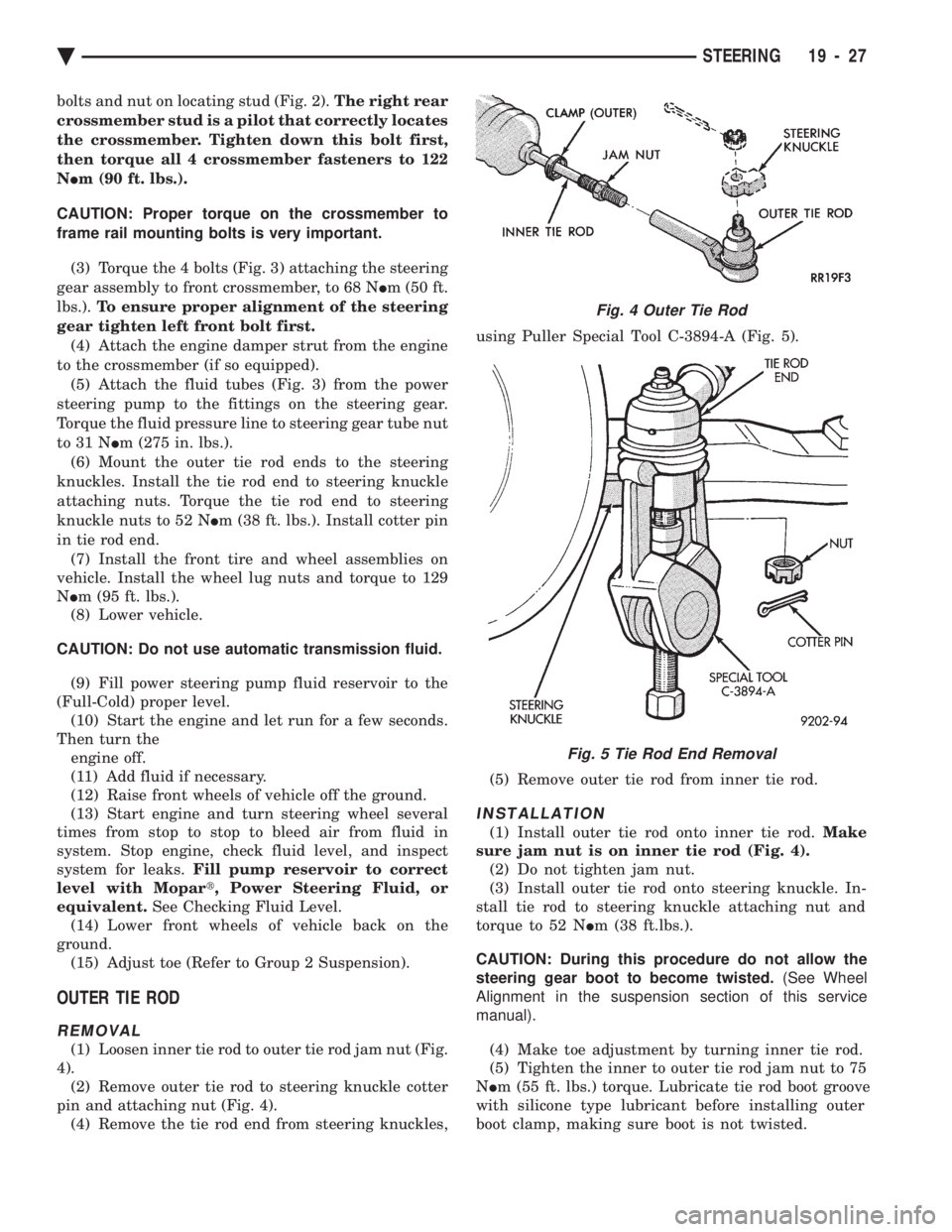

OUTER TIE ROD

REMOVAL

(1) Loosen inner tie rod to outer tie rod jam nut (Fig.

4). (2) Remove outer tie rod to steering knuckle cotter

pin and attaching nut (Fig. 4). (4) Remove the tie rod end from steering knuckles, using Puller Special Tool C-3894-A (Fig. 5).

(5) Remove outer tie rod from inner tie rod.

INSTALLATION

(1) Install outer tie rod onto inner tie rod. Make

sure jam nut is on inner tie rod (Fig. 4). (2) Do not tighten jam nut.

(3) Install outer tie rod onto steering knuckle. In-

stall tie rod to steering knuckle attaching nut and

torque to 52 N Im (38 ft.lbs.).

CAUTION: During this procedure do not allow the

steering gear boot to become twisted. (See Wheel

Alignment in the suspension section of this service

manual).

(4) Make toe adjustment by turning inner tie rod.

(5) Tighten the inner to outer tie rod jam nut to 75

N Im (55 ft. lbs.) torque. Lubricate tie rod boot groove

with silicone type lubricant before installing outer

boot clamp, making sure boot is not twisted.

Fig. 4 Outer Tie Rod

Fig. 5 Tie Rod End Removal

Ä STEERING 19 - 27

Page 1946 of 2438

ACUSTAR STANDARD AND TILT STEERING COLUMN INDEX

page page

General Information ....................... 28

Ignition Switch Service .................... 34 Steering Column Component Service

......... 34

Steering Column Service Procedures .......... 30

GENERAL INFORMATION

WARNING: THE AIR BAG SYSTEM IS A SENSITIVE,

COMPLEX ELECTRO-MECHANICAL UNIT. BEFORE

ATTEMPTING TO DIAGNOSE, REMOVE OR IN-

STALL THE AIR BAG SYSTEM COMPONENTS YOU

MUST FIRST DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE. FAILURE

TO DO SO COULD RESULT IN ACCIDENTAL DE-

PLOYMENT OF THE AIR BAG AND POSSIBLE PER-

SONAL INJURY. THE FASTENERS, SCREWS, AND BOLTS, ORIGI-

NALLY USED FOR THE AIR BAG COMPONENTS,

HAVE SPECIAL COATINGS AND ARE SPECIFI- CALLY DESIGNED FOR THE AIR BAG SYSTEM.

THEY MUST NEVER BE REPLACED WITH ANY

SUBSTITUTES. ANYTIME A NEW FASTENER IS

NEEDED, REPLACE WITH THE CORRECT FASTEN-

ERS PROVIDED IN THE SERVICE PACKAGE OR

FASTENERS LISTED IN THE PARTS BOOKS. BEFORE SERVICING A STEERING COLUMN

EQUIPPED WITH AN AIR BAG, REFER TO GROUP

8M, ELECTRICAL FOR PROPER AND SAFE SER-

VICE PROCEDURES.

Safety goggles should be worn at all times

when working on steering columns.

19 - 28 STEERING Ä

Page 1947 of 2438

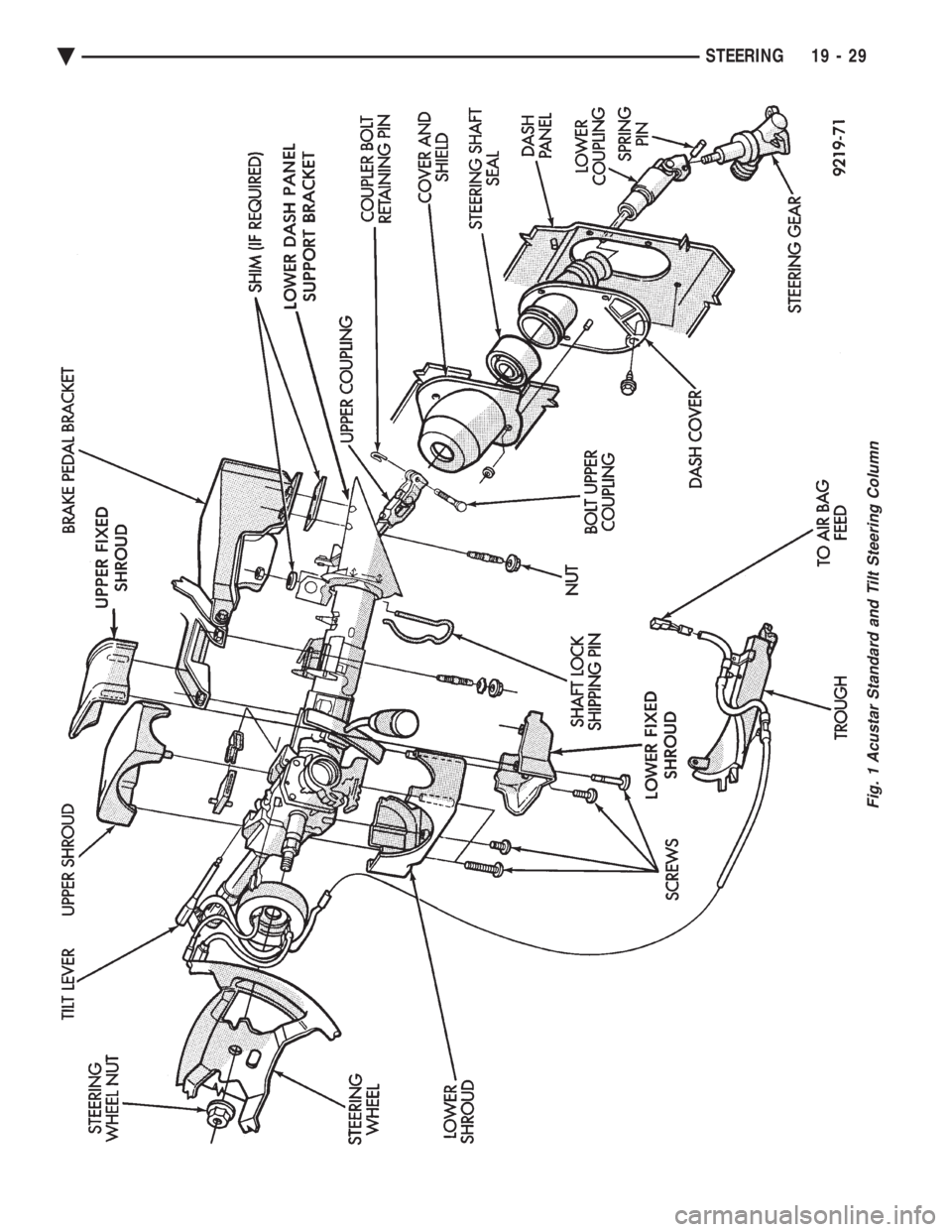

Fig. 1 Acustar Standard and Tilt Steering Column

Ä STEERING 19 - 29

Page 1948 of 2438

The Acustar tilt and standard column (Fig. 1) has

been designed to be serviced as an assembly; less wir-

ing, switches, shrouds, steering wheel, etc. Also, most

steering column components can be serviced without re-

moving the steering column from the vehicle.

CAUTION: Disconnect negative (ground) cable from

battery, before servicing any column component.

CAUTION: Do not attempt to remove the pivot pins

to disassemble the tilting mechanism. Damage will

occur.

STEERING COLUMN SERVICE PROCEDURES

To service the steering wheel and its components

or the air bag, refer to Group 8M, Restraint Systems.

Follow all WARNINGS. To service the switches, refer to the appropriate

section of Group 8, Electrical.

To replace the steering column assembly, refer to the

steering column removal procedure. For location of com-

ponents referred to in the procedure see (Fig. 1).

WARNING: BEFORE BEGINNING ANY AIR BAG

SYSTEM COMPONENT INSTALLATION OR RE-

MOVAL PROCEDURES. REMOVE AND ISOLATE

THE NEGATIVE (-) BATTERY CABLE (GROUND)

FROM THE VEHICLE BATTERY. THIS IS THE ONLY

SURE WAY TO DISABLE THE AIR BAG SYSTEM.

FAILURE TO DO THIS COULD RESULT IN ACCI-

DENTAL AIR BAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

STEERING COLUMN REMOVAL

(1) Make sure the front wheels of the vehicle are

in the straight ahead position.

(2) Disconnect the negative (ground) cable from

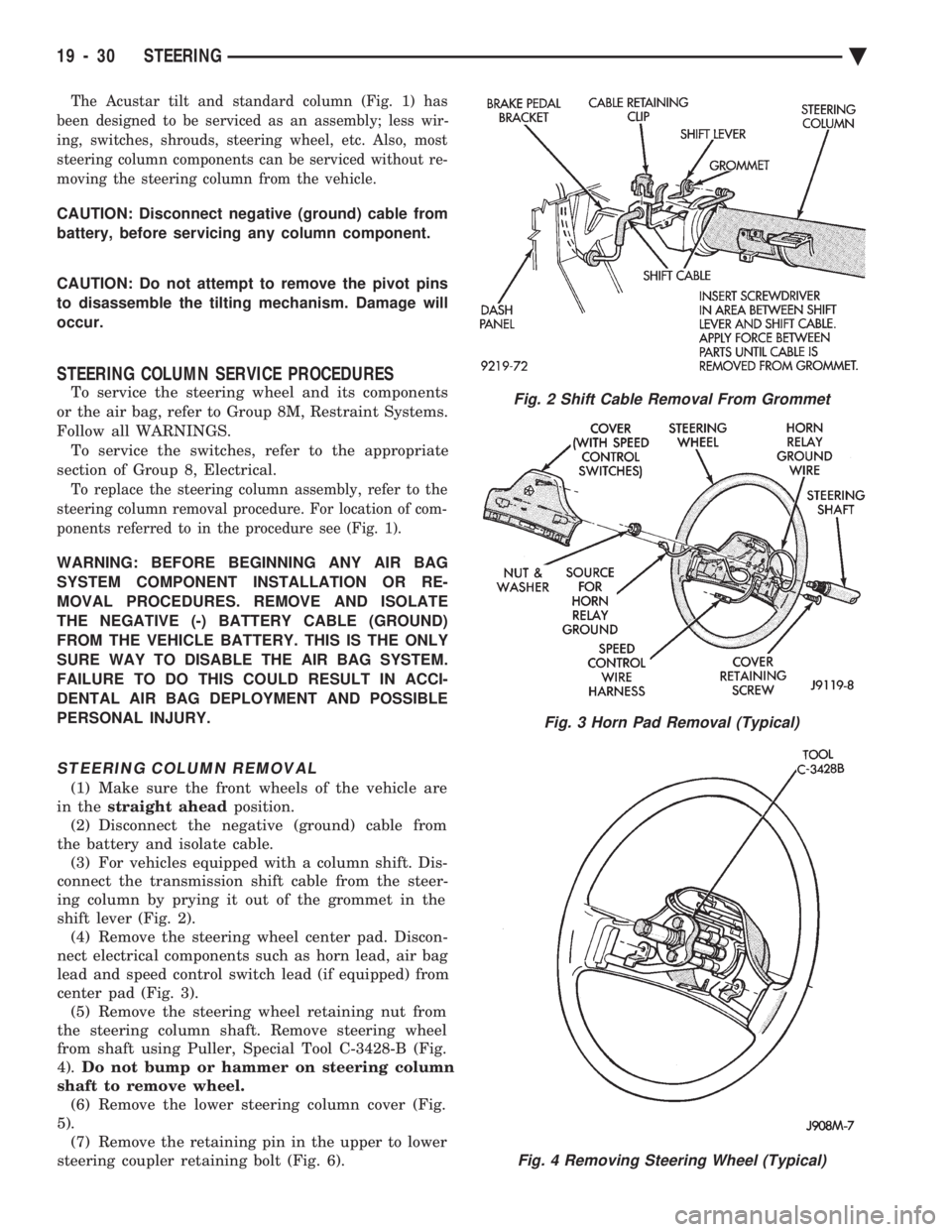

the battery and isolate cable. (3) For vehicles equipped with a column shift. Dis-

connect the transmission shift cable from the steer-

ing column by prying it out of the grommet in the

shift lever (Fig. 2). (4) Remove the steering wheel center pad. Discon-

nect electrical components such as horn lead, air bag

lead and speed control switch lead (if equipped) from

center pad (Fig. 3). (5) Remove the steering wheel retaining nut from

the steering column shaft. Remove steering wheel

from shaft using Puller, Special Tool C-3428-B (Fig.

4). Do not bump or hammer on steering column

shaft to remove wheel. (6) Remove the lower steering column cover (Fig.

5). (7) Remove the retaining pin in the upper to lower

steering coupler retaining bolt (Fig. 6).

Fig. 2 Shift Cable Removal From Grommet

Fig. 3 Horn Pad Removal (Typical)

Fig. 4 Removing Steering Wheel (Typical)

19 - 30 STEERING Ä