steering CHEVROLET DYNASTY 1993 Service Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 1959 of 2438

CAUTION: Interlock cable must by completely

clipped to the throttle pedal bracket with both barbs

of clip fully installed through mounting holes. This

is to prevent interference with throttle pedal.

(6) Snap the interlock cable routing clip into the 2

holes on the throttle pedal mounting bracket (Fig.

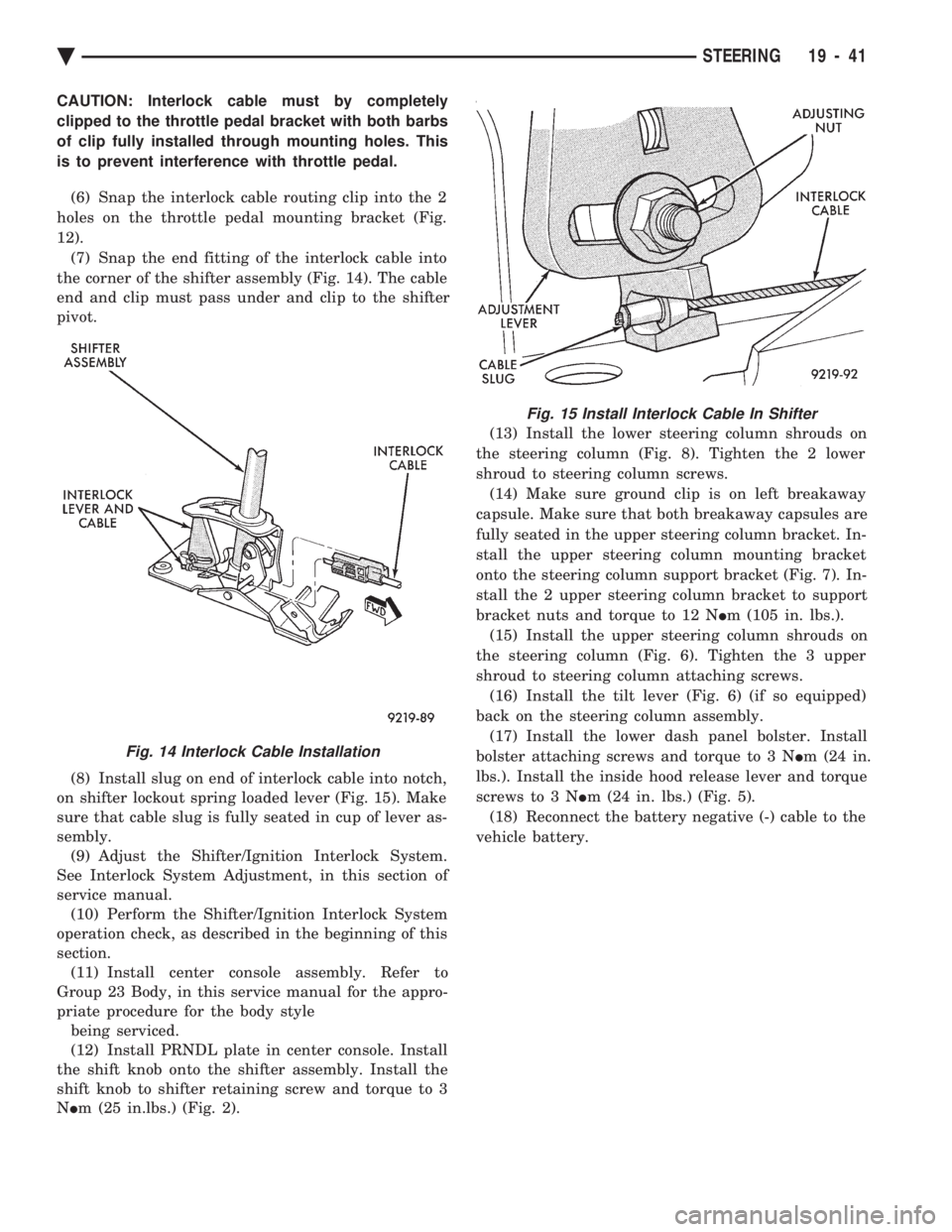

12). (7) Snap the end fitting of the interlock cable into

the corner of the shifter assembly (Fig. 14). The cable

end and clip must pass under and clip to the shifter

pivot.

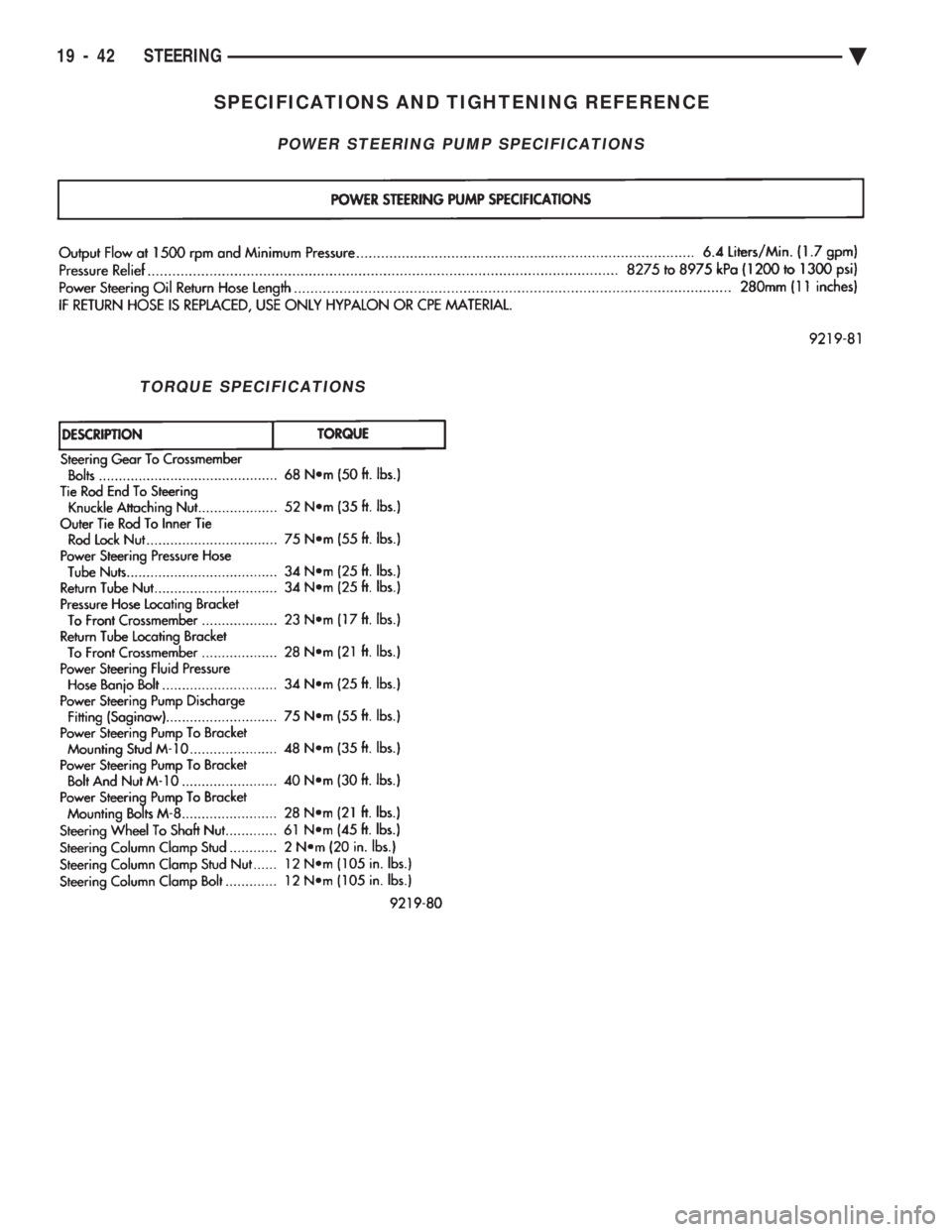

(8) Install slug on end of interlock cable into notch,

on shifter lockout spring loaded lever (Fig. 15). Make

sure that cable slug is fully seated in cup of lever as-

sembly. (9) Adjust the Shifter/Ignition Interlock System.

See Interlock System Adjustment, in this section of

service manual. (10) Perform the Shifter/Ignition Interlock System

operation check, as described in the beginning of this

section. (11) Install center console assembly. Refer to

Group 23 Body, in this service manual for the appro-

priate procedure for the body style being serviced.

(12) Install PRNDL plate in center console. Install

the shift knob onto the shifter assembly. Install the

shift knob to shifter retaining screw and torque to 3

N Im (25 in.lbs.) (Fig. 2). (13) Install the lower steering column shrouds on

the steering column (Fig. 8). Tighten the 2 lower

shroud to steering column screws. (14) Make sure ground clip is on left breakaway

capsule. Make sure that both breakaway capsules are

fully seated in the upper steering column bracket. In-

stall the upper steering column mounting bracket

onto the steering column support bracket (Fig. 7). In-

stall the 2 upper steering column bracket to support

bracket nuts and torque to 12 N Im (105 in. lbs.).

(15) Install the upper steering column shrouds on

the steering column (Fig. 6). Tighten the 3 upper

shroud to steering column attaching screws. (16) Install the tilt lever (Fig. 6) (if so equipped)

back on the steering column assembly. (17) Install the lower dash panel bolster. Install

bolster attaching screws and torque to 3 N Im (24 in.

lbs.). Install the inside hood release lever and torque

screws to 3 N Im (24 in. lbs.) (Fig. 5).

(18) Reconnect the battery negative (-) cable to the

vehicle battery.

Fig. 14 Interlock Cable Installation

Fig. 15 Install Interlock Cable In Shifter

Ä STEERING 19 - 41

Page 1960 of 2438

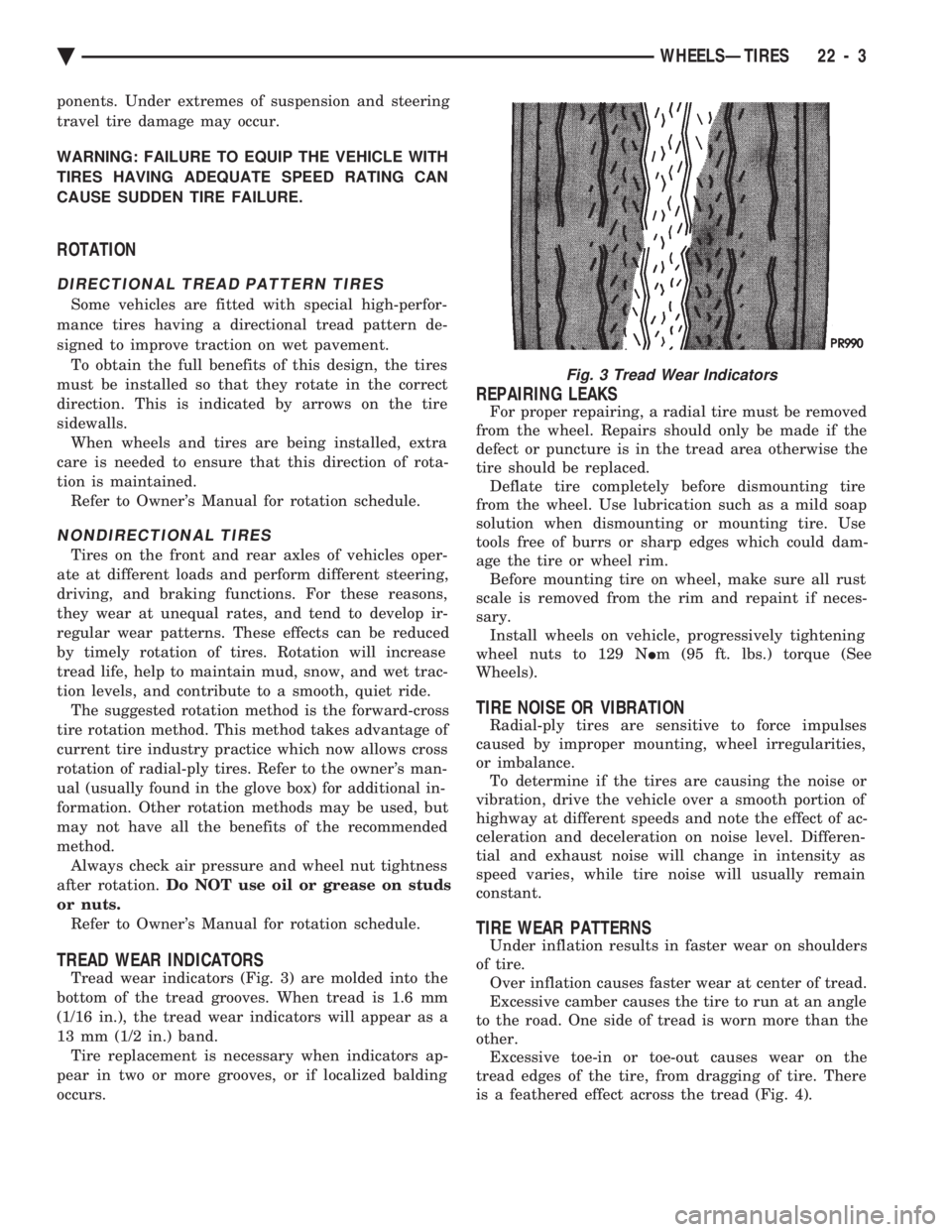

SPECIFICATIONS AND TIGHTENING REFERENCE

POWER STEERING PUMP SPECIFICATIONS

TORQUE SPECIFICATIONS

19 - 42 STEERING Ä

Page 1996 of 2438

TORQUE CONVERTER CLUTCH

The torque converter clutch is standard on all ve-

hicles. It is activated only in direct drive and is con-

trolled by the engine electronics. A solenoid on the

valve body, is powered by the powertrain control mod-

ule to activate torque converter clutch.

HYDRAULIC CONTROL SYSTEM

The hydraulic control circuits show the position of

the various valves. They indicate those under hydrau-

lic pressure for all operations of the transaxle. The hydraulic control system makes the transaxle

fully automatic, and has four important functions to

perform. In a general way, the components of any

automatic control system may be grouped into the

following basic groups: The pressure supply system, the pressure regulating

valves, the flow control valves, the clutches, and band

servos. Taking each of these basic groups or systems in turn,

the control system may be described as follows:

PRESSURE SUPPLY SYSTEM

The pressure supply system consists of an oil pump

driven by the engine through the torque converter. The

single pump furnishes pressure for all the hydraulic

and lubrication requirements. Oil pump housing

assemblies are available with preselected pump

gears.

PRESSURE REGULATING VALVES

The pressure regulating valve controls line pressure

dependent on throttle opening. The governor valve

transmits regulated pressure to the valve body (in

conjunction with vehicle speed) to control upshift and

downshift. The throttle valve transmits regulated pressure to

the transaxle (dependent on throttle position) to con-

trol upshift and downshift.

FLOW CONTROL VALVES

The manual valve provides the different transaxle

drive ranges as selected by the vehicle operator. The 1-2 shift valve automatically shifts the transaxle

from first to second or from second to first, depending

on the vehicle operation. The 2-3 shift valve automatically shifts the transaxle

from second to third or from third to second depending

on the vehicle operation. The kickdown valve makes possible a forced down-

shift from third to second, second to first, or third to

first (depending on vehicle speed). This can be done by

depressing the accelerator pedal past the detent ``feel''

near wide open throttle. The shuttle valve has two separate functions and

performs each independently of the other. The first

provides fast release of the kickdown band, and

smooth front clutch engagement, when the driver makes a

lift-footupshift from second to third. The

second function of the shuttle valve is to regulate the

application of the kickdown servo and band when

making third to second kickdown. The by-pass valve provides for smooth application of

the kickdown band on 1-2 upshifts. The torque converter clutch solenoid allows for the

electronic control of the clutch inside the torque con-

verter. It also disengages the torque converter at closed

throttle, during engine warm-up, and during part-

throttle acceleration. The switch valve directs oil to apply the torque

converter clutch in one position and releases the torque

converter clutch in the other position.

CLUTCH, BAND SERVO, AND ACCUMULATOR

The front and rear clutch pistons, and both servo

pistons are moved hydraulically to engage the clutches

and apply the bands. The pistons are released by

spring tension when hydraulic pressure is released. On

the 2-3 upshift, the kickdown servo piston is released

by spring tension and hydraulic pressure. The accumulator controls the hydraulic pressure on

the apply side of the kickdown servo during the 1-2

upshift; thereby, cushioning the kickdown band appli-

cation at any throttle position.

GEARSHIFT AND PARKING LOCK CONTROLS

The transaxle is controlled by a lever typegearshift

incorporated within the console or the steering column.

The control has six selector lever positions: P (park), R

(reverse), N (neutral), and D (drive), 2 (second), and 1

(first). The parking lock is applied by moving the

selector lever past a gate to the Pposition. Do not

apply the parking lock until the vehicle has

stopped; otherwise, a severe banging noise will

occur.

THREE SPEED TORQUEFLITE GENERAL DIAGNO-

SIS

Automatic transaxle malfunctions may be caused by

four general conditions:

² Poor engine performance

² Improper adjustments

² Hydraulic malfunctions

² Mechanical malfunctions.

Diagnosis of these problems should always begin by

checking the easily accessible variables: fluid level and

condition, gearshift cable adjustment, and throttle

pressure cable adjustment. Then perform a road test to

determine if the problem has been corrected or that

more diagnosis is necessary. If the problem exists after

the preliminary tests and corrections are completed,

hydraulic pressure tests should be performed.

21 - 36 TRANSAXLE Ä

Page 2151 of 2438

ponents. Under extremes of suspension and steering

travel tire damage may occur.

WARNING: FAILURE TO EQUIP THE VEHICLE WITH

TIRES HAVING ADEQUATE SPEED RATING CAN

CAUSE SUDDEN TIRE FAILURE.

ROTATION

DIRECTIONAL TREAD PATTERN TIRES

Some vehicles are fitted with special high-perfor-

mance tires having a directional tread pattern de-

signed to improve traction on wet pavement. To obtain the full benefits of this design, the tires

must be installed so that they rotate in the correct

direction. This is indicated by arrows on the tire

sidewalls. When wheels and tires are being installed, extra

care is needed to ensure that this direction of rota-

tion is maintained. Refer to Owner's Manual for rotation schedule.

NONDIRECTIONAL TIRES

Tires on the front and rear axles of vehicles oper-

ate at different loads and perform different steering,

driving, and braking functions. For these reasons,

they wear at unequal rates, and tend to develop ir-

regular wear patterns. These effects can be reduced

by timely rotation of tires. Rotation will increase

tread life, help to maintain mud, snow, and wet trac-

tion levels, and contribute to a smooth, quiet ride. The suggested rotation method is the forward-cross

tire rotation method. This method takes advantage of

current tire industry practice which now allows cross

rotation of radial-ply tires. Refer to the owner's man-

ual (usually found in the glove box) for additional in-

formation. Other rotation methods may be used, but

may not have all the benefits of the recommended

method. Always check air pressure and wheel nut tightness

after rotation. Do NOT use oil or grease on studs

or nuts. Refer to Owner's Manual for rotation schedule.

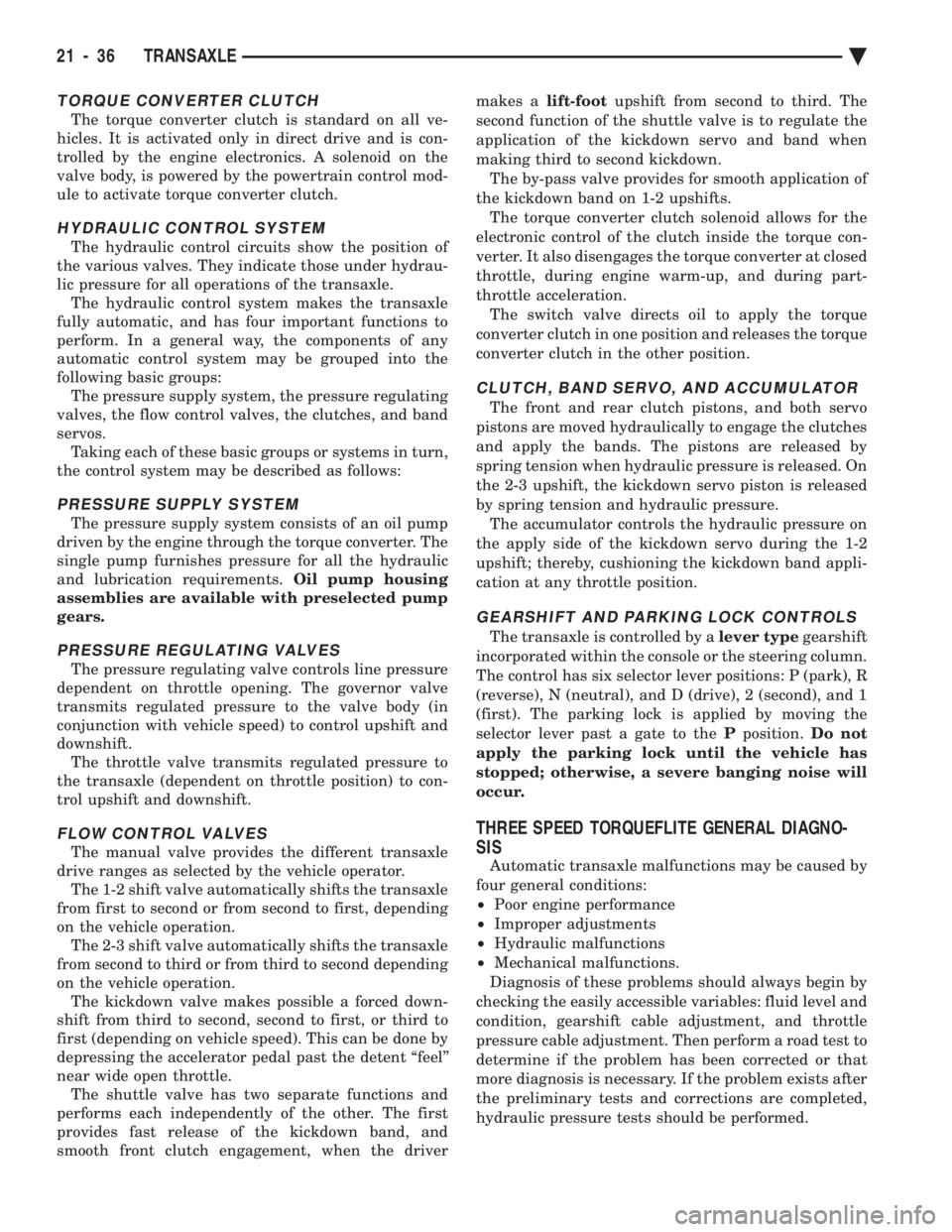

TREAD WEAR INDICATORS

Tread wear indicators (Fig. 3) are molded into the

bottom of the tread grooves. When tread is 1.6 mm

(1/16 in.), the tread wear indicators will appear as a

13 mm (1/2 in.) band. Tire replacement is necessary when indicators ap-

pear in two or more grooves, or if localized balding

occurs.

REPAIRING LEAKS

For proper repairing, a radial tire must be removed

from the wheel. Repairs should only be made if the

defect or puncture is in the tread area otherwise the

tire should be replaced. Deflate tire completely before dismounting tire

from the wheel. Use lubrication such as a mild soap

solution when dismounting or mounting tire. Use

tools free of burrs or sharp edges which could dam-

age the tire or wheel rim. Before mounting tire on wheel, make sure all rust

scale is removed from the rim and repaint if neces-

sary. Install wheels on vehicle, progressively tightening

wheel nuts to 129 N Im (95 ft. lbs.) torque (See

Wheels).

TIRE NOISE OR VIBRATION

Radial-ply tires are sensitive to force impulses

caused by improper mounting, wheel irregularities,

or imbalance. To determine if the tires are causing the noise or

vibration, drive the vehicle over a smooth portion of

highway at different speeds and note the effect of ac-

celeration and deceleration on noise level. Differen-

tial and exhaust noise will change in intensity as

speed varies, while tire noise will usually remain

constant.

TIRE WEAR PATTERNS

Under inflation results in faster wear on shoulders

of tire. Over inflation causes faster wear at center of tread.

Excessive camber causes the tire to run at an angle

to the road. One side of tread is worn more than the

other. Excessive toe-in or toe-out causes wear on the

tread edges of the tire, from dragging of tire. There

is a feathered effect across the tread (Fig. 4).

Fig. 3 Tread Wear Indicators

Ä WHEELSÐTIRES 22 - 3

Page 2154 of 2438

WHEELS SERVICE PROCEDURES INDEX

page page

General Information ........................ 6

Tire and Wheel Balance .................... 6

Tire and Wheel Run Out .................... 7 Wheel Installation

......................... 6

Wheel Replacement ....................... 6

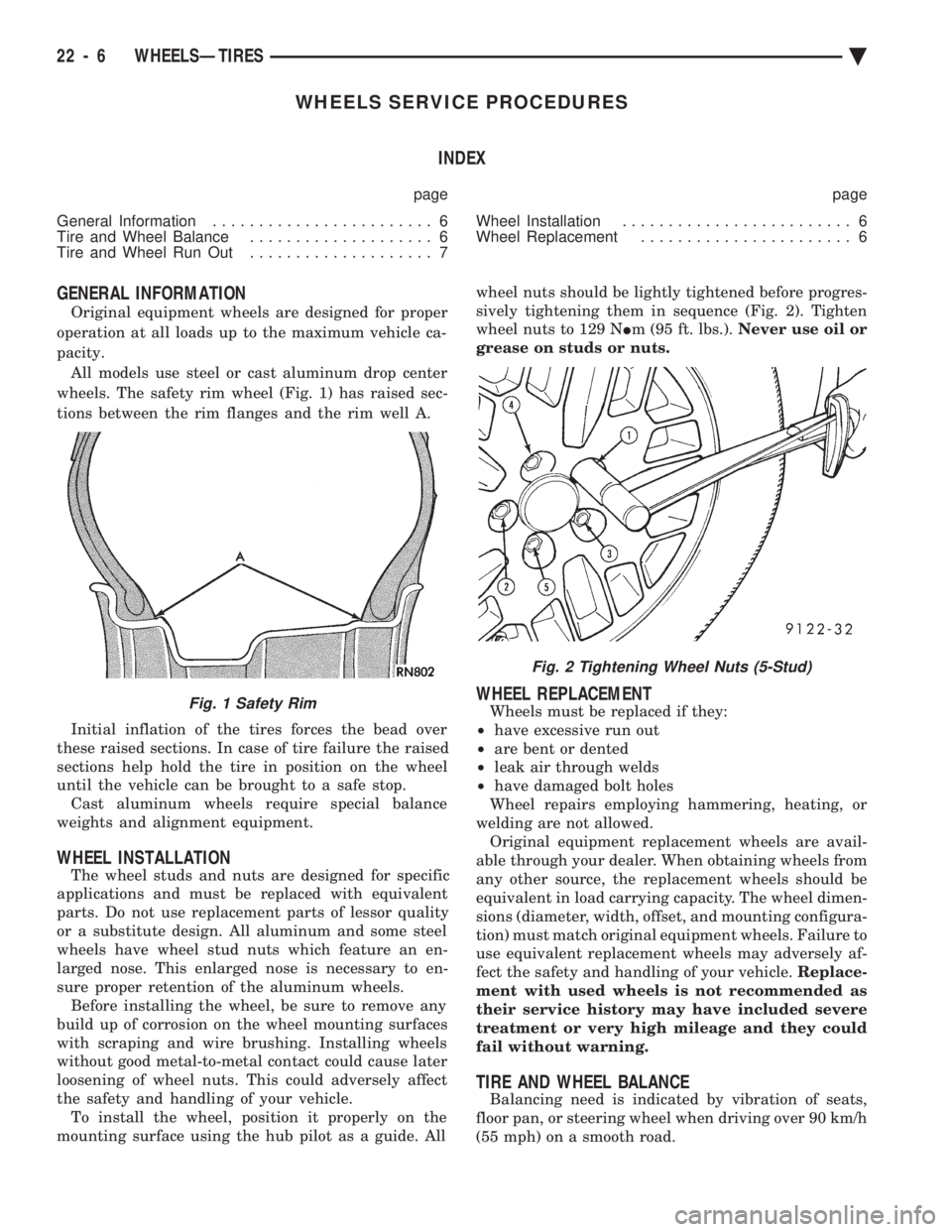

GENERAL INFORMATION

Original equipment wheels are designed for proper

operation at all loads up to the maximum vehicle ca-

pacity. All models use steel or cast aluminum drop center

wheels. The safety rim wheel (Fig. 1) has raised sec-

tions between the rim flanges and the rim well A.

Initial inflation of the tires forces the bead over

these raised sections. In case of tire failure the raised

sections help hold the tire in position on the wheel

until the vehicle can be brought to a safe stop. Cast aluminum wheels require special balance

weights and alignment equipment.

WHEEL INSTALLATION

The wheel studs and nuts are designed for specific

applications and must be replaced with equivalent

parts. Do not use replacement parts of lessor quality

or a substitute design. All aluminum and some steel

wheels have wheel stud nuts which feature an en-

larged nose. This enlarged nose is necessary to en-

sure proper retention of the aluminum wheels. Before installing the wheel, be sure to remove any

build up of corrosion on the wheel mounting surfaces

with scraping and wire brushing. Installing wheels

without good metal-to-metal contact could cause later

loosening of wheel nuts. This could adversely affect

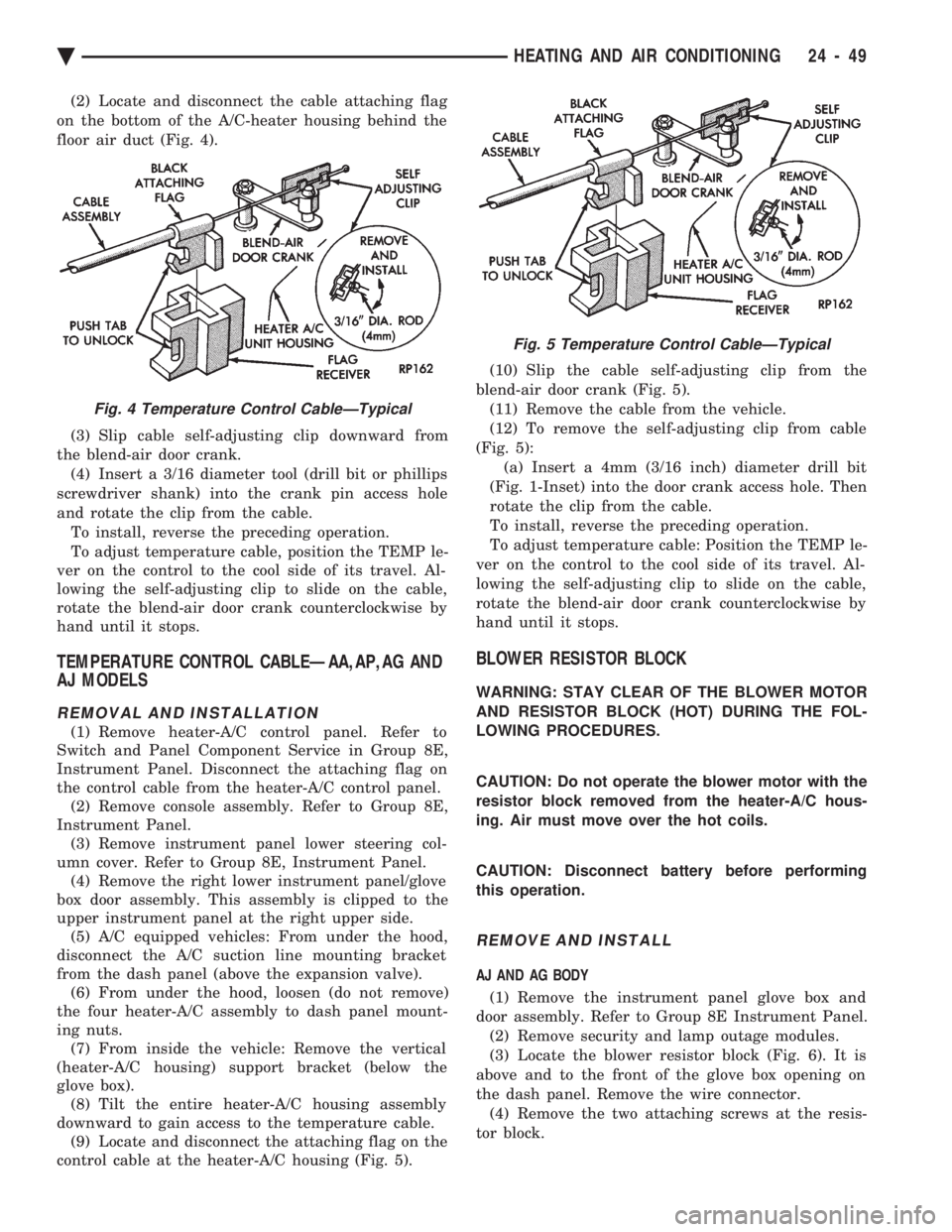

the safety and handling of your vehicle. To install the wheel, position it properly on the

mounting surface using the hub pilot as a guide. All wheel nuts should be lightly tightened before progres-

sively tightening them in sequence (Fig. 2). Tighten

wheel nuts to 129 N Im (95 ft. lbs.). Never use oil or

grease on studs or nuts.

WHEEL REPLACEMENT

Wheels must be replaced if they:

² have excessive run out

² are bent or dented

² leak air through welds

² have damaged bolt holes

Wheel repairs employing hammering, heating, or

welding are not allowed. Original equipment replacement wheels are avail-

able through your dealer. When obtaining wheels from

any other source, the replacement wheels should be

equivalent in load carrying capacity. The wheel dimen-

sions (diameter, width, offset, and mounting configura-

tion) must match original equipment wheels. Failure to

use equivalent replacement wheels may adversely af-

fect the safety and handling of your vehicle. Replace-

ment with used wheels is not recommended as

their service history may have included severe

treatment or very high mileage and they could

fail without warning.

TIRE AND WHEEL BALANCE

Balancing need is indicated by vibration of seats,

floor pan, or steering wheel when driving over 90 km/h

(55 mph) on a smooth road.

Fig. 1 Safety Rim

Fig. 2 Tightening Wheel Nuts (5-Stud)

22 - 6 WHEELSÐTIRES Ä

Page 2353 of 2438

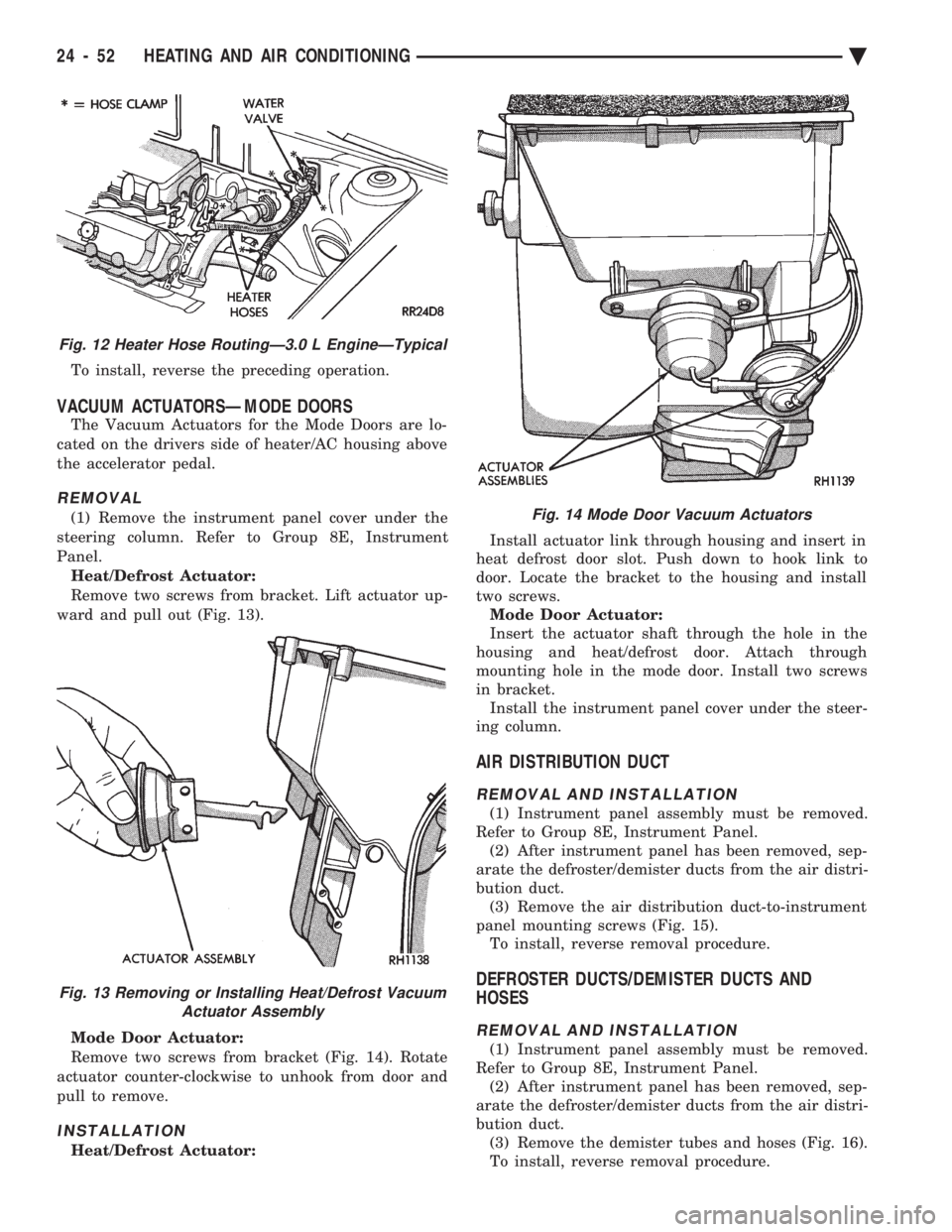

(2) Locate and disconnect the cable attaching flag

on the bottom of the A/C-heater housing behind the

floor air duct (Fig. 4).

(3) Slip cable self-adjusting clip downward from

the blend-air door crank. (4) Insert a 3/16 diameter tool (drill bit or phillips

screwdriver shank) into the crank pin access hole

and rotate the clip from the cable. To install, reverse the preceding operation.

To adjust temperature cable, position the TEMP le-

ver on the control to the cool side of its travel. Al-

lowing the self-adjusting clip to slide on the cable,

rotate the blend-air door crank counterclockwise by

hand until it stops.

TEMPERATURE CONTROL CABLEÐAA,AP,AG AND

AJ MODELS

REMOVAL AND INSTALLATION

(1) Remove heater-A/C control panel. Refer to

Switch and Panel Component Service in Group 8E,

Instrument Panel. Disconnect the attaching flag on

the control cable from the heater-A/C control panel. (2) Remove console assembly. Refer to Group 8E,

Instrument Panel. (3) Remove instrument panel lower steering col-

umn cover. Refer to Group 8E, Instrument Panel. (4) Remove the right lower instrument panel/glove

box door assembly. This assembly is clipped to the

upper instrument panel at the right upper side. (5) A/C equipped vehicles: From under the hood,

disconnect the A/C suction line mounting bracket

from the dash panel (above the expansion valve). (6) From under the hood, loosen (do not remove)

the four heater-A/C assembly to dash panel mount-

ing nuts. (7) From inside the vehicle: Remove the vertical

(heater-A/C housing) support bracket (below the

glove box). (8) Tilt the entire heater-A/C housing assembly

downward to gain access to the temperature cable. (9) Locate and disconnect the attaching flag on the

control cable at the heater-A/C housing (Fig. 5). (10) Slip the cable self-adjusting clip from the

blend-air door crank (Fig. 5). (11) Remove the cable from the vehicle.

(12) To remove the self-adjusting clip from cable

(Fig. 5): (a) Insert a 4mm (3/16 inch) diameter drill bit

(Fig. 1-Inset) into the door crank access hole. Then

rotate the clip from the cable.

To install, reverse the preceding operation.

To adjust temperature cable: Position the TEMP le-

ver on the control to the cool side of its travel. Al-

lowing the self-adjusting clip to slide on the cable,

rotate the blend-air door crank counterclockwise by

hand until it stops.

BLOWER RESISTOR BLOCK

WARNING: STAY CLEAR OF THE BLOWER MOTOR

AND RESISTOR BLOCK (HOT) DURING THE FOL-

LOWING PROCEDURES.

CAUTION: Do not operate the blower motor with the

resistor block removed from the heater-A/C hous-

ing. Air must move over the hot coils.

CAUTION: Disconnect battery before performing

this operation.

REMOVE AND INSTALL

AJ AND AG BODY

(1) Remove the instrument panel glove box and

door assembly. Refer to Group 8E Instrument Panel. (2) Remove security and lamp outage modules.

(3) Locate the blower resistor block (Fig. 6). It is

above and to the front of the glove box opening on

the dash panel. Remove the wire connector. (4) Remove the two attaching screws at the resis-

tor block.

Fig. 4 Temperature Control CableÐTypical

Fig. 5 Temperature Control CableÐTypical

Ä HEATING AND AIR CONDITIONING 24 - 49

Page 2356 of 2438

To install, reverse the preceding operation.

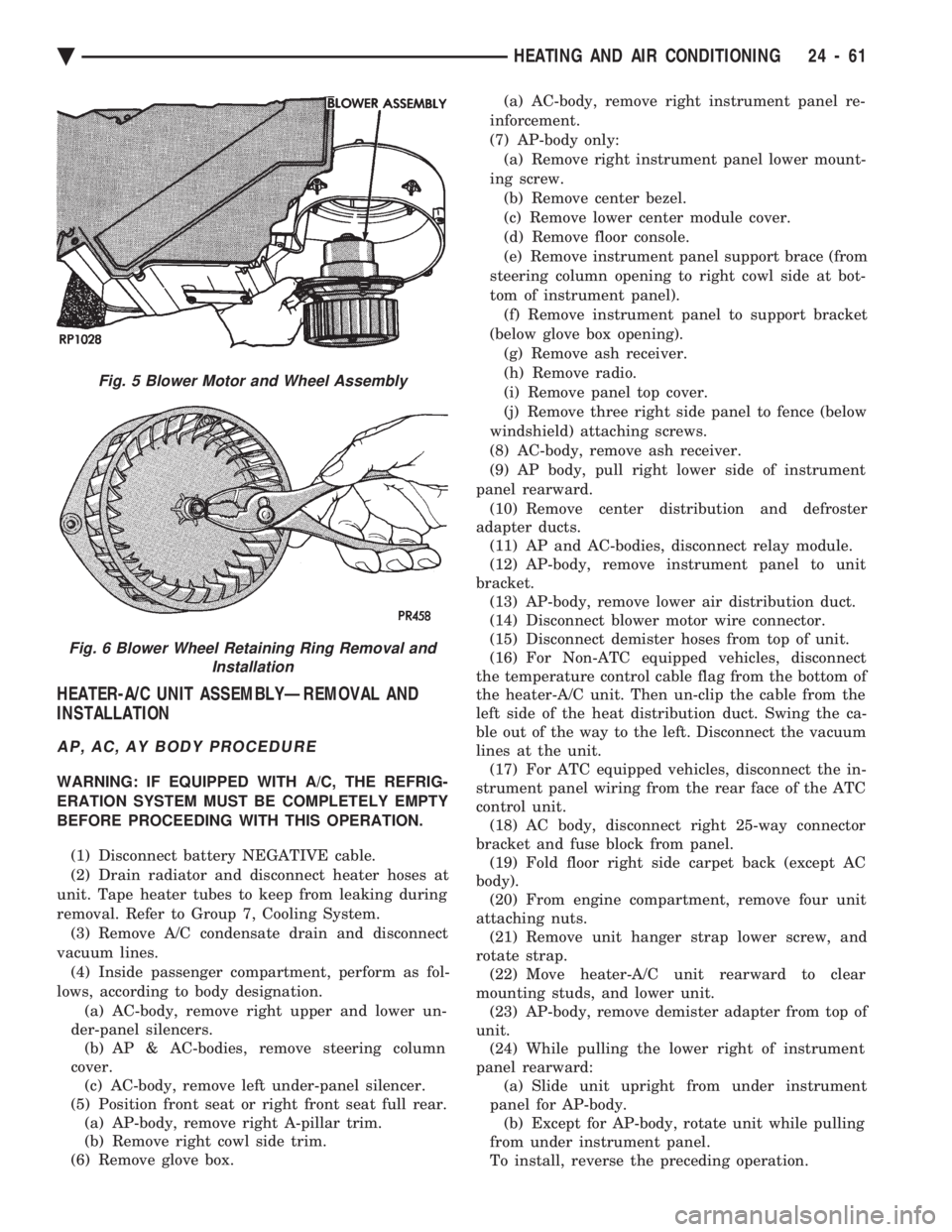

VACUUM ACTUATORSÐMODE DOORS

The Vacuum Actuators for the Mode Doors are lo-

cated on the drivers side of heater/AC housing above

the accelerator pedal.

REMOVAL

(1) Remove the instrument panel cover under the

steering column. Refer to Group 8E, Instrument

Panel. Heat/Defrost Actuator:

Remove two screws from bracket. Lift actuator up-

ward and pull out (Fig. 13).

Mode Door Actuator:

Remove two screws from bracket (Fig. 14). Rotate

actuator counter-clockwise to unhook from door and

pull to remove.

INSTALLATION

Heat/Defrost Actuator: Install actuator link through housing and insert in

heat defrost door slot. Push down to hook link to

door. Locate the bracket to the housing and install

two screws. Mode Door Actuator:

Insert the actuator shaft through the hole in the

housing and heat/defrost door. Attach through

mounting hole in the mode door. Install two screws

in bracket. Install the instrument panel cover under the steer-

ing column.

AIR DISTRIBUTION DUCT

REMOVAL AND INSTALLATION

(1) Instrument panel assembly must be removed.

Refer to Group 8E, Instrument Panel. (2) After instrument panel has been removed, sep-

arate the defroster/demister ducts from the air distri-

bution duct. (3) Remove the air distribution duct-to-instrument

panel mounting screws (Fig. 15). To install, reverse removal procedure.

DEFROSTER DUCTS/DEMISTER DUCTS AND

HOSES

REMOVAL AND INSTALLATION

(1) Instrument panel assembly must be removed.

Refer to Group 8E, Instrument Panel. (2) After instrument panel has been removed, sep-

arate the defroster/demister ducts from the air distri-

bution duct. (3) Remove the demister tubes and hoses (Fig. 16).

To install, reverse removal procedure.

Fig. 12 Heater Hose RoutingÐ3.0 L EngineÐTypical

Fig. 13 Removing or Installing Heat/Defrost Vacuum Actuator Assembly

Fig. 14 Mode Door Vacuum Actuators

24 - 52 HEATING AND AIR CONDITIONING Ä

Page 2365 of 2438

HEATER-A/C UNIT ASSEMBLYÐREMOVAL AND

INSTALLATION

AP, AC, AY BODY PROCEDURE

WARNING: IF EQUIPPED WITH A/C, THE REFRIG-

ERATION SYSTEM MUST BE COMPLETELY EMPTY

BEFORE PROCEEDING WITH THIS OPERATION.

(1) Disconnect battery NEGATIVE cable.

(2) Drain radiator and disconnect heater hoses at

unit. Tape heater tubes to keep from leaking during

removal. Refer to Group 7, Cooling System. (3) Remove A/C condensate drain and disconnect

vacuum lines. (4) Inside passenger compartment, perform as fol-

lows, according to body designation. (a) AC-body, remove right upper and lower un-

der-panel silencers. (b) AP & AC-bodies, remove steering column

cover. (c) AC-body, remove left under-panel silencer.

(5) Position front seat or right front seat full rear. (a) AP-body, remove right A-pillar trim.

(b) Remove right cowl side trim.

(6) Remove glove box. (a) AC-body, remove right instrument panel re-

inforcement.

(7) AP-body only: (a) Remove right instrument panel lower mount-

ing screw. (b) Remove center bezel.

(c) Remove lower center module cover.

(d) Remove floor console.

(e) Remove instrument panel support brace (from

steering column opening to right cowl side at bot-

tom of instrument panel). (f) Remove instrument panel to support bracket

(below glove box opening). (g) Remove ash receiver.

(h) Remove radio.

(i) Remove panel top cover.

(j) Remove three right side panel to fence (below

windshield) attaching screws.

(8) AC-body, remove ash receiver.

(9) AP body, pull right lower side of instrument

panel rearward. (10) Remove center distribution and defroster

adapter ducts. (11) AP and AC-bodies, disconnect relay module.

(12) AP-body, remove instrument panel to unit

bracket. (13) AP-body, remove lower air distribution duct.

(14) Disconnect blower motor wire connector.

(15) Disconnect demister hoses from top of unit.

(16) For Non-ATC equipped vehicles, disconnect

the temperature control cable flag from the bottom of

the heater-A/C unit. Then un-clip the cable from the

left side of the heat distribution duct. Swing the ca-

ble out of the way to the left. Disconnect the vacuum

lines at the unit. (17) For ATC equipped vehicles, disconnect the in-

strument panel wiring from the rear face of the ATC

control unit. (18) AC body, disconnect right 25-way connector

bracket and fuse block from panel. (19) Fold floor right side carpet back (except AC

body). (20) From engine compartment, remove four unit

attaching nuts. (21) Remove unit hanger strap lower screw, and

rotate strap. (22) Move heater-A/C unit rearward to clear

mounting studs, and lower unit. (23) AP-body, remove demister adapter from top of

unit. (24) While pulling the lower right of instrument

panel rearward: (a) Slide unit upright from under instrument

panel for AP-body. (b) Except for AP-body, rotate unit while pulling

from under instrument panel.

To install, reverse the preceding operation.

Fig. 5 Blower Motor and Wheel Assembly

Fig. 6 Blower Wheel Retaining Ring Removal and Installation

Ä HEATING AND AIR CONDITIONING 24 - 61

Page 2366 of 2438

AA BODY PROCEDURE

WARNING: IF EQUIPPED WITH A/C, THE REFRIG-

ERATION SYSTEM MUST BE COMPLETELY EMPTY

BEFORE PROCEEDING WITH THIS OPERATION. Refer to Group 8E and Group 23 for component re-

moval and installation when performing this opera-

tion. (1) Perform steps 1 through 7 of Blower Motor re-

moval and installation. (2) Remove relay panel above glove compartment

opening. (3) Disconnect the A/C vacuum line connector and

radio noise capacitor connectors. (4) Remove left windshield pillar trim cover.

(5) Remove left lower side cowl trim cover.

(6) Remove hood release handle mechanism attach-

ing screws. (7) Remove steering column trim covers.

(8) Disconnect parking brake release mechanism

connecting rod. Gain access through fuse panel open-

ing. (9) Remove lower left instrument panel silencer.

(10) Remove lower left instrument panel reinforce-

ment. (11) Remove instrument panel center (radio) bezel.

(12) Remove forward floor console.

(13) Remove the radio.

(14) Remove the heater-A/C control.

(15) Remove cigar lighter.

(16) Remove message center/trip computer, if

equipped. (17) Disconnect side window demister tubes from

top of heat A/C unit. (18) Remove steering column upper attaching bolts

and allow the steering wheel to rest on the driver

seat cushion. (19) Remove upper instrument panel (defroster

outlet) cover. (20) Remove upper instrument panel attaching

screws from below the windshield opening. (21) Loosen (do not remove) the left lower cowl in-

strument panel attaching screw. (22) Remove the right lower cowl instrument panel

attaching screw.

CAUTION: Protect the passenger seat cover from

soiling or damage using a suitable cover.

(23) Carefully pull the right side of the instrument

panel away from the vehicle. Allow the instrument

panel to rest on the passenger seat cushion.

CAUTION: Before proceeding with the next opera-

tion, review the Safety Precautions and Warnings at

the front of this Group. (24) From the engine compartment, drain the cool-

ing system and disconnect the heater hoses from the

heater core nipples. Plug the nipples to avoid spilling

coolant inside the vehicle. (25) Disconnect the refrigerant lines from the ex-

pansion-valve at the dash panel on the right side of

the vehicle. Seal the refrigerant lines to prevent con-

tamination. (26) Remove the expansion valve from the evapo-

rator plate. Seal the valve to avoid contamination. (27) Remove the condensate drain tube.

(28) Remove heater-A/C unit to dash panel attach-

ing nuts. (29) From inside the vehicle, pull rearward on the

heater-A/C unit to clear the dash panel silencer and

remove the unit from the vehicle. To install, reverse the preceding operation. Refill

cooling system and test for leaks. Evacuate and

charge the refrigerant system and test overall perfor-

mance.

AG, AJ BODY PROCEDURE

WARNING: IF EQUIPPED WITH A/C, THE REFRIG-

ERATION SYSTEM MUST BE COMPLETELY EMPTY

BEFORE PROCEEDING WITH THIS OPERATION.

(1) Disconnect the battery negative cable.

(2) Drain the coolant from cooling system. Refer to

Group 7, Cooling System. (3) Remove the air conditioner expansion valve (if

equipped). (4) Disconnect the heater hoses from heater core.

Then plug or cap the tubes on heater core. This will

prevent spilling coolant into the interior of vehicle

during unit removal. (5) Remove the condensate drain tube.

(6) Disconnect the A/C-heater vacuum supply line

from vacuum supply nipple (in the engine compart-

ment). (7) Remove the four A/C-heater assembly-to-dash

panel attaching nuts. (8) Remove the passenger side front seat. Refer to

Group 23, Body. (9) Remove the kick panel/sill cover at right door

opening. (10) Remove the body computer (Fig. 6) located at

the lower right section of the right front door pillar. (11) Remove the glove box assembly. Refer to

Group 8E, Instrument Panel. (12) Remove the carpeted panels from both sides of

the console. (13) Un-clip the radio antenna cable from the

metal support (Fig. 6) located behind and below the

glove box opening. (14) Instrument panel removal is not necessary to

remove the A/C-heater assembly from the vehicle.

24 - 62 HEATING AND AIR CONDITIONING Ä

Page 2367 of 2438

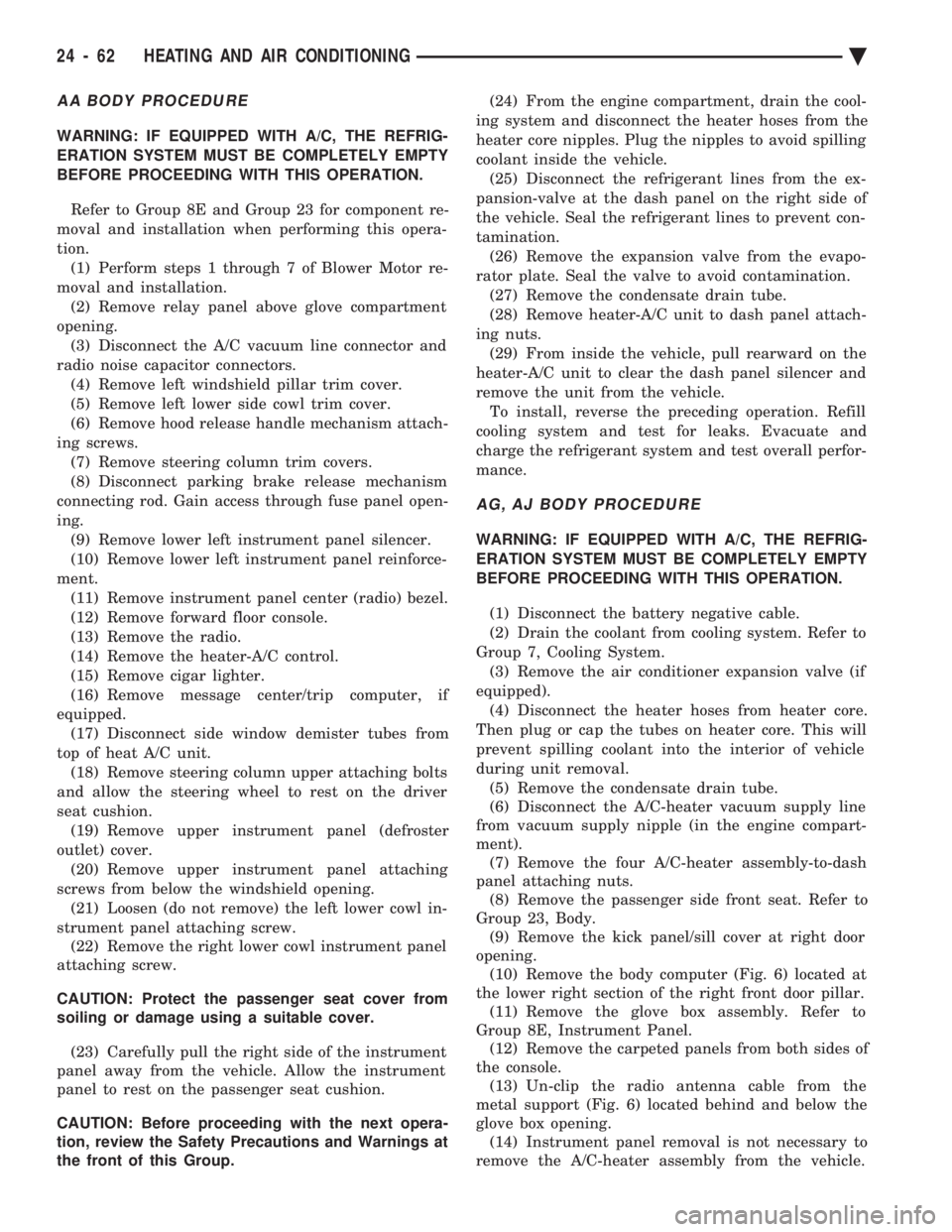

Although, part of the lower instrument panel must

be cut. The cut line is marked: CUT HERE FOR

A/C HTR REMOVAL. This cut line is stamped (indented) into the right-

outer side of the instrument panel padding (outboard

of the glove box opening). Using a hacksaw blade,

cut the instrument panel padding along the indented

line from point A to point B (Fig. 7). CUT THE

PLASTIC ONLY . Do not cut the metal support be-

hind the instrument panel padding.

(15) Remove the metal support behind and below

the glove box opening, and the previously cut piece of

the instrument panel that is riveted to it. (16) Remove the radio choke, security alarm mod-

ule and the lamp outage module from above the

glove box opening (if equipped). (17) Remove the plastic cover under the steering

column. (18) Remove the metal support under the steering

column. (19) AJ Body only: Remove the under-panel si-

lencer pad from under the glove box opening. (20) Remove the lower heat distribution duct (3

screws). (21) Remove the air distribution duct through the

opening at the left side of instrument panel. (22) Reach through glove box opening and discon-

nect the demister hoses from the top of the A/C-heat-

er assembly. (23) Disconnect the temperature control cable from

the bottom of the A/C-heater assembly and position

out of the way. (24) Disconnect wiring at the blower motor and

fin-sensing cycling clutch switch electrical connectors. (25) Un-plug the antenna cable from the radio.

(26) Remove the metal (A/C-heater-to-instrument

panel) hanger strap from the upper part of the A/C-

heater assembly. (27) Roll back the floor carpeting from under the

A/C-heater assembly far enough to avoid restricting

unit removal. (28) Remove the A/C-heater assembly through the

opening on the right side of the console, and remove

unit from vehicle. The instrument panel (to the left side of the glove box

opening) must be slightly folded back to remove the

unit from the vehicle. If wrinkles appear in the instru-

ment panel after the unit has been installed, they may

be removed using a heat gun. Refer to Installation AG,

AJ Body for instructions. To install, reverse steps (28) through (13). If wrinkles

have appeared in the instrument panel, apply low heat

from a heat gun over the wrinkled area. Do not

overheat the instrument panel padding or the

surrounding area. Reverse steps (12) through (1). If equipped with A/C,

evacuate and charge the refrigerant system.

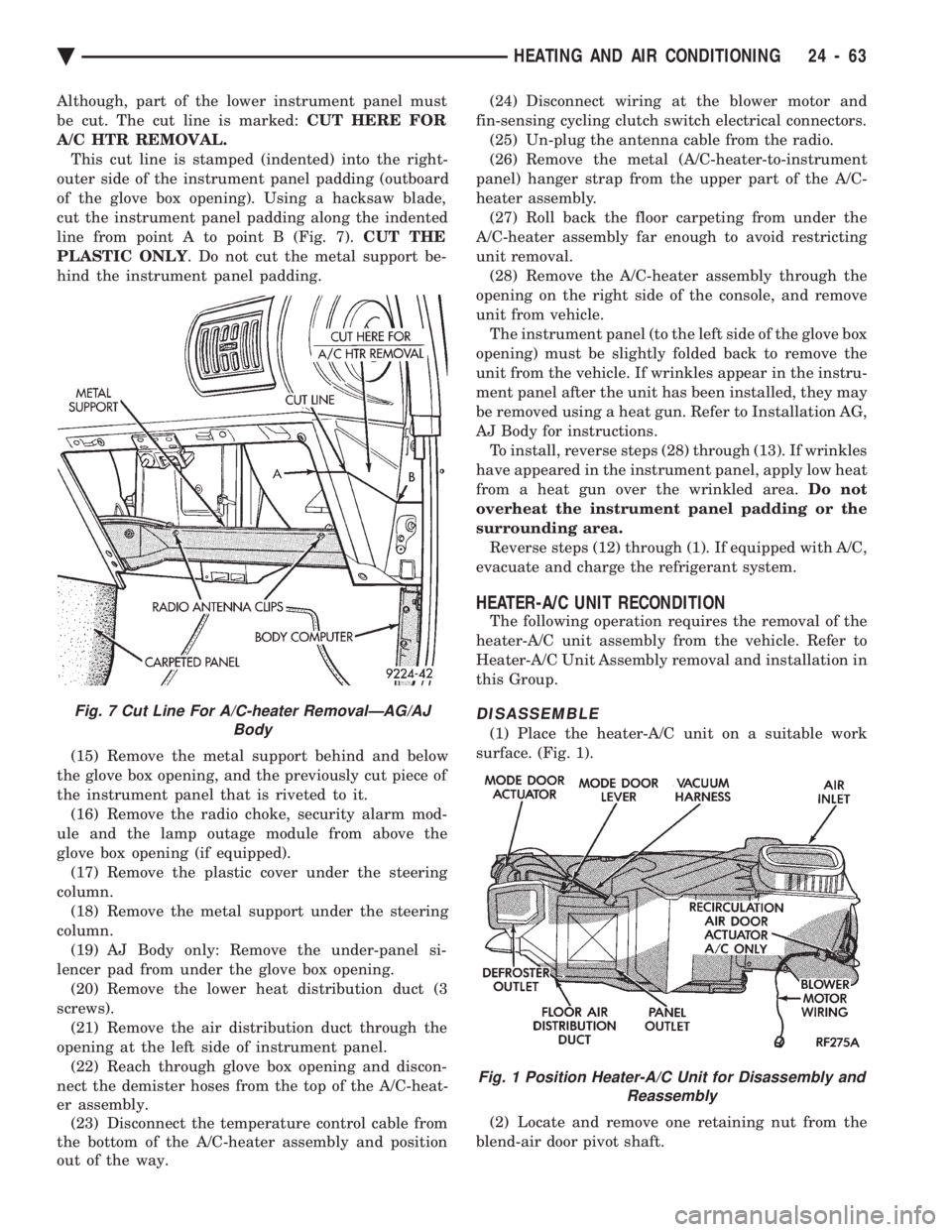

HEATER-A/C UNIT RECONDITION

The following operation requires the removal of the

heater-A/C unit assembly from the vehicle. Refer to

Heater-A/C Unit Assembly removal and installation in

this Group.

DISASSEMBLE

(1) Place the heater-A/C unit on a suitable work

surface. (Fig. 1).

(2) Locate and remove one retaining nut from the

blend-air door pivot shaft.

Fig. 7 Cut Line For A/C-heater RemovalÐAG/AJ Body

Fig. 1 Position Heater-A/C Unit for Disassembly andReassembly

Ä HEATING AND AIR CONDITIONING 24 - 63