buttons CHEVROLET DYNASTY 1993 User Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 433 of 2438

(4) Drive the vehicle 1 to 3 complete circles. The

CAL light will then go off, showing the compass is

calibrated. If the compass portion of the display:

² It does not display.

² Readings are not accurate after calibration.

² The vehicle may have too much magnetism for the

compass to be accurate.

² The compass circuitry is not working properly.

² Refer to Variance Procedure, Demagnetizing Pro-

cedure and/or Compass Diagnostics.

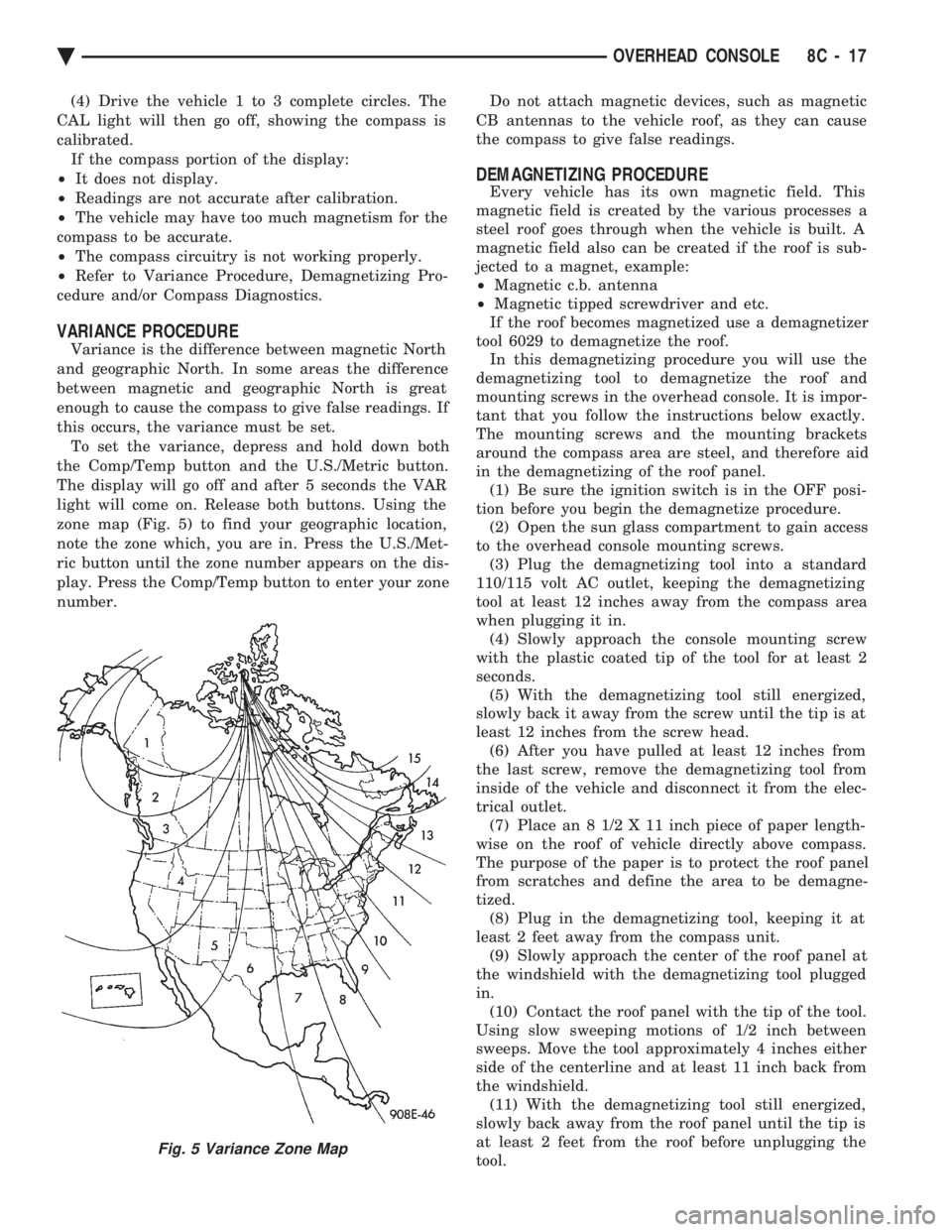

VARIANCE PROCEDURE

Variance is the difference between magnetic North

and geographic North. In some areas the difference

between magnetic and geographic North is great

enough to cause the compass to give false readings. If

this occurs, the variance must be set. To set the variance, depress and hold down both

the Comp/Temp button and the U.S./Metric button.

The display will go off and after 5 seconds the VAR

light will come on. Release both buttons. Using the

zone map (Fig. 5) to find your geographic location,

note the zone which, you are in. Press the U.S./Met-

ric button until the zone number appears on the dis-

play. Press the Comp/Temp button to enter your zone

number. Do not attach magnetic devices, such as magnetic

CB antennas to the vehicle roof, as they can cause

the compass to give false readings.

DEMAGNETIZING PROCEDURE

Every vehicle has its own magnetic field. This

magnetic field is created by the various processes a

steel roof goes through when the vehicle is built. A

magnetic field also can be created if the roof is sub-

jected to a magnet, example:

² Magnetic c.b. antenna

² Magnetic tipped screwdriver and etc.

If the roof becomes magnetized use a demagnetizer

tool 6029 to demagnetize the roof. In this demagnetizing procedure you will use the

demagnetizing tool to demagnetize the roof and

mounting screws in the overhead console. It is impor-

tant that you follow the instructions below exactly.

The mounting screws and the mounting brackets

around the compass area are steel, and therefore aid

in the demagnetizing of the roof panel. (1) Be sure the ignition switch is in the OFF posi-

tion before you begin the demagnetize procedure. (2) Open the sun glass compartment to gain access

to the overhead console mounting screws. (3) Plug the demagnetizing tool into a standard

110/115 volt AC outlet, keeping the demagnetizing

tool at least 12 inches away from the compass area

when plugging it in. (4) Slowly approach the console mounting screw

with the plastic coated tip of the tool for at least 2

seconds. (5) With the demagnetizing tool still energized,

slowly back it away from the screw until the tip is at

least 12 inches from the screw head. (6) After you have pulled at least 12 inches from

the last screw, remove the demagnetizing tool from

inside of the vehicle and disconnect it from the elec-

trical outlet. (7) Place an 8 1/2 X 11 inch piece of paper length-

wise on the roof of vehicle directly above compass.

The purpose of the paper is to protect the roof panel

from scratches and define the area to be demagne-

tized. (8) Plug in the demagnetizing tool, keeping it at

least 2 feet away from the compass unit. (9) Slowly approach the center of the roof panel at

the windshield with the demagnetizing tool plugged

in. (10) Contact the roof panel with the tip of the tool.

Using slow sweeping motions of 1/2 inch between

sweeps. Move the tool approximately 4 inches either

side of the centerline and at least 11 inch back from

the windshield. (11) With the demagnetizing tool still energized,

slowly back away from the roof panel until the tip is

at least 2 feet from the roof before unplugging the

tool.

Fig. 5 Variance Zone Map

Ä OVERHEAD CONSOLE 8C - 17

Page 437 of 2438

AP BODY INDEX

page page

Ambient Temperature Sensor Removal ........ 25

Compass Calibration ...................... 21

Compass Diagnostics ..................... 23

Compass Module Replacement .............. 25

Demagnetizing Procedure .................. 22 Map Reading Lamps Operation

.............. 21

Overhead Console Replacement ............. 25

Thermometer and Compass ................ 21

Variance Procedure ....................... 22

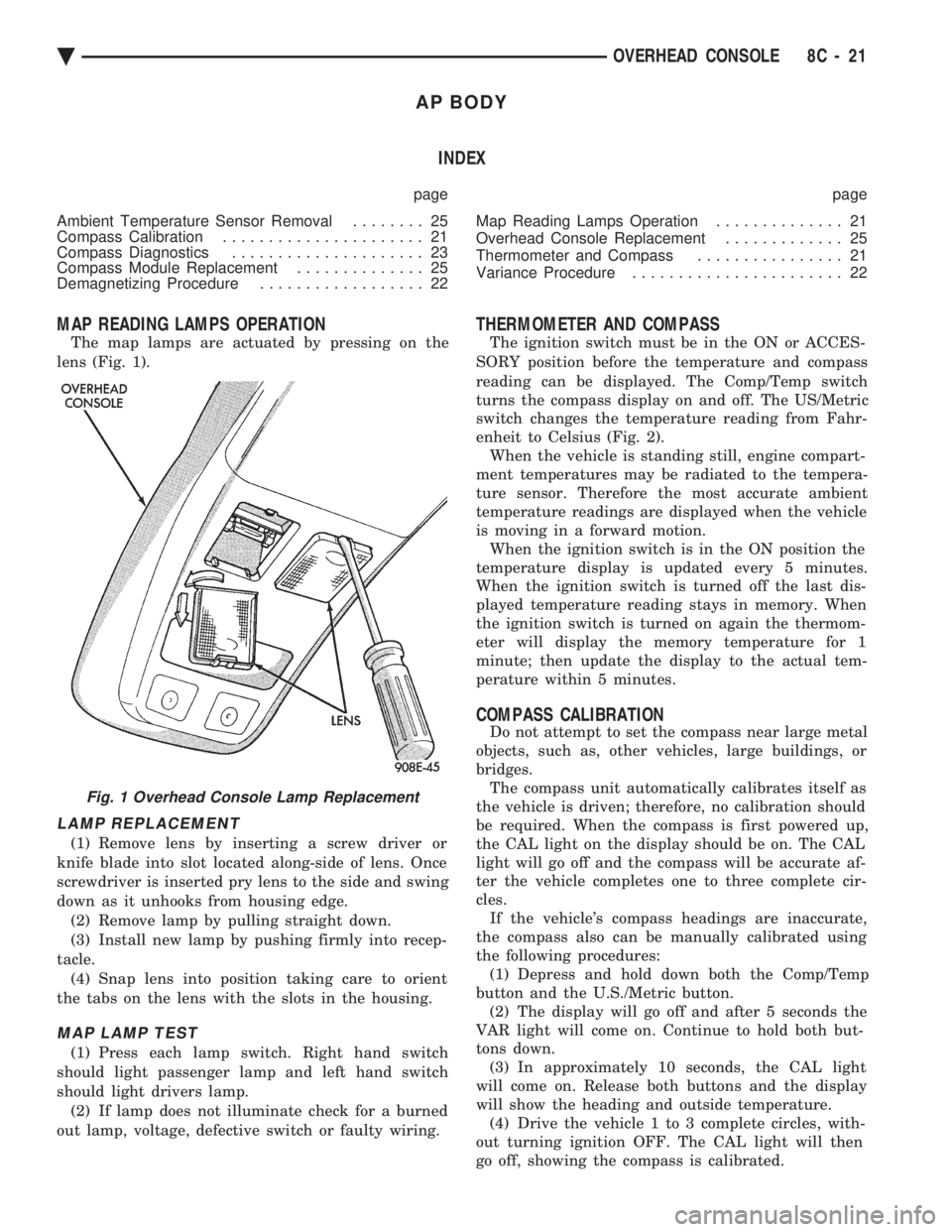

MAP READING LAMPS OPERATION

The map lamps are actuated by pressing on the

lens (Fig. 1).

LAMP REPLACEMENT

(1) Remove lens by inserting a screw driver or

knife blade into slot located along-side of lens. Once

screwdriver is inserted pry lens to the side and swing

down as it unhooks from housing edge. (2) Remove lamp by pulling straight down.

(3) Install new lamp by pushing firmly into recep-

tacle. (4) Snap lens into position taking care to orient

the tabs on the lens with the slots in the housing.

MAP LAMP TEST

(1) Press each lamp switch. Right hand switch

should light passenger lamp and left hand switch

should light drivers lamp. (2) If lamp does not illuminate check for a burned

out lamp, voltage, defective switch or faulty wiring.

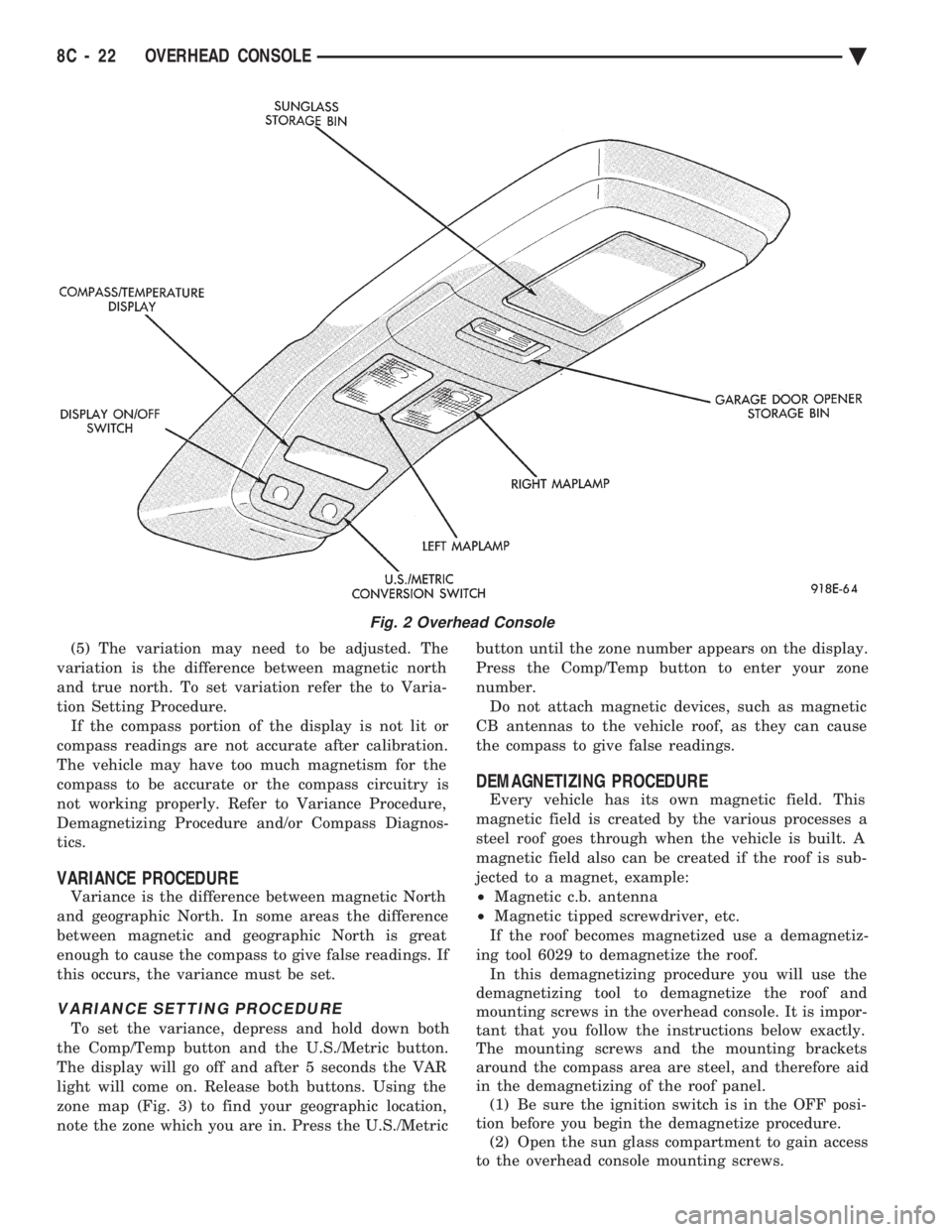

THERMOMETER AND COMPASS

The ignition switch must be in the ON or ACCES-

SORY position before the temperature and compass

reading can be displayed. The Comp/Temp switch

turns the compass display on and off. The US/Metric

switch changes the temperature reading from Fahr-

enheit to Celsius (Fig. 2). When the vehicle is standing still, engine compart-

ment temperatures may be radiated to the tempera-

ture sensor. Therefore the most accurate ambient

temperature readings are displayed when the vehicle

is moving in a forward motion. When the ignition switch is in the ON position the

temperature display is updated every 5 minutes.

When the ignition switch is turned off the last dis-

played temperature reading stays in memory. When

the ignition switch is turned on again the thermom-

eter will display the memory temperature for 1

minute; then update the display to the actual tem-

perature within 5 minutes.

COMPASS CALIBRATION

Do not attempt to set the compass near large metal

objects, such as, other vehicles, large buildings, or

bridges. The compass unit automatically calibrates itself as

the vehicle is driven; therefore, no calibration should

be required. When the compass is first powered up,

the CAL light on the display should be on. The CAL

light will go off and the compass will be accurate af-

ter the vehicle completes one to three complete cir-

cles. If the vehicle's compass headings are inaccurate,

the compass also can be manually calibrated using

the following procedures: (1) Depress and hold down both the Comp/Temp

button and the U.S./Metric button. (2) The display will go off and after 5 seconds the

VAR light will come on. Continue to hold both but-

tons down. (3) In approximately 10 seconds, the CAL light

will come on. Release both buttons and the display

will show the heading and outside temperature. (4) Drive the vehicle 1 to 3 complete circles, with-

out turning ignition OFF. The CAL light will then

go off, showing the compass is calibrated.

Fig. 1 Overhead Console Lamp Replacement

Ä OVERHEAD CONSOLE 8C - 21

Page 438 of 2438

(5) The variation may need to be adjusted. The

variation is the difference between magnetic north

and true north. To set variation refer the to Varia-

tion Setting Procedure. If the compass portion of the display is not lit or

compass readings are not accurate after calibration.

The vehicle may have too much magnetism for the

compass to be accurate or the compass circuitry is

not working properly. Refer to Variance Procedure,

Demagnetizing Procedure and/or Compass Diagnos-

tics.

VARIANCE PROCEDURE

Variance is the difference between magnetic North

and geographic North. In some areas the difference

between magnetic and geographic North is great

enough to cause the compass to give false readings. If

this occurs, the variance must be set.

VARIANCE SETTING PROCEDURE

To set the variance, depress and hold down both

the Comp/Temp button and the U.S./Metric button.

The display will go off and after 5 seconds the VAR

light will come on. Release both buttons. Using the

zone map (Fig. 3) to find your geographic location,

note the zone which you are in. Press the U.S./Metric button until the zone number appears on the display.

Press the Comp/Temp button to enter your zone

number. Do not attach magnetic devices, such as magnetic

CB antennas to the vehicle roof, as they can cause

the compass to give false readings.

DEMAGNETIZING PROCEDURE

Every vehicle has its own magnetic field. This

magnetic field is created by the various processes a

steel roof goes through when the vehicle is built. A

magnetic field also can be created if the roof is sub-

jected to a magnet, example:

² Magnetic c.b. antenna

² Magnetic tipped screwdriver, etc.

If the roof becomes magnetized use a demagnetiz-

ing tool 6029 to demagnetize the roof. In this demagnetizing procedure you will use the

demagnetizing tool to demagnetize the roof and

mounting screws in the overhead console. It is impor-

tant that you follow the instructions below exactly.

The mounting screws and the mounting brackets

around the compass area are steel, and therefore aid

in the demagnetizing of the roof panel. (1) Be sure the ignition switch is in the OFF posi-

tion before you begin the demagnetize procedure. (2) Open the sun glass compartment to gain access

to the overhead console mounting screws.

Fig. 2 Overhead Console

8C - 22 OVERHEAD CONSOLE Ä

Page 513 of 2438

(3) Remove four screws from ash receiver/cup

holder housing. (4) For installation reverse above procedures.

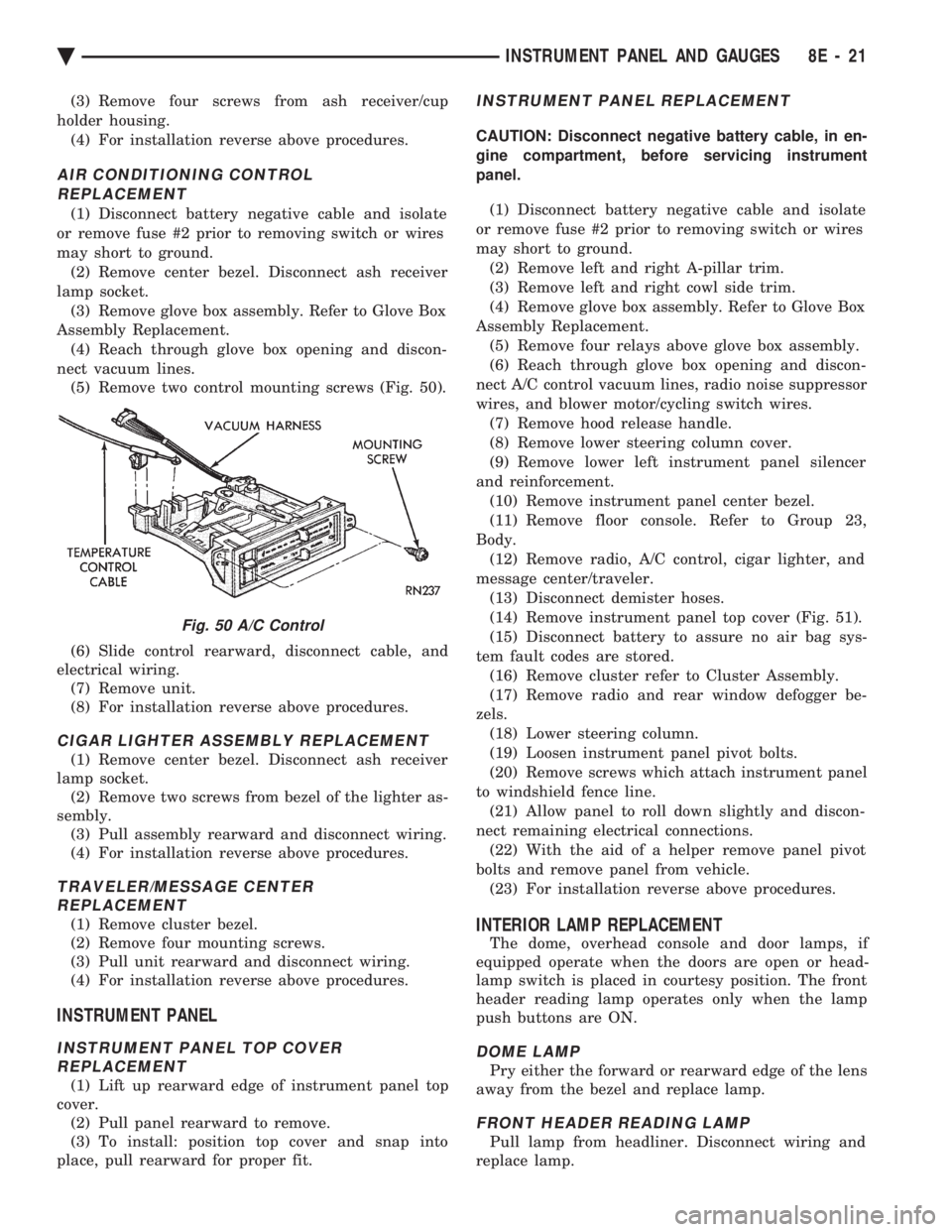

AIR CONDITIONING CONTROLREPLACEMENT

(1) Disconnect battery negative cable and isolate

or remove fuse #2 prior to removing switch or wires

may short to ground. (2) Remove center bezel. Disconnect ash receiver

lamp socket. (3) Remove glove box assembly. Refer to Glove Box

Assembly Replacement. (4) Reach through glove box opening and discon-

nect vacuum lines. (5) Remove two control mounting screws (Fig. 50).

(6) Slide control rearward, disconnect cable, and

electrical wiring. (7) Remove unit.

(8) For installation reverse above procedures.

CIGAR LIGHTER ASSEMBLY REPLACEMENT

(1) Remove center bezel. Disconnect ash receiver

lamp socket. (2) Remove two screws from bezel of the lighter as-

sembly. (3) Pull assembly rearward and disconnect wiring.

(4) For installation reverse above procedures.

TRAVELER/MESSAGE CENTER REPLACEMENT

(1) Remove cluster bezel.

(2) Remove four mounting screws.

(3) Pull unit rearward and disconnect wiring.

(4) For installation reverse above procedures.

INSTRUMENT PANEL

INSTRUMENT PANEL TOP COVER REPLACEMENT

(1) Lift up rearward edge of instrument panel top

cover. (2) Pull panel rearward to remove.

(3) To install: position top cover and snap into

place, pull rearward for proper fit.

INSTRUMENT PANEL REPLACEMENT

CAUTION: Disconnect negative battery cable, in en-

gine compartment, before servicing instrument

panel.

(1) Disconnect battery negative cable and isolate

or remove fuse #2 prior to removing switch or wires

may short to ground. (2) Remove left and right A-pillar trim.

(3) Remove left and right cowl side trim.

(4) Remove glove box assembly. Refer to Glove Box

Assembly Replacement. (5) Remove four relays above glove box assembly.

(6) Reach through glove box opening and discon-

nect A/C control vacuum lines, radio noise suppressor

wires, and blower motor/cycling switch wires. (7) Remove hood release handle.

(8) Remove lower steering column cover.

(9) Remove lower left instrument panel silencer

and reinforcement. (10) Remove instrument panel center bezel.

(11) Remove floor console. Refer to Group 23,

Body. (12) Remove radio, A/C control, cigar lighter, and

message center/traveler. (13) Disconnect demister hoses.

(14) Remove instrument panel top cover (Fig. 51).

(15) Disconnect battery to assure no air bag sys-

tem fault codes are stored. (16) Remove cluster refer to Cluster Assembly.

(17) Remove radio and rear window defogger be-

zels. (18) Lower steering column.

(19) Loosen instrument panel pivot bolts.

(20) Remove screws which attach instrument panel

to windshield fence line. (21) Allow panel to roll down slightly and discon-

nect remaining electrical connections. (22) With the aid of a helper remove panel pivot

bolts and remove panel from vehicle. (23) For installation reverse above procedures.

INTERIOR LAMP REPLACEMENT

The dome, overhead console and door lamps, if

equipped operate when the doors are open or head-

lamp switch is placed in courtesy position. The front

header reading lamp operates only when the lamp

push buttons are ON.

DOME LAMP

Pry either the forward or rearward edge of the lens

away from the bezel and replace lamp.

FRONT HEADER READING LAMP

Pull lamp from headliner. Disconnect wiring and

replace lamp.

Fig. 50 A/C Control

Ä INSTRUMENT PANEL AND GAUGES 8E - 21

Page 529 of 2438

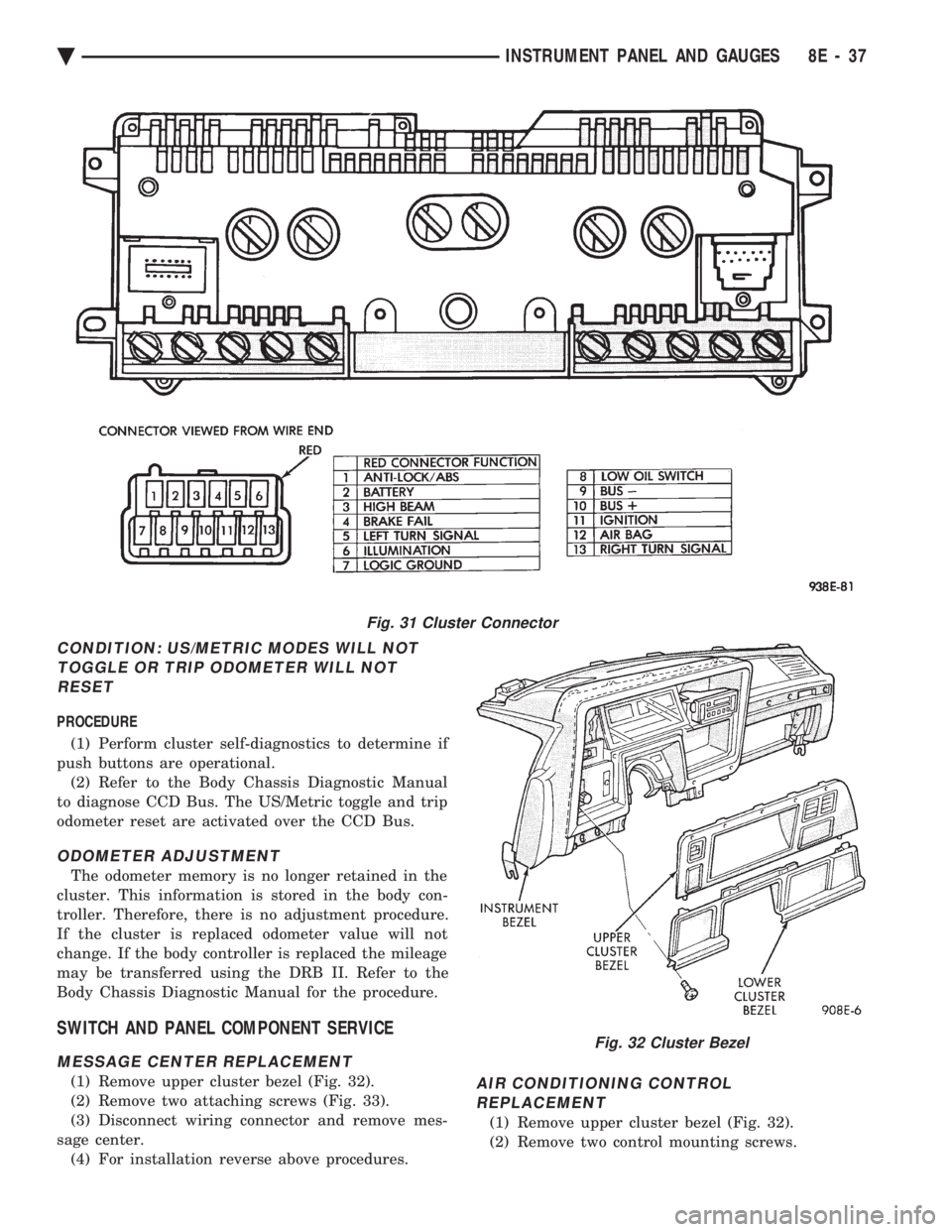

CONDITION: US/METRIC MODES WILL NOT TOGGLE OR TRIP ODOMETER WILL NOTRESET

PROCEDURE

(1) Perform cluster self-diagnostics to determine if

push buttons are operational. (2) Refer to the Body Chassis Diagnostic Manual

to diagnose CCD Bus. The US/Metric toggle and trip

odometer reset are activated over the CCD Bus.

ODOMETER ADJUSTMENT

The odometer memory is no longer retained in the

cluster. This information is stored in the body con-

troller. Therefore, there is no adjustment procedure.

If the cluster is replaced odometer value will not

change. If the body controller is replaced the mileage

may be transferred using the DRB II. Refer to the

Body Chassis Diagnostic Manual for the procedure.

SWITCH AND PANEL COMPONENT SERVICE

MESSAGE CENTER REPLACEMENT

(1) Remove upper cluster bezel (Fig. 32).

(2) Remove two attaching screws (Fig. 33).

(3) Disconnect wiring connector and remove mes-

sage center. (4) For installation reverse above procedures.AIR CONDITIONING CONTROLREPLACEMENT

(1) Remove upper cluster bezel (Fig. 32).

(2) Remove two control mounting screws.

Fig. 31 Cluster Connector

Fig. 32 Cluster Bezel

Ä INSTRUMENT PANEL AND GAUGES 8E - 37

Page 543 of 2438

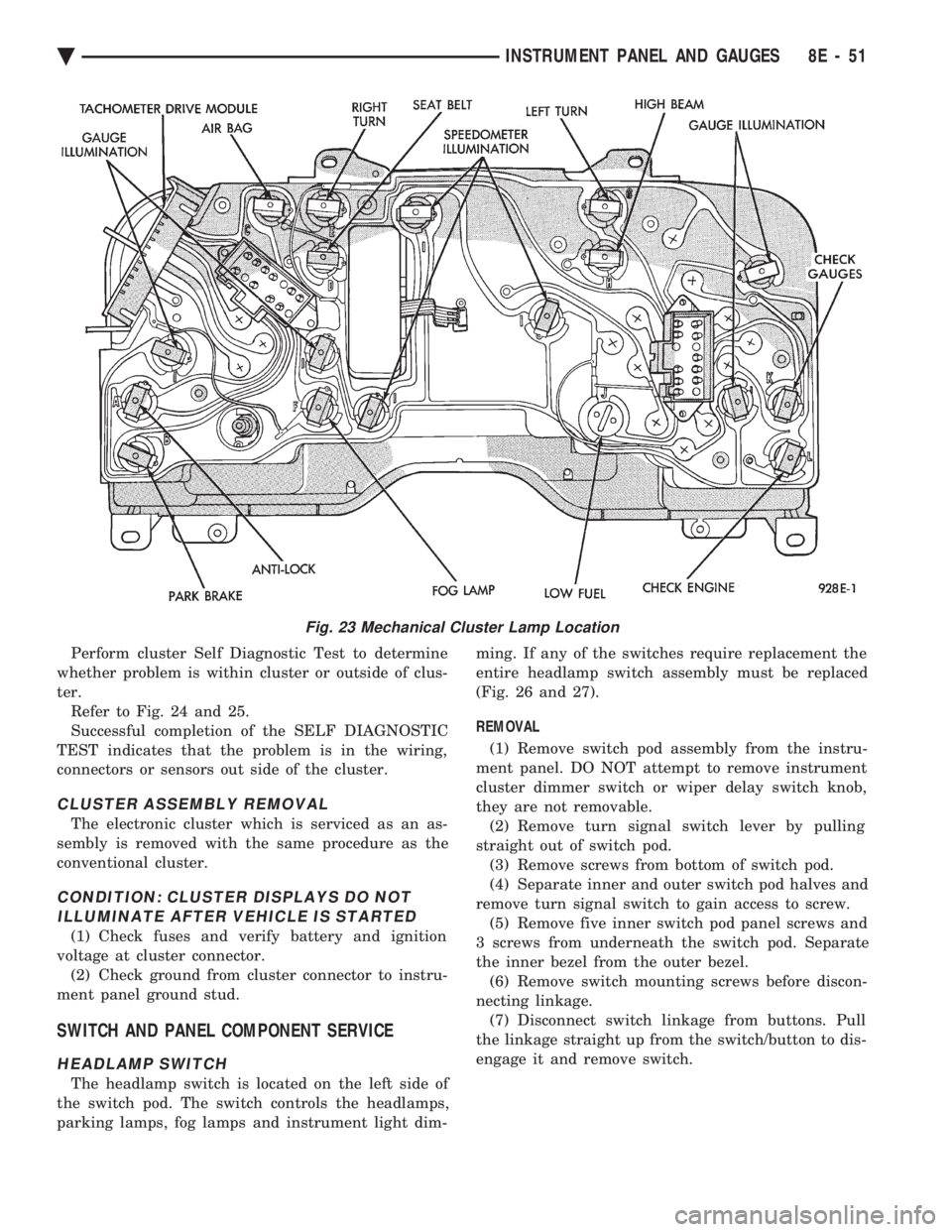

Perform cluster Self Diagnostic Test to determine

whether problem is within cluster or outside of clus-

ter. Refer to Fig. 24 and 25.

Successful completion of the SELF DIAGNOSTIC

TEST indicates that the problem is in the wiring,

connectors or sensors out side of the cluster.

CLUSTER ASSEMBLY REMOVAL

The electronic cluster which is serviced as an as-

sembly is removed with the same procedure as the

conventional cluster.

CONDITION: CLUSTER DISPLAYS DO NOT ILLUMINATE AFTER VEHICLE IS STARTED

(1) Check fuses and verify battery and ignition

voltage at cluster connector. (2) Check ground from cluster connector to instru-

ment panel ground stud.

SWITCH AND PANEL COMPONENT SERVICE

HEADLAMP SWITCH

The headlamp switch is located on the left side of

the switch pod. The switch controls the headlamps,

parking lamps, fog lamps and instrument light dim- ming. If any of the switches require replacement the

entire headlamp switch assembly must be replaced

(Fig. 26 and 27).

REMOVAL

(1) Remove switch pod assembly from the instru-

ment panel. DO NOT attempt to remove instrument

cluster dimmer switch or wiper delay switch knob,

they are not removable. (2) Remove turn signal switch lever by pulling

straight out of switch pod. (3) Remove screws from bottom of switch pod.

(4) Separate inner and outer switch pod halves and

remove turn signal switch to gain access to screw. (5) Remove five inner switch pod panel screws and

3 screws from underneath the switch pod. Separate

the inner bezel from the outer bezel. (6) Remove switch mounting screws before discon-

necting linkage. (7) Disconnect switch linkage from buttons. Pull

the linkage straight up from the switch/button to dis-

engage it and remove switch.

Fig. 23 Mechanical Cluster Lamp Location

Ä INSTRUMENT PANEL AND GAUGES 8E - 51

Page 546 of 2438

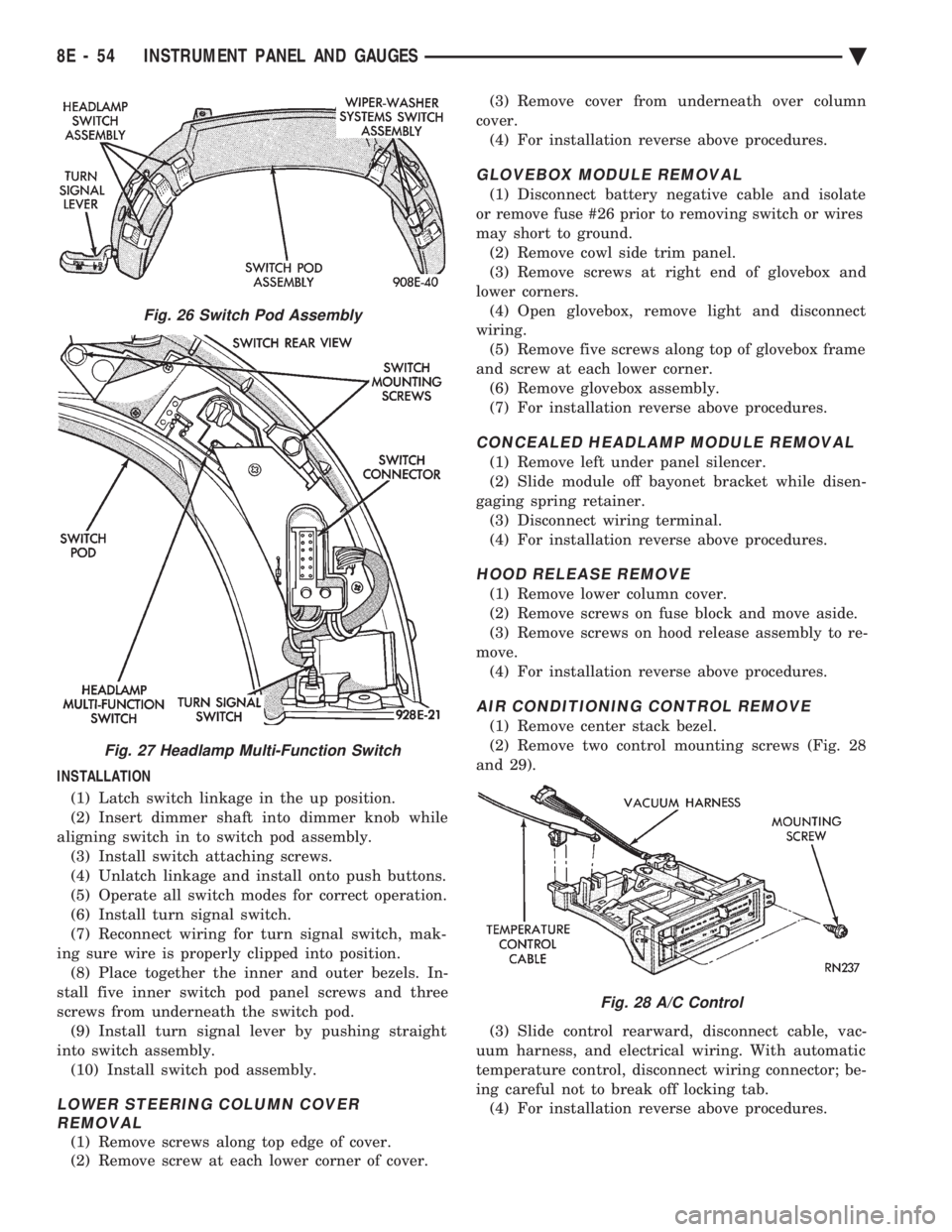

INSTALLATION (1) Latch switch linkage in the up position.

(2) Insert dimmer shaft into dimmer knob while

aligning switch in to switch pod assembly. (3) Install switch attaching screws.

(4) Unlatch linkage and install onto push buttons.

(5) Operate all switch modes for correct operation.

(6) Install turn signal switch.

(7) Reconnect wiring for turn signal switch, mak-

ing sure wire is properly clipped into position. (8) Place together the inner and outer bezels. In-

stall five inner switch pod panel screws and three

screws from underneath the switch pod. (9) Install turn signal lever by pushing straight

into switch assembly. (10) Install switch pod assembly.

LOWER STEERING COLUMN COVER REMOVAL

(1) Remove screws along top edge of cover.

(2) Remove screw at each lower corner of cover. (3) Remove cover from underneath over column

cover. (4) For installation reverse above procedures.

GLOVEBOX MODULE REMOVAL

(1) Disconnect battery negative cable and isolate

or remove fuse #26 prior to removing switch or wires

may short to ground. (2) Remove cowl side trim panel.

(3) Remove screws at right end of glovebox and

lower corners. (4) Open glovebox, remove light and disconnect

wiring. (5) Remove five screws along top of glovebox frame

and screw at each lower corner. (6) Remove glovebox assembly.

(7) For installation reverse above procedures.

CONCEALED HEADLAMP MODULE REMOVAL

(1) Remove left under panel silencer.

(2) Slide module off bayonet bracket while disen-

gaging spring retainer. (3) Disconnect wiring terminal.

(4) For installation reverse above procedures.

HOOD RELEASE REMOVE

(1) Remove lower column cover.

(2) Remove screws on fuse block and move aside.

(3) Remove screws on hood release assembly to re-

move. (4) For installation reverse above procedures.

AIR CONDITIONING CONTROL REMOVE

(1) Remove center stack bezel.

(2) Remove two control mounting screws (Fig. 28

and 29).

(3) Slide control rearward, disconnect cable, vac-

uum harness, and electrical wiring. With automatic

temperature control, disconnect wiring connector; be-

ing careful not to break off locking tab. (4) For installation reverse above procedures.

Fig. 26 Switch Pod Assembly

Fig. 27 Headlamp Multi-Function Switch

Fig. 28 A/C Control

8E - 54 INSTRUMENT PANEL AND GAUGES Ä

Page 599 of 2438

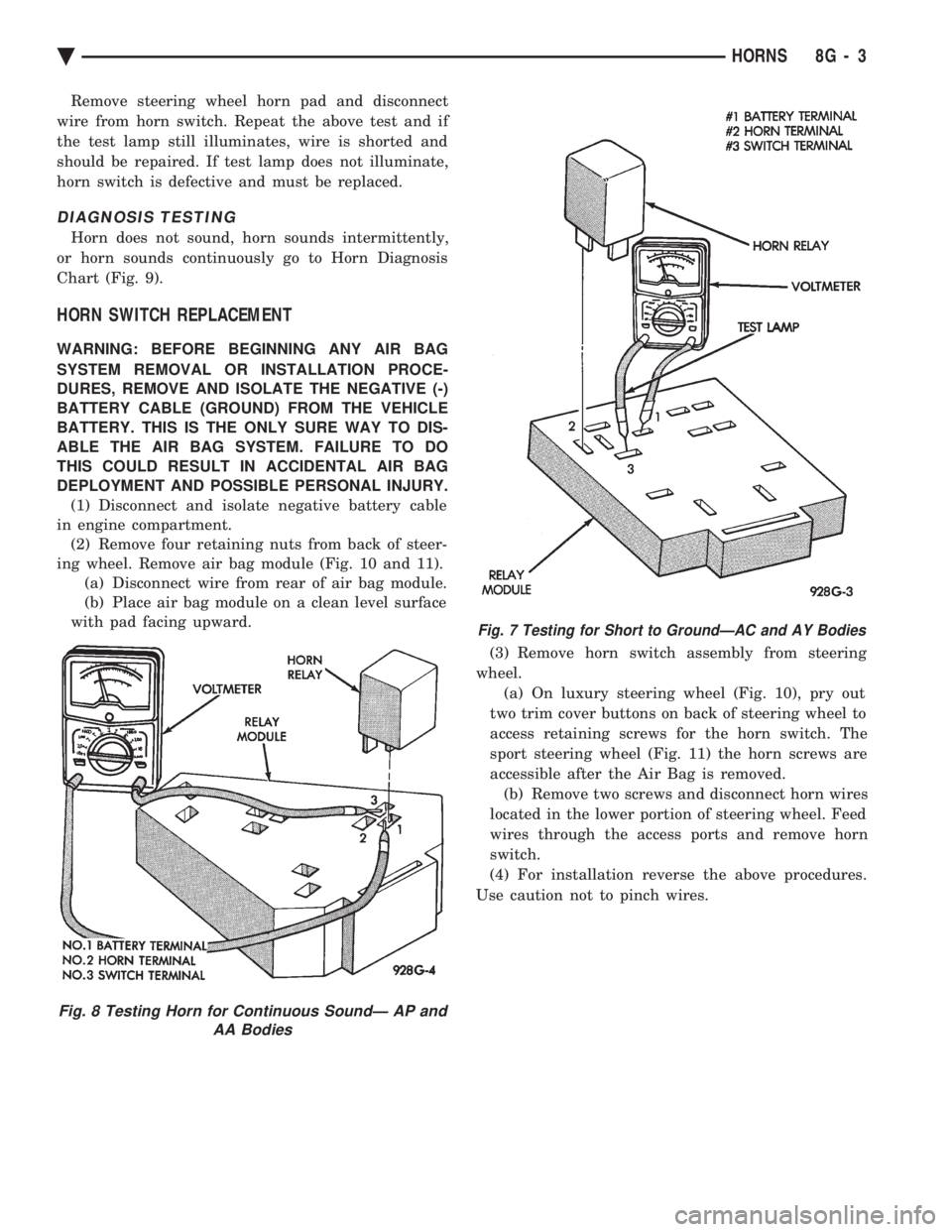

Remove steering wheel horn pad and disconnect

wire from horn switch. Repeat the above test and if

the test lamp still illuminates, wire is shorted and

should be repaired. If test lamp does not illuminate,

horn switch is defective and must be replaced.

DIAGNOSIS TESTING

Horn does not sound, horn sounds intermittently,

or horn sounds continuously go to Horn Diagnosis

Chart (Fig. 9).

HORN SWITCH REPLACEMENT

WARNING: BEFORE BEGINNING ANY AIR BAG

SYSTEM REMOVAL OR INSTALLATION PROCE-

DURES, REMOVE AND ISOLATE THE NEGATIVE (-)

BATTERY CABLE (GROUND) FROM THE VEHICLE

BATTERY. THIS IS THE ONLY SURE WAY TO DIS-

ABLE THE AIR BAG SYSTEM. FAILURE TO DO

THIS COULD RESULT IN ACCIDENTAL AIR BAG

DEPLOYMENT AND POSSIBLE PERSONAL INJURY. (1) Disconnect and isolate negative battery cable

in engine compartment. (2) Remove four retaining nuts from back of steer-

ing wheel. Remove air bag module (Fig. 10 and 11). (a) Disconnect wire from rear of air bag module.

(b) Place air bag module on a clean level surface

with pad facing upward.

(3) Remove horn switch assembly from steering

wheel. (a) On luxury steering wheel (Fig. 10), pry out

two trim cover buttons on back of steering wheel to

access retaining screws for the horn switch. The

sport steering wheel (Fig. 11) the horn screws are

accessible after the Air Bag is removed. (b) Remove two screws and disconnect horn wires

located in the lower portion of steering wheel. Feed

wires through the access ports and remove horn

switch.

(4) For installation reverse the above procedures.

Use caution not to pinch wires.

Fig. 8 Testing Horn for Continuous SoundÐ AP and AA Bodies

Fig. 7 Testing for Short to GroundÐAC and AY Bodies

Ä HORNS 8G - 3

Page 603 of 2438

VEHICLE SPEED CONTROL

CONTENTS

page page

CHECKING FOR FAULT CODE .............. 3

DIAGNOSIS PROCEDURES ................ 2

GENERAL INFORMATION .................. 1

INOPERATIVE SYSTEM ................... 3

POWERTRAIN CONTROL MODULE ELECTRICAL TEST ................................ 5

ROAD TEST ............................ 2

SERVO ELECTRICAL TESTS ............... 4

SERVO UNIT ............................ 9 SERVO VACUUM TEST

................... 9

STOP LAMP VEHICLE SPEED CONTROL SWITCH TEST ......................... 8

VACUUM SUPPLY TEST .................. 9

VEHICLE SPEED CONTROL SWITCH REMOVAL ........................... 10

VEHICLE SPEED CONTROL SWITCH TEST . . . 8

VEHICLE SPEED CONTROL ELECTRICAL TESTS ............................... 3

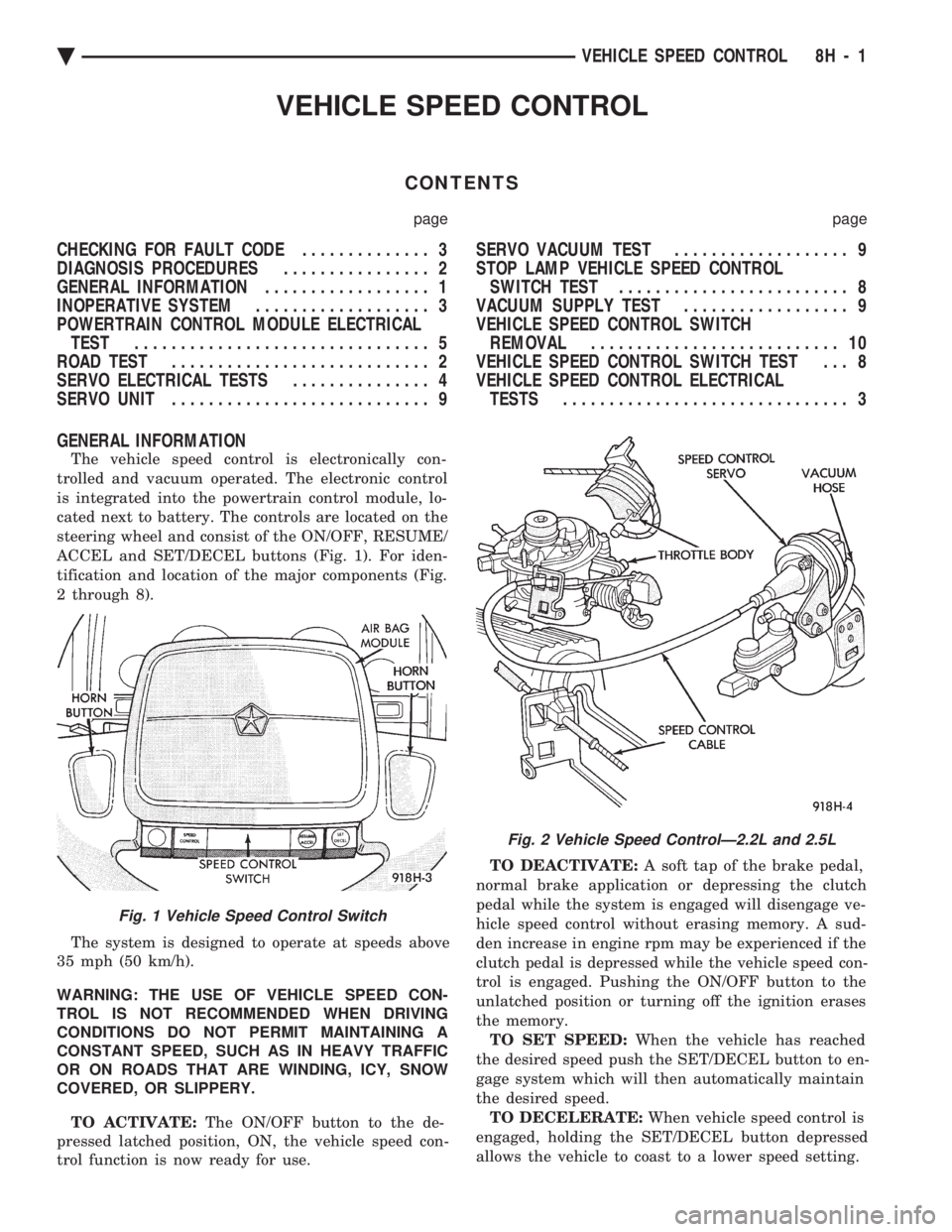

GENERAL INFORMATION

The vehicle speed control is electronically con-

trolled and vacuum operated. The electronic control

is integrated into the powertrain control module, lo-

cated next to battery. The controls are located on the

steering wheel and consist of the ON/OFF, RESUME/

ACCEL and SET/DECEL buttons (Fig. 1). For iden-

tification and location of the major components (Fig.

2 through 8).

The system is designed to operate at speeds above

35 mph (50 km/h).

WARNING: THE USE OF VEHICLE SPEED CON-

TROL IS NOT RECOMMENDED WHEN DRIVING

CONDITIONS DO NOT PERMIT MAINTAINING A

CONSTANT SPEED, SUCH AS IN HEAVY TRAFFIC

OR ON ROADS THAT ARE WINDING, ICY, SNOW

COVERED, OR SLIPPERY.

TO ACTIVATE: The ON/OFF button to the de-

pressed latched position, ON, the vehicle speed con-

trol function is now ready for use. TO DEACTIVATE:

A soft tap of the brake pedal,

normal brake application or depressing the clutch

pedal while the system is engaged will disengage ve-

hicle speed control without erasing memory. A sud-

den increase in engine rpm may be experienced if the

clutch pedal is depressed while the vehicle speed con-

trol is engaged. Pushing the ON/OFF button to the

unlatched position or turning off the ignition erases

the memory. TO SET SPEED: When the vehicle has reached

the desired speed push the SET/DECEL button to en-

gage system which will then automatically maintain

the desired speed. TO DECELERATE: When vehicle speed control is

engaged, holding the SET/DECEL button depressed

allows the vehicle to coast to a lower speed setting.

Fig. 1 Vehicle Speed Control Switch

Fig. 2 Vehicle Speed ControlÐ2.2L and 2.5L

Ä VEHICLE SPEED CONTROL 8H - 1

Page 635 of 2438

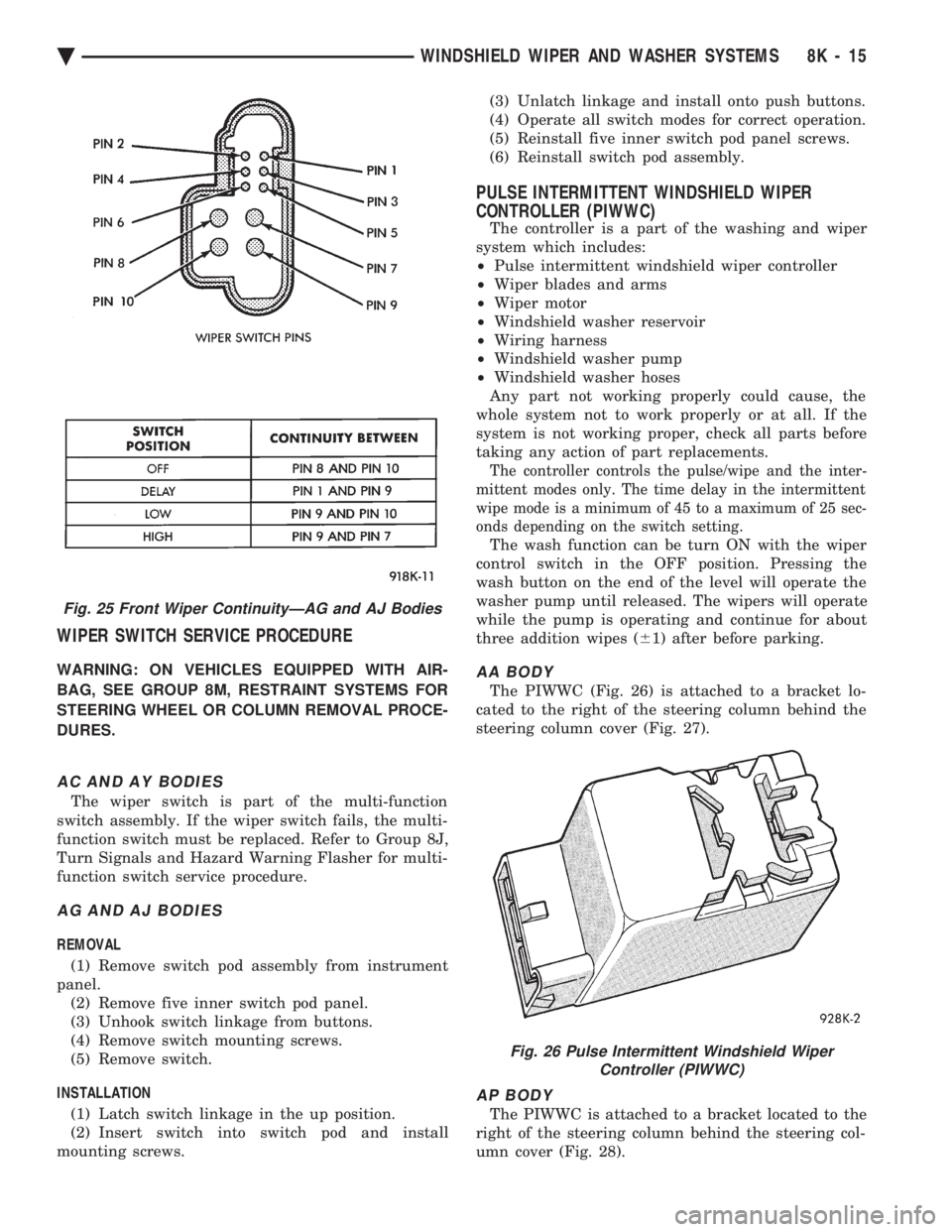

WIPER SWITCH SERVICE PROCEDURE

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAG, SEE GROUP 8M, RESTRAINT SYSTEMS FOR

STEERING WHEEL OR COLUMN REMOVAL PROCE-

DURES.

AC AND AY BODIES

The wiper switch is part of the multi-function

switch assembly. If the wiper switch fails, the multi-

function switch must be replaced. Refer to Group 8J,

Turn Signals and Hazard Warning Flasher for multi-

function switch service procedure.

AG AND AJ BODIES

REMOVAL

(1) Remove switch pod assembly from instrument

panel. (2) Remove five inner switch pod panel.

(3) Unhook switch linkage from buttons.

(4) Remove switch mounting screws.

(5) Remove switch.

INSTALLATION (1) Latch switch linkage in the up position.

(2) Insert switch into switch pod and install

mounting screws. (3) Unlatch linkage and install onto push buttons.

(4) Operate all switch modes for correct operation.

(5) Reinstall five inner switch pod panel screws.

(6) Reinstall switch pod assembly.

PULSE INTERMITTENT WINDSHIELD WIPER

CONTROLLER (PIWWC)

The controller is a part of the washing and wiper

system which includes:

² Pulse intermittent windshield wiper controller

² Wiper blades and arms

² Wiper motor

² Windshield washer reservoir

² Wiring harness

² Windshield washer pump

² Windshield washer hoses

Any part not working properly could cause, the

whole system not to work properly or at all. If the

system is not working proper, check all parts before

taking any action of part replacements.

The controller controls the pulse/wipe and the inter-

mittent modes only. The time delay in the intermittent

wipe mode is a minimum of 45 to a maximum of 25 sec-

onds depending on the switch setting.

The wash function can be turn ON with the wiper

control switch in the OFF position. Pressing the

wash button on the end of the level will operate the

washer pump until released. The wipers will operate

while the pump is operating and continue for about

three addition wipes ( 61) after before parking.

AA BODY

The PIWWC (Fig. 26) is attached to a bracket lo-

cated to the right of the steering column behind the

steering column cover (Fig. 27).

AP BODY

The PIWWC is attached to a bracket located to the

right of the steering column behind the steering col-

umn cover (Fig. 28).

Fig. 25 Front Wiper ContinuityÐAG and AJ Bodies

Fig. 26 Pulse Intermittent Windshield Wiper Controller (PIWWC)

Ä WINDSHIELD WIPER AND WASHER SYSTEMS 8K - 15