clutch CHEVROLET DYNASTY 1993 User Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 339 of 2438

hicle is steam cleaned. The facing of the disc will

absorb moisture. The force exerted by the pressure

plate will bond the facings to flywheel and/or, pres-

sure plate, if vehicle is allowed to stand for some

time before use. If this condition occurs, it will re- quire replacement of disc assembly, flywheel, and/or

clutch assembly. After cleaning, drive the vehicle to

its normal clutch operating temperature. This will

dry off disc assembly, pressure plate, and flywheel.

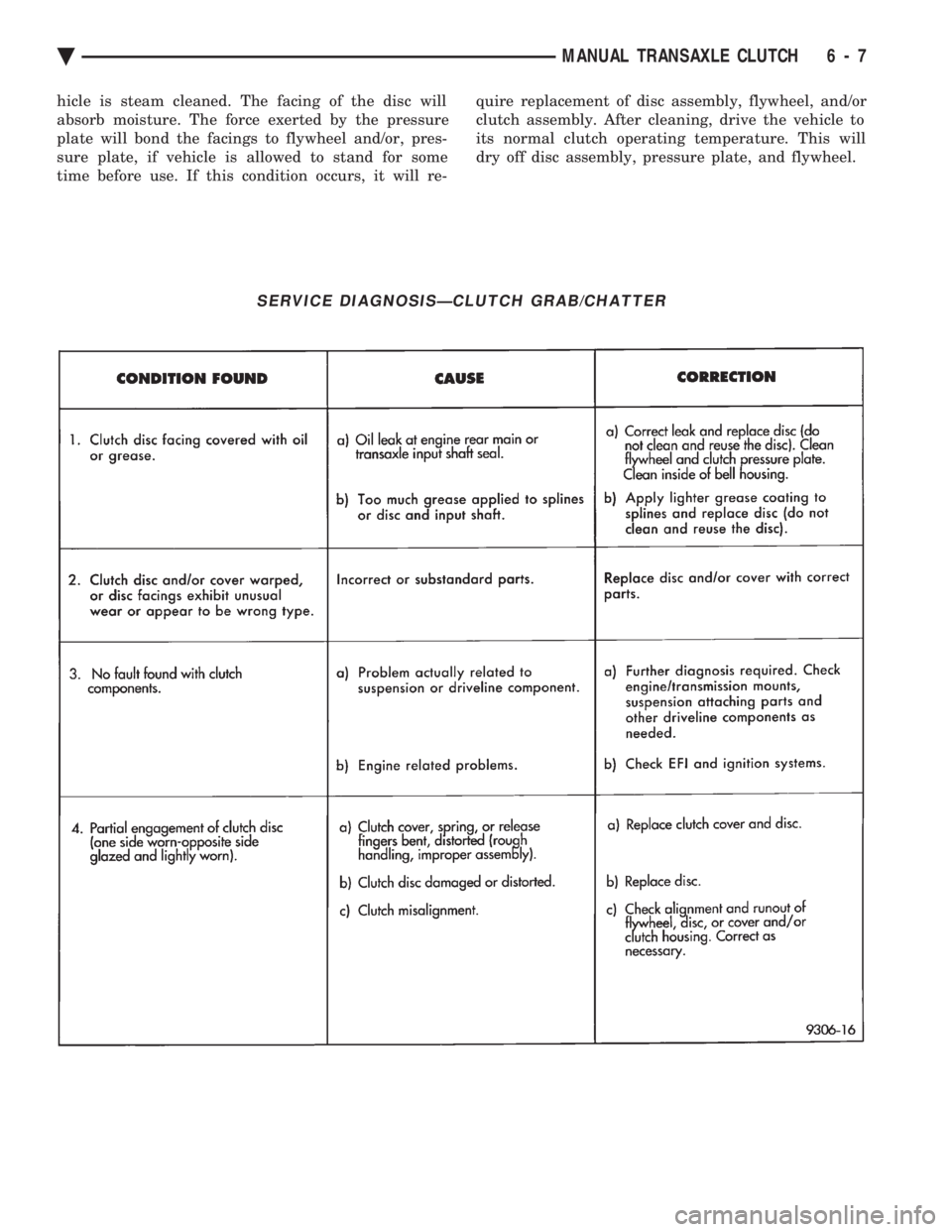

SERVICE DIAGNOSISÐCLUTCH GRAB/CHATTER

Ä MANUAL TRANSAXLE CLUTCH 6 - 7

Page 340 of 2438

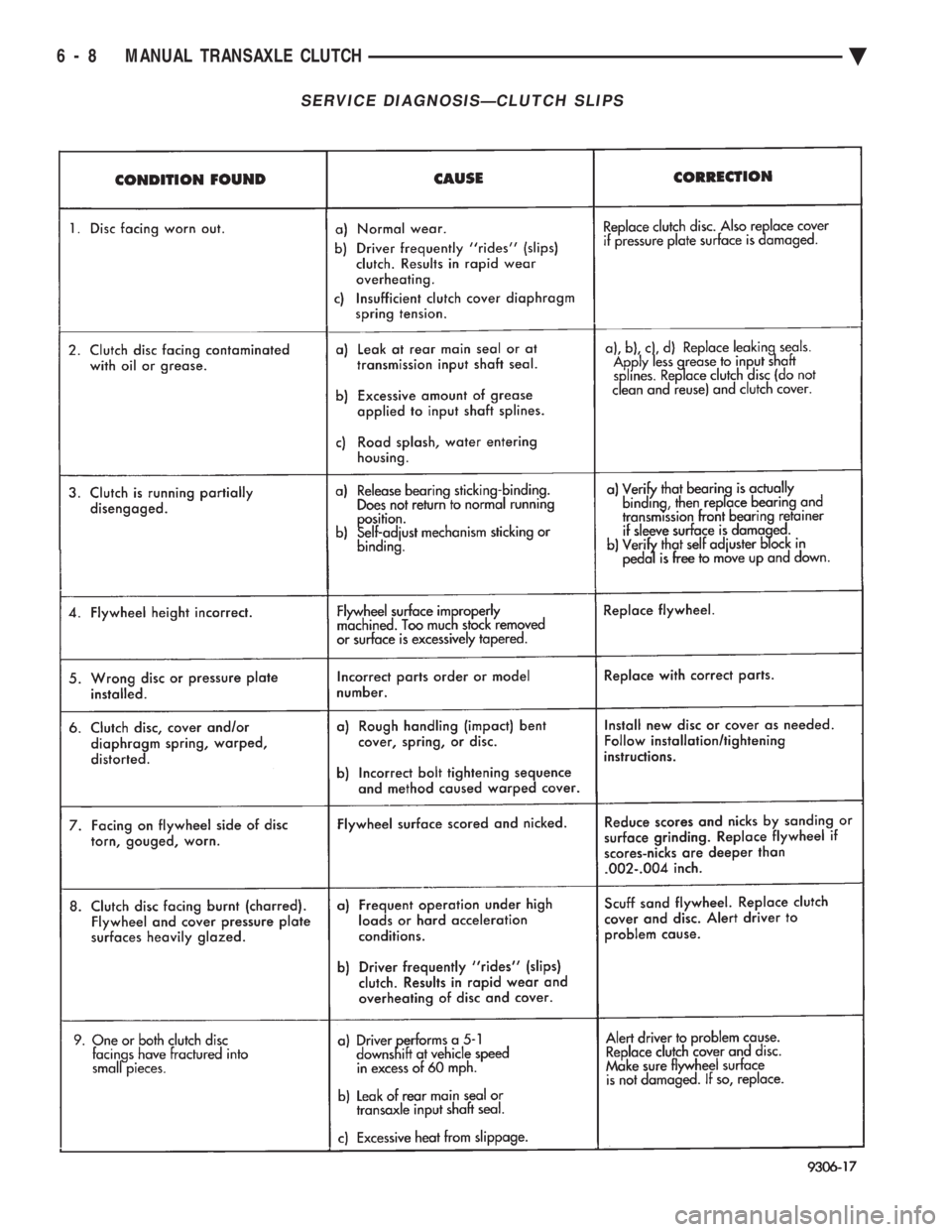

SERVICE DIAGNOSISÐCLUTCH SLIPS

6 - 8 MANUAL TRANSAXLE CLUTCH Ä

Page 341 of 2438

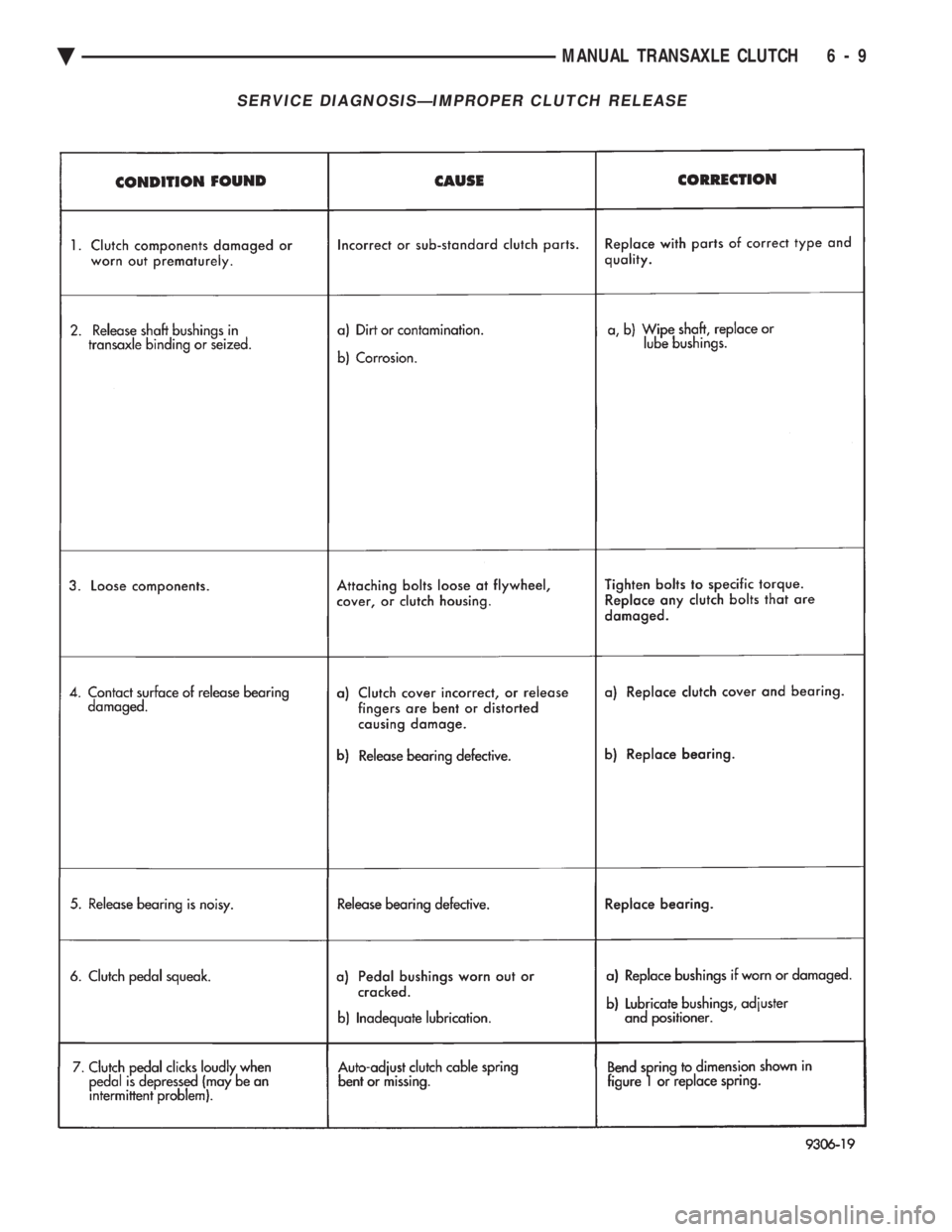

SERVICE DIAGNOSISÐIMPROPER CLUTCH RELEASE

Ä MANUAL TRANSAXLE CLUTCH 6 - 9

Page 342 of 2438

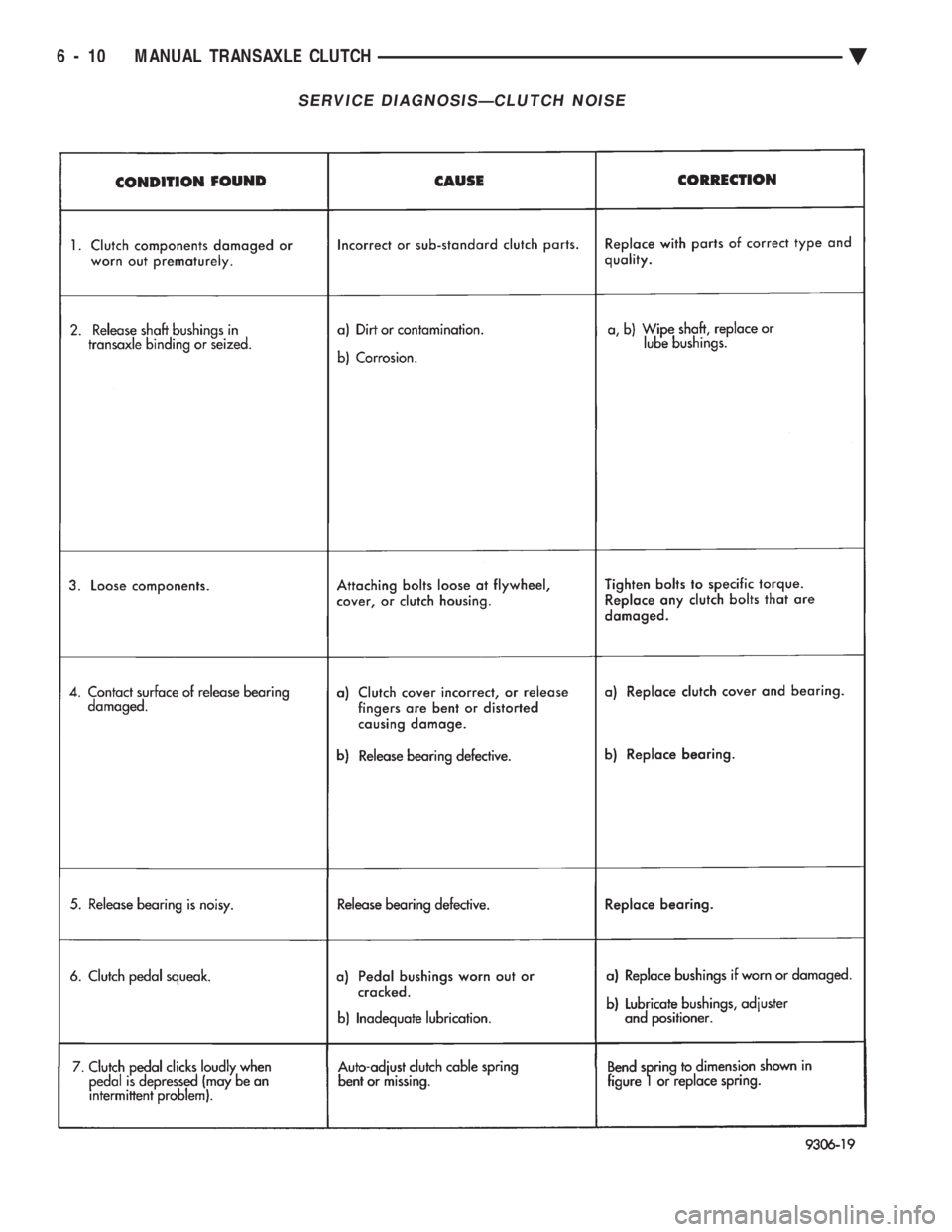

SERVICE DIAGNOSISÐCLUTCH NOISE

6 - 10 MANUAL TRANSAXLE CLUTCH Ä

Page 363 of 2438

RADIATOR HOSES

The hoses are removed using Constant Tension

Clamp pliers to compress hose clamp. A hardened, cracked, swollen or restricted hose

should be replaced. Do not damage radiator inlet and

outlet when loosening hoses. Radiator hoses should be routed without any kinks

and indexed as designed. The use of molded hoses is

recommended. Spring type hose clamps are used in all applica-

tions. If replacement is necessary replace with the

original style spring type clamp.

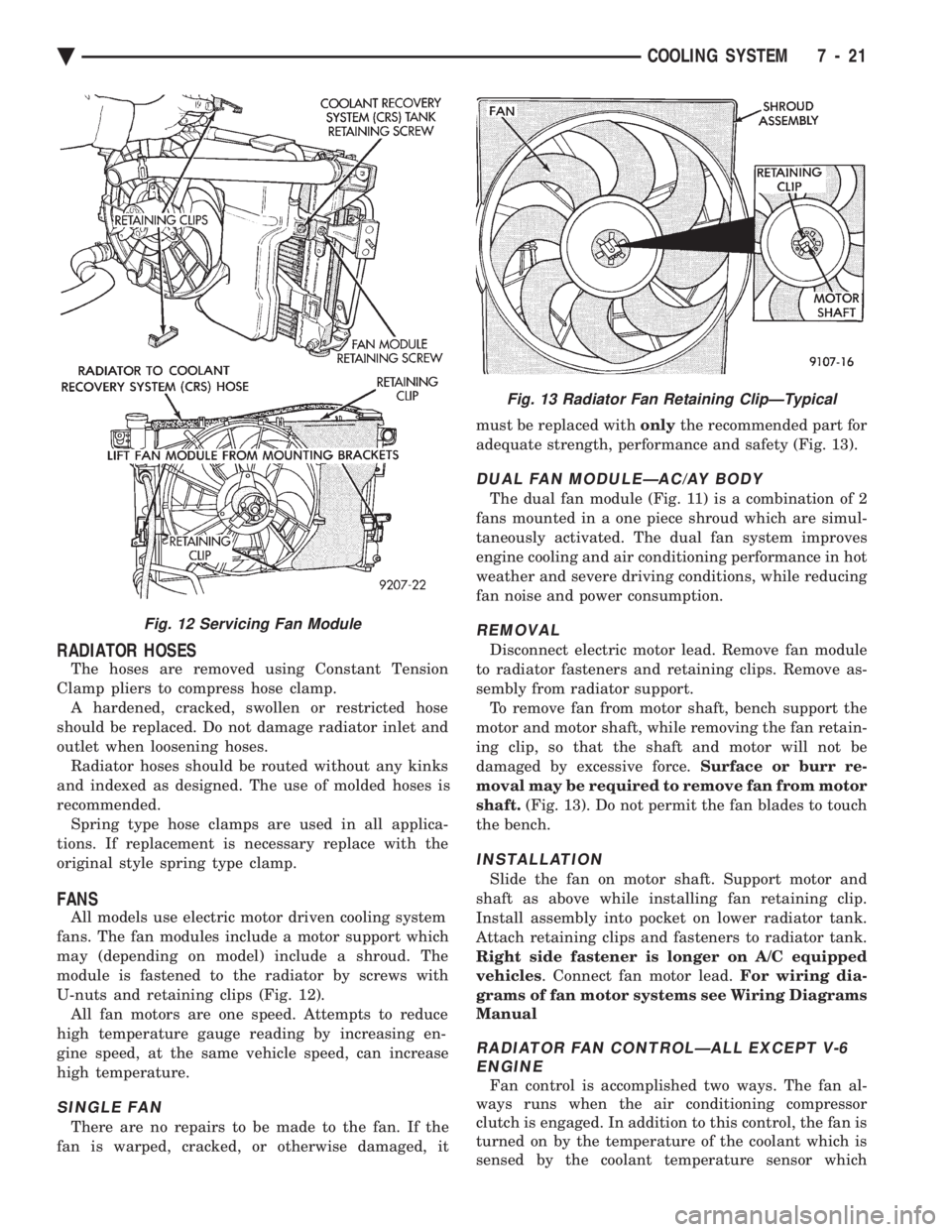

FANS

All models use electric motor driven cooling system

fans. The fan modules include a motor support which

may (depending on model) include a shroud. The

module is fastened to the radiator by screws with

U-nuts and retaining clips (Fig. 12). All fan motors are one speed. Attempts to reduce

high temperature gauge reading by increasing en-

gine speed, at the same vehicle speed, can increase

high temperature.

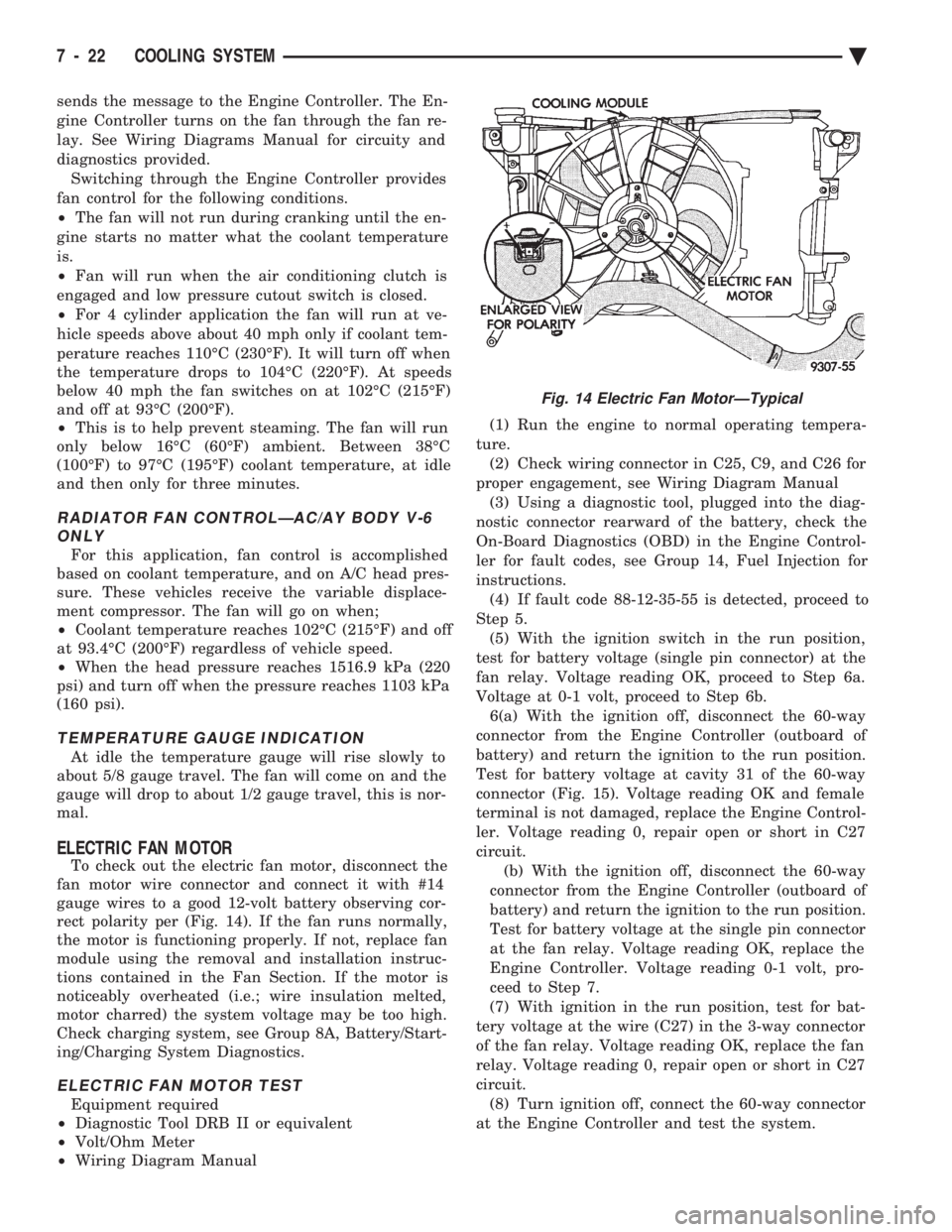

SINGLE FAN

There are no repairs to be made to the fan. If the

fan is warped, cracked, or otherwise damaged, it must be replaced with

onlythe recommended part for

adequate strength, performance and safety (Fig. 13).

DUAL FAN MODULEÐAC/AY BODY

The dual fan module (Fig. 11) is a combination of 2

fans mounted in a one piece shroud which are simul-

taneously activated. The dual fan system improves

engine cooling and air conditioning performance in hot

weather and severe driving conditions, while reducing

fan noise and power consumption.

REMOVAL

Disconnect electric motor lead. Remove fan module

to radiator fasteners and retaining clips. Remove as-

sembly from radiator support. To remove fan from motor shaft, bench support the

motor and motor shaft, while removing the fan retain-

ing clip, so that the shaft and motor will not be

damaged by excessive force. Surface or burr re-

moval may be required to remove fan from motor

shaft. (Fig. 13). Do not permit the fan blades to touch

the bench.

INSTALLATION

Slide the fan on motor shaft. Support motor and

shaft as above while installing fan retaining clip.

Install assembly into pocket on lower radiator tank.

Attach retaining clips and fasteners to radiator tank.

Right side fastener is longer on A/C equipped

vehicles . Connect fan motor lead. For wiring dia-

grams of fan motor systems see Wiring Diagrams

Manual

RADIATOR FAN CONTROLÐALL EXCEPT V-6 ENGINE

Fan control is accomplished two ways. The fan al-

ways runs when the air conditioning compressor

clutch is engaged. In addition to this control, the fan is

turned on by the temperature of the coolant which is

sensed by the coolant temperature sensor which

Fig. 12 Servicing Fan Module

Fig. 13 Radiator Fan Retaining ClipÐTypical

Ä COOLING SYSTEM 7 - 21

Page 364 of 2438

sends the message to the Engine Controller. The En-

gine Controller turns on the fan through the fan re-

lay. See Wiring Diagrams Manual for circuity and

diagnostics provided.Switching through the Engine Controller provides

fan control for the following conditions.

² The fan will not run during cranking until the en-

gine starts no matter what the coolant temperature

is.

² Fan will run when the air conditioning clutch is

engaged and low pressure cutout switch is closed.

² For 4 cylinder application the fan will run at ve-

hicle speeds above about 40 mph only if coolant tem-

perature reaches 110ÉC (230ÉF). It will turn off when

the temperature drops to 104ÉC (220ÉF). At speeds

below 40 mph the fan switches on at 102ÉC (215ÉF)

and off at 93ÉC (200ÉF).

² This is to help prevent steaming. The fan will run

only below 16ÉC (60ÉF) ambient. Between 38ÉC

(100ÉF) to 97ÉC (195ÉF) coolant temperature, at idle

and then only for three minutes.

RADIATOR FAN CONTROLÐAC/AY BODY V-6 ONLY

For this application, fan control is accomplished

based on coolant temperature, and on A/C head pres-

sure. These vehicles receive the variable displace-

ment compressor. The fan will go on when;

² Coolant temperature reaches 102ÉC (215ÉF) and off

at 93.4ÉC (200ÉF) regardless of vehicle speed.

² When the head pressure reaches 1516.9 kPa (220

psi) and turn off when the pressure reaches 1103 kPa

(160 psi).

TEMPERATURE GAUGE INDICATION

At idle the temperature gauge will rise slowly to

about 5/8 gauge travel. The fan will come on and the

gauge will drop to about 1/2 gauge travel, this is nor-

mal.

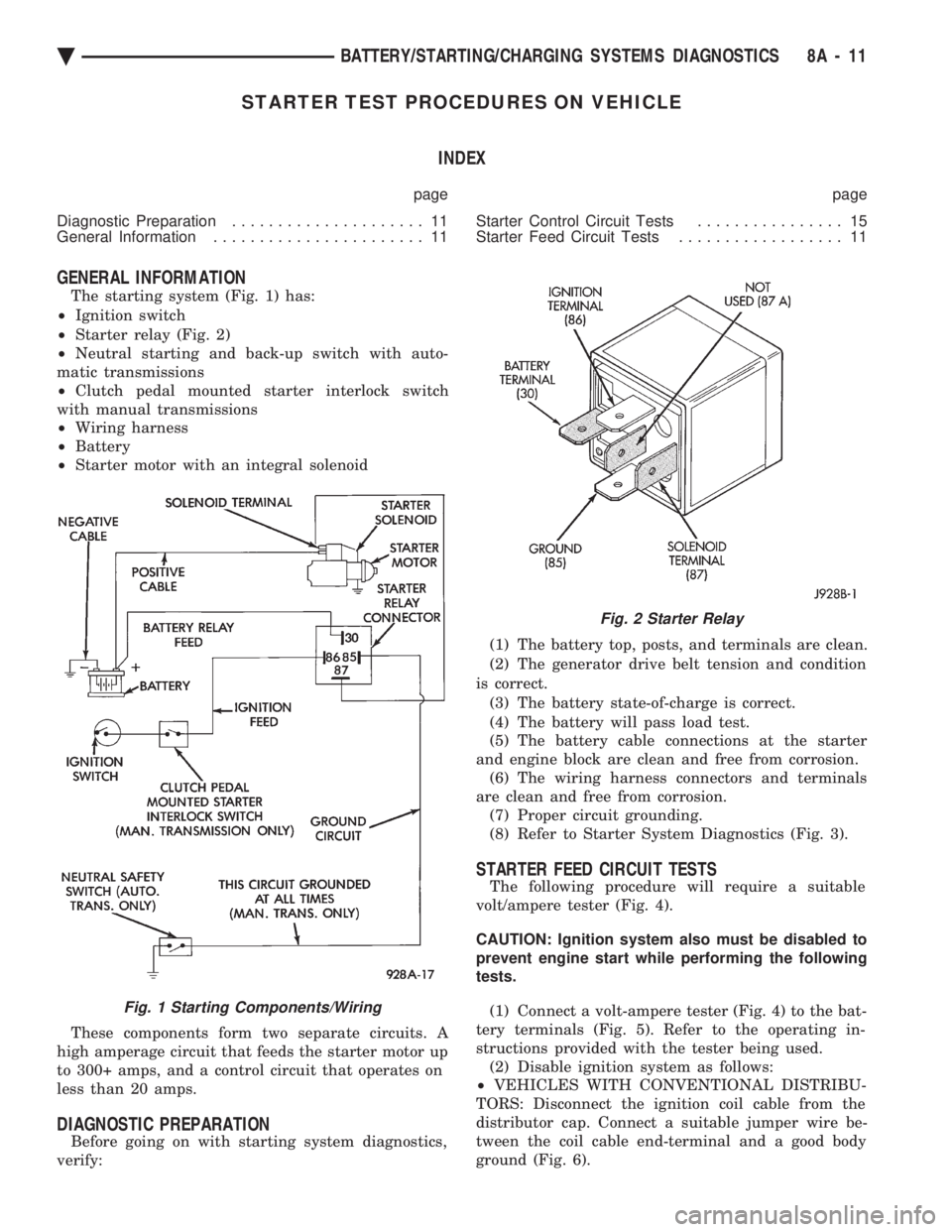

ELECTRIC FAN MOTOR

To check out the electric fan motor, disconnect the

fan motor wire connector and connect it with #14

gauge wires to a good 12-volt battery observing cor-

rect polarity per (Fig. 14). If the fan runs normally,

the motor is functioning properly. If not, replace fan

module using the removal and installation instruc-

tions contained in the Fan Section. If the motor is

noticeably overheated (i.e.; wire insulation melted,

motor charred) the system voltage may be too high.

Check charging system, see Group 8A, Battery/Start-

ing/Charging System Diagnostics.

ELECTRIC FAN MOTOR TEST

Equipment required

² Diagnostic Tool DRB II or equivalent

² Volt/Ohm Meter

² Wiring Diagram Manual (1) Run the engine to normal operating tempera-

ture. (2) Check wiring connector in C25, C9, and C26 for

proper engagement, see Wiring Diagram Manual (3) Using a diagnostic tool, plugged into the diag-

nostic connector rearward of the battery, check the

On-Board Diagnostics (OBD) in the Engine Control-

ler for fault codes, see Group 14, Fuel Injection for

instructions. (4) If fault code 88-12-35-55 is detected, proceed to

Step 5. (5) With the ignition switch in the run position,

test for battery voltage (single pin connector) at the

fan relay. Voltage reading OK, proceed to Step 6a.

Voltage at 0-1 volt, proceed to Step 6b. 6(a) With the ignition off, disconnect the 60-way

connector from the Engine Controller (outboard of

battery) and return the ignition to the run position.

Test for battery voltage at cavity 31 of the 60-way

connector (Fig. 15). Voltage reading OK and female

terminal is not damaged, replace the Engine Control-

ler. Voltage reading 0, repair open or short in C27

circuit. (b) With the ignition off, disconnect the 60-way

connector from the Engine Controller (outboard of

battery) and return the ignition to the run position.

Test for battery voltage at the single pin connector

at the fan relay. Voltage reading OK, replace the

Engine Controller. Voltage reading 0-1 volt, pro-

ceed to Step 7.

(7) With ignition in the run position, test for bat-

tery voltage at the wire (C27) in the 3-way connector

of the fan relay. Voltage reading OK, replace the fan

relay. Voltage reading 0, repair open or short in C27

circuit. (8) Turn ignition off, connect the 60-way connector

at the Engine Controller and test the system.

Fig. 14 Electric Fan MotorÐTypical

7 - 22 COOLING SYSTEM Ä

Page 383 of 2438

STARTER TEST PROCEDURES ON VEHICLE INDEX

page page

Diagnostic Preparation ..................... 11

General Information ....................... 11 Starter Control Circuit Tests

................ 15

Starter Feed Circuit Tests .................. 11

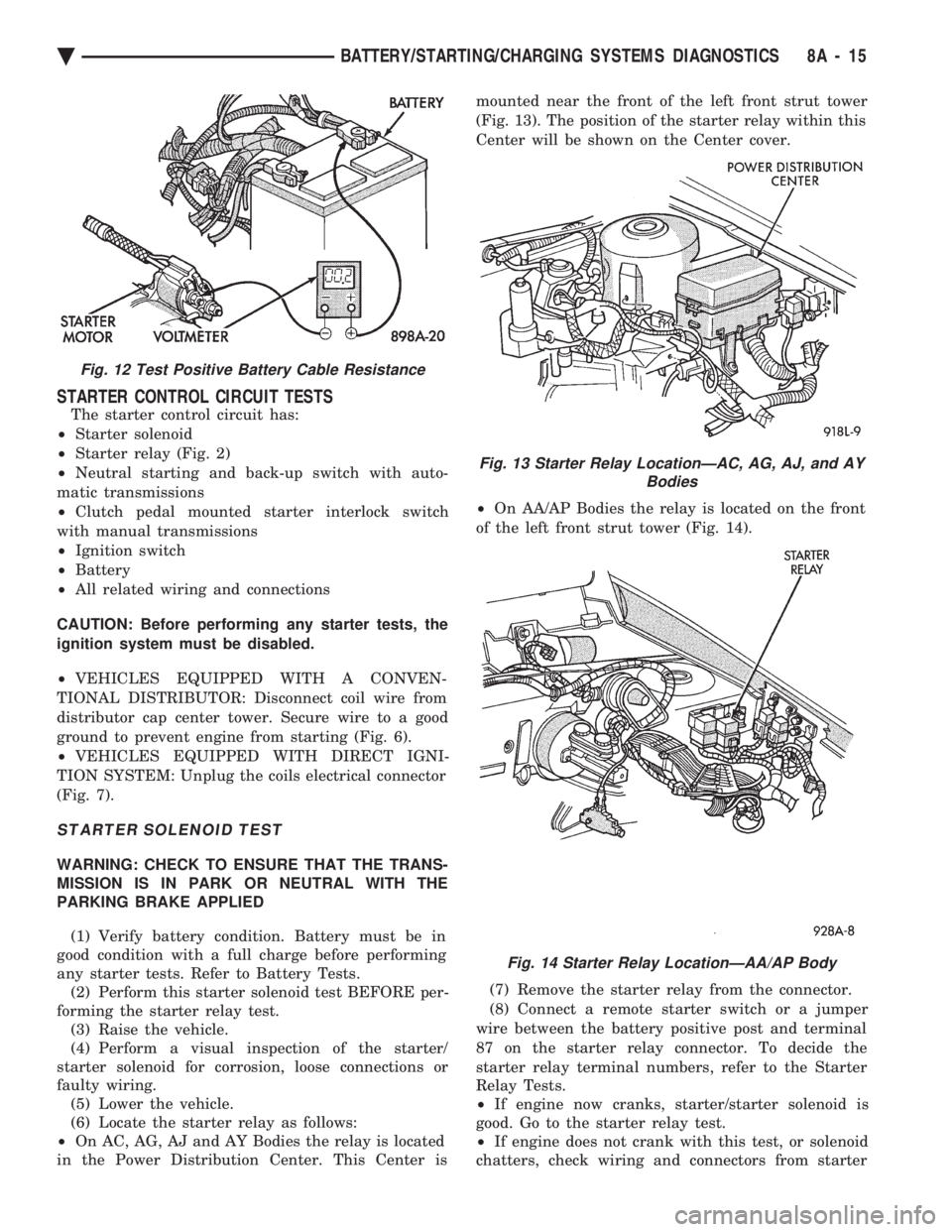

GENERAL INFORMATION

The starting system (Fig. 1) has:

² Ignition switch

² Starter relay (Fig. 2)

² Neutral starting and back-up switch with auto-

matic transmissions

² Clutch pedal mounted starter interlock switch

with manual transmissions

² Wiring harness

² Battery

² Starter motor with an integral solenoid

These components form two separate circuits. A

high amperage circuit that feeds the starter motor up

to 300+ amps, and a control circuit that operates on

less than 20 amps.

DIAGNOSTIC PREPARATION

Before going on with starting system diagnostics,

verify: (1) The battery top, posts, and terminals are clean.

(2) The generator drive belt tension and condition

is correct. (3) The battery state-of-charge is correct.

(4) The battery will pass load test.

(5) The battery cable connections at the starter

and engine block are clean and free from corrosion. (6) The wiring harness connectors and terminals

are clean and free from corrosion. (7) Proper circuit grounding.

(8) Refer to Starter System Diagnostics (Fig. 3).

STARTER FEED CIRCUIT TESTS

The following procedure will require a suitable

volt/ampere tester (Fig. 4).

CAUTION: Ignition system also must be disabled to

prevent engine start while performing the following

tests.

(1) Connect a volt-ampere tester (Fig. 4) to the bat-

tery terminals (Fig. 5). Refer to the operating in-

structions provided with the tester being used. (2) Disable ignition system as follows:

² VEHICLES WITH CONVENTIONAL DISTRIBU-

TORS: Disconnect the ignition coil cable from the

distributor cap. Connect a suitable jumper wire be-

tween the coil cable end-terminal and a good body

ground (Fig. 6).

Fig. 1 Starting Components/Wiring

Fig. 2 Starter Relay

Ä BATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICS 8A - 11

Page 387 of 2438

STARTER CONTROL CIRCUIT TESTS

The starter control circuit has:

² Starter solenoid

² Starter relay (Fig. 2)

² Neutral starting and back-up switch with auto-

matic transmissions

² Clutch pedal mounted starter interlock switch

with manual transmissions

² Ignition switch

² Battery

² All related wiring and connections

CAUTION: Before performing any starter tests, the

ignition system must be disabled.

² VEHICLES EQUIPPED WITH A CONVEN-

TIONAL DISTRIBUTOR: Disconnect coil wire from

distributor cap center tower. Secure wire to a good

ground to prevent engine from starting (Fig. 6).

² VEHICLES EQUIPPED WITH DIRECT IGNI-

TION SYSTEM: Unplug the coils electrical connector

(Fig. 7).

STARTER SOLENOID TEST

WARNING: CHECK TO ENSURE THAT THE TRANS-

MISSION IS IN PARK OR NEUTRAL WITH THE

PARKING BRAKE APPLIED

(1) Verify battery condition. Battery must be in

good condition with a full charge before performing

any starter tests. Refer to Battery Tests. (2) Perform this starter solenoid test BEFORE per-

forming the starter relay test. (3) Raise the vehicle.

(4) Perform a visual inspection of the starter/

starter solenoid for corrosion, loose connections or

faulty wiring. (5) Lower the vehicle.

(6) Locate the starter relay as follows:

² On AC, AG, AJ and AY Bodies the relay is located

in the Power Distribution Center. This Center is mounted near the front of the left front strut tower

(Fig. 13). The position of the starter relay within this

Center will be shown on the Center cover.

² On AA/AP Bodies the relay is located on the front

of the left front strut tower (Fig. 14).

(7) Remove the starter relay from the connector.

(8) Connect a remote starter switch or a jumper

wire between the battery positive post and terminal

87 on the starter relay connector. To decide the

starter relay terminal numbers, refer to the Starter

Relay Tests.

² If engine now cranks, starter/starter solenoid is

good. Go to the starter relay test.

² If engine does not crank with this test, or solenoid

chatters, check wiring and connectors from starter

Fig. 12 Test Positive Battery Cable Resistance

Fig. 13 Starter Relay LocationÐAC, AG, AJ, and AY Bodies

Fig. 14 Starter Relay LocationÐAA/AP Body

Ä BATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICS 8A - 15

Page 388 of 2438

relay to starter solenoid for loose or corroded connec-

tions. Particularly at starter terminals.

² Repeat test. If engine still fails to crank properly,

trouble is within starter or starter mounted solenoid,

and it must be removed for repairs. Refer to Group

8B, Battery/Starter/Generator Service, Starter re-

placement.

STARTER RELAY TEST

WARNING: CHECK TO ENSURE THAT THE TRANS-

MISSION IS IN PARK OR NEUTRAL WITH THE

PARKING BRAKE APPLIED

(1) Verify battery condition. Battery must be in

good condition with a full charge before performing

any starter tests. Refer to Battery Tests. (2) Perform the preceding starter solenoid tests

BEFORE performing starter relay tests. Refer to

Starter Solenoid Test. (3) Locate and remove the starter relay. For

starter relay locations, refer to Starter Solenoid Test

(Fig. 13 or 14). (4) After the starter relay has been located and re-

moved, refer to Starter Relay Tests (Fig. 15).

NEUTRAL STARTING AND BACK-UP SWITCH

AUTOMATIC TRANSMISSION ONLY

For electrical diagnostics, when checking starter

circuits, refer to Starter Relay Tests (Fig. 15). For replacement of switch, refer to Group 21, Tran-

saxle, Neutral Starting and Switch Replacement.

STARTER INTERLOCK SWITCHÐCLUTCH PEDAL MOUNTED

MANUAL TRANSMISSION ONLY

For electrical diagnostics, refer to the Starter Relay

Tests. For replacement and/or adjustment of the switch,

refer to Group 6, Manual Transaxle Clutch, Manual

Transaxle Starter Interlock Switch.

IGNITION SWITCH TEST

After testing the starter solenoid and relay, test ig-

nition switch and wiring. Refer to Group 8D, Ignition

Systems, or the Front Wheel Drive Car Wiring Dia-

grams Service Manual. Check all wiring for opens or

shorts, and all connectors for being loose or corroded.

BENCH TESTING STARTER SOLENOID

(1) Disconnect field coil wire from field coil termi-

nal (Fig. 16 or 17). (2) Check for continuity between solenoid terminal

and field coil terminal with a continuity tester. Con-

tinuity should be detected (Fig. 18 or 19). (3) Check for continuity between solenoid terminal

and solenoid housing (Fig. 20 or 21). Continuity

should be detected. If continuity is detected, solenoid

is good. (4) If continuity is not detected in either test, sole-

noid has an open circuit and is defective. If equipped

with:

² BOSCH STARTER: Replace the solenoid.

² NIPPONDENSO STARTER: Replace the starter

assembly.

8A - 16 BATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICS Ä

Page 406 of 2438

STARTER INDEX

page page

General Information ........................ 4

Neutral Starter and Back-Up Switch ........... 8

Starter Component Replacement .............. 5

Starter Interlock Switch: Clutch Pedal Mounted/ Manual Transmission Only ................. 7 Starter Motor Replacement

.................. 4

Starting System ........................... 4

Supply Circuit and Control Circuit ............. 4

GENERAL INFORMATION

This section will cover Starter replacement and

service procedures only. For starter diagnostic proce-

dures, refer to Group 8A, Battery/Starting/Charging

Systems Diagnostics.

STARTING SYSTEM

The starting system has:

² Ignition switch

² Starter relay

² Neutral starting and back-up switch with auto-

matic transmissions

² Clutch pedal mounted starter interlock switch

with manual transmissions

² Wiring harness

² Battery

² Starter motor with an integral solenoid

BOSCH STARTERS

²A Bosch permanent magnet starter motor is avail-

able on 2.2L, 2.5L and 3.0L engines on all vehicles.

A planetary gear train transmits power between

starter motor and pinion shaft. The fields consist of

six permanent magnets.

NIPPONDENSO STARTERS

² A Nippondenso reduction gear-field coil starter

motor is available on 3.0L, 3.3L and 3.8L engines.

SUPPLY CIRCUIT AND CONTROL CIRCUIT

Both starter systems consist of two separate cir-

cuits:

² A high amperage supply to feed the starter motor.

² A low amperage circuit to control the starter sole-

noid. For additional information on starter motor supply

and control circuits, refer to Group 8A, Battery/Start-

ing/Charging Systems Diagnostics.

STARTER MOTOR REPLACEMENT

BOSCH STARTERÐ2.2L/2.5L ENGINE

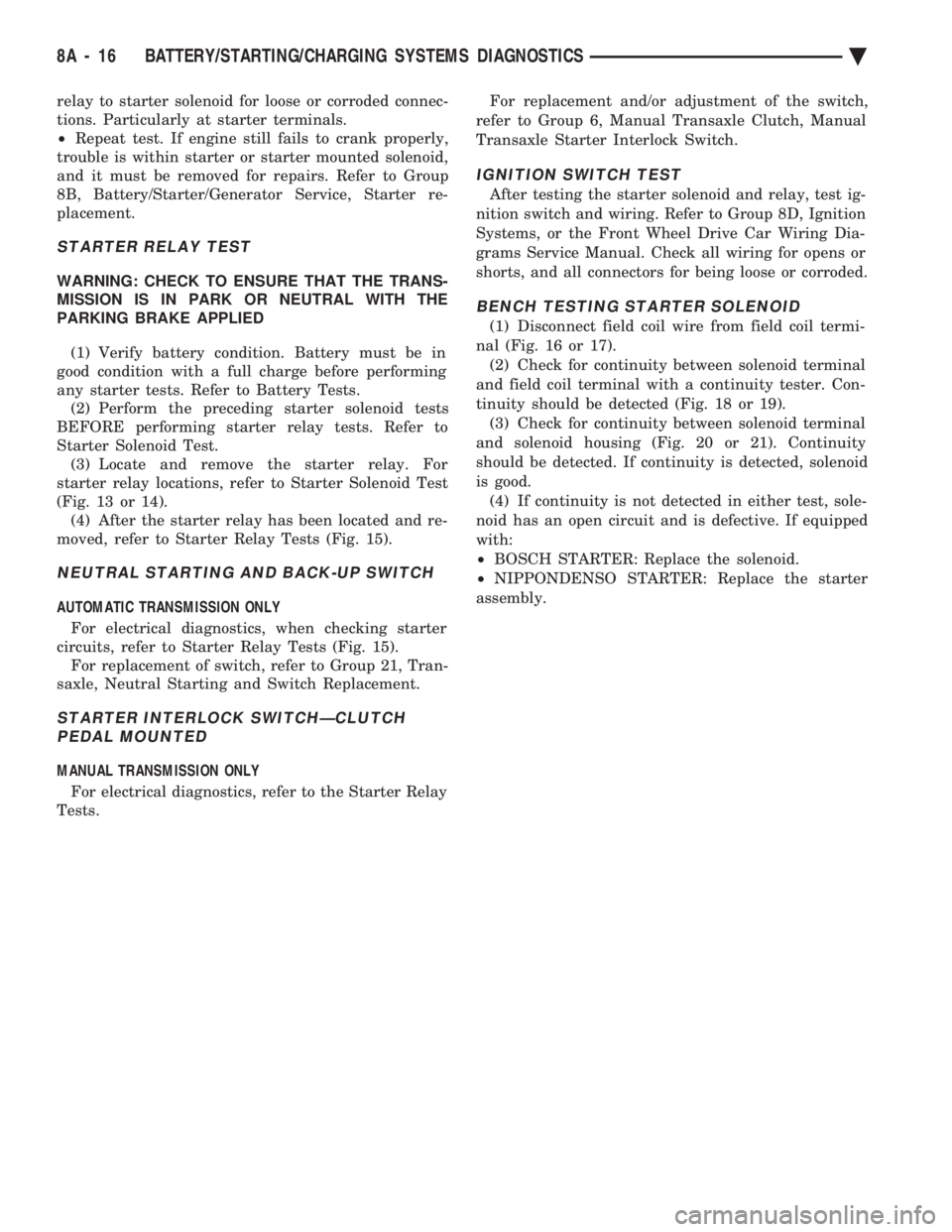

(1) Disconnect battery negative cable (Fig. 1).

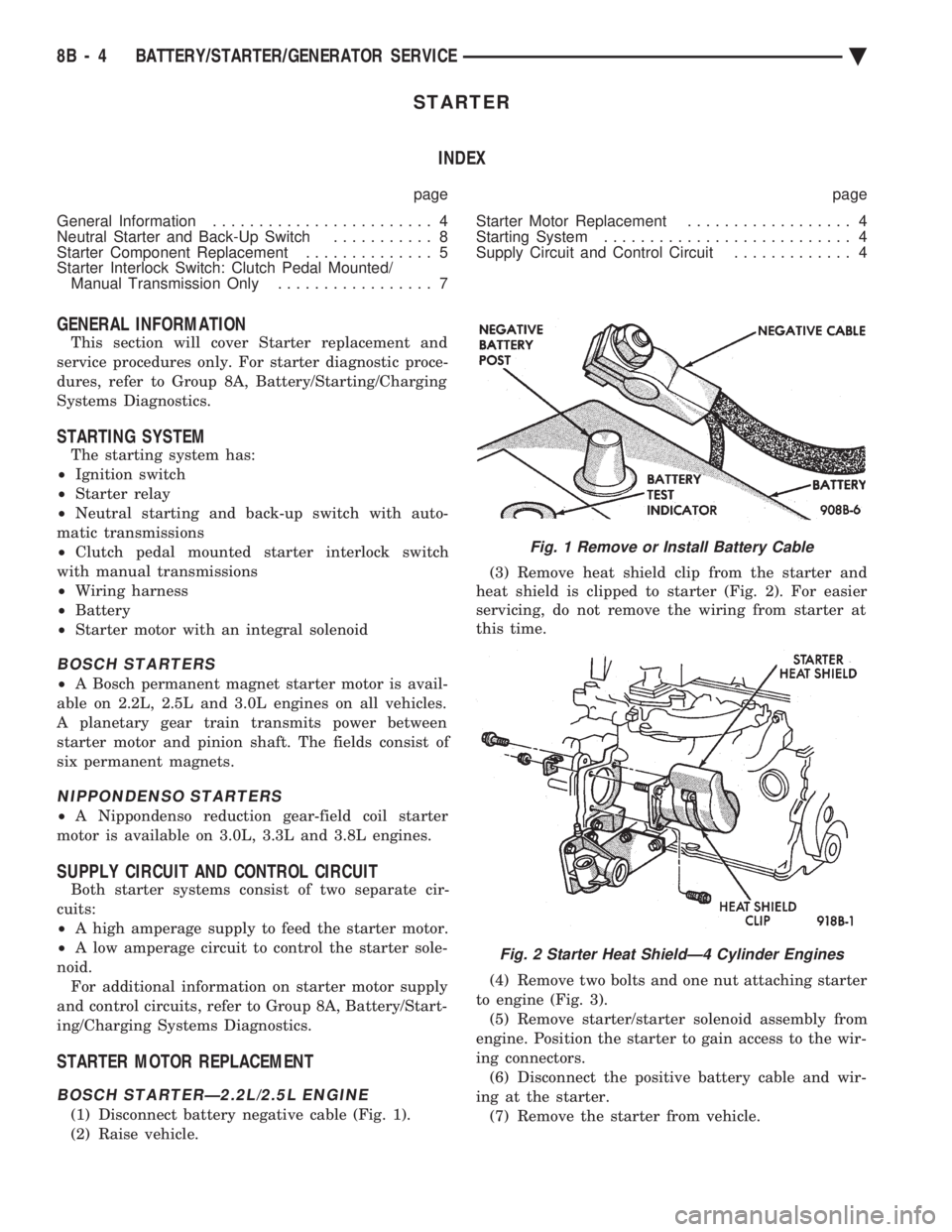

(2) Raise vehicle. (3) Remove heat shield clip from the starter and

heat shield is clipped to starter (Fig. 2). For easier

servicing, do not remove the wiring from starter at

this time.

(4) Remove two bolts and one nut attaching starter

to engine (Fig. 3). (5) Remove starter/starter solenoid assembly from

engine. Position the starter to gain access to the wir-

ing connectors. (6) Disconnect the positive battery cable and wir-

ing at the starter. (7) Remove the starter from vehicle.

Fig. 1 Remove or Install Battery Cable

Fig. 2 Starter Heat ShieldÐ4 Cylinder Engines

8B - 4 BATTERY/STARTER/GENERATOR SERVICE Ä