clutch CHEVROLET DYNASTY 1993 Workshop Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 1470 of 2438

Wiring Diagram

Name Sheet Number

Right Rear Motor ...........................58

Right Rear Switch ...........................58

Printed Circuit Board ....................... .74, 75

Printed Circuit Board Connectors ...................73

Radiator Fan Fuse ......................... .45, 50

Radio Speakers-Door and Rear ....................66

Radio-Stereo ................................65

Name Brand Speaker Relay .....................65

Rear Lighting ....................... .69, 70, 71, 72

Back-Up Lamps .................... .69, 70, 71, 72

Center High Mounted Stop Lamps ..............70, 72

Courtesy Lamps ............................72

License Lamps ......................... .70, 72

Side Marker Lamps ................. .69, 70, 71, 72

Tail, Stop and Turn Signal Lamps .........69, 70, 71, 72

Relay Module ...............................77

Relays ABS System Relay ..........................28

A/C Compressor Clutch Relay ...................50

ABS Yellow Light Relay .......................28

ABS Pump Motor Relay .......................27

Automatic Shut Down ....................2,14,22

Back-Up Lamp Relay .........................23

Engine Starter Relay ....................7,8,9,10

Fuel Pump ............................ .14, 22

Horn ...................................42

Fan Control Relay ....................... .45, 50

Name Brand Speaker .........................65

Safety Shut Down Relay .......................25

Time Delay ...............................44

Right Front Wheel Sensor .......................26

Right Instrument Panel Interface ...................89

Right Rear Wheel Sensor ........................26

Seat Belt Warning System and Courtesy Lamps .......43, 44

Halo Lamp ...............................44

Seat Belt Warning Chime ......................43

Seat Belt Switch ............................44

Time Delay Relay ...........................44

Seat-Power System, Left ........................60

Sensors ABS Wheel Sensors ..........................26

A/C Ambient Temperature Sensor .................41

Airbag ..................................35

Engine Coolant Temperature ..................15, 18

Heated Oxygen ......................... .17, 18

MAP ................................ .15, 20

Output Speed Sensor .........................24

Throttle Position ........................ .16, 20

Turbine Speed .............................24

Vehicle Speed Sensor ..................... .15, 18

Washer Low Fluid Sensor ......................53

Solenoids EVAP/Purge Solenoid ..................... .13, 19

Exhaust Gas Recirculation .................. .13, 20

Transmission EMCC Solenoid ....................8

Transmission Solenoid ........................25

Speakers, Radio ..............................66Wiring Diagram

Name Sheet Number

Splices Splice A0-1 ...........................1,2,4,6

Splice A0-2 ............................2,4,6

Splice A1 ..............................2,4,6

Splice A2 ..............................2,4,6

Splice A3 ..............................1,36

Splice A3-1 ............................1,4,6

Splice A4 ..............................2,3,5

Splice A4-1 ............................2,4,6

Splice A11 .............................1,4,6

Splice A14 .............................2,4,6

Splice A14-1 ..............................14

Splice A14-2 ..............................22

Splice A15 .............................1,3,5

Splice A15-1 ...........................1,3,5

Splice A16 .............................2,4,6

Splice A20 ...............................28

Splice A21 ...............................11

Splice A21-1 ..........................2,13,21

Splice A21-2 ........................... .13, 21

Splice A21-3 ..............................23

Splice A142-1 .............................14

Splice A142-2 ..........................4,6,14

Splice B47 ...............................28

Splice C7 ............................. .46, 48

Splice D1 ................................24

Splice D2 ................................24

Splice E2 .............. .31, 33, 37, 41, 46, 47, 65, 67

Splice E2-1 ............ .31, 33, 37, 41, 46, 47, 65, 67

Splice F20 .......................... .35, 41, 67

Splice F20-1 .........................7,8,9,23

Splice F30 .......................... .35, 42, 65

Splice F35 ............................ .61, 63

Splice G5 ............................. .35, 43

Splice G7 .......................... .15, 18, 30

Splice K4 ................................15

Splice K4-1 ........................... .15, 18

Splice K4-2 ........................... .19, 20

Splice K6 ............................. .16, 20

Splice K7-1 ........................... .15, 18

Splice K22 ...............................20

Splice K24 ...............................18

Splice L3 ............................. .31, 33

Splice L4 ............................. .31, 33

Splice L7-1 ........................... .32, 34

Splice L7-2 ........................... .31, 33

Splice L7-3 ...............................36

Splice L7-4 ........................... .69, 71

Splice L7-5 ........................... .31, 33

Splice L20 ..............................1,36

Splice L39 ............................ .31, 33

Splice L50 ...............................52

Splice L60 ............................ .31, 33

Splice L60-1 ..............................52

Splice L61 ............................ .32, 34

Splice L61-1 ..............................52

Splice M1-1 ...................... .39, 44, 55, 65

8W - 720 WIRING DIAGRAMS AP BODY D-P Ä

Page 1471 of 2438

Wiring Diagram

Name Sheet Number

Splice M1-3 ........................... .40, 55

Splice M2-1 ...............................39

Splice P33 ............................ .62, 64

Splice P34 ............................ .62, 64

Splice Q1 ................................58

Splice T13 ...............................24

Splice T16 ...............................25

Splice T41 ...............................23

Splice T41-1 ............................9,10

Splice X2 ................................42

Splice X2-1 ...............................42

Splice X13 ...............................66

Splice X15 ...............................66

Splice Z0 .................................3

Splice Z0-1 ...............................14

Splice Z0-2 ...............................21

Splice Z1 ......... .40, 44, 55, 57, 60, 61, 63, 68, 69, 71

Splice Z1-1 ...................... .38, 46, 47, 66

Splice Z1-2 ......................... .31, 33, 42

Splice Z1-3 ......................... .32, 34, 42

Splice Z1-4 ............7,27,28,29,32,34,42,45,49

Splice Z1-5 .................... .55, 57, 60, 61, 63

Splice Z1-6 ...............................38

Splice Z1-7 ........................... .70, 72

Splice Z1-8 ........................... .67, 70

Splice Z1-10 ........................... .32, 34

Splice Z1-11 ........................ .32, 34, 42

Splice Z1-12 .............. .55, 57, 60, 61, 63, 69, 71

Splice Z1-14 ........................... .27, 28

Splice Z2 ................................38

Splice Z12 ............................ .14, 21

Splice Z13 ...............................25

Splice Z14 ...............................25

Steering Column Connectors ......................81

Steering Multi-Function Switch Column Connectors .......82

Stereo Radio ................................65

Stop Lamp System ............................29

Stop Lamp Switch ............................29

Switches A/C Cycling Clutch Switch ......................48

A/C Switch ...............................47

A/C Heater Blower Switch ......................47

A/C High Pressure Switch ......................48

A/C Low Pressure Switch ......................48

Back-Up Lamp Switch .....................7,8,9

Blower Switch-A/C Heater ......................47

Brake Warning Lamp Switch ....................11

Clutch Pedal Position Switch ...................7,9

Defrost Switch .............................47

Door Lock Switch (2-dr) ................... .61, 62

Door Lock Switch (4-dr) ................... .63, 64

Door Jamb Switch ....................... .39, 40

Dual Mirror Control Switch .....................55

Engine Oil Pressure Switch .....................12

Fog Lamp Switch ........................ .31, 33

Glove Box Lamp Switch .......................39

Hazard Flasher Switch ........................52Wiring Diagram

Name Sheet Number

Headlamp Switch .........................1,36

Heated Rear Window Switch ....................67

Heater Bi-level Control Switch ...................46

Horn Switch ..............................42

Ignition Switch ...........................2,11

Liftgate Latch Switch .........................40

Mercury Switch ............................12

Park Brake Switch ...........................11

Park/Neutral Position Switch .....................8

Park/Neutral Start Switch ......................23

Power Mirrors Switch ........................55

Power Seat Switch ..........................60

Power Steering Pressure Switch ..................19

Power Window Switch (2 Dr) ...................57

Power Window Switch (4 Dr) ...................58

Seat Belt Warning Switch ......................44

Speed Control Switch ........................29

Stop Lamp Switch ..........................29

Transmission Range Switch .....................25

Transmission Solenoids and Pressure Switch ..........25

Turn Signal Flasher Switch .....................52

Vehicle Speed Control Switch ...................29

Wiper Park Switch ..........................54

Wiper Switch ..............................53

Temperature Sending Unit .......................18

Time Delay Relay .............................44

Throttle Position (Sensor) 2.2L ....................16

Throttle Position (Sensor) 2.5L ....................16

THrottle Position (Sensor) 3.0L ....................20

Transmission Control Module Connector ..............91

Transmission Control System ................23, 24, 25

Back-up Lamp Relay .........................23

Output Speed Sensor .........................24

Park/Neutral Switch ..........................23

Safety Shut Down Relay .......................25

Transmission Control Module ...............23, 24, 25

Transmission Range Switch .....................25

Transmission Solenoids and Pressure Switch ..........25

Turbine Speed Sensor ........................24

Transmission EMCC Solenoid ......................8

Transmission Solenoid Connector ..................92

Transmission Solenoids and Pressure Switch ...........25

Turn and Hazard Flasher System .................51, 52

Hazard Flasher ......................... .51, 52

Switch ..................................52

Turn Signal Flasher ..........................51

Turn Signal Lamps ..........31, 32, 33, 34, 69, 70, 71, 72

Underhood Lamp .............................12

Vehicle Speed Control Servo ......................29

Vehicle Speed Control and Stop Lamp System ..........29

Clockspring ................................29

Powertrain Control Module .......................29

Stop Lamp Switch with Vehicle Speed Control ..........29

Stop Lamp without Vehicle Speed Control .............29

Vehicle Speed Control Servo ......................29

Vehicle Speed Control Switch .....................29

Wiper System ........................... .53, 54

Ä WIRING DIAGRAMS AP BODY D-P 8W - 721

Page 1579 of 2438

² Drive shaft distress: See Driveshafts in Suspension,

Group 2.

² Any front end structural damage (after repair).

² Insulator replacement.

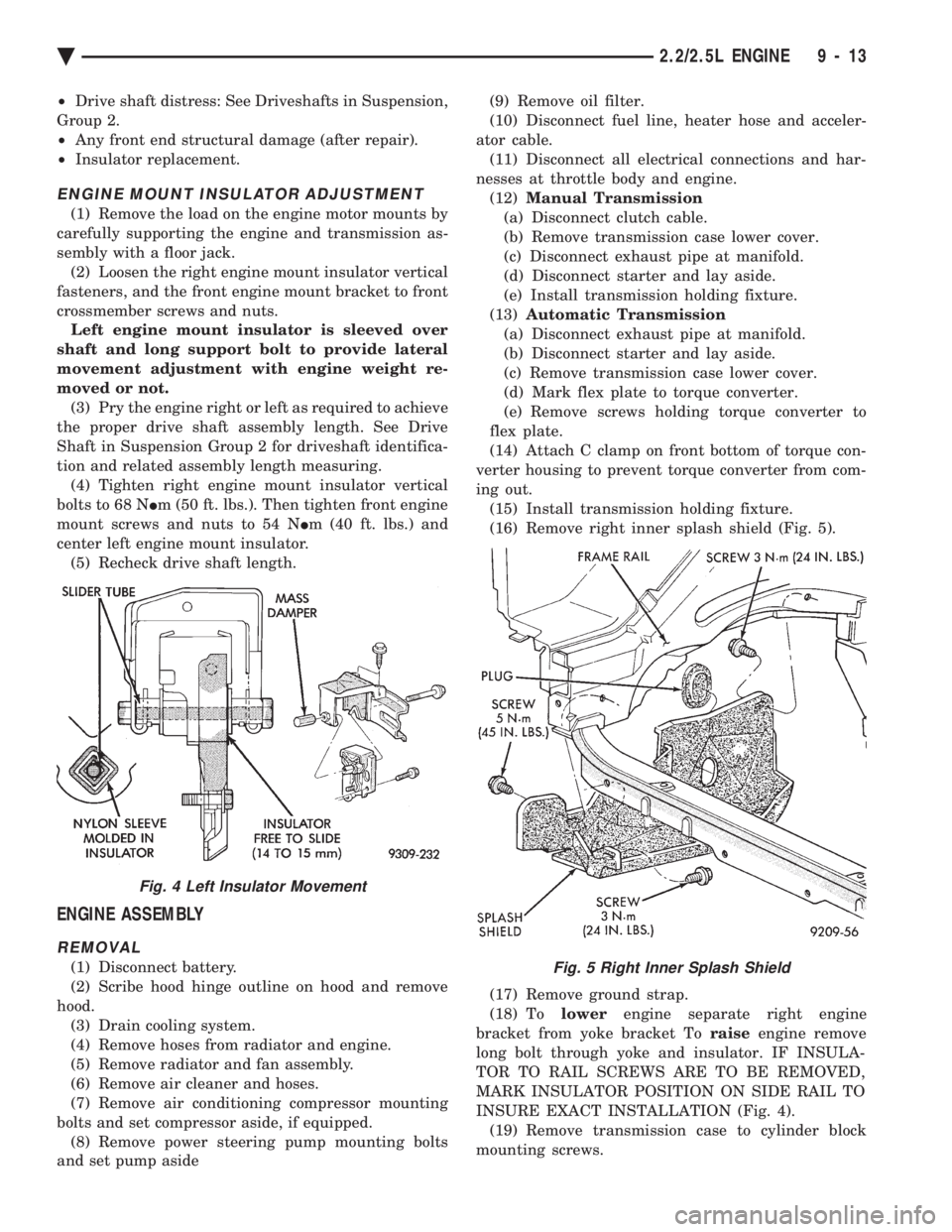

ENGINE MOUNT INSULATOR ADJUSTMENT

(1) Remove the load on the engine motor mounts by

carefully supporting the engine and transmission as-

sembly with a floor jack. (2) Loosen the right engine mount insulator vertical

fasteners, and the front engine mount bracket to front

crossmember screws and nuts. Left engine mount insulator is sleeved over

shaft and long support bolt to provide lateral

movement adjustment with engine weight re-

moved or not. (3) Pry the engine right or left as required to achieve

the proper drive shaft assembly length. See Drive

Shaft in Suspension Group 2 for driveshaft identifica-

tion and related assembly length measuring. (4) Tighten right engine mount insulator vertical

bolts to 68 N Im (50 ft. lbs.). Then tighten front engine

mount screws and nuts to 54 N Im (40 ft. lbs.) and

center left engine mount insulator. (5) Recheck drive shaft length.

ENGINE ASSEMBLY

REMOVAL

(1) Disconnect battery.

(2) Scribe hood hinge outline on hood and remove

hood. (3) Drain cooling system.

(4) Remove hoses from radiator and engine.

(5) Remove radiator and fan assembly.

(6) Remove air cleaner and hoses.

(7) Remove air conditioning compressor mounting

bolts and set compressor aside, if equipped. (8) Remove power steering pump mounting bolts

and set pump aside (9) Remove oil filter.

(10) Disconnect fuel line, heater hose and acceler-

ator cable. (11) Disconnect all electrical connections and har-

nesses at throttle body and engine. (12) Manual Transmission

(a) Disconnect clutch cable.

(b) Remove transmission case lower cover.

(c) Disconnect exhaust pipe at manifold.

(d) Disconnect starter and lay aside.

(e) Install transmission holding fixture.

(13) Automatic Transmission

(a) Disconnect exhaust pipe at manifold.

(b) Disconnect starter and lay aside.

(c) Remove transmission case lower cover.

(d) Mark flex plate to torque converter.

(e) Remove screws holding torque converter to

flex plate.

(14) Attach C clamp on front bottom of torque con-

verter housing to prevent torque converter from com-

ing out. (15) Install transmission holding fixture.

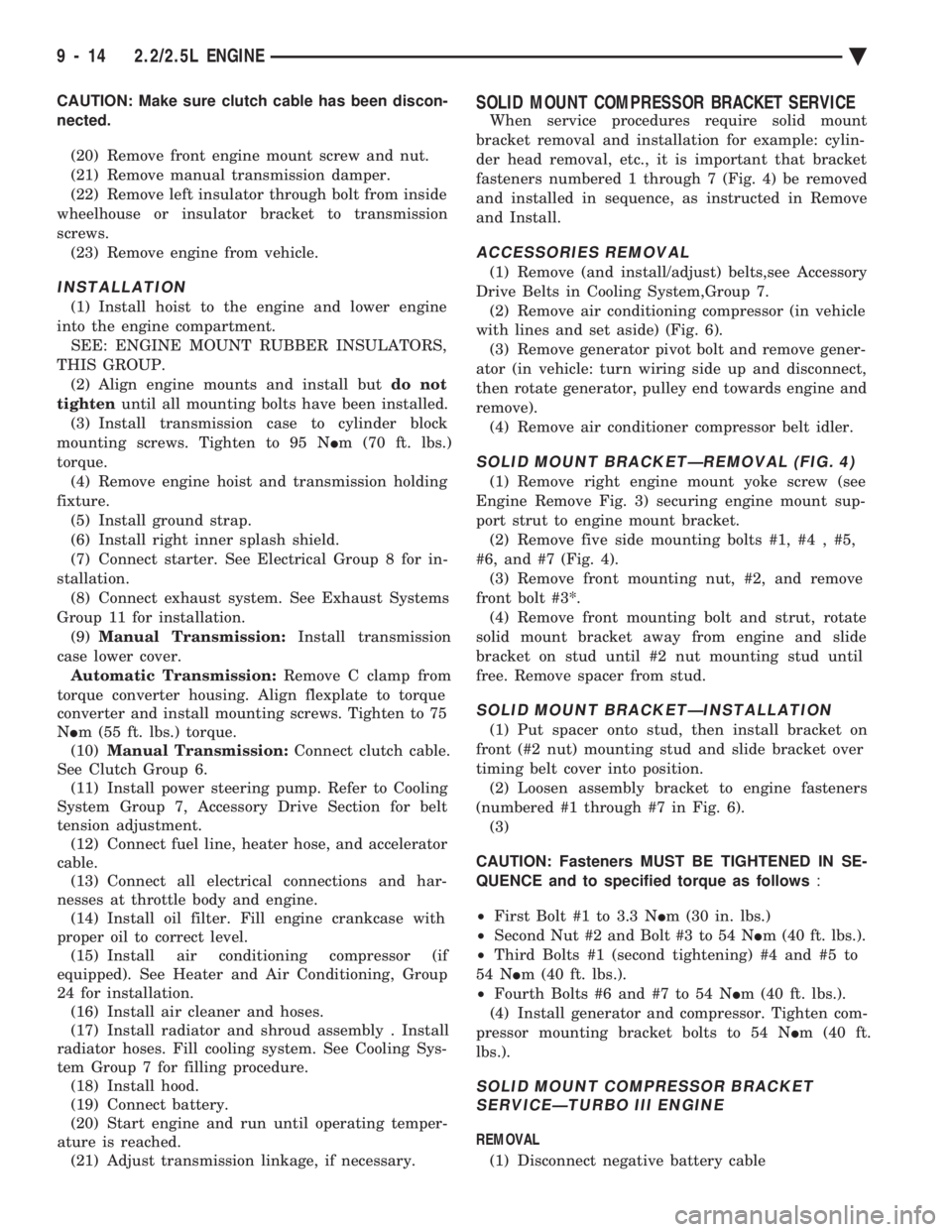

(16) Remove right inner splash shield (Fig. 5).

(17) Remove ground strap.

(18) To lowerengine separate right engine

bracket from yoke bracket To raiseengine remove

long bolt through yoke and insulator. IF INSULA-

TOR TO RAIL SCREWS ARE TO BE REMOVED,

MARK INSULATOR POSITION ON SIDE RAIL TO

INSURE EXACT INSTALLATION (Fig. 4). (19) Remove transmission case to cylinder block

mounting screws.Fig. 5 Right Inner Splash Shield

Fig. 4 Left Insulator Movement

Ä 2.2/2.5L ENGINE 9 - 13

Page 1580 of 2438

CAUTION: Make sure clutch cable has been discon-

nected. (20) Remove front engine mount screw and nut.

(21) Remove manual transmission damper.

(22) Remove left insulator through bolt from inside

wheelhouse or insulator bracket to transmission

screws. (23) Remove engine from vehicle.

INSTALLATION

(1) Install hoist to the engine and lower engine

into the engine compartment. SEE: ENGINE MOUNT RUBBER INSULATORS,

THIS GROUP. (2) Align engine mounts and install but do not

tighten until all mounting bolts have been installed.

(3) Install transmission case to cylinder block

mounting screws. Tighten to 95 N Im (70 ft. lbs.)

torque. (4) Remove engine hoist and transmission holding

fixture. (5) Install ground strap.

(6) Install right inner splash shield.

(7) Connect starter. See Electrical Group 8 for in-

stallation. (8) Connect exhaust system. See Exhaust Systems

Group 11 for installation. (9) Manual Transmission: Install transmission

case lower cover. Automatic Transmission: Remove C clamp from

torque converter housing. Align flexplate to torque

converter and install mounting screws. Tighten to 75

N Im (55 ft. lbs.) torque.

(10) Manual Transmission: Connect clutch cable.

See Clutch Group 6. (11) Install power steering pump. Refer to Cooling

System Group 7, Accessory Drive Section for belt

tension adjustment. (12) Connect fuel line, heater hose, and accelerator

cable. (13) Connect all electrical connections and har-

nesses at throttle body and engine. (14) Install oil filter. Fill engine crankcase with

proper oil to correct level. (15) Install air conditioning compressor (if

equipped). See Heater and Air Conditioning, Group

24 for installation. (16) Install air cleaner and hoses.

(17) Install radiator and shroud assembly . Install

radiator hoses. Fill cooling system. See Cooling Sys-

tem Group 7 for filling procedure. (18) Install hood.

(19) Connect battery.

(20) Start engine and run until operating temper-

ature is reached. (21) Adjust transmission linkage, if necessary.

SOLID MOUNT COMPRESSOR BRACKET SERVICE

When service procedures require solid mount

bracket removal and installation for example: cylin-

der head removal, etc., it is important that bracket

fasteners numbered 1 through 7 (Fig. 4) be removed

and installed in sequence, as instructed in Remove

and Install.

ACCESSORIES REMOVAL

(1) Remove (and install/adjust) belts,see Accessory

Drive Belts in Cooling System,Group 7. (2) Remove air conditioning compressor (in vehicle

with lines and set aside) (Fig. 6). (3) Remove generator pivot bolt and remove gener-

ator (in vehicle: turn wiring side up and disconnect,

then rotate generator, pulley end towards engine and

remove). (4) Remove air conditioner compressor belt idler.

SOLID MOUNT BRACKETÐREMOVAL (FIG. 4)

(1) Remove right engine mount yoke screw (see

Engine Remove Fig. 3) securing engine mount sup-

port strut to engine mount bracket. (2) Remove five side mounting bolts #1, #4 , #5,

#6, and #7 (Fig. 4). (3) Remove front mounting nut, #2, and remove

front bolt #3*. (4) Remove front mounting bolt and strut, rotate

solid mount bracket away from engine and slide

bracket on stud until #2 nut mounting stud until

free. Remove spacer from stud.

SOLID MOUNT BRACKETÐINSTALLATION

(1) Put spacer onto stud, then install bracket on

front (#2 nut) mounting stud and slide bracket over

timing belt cover into position. (2) Loosen assembly bracket to engine fasteners

(numbered #1 through #7 in Fig. 6). (3)

CAUTION: Fasteners MUST BE TIGHTENED IN SE-

QUENCE and to specified torque as follows :

² First Bolt #1 to 3.3 N Im (30 in. lbs.)

² Second Nut #2 and Bolt #3 to 54 N Im (40 ft. lbs.).

² Third Bolts #1 (second tightening) #4 and #5 to

54 N Im (40 ft. lbs.).

² Fourth Bolts #6 and #7 to 54 N Im (40 ft. lbs.).

(4) Install generator and compressor. Tighten com-

pressor mounting bracket bolts to 54 N Im (40 ft.

lbs.).

SOLID MOUNT COMPRESSOR BRACKET SERVICEÐTURBO III ENGINE

REMOVAL

(1) Disconnect negative battery cable

9 - 14 2.2/2.5L ENGINE Ä

Page 1764 of 2438

2.2L/2.5L SINGLE POINT FUEL INJECTIONÐSYSTEM OPERATION INDEX

page page

Air Conditioning (A/C) Clutch RelayÐPCM Output.28

Air Conditioning Switch SenseÐPCM Input ..... 26

Auto Shutdown (ASD) Relay and Fuel Pump RelayÐPCM Output ..................... 29

Battery VoltageÐPCM Input ................ 26

Brake SwitchÐPCM Input .................. 26

EVAP Canister Purge SolenoidÐPCM Output . . . 29

CCD Bus .............................. 25

Coolant Temperature SensorÐPCM Input ...... 26

Data Link ConnectorÐPCM Output ........... 30

Distributor (Hall Effect) Pick-UpÐPCM Input .... 26

Electric Electronic Gas RecirculationÐPCM Output.30

Fuel InjectorÐPCM Output ................. 31

Fuel Pressure Regulator ................... 33

General Information ....................... 24

Generator FieldÐPCM Output ............... 31

Heated Oxygen Sensor (O

2Sensor)ÐPCM Input . 27

Idle Air Control MotorÐPCM Output .......... 29 Ignition CoilÐPCM Output

.................. 31

Malfunction Indicator Lamp (Check Engine)ÐPCM Output ............................... 30

Manifold Absolute Pressure (MAP) SensorÐPCM Input ................................ 27

Modes of Operation ....................... 32

Part Throttle Unlock SolenoidÐPCM Output .... 31

Powertrain Control Module ................. 25

Radiator Fan RelayÐPCM Output ............ 31

Speed Control SolenoidsÐPCM Output ........ 31

Speed ControlÐPCM Input ................. 27

System Diagnosis ........................ 25

TachometerÐPCM Output .................. 32

Throttle Body ............................ 33

Throttle Position Sensor (TPS)ÐPCM Input ..... 28

Transaxle Park/Neutral SwitchÐPCM Input ..... 28

Vehicle Speed SensorÐPCM Input ........... 28

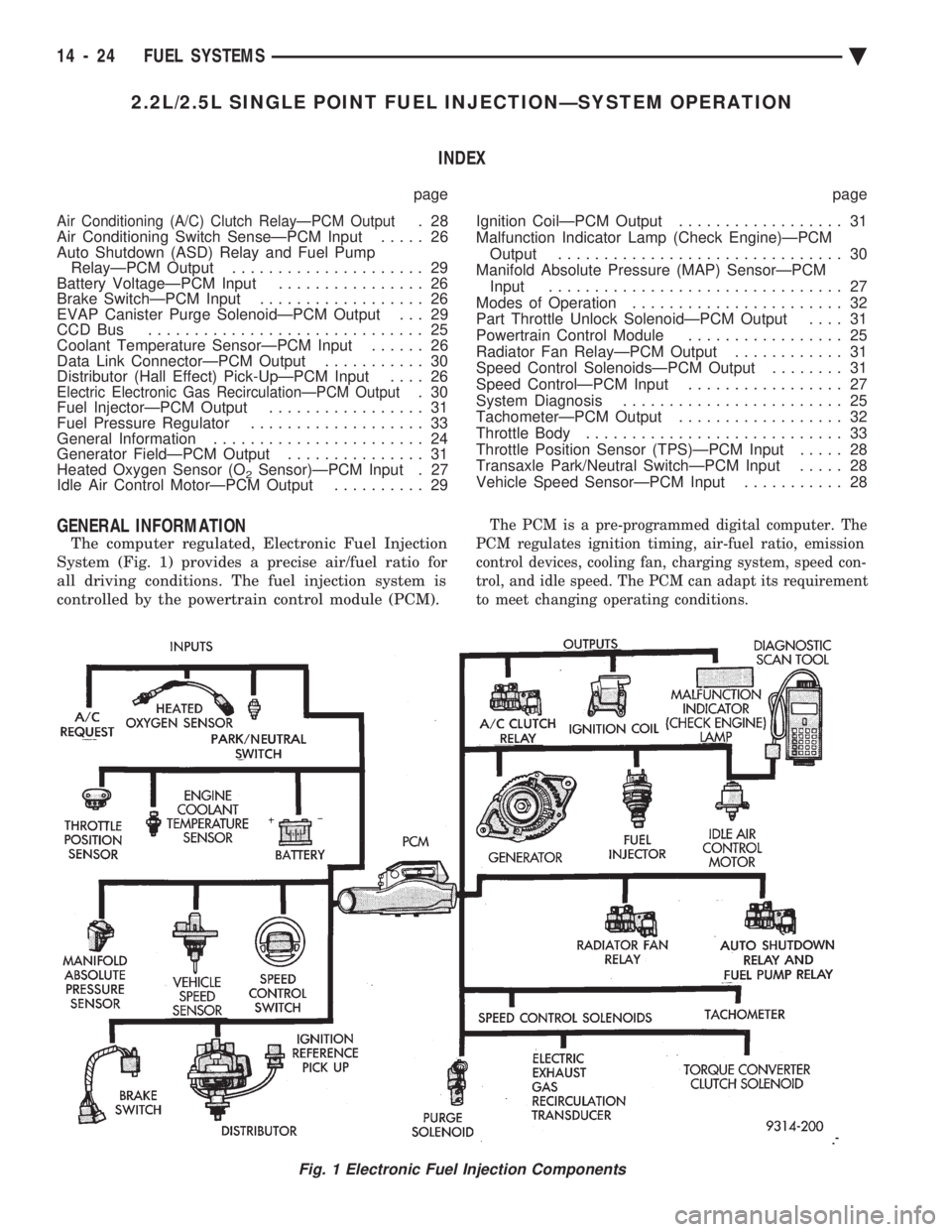

GENERAL INFORMATION

The computer regulated, Electronic Fuel Injection

System (Fig. 1) provides a precise air/fuel ratio for

all driving conditions. The fuel injection system is

controlled by the powertrain control module (PCM).

The PCM is a pre-programmed digital computer. The

PCM regulates ignition timing, air-fuel ratio, emission

control devices, cooling fan, charging system, speed con-

trol, and idle speed. The PCM can adapt its requirement

to meet changing operating conditions.

Fig. 1 Electronic Fuel Injection Components

14 - 24 FUEL SYSTEMS Ä

Page 1765 of 2438

Various sensors provide the inputs necessary for

the PCM to correctly regulate fuel flow at the fuel

injector. These include the manifold absolute pres-

sure, throttle position, oxygen sensor, coolant tem-

perature, and vehicle speed sensors. In addition to

the sensors, various switches and relays provide im-

portant information and system control. The inputs

include the park/neutral switch and air conditioning

clutch switch. The outputs include the auto shutdown

relay and fuel pump relay. All inputs to the PCM are converted into signals.

Based on these inputs the PCM adjusts air-fuel ratio,

ignition timing and other controlled outputs. The

PCM adjusts the air-fuel ratio by changing the injec-

tor pulse width. Injector pulse width is the period of

time the injector is energized.

SYSTEM DIAGNOSIS

The PCM tests many of its own input and output

circuits. If a fault is found in a major system, the in-

formation is stored in memory. Technicians can dis-

play fault information through the instrument panel

Malfunction Indicator lamp (instrument panel Check

Engine lamp) or by connecting the DRBII scan tool.

For diagnostic trouble code information, refer to On

Board Diagnostics in 2.2L/2.5L Single Point Fuel In-

jectionÐGeneral Diagnosis section of this group.

CCD BUS

Various modules exchange information through a

communications port called the CCD Bus. The pow-

ertrain control module (PCM) transmits vehicle load

data on the CCD Bus.

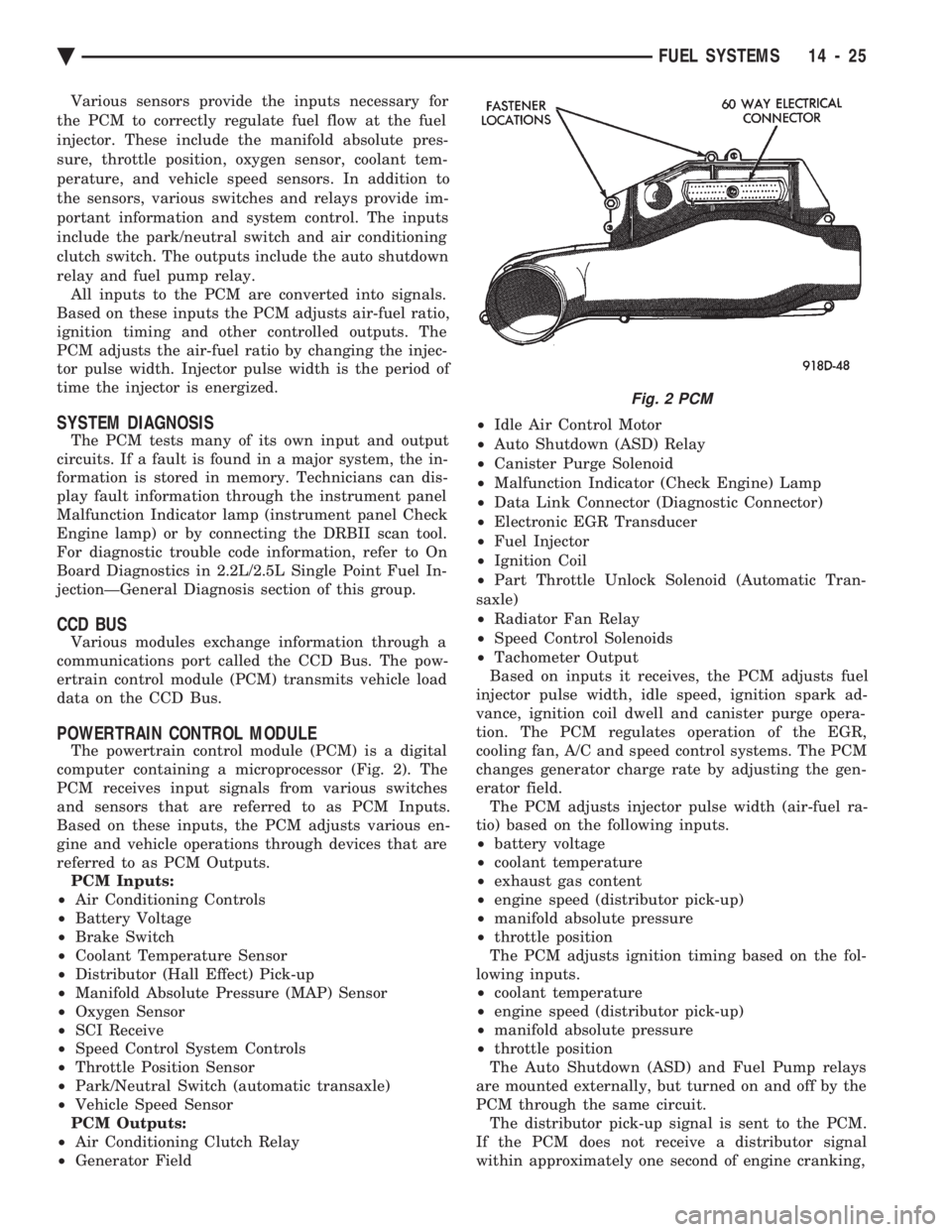

POWERTRAIN CONTROL MODULE

The powertrain control module (PCM) is a digital

computer containing a microprocessor (Fig. 2). The

PCM receives input signals from various switches

and sensors that are referred to as PCM Inputs.

Based on these inputs, the PCM adjusts various en-

gine and vehicle operations through devices that are

referred to as PCM Outputs. PCM Inputs:

² Air Conditioning Controls

² Battery Voltage

² Brake Switch

² Coolant Temperature Sensor

² Distributor (Hall Effect) Pick-up

² Manifold Absolute Pressure (MAP) Sensor

² Oxygen Sensor

² SCI Receive

² Speed Control System Controls

² Throttle Position Sensor

² Park/Neutral Switch (automatic transaxle)

² Vehicle Speed Sensor

PCM Outputs:

² Air Conditioning Clutch Relay

² Generator Field ²

Idle Air Control Motor

² Auto Shutdown (ASD) Relay

² Canister Purge Solenoid

² Malfunction Indicator (Check Engine) Lamp

² Data Link Connector (Diagnostic Connector)

² Electronic EGR Transducer

² Fuel Injector

² Ignition Coil

² Part Throttle Unlock Solenoid (Automatic Tran-

saxle)

² Radiator Fan Relay

² Speed Control Solenoids

² Tachometer Output

Based on inputs it receives, the PCM adjusts fuel

injector pulse width, idle speed, ignition spark ad-

vance, ignition coil dwell and canister purge opera-

tion. The PCM regulates operation of the EGR,

cooling fan, A/C and speed control systems. The PCM

changes generator charge rate by adjusting the gen-

erator field. The PCM adjusts injector pulse width (air-fuel ra-

tio) based on the following inputs.

² battery voltage

² coolant temperature

² exhaust gas content

² engine speed (distributor pick-up)

² manifold absolute pressure

² throttle position

The PCM adjusts ignition timing based on the fol-

lowing inputs.

² coolant temperature

² engine speed (distributor pick-up)

² manifold absolute pressure

² throttle position

The Auto Shutdown (ASD) and Fuel Pump relays

are mounted externally, but turned on and off by the

PCM through the same circuit. The distributor pick-up signal is sent to the PCM.

If the PCM does not receive a distributor signal

within approximately one second of engine cranking,

Fig. 2 PCM

Ä FUEL SYSTEMS 14 - 25

Page 1766 of 2438

it de-activates the ASD relay and fuel pump relay.

When these relays are deactivated, power is shut off

from the fuel injector, fuel pump, ignition coil, and

oxygen sensor heater element. The PCM contains a voltage converter that

changes battery voltage to a regulated 8.0 volts to

power the distributor pick-up and vehicle speed sen-

sor. The PCM also provides a 5.0 volts supply for the

coolant temperature sensor, manifold absolute pres-

sure sensor and throttle position sensor.

AIR CONDITIONING SWITCH SENSEÐPCM INPUT

ALL VEHICLES EXCEPT AC-BODY

When the air conditioning or defrost switch is put

in the ON position and the low pressure and high

pressure switches are closed, the PCM receives an in-

put indicating that the air conditioning has been se-

lected. After receiving this input, the PCM activates

the A/C compressor clutch by grounding the A/C

clutch relay. The PCM also adjusts idle speed to a

scheduled RPM to compensate for increased engine

load.

AC-BODY VEHICLES

When the air conditioning or defrost switch is put

in the ON position and the low pressure switch, high

pressure switch and electronic cycling switch close,

the PCM receives an air conditioning select input.

After receiving this input, the PCM activates the

A/C compressor clutch by grounding the A/C com-

pressor clutch relay. The PCM also adjusts idle speed

to a scheduled RPM to compensate for increased en-

gine load.

BATTERY VOLTAGEÐPCM INPUT

The PCM monitors the battery voltage input to de-

termine fuel injector pulse width and generator field

control. If battery voltage is low, the PCM increases

injector pulse width.

BRAKE SWITCHÐPCM INPUT

When the brake switch is activated, the PCM re-

ceives an input indicating that the brakes are being

applied. After receiving the input, the PCM vents the

speed control servo. Venting the servo turns the

speed control system off.

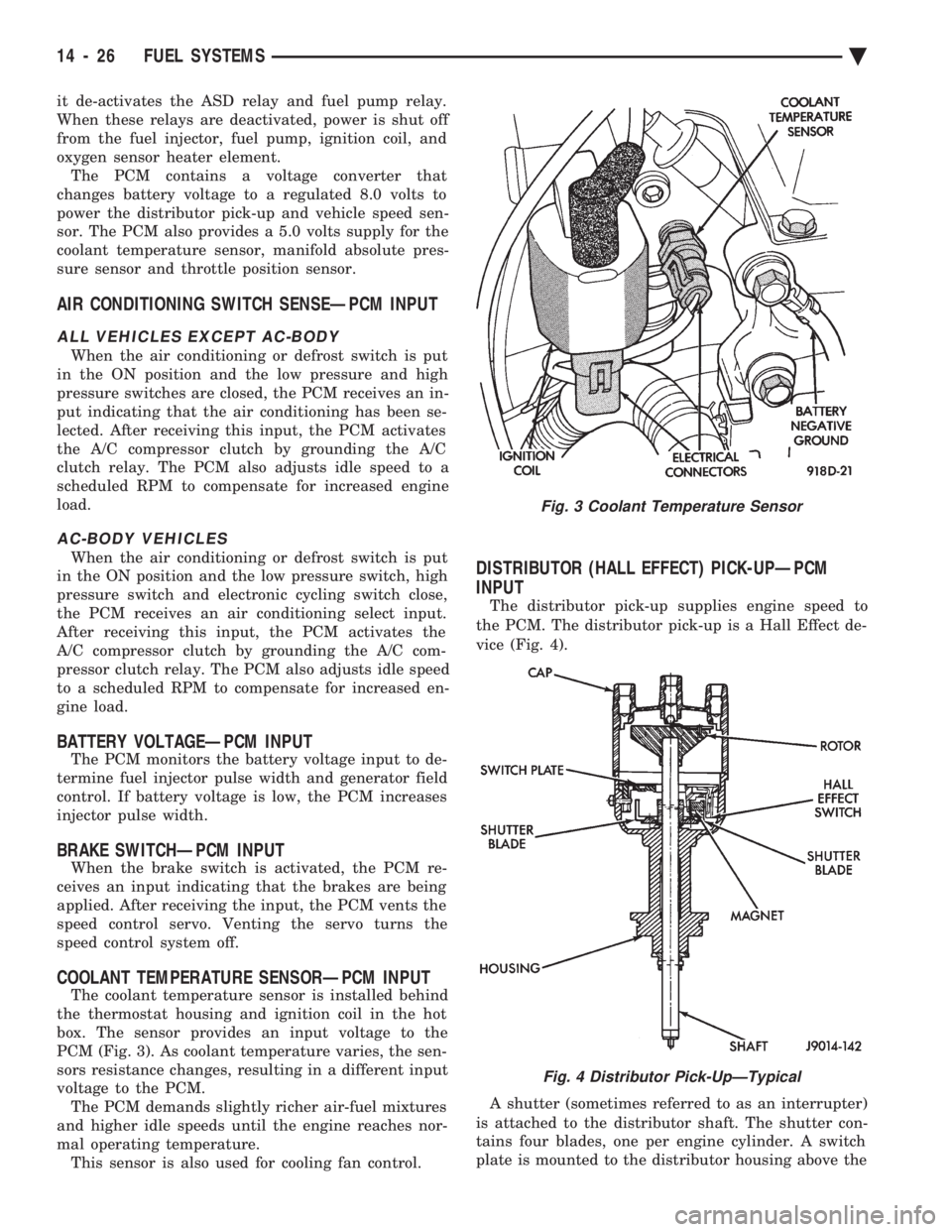

COOLANT TEMPERATURE SENSORÐPCM INPUT

The coolant temperature sensor is installed behind

the thermostat housing and ignition coil in the hot

box. The sensor provides an input voltage to the

PCM (Fig. 3). As coolant temperature varies, the sen-

sors resistance changes, resulting in a different input

voltage to the PCM. The PCM demands slightly richer air-fuel mixtures

and higher idle speeds until the engine reaches nor-

mal operating temperature. This sensor is also used for cooling fan control.

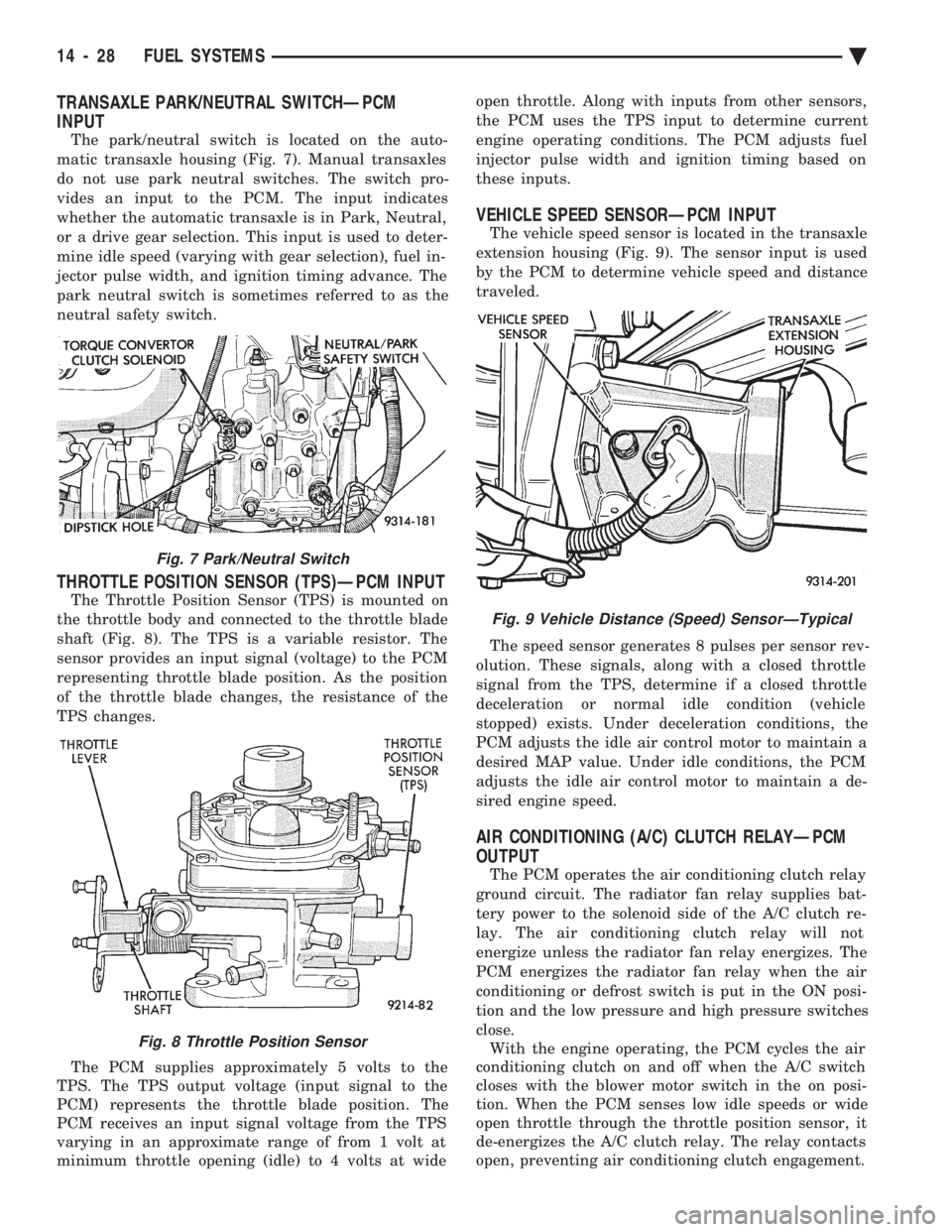

DISTRIBUTOR (HALL EFFECT) PICK-UPÐPCM

INPUT

The distributor pick-up supplies engine speed to

the PCM. The distributor pick-up is a Hall Effect de-

vice (Fig. 4).

A shutter (sometimes referred to as an interrupter)

is attached to the distributor shaft. The shutter con-

tains four blades, one per engine cylinder. A switch

plate is mounted to the distributor housing above the

Fig. 3 Coolant Temperature Sensor

Fig. 4 Distributor Pick-UpÐTypical

14 - 26 FUEL SYSTEMS Ä

Page 1768 of 2438

TRANSAXLE PARK/NEUTRAL SWITCHÐPCM

INPUT

The park/neutral switch is located on the auto-

matic transaxle housing (Fig. 7). Manual transaxles

do not use park neutral switches. The switch pro-

vides an input to the PCM. The input indicates

whether the automatic transaxle is in Park, Neutral,

or a drive gear selection. This input is used to deter-

mine idle speed (varying with gear selection), fuel in-

jector pulse width, and ignition timing advance. The

park neutral switch is sometimes referred to as the

neutral safety switch.

THROTTLE POSITION SENSOR (TPS)ÐPCM INPUT

The Throttle Position Sensor (TPS) is mounted on

the throttle body and connected to the throttle blade

shaft (Fig. 8). The TPS is a variable resistor. The

sensor provides an input signal (voltage) to the PCM

representing throttle blade position. As the position

of the throttle blade changes, the resistance of the

TPS changes.

The PCM supplies approximately 5 volts to the

TPS. The TPS output voltage (input signal to the

PCM) represents the throttle blade position. The

PCM receives an input signal voltage from the TPS

varying in an approximate range of from 1 volt at

minimum throttle opening (idle) to 4 volts at wide open throttle. Along with inputs from other sensors,

the PCM uses the TPS input to determine current

engine operating conditions. The PCM adjusts fuel

injector pulse width and ignition timing based on

these inputs.

VEHICLE SPEED SENSORÐPCM INPUT

The vehicle speed sensor is located in the transaxle

extension housing (Fig. 9). The sensor input is used

by the PCM to determine vehicle speed and distance

traveled.

The speed sensor generates 8 pulses per sensor rev-

olution. These signals, along with a closed throttle

signal from the TPS, determine if a closed throttle

deceleration or normal idle condition (vehicle

stopped) exists. Under deceleration conditions, the

PCM adjusts the idle air control motor to maintain a

desired MAP value. Under idle conditions, the PCM

adjusts the idle air control motor to maintain a de-

sired engine speed.

AIR CONDITIONING (A/C) CLUTCH RELAYÐPCM

OUTPUT

The PCM operates the air conditioning clutch relay

ground circuit. The radiator fan relay supplies bat-

tery power to the solenoid side of the A/C clutch re-

lay. The air conditioning clutch relay will not

energize unless the radiator fan relay energizes. The

PCM energizes the radiator fan relay when the air

conditioning or defrost switch is put in the ON posi-

tion and the low pressure and high pressure switches

close. With the engine operating, the PCM cycles the air

conditioning clutch on and off when the A/C switch

closes with the blower motor switch in the on posi-

tion. When the PCM senses low idle speeds or wide

open throttle through the throttle position sensor, it

de-energizes the A/C clutch relay. The relay contacts

open, preventing air conditioning clutch engagement.

Fig. 7 Park/Neutral Switch

Fig. 8 Throttle Position Sensor

Fig. 9 Vehicle Distance (Speed) SensorÐTypical

14 - 28 FUEL SYSTEMS Ä

Page 1769 of 2438

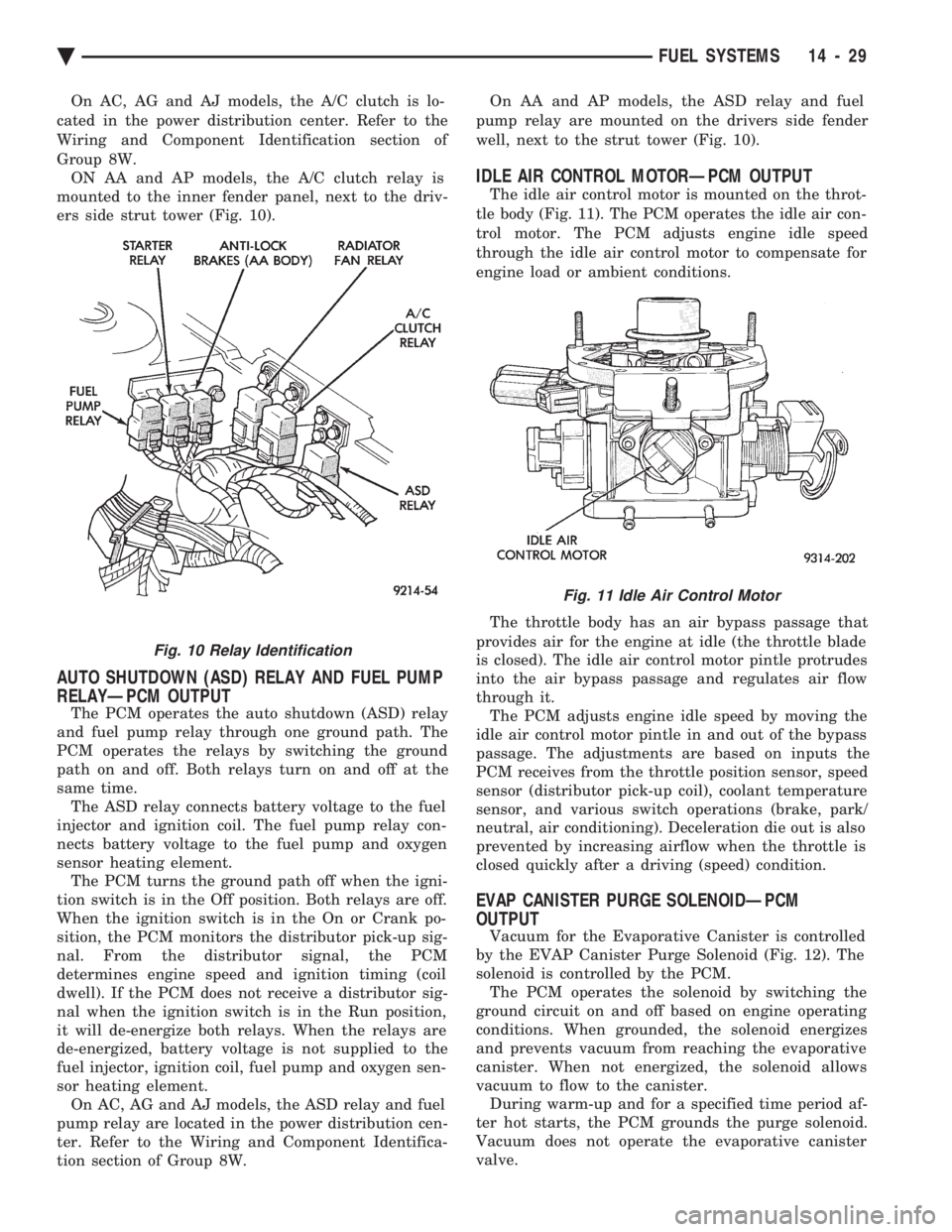

On AC, AG and AJ models, the A/C clutch is lo-

cated in the power distribution center. Refer to the

Wiring and Component Identification section of

Group 8W. ON AA and AP models, the A/C clutch relay is

mounted to the inner fender panel, next to the driv-

ers side strut tower (Fig. 10).

AUTO SHUTDOWN (ASD) RELAY AND FUEL PUMP

RELAYÐPCM OUTPUT

The PCM operates the auto shutdown (ASD) relay

and fuel pump relay through one ground path. The

PCM operates the relays by switching the ground

path on and off. Both relays turn on and off at the

same time. The ASD relay connects battery voltage to the fuel

injector and ignition coil. The fuel pump relay con-

nects battery voltage to the fuel pump and oxygen

sensor heating element. The PCM turns the ground path off when the igni-

tion switch is in the Off position. Both relays are off.

When the ignition switch is in the On or Crank po-

sition, the PCM monitors the distributor pick-up sig-

nal. From the distributor signal, the PCM

determines engine speed and ignition timing (coil

dwell). If the PCM does not receive a distributor sig-

nal when the ignition switch is in the Run position,

it will de-energize both relays. When the relays are

de-energized, battery voltage is not supplied to the

fuel injector, ignition coil, fuel pump and oxygen sen-

sor heating element. On AC, AG and AJ models, the ASD relay and fuel

pump relay are located in the power distribution cen-

ter. Refer to the Wiring and Component Identifica-

tion section of Group 8W. On AA and AP models, the ASD relay and fuel

pump relay are mounted on the drivers side fender

well, next to the strut tower (Fig. 10).

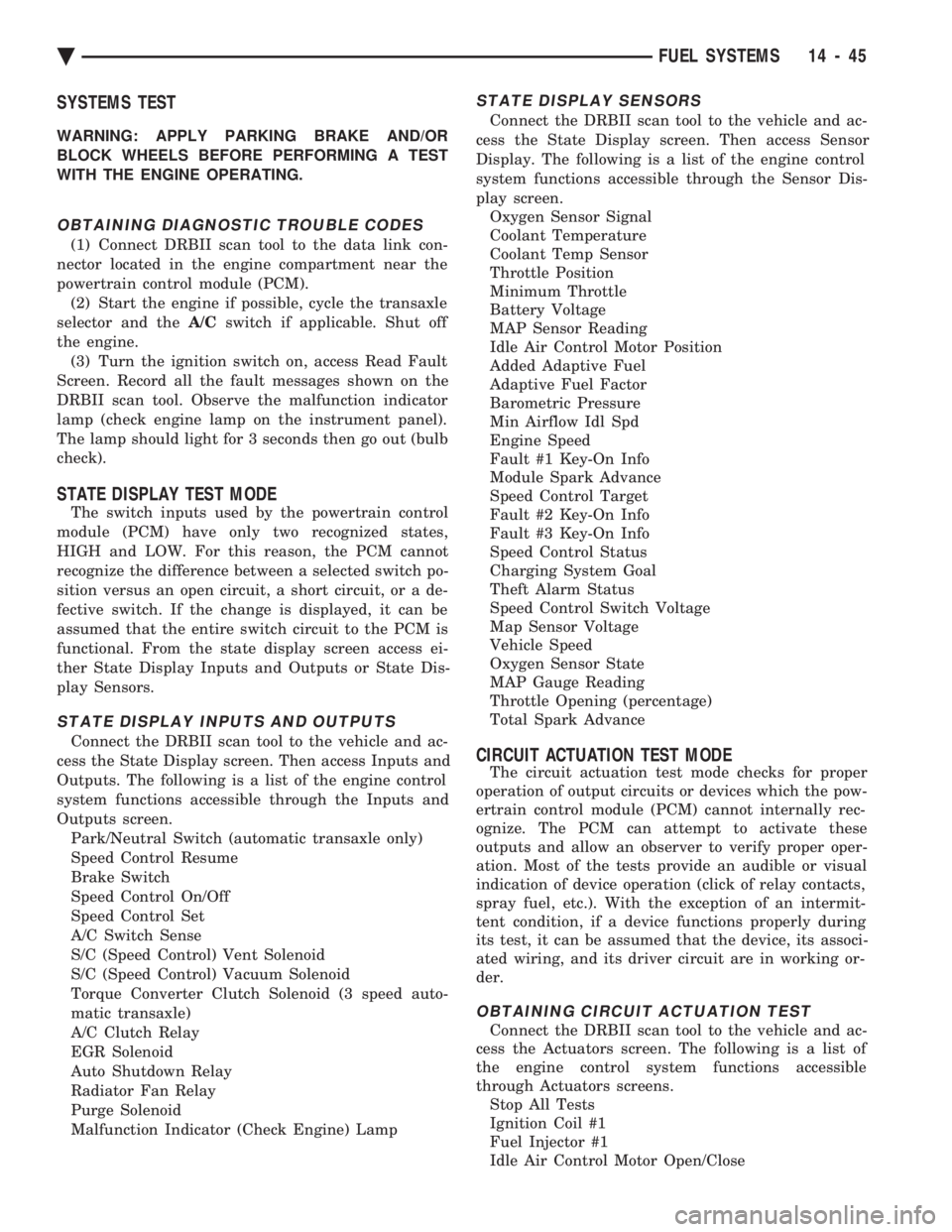

IDLE AIR CONTROL MOTORÐPCM OUTPUT

The idle air control motor is mounted on the throt-

tle body (Fig. 11). The PCM operates the idle air con-

trol motor. The PCM adjusts engine idle speed

through the idle air control motor to compensate for

engine load or ambient conditions.

The throttle body has an air bypass passage that

provides air for the engine at idle (the throttle blade

is closed). The idle air control motor pintle protrudes

into the air bypass passage and regulates air flow

through it. The PCM adjusts engine idle speed by moving the

idle air control motor pintle in and out of the bypass

passage. The adjustments are based on inputs the

PCM receives from the throttle position sensor, speed

sensor (distributor pick-up coil), coolant temperature

sensor, and various switch operations (brake, park/

neutral, air conditioning). Deceleration die out is also

prevented by increasing airflow when the throttle is

closed quickly after a driving (speed) condition.

EVAP CANISTER PURGE SOLENOIDÐPCM

OUTPUT

Vacuum for the Evaporative Canister is controlled

by the EVAP Canister Purge Solenoid (Fig. 12). The

solenoid is controlled by the PCM. The PCM operates the solenoid by switching the

ground circuit on and off based on engine operating

conditions. When grounded, the solenoid energizes

and prevents vacuum from reaching the evaporative

canister. When not energized, the solenoid allows

vacuum to flow to the canister. During warm-up and for a specified time period af-

ter hot starts, the PCM grounds the purge solenoid.

Vacuum does not operate the evaporative canister

valve.

Fig. 10 Relay Identification

Fig. 11 Idle Air Control Motor

Ä FUEL SYSTEMS 14 - 29

Page 1785 of 2438

SYSTEMS TEST

WARNING: APPLY PARKING BRAKE AND/OR

BLOCK WHEELS BEFORE PERFORMING A TEST

WITH THE ENGINE OPERATING.

OBTAINING DIAGNOSTIC TROUBLE CODES

(1) Connect DRBII scan tool to the data link con-

nector located in the engine compartment near the

powertrain control module (PCM). (2) Start the engine if possible, cycle the transaxle

selector and the A/Cswitch if applicable. Shut off

the engine. (3) Turn the ignition switch on, access Read Fault

Screen. Record all the fault messages shown on the

DRBII scan tool. Observe the malfunction indicator

lamp (check engine lamp on the instrument panel).

The lamp should light for 3 seconds then go out (bulb

check).

STATE DISPLAY TEST MODE

The switch inputs used by the powertrain control

module (PCM) have only two recognized states,

HIGH and LOW. For this reason, the PCM cannot

recognize the difference between a selected switch po-

sition versus an open circuit, a short circuit, or a de-

fective switch. If the change is displayed, it can be

assumed that the entire switch circuit to the PCM is

functional. From the state display screen access ei-

ther State Display Inputs and Outputs or State Dis-

play Sensors.

STATE DISPLAY INPUTS AND OUTPUTS

Connect the DRBII scan tool to the vehicle and ac-

cess the State Display screen. Then access Inputs and

Outputs. The following is a list of the engine control

system functions accessible through the Inputs and

Outputs screen. Park/Neutral Switch (automatic transaxle only)

Speed Control Resume

Brake Switch

Speed Control On/Off

Speed Control Set

A/C Switch Sense

S/C (Speed Control) Vent Solenoid

S/C (Speed Control) Vacuum Solenoid

Torque Converter Clutch Solenoid (3 speed auto-

matic transaxle)

A/C Clutch Relay

EGR Solenoid

Auto Shutdown Relay

Radiator Fan Relay

Purge Solenoid

Malfunction Indicator (Check Engine) Lamp

STATE DISPLAY SENSORS

Connect the DRBII scan tool to the vehicle and ac-

cess the State Display screen. Then access Sensor

Display. The following is a list of the engine control

system functions accessible through the Sensor Dis-

play screen. Oxygen Sensor Signal

Coolant Temperature

Coolant Temp Sensor

Throttle Position

Minimum Throttle

Battery Voltage

MAP Sensor Reading

Idle Air Control Motor Position

Added Adaptive Fuel

Adaptive Fuel Factor

Barometric Pressure

Min Airflow Idl Spd

Engine Speed

Fault #1 Key-On Info

Module Spark Advance

Speed Control Target

Fault #2 Key-On Info

Fault #3 Key-On Info

Speed Control Status

Charging System Goal

Theft Alarm Status

Speed Control Switch Voltage

Map Sensor Voltage

Vehicle Speed

Oxygen Sensor State

MAP Gauge Reading

Throttle Opening (percentage)

Total Spark Advance

CIRCUIT ACTUATION TEST MODE

The circuit actuation test mode checks for proper

operation of output circuits or devices which the pow-

ertrain control module (PCM) cannot internally rec-

ognize. The PCM can attempt to activate these

outputs and allow an observer to verify proper oper-

ation. Most of the tests provide an audible or visual

indication of device operation (click of relay contacts,

spray fuel, etc.). With the exception of an intermit-

tent condition, if a device functions properly during

its test, it can be assumed that the device, its associ-

ated wiring, and its driver circuit are in working or-

der.

OBTAINING CIRCUIT ACTUATION TEST

Connect the DRBII scan tool to the vehicle and ac-

cess the Actuators screen. The following is a list of

the engine control system functions accessible

through Actuators screens. Stop All Tests

Ignition Coil #1

Fuel Injector #1

Idle Air Control Motor Open/Close

Ä FUEL SYSTEMS 14 - 45