clutch CHEVROLET DYNASTY 1993 Owner's Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 408 of 2438

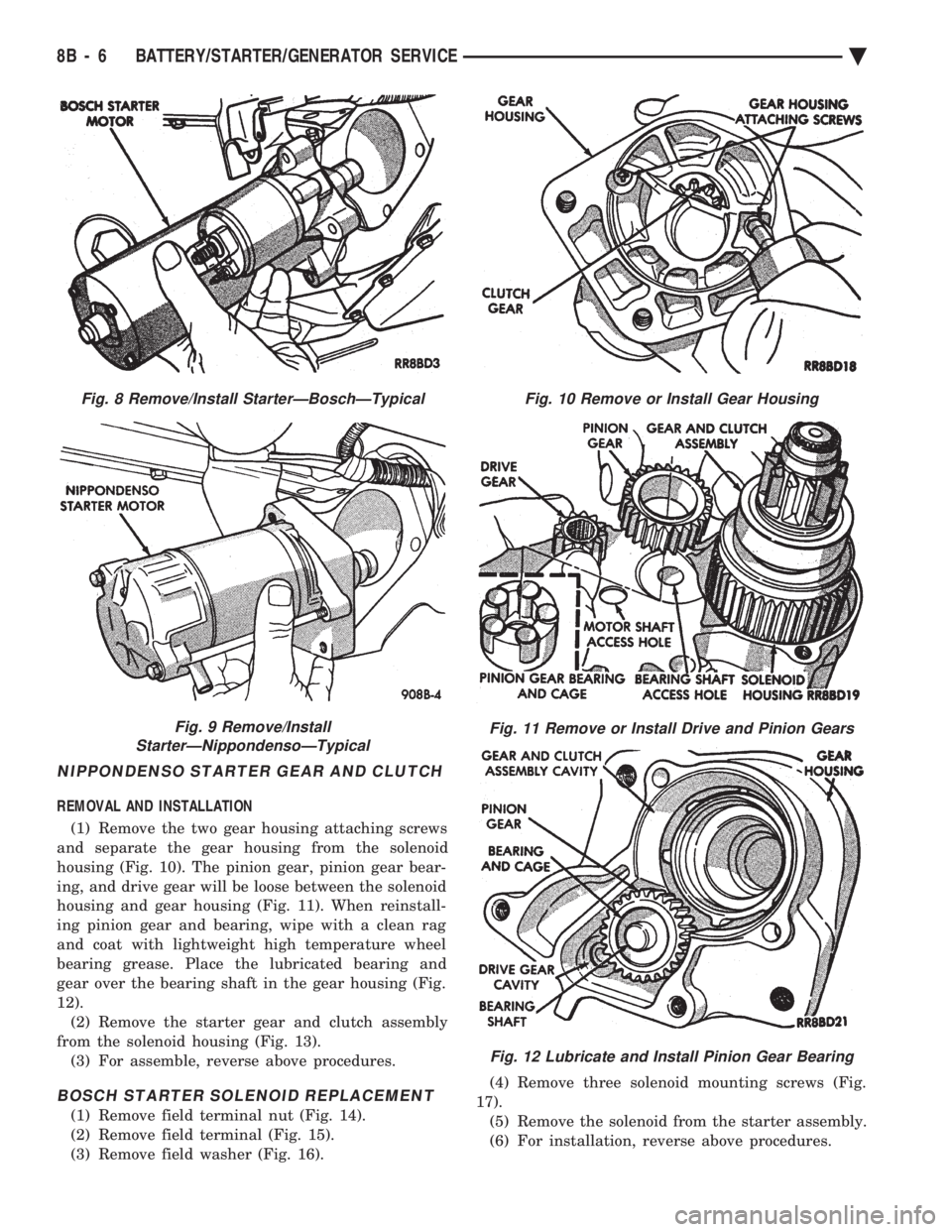

NIPPONDENSO STARTER GEAR AND CLUTCH

REMOVAL AND INSTALLATION (1) Remove the two gear housing attaching screws

and separate the gear housing from the solenoid

housing (Fig. 10). The pinion gear, pinion gear bear-

ing, and drive gear will be loose between the solenoid

housing and gear housing (Fig. 11). When reinstall-

ing pinion gear and bearing, wipe with a clean rag

and coat with lightweight high temperature wheel

bearing grease. Place the lubricated bearing and

gear over the bearing shaft in the gear housing (Fig.

12). (2) Remove the starter gear and clutch assembly

from the solenoid housing (Fig. 13). (3) For assemble, reverse above procedures.

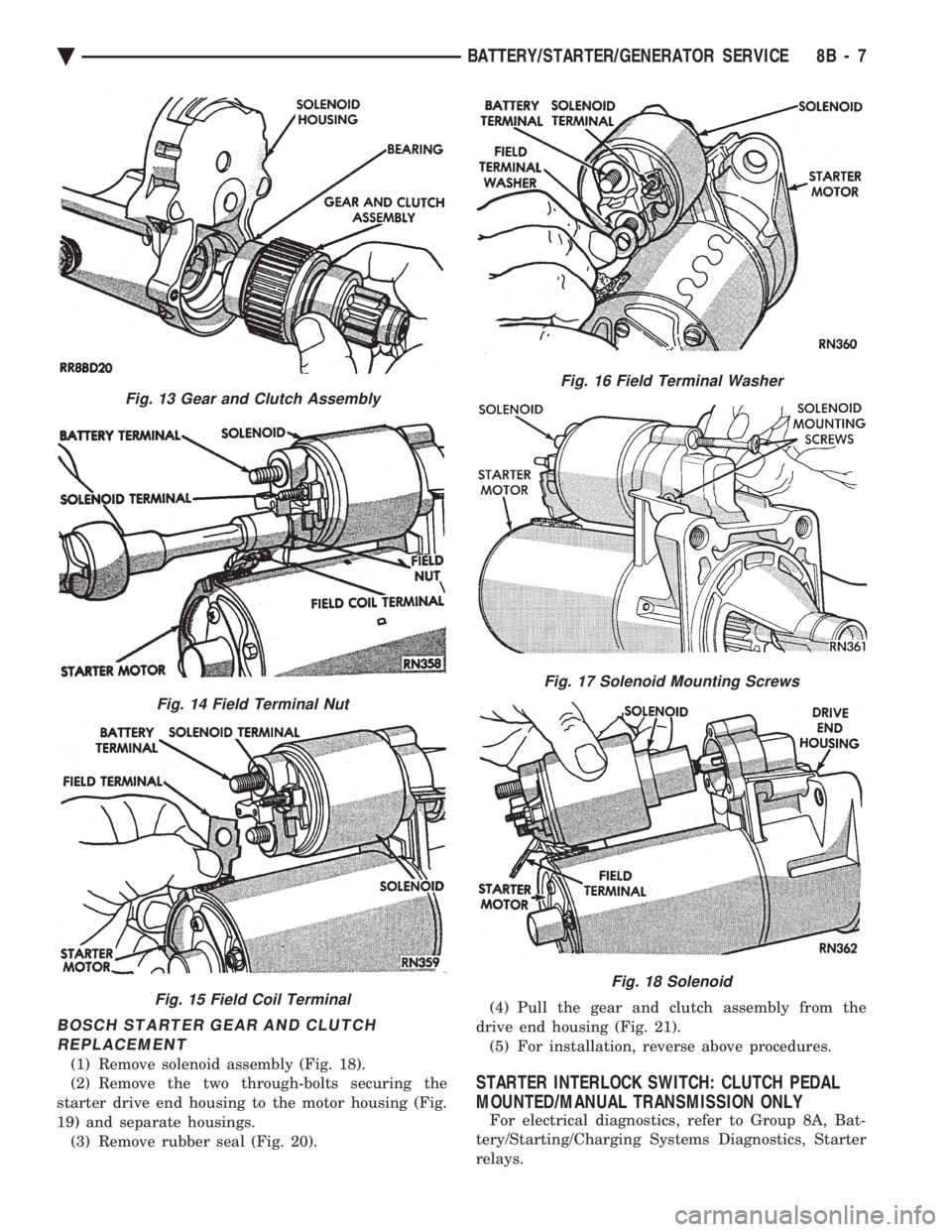

BOSCH STARTER SOLENOID REPLACEMENT

(1) Remove field terminal nut (Fig. 14).

(2) Remove field terminal (Fig. 15).

(3) Remove field washer (Fig. 16). (4) Remove three solenoid mounting screws (Fig.

17). (5) Remove the solenoid from the starter assembly.

(6) For installation, reverse above procedures.

Fig. 8 Remove/Install StarterÐBoschÐTypical

Fig. 9 Remove/Install

StarterÐNippondensoÐTypical

Fig. 10 Remove or Install Gear Housing

Fig. 11 Remove or Install Drive and Pinion Gears

Fig. 12 Lubricate and Install Pinion Gear Bearing

8B - 6 BATTERY/STARTER/GENERATOR SERVICE Ä

Page 409 of 2438

BOSCH STARTER GEAR AND CLUTCH REPLACEMENT

(1) Remove solenoid assembly (Fig. 18).

(2) Remove the two through-bolts securing the

starter drive end housing to the motor housing (Fig.

19) and separate housings. (3) Remove rubber seal (Fig. 20). (4) Pull the gear and clutch assembly from the

drive end housing (Fig. 21). (5) For installation, reverse above procedures.

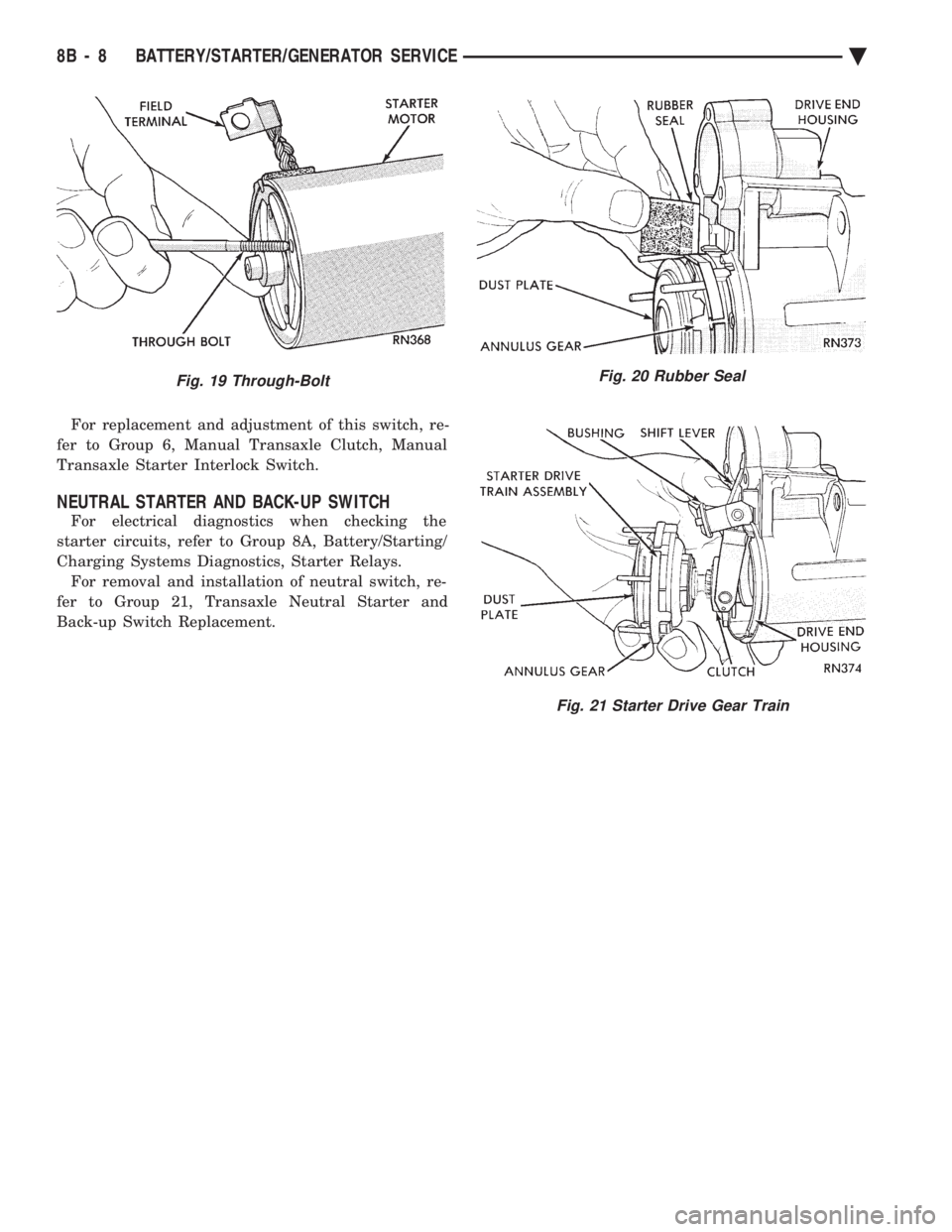

STARTER INTERLOCK SWITCH: CLUTCH PEDAL

MOUNTED/MANUAL TRANSMISSION ONLY

For electrical diagnostics, refer to Group 8A, Bat-

tery/Starting/Charging Systems Diagnostics, Starter

relays.

Fig. 13 Gear and Clutch Assembly

Fig. 14 Field Terminal Nut

Fig. 15 Field Coil Terminal

Fig. 16 Field Terminal Washer

Fig. 17 Solenoid Mounting Screws

Fig. 18 Solenoid

Ä BATTERY/STARTER/GENERATOR SERVICE 8B - 7

Page 410 of 2438

For replacement and adjustment of this switch, re-

fer to Group 6, Manual Transaxle Clutch, Manual

Transaxle Starter Interlock Switch.

NEUTRAL STARTER AND BACK-UP SWITCH

For electrical diagnostics when checking the

starter circuits, refer to Group 8A, Battery/Starting/

Charging Systems Diagnostics, Starter Relays. For removal and installation of neutral switch, re-

fer to Group 21, Transaxle Neutral Starter and

Back-up Switch Replacement.

Fig. 19 Through-BoltFig. 20 Rubber Seal

Fig. 21 Starter Drive Gear Train

8B - 8 BATTERY/STARTER/GENERATOR SERVICE Ä

Page 460 of 2438

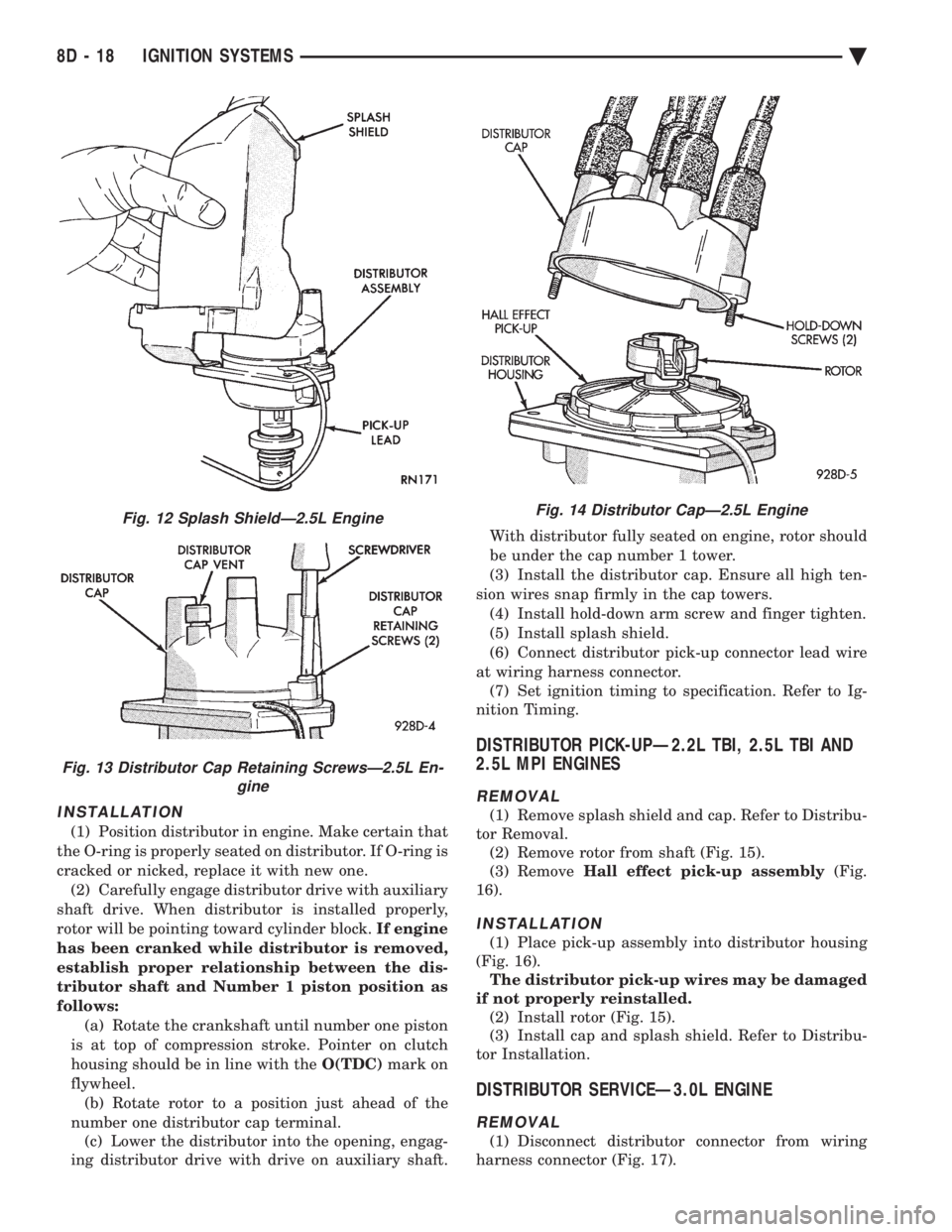

INSTALLATION

(1) Position distributor in engine. Make certain that

the O-ring is properly seated on distributor. If O-ring is

cracked or nicked, replace it with new one. (2) Carefully engage distributor drive with auxiliary

shaft drive. When distributor is installed properly,

rotor will be pointing toward cylinder block. If engine

has been cranked while distributor is removed,

establish proper relationship between the dis-

tributor shaft and Number 1 piston position as

follows: (a) Rotate the crankshaft until number one piston

is at top of compression stroke. Pointer on clutch

housing should be in line with the O(TDC)mark on

flywheel. (b) Rotate rotor to a position just ahead of the

number one distributor cap terminal. (c) Lower the distributor into the opening, engag-

ing distributor drive with drive on auxiliary shaft. With distributor fully seated on engine, rotor should

be under the cap number 1 tower.

(3) Install the distributor cap. Ensure all high ten-

sion wires snap firmly in the cap towers. (4) Install hold-down arm screw and finger tighten.

(5) Install splash shield.

(6) Connect distributor pick-up connector lead wire

at wiring harness connector. (7) Set ignition timing to specification. Refer to Ig-

nition Timing.

DISTRIBUTOR PICK-UPÐ2.2L TBI, 2.5L TBI AND

2.5L MPI ENGINES

REMOVAL

(1) Remove splash shield and cap. Refer to Distribu-

tor Removal. (2) Remove rotor from shaft (Fig. 15).

(3) Remove Hall effect pick-up assembly (Fig.

16).

INSTALLATION

(1) Place pick-up assembly into distributor housing

(Fig. 16). The distributor pick-up wires may be damaged

if not properly reinstalled. (2) Install rotor (Fig. 15).

(3) Install cap and splash shield. Refer to Distribu-

tor Installation.

DISTRIBUTOR SERVICEÐ3.0L ENGINE

REMOVAL

(1) Disconnect distributor connector from wiring

harness connector (Fig. 17).

Fig. 12 Splash ShieldÐ2.5L Engine

Fig. 13 Distributor Cap Retaining ScrewsÐ2.5L En- gine

Fig. 14 Distributor CapÐ2.5L Engine

8D - 18 IGNITION SYSTEMS Ä

Page 587 of 2438

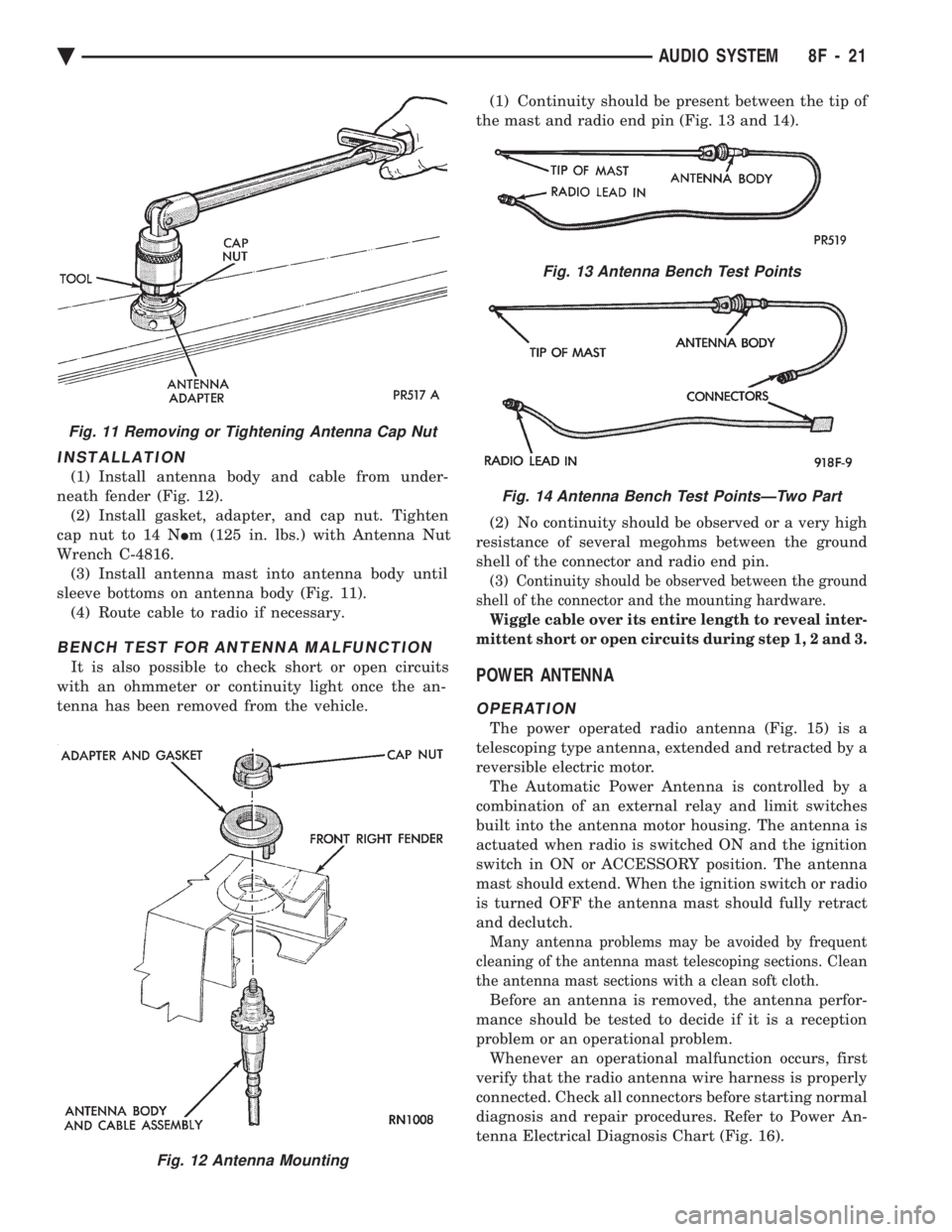

INSTALLATION

(1) Install antenna body and cable from under-

neath fender (Fig. 12). (2) Install gasket, adapter, and cap nut. Tighten

cap nut to 14 N Im (125 in. lbs.) with Antenna Nut

Wrench C-4816. (3) Install antenna mast into antenna body until

sleeve bottoms on antenna body (Fig. 11). (4) Route cable to radio if necessary.

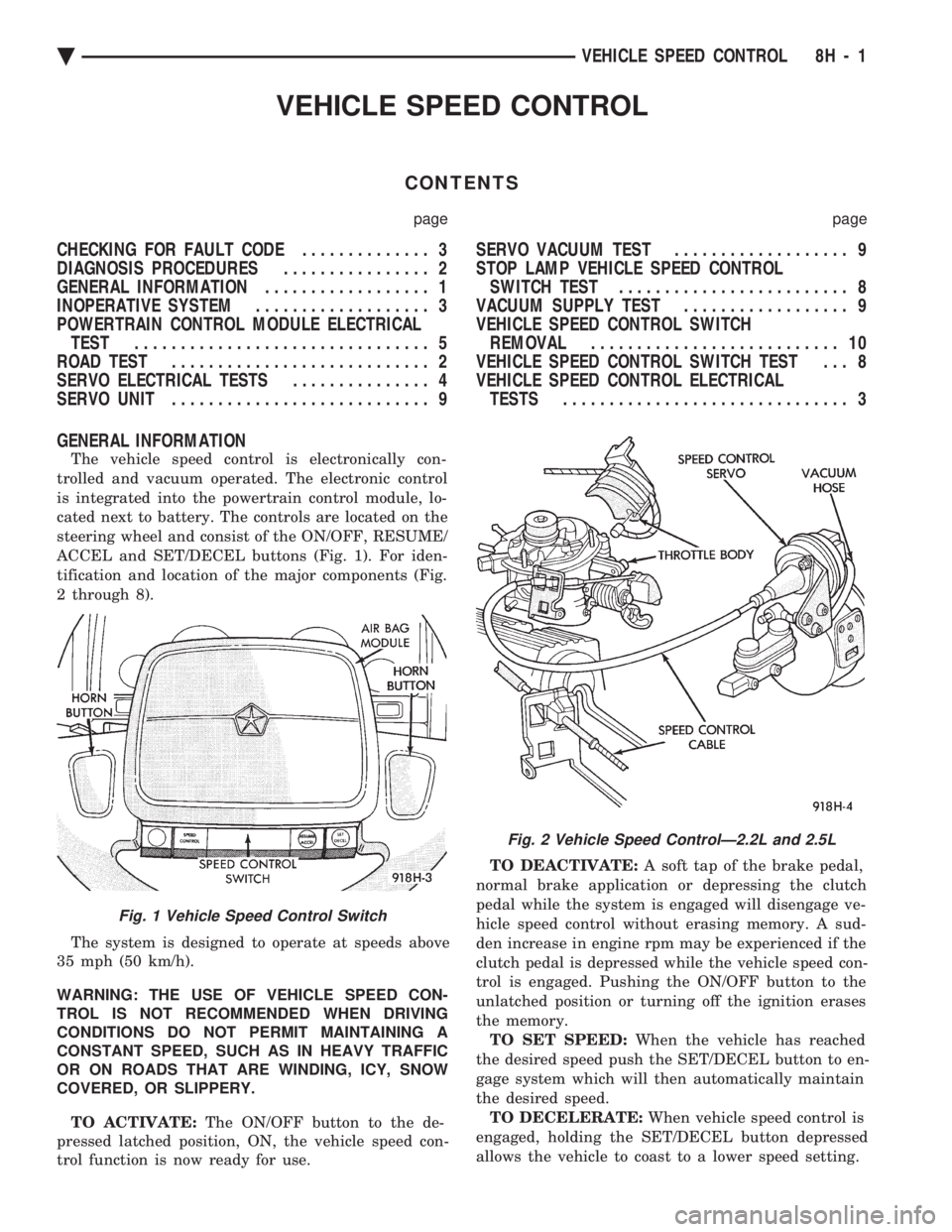

BENCH TEST FOR ANTENNA MALFUNCTION

It is also possible to check short or open circuits

with an ohmmeter or continuity light once the an-

tenna has been removed from the vehicle. (1) Continuity should be present between the tip of

the mast and radio end pin (Fig. 13 and 14).

(2) No continuity should be observed or a very high

resistance of several megohms between the ground

shell of the connector and radio end pin.

(3) Continuity should be observed between the ground

shell of the connector and the mounting hardware.

Wiggle cable over its entire length to reveal inter-

mittent short or open circuits during step 1, 2 and 3.

POWER ANTENNA

OPERATION

The power operated radio antenna (Fig. 15) is a

telescoping type antenna, extended and retracted by a

reversible electric motor. The Automatic Power Antenna is controlled by a

combination of an external relay and limit switches

built into the antenna motor housing. The antenna is

actuated when radio is switched ON and the ignition

switch in ON or ACCESSORY position. The antenna

mast should extend. When the ignition switch or radio

is turned OFF the antenna mast should fully retract

and declutch.

Many antenna problems may be avoided by frequent

cleaning of the antenna mast telescoping sections. Clean

the antenna mast sections with a clean soft cloth.

Before an antenna is removed, the antenna perfor-

mance should be tested to decide if it is a reception

problem or an operational problem. Whenever an operational malfunction occurs, first

verify that the radio antenna wire harness is properly

connected. Check all connectors before starting normal

diagnosis and repair procedures. Refer to Power An-

tenna Electrical Diagnosis Chart (Fig. 16).

Fig. 12 Antenna Mounting

Fig. 11 Removing or Tightening Antenna Cap Nut

Fig. 13 Antenna Bench Test Points

Fig. 14 Antenna Bench Test PointsÐTwo Part

Ä AUDIO SYSTEM 8F - 21

Page 603 of 2438

VEHICLE SPEED CONTROL

CONTENTS

page page

CHECKING FOR FAULT CODE .............. 3

DIAGNOSIS PROCEDURES ................ 2

GENERAL INFORMATION .................. 1

INOPERATIVE SYSTEM ................... 3

POWERTRAIN CONTROL MODULE ELECTRICAL TEST ................................ 5

ROAD TEST ............................ 2

SERVO ELECTRICAL TESTS ............... 4

SERVO UNIT ............................ 9 SERVO VACUUM TEST

................... 9

STOP LAMP VEHICLE SPEED CONTROL SWITCH TEST ......................... 8

VACUUM SUPPLY TEST .................. 9

VEHICLE SPEED CONTROL SWITCH REMOVAL ........................... 10

VEHICLE SPEED CONTROL SWITCH TEST . . . 8

VEHICLE SPEED CONTROL ELECTRICAL TESTS ............................... 3

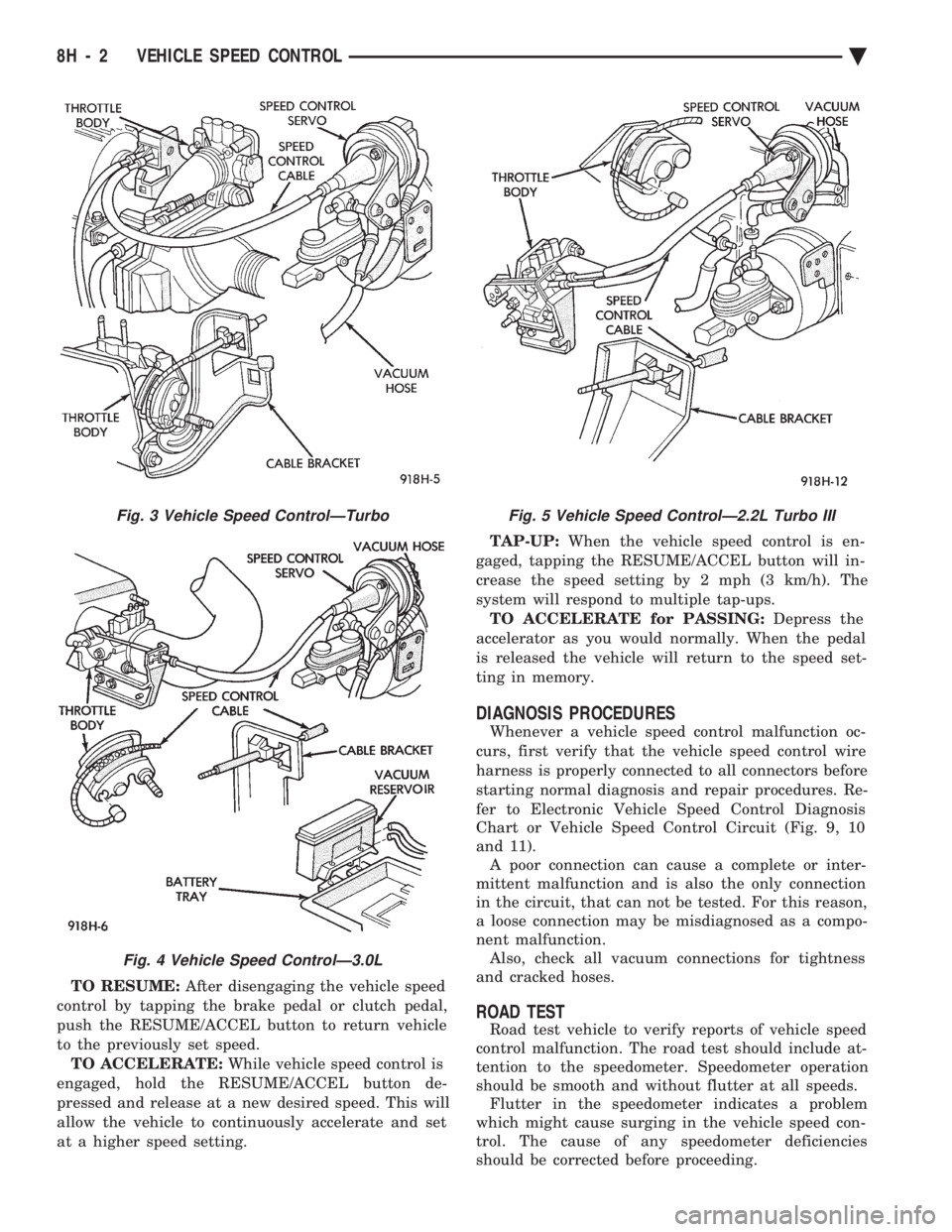

GENERAL INFORMATION

The vehicle speed control is electronically con-

trolled and vacuum operated. The electronic control

is integrated into the powertrain control module, lo-

cated next to battery. The controls are located on the

steering wheel and consist of the ON/OFF, RESUME/

ACCEL and SET/DECEL buttons (Fig. 1). For iden-

tification and location of the major components (Fig.

2 through 8).

The system is designed to operate at speeds above

35 mph (50 km/h).

WARNING: THE USE OF VEHICLE SPEED CON-

TROL IS NOT RECOMMENDED WHEN DRIVING

CONDITIONS DO NOT PERMIT MAINTAINING A

CONSTANT SPEED, SUCH AS IN HEAVY TRAFFIC

OR ON ROADS THAT ARE WINDING, ICY, SNOW

COVERED, OR SLIPPERY.

TO ACTIVATE: The ON/OFF button to the de-

pressed latched position, ON, the vehicle speed con-

trol function is now ready for use. TO DEACTIVATE:

A soft tap of the brake pedal,

normal brake application or depressing the clutch

pedal while the system is engaged will disengage ve-

hicle speed control without erasing memory. A sud-

den increase in engine rpm may be experienced if the

clutch pedal is depressed while the vehicle speed con-

trol is engaged. Pushing the ON/OFF button to the

unlatched position or turning off the ignition erases

the memory. TO SET SPEED: When the vehicle has reached

the desired speed push the SET/DECEL button to en-

gage system which will then automatically maintain

the desired speed. TO DECELERATE: When vehicle speed control is

engaged, holding the SET/DECEL button depressed

allows the vehicle to coast to a lower speed setting.

Fig. 1 Vehicle Speed Control Switch

Fig. 2 Vehicle Speed ControlÐ2.2L and 2.5L

Ä VEHICLE SPEED CONTROL 8H - 1

Page 604 of 2438

TO RESUME: After disengaging the vehicle speed

control by tapping the brake pedal or clutch pedal,

push the RESUME/ACCEL button to return vehicle

to the previously set speed. TO ACCELERATE: While vehicle speed control is

engaged, hold the RESUME/ACCEL button de-

pressed and release at a new desired speed. This will

allow the vehicle to continuously accelerate and set

at a higher speed setting. TAP-UP:

When the vehicle speed control is en-

gaged, tapping the RESUME/ACCEL button will in-

crease the speed setting by 2 mph (3 km/h). The

system will respond to multiple tap-ups. TO ACCELERATE for PASSING: Depress the

accelerator as you would normally. When the pedal

is released the vehicle will return to the speed set-

ting in memory.

DIAGNOSIS PROCEDURES

Whenever a vehicle speed control malfunction oc-

curs, first verify that the vehicle speed control wire

harness is properly connected to all connectors before

starting normal diagnosis and repair procedures. Re-

fer to Electronic Vehicle Speed Control Diagnosis

Chart or Vehicle Speed Control Circuit (Fig. 9, 10

and 11). A poor connection can cause a complete or inter-

mittent malfunction and is also the only connection

in the circuit, that can not be tested. For this reason,

a loose connection may be misdiagnosed as a compo-

nent malfunction. Also, check all vacuum connections for tightness

and cracked hoses.

ROAD TEST

Road test vehicle to verify reports of vehicle speed

control malfunction. The road test should include at-

tention to the speedometer. Speedometer operation

should be smooth and without flutter at all speeds. Flutter in the speedometer indicates a problem

which might cause surging in the vehicle speed con-

trol. The cause of any speedometer deficiencies

should be corrected before proceeding.

Fig. 3 Vehicle Speed ControlÐTurbo

Fig. 4 Vehicle Speed ControlÐ3.0L

Fig. 5 Vehicle Speed ControlÐ2.2L Turbo III

8H - 2 VEHICLE SPEED CONTROL Ä

Page 931 of 2438

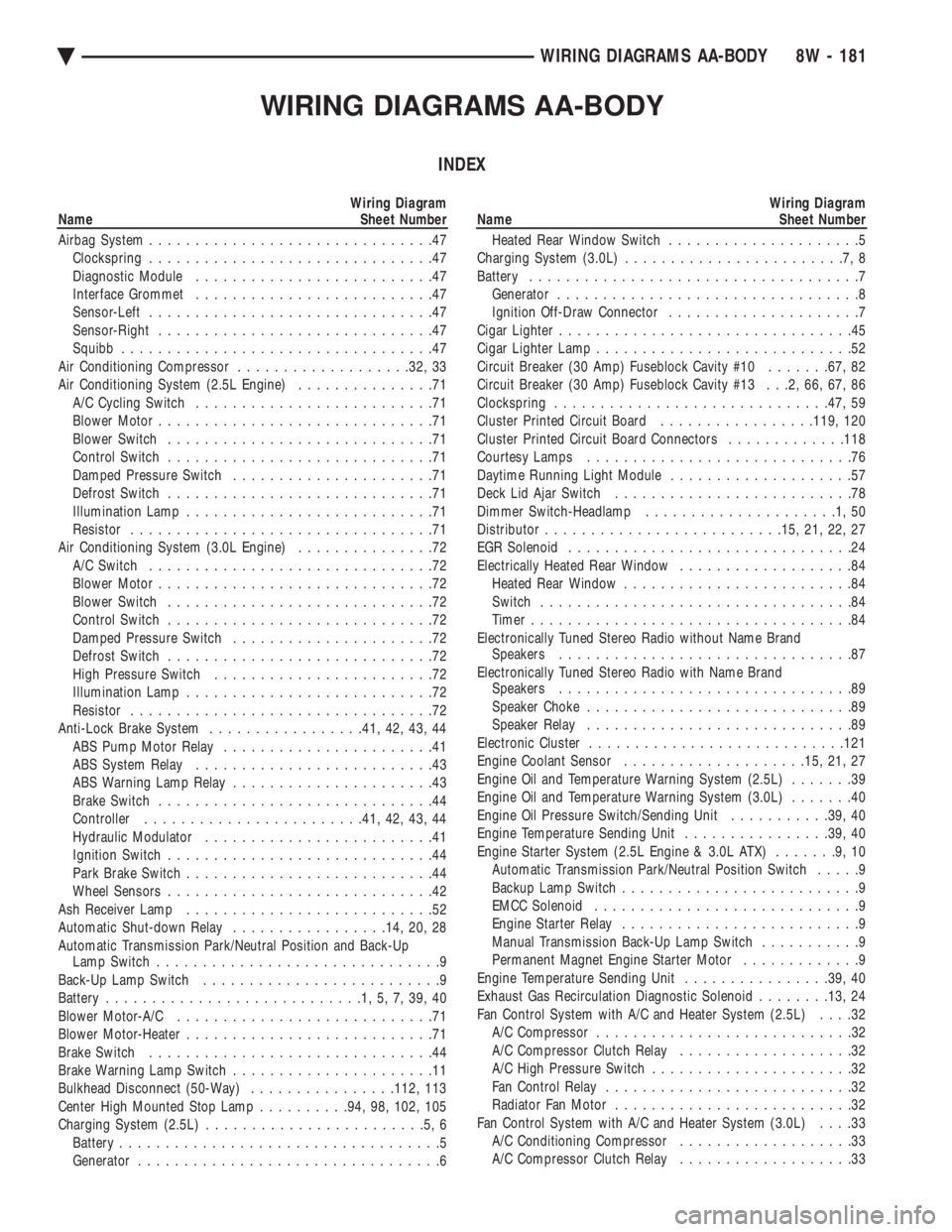

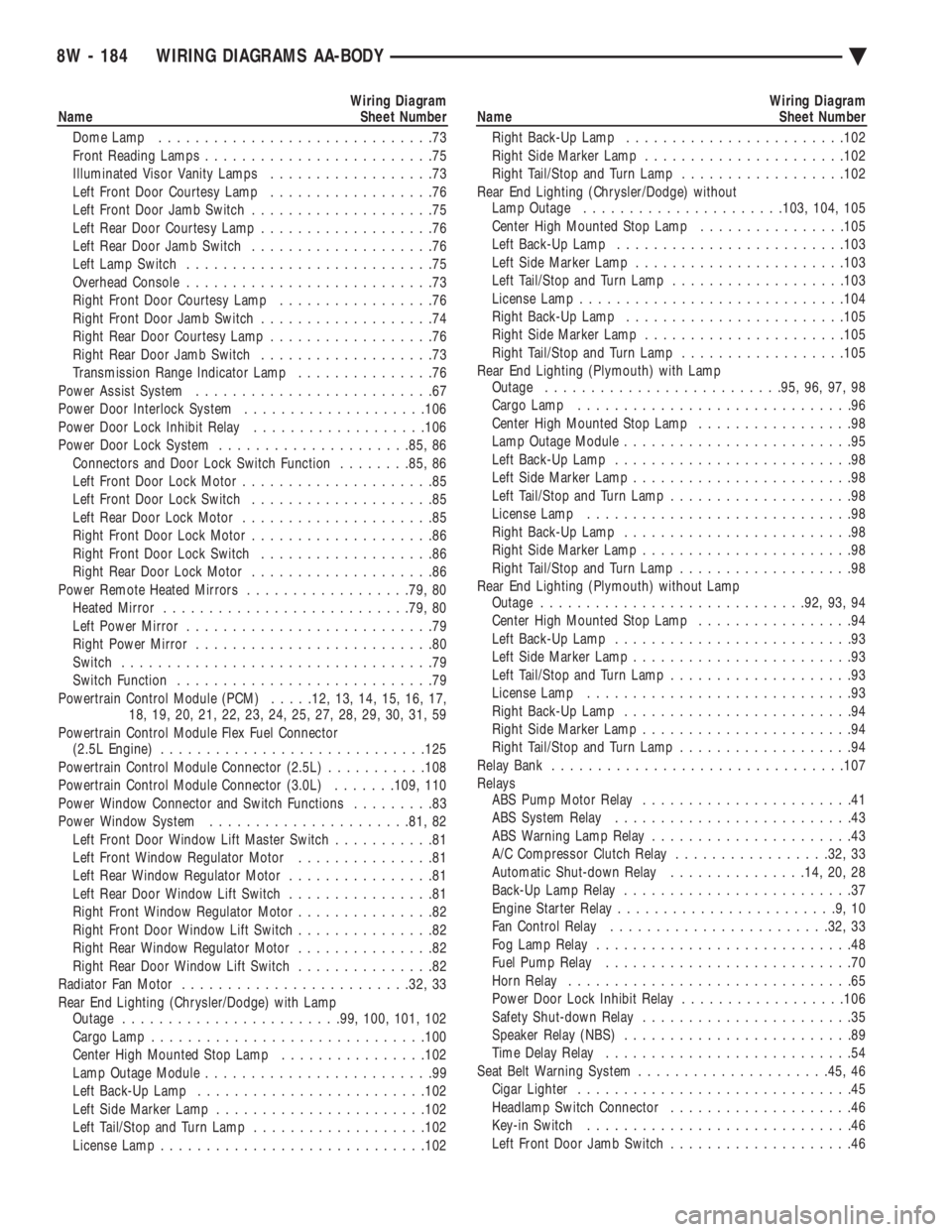

WIRING DIAGRAMS AA-BODY

INDEX

Wiring Diagram

Name Sheet Number

Airbag System ...............................47

Clockspring ...............................47

Diagnostic Module ..........................47

Interface Grommet ..........................47

Sensor-Left ...............................47

Sensor-Right ..............................47

Squibb ..................................47

Air Conditioning Compressor ...................32, 33

Air Conditioning System (2.5L Engine) ...............71

A/C Cycling Switch ..........................71

Blower Motor ..............................71

Blower Switch .............................71

Control Switch .............................71

Damped Pressure Switch ......................71

Defrost Switch .............................71

Illumination Lamp ...........................71

Resistor .................................71

Air Conditioning System (3.0L Engine) ...............72

A/C Switch ...............................72

Blower Motor ..............................72

Blower Switch .............................72

Control Switch .............................72

Damped Pressure Switch ......................72

Defrost Switch .............................72

High Pressure Switch ........................72

Illumination Lamp ...........................72

Resistor .................................72

Anti-Lock Brake System .................41, 42, 43, 44

ABS Pump Motor Relay .......................41

ABS System Relay ..........................43

ABS Warning Lamp Relay ......................43

Brake Switch ..............................44

Controller ....................... .41, 42, 43, 44

Hydraulic Modulator .........................41

Ignition Switch .............................44

Park Brake Switch ...........................44

Wheel Sensors .............................42

Ash Receiver Lamp ...........................52

Automatic Shut-down Relay .................14, 20, 28

Automatic Transmission Park/Neutral Position and Back-Up Lamp Switch ...............................9

Back-Up Lamp Switch ..........................9

Battery ............................1,5,7,39,40

Blower Motor-A/C ............................71

Blower Motor-Heater ...........................71

Brake Switch ...............................44

Brake Warning Lamp Switch ......................11

Bulkhead Disconnect (50-Way) ................112, 113

Center High Mounted Stop Lamp ..........94, 98, 102, 105

Charging System (2.5L) ........................5,6

Battery ...................................5

Generator .................................6Wiring Diagram

Name Sheet Number

Heated Rear Window Switch .....................5

Charging System (3.0L) ........................7,8

Battery ....................................7

Generator .................................8

Ignition Off-Draw Connector .....................7

Cigar Lighter ................................45

Cigar Lighter Lamp ............................52

Circuit Breaker (30 Amp) Fuseblock Cavity #10 .......67, 82

Circuit Breaker (30 Amp) Fuseblock Cavity #13 . . .2, 66, 67, 86

Clockspring ............................. .47, 59

Cluster Printed Circuit Board .................119, 120

Cluster Printed Circuit Board Connectors .............118

Courtesy Lamps .............................76

Daytime Running Light Module ....................57

Deck Lid Ajar Switch ..........................78

Dimmer Switch-Headlamp .....................1,50

Distributor ......................... .15, 21, 22, 27

EGR Solenoid ...............................24

Electrically Heated Rear Window ...................84

Heated Rear Window .........................84

Switch ..................................84

Timer ...................................84

Electronically Tuned Stereo Radio without Name Brand Speakers ................................87

Electronically Tuned Stereo Radio with Name Brand Speakers ................................89

Speaker Choke .............................89

Speaker Relay .............................89

Electronic Cluster ........................... .121

Engine Coolant Sensor ................... .15, 21, 27

Engine Oil and Temperature Warning System (2.5L) .......39

Engine Oil and Temperature Warning System (3.0L) .......40

Engine Oil Pressure Switch/Sending Unit ...........39, 40

Engine Temperature Sending Unit ................39, 40

Engine Starter System (2.5L Engine & 3.0L ATX) .......9,10

Automatic Transmission Park/Neutral Position Switch .....9

Backup Lamp Switch ..........................9

EMCC Solenoid .............................9

Engine Starter Relay ..........................9

Manual Transmission Back-Up Lamp Switch ...........9

Permanent Magnet Engine Starter Motor .............9

Engine Temperature Sending Unit ................39, 40

Exhaust Gas Recirculation Diagnostic Solenoid ........13, 24

Fan Control System with A/C and Heater System (2.5L) ....32

A/C Compressor ............................32

A/C Compressor Clutch Relay ...................32

A/C High Pressure Switch ......................32

Fan Control Relay ...........................32

Radiator Fan Motor ..........................32

Fan Control System with A/C and Heater System (3.0L) ....33

A/C Conditioning Compressor ...................33

A/C Compressor Clutch Relay ...................33

Ä WIRING DIAGRAMS AA-BODY 8W - 181

Page 934 of 2438

Wiring Diagram

Name Sheet Number

Dome Lamp ..............................73

Front Reading Lamps .........................75

Illuminated Visor Vanity Lamps ..................73

Left Front Door Courtesy Lamp ..................76

Left Front Door Jamb Switch ....................75

Left Rear Door Courtesy Lamp ...................76

Left Rear Door Jamb Switch ....................76

Left Lamp Switch ...........................75

Overhead Console ...........................73

Right Front Door Courtesy Lamp .................76

Right Front Door Jamb Switch ...................74

Right Rear Door Courtesy Lamp ..................76

Right Rear Door Jamb Switch ...................73

Transmission Range Indicator Lamp ...............76

Power Assist System ..........................67

Power Door Interlock System ....................106

Power Door Lock Inhibit Relay ...................106

Power Door Lock System .................... .85, 86

Connectors and Door Lock Switch Function ........85, 86

Left Front Door Lock Motor .....................85

Left Front Door Lock Switch ....................85

Left Rear Door Lock Motor .....................85

Right Front Door Lock Motor ....................86

Right Front Door Lock Switch ...................86

Right Rear Door Lock Motor ....................86

Power Remote Heated Mirrors ..................79, 80

Heated Mirror .......................... .79, 80

Left Power Mirror ...........................79

Right Power Mirror ..........................80

Switch ..................................79

Switch Function ............................79

Powertrain Control Module (PCM) .....12, 13, 14, 15, 16, 17,

18, 19, 20, 21, 22, 23, 24, 25, 27, 28, 29, 30, 31, 59

Powertrain Control Module Flex Fuel Connector (2.5L Engine) ............................ .125

Powertrain Control Module Connector (2.5L) ...........108

Powertrain Control Module Connector (3.0L) .......109, 110

Power Window Connector and Switch Functions .........83

Power Window System ..................... .81, 82

Left Front Door Window Lift Master Switch ...........81

Left Front Window Regulator Motor ...............81

Left Rear Window Regulator Motor ................81

Left Rear Door Window Lift Switch ................81

Right Front Window Regulator Motor ...............82

Right Front Door Window Lift Switch ...............82

Right Rear Window Regulator Motor ...............82

Right Rear Door Window Lift Switch ...............82

Radiator Fan Motor ........................ .32, 33

Rear End Lighting (Chrysler/Dodge) with Lamp Outage ....................... .99, 100, 101, 102

Cargo Lamp ............................. .100

Center High Mounted Stop Lamp ................102

Lamp Outage Module .........................99

Left Back-Up Lamp ........................ .102

Left Side Marker Lamp ...................... .102

Left Tail/Stop and Turn Lamp ...................102

License Lamp ............................ .102Wiring Diagram

Name Sheet Number

Right Back-Up Lamp ....................... .102

Right Side Marker Lamp ..................... .102

Right Tail/Stop and Turn Lamp ..................102

Rear End Lighting (Chrysler/Dodge) without Lamp Outage ..................... .103, 104, 105

Center High Mounted Stop Lamp ................105

Left Back-Up Lamp ........................ .103

Left Side Marker Lamp ...................... .103

Left Tail/Stop and Turn Lamp ...................103

License Lamp ............................ .104

Right Back-Up Lamp ....................... .105

Right Side Marker Lamp ..................... .105

Right Tail/Stop and Turn Lamp ..................105

Rear End Lighting (Plymouth) with Lamp Outage ......................... .95, 96, 97, 98

Cargo Lamp ..............................96

Center High Mounted Stop Lamp .................98

Lamp Outage Module .........................95

Left Back-Up Lamp ..........................98

Left Side Marker Lamp ........................98

Left Tail/Stop and Turn Lamp ....................98

License Lamp .............................98

Right Back-Up Lamp .........................98

Right Side Marker Lamp .......................98

Right Tail/Stop and Turn Lamp ...................98

Rear End Lighting (Plymouth) without Lamp Outage ............................ .92, 93, 94

Center High Mounted Stop Lamp .................94

Left Back-Up Lamp ..........................93

Left Side Marker Lamp ........................93

Left Tail/Stop and Turn Lamp ....................93

License Lamp .............................93

Right Back-Up Lamp .........................94

Right Side Marker Lamp .......................94

Right Tail/Stop and Turn Lamp ...................94

Relay Bank ............................... .107

Relays ABS Pump Motor Relay .......................41

ABS System Relay ..........................43

ABS Warning Lamp Relay ......................43

A/C Compressor Clutch Relay .................32, 33

Automatic Shut-down Relay ...............14, 20, 28

Back-Up Lamp Relay .........................37

Engine Starter Relay ........................9,10

Fan Control Relay ....................... .32, 33

Fog Lamp Relay ............................48

Fuel Pump Relay ...........................70

Horn Relay ...............................65

Power Door Lock Inhibit Relay ..................106

Safety Shut-down Relay .......................35

Speaker Relay (NBS) .........................89

Time Delay Relay ...........................54

Seat Belt Warning System .................... .45, 46

Cigar Lighter ..............................45

Headlamp Switch Connector ....................46

Key-in Switch .............................46

Left Front Door Jamb Switch ....................46

8W - 184 WIRING DIAGRAMS AA-BODY Ä

Page 1063 of 2438

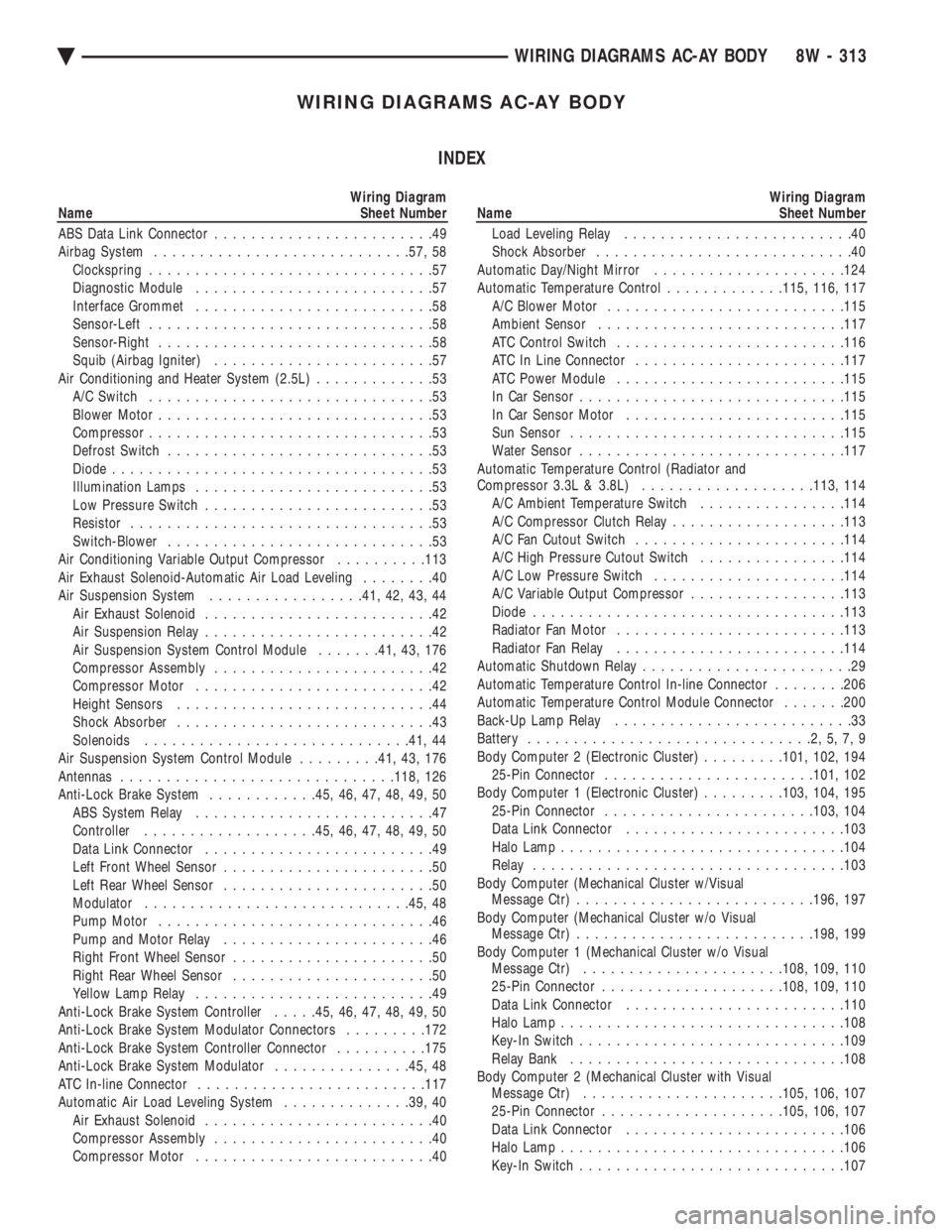

WIRING DIAGRAMS AC-AY BODY INDEX

Wiring Diagram

Name Sheet Number

ABS Data Link Connector ........................49

Airbag System ........................... .57, 58

Clockspring ...............................57

Diagnostic Module ..........................57

Interface Grommet ..........................58

Sensor-Left ...............................58

Sensor-Right ..............................58

Squib (Airbag Igniter) ........................57

Air Conditioning and Heater System (2.5L) .............53

A/C Switch ...............................53

Blower Motor ..............................53

Compressor ...............................53

Defrost Switch .............................53

Diode ...................................53

Illumination Lamps ..........................53

Low Pressure Switch .........................53

Resistor .................................53

Switch-Blower .............................53

Air Conditioning Variable Output Compressor ..........113

Air Exhaust Solenoid-Automatic Air Load Leveling ........40

Air Suspension System .................41, 42, 43, 44

Air Exhaust Solenoid .........................42

Air Suspension Relay .........................42

Air Suspension System Control Module .......41, 43, 176

Compressor Assembly ........................42

Compressor Motor ..........................42

Height Sensors ............................44

Shock Absorber ............................43

Solenoids ............................ .41, 44

Air Suspension System Control Module .........41, 43, 176

Antennas ............................. .118, 126

Anti-Lock Brake System ............45, 46, 47, 48, 49, 50

ABS System Relay ..........................47

Controller .................. .45, 46, 47, 48, 49, 50

Data Link Connector .........................49

Left Front Wheel Sensor .......................50

Left Rear Wheel Sensor .......................50

Modulator ............................ .45, 48

Pump Motor ..............................46

Pump and Motor Relay .......................46

Right Front Wheel Sensor ......................50

Right Rear Wheel Sensor ......................50

Yellow Lamp Relay ..........................49

Anti-Lock Brake System Controller .....45, 46, 47, 48, 49, 50

Anti-Lock Brake System Modulator Connectors .........172

Anti-Lock Brake System Controller Connector ..........175

Anti-Lock Brake System Modulator ...............45, 48

ATC In-line Connector ........................ .117

Automatic Air Load Leveling System ..............39, 40

Air Exhaust Solenoid .........................40

Compressor Assembly ........................40

Compressor Motor ..........................40Wiring Diagram

Name Sheet Number

Load Leveling Relay .........................40

Shock Absorber ............................40

Automatic Day/Night Mirror .................... .124

Automatic Temperature Control .............115, 116, 117

A/C Blower Motor ......................... .115

Ambient Sensor .......................... .117

ATC Control Switch ........................ .116

ATC In Line Connector ...................... .117

ATC Power Module ........................ .115

In Car Senso r............................ .115

In Car Sensor Motor ....................... .115

Sun Sensor ............................. .115

Water Sensor ............................ .117

Automatic Temperature Control (Radiator and

Compressor 3.3L & 3.8L) .................. .113, 114

A/C Ambient Temperature Switch ................114

A/C Compressor Clutch Relay ...................113

A/C Fan Cutout Switch ...................... .114

A/C High Pressure Cutout Switch ................114

A/C Low Pressure Switch .................... .114

A/C Variable Output Compressor .................113

Diode ................................. .113

Radiator Fan Motor ........................ .113

Radiator Fan Relay ........................ .114

Automatic Shutdown Relay .......................29

Automatic Temperature Control In-line Connector ........206

Automatic Temperature Control Module Connector .......200

Back-Up Lamp Relay ..........................33

Battery ...............................2,5,7,9

Body Computer 2 (Electronic Cluster) .........101, 102, 194

25-Pin Connector ...................... .101, 102

Body Computer 1 (Electronic Cluster) .........103, 104, 195

25-Pin Connector ...................... .103, 104

Data Link Connector ....................... .103

Halo Lamp .............................. .104

Relay ................................. .103

Body Computer (Mechanical Cluster w/Visual Message Ctr) ......................... .196, 197

Body Computer (Mechanical Cluster w/o Visual Message Ctr) ......................... .198, 199

Body Computer 1 (Mechanical Cluster w/o Visual Message Ctr) ..................... .108, 109, 110

25-Pin Connector ................... .108, 109, 110

Data Link Connector ....................... .110

Halo Lamp .............................. .108

Key-In Switch ............................ .109

Relay Bank ............................. .108

Body Computer 2 (Mechanical Cluster with Visual Message Ctr) ..................... .105, 106, 107

25-Pin Connector ................... .105, 106, 107

Data Link Connector ....................... .106

Halo Lamp .............................. .106

Key-In Switch ............................ .107

Ä WIRING DIAGRAMS AC-AY BODY 8W - 313