differential CHEVROLET DYNASTY 1993 User Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 260 of 2438

(7) Using needle nose pliers, install the 3 brake fluid

reservoir to hydraulic assembly retaining pins (Fig.

14). Be sure retaining pins are fully installed with

barbs extending out past reservoir on opposite

side. (8) Install high pressure hose banjo fitting onto

hydraulic assembly and install banjo fitting attaching

bolt. Torque banjo fitting to hydraulic assembly banjo

bolt to 13 N Im (10 ft. lbs.).

(9) Install brake fluid spray shield onto hydraulic

assembly. Install bladder accumulator into hydraulic

assembly by hand (using care not to cross thread

accumulator) until O-ring seal is fully seated into

hydraulic assembly. (10) Using Oil Filter Band Wrench, Special Tool

C-4065 or equivalent, (Fig. 12) torque bladder accumu-

lator to 48 N Im (35 ft. lbs.).

(11) Fill hydraulic assembly fluid reservoir to the top

of the screen on the filter rainer. Use only fresh clean

brake fluid conforming to DOT 3 requirements, such as

Mopar tor equivalent.

(12) Bleed the brake hydraulic system using proce-

dure shown in Bleeding Brake System in this section of

the service manual.

DIFFERENTIAL PRESSURE SWITCH

REMOVE

WARNING: FAILURE TO FULLY DE-PRESSURIZE THE

HYDRAULIC BLADDER ACCUMULATOR PRIOR TO

REMOVING DIFFERENTIAL PRESSURE SWITCH.

WILL RESULT IN PERSONAL INJURY AND/OR DAM-

AGE TO PAINTED SURFACES OF THE VEHICLE.

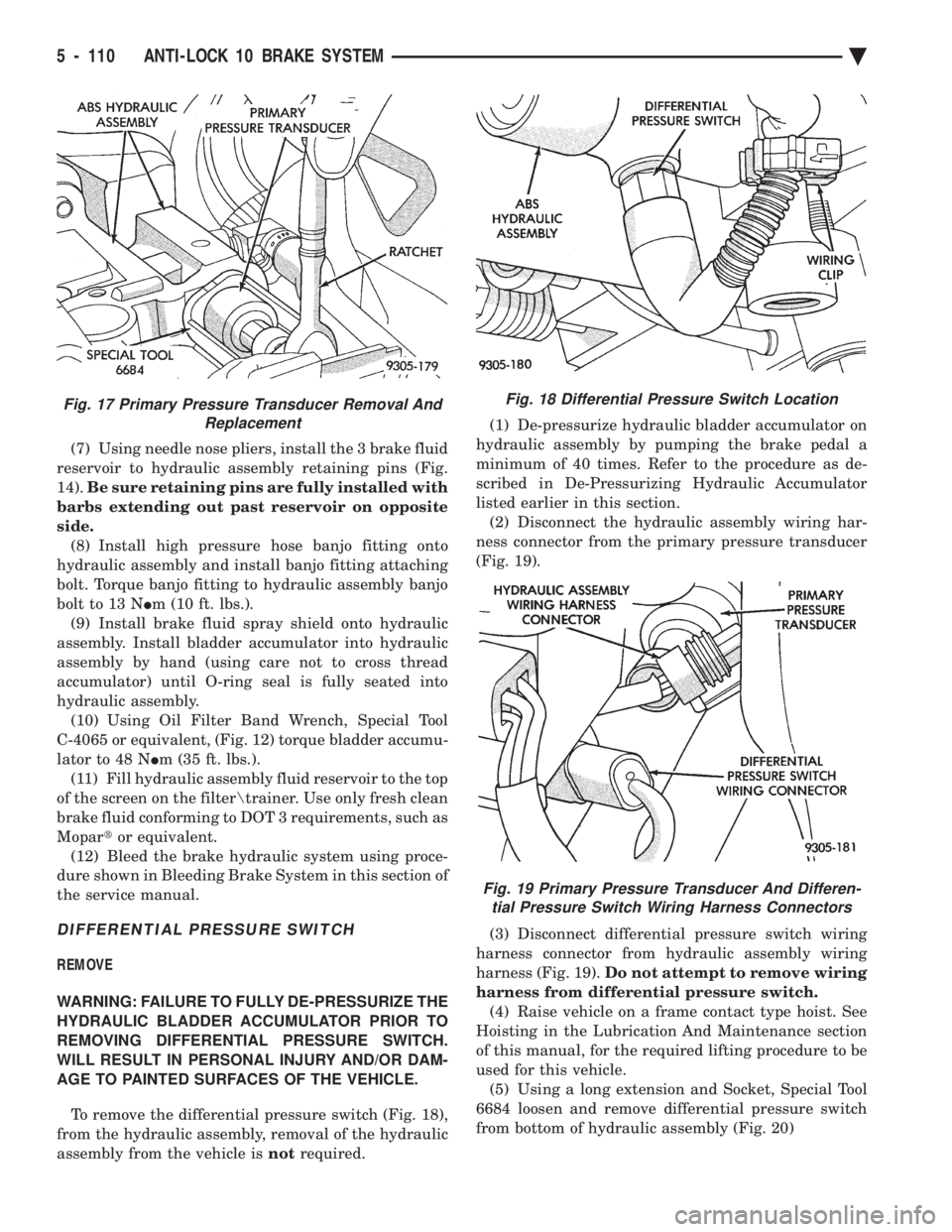

To remove the differential pressure switch (Fig. 18),

from the hydraulic assembly, removal of the hydraulic

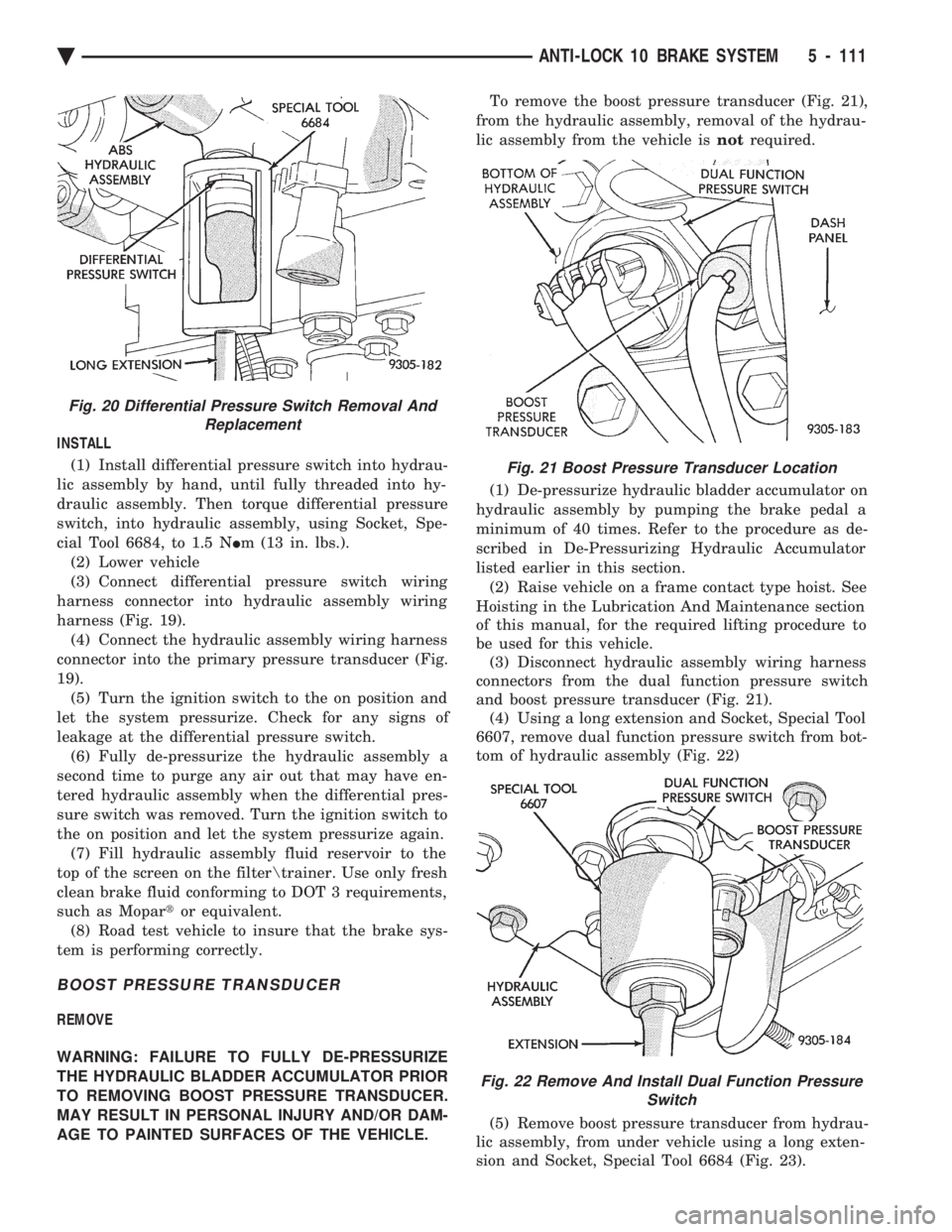

assembly from the vehicle is notrequired. (1) De-pressurize hydraulic bladder accumulator on

hydraulic assembly by pumping the brake pedal a

minimum of 40 times. Refer to the procedure as de-

scribed in De-Pressurizing Hydraulic Accumulator

listed earlier in this section. (2) Disconnect the hydraulic assembly wiring har-

ness connector from the primary pressure transducer

(Fig. 19).

(3) Disconnect differential pressure switch wiring

harness connector from hydraulic assembly wiring

harness (Fig. 19). Do not attempt to remove wiring

harness from differential pressure switch. (4) Raise vehicle on a frame contact type hoist. See

Hoisting in the Lubrication And Maintenance section

of this manual, for the required lifting procedure to be

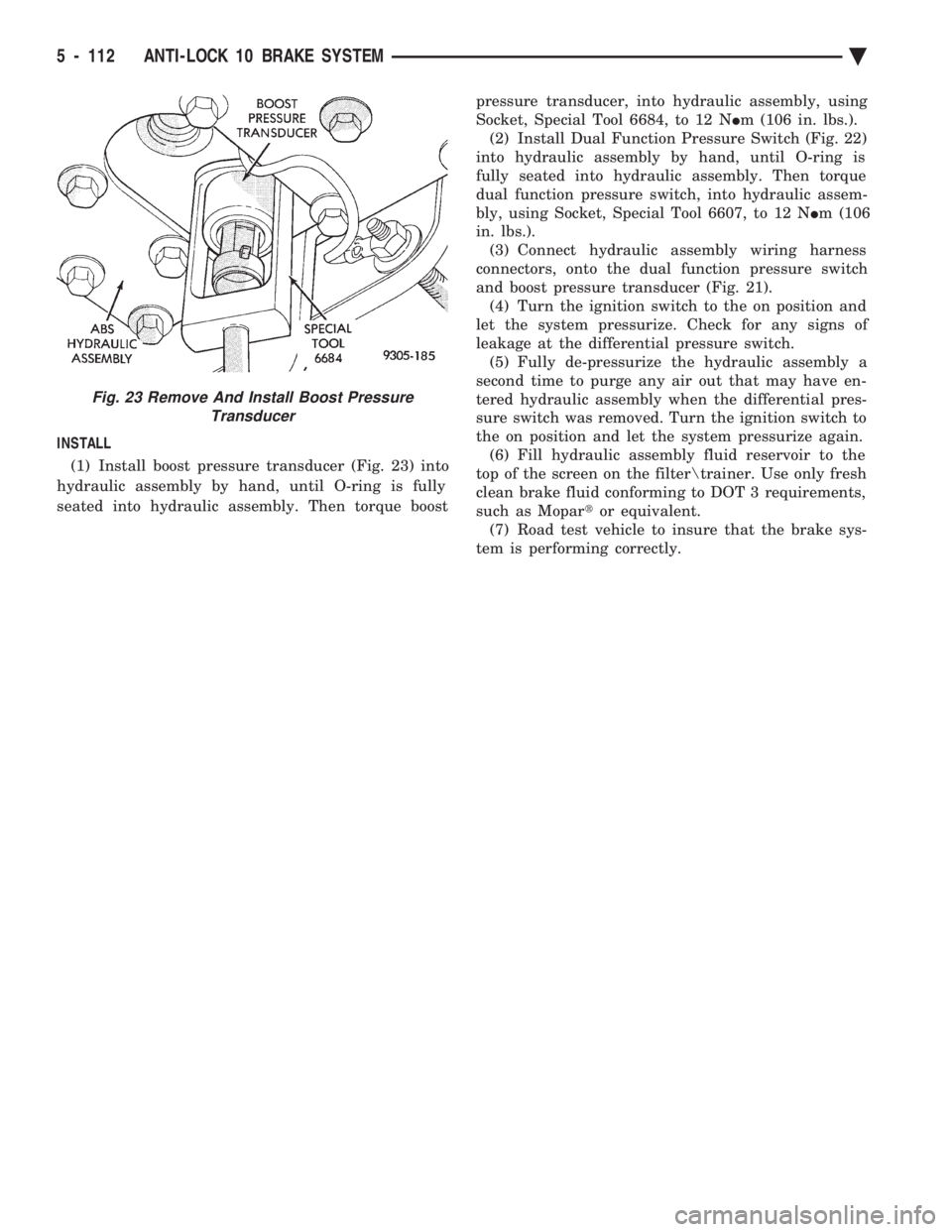

used for this vehicle. (5) Using a long extension and Socket, Special Tool

6684 loosen and remove differential pressure switch

from bottom of hydraulic assembly (Fig. 20)

Fig. 18 Differential Pressure Switch Location

Fig. 19 Primary Pressure Transducer And Differen- tial Pressure Switch Wiring Harness Connectors

Fig. 17 Primary Pressure Transducer Removal And Replacement

5 - 110 ANTI-LOCK 10 BRAKE SYSTEM Ä

Page 261 of 2438

INSTALL (1) Install differential pressure switch into hydrau-

lic assembly by hand, until fully threaded into hy-

draulic assembly. Then torque differential pressure

switch, into hydraulic assembly, using Socket, Spe-

cial Tool 6684, to 1.5 N Im (13 in. lbs.).

(2) Lower vehicle

(3) Connect differential pressure switch wiring

harness connector into hydraulic assembly wiring

harness (Fig. 19). (4) Connect the hydraulic assembly wiring harness

connector into the primary pressure transducer (Fig.

19). (5) Turn the ignition switch to the on position and

let the system pressurize. Check for any signs of

leakage at the differential pressure switch. (6) Fully de-pressurize the hydraulic assembly a

second time to purge any air out that may have en-

tered hydraulic assembly when the differential pres-

sure switch was removed. Turn the ignition switch to

the on position and let the system pressurize again. (7) Fill hydraulic assembly fluid reservoir to the

top of the screen on the filter rainer. Use only fresh

clean brake fluid conforming to DOT 3 requirements,

such as Mopar tor equivalent.

(8) Road test vehicle to insure that the brake sys-

tem is performing correctly.

BOOST PRESSURE TRANSDUCER

REMOVE

WARNING: FAILURE TO FULLY DE-PRESSURIZE

THE HYDRAULIC BLADDER ACCUMULATOR PRIOR

TO REMOVING BOOST PRESSURE TRANSDUCER.

MAY RESULT IN PERSONAL INJURY AND/OR DAM-

AGE TO PAINTED SURFACES OF THE VEHICLE. To remove the boost pressure transducer (Fig. 21),

from the hydraulic assembly, removal of the hydrau-

lic assembly from the vehicle is notrequired.

(1) De-pressurize hydraulic bladder accumulator on

hydraulic assembly by pumping the brake pedal a

minimum of 40 times. Refer to the procedure as de-

scribed in De-Pressurizing Hydraulic Accumulator

listed earlier in this section. (2) Raise vehicle on a frame contact type hoist. See

Hoisting in the Lubrication And Maintenance section

of this manual, for the required lifting procedure to

be used for this vehicle. (3) Disconnect hydraulic assembly wiring harness

connectors from the dual function pressure switch

and boost pressure transducer (Fig. 21). (4) Using a long extension and Socket, Special Tool

6607, remove dual function pressure switch from bot-

tom of hydraulic assembly (Fig. 22)

(5) Remove boost pressure transducer from hydrau-

lic assembly, from under vehicle using a long exten-

sion and Socket, Special Tool 6684 (Fig. 23).

Fig. 20 Differential Pressure Switch Removal And Replacement

Fig. 21 Boost Pressure Transducer Location

Fig. 22 Remove And Install Dual Function Pressure Switch

Ä ANTI-LOCK 10 BRAKE SYSTEM 5 - 111

Page 262 of 2438

INSTALL (1) Install boost pressure transducer (Fig. 23) into

hydraulic assembly by hand, until O-ring is fully

seated into hydraulic assembly. Then torque boost pressure transducer, into hydraulic assembly, using

Socket, Special Tool 6684, to 12 N Im (106 in. lbs.).

(2) Install Dual Function Pressure Switch (Fig. 22)

into hydraulic assembly by hand, until O-ring is

fully seated into hydraulic assembly. Then torque

dual function pressure switch, into hydraulic assem-

bly, using Socket, Special Tool 6607, to 12 N Im (106

in. lbs.). (3) Connect hydraulic assembly wiring harness

connectors, onto the dual function pressure switch

and boost pressure transducer (Fig. 21). (4) Turn the ignition switch to the on position and

let the system pressurize. Check for any signs of

leakage at the differential pressure switch. (5) Fully de-pressurize the hydraulic assembly a

second time to purge any air out that may have en-

tered hydraulic assembly when the differential pres-

sure switch was removed. Turn the ignition switch to

the on position and let the system pressurize again. (6) Fill hydraulic assembly fluid reservoir to the

top of the screen on the filter rainer. Use only fresh

clean brake fluid conforming to DOT 3 requirements,

such as Mopar tor equivalent.

(7) Road test vehicle to insure that the brake sys-

tem is performing correctly.

Fig. 23 Remove And Install Boost Pressure Transducer

5 - 112 ANTI-LOCK 10 BRAKE SYSTEM Ä

Page 266 of 2438

If the vehicle is not set in motion within 3 minutes

from the time the ignition switch is set in the on po-

sition. The solenoid test is bypassed but the pump/

motor is activated briefly to verify that it is

operating correctly.

WARNING SYSTEMS OPERATION

The ABS system uses an Amber Anti-Lock Warn-

ing Lamp, located in the instrument cluster. The

purpose of the warning lamp is discussed in detail

below. The Amber Anti-Lock Warning Light will turn on

when the (CAB) detects a condition which results in

a shutdown of the Anti-Lock function. The Amber

Anti-Lock Warning Lamp is normally on until the

(CAB) completes its self tests and turns the lamp off

(approximately 1-2 seconds). When the Amber Anti-

Lock Warning Light is on only the Anti-Lock func-

tion of the brake system if affected. The standard

brake system and the ability to stop the car will not

be affected when only the Amber Anti-Lock Warning

Light is on.

NORMAL OPERATION OF WARNING LAMP

With the ignition in the Crank position, the Red

Brake Warning Lamp will turn on as a bulb check.

The Amber Anti-Lock Warning Lamp will stay on for

1-2 seconds then turn off. Once verification of the self

diagnosis is completed.

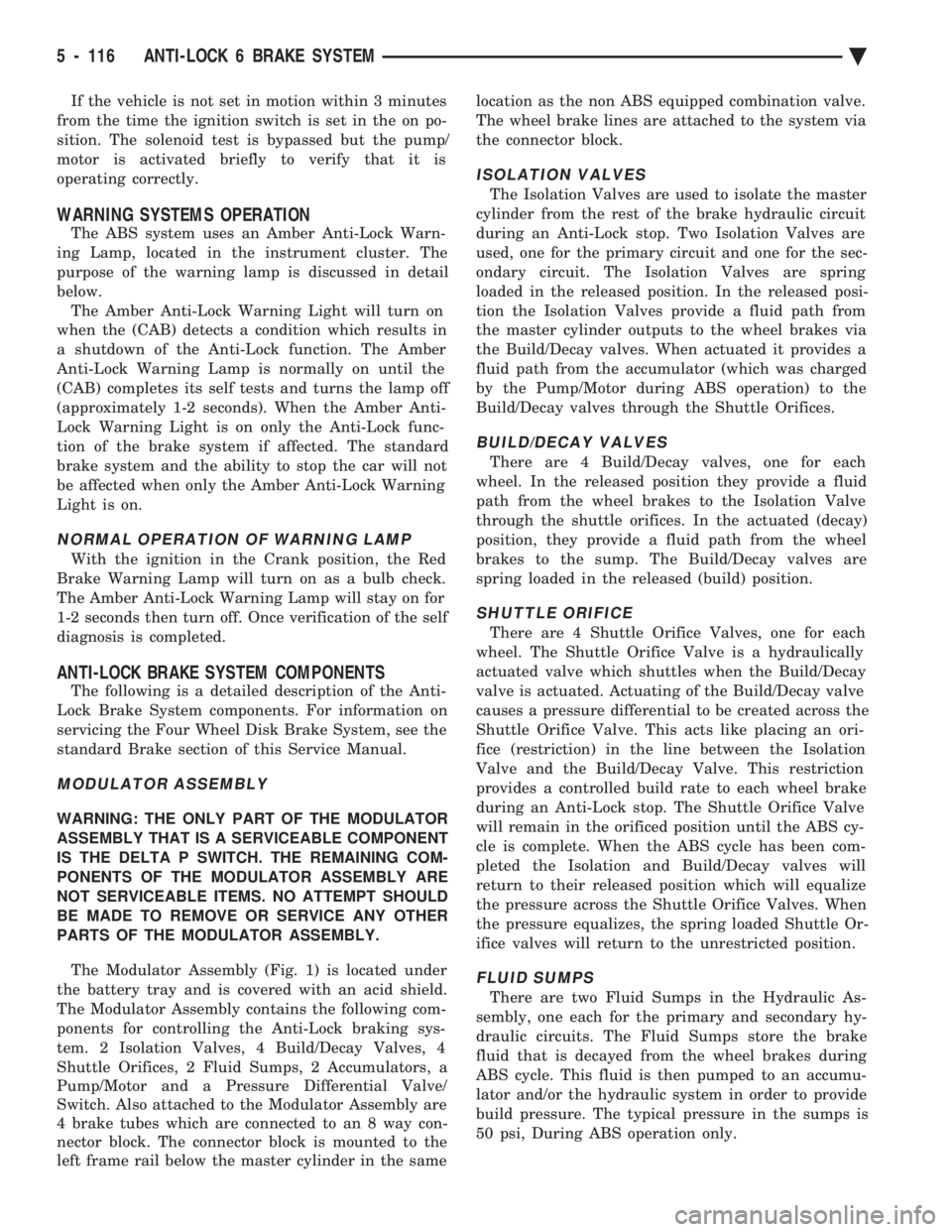

ANTI-LOCK BRAKE SYSTEM COMPONENTS

The following is a detailed description of the Anti-

Lock Brake System components. For information on

servicing the Four Wheel Disk Brake System, see the

standard Brake section of this Service Manual.

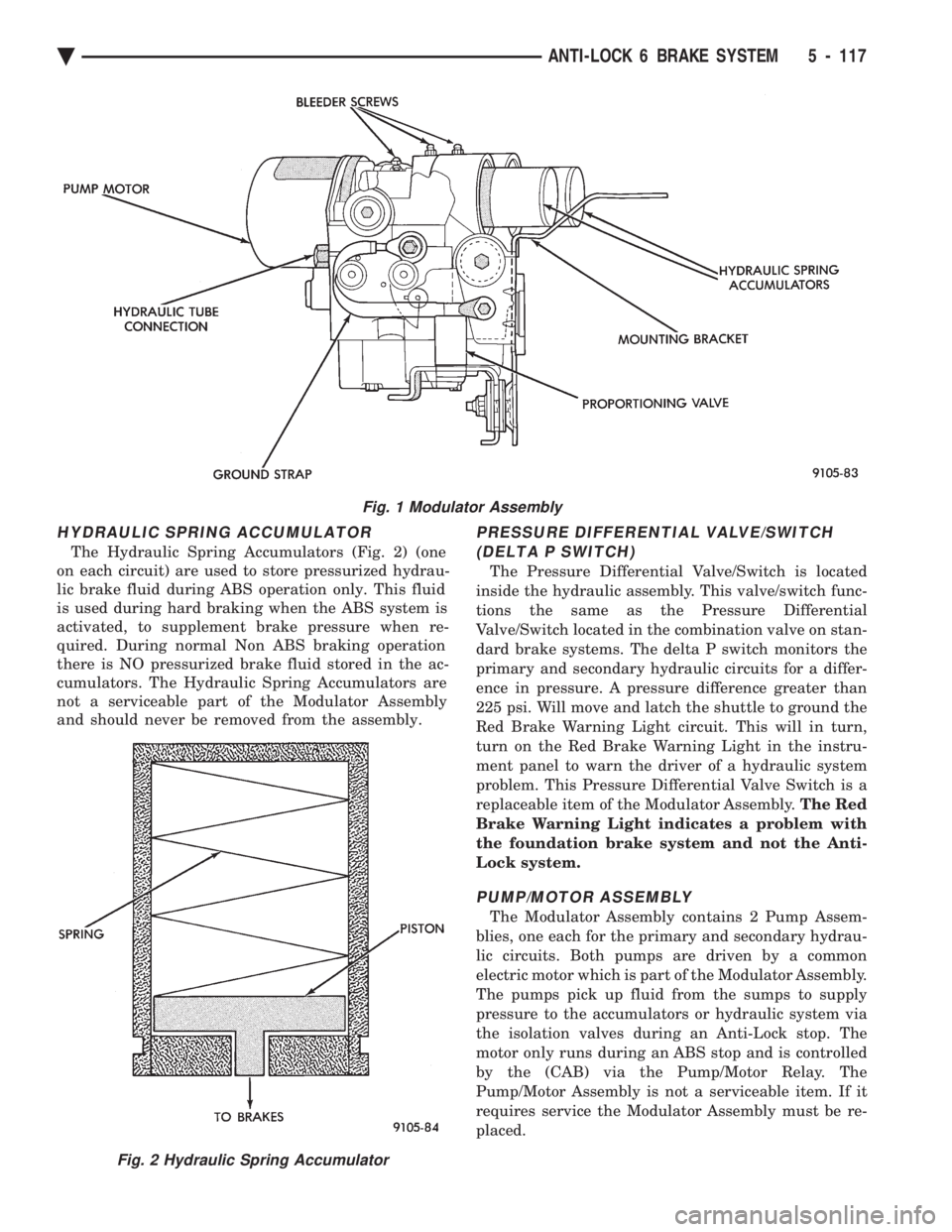

MODULATOR ASSEMBLY

WARNING: THE ONLY PART OF THE MODULATOR

ASSEMBLY THAT IS A SERVICEABLE COMPONENT

IS THE DELTA P SWITCH. THE REMAINING COM-

PONENTS OF THE MODULATOR ASSEMBLY ARE

NOT SERVICEABLE ITEMS. NO ATTEMPT SHOULD

BE MADE TO REMOVE OR SERVICE ANY OTHER

PARTS OF THE MODULATOR ASSEMBLY.

The Modulator Assembly (Fig. 1) is located under

the battery tray and is covered with an acid shield.

The Modulator Assembly contains the following com-

ponents for controlling the Anti-Lock braking sys-

tem. 2 Isolation Valves, 4 Build/Decay Valves, 4

Shuttle Orifices, 2 Fluid Sumps, 2 Accumulators, a

Pump/Motor and a Pressure Differential Valve/

Switch. Also attached to the Modulator Assembly are

4 brake tubes which are connected to an 8 way con-

nector block. The connector block is mounted to the

left frame rail below the master cylinder in the same location as the non ABS equipped combination valve.

The wheel brake lines are attached to the system via

the connector block.

ISOLATION VALVES

The Isolation Valves are used to isolate the master

cylinder from the rest of the brake hydraulic circuit

during an Anti-Lock stop. Two Isolation Valves are

used, one for the primary circuit and one for the sec-

ondary circuit. The Isolation Valves are spring

loaded in the released position. In the released posi-

tion the Isolation Valves provide a fluid path from

the master cylinder outputs to the wheel brakes via

the Build/Decay valves. When actuated it provides a

fluid path from the accumulator (which was charged

by the Pump/Motor during ABS operation) to the

Build/Decay valves through the Shuttle Orifices.

BUILD/DECAY VALVES

There are 4 Build/Decay valves, one for each

wheel. In the released position they provide a fluid

path from the wheel brakes to the Isolation Valve

through the shuttle orifices. In the actuated (decay)

position, they provide a fluid path from the wheel

brakes to the sump. The Build/Decay valves are

spring loaded in the released (build) position.

SHUTTLE ORIFICE

There are 4 Shuttle Orifice Valves, one for each

wheel. The Shuttle Orifice Valve is a hydraulically

actuated valve which shuttles when the Build/Decay

valve is actuated. Actuating of the Build/Decay valve

causes a pressure differential to be created across the

Shuttle Orifice Valve. This acts like placing an ori-

fice (restriction) in the line between the Isolation

Valve and the Build/Decay Valve. This restriction

provides a controlled build rate to each wheel brake

during an Anti-Lock stop. The Shuttle Orifice Valve

will remain in the orificed position until the ABS cy-

cle is complete. When the ABS cycle has been com-

pleted the Isolation and Build/Decay valves will

return to their released position which will equalize

the pressure across the Shuttle Orifice Valves. When

the pressure equalizes, the spring loaded Shuttle Or-

ifice valves will return to the unrestricted position.

FLUID SUMPS

There are two Fluid Sumps in the Hydraulic As-

sembly, one each for the primary and secondary hy-

draulic circuits. The Fluid Sumps store the brake

fluid that is decayed from the wheel brakes during

ABS cycle. This fluid is then pumped to an accumu-

lator and/or the hydraulic system in order to provide

build pressure. The typical pressure in the sumps is

50 psi, During ABS operation only.

5 - 116 ANTI-LOCK 6 BRAKE SYSTEM Ä

Page 267 of 2438

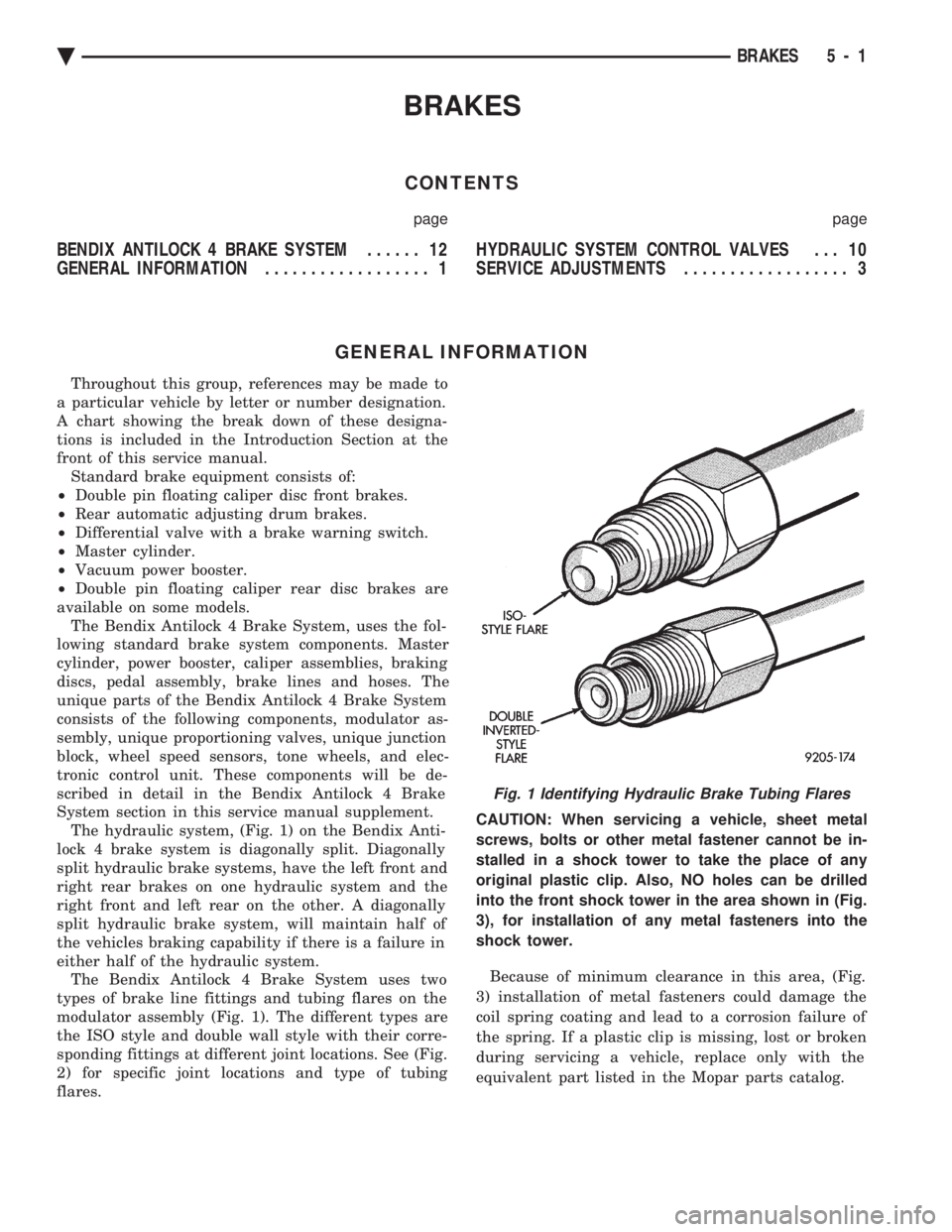

HYDRAULIC SPRING ACCUMULATOR

The Hydraulic Spring Accumulators (Fig. 2) (one

on each circuit) are used to store pressurized hydrau-

lic brake fluid during ABS operation only. This fluid

is used during hard braking when the ABS system is

activated, to supplement brake pressure when re-

quired. During normal Non ABS braking operation

there is NO pressurized brake fluid stored in the ac-

cumulators. The Hydraulic Spring Accumulators are

not a serviceable part of the Modulator Assembly

and should never be removed from the assembly.

PRESSURE DIFFERENTIAL VALVE/SWITCH

(DELTA P SWITCH)

The Pressure Differential Valve/Switch is located

inside the hydraulic assembly. This valve/switch func-

tions the same as the Pressure Differential

Valve/Switch located in the combination valve on stan-

dard brake systems. The delta P switch monitors the

primary and secondary hydraulic circuits for a differ-

ence in pressure. A pressure difference greater than

225 psi. Will move and latch the shuttle to ground the

Red Brake Warning Light circuit. This will in turn,

turn on the Red Brake Warning Light in the instru-

ment panel to warn the driver of a hydraulic system

problem. This Pressure Differential Valve Switch is a

replaceable item of the Modulator Assembly. The Red

Brake Warning Light indicates a problem with

the foundation brake system and not the Anti-

Lock system.

PUMP/MOTOR ASSEMBLY

The Modulator Assembly contains 2 Pump Assem-

blies, one each for the primary and secondary hydrau-

lic circuits. Both pumps are driven by a common

electric motor which is part of the Modulator Assembly.

The pumps pick up fluid from the sumps to supply

pressure to the accumulators or hydraulic system via

the isolation valves during an Anti-Lock stop. The

motor only runs during an ABS stop and is controlled

by the (CAB) via the Pump/Motor Relay. The

Pump/Motor Assembly is not a serviceable item. If it

requires service the Modulator Assembly must be re-

placed.

Fig. 1 Modulator Assembly

Fig. 2 Hydraulic Spring Accumulator

Ä ANTI-LOCK 6 BRAKE SYSTEM 5 - 117

Page 287 of 2438

BRAKES

CONTENTS

page page

BENDIX ANTILOCK 4 BRAKE SYSTEM ...... 12

GENERAL INFORMATION .................. 1 HYDRAULIC SYSTEM CONTROL VALVES . . . 10

SERVICE ADJUSTMENTS

.................. 3

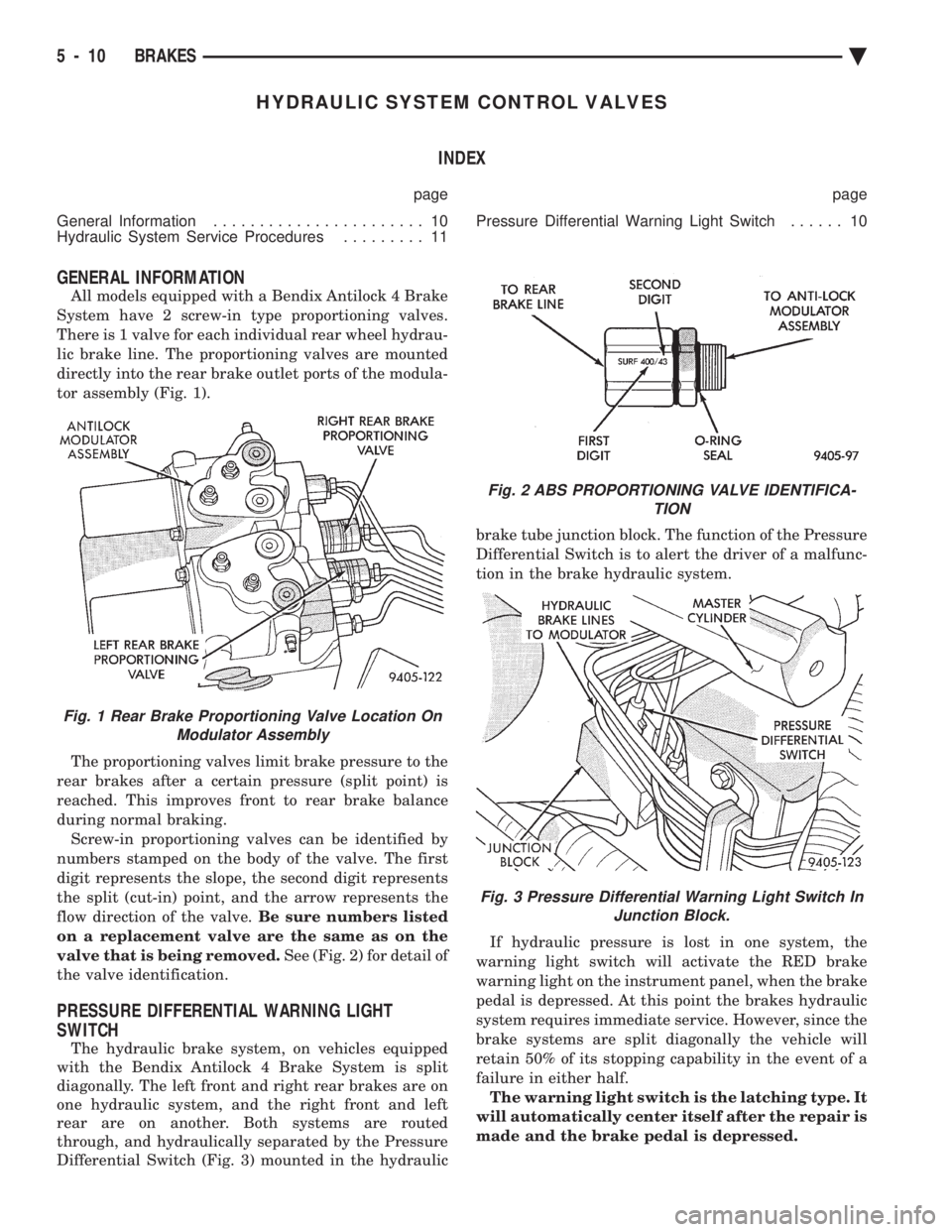

GENERAL INFORMATION

Throughout this group, references may be made to

a particular vehicle by letter or number designation.

A chart showing the break down of these designa-

tions is included in the Introduction Section at the

front of this service manual. Standard brake equipment consists of:

² Double pin floating caliper disc front brakes.

² Rear automatic adjusting drum brakes.

² Differential valve with a brake warning switch.

² Master cylinder.

² Vacuum power booster.

² Double pin floating caliper rear disc brakes are

available on some models. The Bendix Antilock 4 Brake System, uses the fol-

lowing standard brake system components. Master

cylinder, power booster, caliper assemblies, braking

discs, pedal assembly, brake lines and hoses. The

unique parts of the Bendix Antilock 4 Brake System

consists of the following components, modulator as-

sembly, unique proportioning valves, unique junction

block, wheel speed sensors, tone wheels, and elec-

tronic control unit. These components will be de-

scribed in detail in the Bendix Antilock 4 Brake

System section in this service manual supplement. The hydraulic system, (Fig. 1) on the Bendix Anti-

lock 4 brake system is diagonally split. Diagonally

split hydraulic brake systems, have the left front and

right rear brakes on one hydraulic system and the

right front and left rear on the other. A diagonally

split hydraulic brake system, will maintain half of

the vehicles braking capability if there is a failure in

either half of the hydraulic system. The Bendix Antilock 4 Brake System uses two

types of brake line fittings and tubing flares on the

modulator assembly (Fig. 1). The different types are

the ISO style and double wall style with their corre-

sponding fittings at different joint locations. See (Fig.

2) for specific joint locations and type of tubing

flares. CAUTION: When servicing a vehicle, sheet metal

screws, bolts or other metal fastener cannot be in-

stalled in a shock tower to take the place of any

original plastic clip. Also, NO holes can be drilled

into the front shock tower in the area shown in (Fig.

3), for installation of any metal fasteners into the

shock tower.

Because of minimum clearance in this area, (Fig.

3) installation of metal fasteners could damage the

coil spring coating and lead to a corrosion failure of

the spring. If a plastic clip is missing, lost or broken

during servicing a vehicle, replace only with the

equivalent part listed in the Mopar parts catalog.

Fig. 1 Identifying Hydraulic Brake Tubing Flares

Ä BRAKES 5 - 1

Page 296 of 2438

HYDRAULIC SYSTEM CONTROL VALVES INDEX

page page

General Information ....................... 10

Hydraulic System Service Procedures ......... 11 Pressure Differential Warning Light Switch

...... 10

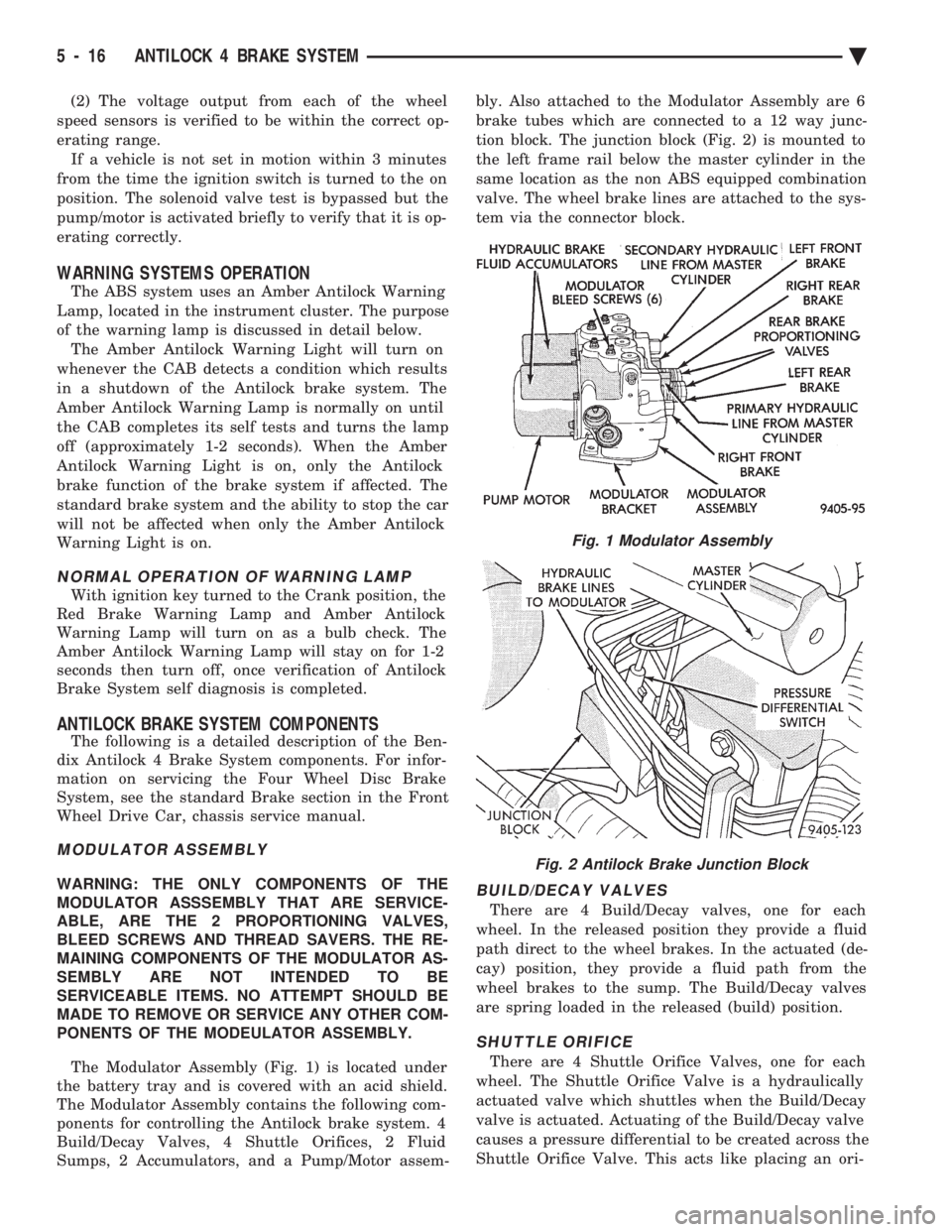

GENERAL INFORMATION

All models equipped with a Bendix Antilock 4 Brake

System have 2 screw-in type proportioning valves.

There is 1 valve for each individual rear wheel hydrau-

lic brake line. The proportioning valves are mounted

directly into the rear brake outlet ports of the modula-

tor assembly (Fig. 1).

The proportioning valves limit brake pressure to the

rear brakes after a certain pressure (split point) is

reached. This improves front to rear brake balance

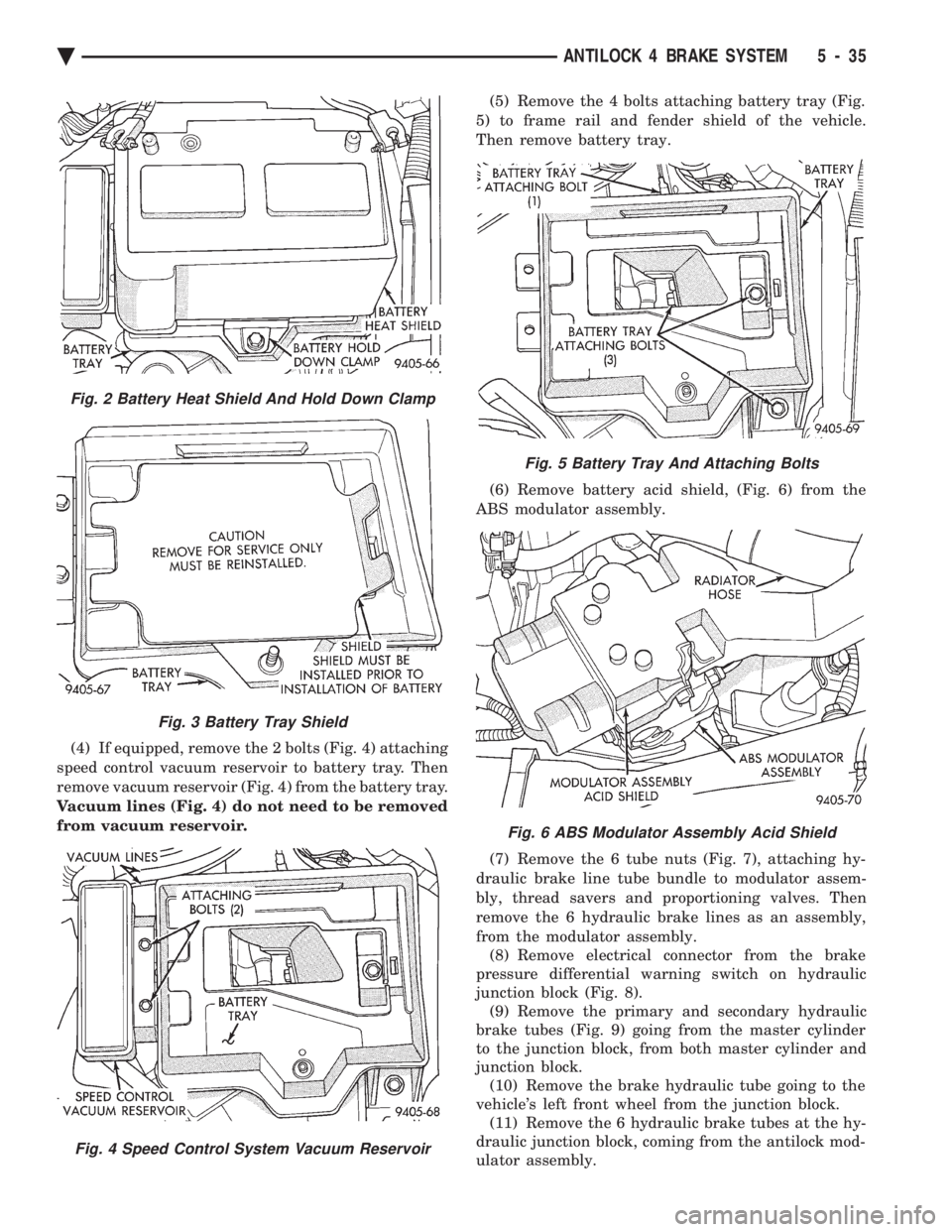

during normal braking. Screw-in proportioning valves can be identified by

numbers stamped on the body of the valve. The first

digit represents the slope, the second digit represents

the split (cut-in) point, and the arrow represents the

flow direction of the valve. Be sure numbers listed

on a replacement valve are the same as on the

valve that is being removed. See (Fig. 2) for detail of

the valve identification.

PRESSURE DIFFERENTIAL WARNING LIGHT

SWITCH

The hydraulic brake system, on vehicles equipped

with the Bendix Antilock 4 Brake System is split

diagonally. The left front and right rear brakes are on

one hydraulic system, and the right front and left

rear are on another. Both systems are routed

through, and hydraulically separated by the Pressure

Differential Switch (Fig. 3) mounted in the hydraulic brake tube junction block. The function of the Pressure

Differential Switch is to alert the driver of a malfunc-

tion in the brake hydraulic system.

If hydraulic pressure is lost in one system, the

warning light switch will activate the RED brake

warning light on the instrument panel, when the brake

pedal is depressed. At this point the brakes hydraulic

system requires immediate service. However, since the

brake systems are split diagonally the vehicle will

retain 50% of its stopping capability in the event of a

failure in either half. The warning light switch is the latching type. It

will automatically center itself after the repair is

made and the brake pedal is depressed.

Fig. 1 Rear Brake Proportioning Valve Location On Modulator Assembly

Fig. 2 ABS PROPORTIONING VALVE IDENTIFICA- TION

Fig. 3 Pressure Differential Warning Light Switch InJunction Block.

5 - 10 BRAKES Ä

Page 302 of 2438

(2) The voltage output from each of the wheel

speed sensors is verified to be within the correct op-

erating range. If a vehicle is not set in motion within 3 minutes

from the time the ignition switch is turned to the on

position. The solenoid valve test is bypassed but the

pump/motor is activated briefly to verify that it is op-

erating correctly.

WARNING SYSTEMS OPERATION

The ABS system uses an Amber Antilock Warning

Lamp, located in the instrument cluster. The purpose

of the warning lamp is discussed in detail below. The Amber Antilock Warning Light will turn on

whenever the CAB detects a condition which results

in a shutdown of the Antilock brake system. The

Amber Antilock Warning Lamp is normally on until

the CAB completes its self tests and turns the lamp

off (approximately 1-2 seconds). When the Amber

Antilock Warning Light is on, only the Antilock

brake function of the brake system if affected. The

standard brake system and the ability to stop the car

will not be affected when only the Amber Antilock

Warning Light is on.

NORMAL OPERATION OF WARNING LAMP

With ignition key turned to the Crank position, the

Red Brake Warning Lamp and Amber Antilock

Warning Lamp will turn on as a bulb check. The

Amber Antilock Warning Lamp will stay on for 1-2

seconds then turn off, once verification of Antilock

Brake System self diagnosis is completed.

ANTILOCK BRAKE SYSTEM COMPONENTS

The following is a detailed description of the Ben-

dix Antilock 4 Brake System components. For infor-

mation on servicing the Four Wheel Disc Brake

System, see the standard Brake section in the Front

Wheel Drive Car, chassis service manual.

MODULATOR ASSEMBLY

WARNING: THE ONLY COMPONENTS OF THE

MODULATOR ASSSEMBLY THAT ARE SERVICE-

ABLE, ARE THE 2 PROPORTIONING VALVES,

BLEED SCREWS AND THREAD SAVERS. THE RE-

MAINING COMPONENTS OF THE MODULATOR AS-

SEMBLY ARE NOT INTENDED TO BE

SERVICEABLE ITEMS. NO ATTEMPT SHOULD BE

MADE TO REMOVE OR SERVICE ANY OTHER COM-

PONENTS OF THE MODEULATOR ASSEMBLY.

The Modulator Assembly (Fig. 1) is located under

the battery tray and is covered with an acid shield.

The Modulator Assembly contains the following com-

ponents for controlling the Antilock brake system. 4

Build/Decay Valves, 4 Shuttle Orifices, 2 Fluid

Sumps, 2 Accumulators, and a Pump/Motor assem- bly. Also attached to the Modulator Assembly are 6

brake tubes which are connected to a 12 way junc-

tion block. The junction block (Fig. 2) is mounted to

the left frame rail below the master cylinder in the

same location as the non ABS equipped combination

valve. The wheel brake lines are attached to the sys-

tem via the connector block.BUILD/DECAY VALVES

There are 4 Build/Decay valves, one for each

wheel. In the released position they provide a fluid

path direct to the wheel brakes. In the actuated (de-

cay) position, they provide a fluid path from the

wheel brakes to the sump. The Build/Decay valves

are spring loaded in the released (build) position.

SHUTTLE ORIFICE

There are 4 Shuttle Orifice Valves, one for each

wheel. The Shuttle Orifice Valve is a hydraulically

actuated valve which shuttles when the Build/Decay

valve is actuated. Actuating of the Build/Decay valve

causes a pressure differential to be created across the

Shuttle Orifice Valve. This acts like placing an ori-

Fig. 1 Modulator Assembly

Fig. 2 Antilock Brake Junction Block

5 - 16 ANTILOCK 4 BRAKE SYSTEM Ä

Page 303 of 2438

fice (restriction) in the line between the wheel and

the Build/Decay Valve. This restriction provides a

controlled build rate to each wheel brake during an

Antilock stop. The Shuttle Orifice Valve will remain

in the orificed position until the ABS cycle is com-

plete. When the ABS cycle has been completed the

Build/Decay valves will return to their released posi-

tion which will equalize the pressure across the

Shuttle Orifice Valves. When the pressure equalizes,

the spring loaded Shuttle Orifice valves will return

to the unrestricted position.

FLUID SUMPS

There are two Fluid Sumps in the Hydraulic As-

sembly, one for the primary and secondary hydraulic

circuits. The Fluid Sumps store the brake fluid that

is decayed from the wheel brakes during an ABS cy-

cle. This fluid is then pumped to an accumulator

and/or the hydraulic system in order to provide build

pressure. The typical pressure in the sumps is 50 psi,

during ABS operation only.

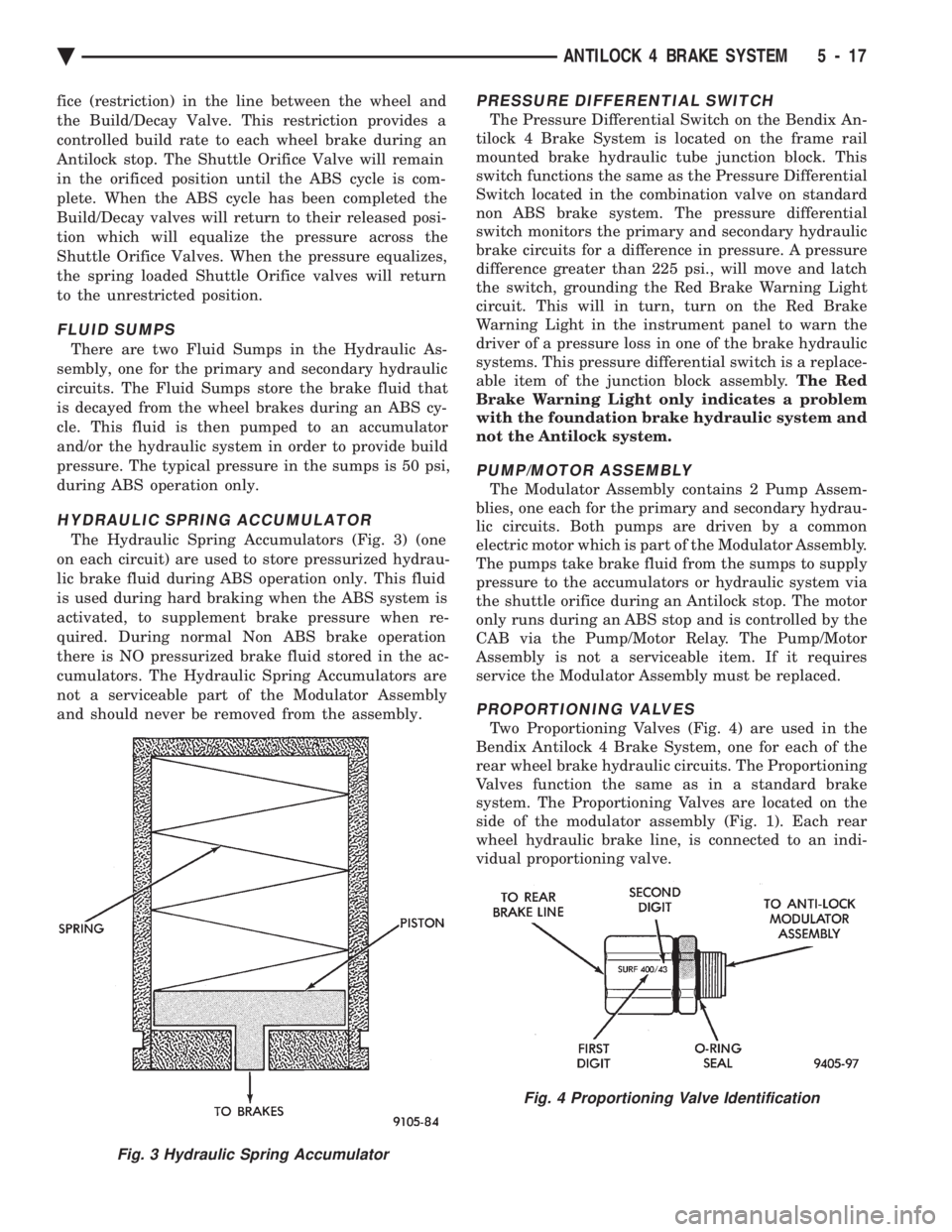

HYDRAULIC SPRING ACCUMULATOR

The Hydraulic Spring Accumulators (Fig. 3) (one

on each circuit) are used to store pressurized hydrau-

lic brake fluid during ABS operation only. This fluid

is used during hard braking when the ABS system is

activated, to supplement brake pressure when re-

quired. During normal Non ABS brake operation

there is NO pressurized brake fluid stored in the ac-

cumulators. The Hydraulic Spring Accumulators are

not a serviceable part of the Modulator Assembly

and should never be removed from the assembly.

PRESSURE DIFFERENTIAL SWITCH

The Pressure Differential Switch on the Bendix An-

tilock 4 Brake System is located on the frame rail

mounted brake hydraulic tube junction block. This

switch functions the same as the Pressure Differential

Switch located in the combination valve on standard

non ABS brake system. The pressure differential

switch monitors the primary and secondary hydraulic

brake circuits for a difference in pressure. A pressure

difference greater than 225 psi., will move and latch

the switch, grounding the Red Brake Warning Light

circuit. This will in turn, turn on the Red Brake

Warning Light in the instrument panel to warn the

driver of a pressure loss in one of the brake hydraulic

systems. This pressure differential switch is a replace-

able item of the junction block assembly. The Red

Brake Warning Light only indicates a problem

with the foundation brake hydraulic system and

not the Antilock system.

PUMP/MOTOR ASSEMBLY

The Modulator Assembly contains 2 Pump Assem-

blies, one each for the primary and secondary hydrau-

lic circuits. Both pumps are driven by a common

electric motor which is part of the Modulator Assembly.

The pumps take brake fluid from the sumps to supply

pressure to the accumulators or hydraulic system via

the shuttle orifice during an Antilock stop. The motor

only runs during an ABS stop and is controlled by the

CAB via the Pump/Motor Relay. The Pump/Motor

Assembly is not a serviceable item. If it requires

service the Modulator Assembly must be replaced.

PROPORTIONING VALVES

Two Proportioning Valves (Fig. 4) are used in the

Bendix Antilock 4 Brake System, one for each of the

rear wheel brake hydraulic circuits. The Proportioning

Valves function the same as in a standard brake

system. The Proportioning Valves are located on the

side of the modulator assembly (Fig. 1). Each rear

wheel hydraulic brake line, is connected to an indi-

vidual proportioning valve.

Fig. 3 Hydraulic Spring Accumulator

Fig. 4 Proportioning Valve Identification

Ä ANTILOCK 4 BRAKE SYSTEM 5 - 17

Page 321 of 2438

(4) If equipped, remove the 2 bolts (Fig. 4) attaching

speed control vacuum reservoir to battery tray. Then

remove vacuum reservoir (Fig. 4) from the battery tray.

Vacuum lines (Fig. 4) do not need to be removed

from vacuum reservoir. (5) Remove the 4 bolts attaching battery tray (Fig.

5) to frame rail and fender shield of the vehicle.

Then remove battery tray.

(6) Remove battery acid shield, (Fig. 6) from the

ABS modulator assembly.

(7) Remove the 6 tube nuts (Fig. 7), attaching hy-

draulic brake line tube bundle to modulator assem-

bly, thread savers and proportioning valves. Then

remove the 6 hydraulic brake lines as an assembly,

from the modulator assembly. (8) Remove electrical connector from the brake

pressure differential warning switch on hydraulic

junction block (Fig. 8). (9) Remove the primary and secondary hydraulic

brake tubes (Fig. 9) going from the master cylinder

to the junction block, from both master cylinder and

junction block. (10) Remove the brake hydraulic tube going to the

vehicle's left front wheel from the junction block. (11) Remove the 6 hydraulic brake tubes at the hy-

draulic junction block, coming from the antilock mod-

ulator assembly.

Fig. 5 Battery Tray And Attaching Bolts

Fig. 6 ABS Modulator Assembly Acid Shield

Fig. 2 Battery Heat Shield And Hold Down Clamp

Fig. 3 Battery Tray Shield

Fig. 4 Speed Control System Vacuum Reservoir

Ä ANTILOCK 4 BRAKE SYSTEM 5 - 35